check engine BMW 528i 1998 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 528i, Model: BMW 528i 1998 E39Pages: 1002

Page 768 of 1002

Downloaded from www.Manualslib.com manuals search engine

340-6

1 Brakes

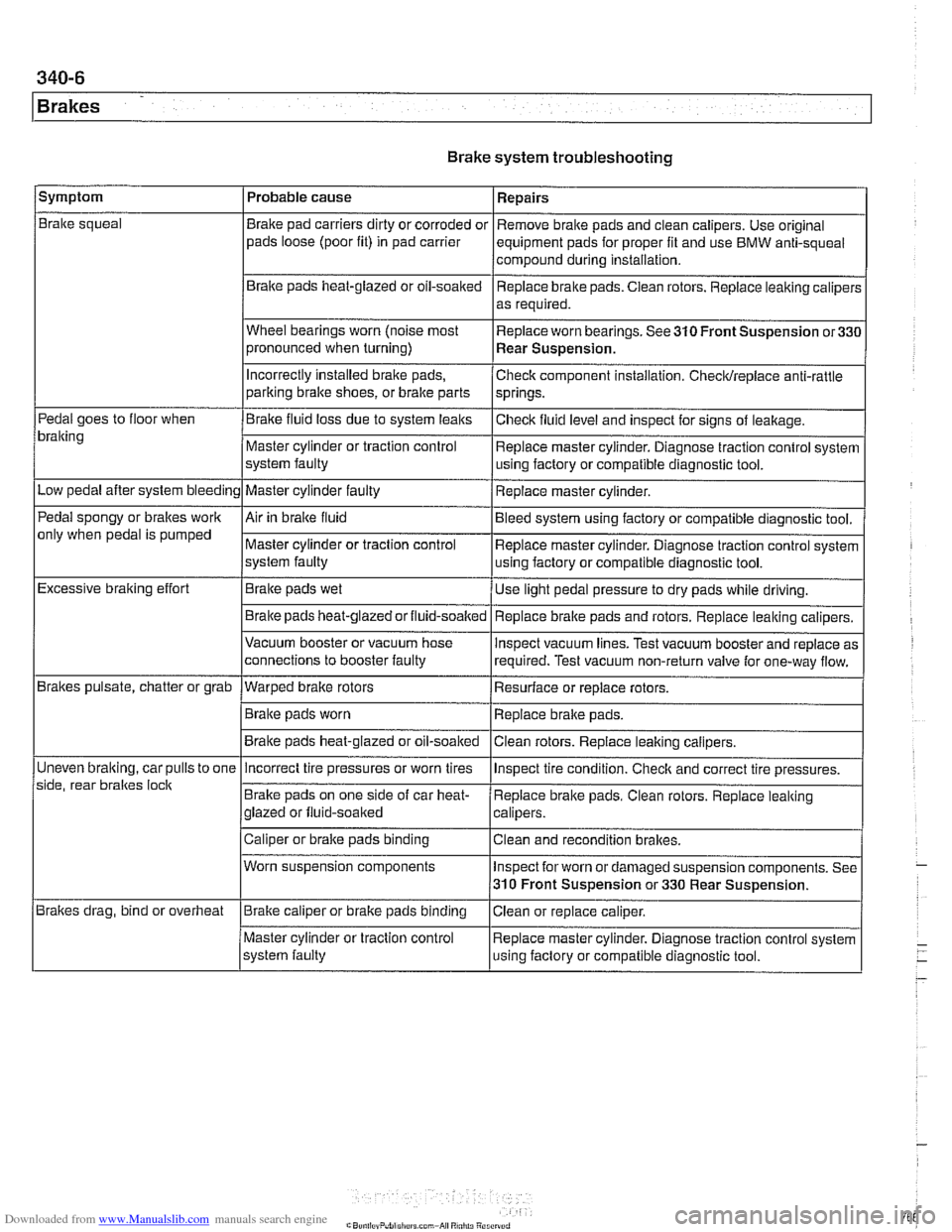

Brake system troubleshooting

/symptom I Probable cause 1 Repairs

Brake squeal

Pedal goes to floor when

bralting

Low pedal after system bleeding

Pedal spongy or brakes work

only when pedal is pumped

Excessive braking effort

Brakes pulsate, chatter or grab

Uneven

bralting, car pulls to one

side, rear braltes

loclt

Brakes drag, bind or overheat Brake

pad carriers dirty or corroded or

pads loose (poor fit) in pad carrier

Braite pads heat-glazed or oil-soaked

Wheel bearings worn (noise most

pronounced when turning)

Incorrectly Installed brake pads,

parking bralte shoes, or bralte parts

Brake fluid loss due to system leaks

Master cylinder or traction control

system faulty

Master cylinder faulty

Air in braite fluid

Master cylinder or traction control

system faulty

Brake pads wet

Brake pads

heat-glazedorfluid-soalted

Vacuum booster or vacuum hose

connections to booster faulty

--- Warped brake rotors

Brake pads worn

Brake pads heat-glazed or oil-soaked Remove

brake pads and clean calipers. Use original

equipment pads for proper fit and use BMW anti-squeal

compound during installation,

Replace brake pads. Ciean rotors. Replace leaking caliper:

as required.

Replace worn bearings. See 310 Front Suspension

or33C

Rear Suspension.

Check component installation. Checldreplace anti-rattle

springs.

Checlt fluid level and inspect for signs of leakage.

Replace master cylinder. Diagnose traction control system

using factory or compatible diagnostic tool.

Replace master cylinder.

Bleed system using factory or compatible diagnostic tool.

Replace master cylinder. Diagnose traction control system

using factory or compatible diagnostic tool.

Use light pedal pressure to dry pads while driving.

