CHERY TIGGO 2009 Service Repair Manual

Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 1321 of 1903

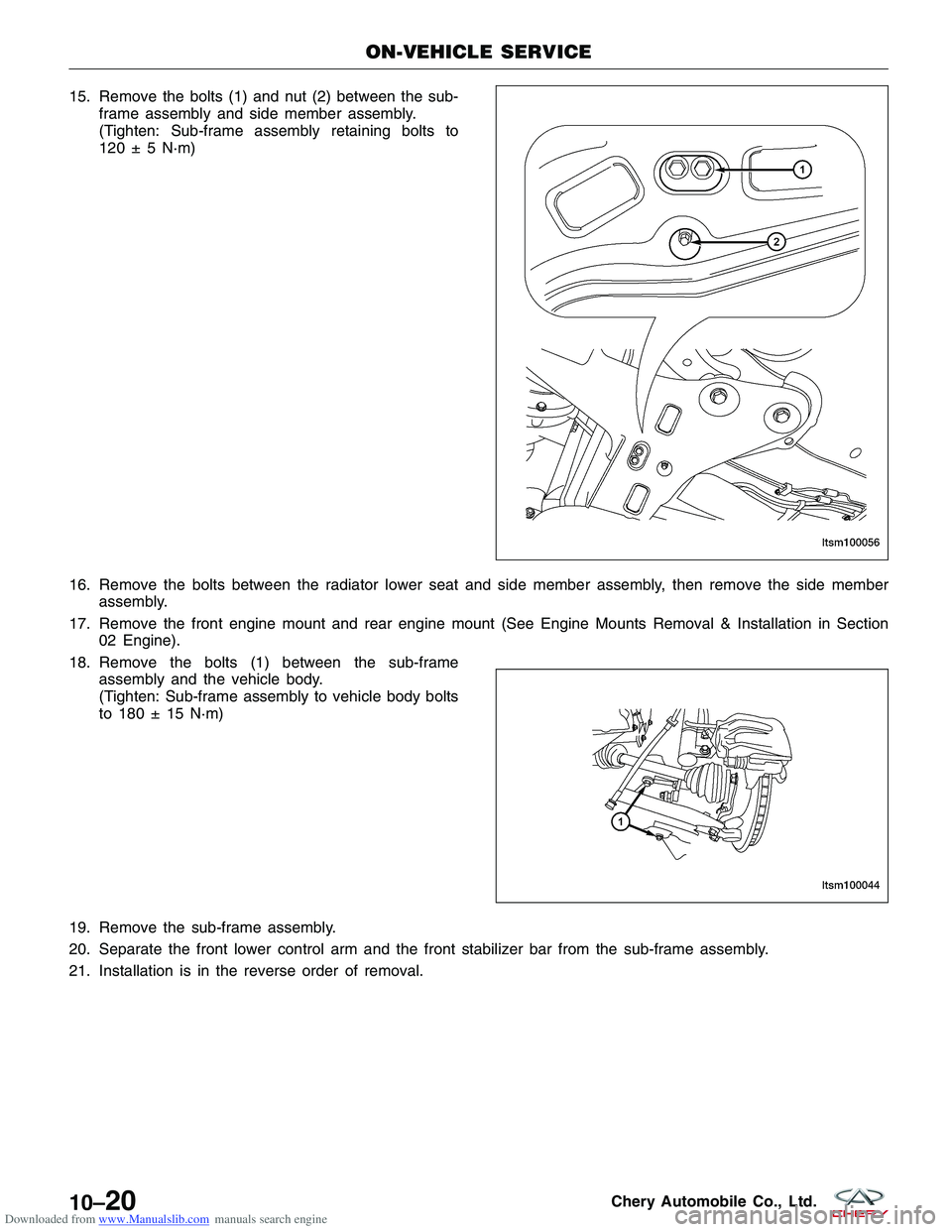

Downloaded from www.Manualslib.com manuals search engine 15. Remove the bolts (1) and nut (2) between the sub-frame assembly and side member assembly.

(Tighten: Sub-frame assembly retaining bolts to

120 ± 5 N·m)

