CHERY TIGGO 2009 Service Repair Manual

Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 1291 of 1903

Downloaded from www.Manualslib.com manuals search engine GENERAL INFORMATION

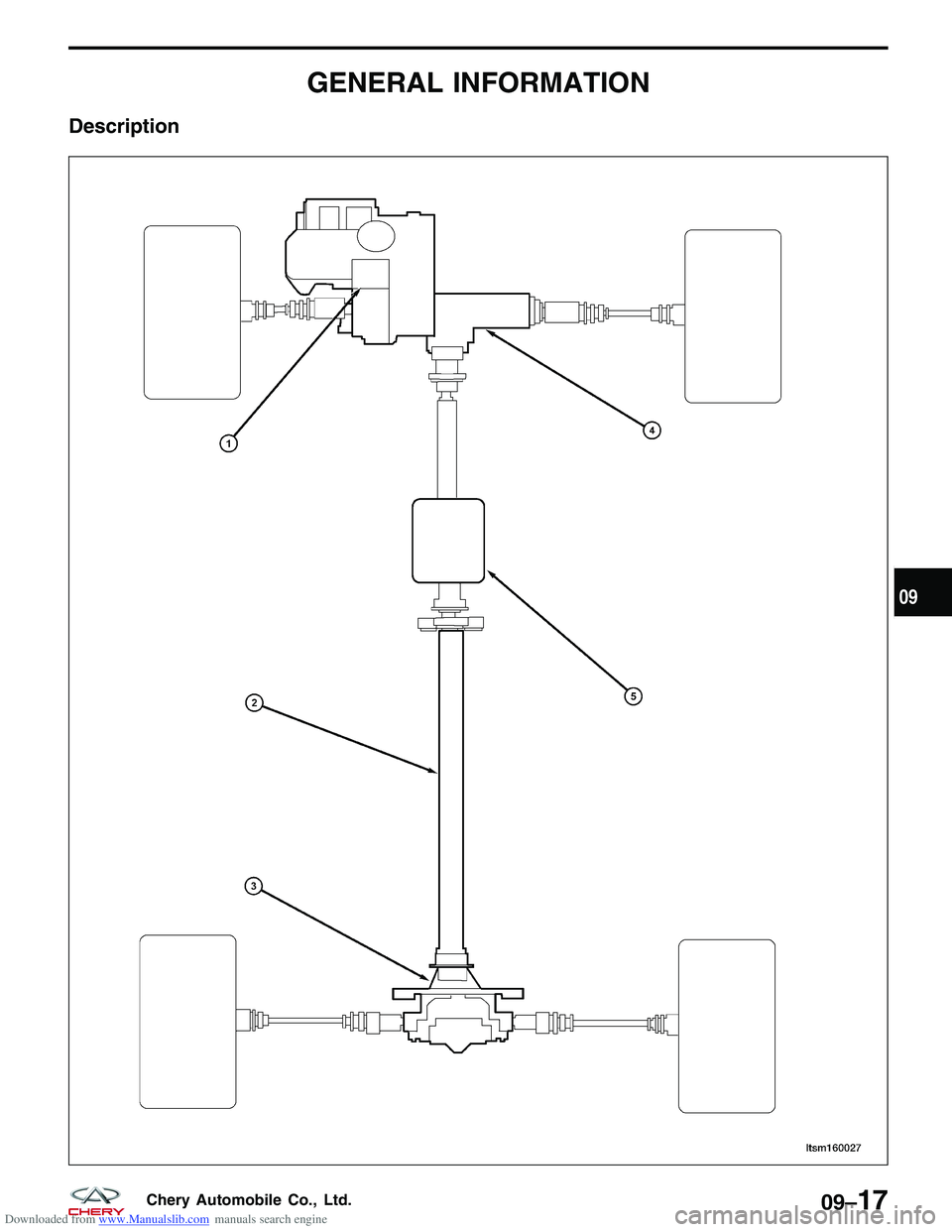

Description

LTSM160027

09

09–17Chery Automobile Co., Ltd.

