torque CHERY TIGGO 2009 Service Owners Manual

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 1213 of 1903

Downloaded from www.Manualslib.com manuals search engine MANUAL TRANSAXLE UNIT REPAIR

Transaxle

Specifications

Torque Specifications

DESCRIPTIONTORQUE (N·m)

Gear Shift Mechanism Housing Bolt 18

Gear Positions Self-Locking Bolt 35

Reverse Gear Bolt 20

Reverse Gear Cap Bolt 20

Rear Transaxle Bearing End-Plate Bolt 6.9

Transaxle To Clutch Housing Bolt 44

Bearing Input Shaft Bolt 18

Disassembly

1. Place the transaxle on a workbench.

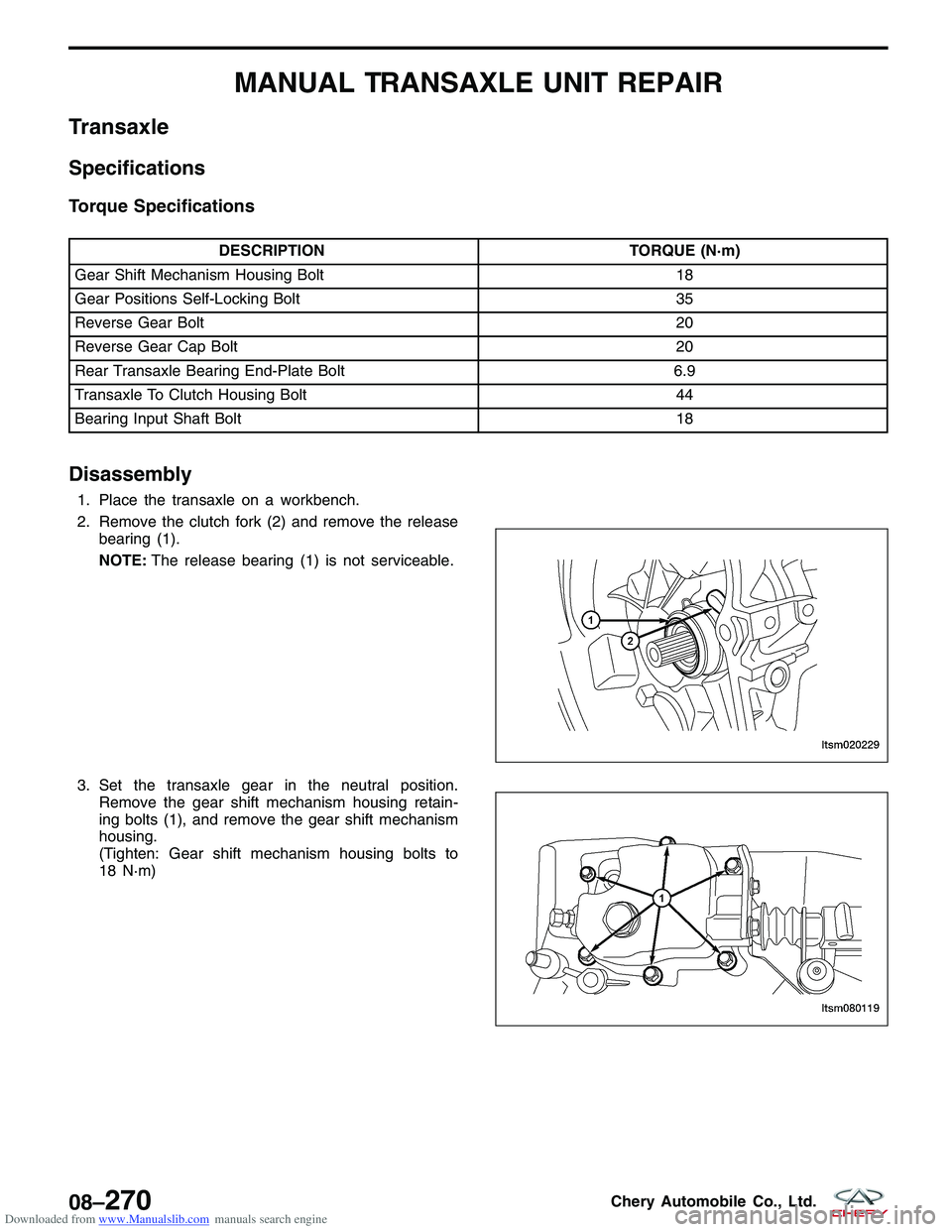

2. Remove the clutch fork (2) and remove the release

bearing (1).

NOTE: The release bearing (1) is not serviceable.

