CHERY TIGGO 2009 Service Repair Manual

Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 1341 of 1903

Downloaded from www.Manualslib.com manuals search engine 3. Check the tires on the vehicle. The tires are to beinflated to the recommended air pressure. All tires

must be the same size and in good condition with

approximately the same tread wear.

4. Check the front tire and wheel assemblies for excessive radial runout.

5. Inspect all suspension component fasteners for looseness and proper torque.

6. Inspect all ball joints and all steering linkage for looseness and any sign of wear or damage.

7. Inspect the rubber bushings on all the suspension components for signs of wear or deterioration. If any bushings show signs of wear or deterioration, they should be replaced prior to aligning the vehicle.

8. Check vehicle curb height.

Wheel Alignment Setup

1. Position the vehicle on an alignment rack.

2. Install all required alignment equipment on the vehicle, per the alignment equipment manufacturer’s instructions. On this vehicle, a four-wheel alignment is recommended.

3. Read the vehicle’s current front and rear alignment settings. Compare the vehicle’s current alignment settings to the vehicle specifications for camber, caster and toe-in.

NOTE :

Prior to reading the vehicle’s alignment readouts, the front and rear of vehicle should be jounced. Induce jounce (rear

first, then front) by grasping the center of the bumper and jouncing each end of the vehicle an equal number of

times. The bumper should always be released when vehicle is at the bottom of the jounce cycle.

Specifications

Torque Specifications

DESCRIPTION TORQUE (N·m)

Camber Adjustment Bolts 100

Inner Tie Rod Adjuster Jam Nut 30

Rear Lower Control Arm Eccentric Cam Bolt 80 - 100

Rear Upper Control Arm Eccentric Cam Bolt 80 - 100

Wheel Mounting Nuts 110

GENERAL INFORMATION

LTSM100027

LTSM110026

10–40Chery Automobile Co., Ltd.

Page 1342 of 1903

Downloaded from www.Manualslib.com manuals search engine Front Axle Alignment Specifications

FRONT WHEEL ALIGNMENTPREFERRED SETTINGACCEPTABLE RANGE

Camber -51’+9’ to -1°51’

Caster +2°50’+3°30’ to +2°5’

Inclination +11°30’+12°15’ to +10°45’

Toe-Individual 0’+5’ to -5’

Rear Axle Alignment Specifications

REAR WHEEL ALIGNMENT PREFERRED SETTINGACCEPTABLE RANGE

Camber -54’+24’ to -1°24’

Toe-Individual -5’+5’ to -15’

GENERAL INFORMATION

10

10–41Chery Automobile Co., Ltd.

Page 1343 of 1903

Downloaded from www.Manualslib.com manuals search engine DIAGNOSIS & TESTING

Vehicle Inspection

Inspect the following for damage:

•Inspect the tires.

• Inspect the rims.

Replace any tire or rim that is found to be damaged.

Tire Wear

Inspect the following for accurate tire wear:

• Check the depth of tire remaining tread.

• Standard tire: not less than 1.6 mm.

• Snow tire: 50% tire tread.

If the tread is below the specifications, the tire should be replaced.