Page 1292 of 1903

Downloaded from www.Manualslib.com manuals search engine The Tiggo 4WD is the first 4WD vehicle produced by Chery. The 4WD system is equipped with a QR523T transaxle

manufactured by Chery.

An active torque transfer system is used, and an interactive torque management system (ITM) is equipped to make

it possible to intelligently distribute the drive force for the front wheels and rear wheels according to different road

conditions. For example, on a smooth road, the vehicle utilizes front-wheel drive. When road conditions worsen, the

ITM will automatically switch to 4WD. The use of ITM allows the Tiggo vehicle to be more economical and more

efficient than the common 4WD system.

Operation

The intelligent 4WD system is controlled by an interactive torque management system (ITM) module. The ITM mod-

ule communicates with the Engine Control Module (ECM) and the Antilock Brake System (ABS) controller through the

CAN network. The ITM module collects data from sensors on the vehicle body to determine the condition of the drive

wheels. Based on the sensor inputs, the ITM module controls the ITM controller. The ITM controller will then distrib-

ute a portion of the torque to the rear drive axle as needed. The ITM controller works as an electromagnetic clutch.

Different torque can be transferred by changing the electric current of the ITM controller. The ITM controller will be

able to distribute the torque of the front drive axle and the rear drive axle at different ratios according to the various

dynamic conditions of the vehicle.

Specification

Transaxle Specifications

MODEL TYPE DISTANCEBETWEENCENTERS (mm) MAX

INPUT

TORQUE (N·m) GEAR / SPEED RATIO

1st 2nd 3rd 4th 5th Reverse Final

Drive

QR523T Front-

Wheel Drive

Transaxle 78 195 3.583 1.947 1.379 1.303 0.821 3.364 4.3125

1 - Transaxle

2 - Drive Line

3 - Rear Axle4 - Power Transfer

5 - ITM Controller

GENERAL INFORMATION

LTSM160027

09–18Chery Automobile Co., Ltd.

Page 1293 of 1903

Downloaded from www.Manualslib.com manuals search engine Torque Specifications

DESCRIPTIONTORQUE (N·m)

Bow Beam to Plate Bolts 60 ± 5

Front Intermediate Shaft to ITM Controller Bolts 70 ± 7

ITM Bracket to Bow Beam Bolts 60 ± 5

ITM Control Module Bolts 9 ± 1

Transaxle to Transfer Case Bolts 80

Rear Intermediate Shaft to ITM Controller Bolts 39 ± 3

Rear Intermediate Shaft to Rear Differential Bolts 65 ± 6

Transfer Case Fluid-Limiting Bolt 40 ± 3

Transfer Case Fluid Fill Bolt 40 ± 3

Transfer Case Fluid Drain Bolt 40 ± 3

Transfer Case Front Housing Bolt 35

Transfer Case Rear Housing Bolts 40

Transfer Case Right Bearing Seat Bolt 35

Transfer Case Vent Bolt 18 ± 3

Fluid Specifications

NAMETYPEQUANTITYMAINTENANCE TERM

Transaxle Gear Fluid GL-4 75w-902.2 Liters1 year / 30,000 km

Transfer Case Gear Fluid GL-5 80w-900.8 Liters50,000 km

Rear Final Drive Gear

Fluid Hypoid 85w-90

0.8 Liters50,000 km

Transfer Case Specifications

Differential Assembly

Side GearType of Gear Straight bevel gear

Number of Gears 14

Planetary Gear Type of Gear

Straight bevel gear

Number of Gears 10

Hypoid G Gear Drive GearNumber of Gears 41

Driven Gear Number of Gears 14

ITM Control Module Electronic Signals

SIGNALSMODE OF PROVISION SIGNAL SOURCE

Signals Of The Four Wheel Speed CANWheel Speed Sensor

Vehicle Speed Signals CANVehicle Speed Sensor

Acceleration Signals CANG Sensor

Engine Speed Signals CANCrankshaft Position Sensor

Throttle Position Signals CANThrottle Position Sensor

Steering Wheel Angle Signals SimulatedITM Module

Ignition Switch Signals DirectIgnition Switch

GENERAL INFORMATION

09

09–19Chery Automobile Co., Ltd.

