CHERY TIGGO 2009 Service Repair Manual

Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 221 of 1903

Downloaded from www.Manualslib.com manuals search engine 11. Installation is in the reverse order of removal.

Installation Notes:

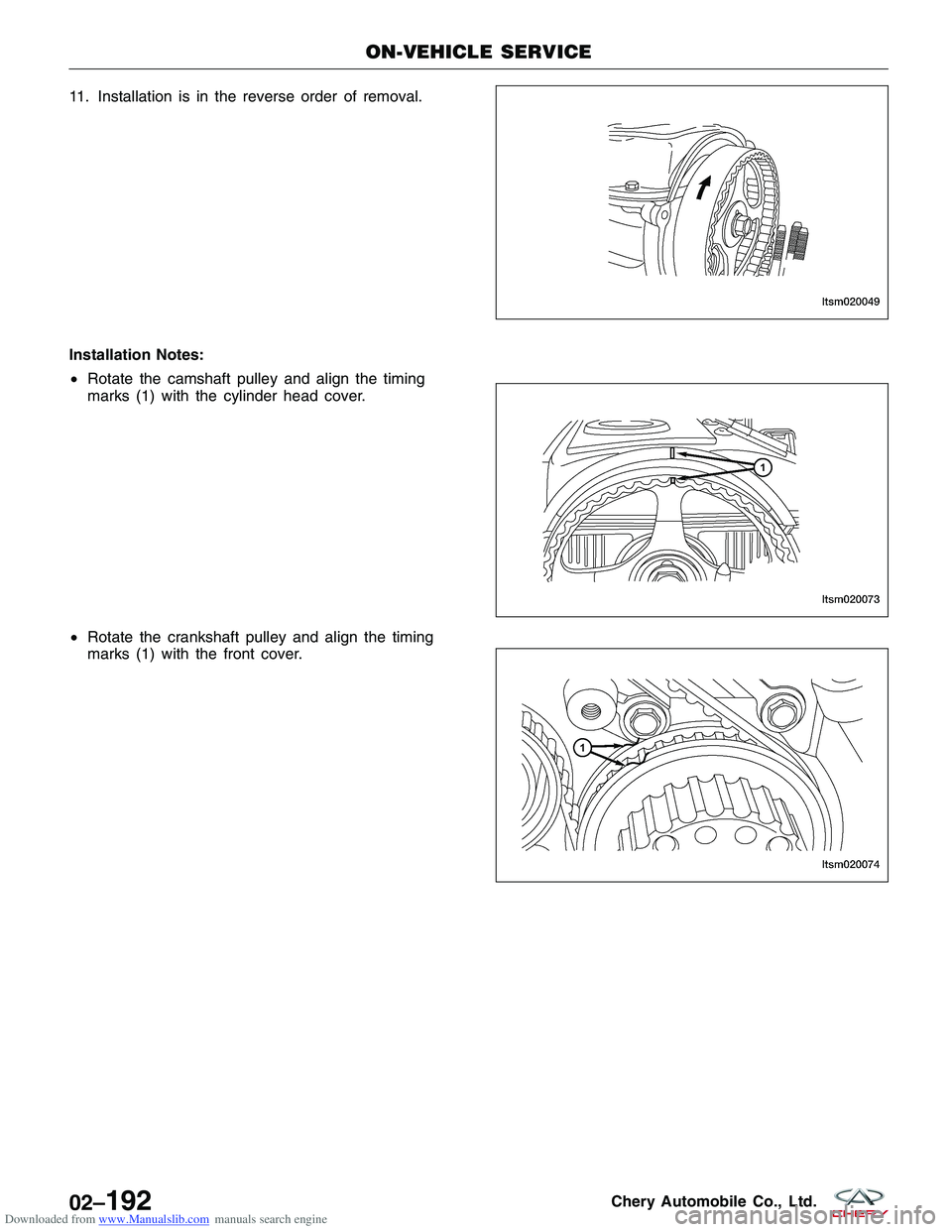

•Rotate the camshaft pulley and align the timing

marks (1) with the cylinder head cover.

• Rotate the crankshaft pulley and align the timing

marks (1) with the front cover.

ON-VEHICLE SERVICE

LTSM020049

LTSM020073

LTSM020074

02–192Chery Automobile Co., Ltd.