Replace

bralte pads and rotors. Replace leaking calipers.

lnspect vacuum lines. Test vacuum booster and replace as

required. Test vacuum non-return valve for one-way flow.

Resurface or replace rotors.

Replace brake pads.

Clean rotors. Replace leaiting calipers.

Incorrect tire pressures or worn tires

Brake pads on one side of car heat-

glazed or fluid-soaked

Caliper or brake pads binding

Worn suspension components

Brake caliper or brake pads binding

Master cylinder or traction control

system faulty lnspect

tire condition. Checlt and correct tire pressures.

Replace brake pads. Clean rotors. Replace leaking

calipers.

Clean and recondition brakes.

Inspect for worn or damaged suspension components. See

310 Front Suspension or 330 Rear Suspension.

Ciean or replace caliper.

Replace master cylinder. Diagnose traction control system

using faclory or compatible diagnostic tool.

Page 772 of 1002

Downloaded from www.Manualslib.com manuals search engine

Brakes

- Open bleeder screw. Carry out bleeding procedure with

BMW Service Tester until clear, bubble-free fluid flows.

Models with DSC: After BMW Service Tester bleeding rou-

tine has finished, press brake pedal to floor

5 times until

clear, bubble-free fluid runs out. Close right rear bleeder

valve.

Models with ASC: Close right rear bleeder valve.

- Repeat procedure at left rear brakes.

- Repeat BMW Service Tester bleeding at right front brakes.

Models with DSC: After

BMW Service Tester bleeding rou-

tine has finished, press brake pedal to floor

5 times until

clear, bubble-free fluid runs out. Close right front bleeder

valve.

Models with ASC: After BMW Service Tester bleeding rou-

tine has finished, press brake pedal to floor

12 times until

clear, bubble-free fluid runs out. Close right front bleeder

valve.

- Repeat procedure at left front brakes.

- Remove brake bleeding apparatus and disconnect BMW

Service Tester. Top up brake fluid. Check to make sure

brake 1

fluid reservoir cap seal is intact.

Tightening torques Bleeder screws (wrench size)

- 7 rnrn screw

3.5 - 5 Nrn (2.5 - 3.7 ft-lb)

11 rnrn screw 12-16Nrn(9-12ft-lb)

Page 774 of 1002

Downloaded from www.Manualslib.com manuals search engine

340-1 2

Brakes Brake pads, checking and replacing

Brake pads can be replaced without disconnecting the brake

fluid hose from the caliper or having to bleed the brakes. The

rotors can be replaced without disassembling wheel hub and

bearing. Always machine or replace rotors in pairs. Replace

pads in sets.

Front and rear brake pad replacement procedures are identical.

WARNING -

* Altllough semi-metallic andmetallic brale friction materials

in brake pads or shoes no longer contain asbestos, they

produce dangerous dust.

Treat all

brale dust as a hazardous material.

Do not create dust by grinding, sanding, or cleaning

brake friction surfaces with compressed air.

CAUTION--

Pressing caliper piston in may cause brake fluid reservoir to

overflow To prevent this, use a clean syringe to first remove

some fluid

from reservoir.

Raise car and remove wheels,

WARNING-

Make sure that the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands beneath structural

chassis points. Do not place jack stands under suspension

parts.

