AUDI TT ROADSTER 2018 Owners Manual

Manufacturer: AUDI, Model Year: 2018, Model line: TT ROADSTER, Model: AUDI TT ROADSTER 2018Pages: 310, PDF Size: 46.95 MB

Page 281 of 310

Cl co .... N ,....

N ...... 0 ,....

Vl co

-Always stor e damaged whee l, jack and too ls

securely in the luggage compartment. Oth erwise, in an accident or sudden maneuver

they could fly forward, caus ing injury to pas

sengers in the vehicle .

Spare tire

General information

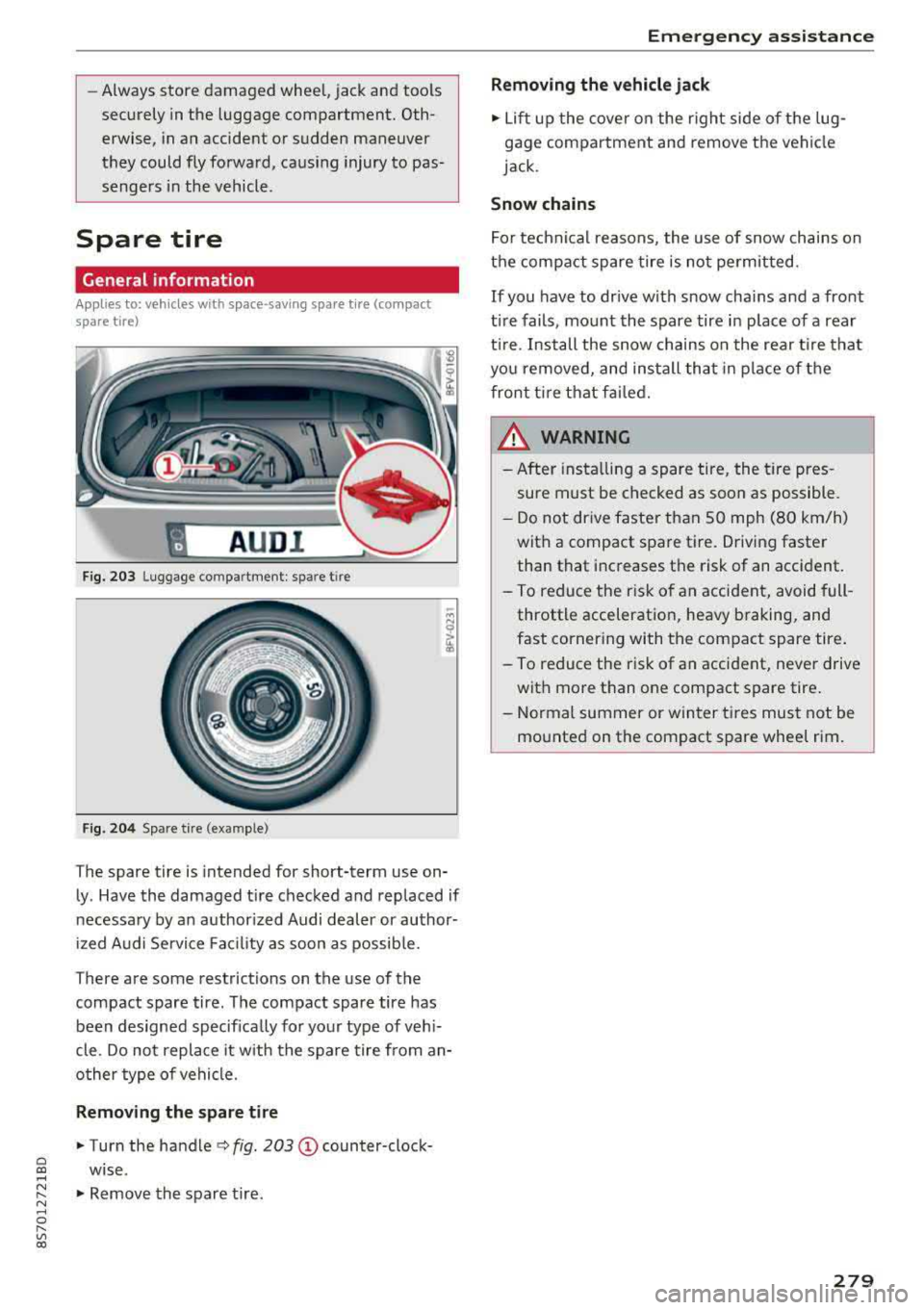

Applies to: veh icles wit h space -saving spa re t ire (compact

spa re t ire)

A U DI

Fig. 203 Lugg age co mpar tment : spar e tir e

F ig . 204 Sp are t ire (ex ample)

The spare tire is intended for short-term use on

ly . Have the damaged t ire checked and replaced if

necessary by an author ized Audi dealer or author

i zed A udi Service Fac ility as soon as possib le.

T here are some restrictions on the use of the

compact spare tire . The compact spare tire has

been designed specifica lly for your type of veh i

cle . Do not replace it w ith the spare tire from an

o ther type of vehicle.

Removing the spare tire

.,. Turn the handle c::> fig . 203 (D counter-clock

wise.

.,. Remove the spare tire .

Emergen cy as sis tanc e

Removing the vehicle jack

.,. Lift up the cover on the right side of the lug

gage compartment and remove the vehicle

jack.

Snow chains

For technical reasons, the use of snow chains on

the compact spare tire is not pe rmit ted.

If you have to dr ive with snow chains and a front

t ire fails , mount the spare tire in place of a rear

t ir e. Install the snow chains on the rear t ire that

yo u removed, and ins tall that in place of the

front t ire that fai led.

_&, WARNING ..

- After insta lling a spare tire, the tire pres

sure must be checked as soon as possible .

- D o not dr ive faster than 50 mph (80 km/h)

with a compact spare tire. Driving faster

than that inc reases the risk of an accident.

- To reduce the r isk of an accident, avoid full

throttle acceleration, heavy braking, and

fast corner ing with the compact spare tire .

-

- To reduce the risk of an accident, neve r drive

with more than one compact spare tire .

- Normal summer or winter tires must not be mounted on the compact spare wheel rim.

279

Page 282 of 310

Fuses and bulbs

Fuses and bulbs

Electrical fuses

Replacing fuses

A fuse that has blown will have metal strips that

have burned through.