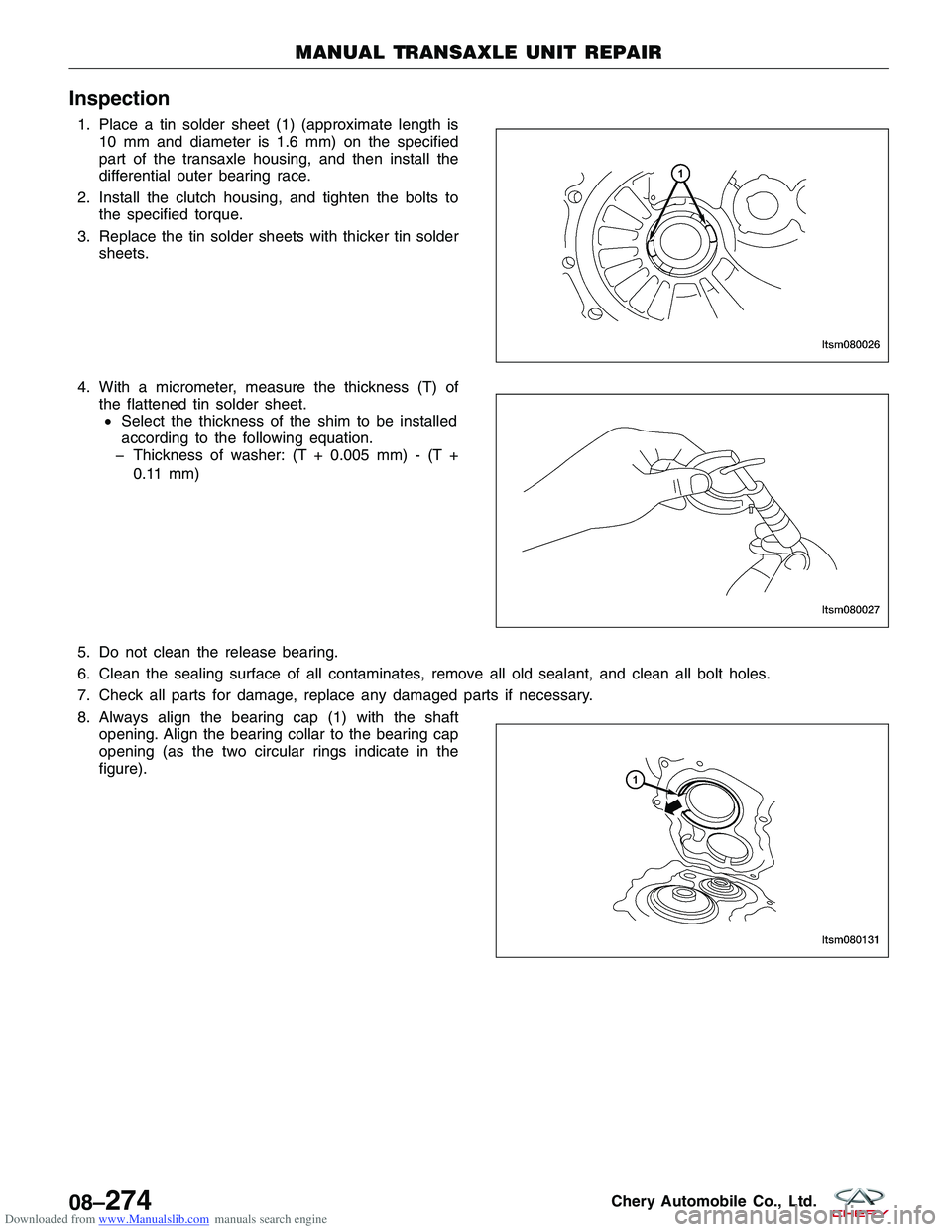

3. Set the transaxle gear in the neutral position. Remove the gear shift mechanism housing retain-

ing bolts (1), and remove the gear shift mechanism

housing.

(Tighten: Gear shift mechanism housing bolts to

18 N·m)

LTSM020229

LTSM080119

08–270Chery Automobile Co., Ltd.

Page 1217 of 1903

Downloaded from www.Manualslib.com manuals search engine Inspection

1. Place a tin solder sheet (1) (approximate length is10 mm and diameter is 1.6 mm) on the specified

part of the transaxle housing, and then install the

differential outer bearing race.

2. Install the clutch housing, and tighten the bolts to the specified torque.

3. Replace the tin solder sheets with thicker tin solder sheets.

4. With a micrometer, measure the thickness (T) of the flattened tin solder sheet.• Select the thickness of the shim to be installed

according to the following equation.

� Thickness of washer: (T + 0.005 mm) - (T +

0.11 mm)