Page 1294 of 1903

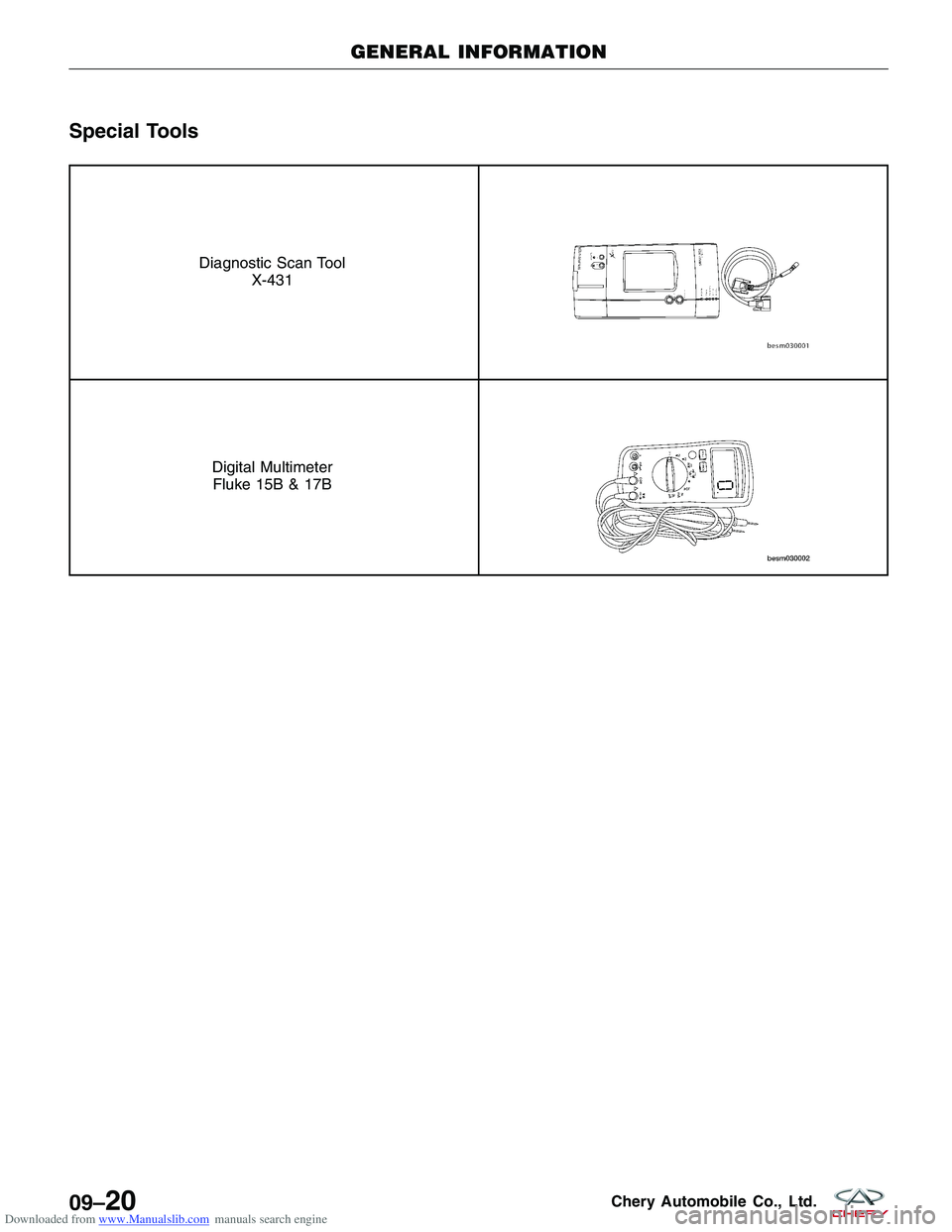

Downloaded from www.Manualslib.com manuals search engine Special Tools

Diagnostic Scan ToolX-431

Digital MultimeterFluke 15B & 17B

GENERAL INFORMATION

09–20Chery Automobile Co., Ltd.