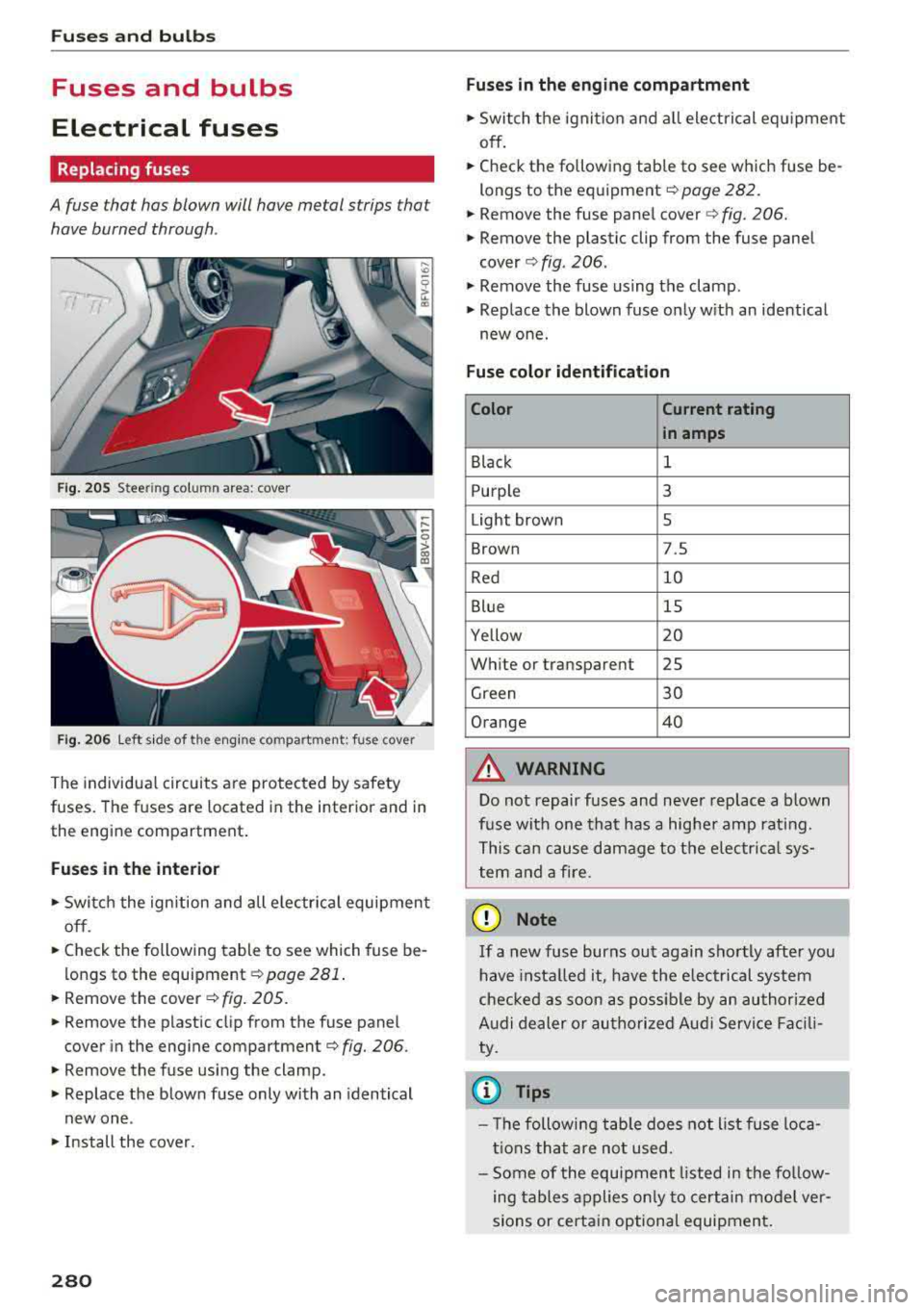

Fig. 20 5 Steering column area: cover

F ig. 20 6 Left side of the e ngine compartment: fuse cover

The individu al circuits are pro tec ted by safety

fuses. The fuses are located in the inter ior and in

the engine compartment .

Fuses in the interior

., Switch the ignition and all e lectr ica l equipment

off.

.. Check the following table to see which fuse be

l ongs to the

equipment ¢ page 281.

.. Remove the cover ¢ fig. 205.

.. Remove the plastic cl ip from the fuse panel

cover in the engine

compartment¢ fig. 206 .

.. Remove the fuse using the clamp.

., Replace the blow n fu se only with an identical

new one .

., Install the cover.

280

Fuses in the engine compartment

.. Switch the ignit io n and all electrical eq uipment

off .

.. Check the following table to see which fuse be

longs to th e eq uipment

¢page 282.

.. Remove the fuse pane l cover c> fig . 206.

.. Remove the plastic clip from the fuse panel

cover ¢ fig. 206 .

., Remove the fuse us ing the clamp .

.. Replace the blown fuse on ly w ith an ident ical

new one.

Fuse color identification

Color Current rating

in amps

Black 1

Purple 3

Light brown 5

Brown 7.S

Red

10

Blue 15

Yellow 20

Wh ite or transparent 25

Green 30

Orange 40

A WARNING

D o not repair fuses and neve r rep lace a blown

f u se with one tha t has a hig her amp rat ing.

T his ca n ca use damage to the e lectr ica l sys

tem and a fire .

(D Note

If a new fuse burns out again sho rtly after you

h ave insta lled it, have the e lectrical system

che cked as soon as possible by an au thori zed

A udi de aler or au tho riz ed Audi Service Fac ili

ty .

0) Tips

- Th e followi ng t able does not list fuse loca

t ions tha t are not used.

- Some of the e quipment listed in the fo llow

ing tables applies on ly to certain mo del ver

sions or certa in option al equipmen t.

Page 283 of 310

Cl co .... N ,....

N ...... 0 ,....