16. Remove the bolts between the radiator lower seat and side member assembly, then remove the side member assembly.

17. Remove the front engine mount and rear engine mount (See Engine Mounts Removal & Installation in Section 02 Engine).

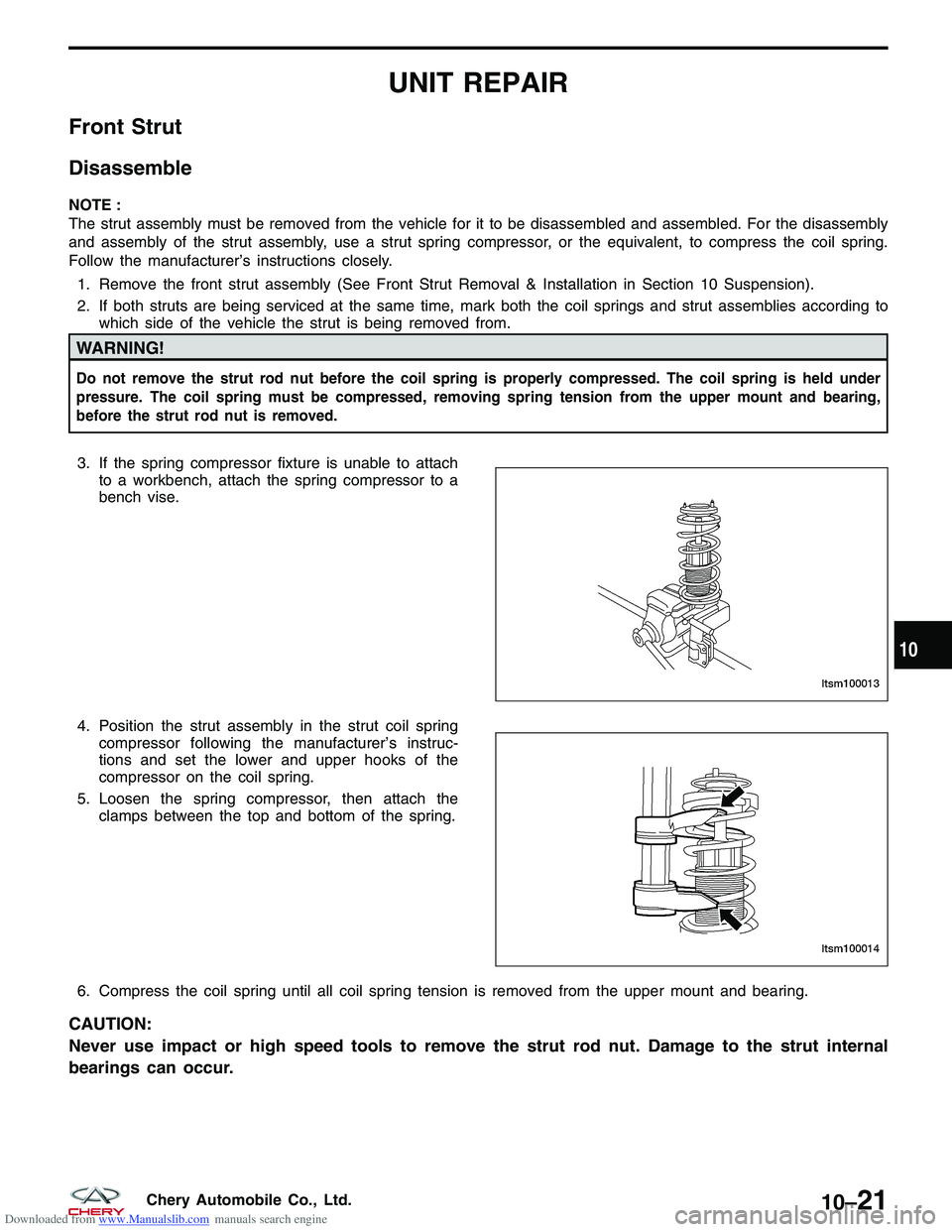

18. Remove the bolts (1) between the sub-frame assembly and the vehicle body.

(Tighten: Sub-frame assembly to vehicle body bolts

to 180 ± 15 N·m)

19. Remove the sub-frame assembly.

20. Separate the front lower control arm and the front stabilizer bar from the sub-frame assembly.

21. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM100056

LTSM100044

10–20Chery Automobile Co., Ltd.

Page 1322 of 1903

Downloaded from www.Manualslib.com manuals search engine UNIT REPAIR

Front Strut

Disassemble

NOTE :

The strut assembly must be removed from the vehicle for it to be disassembled and assembled. For the disassembly

and assembly of the strut assembly, use a strut spring compressor, or the equivalent, to compress the coil spring.

Follow the manufacturer’s instructions closely.1. Remove the front strut assembly (See Front Strut Removal & Installation in Section 10 Suspension).

2. If both struts are being serviced at the same time, mark both the coil springs and strut assemblies according to which side of the vehicle the strut is being removed from.

WARNING!

Do not remove the strut rod nut before the coil spring is properly compressed. The coil spring is held under

pressure. The coil spring must be compressed, removing spring tension from the upper mount and bearing,

before the strut rod nut is removed.