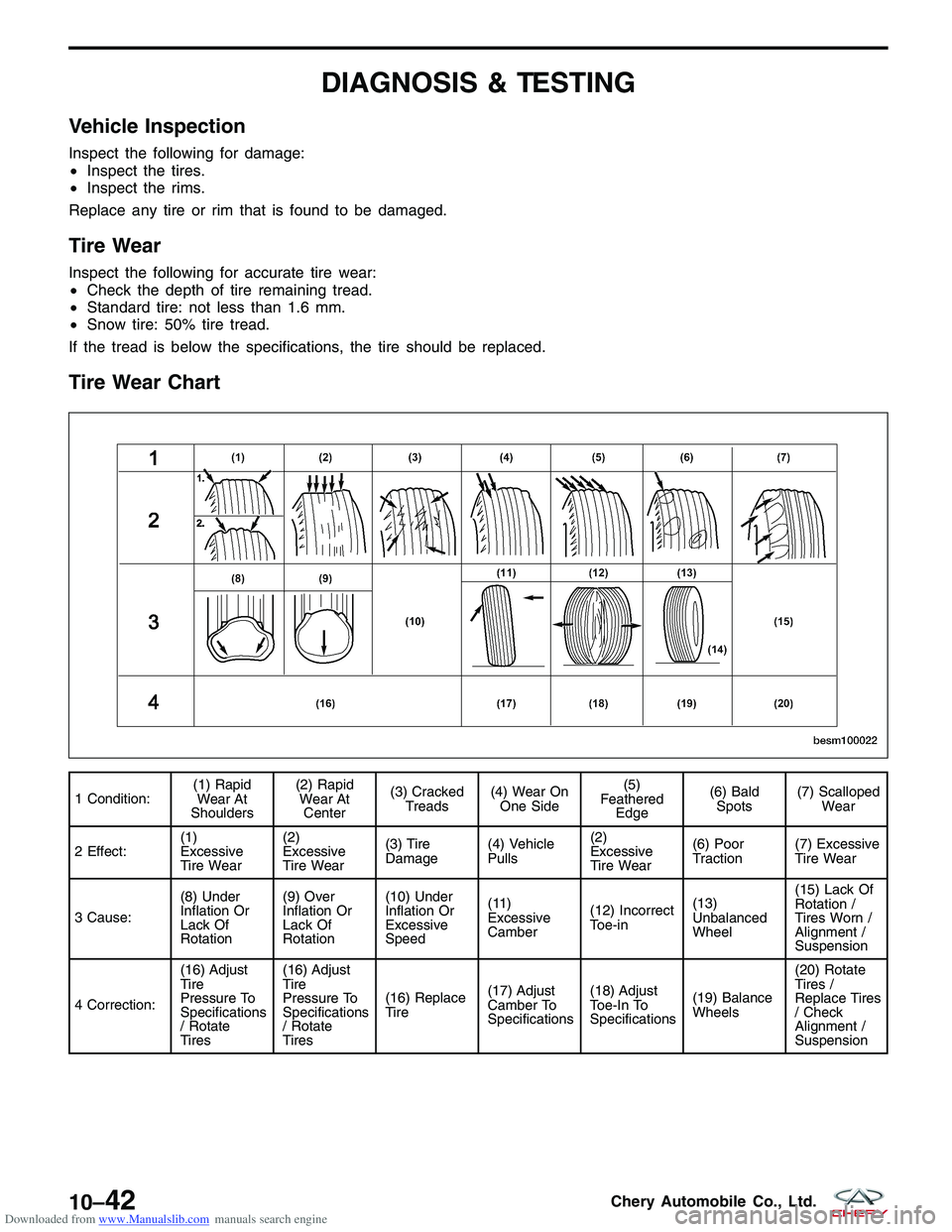

Tire Wear Chart

1 Condition: (1) Rapid

Wear At

Shoulders (2) Rapid

Wear At Center (3) Cracked

Treads (4) Wear On

One Side (5)

Feathered Edge (6) Bald

Spots (7) Scalloped

Wear

2 Effect: (1)

Excessive

Tire Wear(2)

Excessive

Tire Wear

(3) Tire

Damage

(4) Vehicle

Pulls(2)

Excessive

Tire Wear(6) Poor

Traction

(7) Excessive

Tire Wear

3 Cause: (8) Under

Inflation Or

Lack Of

Rotation(9) Over

Inflation Or

Lack Of

Rotation(10) Under

Inflation Or

Excessive

Speed

(11)

Excessive

Camber

(12) Incorrect

Toe-in(13)

Unbalanced

Wheel(15) Lack Of

Rotation /

Tires Worn /

Alignment /

Suspension

4 Correction: (16) Adjust

Tire

Pressure To

Specifications

/ Rotate

Tires(16) Adjust

Tire

Pressure To

Specifications

/ Rotate

Tires

(16) Replace

Tire

(17) Adjust

Camber To

Specifications(18) Adjust

Toe-In To

Specifications

(19) Balance

Wheels(20) Rotate

Tires /

Replace Tires

/ Check

Alignment /

Suspension

BESM100022

10–42Chery Automobile Co., Ltd.