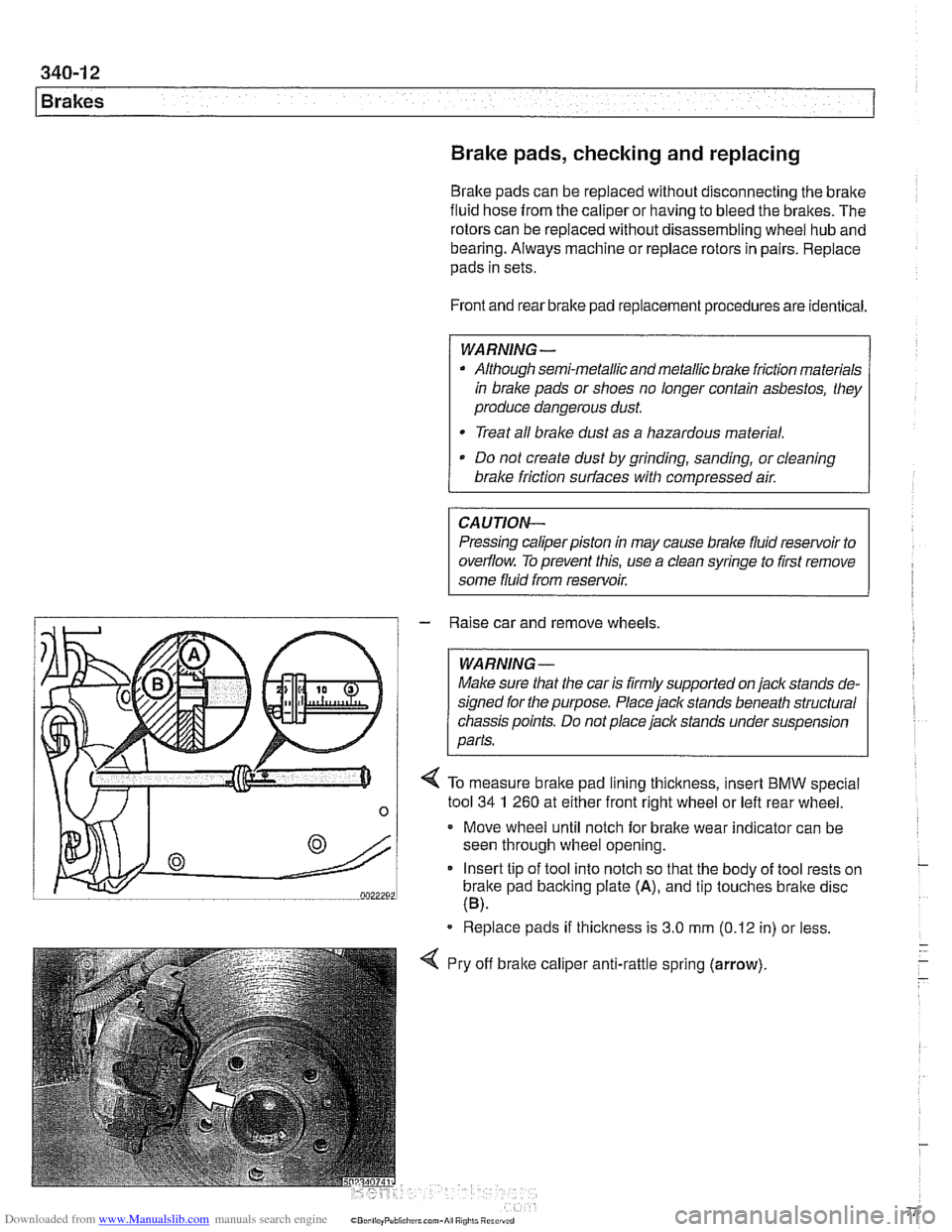

/ 4 To measure brake pad lining thickness, insert BMW special

n 1 tool 34 1 260 at either frontilght wheel or left rear wheel -

Move wheel until notch for brake wear indicator can be

seen through wheel opening.

Insert tip of tool into notch so that the body of tool rests on

brake pad backing plate

(A), and tip touches bralte disc

(B).

Replace pads if thickness is 3.0 mm (0.12 in) or less.

Pry off

bralte calipe~ , anti-rattle spring (arrow).

Page 775 of 1002

Downloaded from www.Manualslib.com manuals search engine

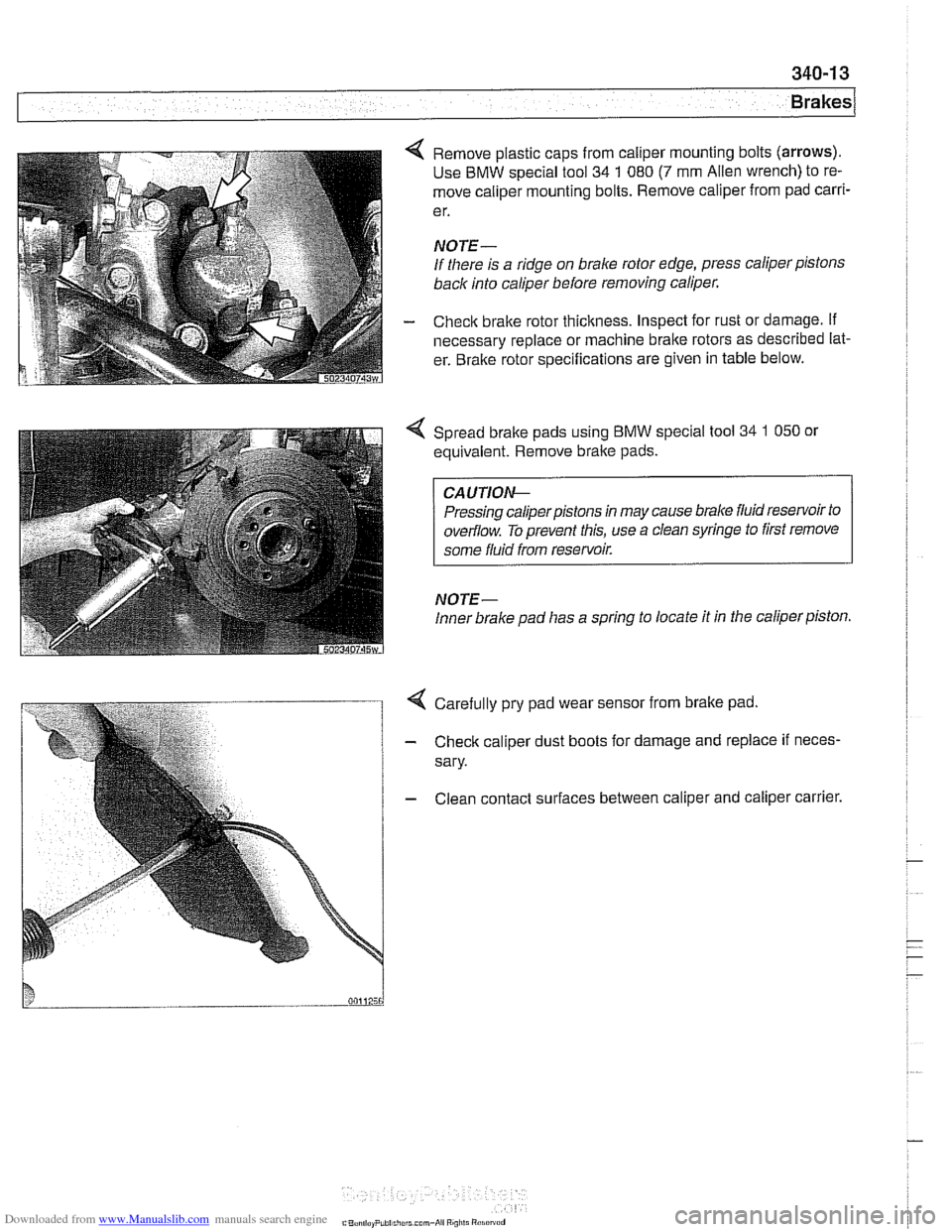

4 Remove plastic caps from caliper mounting bolts (arrows).

Use BMW special tool 34 1 080 (7 mm Alien wrench) to re-

move caliper mounting bolts. Remove caliper from pad

carri-

e r.