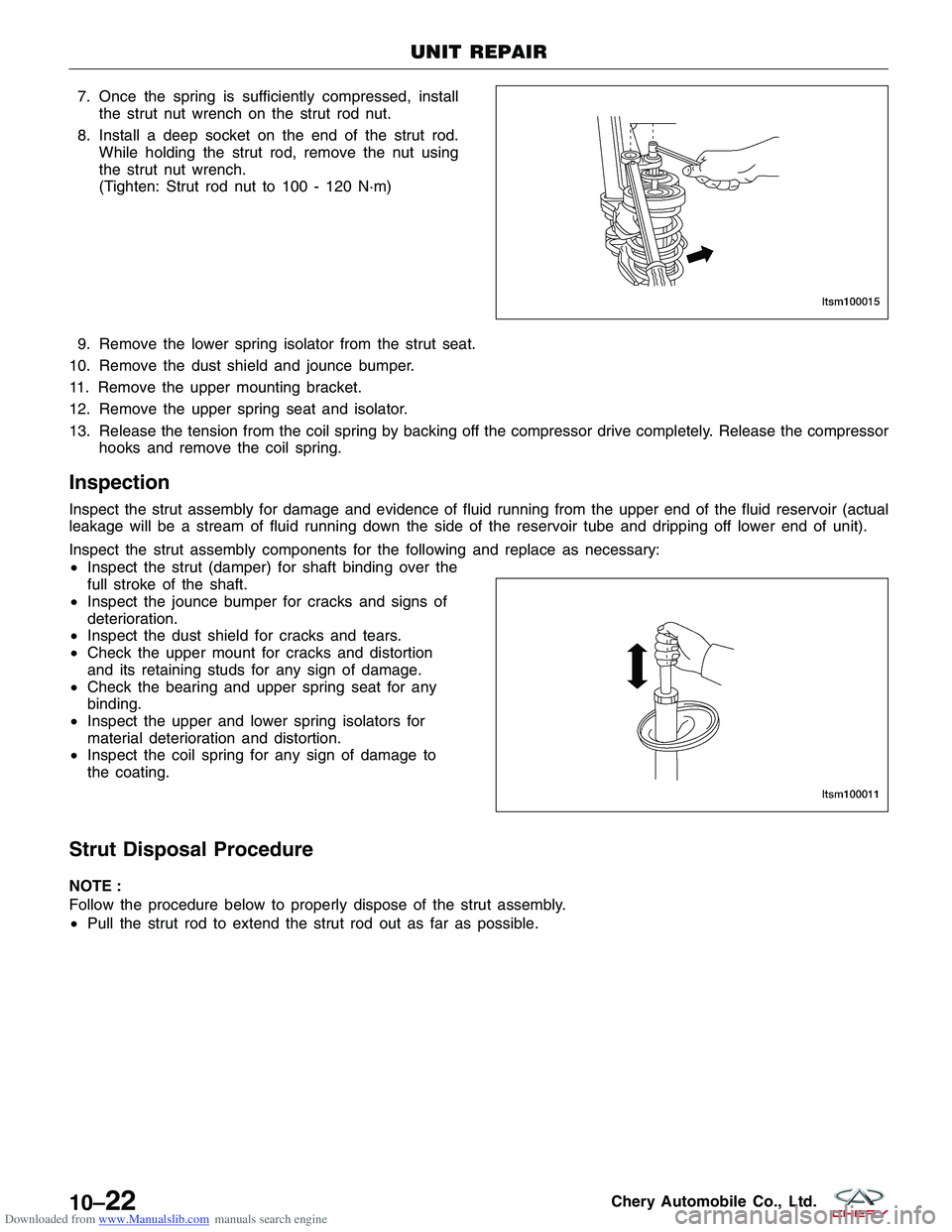

3. If the spring compressor fixture is unable to attachto a workbench, attach the spring compressor to a

bench vise.

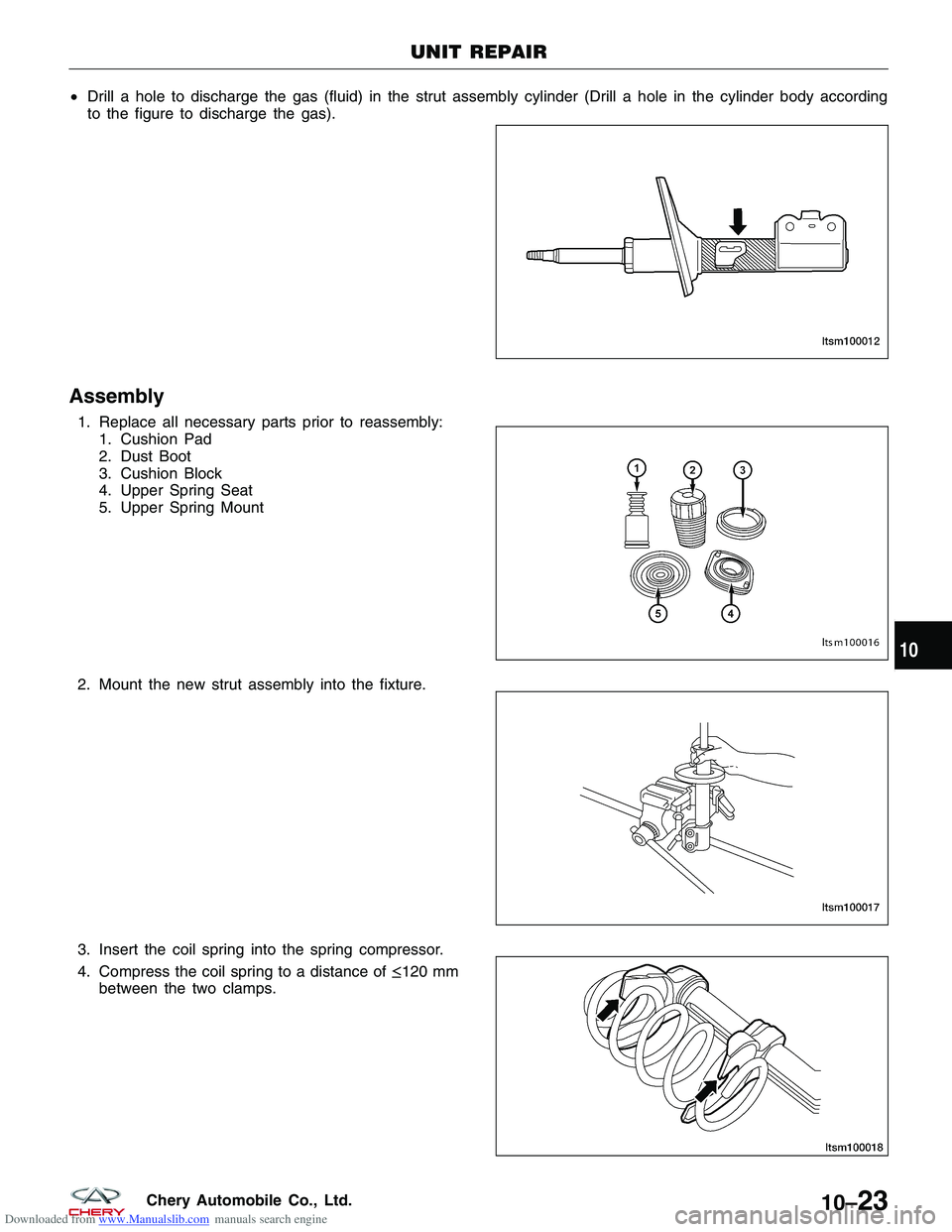

4. Position the strut assembly in the strut coil spring compressor following the manufacturer’s instruc-

tions and set the lower and upper hooks of the

compressor on the coil spring.