Page 1295 of 1903

Downloaded from www.Manualslib.com manuals search engine ON-VEHICLE SERVICE

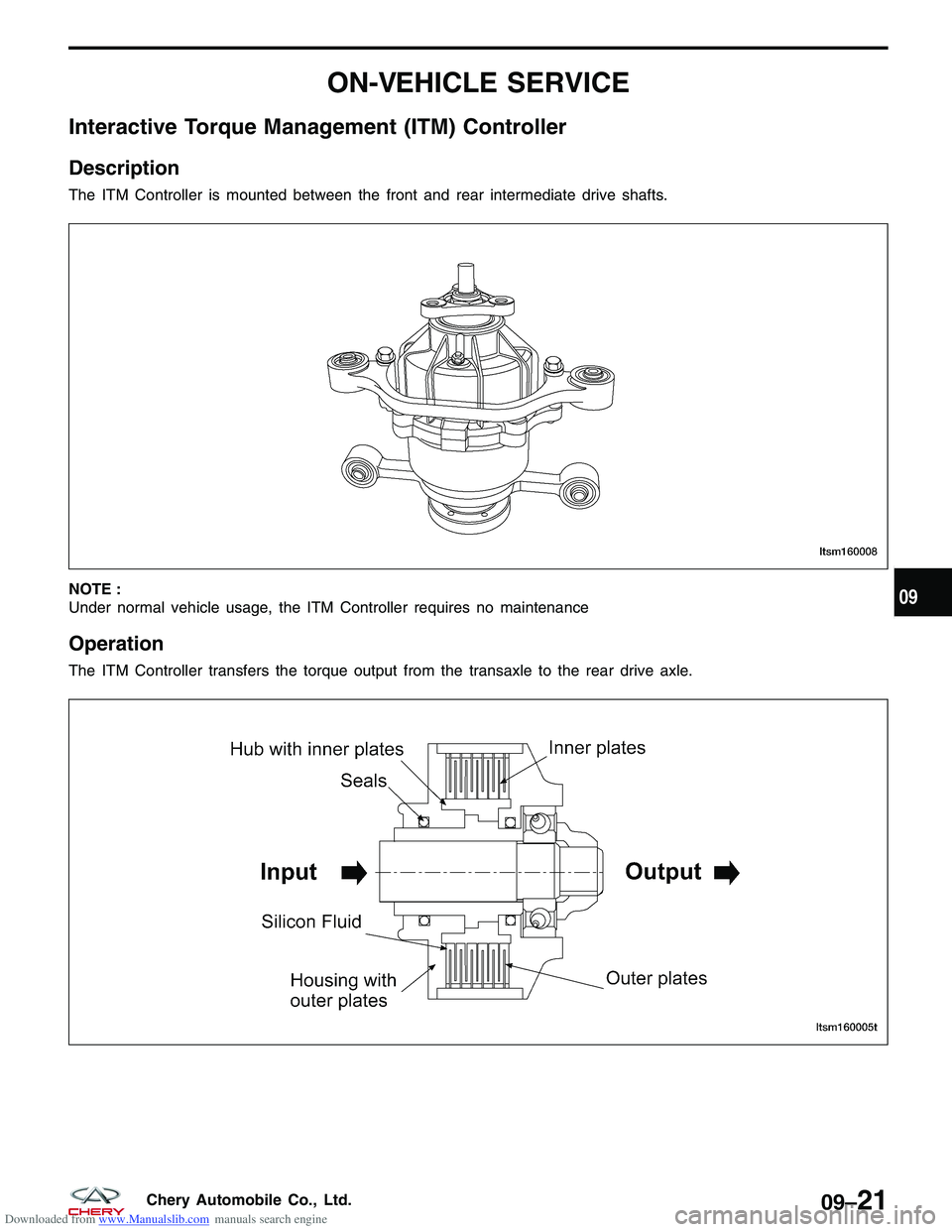

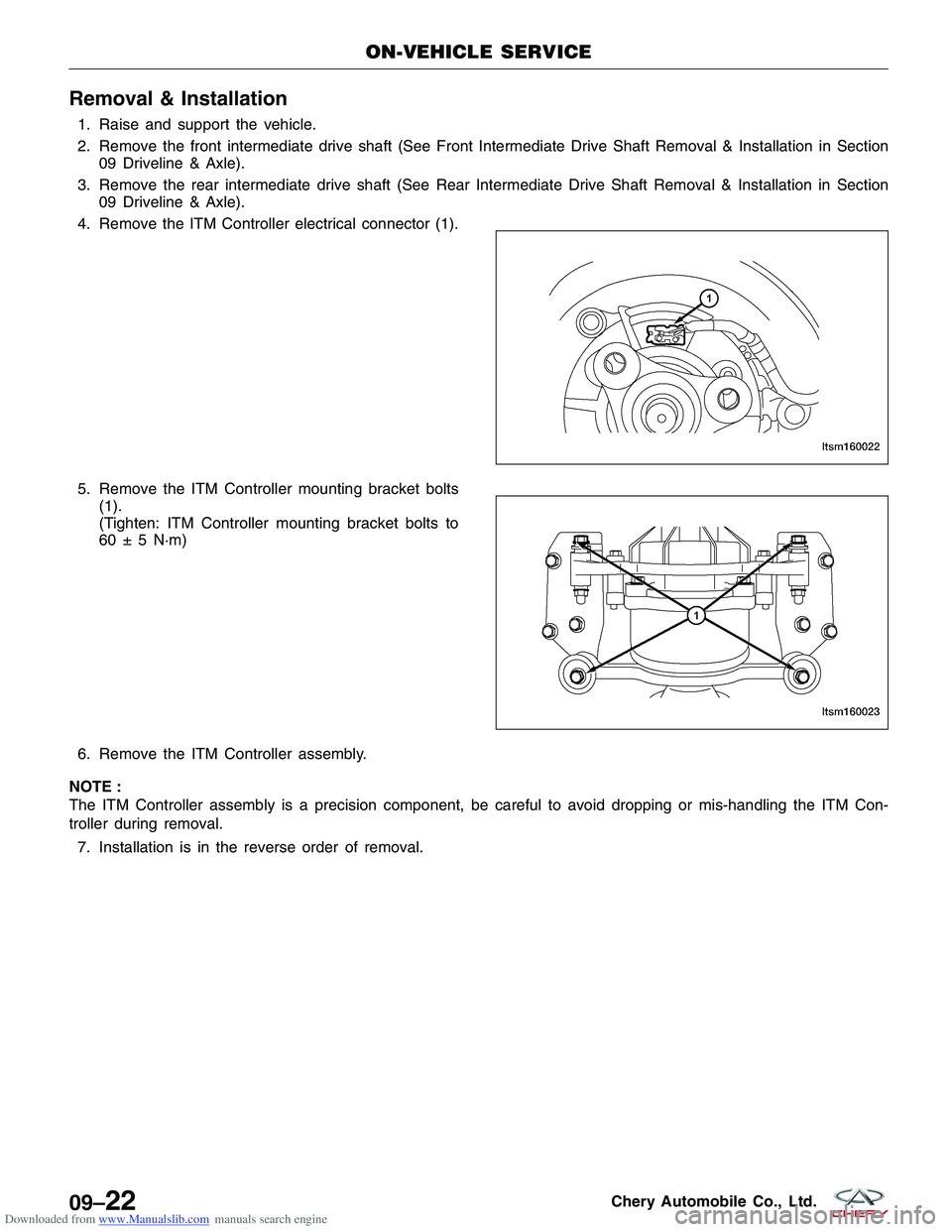

Interactive Torque Management (ITM) Controller

Description

The ITM Controller is mounted between the front and rear intermediate drive shafts.