Page 1344 of 1903

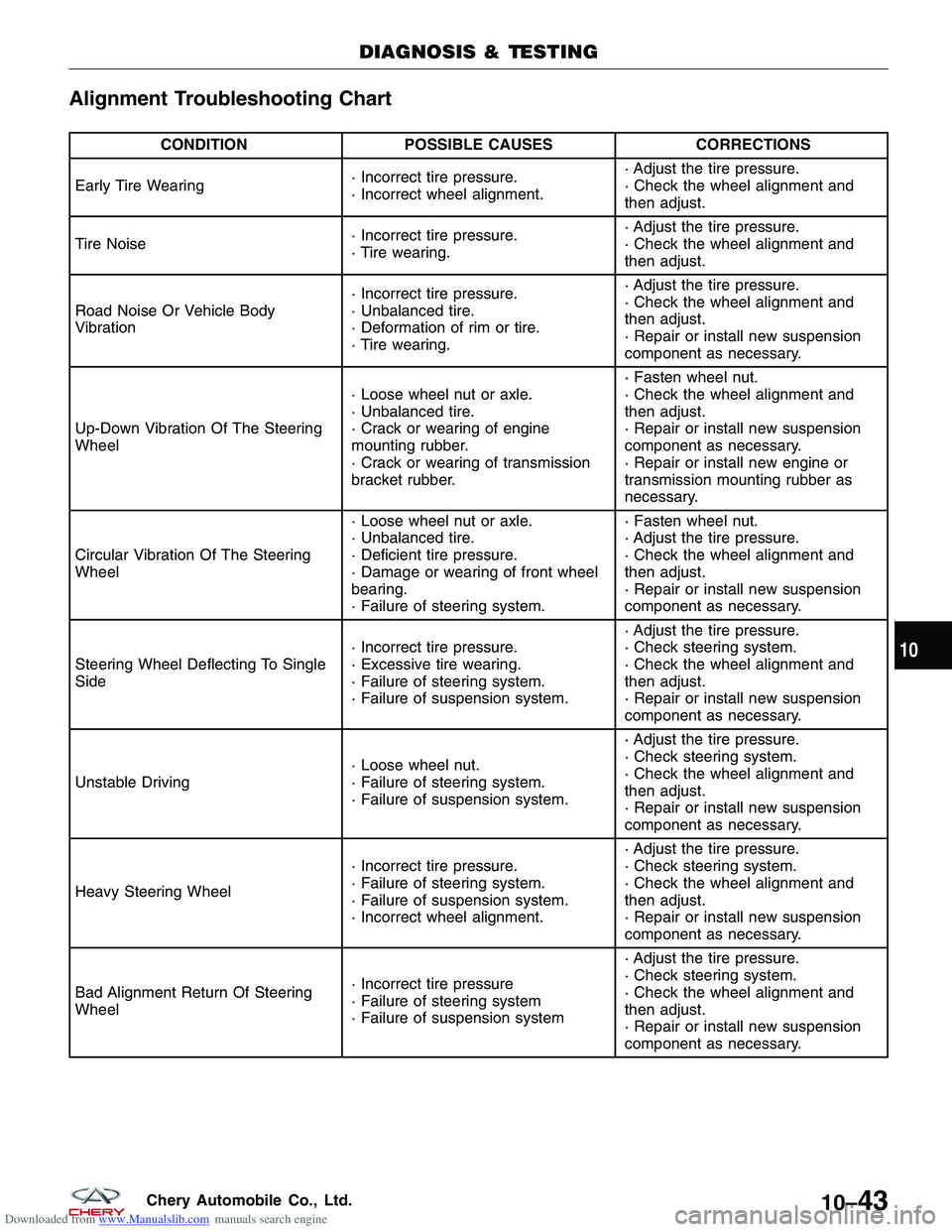

Downloaded from www.Manualslib.com manuals search engine Alignment Troubleshooting Chart

CONDITIONPOSSIBLE CAUSES CORRECTIONS

Early Tire Wearing · Incorrect tire pressure.

· Incorrect wheel alignment.· Adjust the tire pressure.

· Check the wheel alignment and

then adjust.

Tire Noise · Incorrect tire pressure.

· Tire wearing.· Adjust the tire pressure.

· Check the wheel alignment and

then adjust.

Road Noise Or Vehicle Body

Vibration · Incorrect tire pressure.

· Unbalanced tire.

· Deformation of rim or tire.

· Tire wearing.· Adjust the tire pressure.

· Check the wheel alignment and

then adjust.

· Repair or install new suspension

component as necessary.

Up-Down Vibration Of The Steering

Wheel · Loose wheel nut or axle.

· Unbalanced tire.

· Crack or wearing of engine

mounting rubber.

· Crack or wearing of transmission

bracket rubber.· Fasten wheel nut.

· Check the wheel alignment and

then adjust.

· Repair or install new suspension

component as necessary.

· Repair or install new engine or

transmission mounting rubber as

necessary.

Circular Vibration Of The Steering

Wheel · Loose wheel nut or axle.

· Unbalanced tire.

· Deficient tire pressure.

· Damage or wearing of front wheel

bearing.

· Failure of steering system.· Fasten wheel nut.

· Adjust the tire pressure.

· Check the wheel alignment and

then adjust.

· Repair or install new suspension

component as necessary.

Steering Wheel Deflecting To Single

Side · Incorrect tire pressure.

· Excessive tire wearing.

· Failure of steering system.

· Failure of suspension system.· Adjust the tire pressure.

· Check steering system.

· Check the wheel alignment and

then adjust.

· Repair or install new suspension

component as necessary.

Unstable Driving · Loose wheel nut.

· Failure of steering system.

· Failure of suspension system.· Adjust the tire pressure.

· Check steering system.

· Check the wheel alignment and

then adjust.

· Repair or install new suspension

component as necessary.

Heavy Steering Wheel · Incorrect tire pressure.

· Failure of steering system.

· Failure of suspension system.

· Incorrect wheel alignment.· Adjust the tire pressure.

· Check steering system.

· Check the wheel alignment and

then adjust.

· Repair or install new suspension

component as necessary.

Bad Alignment Return Of Steering

Wheel · Incorrect tire pressure

· Failure of steering system

· Failure of suspension system· Adjust the tire pressure.

· Check steering system.

· Check the wheel alignment and

then adjust.

· Repair or install new suspension

component as necessary.

DIAGNOSIS & TESTING

10

10–43Chery Automobile Co., Ltd.