5. Loosen the spring compressor, then attach the clamps between the top and bottom of the spring.

6. Compress the coil spring until all coil spring tension is removed from the upper mount and bearing.

CAUTION:

Never use impact or high speed tools to remove the strut rod nut. Damage to the strut internal

bearings can occur.

LTSM100013

LTSM100014

10

10–21Chery Automobile Co., Ltd.

Page 1323 of 1903

Downloaded from www.Manualslib.com manuals search engine 7. Once the spring is sufficiently compressed, installthe strut nut wrench on the strut rod nut.

8. Install a deep socket on the end of the strut rod. While holding the strut rod, remove the nut using

the strut nut wrench.

(Tighten: Strut rod nut to 100 - 120 N·m)

9. Remove the lower spring isolator from the strut seat.

10. Remove the dust shield and jounce bumper.

11. Remove the upper mounting bracket.

12. Remove the upper spring seat and isolator.

13. Release the tension from the coil spring by backing off the compressor drive completely. Release the compressor hooks and remove the coil spring.

Inspection

Inspect the strut assembly for damage and evidence of fluid running from the upper end of the fluid reservoir (actual

leakage will be a stream of fluid running down the side of the reservoir tube and dripping off lower end of unit).

Inspect the strut assembly components for the following and replace as necessary:

•Inspect the strut (damper) for shaft binding over the

full stroke of the shaft.

• Inspect the jounce bumper for cracks and signs of

deterioration.

• Inspect the dust shield for cracks and tears.

• Check the upper mount for cracks and distortion

and its retaining studs for any sign of damage.

• Check the bearing and upper spring seat for any

binding.

• Inspect the upper and lower spring isolators for

material deterioration and distortion.

• Inspect the coil spring for any sign of damage to

the coating.

Strut Disposal Procedure

NOTE :

Follow the procedure below to properly dispose of the strut assembly.

•Pull the strut rod to extend the strut rod out as far as possible.

UNIT REPAIR

LTSM100015

LTSM100011

10–22Chery Automobile Co., Ltd.

Page 1324 of 1903

Downloaded from www.Manualslib.com manuals search engine •Drill a hole to discharge the gas (fluid) in the strut assembly cylinder (Drill a hole in the cylinder body according

to the figure to discharge the gas).

Assembly

1. Replace all necessary parts prior to reassembly:

1. Cushion Pad

2. Dust Boot

3. Cushion Block

4. Upper Spring Seat

5.

Upper Spring Mount

2. Mount the new strut assembly into the fixture.

3. Insert the coil spring

into the spring compressor.

4. Compress the coil spring to a distance of ≤120 mm

between the two clamps.

UNIT REPAIR

LTSM100012

LTSM100016

LTSM100017

LTSM100018

10

10–23Chery Automobile Co., Ltd.