NOTE-

If there is a ridge on brake rotor edge, press caliper pistons

back into caliper before removing caliper.

- Check brake rotor thickness. Inspect for rust or damage. if

necessary replace or machine brake rotors as described lat-

er. Bralte rotor specifications are given in table below.

Spread bralte pads using BMW special tool

34 1 050 or

equivalent. Remove brake pads.

CA UTIOG

Pressing caliperpistons in may cause brake fluid reservoir to

overflow. To prevent this, use a clean syringe to first remove

some fluid from reservoir.

NOTE-

Inner brake pad lias a spring to locate it in the caliper piston.

4 Carefully pry pad wear sensor from brake pad

- Check caliper dust boots for damage and replace if neces-

sary.

- Clean contact surfaces between caliper and caliper carrier.

C"..., I,.. P,hi..,,,.r.. mm-*ii Ai"i,li "1.i"~"d

Page 777 of 1002

Downloaded from www.Manualslib.com manuals search engine

340-1 5

Brakes

- Remainder of installation is reverse of removal.

- Clean brake caliper mounting bolts (7 mm Allen). Replace

ones which are not in perfect condition. Do not grease.

Top up brake fluid to MAX marking.

- Before driving car, pump bralte pedal several times so that

brake pads contact brake rotors.

Check that brake fluid level is correct. Top up if necessary.

Hold ignition key for at least

30 seconds in accessory po-

sition without starting engine. This clears any fault codes in

memory and turns off brake pad warning light.

Tightening torques Brake caliper to pad carrier

(7 mm Allen)

Front caliper

30 Nm (22 It-lb)

- Rear caliper 28 Nm (21 It-lb)

Road wheel to hub

120i 10 Nm (89i7 ft-lb)

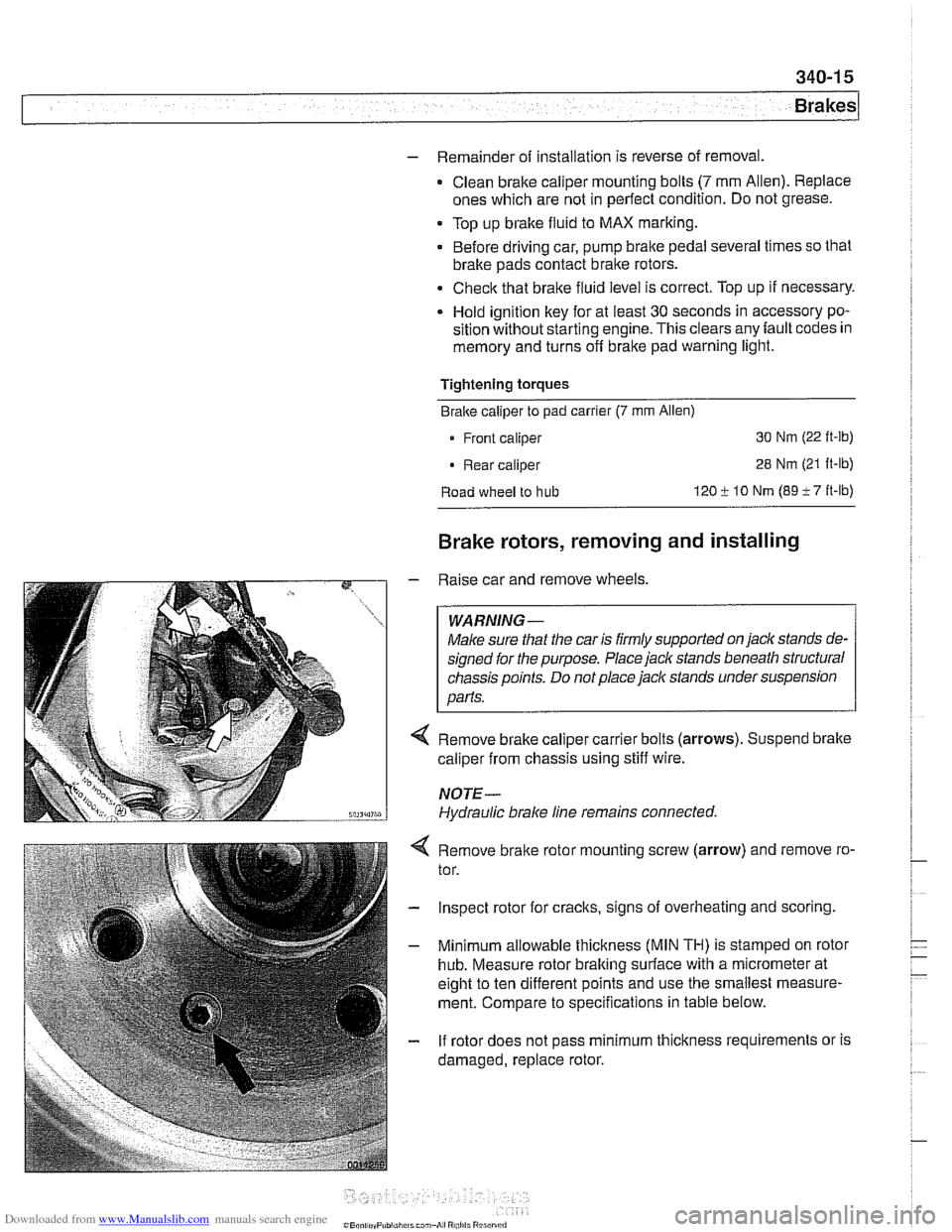

Brake rotors, removing and installing

- Raise car and remove wheels

WARNING-

Male sure that the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands beneath structural

chassis points. Do not place jack stands under suspension

parts.

Remove brake caliper carrier bolts (arrows). Suspend brake

caliper from chassis using stiff wire.

NOTE-

Hydraulic brake line remains connected.