NOTE :

Under normal vehicle usage, the ITM Controller requires no maintenance

Operation

The ITM Controller transfers the torque output from the transaxle to the rear drive axle.

LTSM160008

LTSM160005T

09

09–21Chery Automobile Co., Ltd.

Page 1296 of 1903

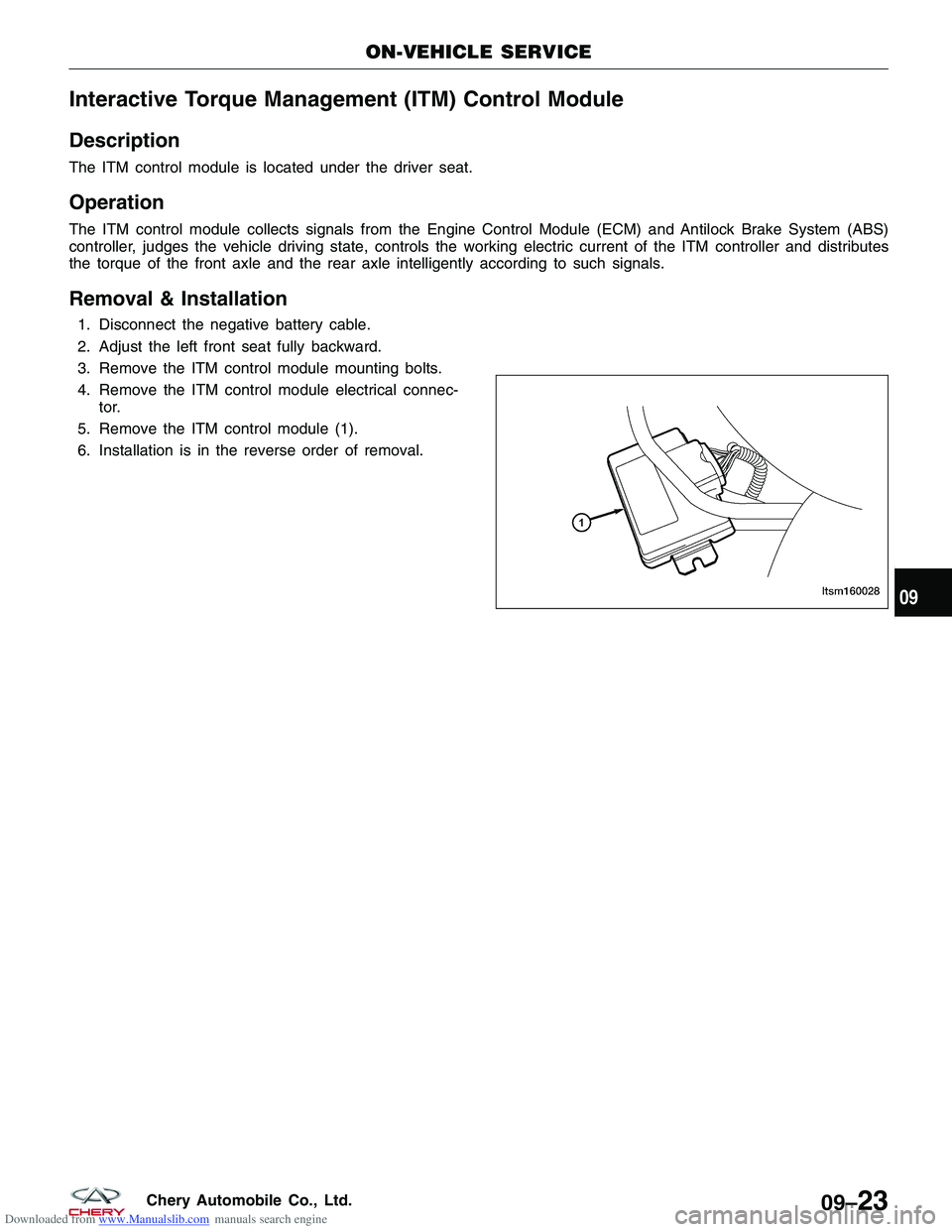

Downloaded from www.Manualslib.com manuals search engine Removal & Installation

1. Raise and support the vehicle.

2. Remove the front intermediate drive shaft (See Front Intermediate Drive Shaft Removal & Installation in Section09 Driveline & Axle).