Page 1325 of 1903

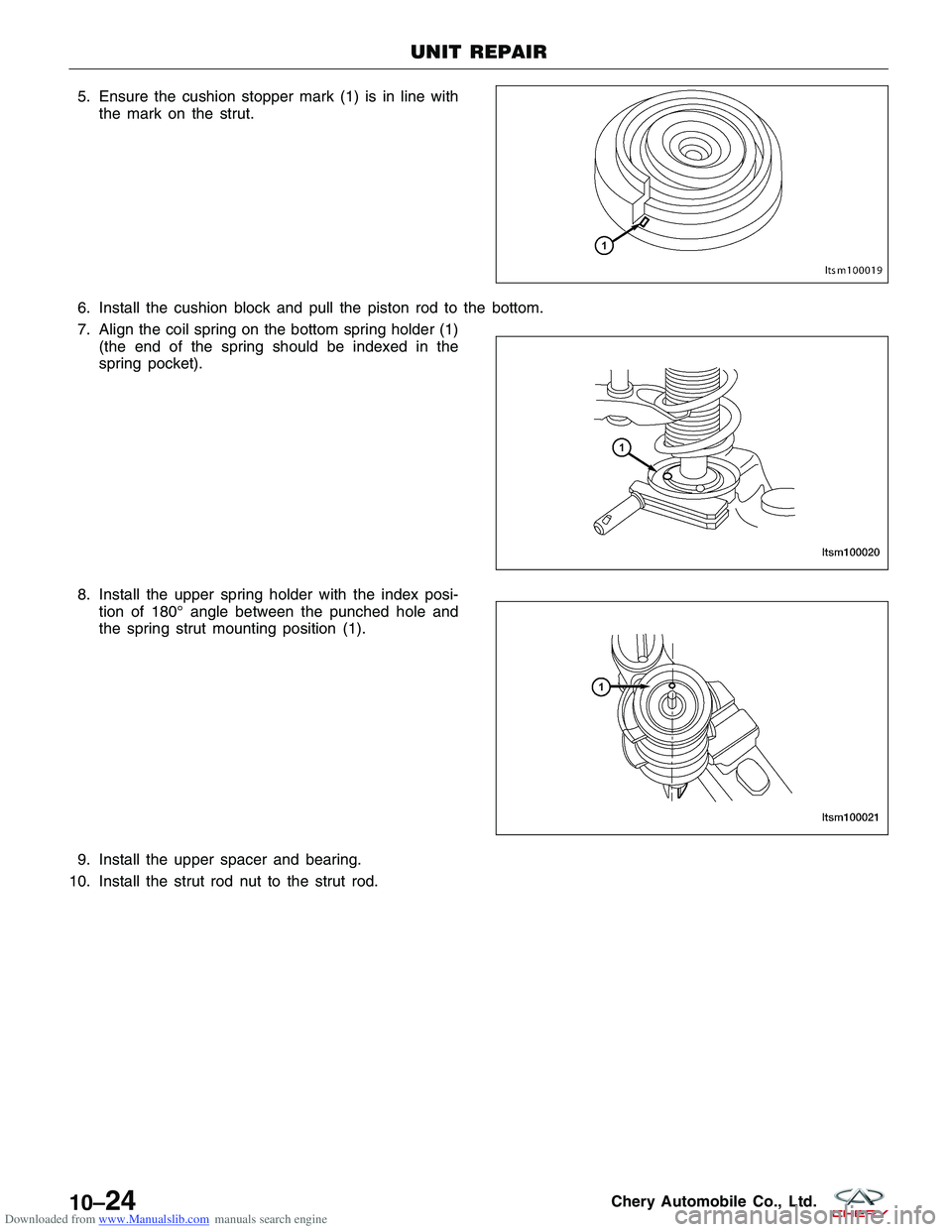

Downloaded from www.Manualslib.com manuals search engine 5. Ensure the cushion stopper mark (1) is in line withthe mark on the strut.

6. Install the cushion block and pull the piston rod to the bottom.

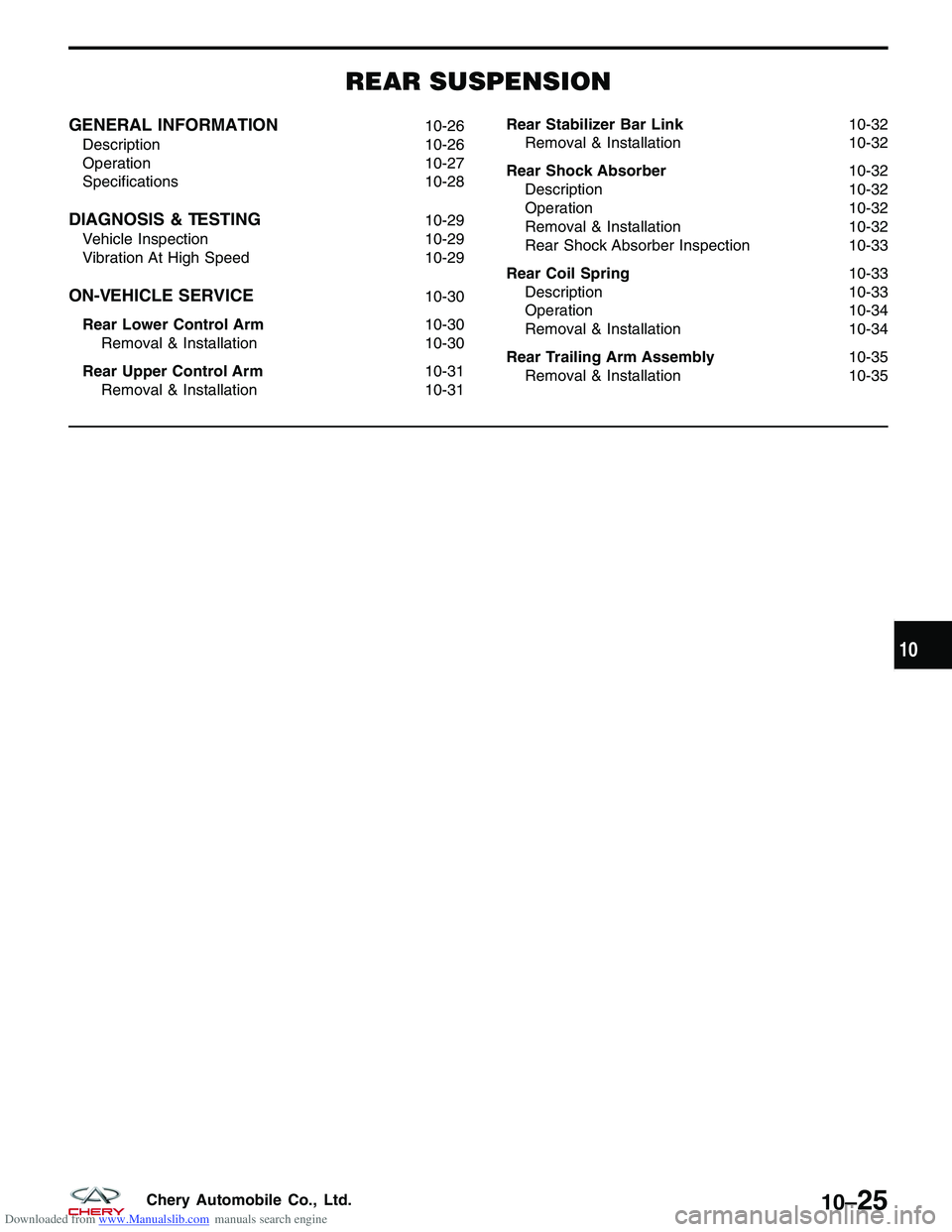

7. Align the coil spring on the bottom spring holder (1) (the end of the spring should be indexed in the

spring pocket).