4 Remove bralte rotor mounting screw (arrow) and remove ro-

tor.

- Inspect rotor for cracks, signs of overheating and scoring.

- Minimum allowable thickness (MIN TH) is stamped on rotor

hub. Measure rotor braking surface with a micrometer at

eight to ten different points and use the smallest measure-

ment. Compare to specifications in table below.

- If rotor does not pass minimum thickness requirements or is

damaged, replace rotor.

Page 781 of 1002

Downloaded from www.Manualslib.com manuals search engine

Brakes

The brake booster is mounted to the bulkhead on driver's side

of the engine compartment, directly behind the brake master

cylinder. Intake manifold vacuum acts on a large diaphragm

in the brake booster to reduce brake pedal effort.

Brake booster check valve

The checlc valve in the bralte booster vacuum line prevents

contamination from engine backfires and other sources from

entering the bralte booster.

Location of

check valve varies, depending on year and mod-

el.

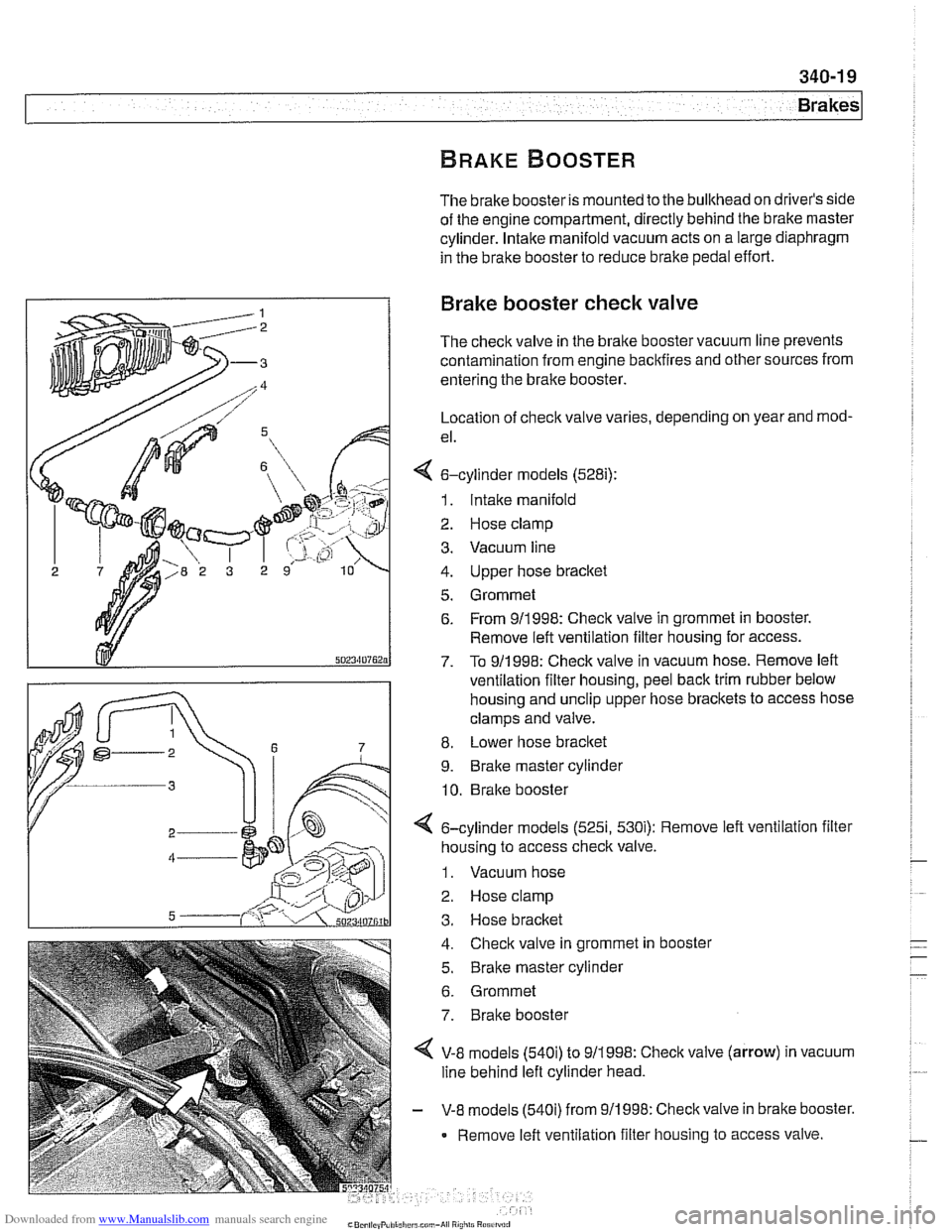

4 6-cylinder models (528i):

1. Intake manifold

2 Hose clamp

3. Vacuum line

4. Upper hose bracket

5. Grommet 6. From 911998: Check valve in grommet in booster.

Remove left ventilation filter housing for access.

7. To 911 998: Check valve in vacuum hose. Remove left

ventilation filter housing, peel back trim rubber below

housing and

unclip upper hose brackets to access hose

clamps and valve.

8. Lower hose

bracket

9. Brake master cylinder

10. Brake booster

< 6-cylinder models (525i, 530i): Remove left ventilation filter

housing to access

checlc valve.

1. Vacuum hose

2. Hose clamp

3. Hose bracket

4. Check valve in grommet in booster

5.

Braite master cylinder

6. Grommet

7. Brake booster

4 V-8 models (540i) to 911998: Check valve (arrow) in vacuum

line behind left cylinder head.

- V-8 models (540i) from 911998: Checkvalve in brake booster.

Remove left ventilation filter housing to access valve.