3. Remove the rear intermediate drive shaft (See Rear Intermediate Drive Shaft Removal & Installation in Section 09 Driveline & Axle).

4. Remove the ITM Controller electrical connector (1).

5. Remove the ITM Controller mounting bracket bolts (1).

(Tighten: ITM Controller mounting bracket bolts to

60 ± 5 N·m)

6. Remove the ITM Controller assembly.

NOTE :

The ITM Controller assembly is a precision component, be careful to avoid dropping or mis-handling the ITM Con-

troller during removal. 7. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM160022

LTSM160023

09–22Chery Automobile Co., Ltd.

Page 1297 of 1903

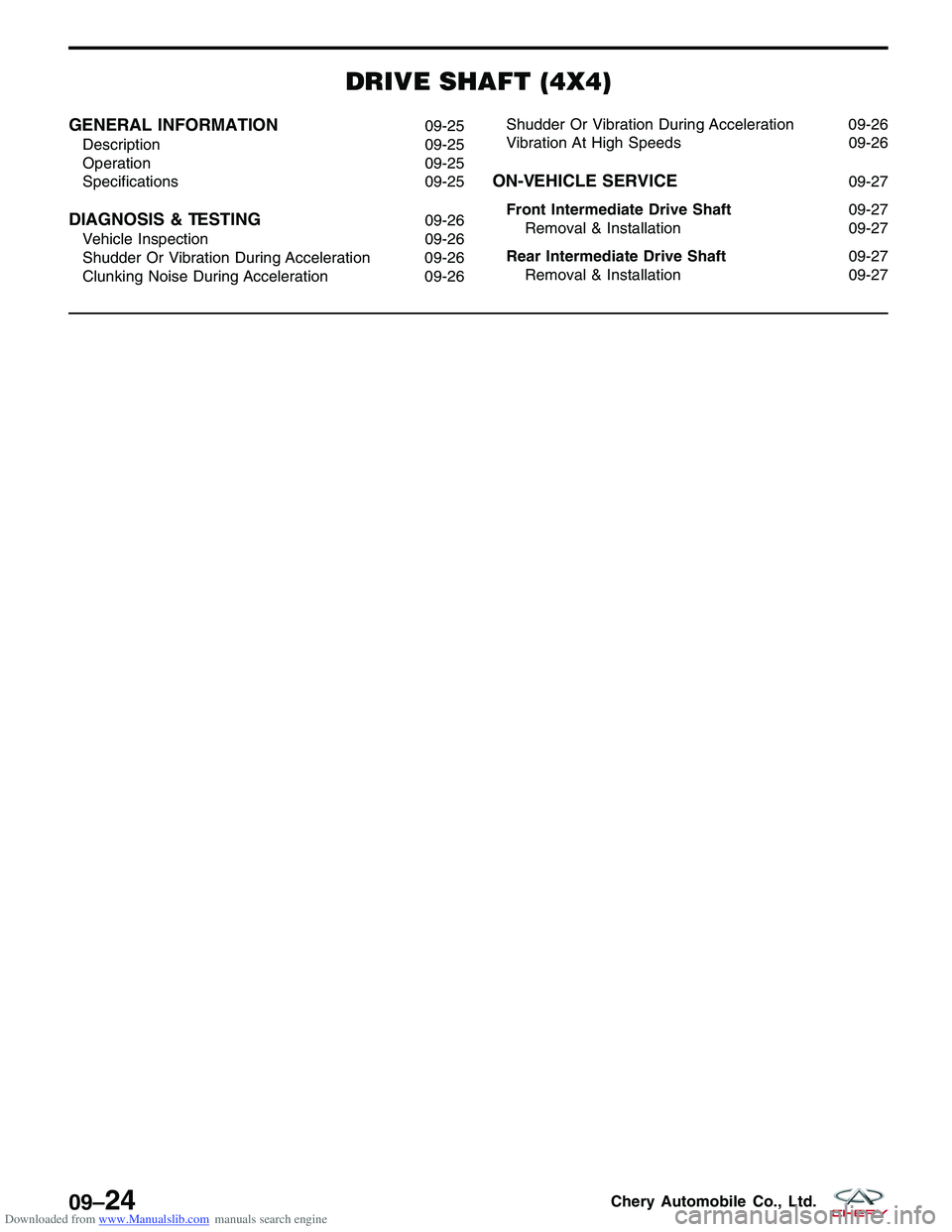

Downloaded from www.Manualslib.com manuals search engine Interactive Torque Management (ITM) Control Module

Description

The ITM control module is located under the driver seat.

Operation

The ITM control module collects signals from the Engine Control Module (ECM) and Antilock Brake System (ABS)

controller, judges the vehicle driving state, controls the working electric current of the ITM controller and distributes

the torque of the front axle and the rear axle intelligently according to such signals.

Removal & Installation

1. Disconnect the negative battery cable.

2. Adjust the left front seat fully backward.

3. Remove the ITM control module mounting bolts.

4. Remove the ITM control module electrical connec-tor.

5. Remove the ITM control module (1).

6. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM16002809

09–23Chery Automobile Co., Ltd.

Page 1298 of 1903

Downloaded from www.Manualslib.com manuals search engine DRIVE SHAFT (4X4)

GENERAL INFORMATION09-25

Description 09-25

Operation 09-25

Specifications 09-25

DIAGNOSIS & TESTING09-26

Vehicle Inspection 09-26

Shudder Or Vibration During Acceleration 09-26

Clunking Noise During Acceleration 09-26 Shudder Or Vibration During Acceleration 09-26

Vibration At High Speeds 09-26

ON-VEHICLE SERVICE09-27

Front Intermediate Drive Shaft 09-27