Page 1345 of 1903

Downloaded from www.Manualslib.com manuals search engine ON-VEHICLE SERVICE

Front Wheel Alignment

Front Wheel Alignment Specifications

NOTE :

If the vehicle has been in an accident causing the front axle components to be damaged, the damaged components

must be replaced before performing a front wheel alignment.

FRONT WHEEL ALIGNMENT

FRONT WHEEL ALIGNMENT PREFERRED SETTINGACCEPTABLE RANGE

Camber -51’+9’ to -1°51’

Caster +2°50’+3°30’ to +2°5’

Inclination +11°30’+12°15’ to +10°45’

Toe-Individual 0’+5’ to -5’

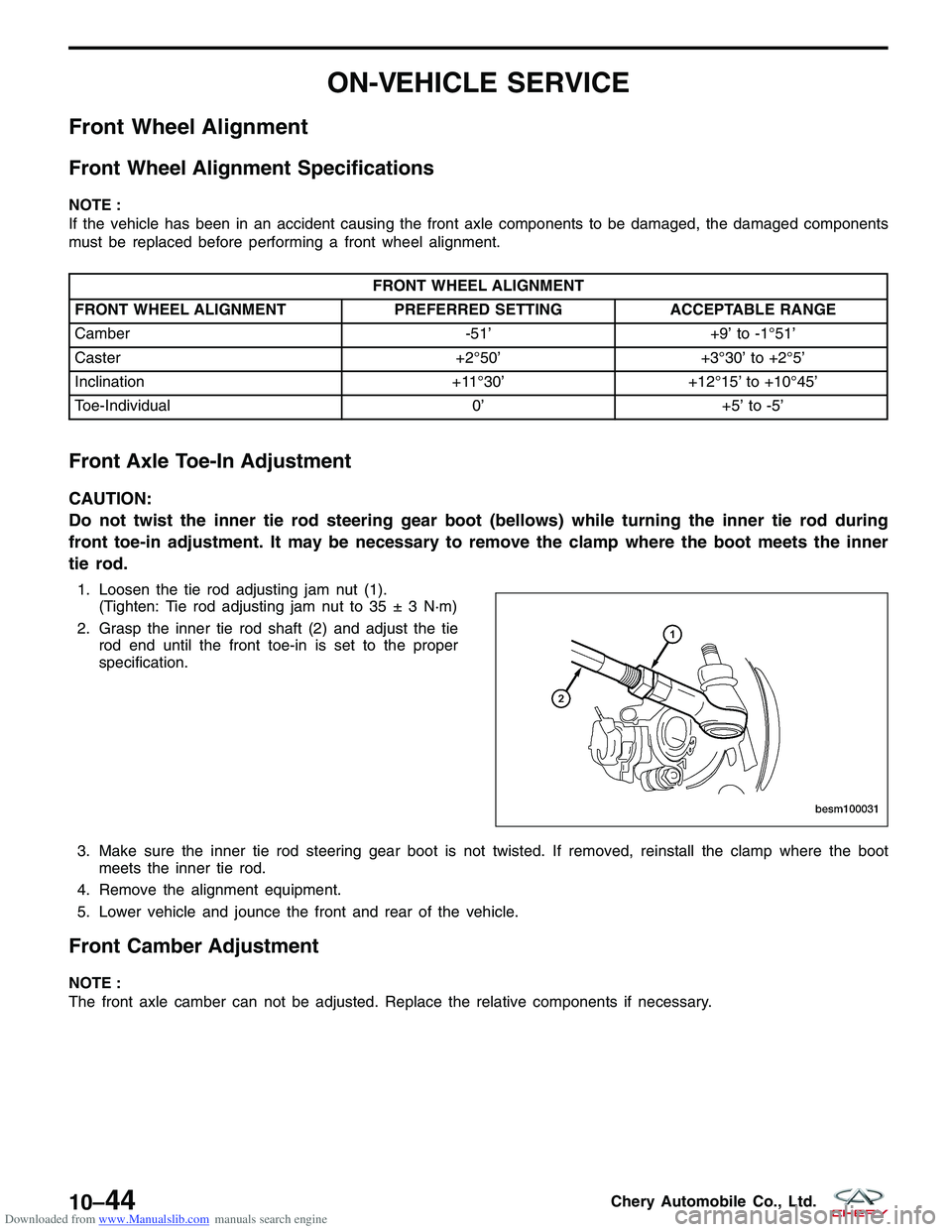

Front Axle Toe-In Adjustment

CAUTION:

Do not twist the inner tie rod steering gear boot (bellows) while turning the inner tie rod during

front toe-in adjustment. It may be necessary to remove the clamp where the boot meets the inner

tie rod.

1. Loosen the tie rod adjusting jam nut (1).

(Tighten: Tie rod adjusting jam nut to 35 ± 3 N·m)

2. Grasp the inner tie rod shaft (2) and adjust the tie rod end until the front toe-in is set to the proper

specification.

3. Make sure the inner tie rod steering gear boot is not twisted. If removed, reinstall the clamp where the boot meets the inner tie rod.