Vl co

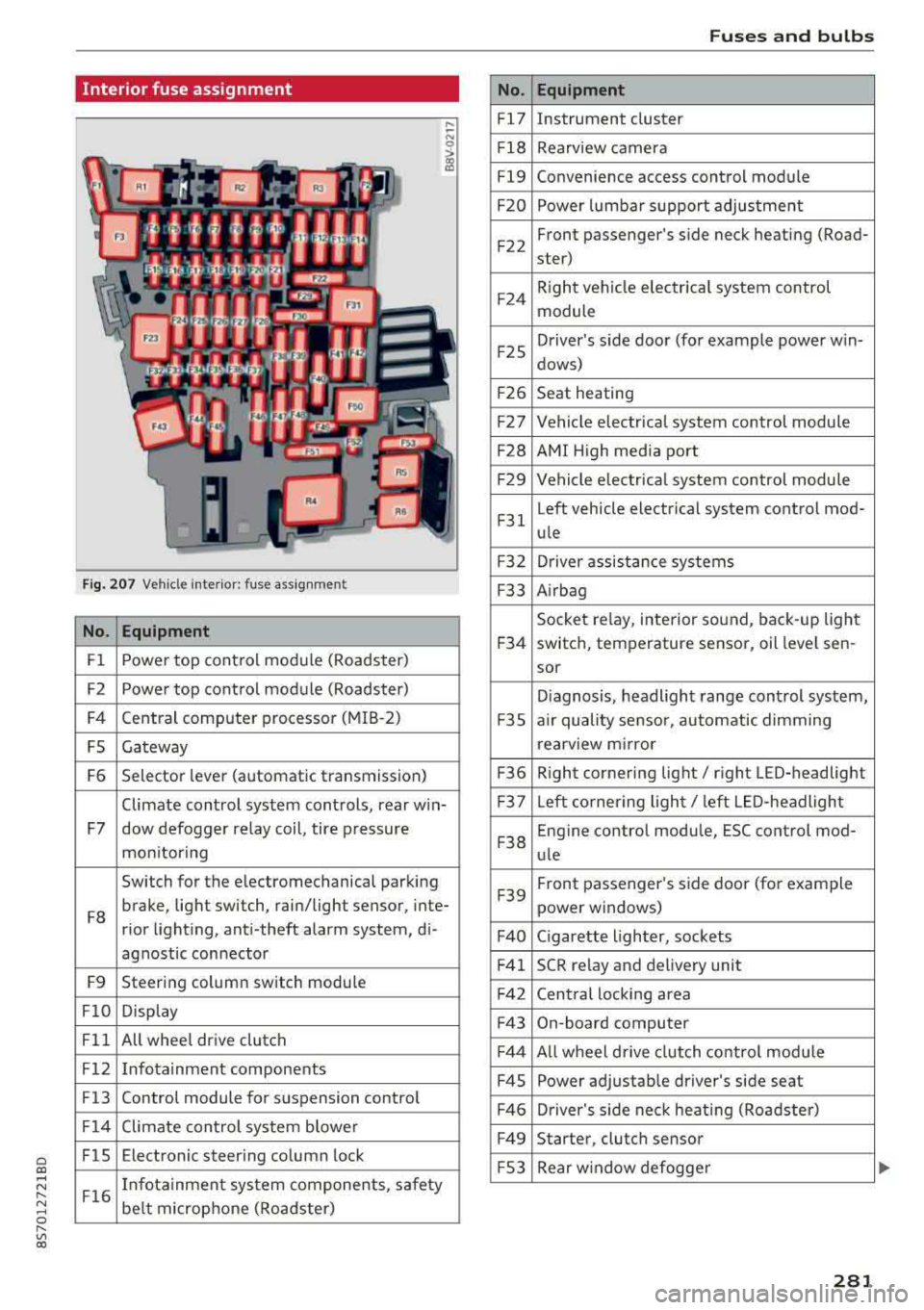

Interior fuse assignment

Fig. 207 Vehicle interior: fuse assignmen t

No. Equipment

Fl Power top cont

rol module (Roadster)

F2 Power top control module (Roadster)

F4 Central computer processor (MIB

-2)

FS Gateway

F6 Selector lever (automatic transmission)

Climate control system controls, rear w in-

F7 dow defogger relay coil, tire pressure

mon itoring

Switch for the electromechanical parking

F8 brake, light switch, rain/light sensor, inte-

rior lighting, anti -theft alarm system, di -

agnostic connector

F9 Steering column switch module

FlO Display

Fll All whee

l drive clutch

F12 Infotainment components

F13 Control module for suspension control

F14 Climate control system blowe r

FlS Electronic steering column

lock

F16 I

nfotainment system components, safety

be lt microphone (Roadster)

No.

Fl7

F1 8

Fl9

F20

F 22

F24

F 25

F 26

F 27

F28

F2 9

F 31

F3 2

F33

F 34

F 35

F36

F37

F3 8

F39

F40

F41

F 42

F43

F44

F45

F46

F49

F S3

Fuses and bulbs

Equipment

Instrument cluster

Rearview camera

Convenience access control module

Power lumbar support adjustment

Front passenger's side neck heating (Road-

ster)

R ight vehicle electrica l system control

module

Driver's s ide door (for example power w in-

dows)

Seat heating

Vehicle electrical system control module

AMI High media port

Vehicle e lectr ical system control module

Left vehicle electrical system contro l mod-

ule

Driver assistance systems

Airbag

Socket relay, inte rior sound , back-up light

switch, temperature sensor, oil leve l sen -

sor

Diagnosis, headlight range control system,

a ir quality sensor, automatic dimming

rearview mirror

R ight cornering light/ right LED-headlight

L eft cornering light/ left LED-headlight

Engine control module, ESC control mod-

ule

Front passenger's side door (for example

power windows)

C igarette lighter, sockets

SCR relay and delivery unit

Central locking area

On-board computer

A ll wheel d rive clutch control module

Power adjustable driver's side seat

Driver's side neck heating (Roadster)