Page 782 of 1002

Downloaded from www.Manualslib.com manuals search engine

Brakes

- Pump brake pedal a few times to reduce vacuum in brake

booster. This makes removal of

check valve easier.

- Remove or loosen hose clamp(s) at check valve.

- Disconnect hoses. Remove valve to test or replace.

NOTE-

If valve is pressed into grommet in vacuum booster, pry it out

carefully.

- Reinstall valve using new hose clamps

NOTE-

Install the valve so that the molded arrow is pointing toward

the intake manifold.

Brake booster, removing and installing

CAUTIO&

All E39 vehicles sold in the USA are equipped with Antiloclc

Braking System (ABS) and either Automatic Stability Control

(ASC) or Dynamic Stability Control (DSC). In order for the

bralchg and stability controls to work properk if brake fluid

lines are disconnected and reconnected,

male sure that the

brake system is bled by an authorized BMW dealer or other

qualified repair facility using the BMW Service Tester: See

Brake Bleeding earlier in this group.

- Disconnect negative (-) cable from battery.

I CAUTION- I

Prior to disconnecting the battery read the battery discon-

nection cautions given in

001 General Cautions and

I Warnings. I

- Remove bralte master cylinder as described earlier.

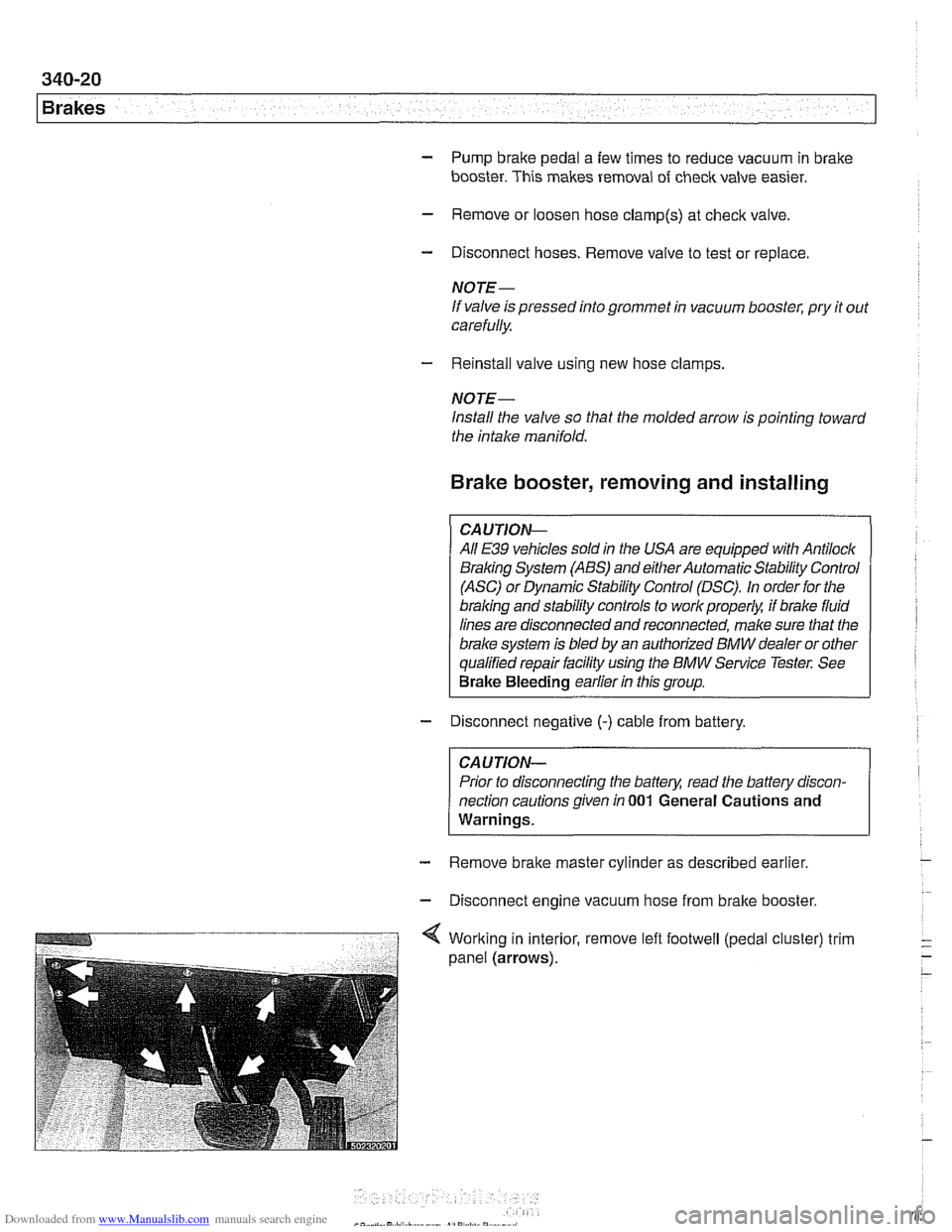

- Disconnect engine vacuum hose from bralte booster.

Page 783 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 Brakes

Pull down panel

If applicable, disconnect electrical harness

rows) from 16-pin OBD-ll plug.