4. Remove the alignment equipment.

5. Lower vehicle and jounce the front and rear of the vehicle.

Front Camber Adjustment

NOTE :

The front axle camber can not be adjusted. Replace the relative components if necessary.

BESM100031

10–44Chery Automobile Co., Ltd.

Page 1346 of 1903

Downloaded from www.Manualslib.com manuals search engine Rear Wheel Alignment

Rear Wheel Alignment Specifications

NOTE :

If the vehicle has been in an accident causing the rear axle components to be damaged, the damaged components

must be replaced before performing a rear wheel alignment.

REAR WHEEL ALIGNMENT

REAR WHEEL ALIGNMENT PREFERRED SETTINGACCEPTABLE RANGE

Camber -54’-24’ to -1°24’

Toe-Individual -5’+5’ to -15’

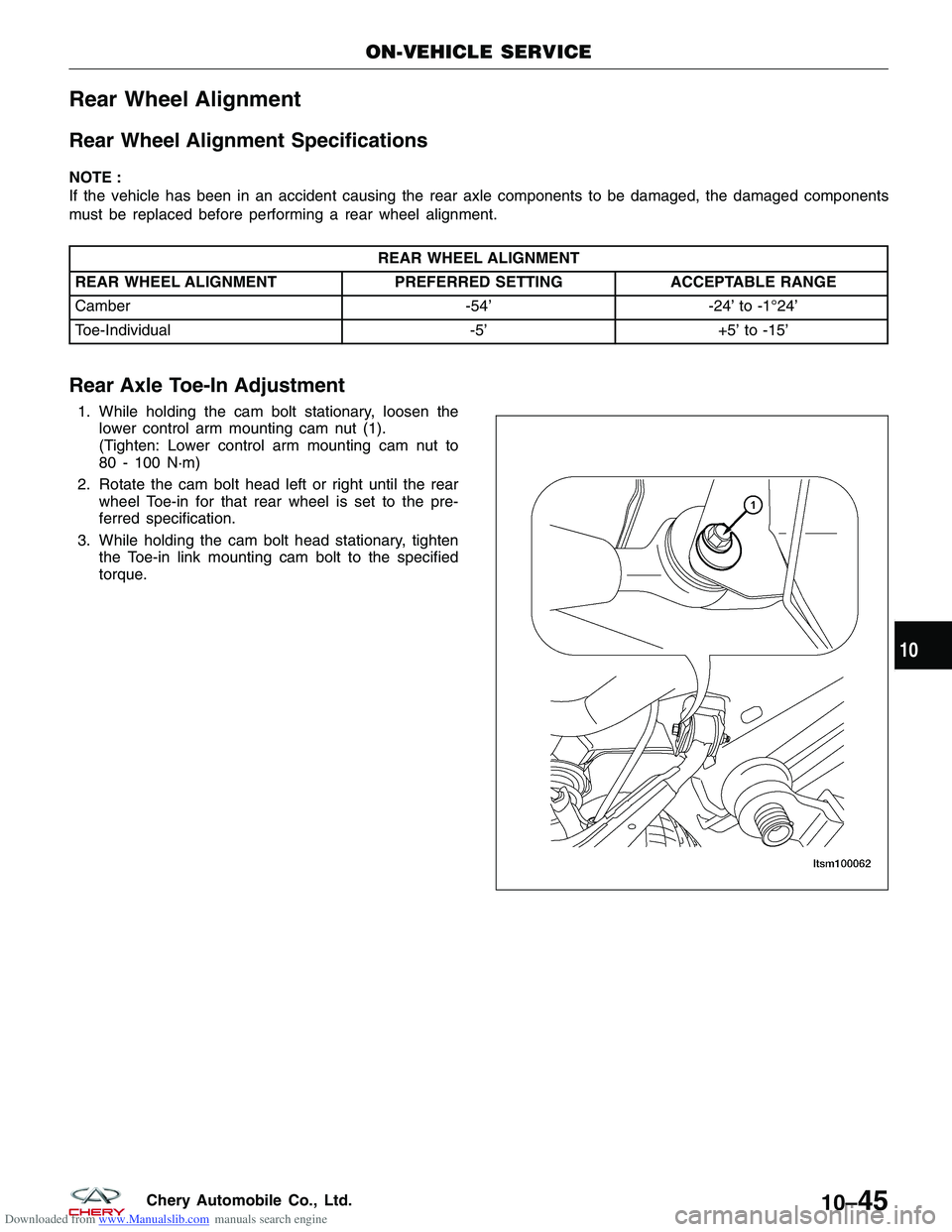

Rear Axle Toe-In Adjustment

1. While holding the cam bolt stationary, loosen the

lower control arm mounting cam nut (1).

(Tighten: Lower control arm mounting cam nut to

80 - 100 N·m)

2. Rotate the cam bolt head left or right until the rear wheel Toe-in for that rear wheel is set to the pre-

ferred specification.