Page 222 of 1903

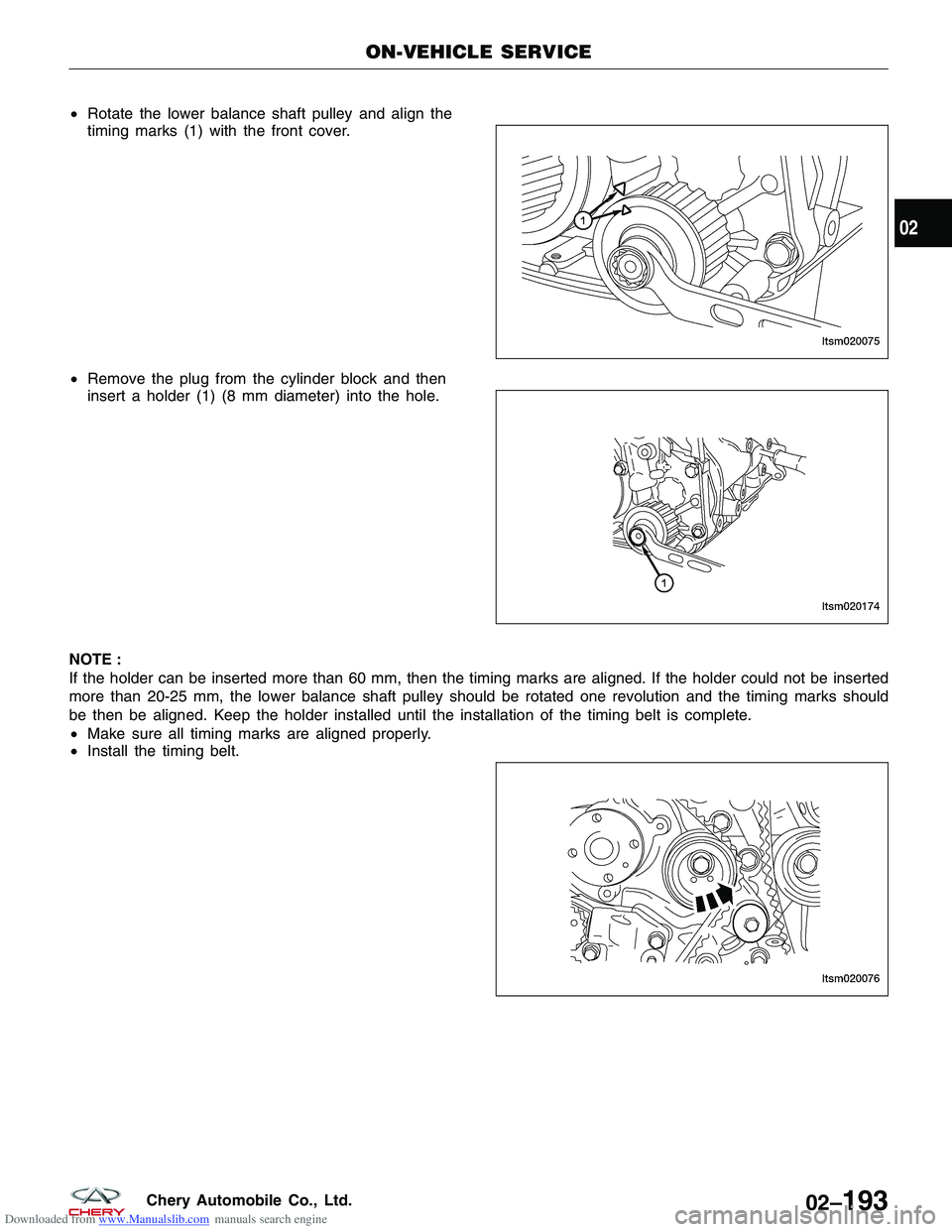

Downloaded from www.Manualslib.com manuals search engine •Rotate the lower balance shaft pulley and align the

timing marks (1) with the front cover.

• Remove the plug from the cylinder block and then

insert a holder (1) (8 mm diameter) into the hole.

NOTE :

If the holder can be inserted more than 60 mm, then the timing marks are aligned. If the holder could not be inserted

more than 20-25 mm, the lower balance shaft pulley should be rotated one revolution and the timing marks should

be then be aligned. Keep the holder installed until the installation of the timing belt is complete.

• Make sure all timing marks are aligned properly.

• Install the timing belt.

ON-VEHICLE SERVICE

LTSM020075

LTSM020174

LTSM020076

02

02–193Chery Automobile Co., Ltd.