5. Do not clean the release bearing.

6. Clean the sealing surface of all contaminates, remove all old sealant, and clean all bolt holes.

7. Check all parts for damage, replace any damaged parts if necessary.

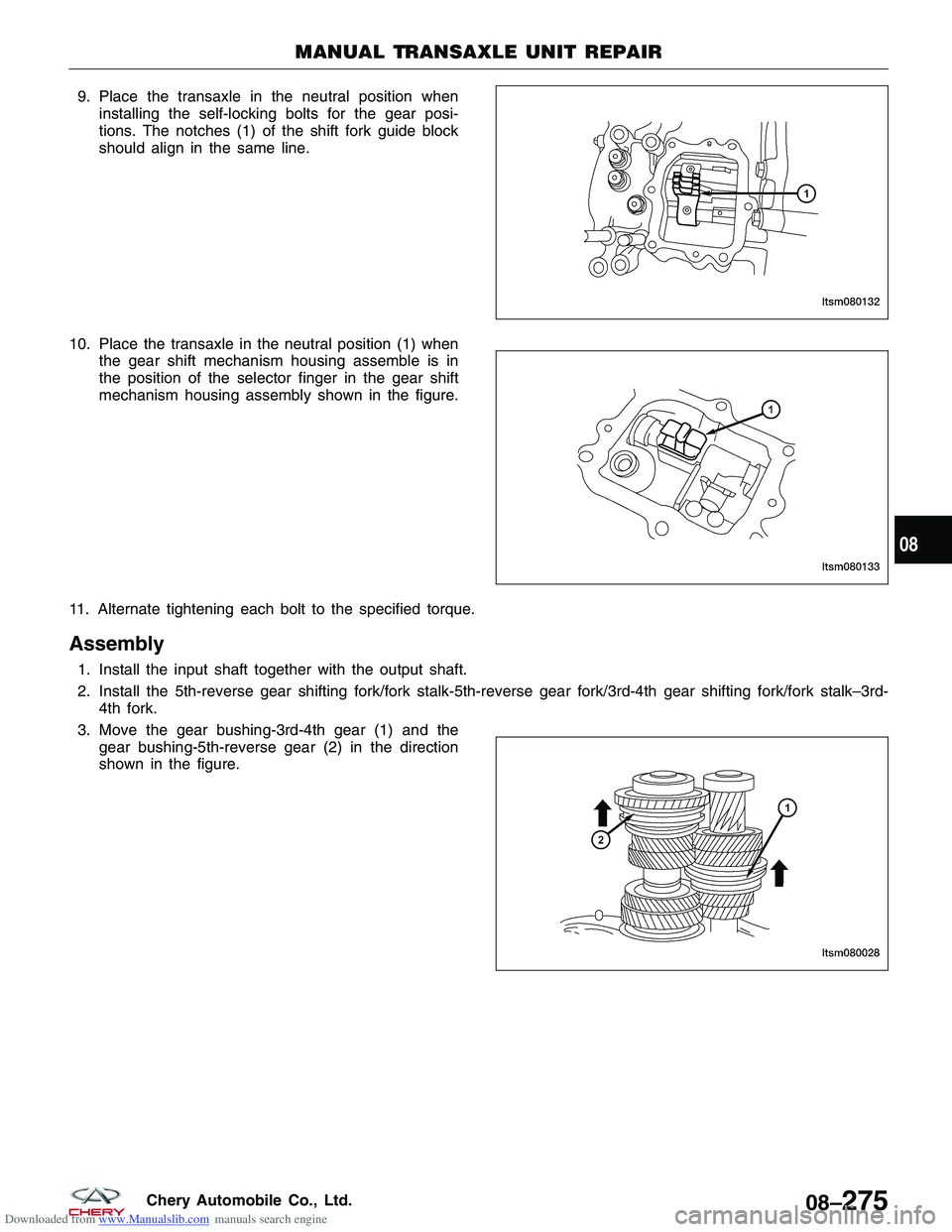

8. Always align the bearing cap (1) with the shaft opening. Align the bearing collar to the bearing cap

opening (as the two circular rings indicate in the

figure).

MANUAL TRANSAXLE UNIT REPAIR

LTSM080026

LTSM080027

LTSM080131

08–274Chery Automobile Co., Ltd.

Page 1218 of 1903

Downloaded from www.Manualslib.com manuals search engine 9. Place the transaxle in the neutral position wheninstalling the self-locking bolts for the gear posi-

tions. The notches (1) of the shift fork guide block

should align in the same line.

10. Place the transaxle in the neutral position (1) when the gear shift mechanism housing assemble is in

the position of the selector finger in the gear shift

mechanism housing assembly shown in the figure.

11. Alternate tightening each bolt to the specified torque.

Assembly

1. Install the input shaft together with the output shaft.

2. Install the 5th-reverse gear shifting fork/fork stalk-5th-reverse gear fork/3rd-4th gear shifting fork/fork stalk–3rd- 4th fork.

3. Move the gear bushing-3rd-4th gear (1) and the gear bushing-5th-reverse gear (2) in the direction

shown in the figure.

MANUAL TRANSAXLE UNIT REPAIR

LTSM080132

LTSM080133

LTSM080028

08

08–275Chery Automobile Co., Ltd.

Page 1220 of 1903

Downloaded from www.Manualslib.com manuals search engine 8. Install the transaxle housing.

9. Applya1mmto1.2mmdiameter of sealant onthe specified position of the transaxle housing.

CAUTION:

The sealant line applied should be uniform and

continuous and without breaks.

10. Tighten the transaxle housing bolts to the specified torque.

11. Install the bottom transaxle cover.

12. Applya1mmto1.2mmdiameter of sealant on the specified position of the transaxle housing.

CAUTION:

The sealant line applied should be uniform and

continuous and without breaks.

13. Apply transaxle fluid to the O-ring of speed sensor.(Transaxle fluid: 75W-90)

MANUAL TRANSAXLE UNIT REPAIR

LTSM080032

LTSM080033

LTSM080034

08

08–277Chery Automobile Co., Ltd.