Remove panel from interior. connectors

(ar-

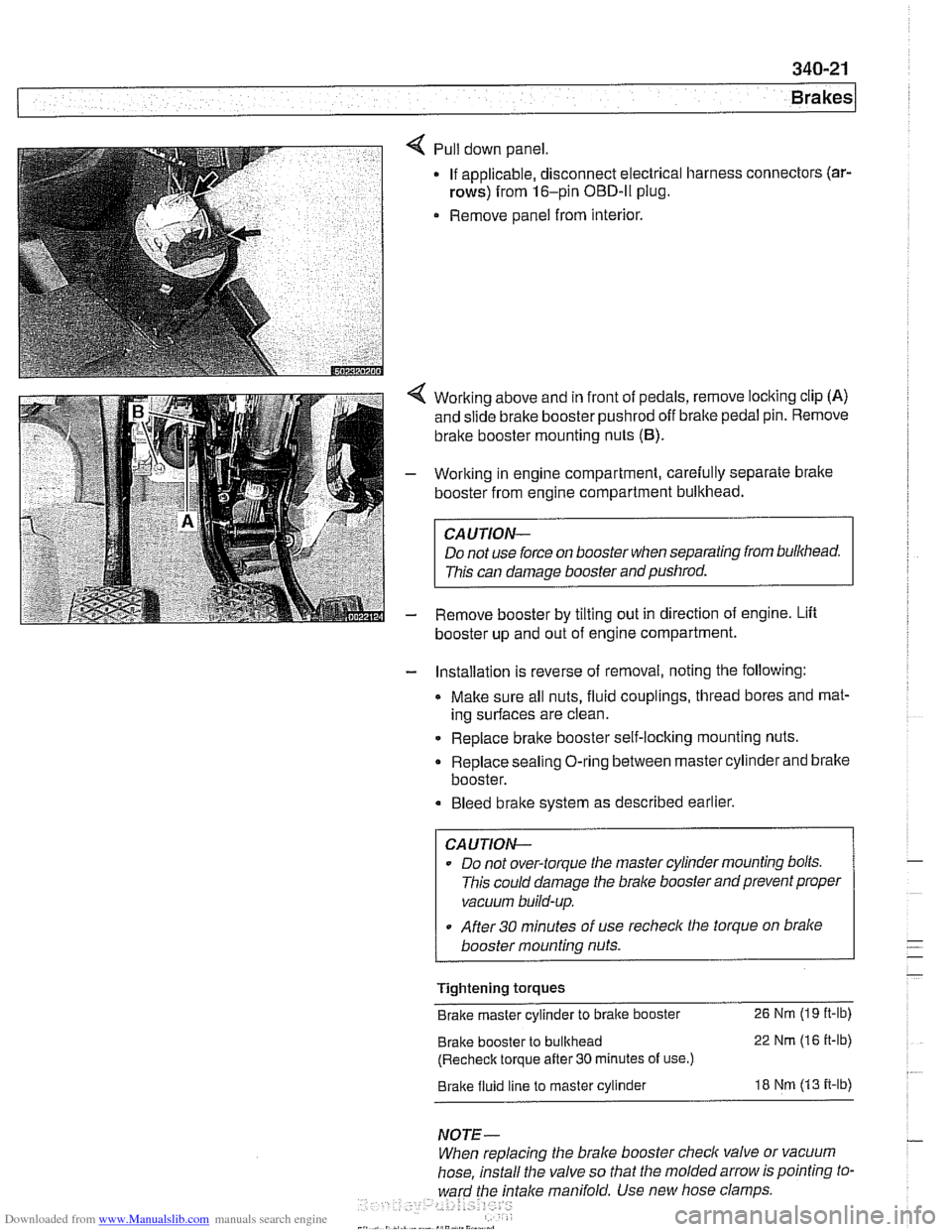

Working

above and in front of pedals, remove locking clip (A)

and slide brake booster pushrod off bralte pedal pin. Remove

brake booster mounting nuts

(6).

Working in engine compartment, carefully separate bralte

booster from engine compartment bulkhead.

CAUTION-

Do not use force on booster when separating from bulkhead.

This can damage booster and pushrod.

Remove booster by tilting out in direction of engine. Lift

booster up and out of engine compartment.

- Installation is reverse of removal, noting the following:

Make sure all nuts, fluid couplings, thread bores and mat-

ing surfaces are clean.

Replace bralte booster self-locking mounting nuts.

Replace sealing O-ring between master cylinder and bralte

booster.

Bleed bralte system as described earlier.

CAUTION--

Do not over-torque tlie master cylinder mounting bolts.

This could damage the

bralce booster and prevent proper

vacuum build-up.

After

30 minutes of use recheclc the torque on bralce

booster mounting nuts.

Tightening torques

Brake master cylinder to brake booster

26 Nm (19 it-lb)

Brake booster to bulkhead 22 Nm (16 it-lb)

(Recheck torque after

30 minutes of use.)

Brake fluid line to master cylinder 18 Nm (13 it-lb)

NOTE-

When replacing the brake booster check valve or vacuum

hose, install the valve so that the molded arrow is pointing to-

ward the

fntalce manifold. Use new hose clamps

Page 792 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 Brakes

- Remove precharge pump mounting bracket fasteners and re-

move pump.

- Installation is reverse of removal, noting the following:

Be sure to replace rubber pump mounts if damaged

01

worn.

Bleed brakes as described earlier.

Tightening torque Brake line

to precharge pump 18 Nrn (13 ft-lb)

DSC pressure sensor (1 999 - 2002 models)

On 1999 and later DSC systems, the DSC pressure sensor is

screwed into the DSC hydraulic unit (right rear of engine com-

partment).

WARNING-

* €39 cars require special BMW service equipment to prop-

erly bleed the brakes. Removal of the

DSCpressure sensor

is not recommended unless this equipment is available. For

safety reasons, the brake system on cars with ABS must be

bled using the procedures described in this repair group.

Switch off ignition and remove

key to male sure brake

system cannot be activated.

- Disconnect electrical harness connector at switch.

- Use BMW special tool 34 5 160 to remove and install sensor.

Inspect threads and sealing surfaces for damage.

* Work quicltly to avoid excessive brake fluid leakage.

Tightening torque

Pressure sensor

to hydraulic 19 Nrn (14ft-lb)

unit

- Reconnect harness connector

- Bleed front brakes as described earlier.