Page 223 of 1903

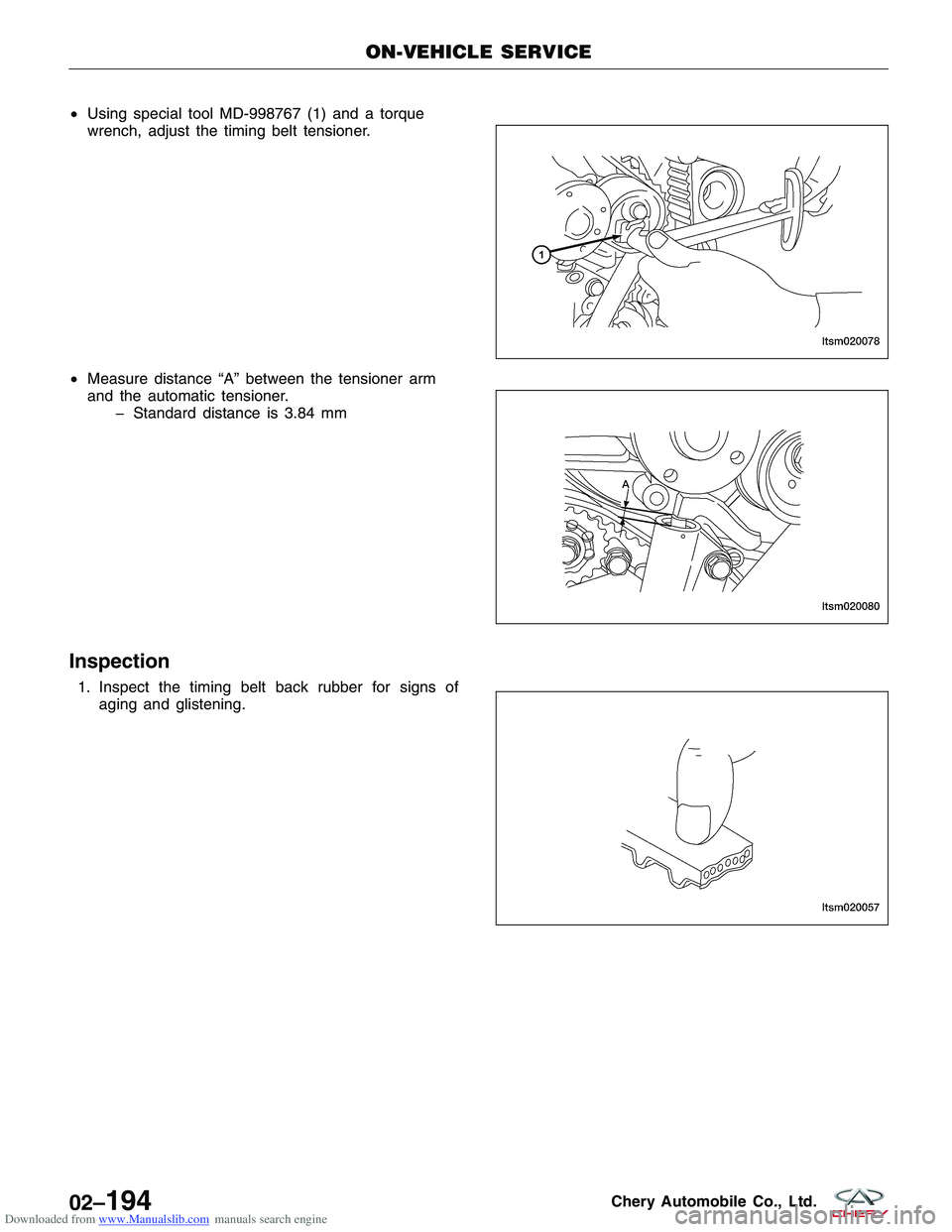

Downloaded from www.Manualslib.com manuals search engine •Using special tool MD-998767 (1) and a torque

wrench, adjust the timing belt tensioner.

• Measure distance “A” between the tensioner arm

and the automatic tensioner.

� Standard distance is 3.84 mm

Inspection

1. Inspect the timing belt back rubber for signs ofaging and glistening.

ON-VEHICLE SERVICE

LTSM020078

LTSM020080

LTSM020057

02–194Chery Automobile Co., Ltd.