Page 1260 of 1903

Downloaded from www.Manualslib.com manuals search engine GENERAL INFORMATION

Description

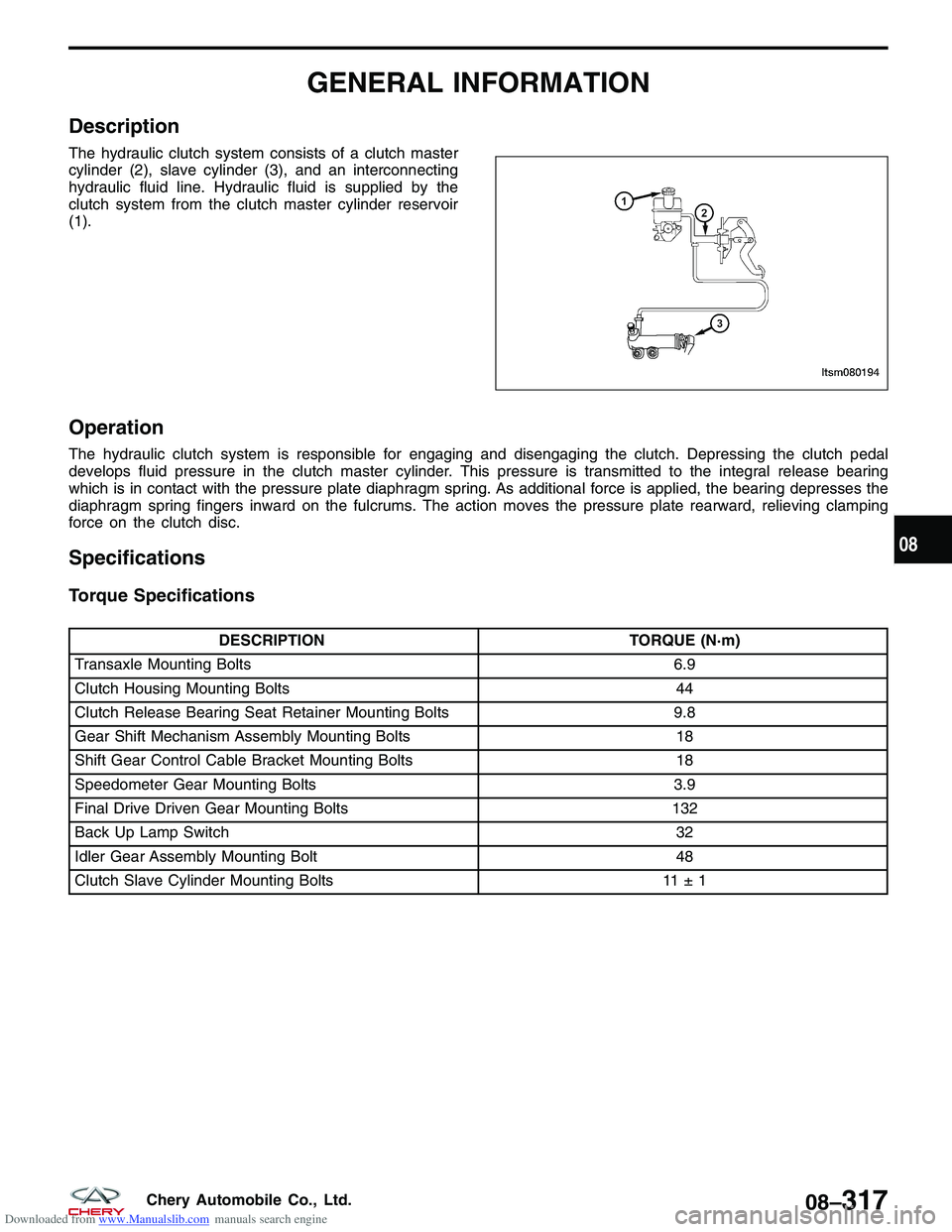

The hydraulic clutch system consists of a clutch master

cylinder (2), slave cylinder (3), and an interconnecting

hydraulic fluid line. Hydraulic fluid is supplied by the

clutch system from the clutch master cylinder reservoir

(1).

Operation

The hydraulic clutch system is responsible for engaging and disengaging the clutch. Depressing the clutch pedal

develops fluid pressure in the clutch master cylinder. This pressure is transmitted to the integral release bearing

which is in contact with the pressure plate diaphragm spring. As additional force is applied, the bearing depresses the

diaphragm spring fingers inward on the fulcrums. The action moves the pressure plate rearward, relieving clamping

force on the clutch disc.

Specifications

Torque Specifications

DESCRIPTIONTORQUE (N·m)

Transaxle Mounting Bolts 6.9

Clutch Housing Mounting Bolts 44

Clutch Release Bearing Seat Retainer Mounting Bolts 9.8

Gear Shift Mechanism Assembly Mounting Bolts 18

Shift Gear Control Cable Bracket Mounting Bolts 18

Speedometer Gear Mounting Bolts 3.9

Final Drive Driven Gear Mounting Bolts 132

Back Up Lamp Switch 32

Idler Gear Assembly Mounting Bolt 48

Clutch Slave Cylinder Mounting Bolts 11 ± 1

LTSM080194

08

08–317Chery Automobile Co., Ltd.

Page 1263 of 1903

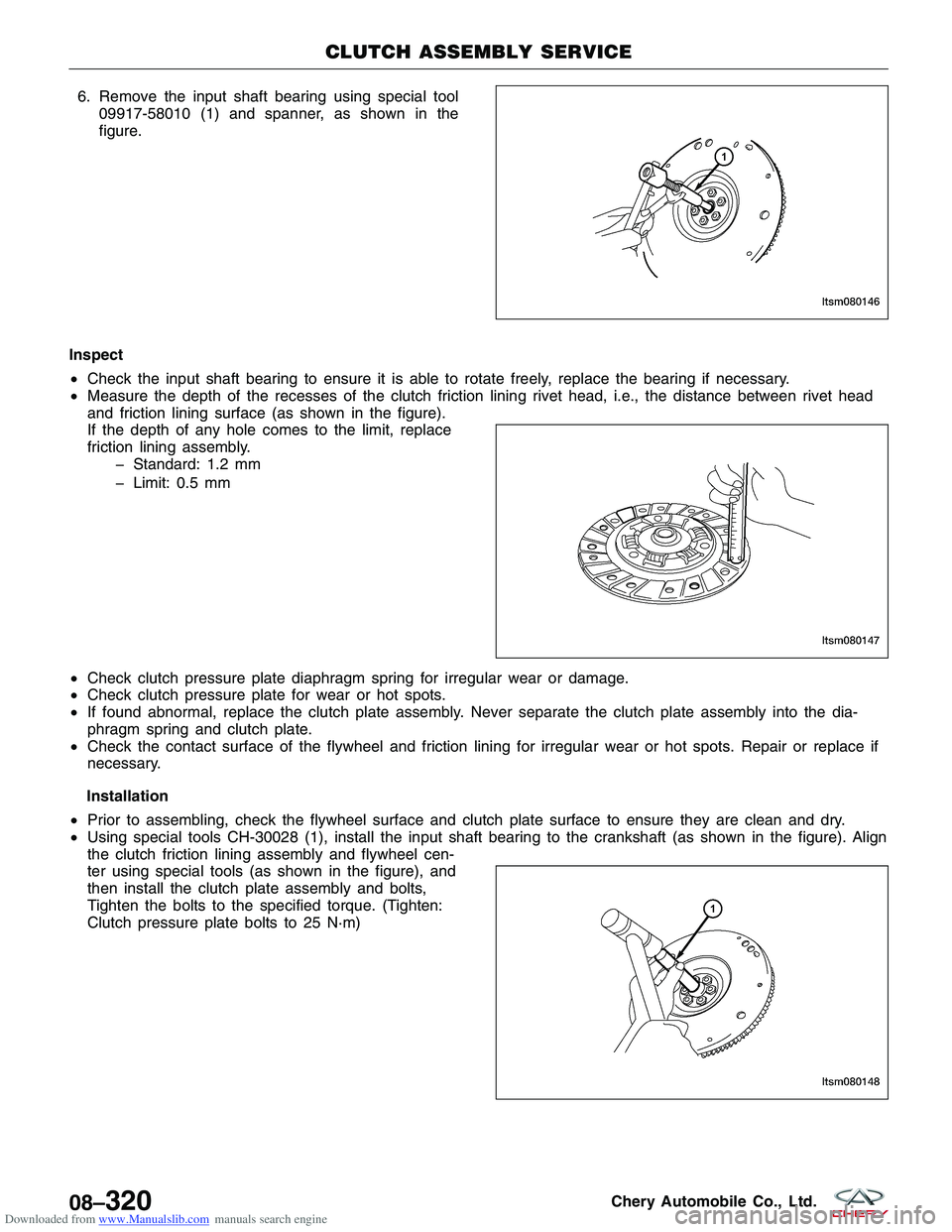

Downloaded from www.Manualslib.com manuals search engine 6. Remove the input shaft bearing using special tool09917-58010 (1) and spanner, as shown in the

figure.