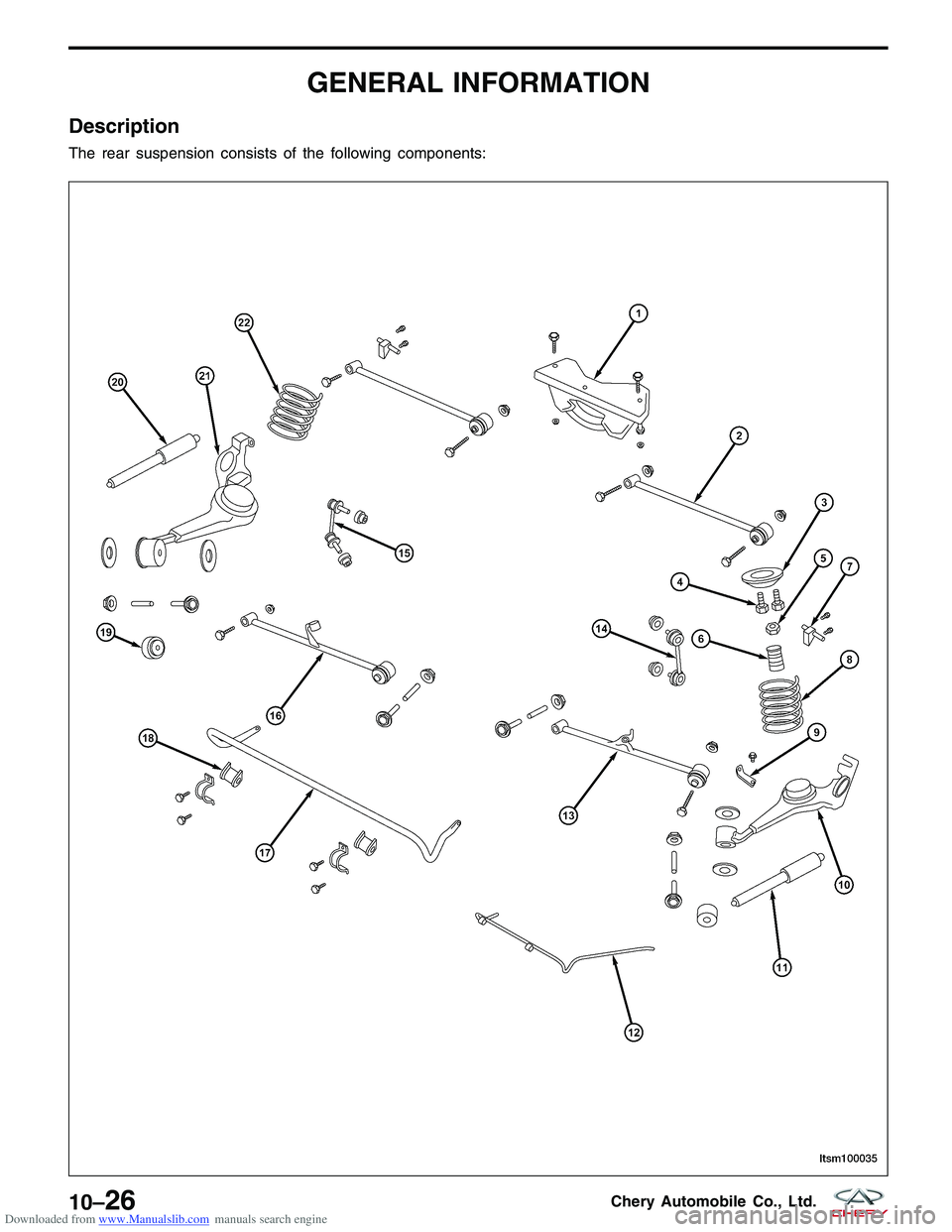

8. Install the upper spring holder with the index posi- tion of 180° angle between the punched hole and

the spring strut mounting position (1).

9. Install the upper spacer and bearing.

10. Install the strut rod nut to the strut rod.

UNIT REPAIR

LTSM100019

LTSM100020

LTSM100021

10–24Chery Automobile Co., Ltd.

Page 1326 of 1903

Downloaded from www.Manualslib.com manuals search engine REAR SUSPENSION

GENERAL INFORMATION10-26

Description 10-26

Operation 10-27

Specifications 10-28

DIAGNOSIS & TESTING10-29

Vehicle Inspection 10-29

Vibration At High Speed 10-29

ON-VEHICLE SERVICE10-30

Rear Lower Control Arm 10-30

Removal & Installation 10-30

Rear Upper Control Arm 10-31

Removal & Installation 10-31 Rear Stabilizer Bar Link

10-32

Removal & Installation 10-32

Rear Shock Absorber 10-32

Description 10-32

Operation 10-32

Removal & Installation 10-32

Rear Shock Absorber Inspection 10-33

Rear Coil Spring 10-33

Description 10-33

Operation 10-34

Removal & Installation 10-34

Rear Trailing Arm Assembly 10-35

Removal & Installation 10-35

10

10–25Chery Automobile Co., Ltd.