3. While holding the cam bolt head stationary, tighten the Toe-in link mounting cam bolt to the specified

torque.

ON-VEHICLE SERVICE

BESM100031

10

10–45Chery Automobile Co., Ltd.

Page 1347 of 1903

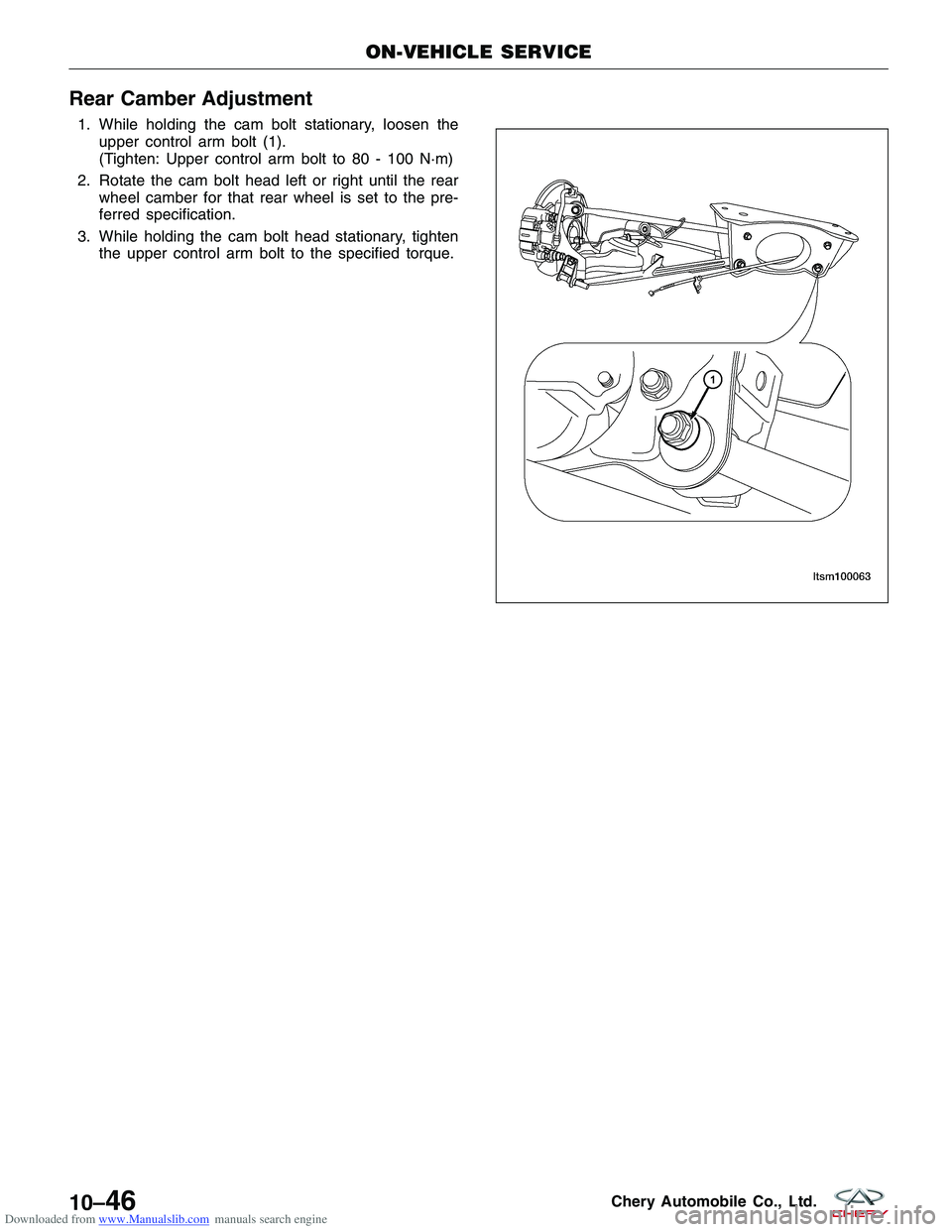

Downloaded from www.Manualslib.com manuals search engine Rear Camber Adjustment

1. While holding the cam bolt stationary, loosen theupper control arm bolt (1).

(Tighten: Upper control arm bolt to 80 - 100 N·m)

2. Rotate the cam bolt head left or right until the rear wheel camber for that rear wheel is set to the pre-

ferred specification.

3. While holding the cam bolt head stationary, tighten the upper control arm bolt to the specified torque.

ON-VEHICLE SERVICE

BESM100031

10–46Chery Automobile Co., Ltd.