Inspect

• Check the input shaft bearing to ensure it is able to rotate freely, replace the bearing if necessary.

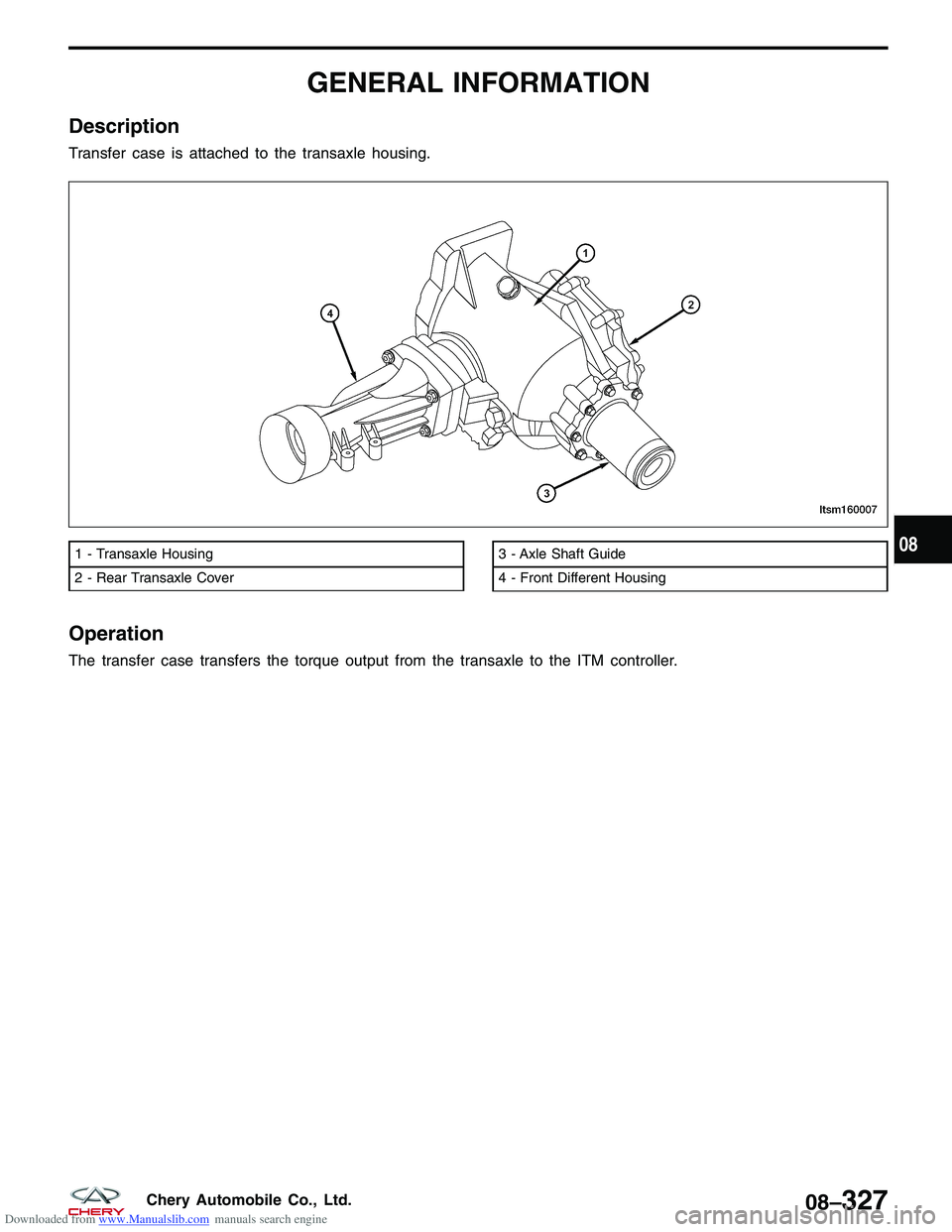

• Measure the depth of the recesses of the clutch friction lining rivet head, i.e., the distance between rivet head

and friction lining surface (as shown in the figure).

If the depth of any hole comes to the limit, replace

friction lining assembly.

� Standard: 1.2 mm

� Limit: 0.5 mm

• Check clutch pressure plate diaphragm spring for irregular wear or damage.

• Check clutch pressure plate for wear or hot spots.

• If found abnormal, replace the clutch plate assembly. Never separate the clutch plate assembly into the dia-

phragm spring and clutch plate.

• Check the contact surface of the flywheel and friction lining for irregular wear or hot spots. Repair or replace if

necessary.