Page 1327 of 1903

Downloaded from www.Manualslib.com manuals search engine GENERAL INFORMATION

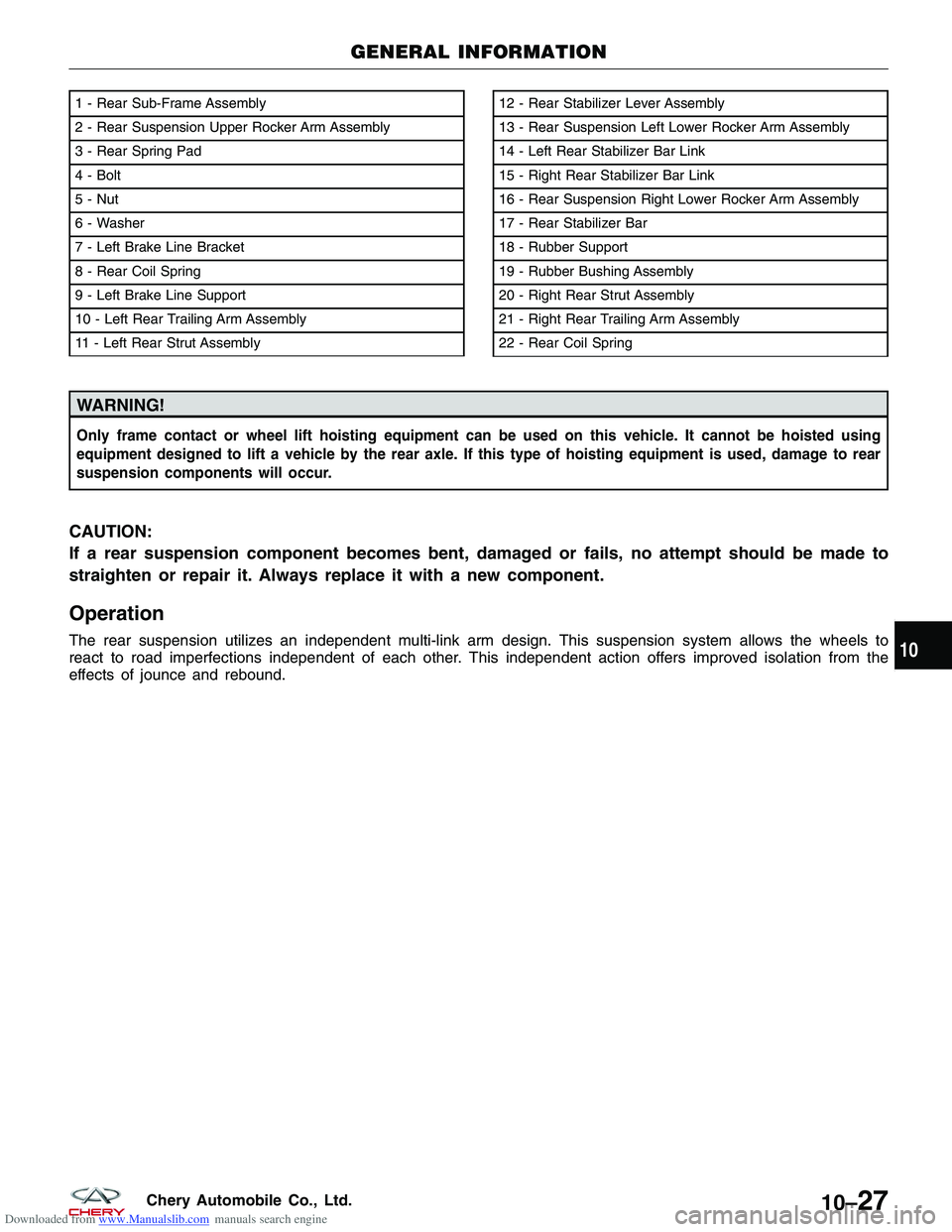

Description

The rear suspension consists of the following components:

LTSM10003510–26Chery Automobile Co., Ltd.

Page 1328 of 1903

Downloaded from www.Manualslib.com manuals search engine WARNING!

Only frame contact or wheel lift hoisting equipment can be used on this vehicle. It cannot be hoisted using

equipment designed to lift a vehicle by the rear axle. If this type of hoisting equipment is used, damage to rear

suspension components will occur.

CAUTION:

If a rear suspension component becomes bent, damaged or fails, no attempt should be made to

straighten or repair it. Always replace it with a new component.

Operation

The rear suspension utilizes an independent multi-link arm design. This suspension system allows the wheels to

react to road imperfections independent of each other. This independent action offers improved isolation from the

effects of jounce and rebound.

1 - Rear Sub-Frame Assembly

2 - Rear Suspension Upper Rocker Arm Assembly

3 - Rear Spring Pad

4 - Bolt

5 - Nut

6 - Washer

7 - Left Brake Line Bracket

8 - Rear Coil Spring

9 - Left Brake Line Support

10 - Left Rear Trailing Arm Assembly

11 - Left Rear Strut Assembly12 - Rear Stabilizer Lever Assembly

13 - Rear Suspension Left Lower Rocker Arm Assembly

14 - Left Rear Stabilizer Bar Link

15 - Right Rear Stabilizer Bar Link

16 - Rear Suspension Right Lower Rocker Arm Assembly

17 - Rear Stabilizer Bar

18 - Rubber Support

19 - Rubber Bushing Assembly

20 - Right Rear Strut Assembly

21 - Right Rear Trailing Arm Assembly

22 - Rear Coil Spring

GENERAL INFORMATION

LTSM100035

10

10–27Chery Automobile Co., Ltd.