Starter, clutch sensor

Rear window defogger

281

Page 284 of 310

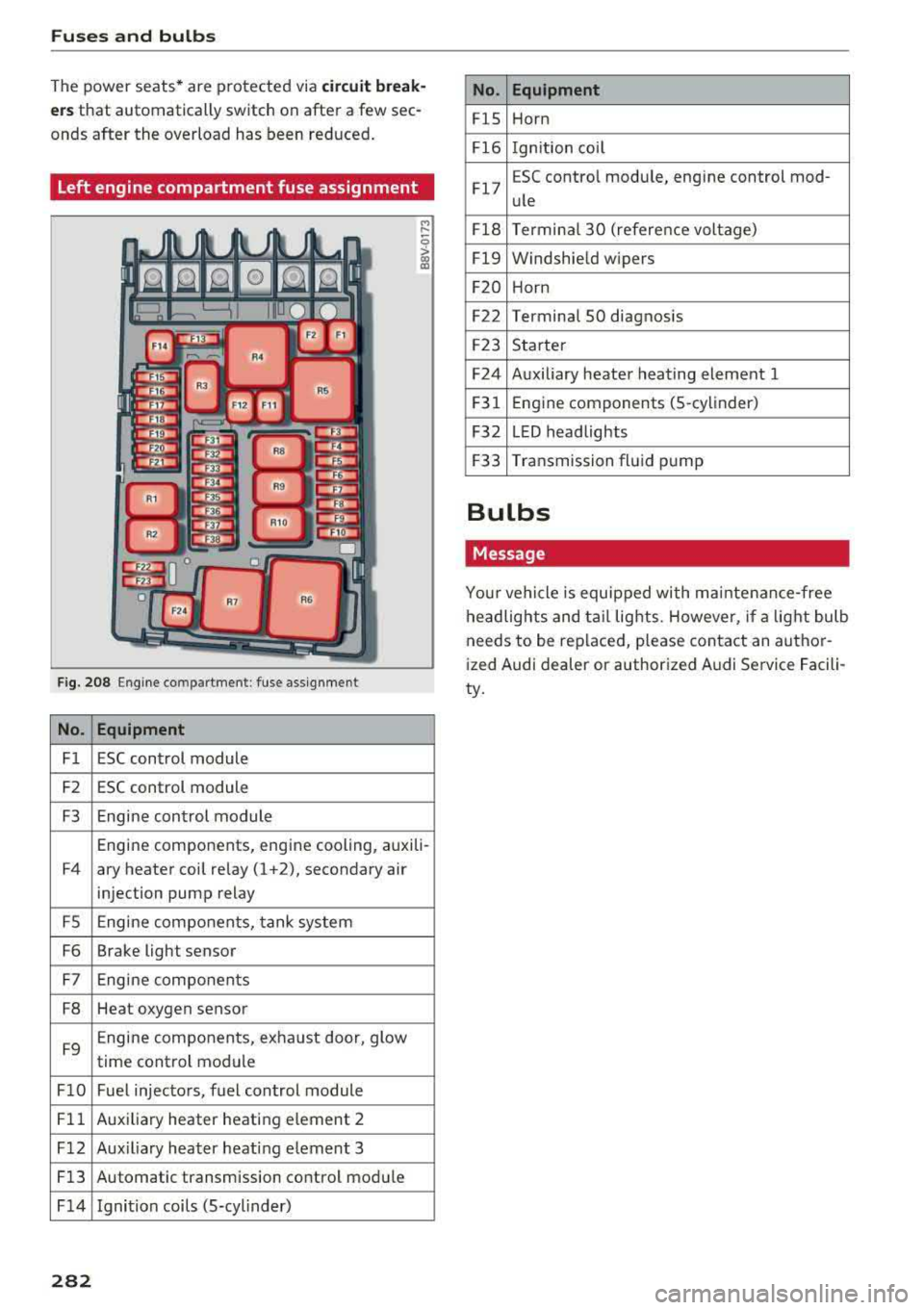

Fuses and bulbs

The power seats* are protected via circuit break

ers

that automatically switch on after a few sec

onds after the overload has been reduced.

Left engine compartment fuse assignment

F ig. 208 Engine co mpartment : fuse assignment

No. Equipment

Fl ESC control module

F2 ESC control module

F3 Engine control module

M

" 0 > a, m

Engine components, engine cooling, auxili-

F4 ary heater coil relay (1 +2), secondary air

injection pump relay

FS Engine components, tank system

F6 Brake light sensor

F7 Engine components

F8 Heat oxygen sensor

F9 Engine components, exhaust door, glow

time control module

FlO Fuel injectors, fuel control module

Fll Auxiliary heater heating e lement 2

F 12 Aux iliary heater heat ing element 3

Fl3 Automatic transmission control module

F 14 Ignition coils (5-cylinder)

282

No. Equipment

FlS Horn

Fl6 Ignition coil

Fl7 E

SC contro l module, engine control mod-

ule

Fl8 Terminal

30 (reference voltage)

Fl9 Windshield wipers

F20 Horn

F22 Terminal SO diagnosis

F23 Starter

F24 Auxiliary heater heating element 1

F31 Engine

components (5 -cylinder)

F32 LED headlights

F33 Transmission fluid pump

Bulbs

Message

Your vehicle is equipped with ma intenance-free

headlights and tail lights. However, if a light bulb

needs to be replaced, please contact an author

ized Audi dealer or authorized Audi Service Facili

ty.

Page 285 of 310

Cl 00 .-< N r--N .-< 0 r--Vl 00

Emergency situations

General

This chapter is intended for trained emergency

crews and working personnel who have the nec

essary tools and equipment to perform these

operations.

Starting by pushing or

towing

~ Note

Vehicles with an automatic transmission can

not be started by pushing or towing.

Starting with jumper

cables

If necessary, the engine can be started by con

necting it to the battery of another vehicle .

If the engine should fail to start because of a dis

charged or weak battery, the battery can be con

nected to the battery of

another vehicle, using a

pair of jumper cables to start the engine.

Jumper cables

Use only jumper cables of sufficiently large cross

section

to carry the starter current safely. Refer

to the manufacturer's specifications.

Use only jumper cables with

insulated terminal

clamps which are distinctly marked :

plus(+) cable in most cases colored red

minus(-) cable

in most cases colored black.

A WARNING -

Batteries contain electricity, acid, and gas.

Any of these can cause very serious or fatal in

jury. Follow the instructions below for safe

handling of your vehicle's battery .

-Always shield your eyes and avoid leaning

over the battery whenever possible.

-A dead battery can freeze at temperatures

around 32 °F (0 °C) . If the vehicle battery is

frozen, you must thaw it before connecting

the jump start cables. If you do not, this in-

Emergency situations

creases the risk of an explosion and chemi

cal burns. After jump starting the vehicle,

drive to an authorized Audi dealer or author ized Audi Service Facility immediately to

have the vehicle battery checked.

- Do not allow battery acid to contact eyes or

skin . Flush any contacted area with water

immediately.

- Improper use of a booster battery to start a

vehicle may cause an explosion .

- Vehicle batteries generate explosive gases .

Keep sparks, flame and lighted cigarettes

away from batteries.

- Do not try to jump start any vehicle with a

low acid level in the battery .

- The voltage of the booster battery must also

have a 12-Volt rating . The capacity (Ah) of

the booster battery should not be lower

than that of the discharged battery. Use of

batteries of different voltage or substantial

ly different "Ah " rating may cause an explo

sion and personal injury.

- Never charge a frozen battery. Gas trapped

in the ice may cause an explosion.

- Never charge or use a battery that has been

frozen. The battery case may have be weak

ened.

- Use of batteries of different voltage or sub

stantially different capacity (Ah) rating may

cause an explosion and injury. The capacity

(Ah) of the booster battery should not be

lower than that of the discharged battery.

- Before you check anything in the engine

compartment, always read and heed all

WARNINGS

c>page 233.

@ Note

- Applying a higher voltage booster battery

will cause expensive damage to sensitive

electronic components, such as control

units, relays, radio, etc.

- There must be no electrical contact between

the vehicles as otherwise current could al

ready start to flow as soon as the positive

( + ) terminals are connected.