Installation

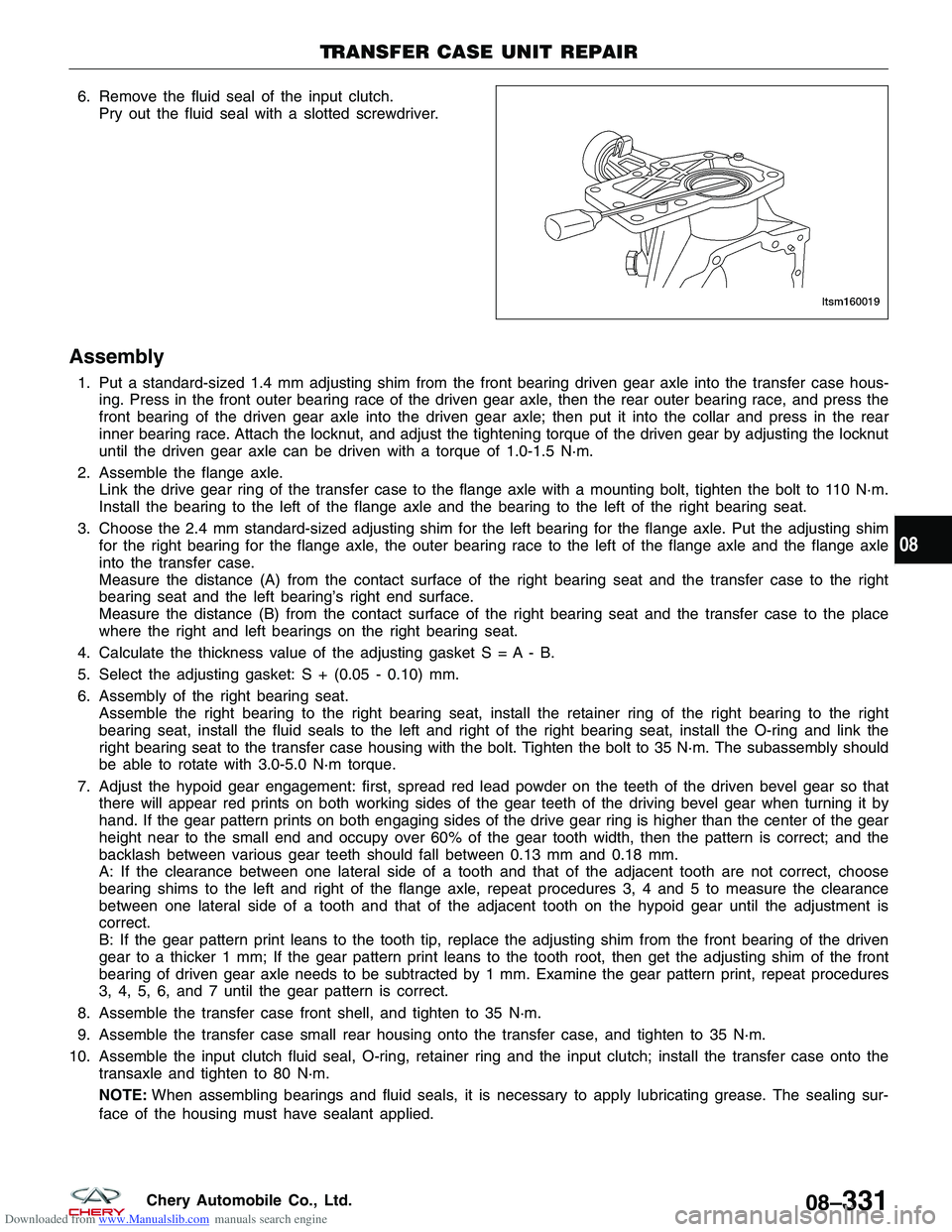

• Prior to assembling, check the flywheel surface and clutch plate surface to ensure they are clean and dry.

• Using special tools CH-30028 (1), install the input shaft bearing to the crankshaft (as shown in the figure). Align

the clutch friction lining assembly and flywheel cen-

ter using special tools (as shown in the figure), and

then install the clutch plate assembly and bolts,

Tighten the bolts to the specified torque. (Tighten:

Clutch pressure plate bolts to 25 N·m)

CLUTCH ASSEMBLY SERVICE

LTSM080146

LTSM080147

LTSM080148

08–320Chery Automobile Co., Ltd.