Page 1348 of 1903

Downloaded from www.Manualslib.com manuals search engine WHEELS AND TIRES

GENERAL INFORMATION10-48

Description 10-48

Operation 10-48

Specifications 10-48

DIAGNOSIS & TESTING10-50

Vehicle Inspection 10-50

Tire and Wheel Vibration 10-50

Tire Wear Patterns 10-50

Wheel Out-Of-Round Inspection 10-50

ON-VEHICLE SERVICE10-51

Tire Repair 10-51

Description 10-51 Replacement Procedure 10-51

Repair Procedure 10-51

Wheel Assembly 10-52

Description 10-52

Removal & Installation 10-52

Wheel Balance 10-52

Description 10-52

Wheel Balance Procedure 10-53

Tire Rotation 10-53

Description 10-53

Non-Directional Tires 10-54

Directional Tires 10-54

10

10–47Chery Automobile Co., Ltd.

Page 1349 of 1903

Downloaded from www.Manualslib.com manuals search engine GENERAL INFORMATION

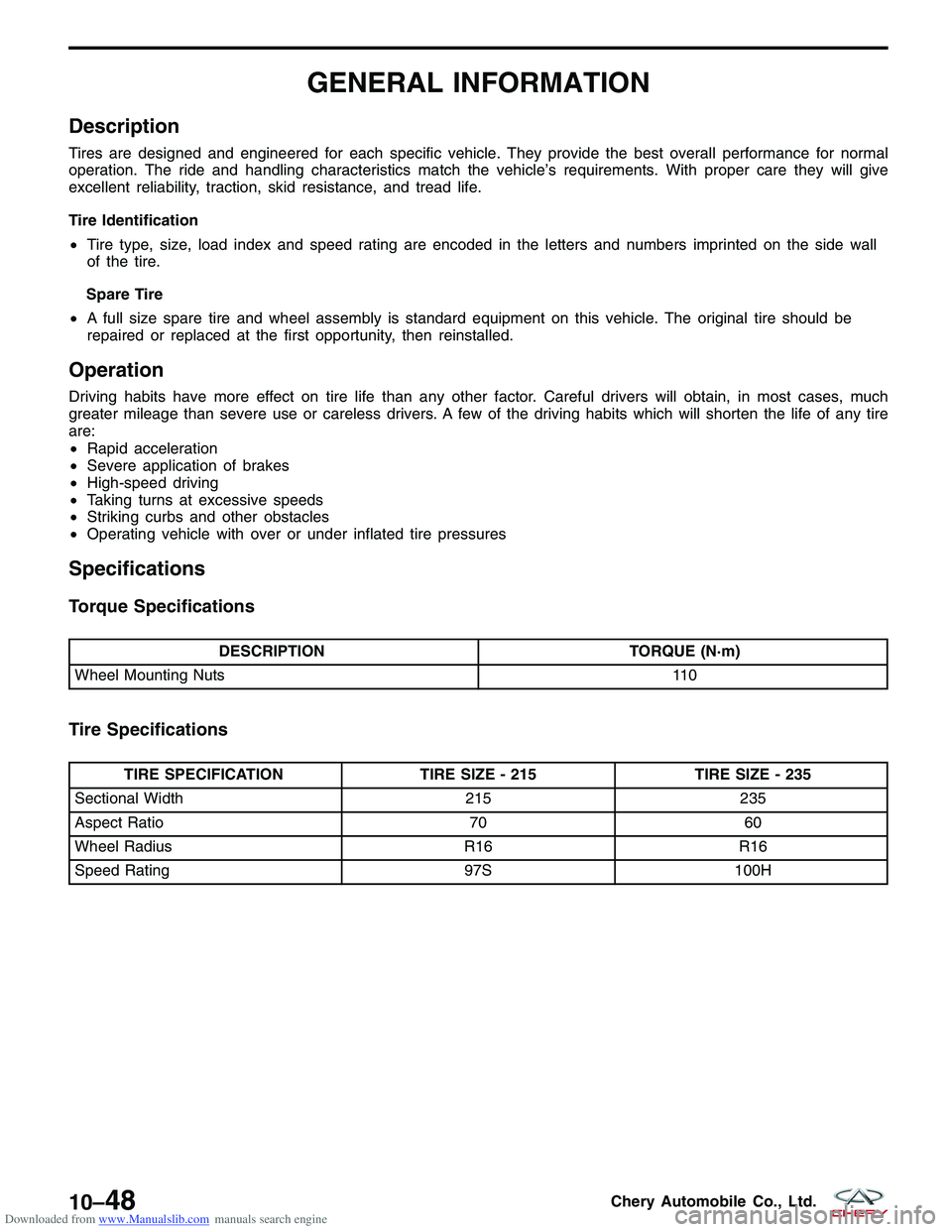

Description

Tires are designed and engineered for each specific vehicle. They provide the best overall performance for normal

operation. The ride and handling characteristics match the vehicle’s requirements. With proper care they will give

excellent reliability, traction, skid resistance, and tread life.

Tire Identification

•Tire type, size, load index and speed rating are encoded in the letters and numbers imprinted on the side wall

of the tire.

Spare Tire

• A full size spare tire and wheel assembly is standard equipment on this vehicle. The original tire should be

repaired or replaced at the first opportunity, then reinstalled.