283

Page 286 of 310

Emergency situations

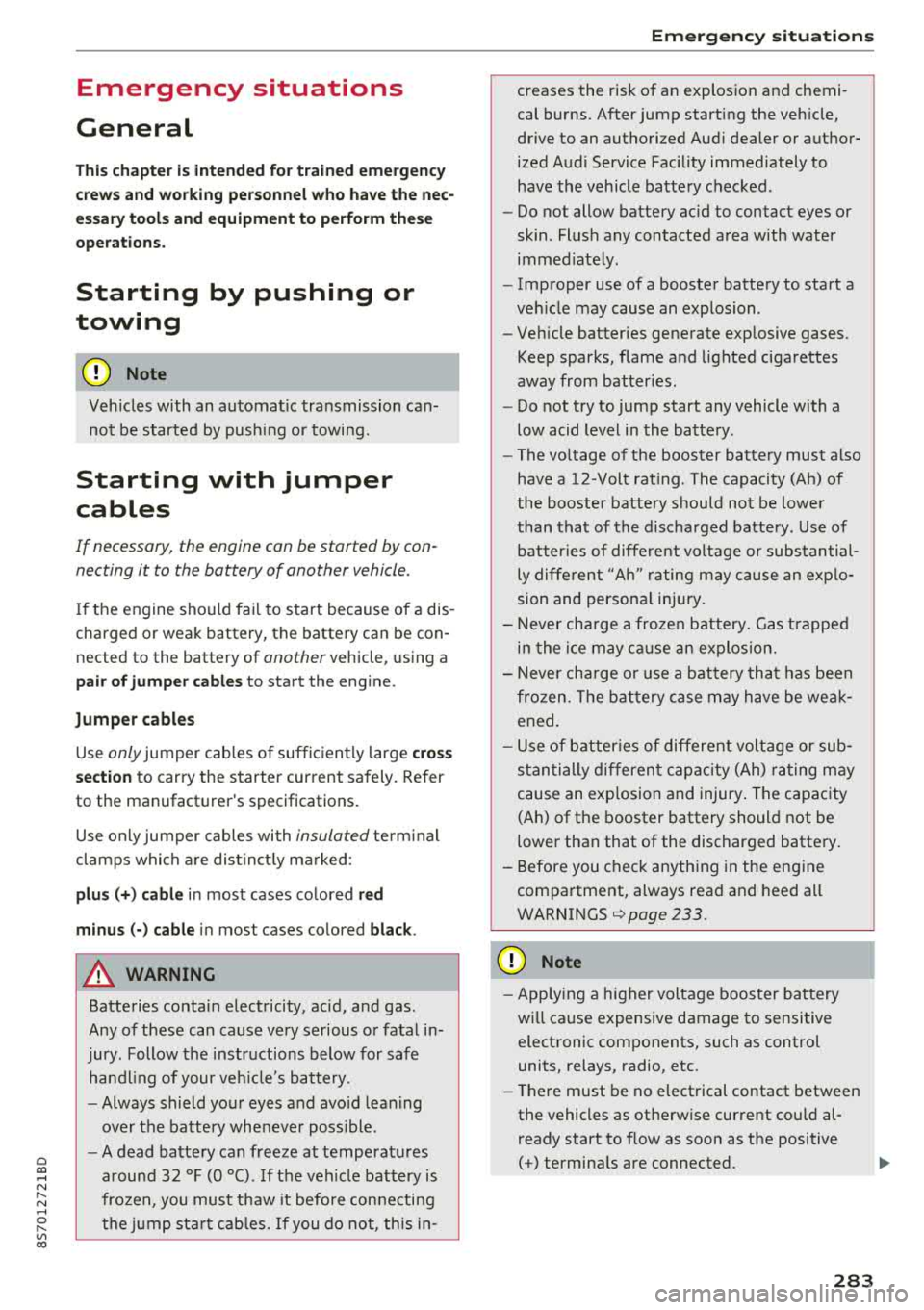

@ Tips

The discharged battery must be properly con·

nected to the vehicle's electrical system .

When jump starting or charging the battery,

never connect the negative ground cable to

the battery negative post because the battery

manager system must be able to detect the

battery's state of charge. Always connect the

negat ive g round cable to the negative ground

post of the battery manager control unit.

Using the jump start

cable

Both jump start cables must be connected in the

correct order!

Fig. 209 luggage compartme nt: connectors for jump start

cables and charg ing unit

Fig. 210 Jump starting usi ng a battery in anot her vehicle:

A· drained, B • provid ing curren t

The procedure described below for connecting

jumper cables is intended to provide a jump start

for your vehicle.

Vehicle with discharged battery:

.. Set the parking brake and select the P (Park)

selector lever position.

284

.. Switch the ignition and all electrical equipment

off.

Connecting the positive cable (red) to the

positive terminal

.. Open the red cover on the positive terminal

<=:>fig. 209.

1. Secure one end of the positive cable (red) to

the ju mp start connection

(D c:> fig. 210 on

the vehicle to be started @.

2 . Secure the other end of the pos itive cable

(red) to the positive terminal @on the vehi·

cle battery prov iding the current @.

Connecting the negative cable (black ) to the

negative terminal

3 . Secure one end of the negative cable (black)

to the negative term inal @ on the vehicle

batte ry that is providing the current @.

4. Secure the other end of the negative cable

(black) to the jump start connection

@of the

vehicle to be started @.

Starting the engine

.,. First start the engine in the vehicle giving the

charge @ and let it run at idle .

.. Now start the engine in the vehicle with the

drained veh icle battery @.

.. If the engine does not start, stop the starting

procedure after 10 seconds and then repeat it

after approximately 30 seconds .

.. Once the engine with the drained vehicle bat·

tery has been started, remove the cables in the

reverse order from the way they were installed .

.. Close the red cover on the pos itive terminal.

The battery is vented to the outside to prevent

gases from enter ing the vehicle interior. Make

sure that the jumper clamps are well connected

with their

metal ports in full contact with the

battery termin als.

.&_ WARNING

To avoid serious personal injury and damage

to the vehicle, heed all warnings and instruc

tions of the jumper cable manufacturer. If in

doubt, call for road service .

- Jumper cables must be long enough so that

the vehicles do not touch.

Page 287 of 310

-When connecting jumper cables, make sure

that they cannot get ca ught in any mov ing

parts in the engine compartment.

- Do not bend over the batteries - danger of

chem ica l burns!

- The battery cell lock ing screws must be

t ightened sec ure ly.

- Be fore you check anything in the e ngine

compartment, a lways read and hee d all

WAR NINGS

q page 233 .

(D Note

Impro per hook -up of jum pe r cables can r uin

the gene rato r.

- Always connect POSITI VE (+ ) to POS ITIV E

( + ), and NEGATIVE( -) to NEGAT IVE( -)

g roun d post of t he battery mana ger contro l

u nit.

- Check that a ll sc rew p lugs on t he battery

cells are screwed in firmly. I f not, t ighten

plugs prior to connecting clamp on negative

batte ry terminal.

- Please note that the procedure fo r con nect

i ng a jumper cab le as desc ribed above ap

p lies specifica lly to the case of yo ur vehicle

being jump starte d. When you are giv ing a

ju mp s ta rt to anothe r vehicle, do

not con

n ect the neg ative (-) cab le to the neg ative

(-) t ermin al on the di sch arged b attery @

q fig. 210. In ste ad , securely connec t the

nega tive ( -) cab le to either a solid me tal

com ponent that is f irm ly bolted to the e n

gine block o r to the engine bloc k itself. If

the battery that is be ing cha rge d does not

vent to the outs ide, escap ing battery gas

could ignite and exp lode!