Page 1329 of 1903

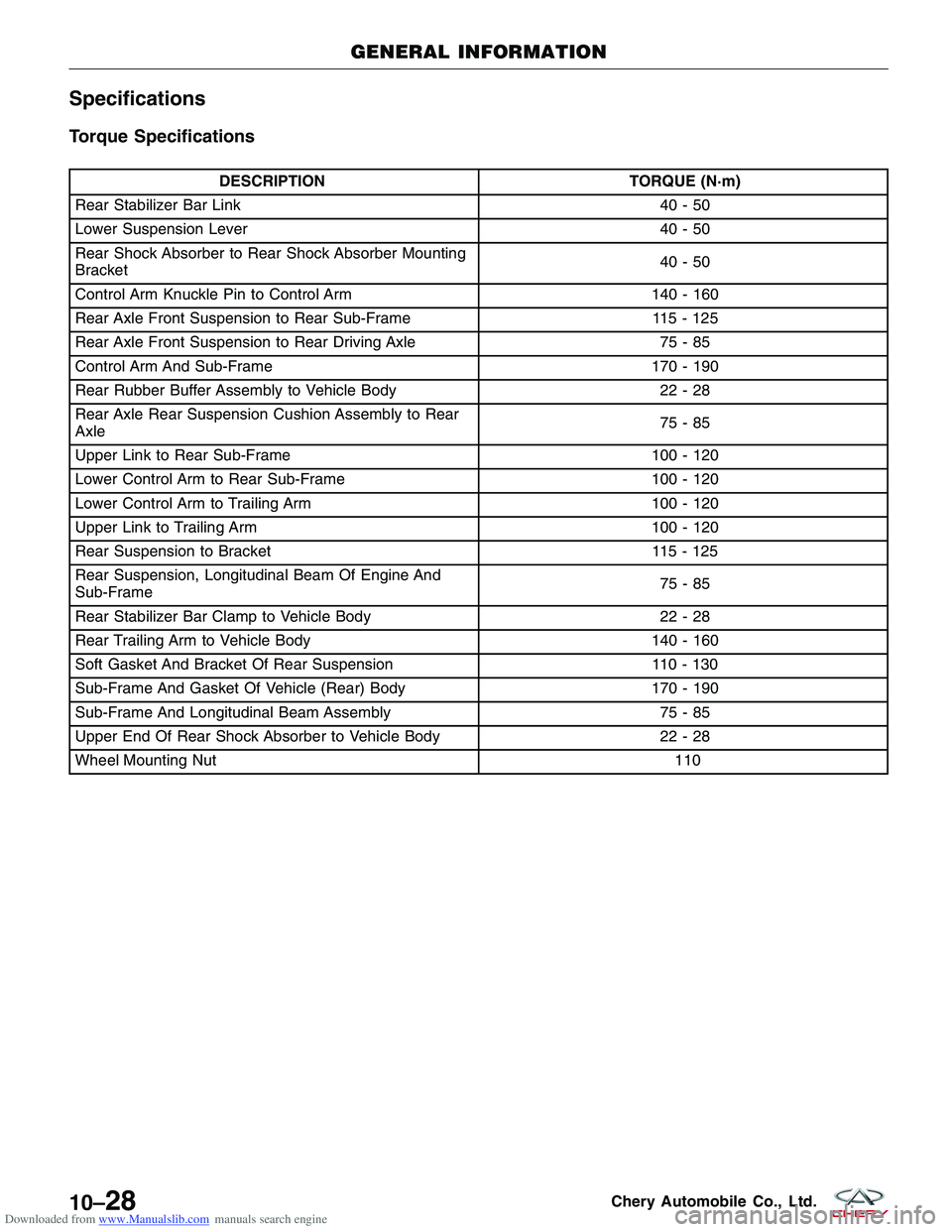

Downloaded from www.Manualslib.com manuals search engine Specifications

Torque Specifications

DESCRIPTIONTORQUE (N·m)

Rear Stabilizer Bar Link 40 - 50

Lower Suspension Lever 40 - 50

Rear Shock Absorber to Rear Shock Absorber Mounting

Bracket 40-50

Control Arm Knuckle Pin to Control Arm 140 - 160

Rear Axle Front Suspension to Rear Sub-Frame 115 - 125

Rear Axle Front Suspension to Rear Driving Axle 75 - 85

Control Arm And Sub-Frame 170 - 190

Rear Rubber Buffer Assembly to Vehicle Body 22 - 28

Rear Axle Rear Suspension Cushion Assembly to Rear

Axle 75-85

Upper Link to Rear Sub-Frame 100 - 120

Lower Control Arm to Rear Sub-Frame 100 - 120

Lower Control Arm to Trailing Arm 100 - 120

Upper Link to Trailing Arm 100 - 120

Rear Suspension to Bracket 115 - 125

Rear Suspension, Longitudinal Beam Of Engine And

Sub-Frame 75-85

Rear Stabilizer Bar Clamp to Vehicle Body 22 - 28

Rear Trailing Arm to Vehicle Body 140 - 160

Soft Gasket And Bracket Of Rear Suspension 110 - 130

Sub-Frame And Gasket Of Vehicle (Rear) Body 170 - 190

Sub-Frame And Longitudinal Beam Assembly 75 - 85

Upper End Of Rear Shock Absorber to Vehicle Body 22 - 28

Wheel Mounting Nut \

11

0

GENERAL INFORMATION

10–28Chery Automobile Co., Ltd.

Page 1330 of 1903

Downloaded from www.Manualslib.com manuals search engine DIAGNOSIS & TESTING

Vehicle Inspection

Inspect the rear axle for the following:

•Check the rear axle for loose bearings.

• Check the rear axle hub for any damage or excessive runout.

Vibration At High Speed

This problem could be a result of the following:

•Foreign material (mud, etc.) packed on the backside of the wheel(s).

• Out of balance tires or wheels.

• Improper tire or wheel runout.

10

10–29Chery Automobile Co., Ltd.