Operation

Driving habits have more effect on tire life than any other factor. Careful drivers will obtain, in most cases, much

greater mileage than severe use or careless drivers. A few of the driving habits which will shorten the life of any tire

are:

•Rapid acceleration

• Severe application of brakes

• High-speed driving

• Taking turns at excessive speeds

• Striking curbs and other obstacles

• Operating vehicle with over or under inflated tire pressures

Specifications

Torque Specifications

DESCRIPTION TORQUE (N·m)

Wheel Mounting Nuts 110

Tire Specifications

TIRE SPECIFICATIONTIRE SIZE - 215TIRE SIZE - 235

Sectional Width 215235

Aspect Ratio 7060

Wheel Radius R16R16

Speed Rating 97S100H

10–48Chery Automobile Co., Ltd.

Page 1350 of 1903

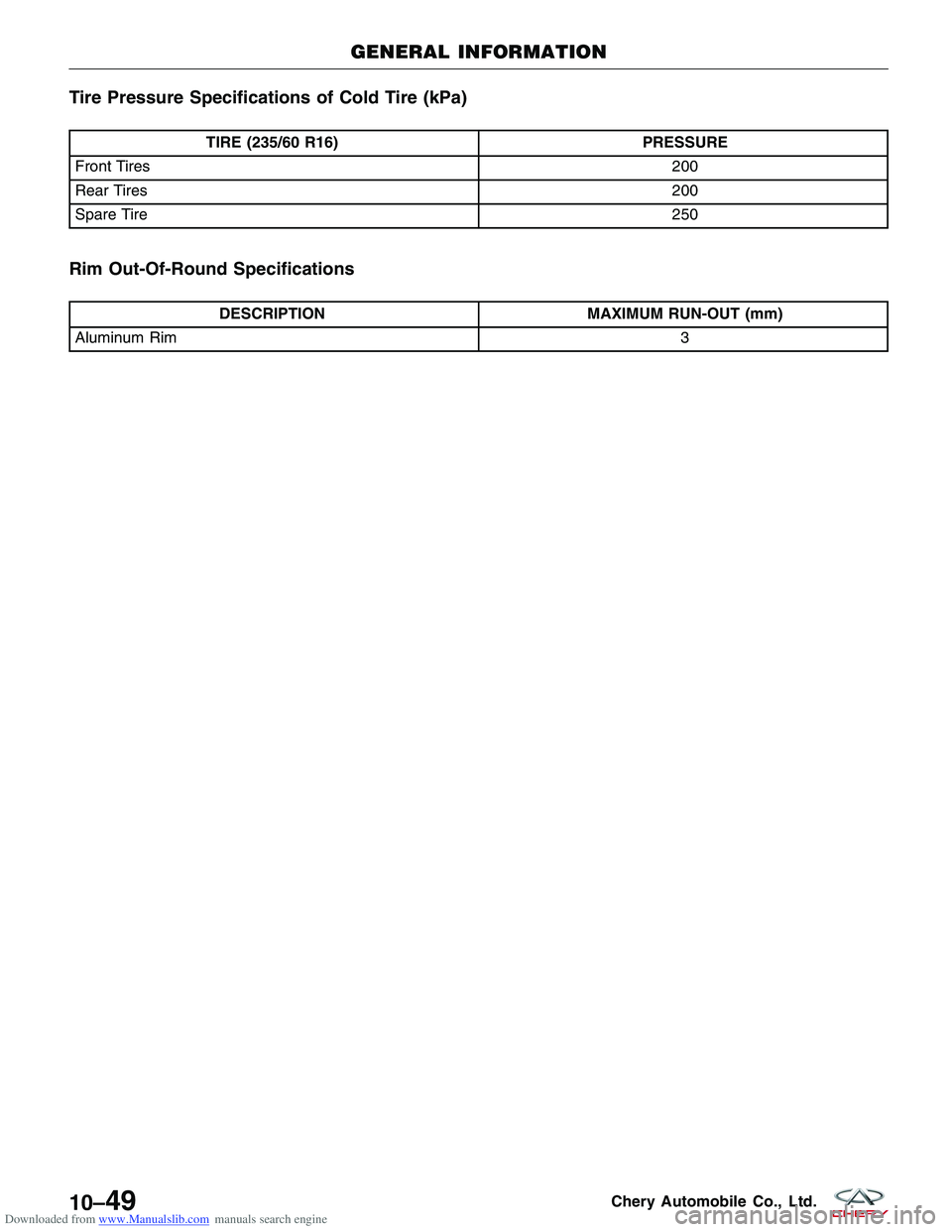

Downloaded from www.Manualslib.com manuals search engine Tire Pressure Specifications of Cold Tire (kPa)

TIRE (235/60 R16)PRESSURE

Front Tires 200

Rear Tires 200

Spare Tire 250

Rim Out-Of-Round Specifications

DESCRIPTIONMAXIMUM RUN-OUT (mm)

Aluminum Rim 3

GENERAL INFORMATION

10–49Chery Automobile Co., Ltd.