Page 1270 of 1903

Downloaded from www.Manualslib.com manuals search engine GENERAL INFORMATION

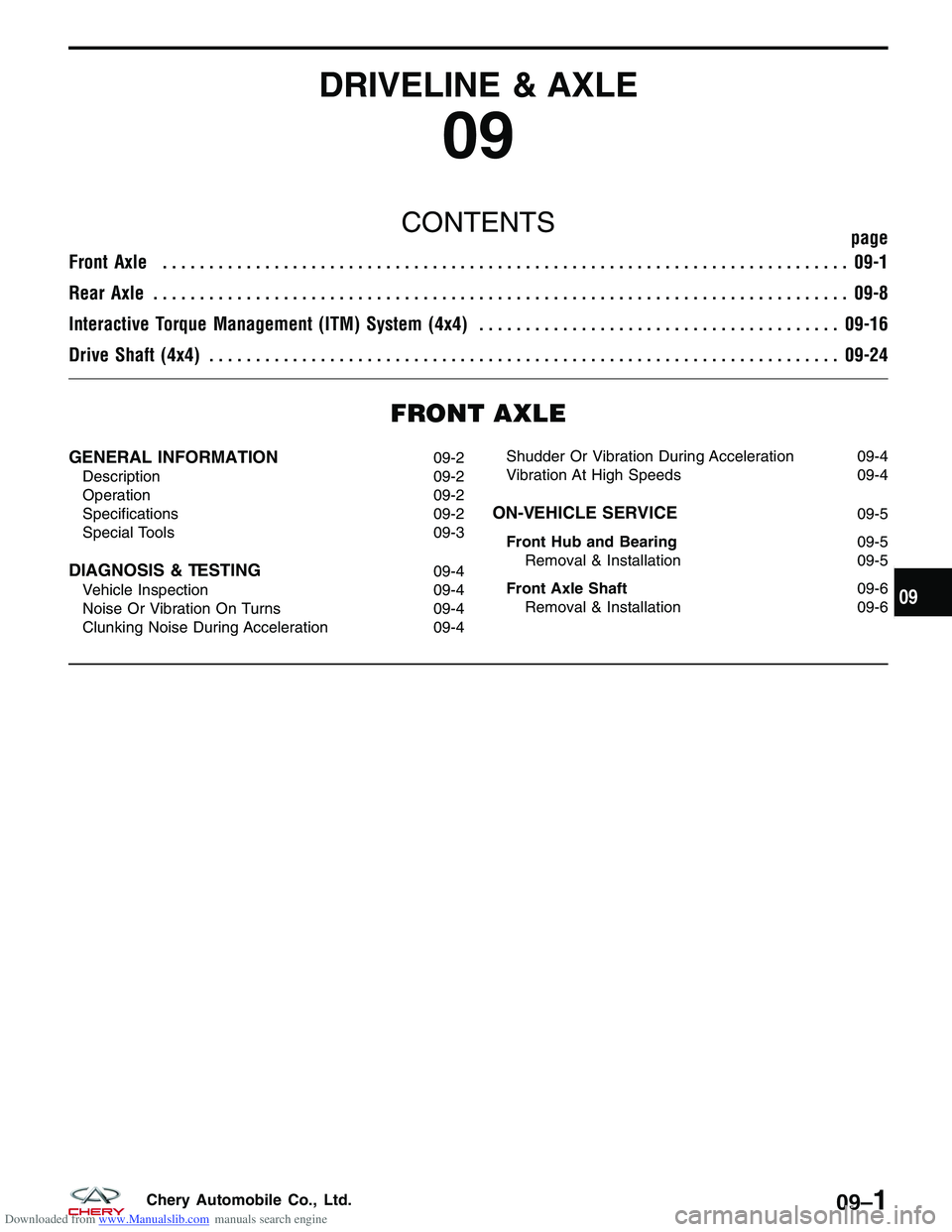

Description

Transfer case is attached to the transaxle housing.

Operation

The transfer case transfers the torque output from the transaxle to the ITM controller.

1 - Transaxle Housing

2 - Rear Transaxle Cover3 - Axle Shaft Guide

4 - Front Different Housing

LTSM160007

08

08–327Chery Automobile Co., Ltd.

Page 1274 of 1903

Downloaded from www.Manualslib.com manuals search engine 6. Remove the fluid seal of the input clutch.Pry out the fluid seal with a slotted screwdriver.

Assembly

1. Put a standard-sized 1.4 mm adjusting shim from the front bearing driven gear axle into the transfer case hous-ing. Press in the front outer bearing race of the driven gear axle, then the rear outer bearing race, and press the

front bearing of the driven gear axle into the driven gear axle; then put it into the collar and press in the rear

inner bearing race. Attach the locknut, and adjust the tightening torque of the driven gear by adjusting the locknut

until the driven gear axle can be driven with a torque of 1.0-1.5 N·m.

2. Assemble the flange axle. Link the drive gear ring of the transfer case to the flange axle with a mounting bolt, tighten the bolt to 110 N·m.

Install the bearing to the left of the flange axle and the bearing to the left of the right bearing seat.

3. Choose the 2.4 mm standard-sized adjusting shim for the left bearing for the flange axle. Put the adjusting shim for the right bearing for the flange axle, the outer bearing race to the left of the flange axle and the flange axle

into the transfer case.

Measure the distance (A) from the contact surface of the right bearing seat and the transfer case to the right

bearing seat and the left bearing’s right end surface.

Measure the distance (B) from the contact surface of the right bearing seat and the transfer case to the place

where the right and left bearings on the right bearing seat.

4. Calculate the thickness value of the adjusting gasket S = A - B.

5. Select the adjusting gasket: S + (0.05 - 0.10) mm.

6. Assembly of the right bearing seat. Assemble the right bearing to the right bearing seat, install the retainer ring of the right bearing to the right

bearing seat, install the fluid seals to the left and right of the right bearing seat, install the O-ring and link the

right bearing seat to the transfer case housing with the bolt. Tighten the bolt to 35 N·m. The subassembly should

be able to rotate with 3.0-5.0 N·m torque.

7. Adjust the hypoid gear engagement: first, spread red lead powder on the teeth of the driven bevel gear so that there will appear red prints on both working sides of the gear teeth of the driving bevel gear when turning it by

hand. If the gear pattern prints on both engaging sides of the drive gear ring is higher than the center of the gear

height near to the small end and occupy over 60% of the gear tooth width, then the pattern is correct; and the

backlash between various gear teeth should fall between 0.13 mm and 0.18 mm.

A: If the clearance between one lateral side of a tooth and that of the adjacent tooth are not correct, choose

bearing shims to the left and right of the flange axle, repeat procedures 3, 4 and 5 to measure the clearance

between one lateral side of a tooth and that of the adjacent tooth on the hypoid gear until the adjustment is

correct.

B: If the gear pattern print leans to the tooth tip, replace the adjusting shim from the front bearing of the driven

gear to a thicker 1 mm; If the gear pattern print leans to the tooth root, then get the adjusting shim of the front

bearing of driven gear axle needs to be subtracted by 1 mm. Examine the gear pattern print, repeat procedures

3, 4, 5, 6, and 7 until the gear pattern is correct.

8. Assemble the transfer case front shell, and tighten to 35 N·m.

9. Assemble the transfer case small rear housing onto the transfer case, and tighten to 35 N·m.

10. Assemble the input clutch fluid seal, O-ring, retainer ring and the input clutch; install the transfer case onto the transaxle and tighten to 80 N·m.

NOTE: When assembling bearings and fluid seals, it is necessary to apply lubricating grease. The sealing sur-

face of the housing must have sealant applied.

TRANSFER CASE UNIT REPAIR

LTSM160019

08

08–331Chery Automobile Co., Ltd.