Towing with a tow truck

General hints

Your Audi requires special handling for towi ng .

The fo llow ing information is to be used by com

mercia l tow tr uck operators who know how to op-

a e rate the ir equip ment safe ly. co ....

~ - Never tow your Audi. Towing will cause dam-

"' 8 age to the engine and transmission . r--Vl co

Emergency situations

-Never wrap the safety chains or winch cables

around the brake lines .

- To prevent unnecessa ry damage , your Audi

must be transported with a flatbed truck.

- To load the vehicle on to the flatbed, use the

towing loop found in the vehicle tools and at

tach to the front or rear anchorage

¢ page 285 and ¢ page 286 .

A WARNING

-A veh icle being towed is not safe for passen-

ge rs. Neve r allow anyone to ride in a vehicle

b eing towed, fo r any r eason.

Front towing loop

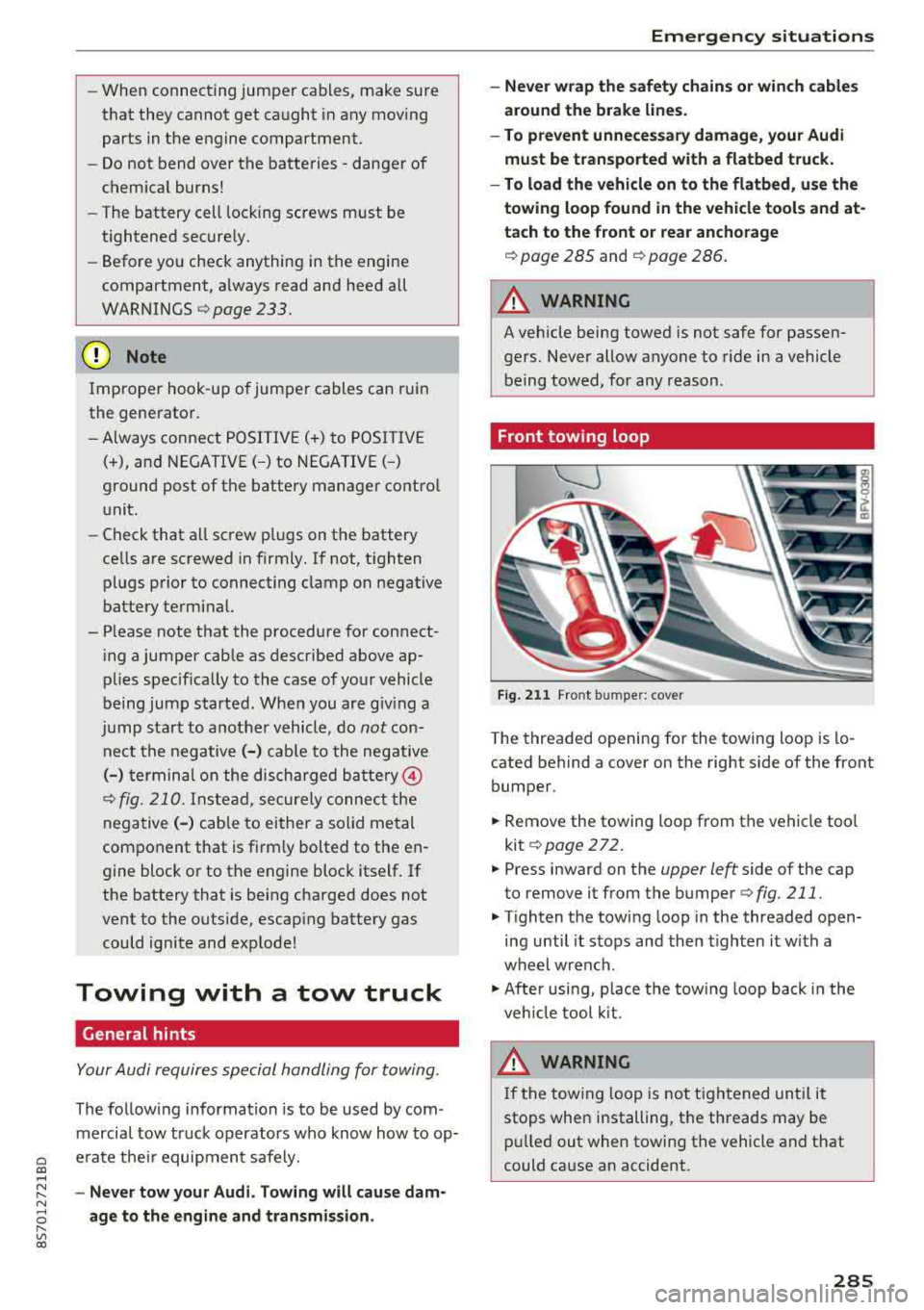

Fig. 2 11 Front bumper: cover

-

The threaded opening for the towing loop is lo

cated behind a cover on the right side of the front

bumper.

.,. Remove the towing loop from the vehicle too l

kit

¢ page 272.

.,. Press inward on the upper left side of the cap

to remove it from the bumper

¢fig. 211.

.,. Tighten the tow ing loop in the threaded open

ing until it sto ps and then tighten it w ith a

whe el wrench .

.,. After usi ng, p lace the tow ing loop b ack i n the

ve hicl e tool kit.

WARNING

If the towing loop is not ti ghtened until it

stops whe n installing, t he threads may be

pull ed out when towing the vehicle a nd that

could ca use an accident.

285

Page 288 of 310

Emergency situations

Rear towing loop

0

-M 0

ct Cl)