- Press on brakes and check for leaks at sensor.

- Turn on ignition and firmly depress brake pedal. Check that

DSC warning light does not come on.

Page 794 of 1002

Downloaded from www.Manualslib.com manuals search engine

340-32

Brakes

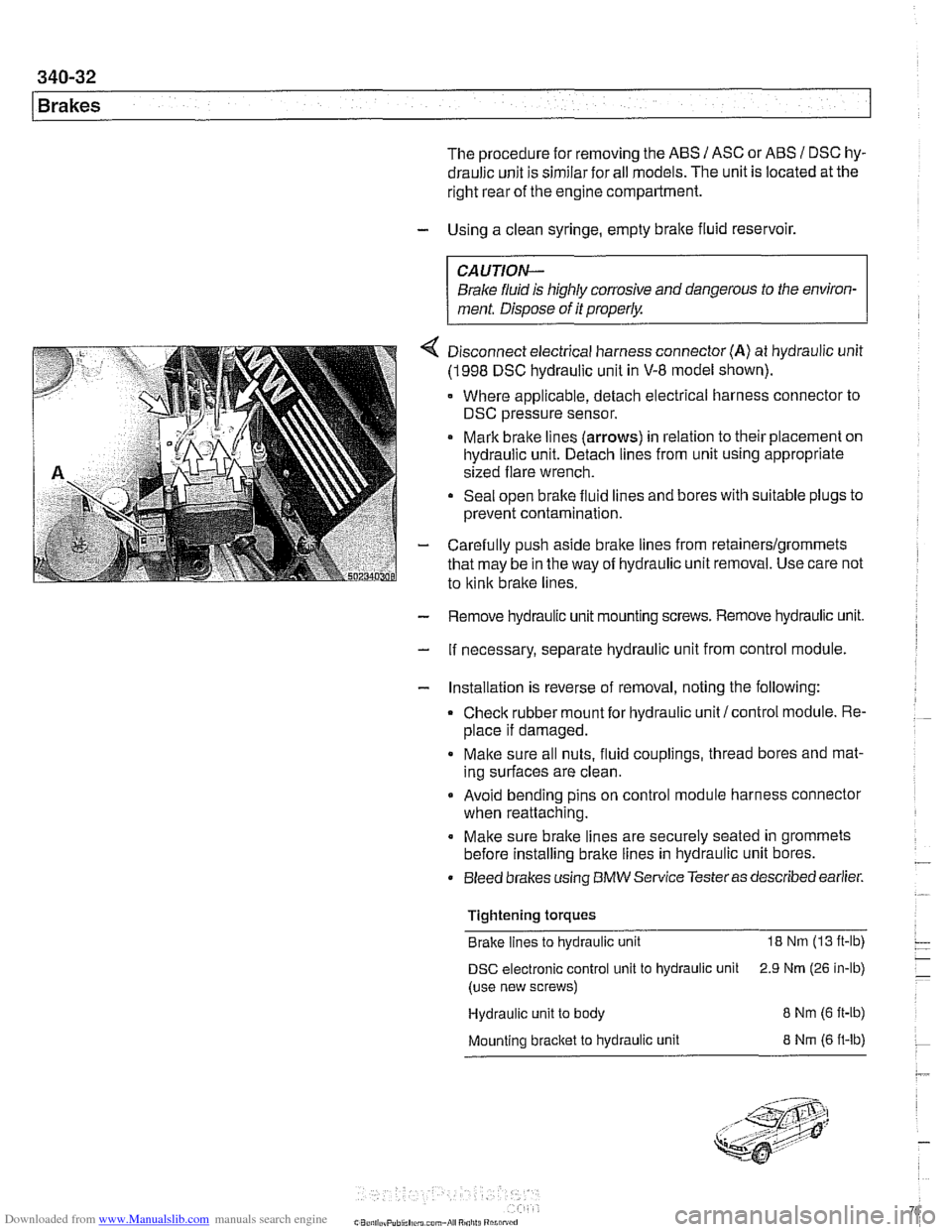

The procedure for removing the ABS I ASC or ABS I DSC hy-

draulic unit is similar for all models. The unit is located at the

right rear of the engine compartment.

- Using a clean syringe, empty brake fluid reservoir.

CAUTION-

Brake fluid is highly corrosive and dangerous to the environ-

ment. Dispose of it

properiw

4 Disconnect electrical harness connector (A) at hydraulic unit

(1998 DSC hydraulic unit in V-8 model shown).

Where applicable, detach electrical harness connector to

DSC pressure sensor.

Mark brake lines

(arrows) in relation to their placement on

hydraulic unit. Detach lines from unit using appropriate

sized flare wrench.

Seal open brake fluid lines and bores with suitable plugs to

prevent contamination.

- Carefully push aside brake lines from retainerslgrommets

that may be in the way of hydraulic unit removal. Use care not

to

kink brake lines.

- Remove hydraulic unit mounting screws. Remove hydraulic unit.

- If necessary, separate hydraulic unit from control module.

- Installation is reverse of removal, noting the following:

Check rubber mount for hydraulic unit/control module. Re-

place if damaged.

Make sure all nuts, fluid couplings, thread bores and mat-

ing surfaces are clean.

Avoid bending pins on control module harness connector

when reattaching.

Make sure brake lines are securely seated in grommets

before installing brake lines in hydraulic unit bores.

Bleed brakes using

BMW Service Testeras described earlier.

Tightening torques Brake lines to hydraulic unit

18 Nm (13 ft-lb)

DSC electronic control unit to hydraulic unit 2.9 Nrn (26 in-lb)

(use new screws)

Hydraulic unit to body

8 Nm (6 ft-ib)

Mounting bracket to hydraulic unit 8 Nrn (6 ft-lb)