Page 1275 of 1903

Downloaded from www.Manualslib.com manuals search engine DRIVELINE & AXLE

09

CONTENTSpage

Front Axle ........................................................................\

.. 09-1

Rear Axle ........................................................................\

... 09-8

Interactive Torque Management (ITM) System (4x4) .......................................09-16

Drive Shaft (4x4) .................................................................... 09-24

FRONT AXLE

GENERAL INFORMATION09-2

Description 09-2

Operation 09-2

Specifications 09-2

Special Tools 09-3

DIAGNOSIS & TESTING09-4

Vehicle Inspection 09-4

Noise Or Vibration On Turns 09-4

Clunking Noise During Acceleration 09-4 Shudder Or Vibration During Acceleration 09-4

Vibration At High Speeds 09-4

ON-VEHICLE SERVICE09-5

Front Hub and Bearing 09-5

Removal & Installation 09-5

Front Axle Shaft 09-6

Removal & Installation 09-6

09

09–1Chery Automobile Co., Ltd.

Page 1276 of 1903

Downloaded from www.Manualslib.com manuals search engine GENERAL INFORMATION

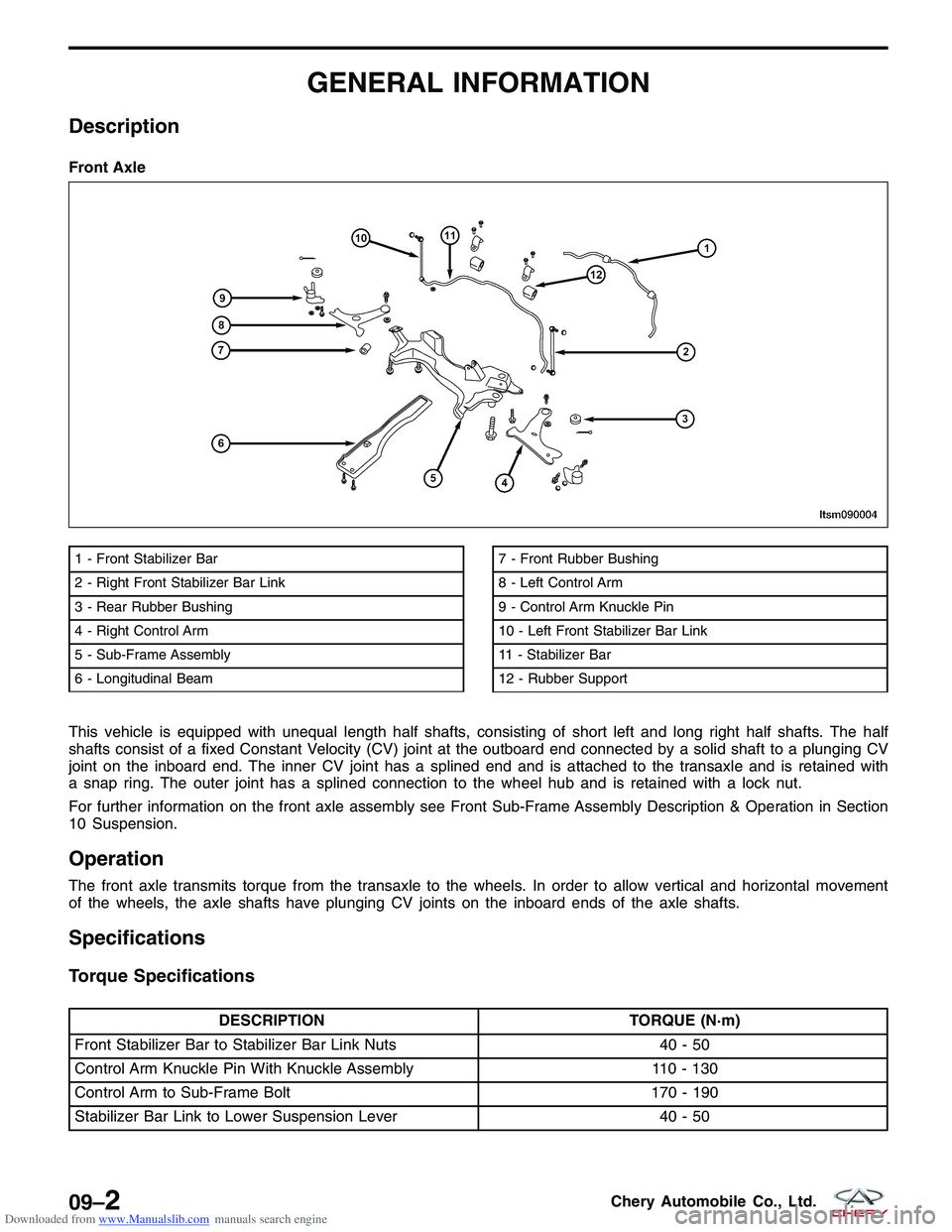

Description

This vehicle is equipped with unequal length half shafts, consisting of short left and long right half shafts. The half

shafts consist of a fixed Constant Velocity (CV) joint at the outboard end connected by a solid shaft to a plunging CV

joint on the inboard end. The inner CV joint has a splined end and is attached to the transaxle and is retained with

a snap ring. The outer joint has a splined connection to the wheel hub and is retained with a lock nut.

For further information on the front axle assembly see Front Sub-Frame Assembly Description & Operation in Section

10 Suspension.

Operation

The front axle transmits torque from the transaxle to the wheels. In order to allow vertical and horizontal movement

of the wheels, the axle shafts have plunging CV joints on the inboard ends of the axle shafts.

Specifications

Torque Specifications

DESCRIPTIONTORQUE (N·m)

Front Stabilizer Bar to Stabilizer Bar Link Nuts 40 - 50

Control Arm Knuckle Pin With Knuckle Assembly 110 - 130

Control Arm to Sub-Frame Bolt 170 - 190

Stabilizer Bar Link to Lower Suspension Lever 40 - 50

Front Axle

1 - Front Stabilizer Bar

2 - Right Front Stabilizer Bar Link

3 - Rear Rubber Bushing

4 - Right Control Arm

5 - Sub-Frame Assembly

6 - Longitudinal Beam7 - Front Rubber Bushing

8 - Left Control Arm

9 - Control Arm Knuckle Pin

10 - Left Front Stabilizer Bar Link

11 - Stabilizer Bar

12 - Rubber Support

LTSM090004

09–2Chery Automobile Co., Ltd.