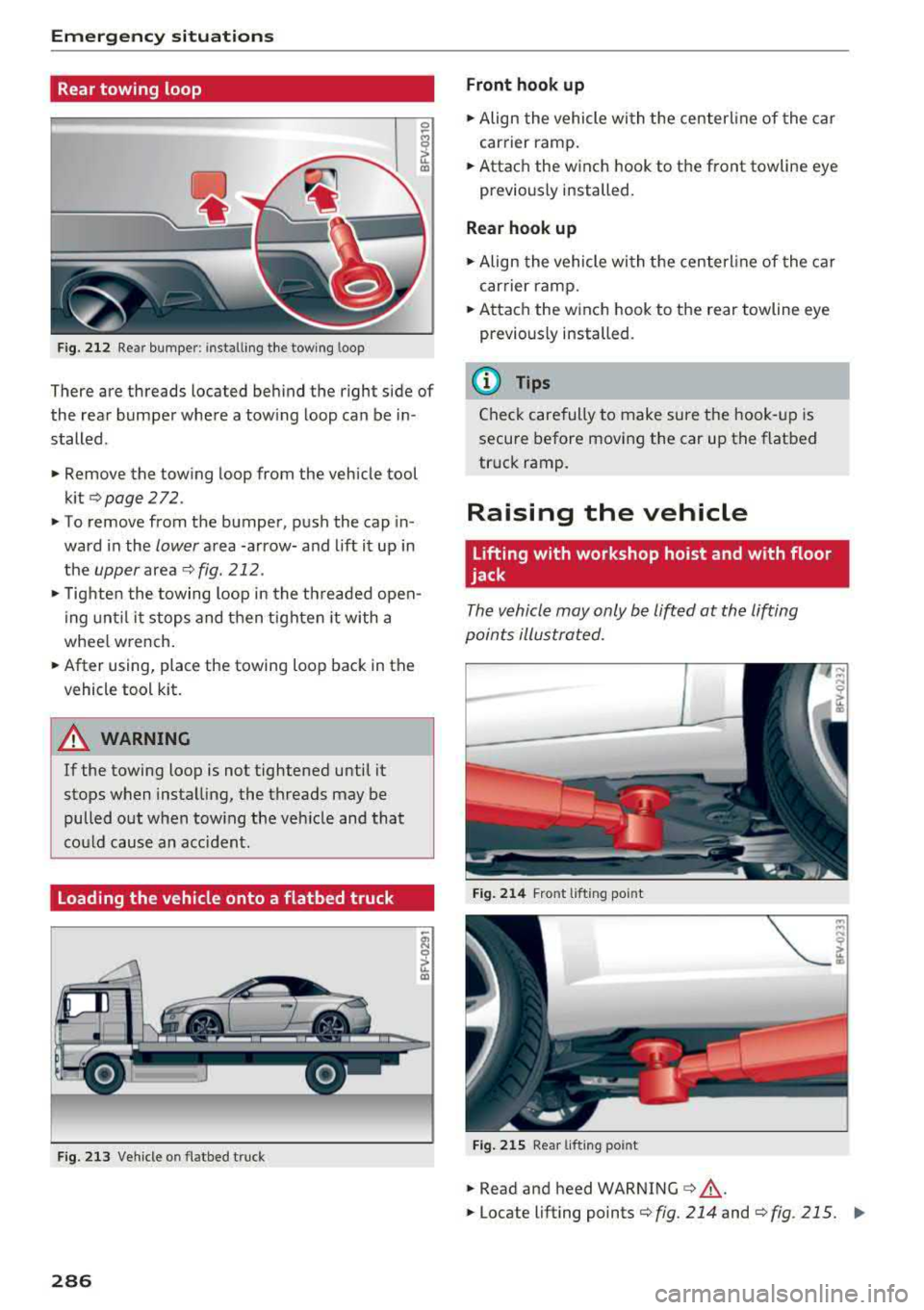

Fig. 212 Rear bumper: i nstalling the towing loop

There are threads located behind the right side of

the rear bumper where a towing loop can be in

stalled.

.. Remove the towing loop from the vehicle tool

kit

Q page 272.

.. To remove from the bumper, push the cap in

ward in the

lower area -arrow- and lift it up in

the

upper area ¢ fig. 212 .

.,. Tighten the towing loop in the threaded open

ing until it stops and then tighten it with a

whee l w rench .

.. After using, place the towing loop back in the

vehicle tool kit.

A WARNING

If the towing loop is not tightened until it

stops when installing, the threads may be

pulled out when tow ing the vehicle and that

cou ld cause an accident.

Loading the vehicle onto a flatbed truck

Fig. 213 Vehicle o n flatbed tru ck

286

Front hook up

.. Align the vehicle with the center line of the car

carrier ramp.

.. Attach the winch hook to the front towline eye

pr eviously installed.

Rear hook up

.,. Align the vehicle with the centerl ine of the car

carrier ramp .

.. Attach the winch hook to the rear towline eye

previously installed.

(D Tips

Check carefully to make sure the hook-up is

secure before moving the car up the flatbed

truck ramp .

Raising the vehicle

Lifting with workshop hoist and with floor

jack

The vehicle may only be lifted at the lifting

points illustrated .

Fig. 214 Front lifting point

Fig. 215 Rear lif ting po int

.,. Read and heed WARNING ¢&, .

.. Locate lifting points ¢fig. 214 and ¢fig . 215. II>

Page 289 of 310

Cl 00 .-< N r-N .-< 0 r-Vl 00

~ Adjust lifting a rms o f wo rkshop ho ist o r floo r

jack to match veh icle lifting points .

~ In se rt a r ubber pad between t he floor jack/

wor kshop hoist and the lifting points.

The vehicle jac k mode* must be activated so that

the automatic a djustment of the Adaptive Air

Suspension* does not make it more difficult to

raise t he ve hicle w it h the floor jac k.

If you must lift your vehicle with a floor jack to

work underneath , be sure the vehicle is safely

supported on stands intended for this purpose.

Front lifting point

T h e lif ting poi nt is locat ed on the floor pan re in

fo rceme nt abou t at t he s ame leve l as t he jac k

mo unt ing poin t

i::> fig . 214. Do not lift the vehi

cle at the vertical sill reinforcement.

Rear lifting point

T h e lif tin g point is loc ated o n the ve rt ical rein

f o rc eme nt of th e lowe r sil l fo r th e on-bo ard jac k

¢fig . 215.

Lifting with vehicle jack

Refer to i::> page 2 76 .

A WARNING

- T o re duc e th e risk of seri ous injur y an d vehi

cl e dama ge.

- A lways lift t he veh icle only at the s pecial

wo rksho p hoist and floo r jack lift po ints il

lust rated

¢ fig. 214 and ¢ fig. 215.

- Fa ilu re to li ft the vehicle at these points

could cause the vehicle t o til t or fa ll from

a li ft if there is a change in veh icle we ig ht

d istr ibu tion a nd balance. Th is m ight hap

p en , fo r e xamp le, wh en h eavy co m po

n e nts s uch a s the engi ne b lock or tran s

mission ar e re mo ved.

- W hen remo ving h eavy compo nents like

t h ese, anchor vehicle to hoi st or add cor re

s p ondi ng we ights to ma inta in t he ce nt er of

g ra vity . Ot herwise, the vehi cle m ight ti lt or

s lip off the hoist, causin g serio us persona l

injury .

Emergency situations

@ Note

-Be aware of t he fo llow ing poin ts befo re lift

in g th e vehicle:

-The vehicle should never be lifted or

jacked up from underneath the engine oil

pan, the transmission housing, the front

or rear axle or the body side members.

This could lead to serious damage.

- To avoid damage to the underbody or

chassis frame, a rubber pad must be in

serted between the floor jack and the lift

points.