Removal & Installation 09-27

Rear Intermediate Drive Shaft 09-27

Removal & Installation 09-27

09–24Chery Automobile Co., Ltd.

Page 1299 of 1903

Downloaded from www.Manualslib.com manuals search engine GENERAL INFORMATION

Description

The drive shafts for the 4x4 are separated into the front intermediate drive shaft and the rear intermediate drive shaft.

The front intermediate drive shaft is installed between the transfer case and the Interactive Torque Management

(ITM) controller. The rear intermediate drive shaft is installed between the ITM controller and the rear axle.

Operation

The drive shafts transfer the torque from the transaxle to the rear axle.

Specifications

Torque Specifications

DESCRIPTIONTORQUE (N·m)

Front Intermediate Drive Shaft to ITM Controller Bolts 70 ± 7

Rear Intermediate Drive Shaft to ITM Controller Bolts 39 ± 3

Rear Intermediate Drive Shaft to Body Bolts 60 ± 5

Rear Intermediate Drive Shaft to Rear Axle Flange 65 ± 6

09

09–25Chery Automobile Co., Ltd.

Page 1300 of 1903

Downloaded from www.Manualslib.com manuals search engine DIAGNOSIS & TESTING

Vehicle Inspection

Inspect the drive shaft for the following:

•Check the drive shaft for loose bearings.

• Check the drive shaft for any damage or excessive runout.

Shudder Or Vibration During Acceleration

This problem could be a result of:

•A worn or damaged drive shaft joint.

• Improper wheel alignment.

Clunking Noise During Acceleration

This noise may be a result of one of the following conditions:

•A worn drive shaft assembly.

• A loose drive shaft assembly.

• A damaged or worn drive shaft joint.

Shudder Or Vibration During Acceleration

This problem could be a result of:

•A worn or damaged drive shaft joint.

• Improper wheel alignment.

Vibration At High Speeds

This problem could be a result of:

•Foreign material (mud, etc.) packed on the backside of the wheel(s).

• Out of balance tires or wheels.

• Improper tire or wheel runout.

09–26Chery Automobile Co., Ltd.