- Before driving over a workshop hoist,

check that the vehicle weight does not

exceed the permissible lifting capacity of

the hoist.

- Before driving over a workshop hoist , en

sure that there is sufficient clearance be

tween the hoist and low parts of the ve

hicle.

287

Page 290 of 310

Technical data

Technical data

Vehicle specifications

XXXXX XX -X -X X XX XXX XX

©-+ = :::t::: XXXXXXXX XX X X X XX XX XX

IYP /rYP! XXX XXX

XX XXXXXXX XX X X XX

XXX

K W XXX

15\_J_ I lllfOlll(S ,/ liTR,kB. xxxx X XX XXX ~ Ut; . OOll / lllANS. 000!

©+ ~

1

:tf:l~

1

XXXX / XXXX XXX / XX

II. · AIJSliT. / OPTIONS

~--

EOA 7D 5 4U B 6XM 5S G 5R W

2 EH JO Z 1 LB 1AS 1BA

3FC

5 M U 7X 1

F O A 9G3 OG7 OY H OJF

TL 6 3KA 8EH U1A X 9B O Z7

lXW 803 908 8Z4 02D

7T6 C V7 7KO 4X3

2K2

3 L4 4KC 3Y O 413 50 2

1S A 7GB 0 1A 4G0

XX . X XX X XX X XXXX

Fig. 21 6 Veh icl e ident ifi cation labe l

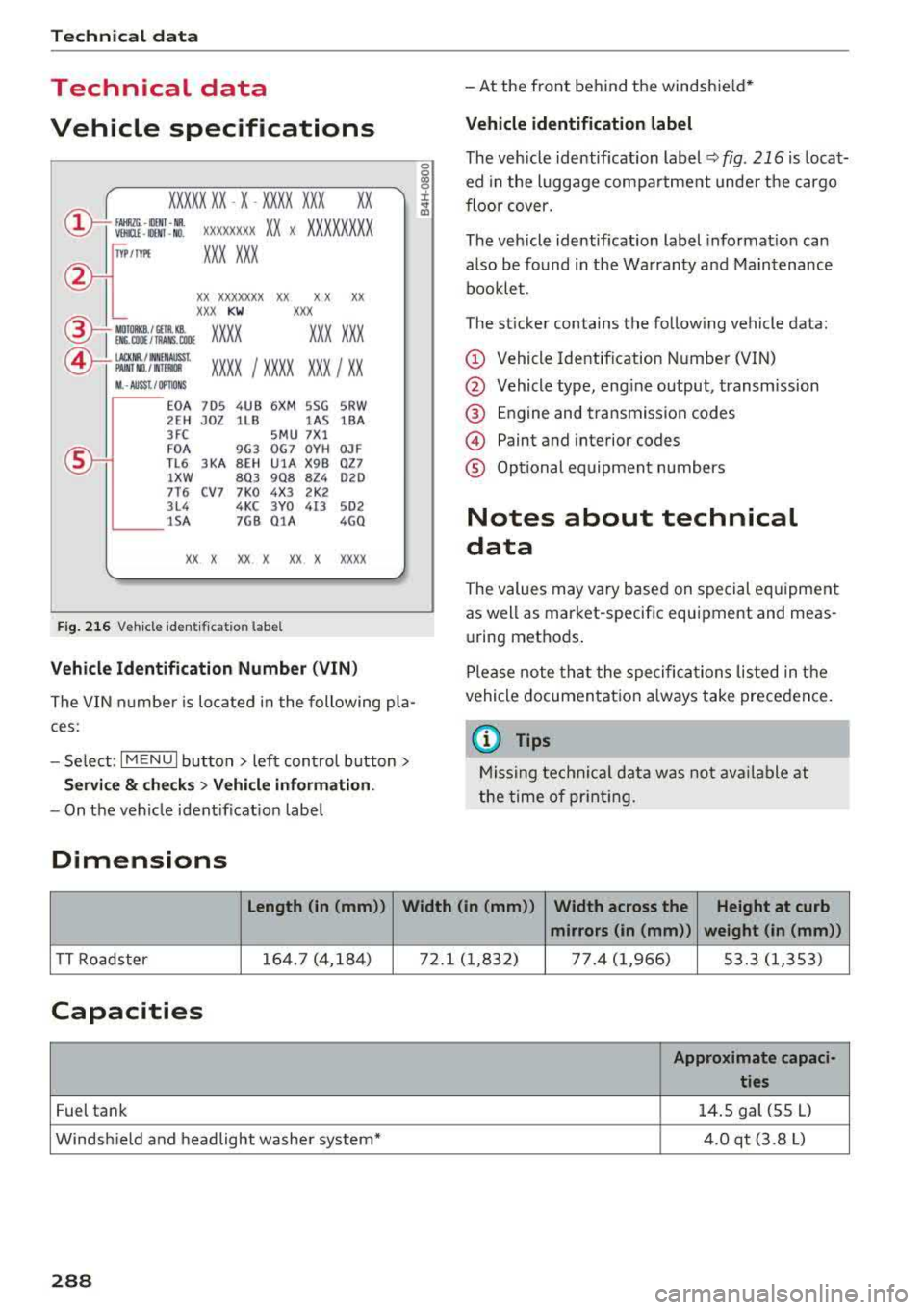

Vehicle Identification Number (VIN)

The VIN n umbe r is lo cated i n the following pla

ces :

-Select : I MENU I but to n > left con trol button>

Service & checks > Vehicle information .

-On the vehicle ident ificat io n label

Dimensions

0

0

~ :x: ... m

-At the front behind the windshie ld*

Vehicle identification label

The veh icle identification label Q fig . 216 is loca t·

ed in the luggage compartme nt unde r the cargo

floor cover.

The veh icle identification label informat ion can

also be found in t he Warranty and Maintenance

bookle t.

The st icker contains the follow ing vehicle data:

© Vehicle Identif ication Number (VIN)

@ Vehicle type, eng ine output, transmission

@ E ngine and transmission codes

© Paint and interior codes

® Op tional equipment numbers

Notes about technical

data

The values may vary based on special equipment

as well as market-specific equipment and meas u ring methods .

Please note that the spe cific ations liste d in the

vehicle documentat io n always take precedence .

a) Tips

Missing technical data w as not ava ilable at

the time of pr int ing.

length (in (mm )) Width (in (mm ))

Width across the Height at curb

mirrors (in (mm )) weight (in (mm))

TT Roadster 164. 7 (4,18

4) 72.1 ( 1,832) 77. 4 (1 ,966) 53.3 (1,353)

Capacities

Approximate capaci -

ties

Fuel tank 14

. 5 gal (55 L)

Windsh ield and headlight washe r system* 4.0 qt (3.8 L)

288