Page 224 of 1903

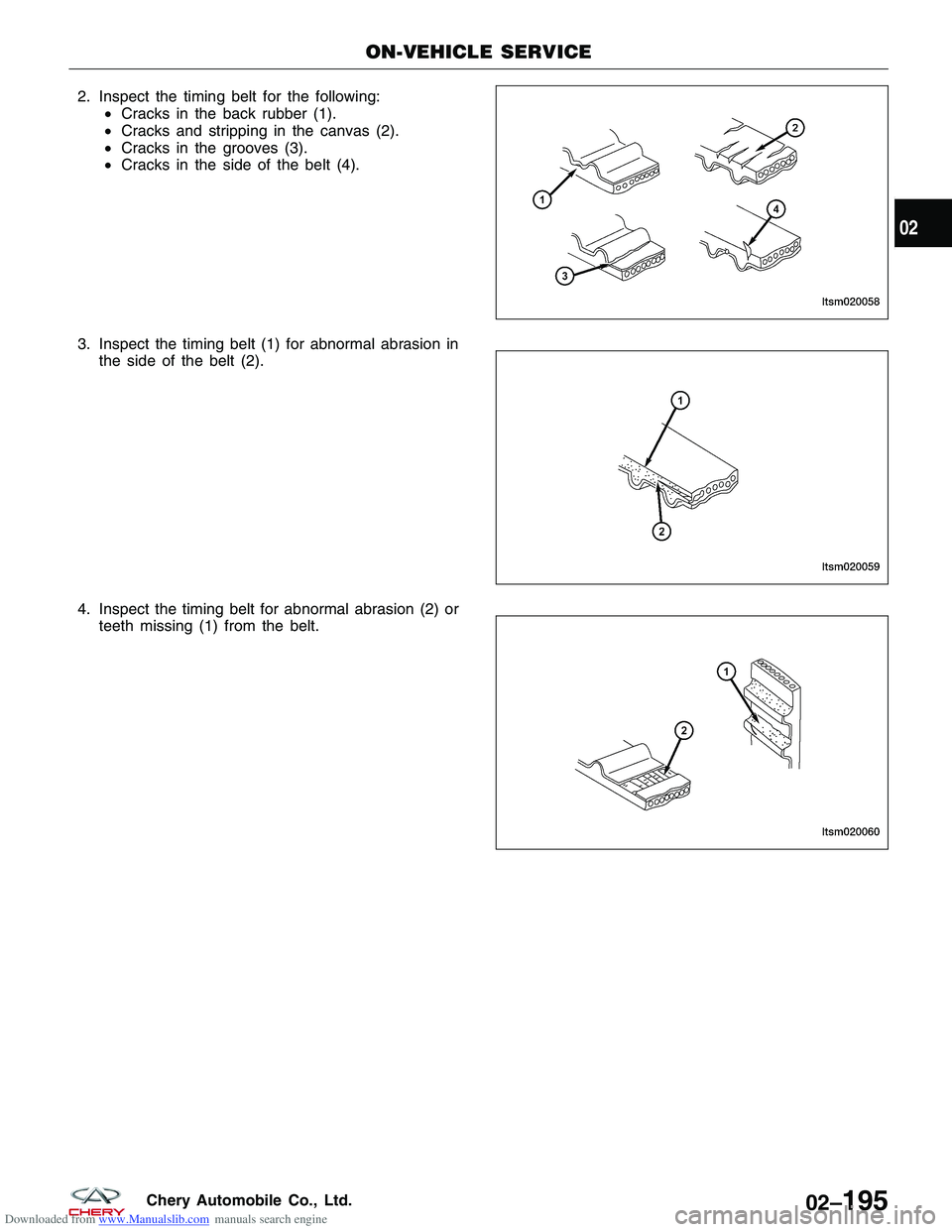

Downloaded from www.Manualslib.com manuals search engine 2. Inspect the timing belt for the following:•Cracks in the back rubber (1).

• Cracks and stripping in the canvas (2).

• Cracks in the grooves (3).

• Cracks in the side of the belt (4).

3. Inspect the timing belt (1) for abnormal abrasion in the side of the belt (2).

4. Inspect the timing belt for abnormal abrasion (2) or teeth missing (1) from the belt.

ON-VEHICLE SERVICE

LTSM020058

LTSM020059

LTSM020060

02

02–195Chery Automobile Co., Ltd.

Page 225 of 1903

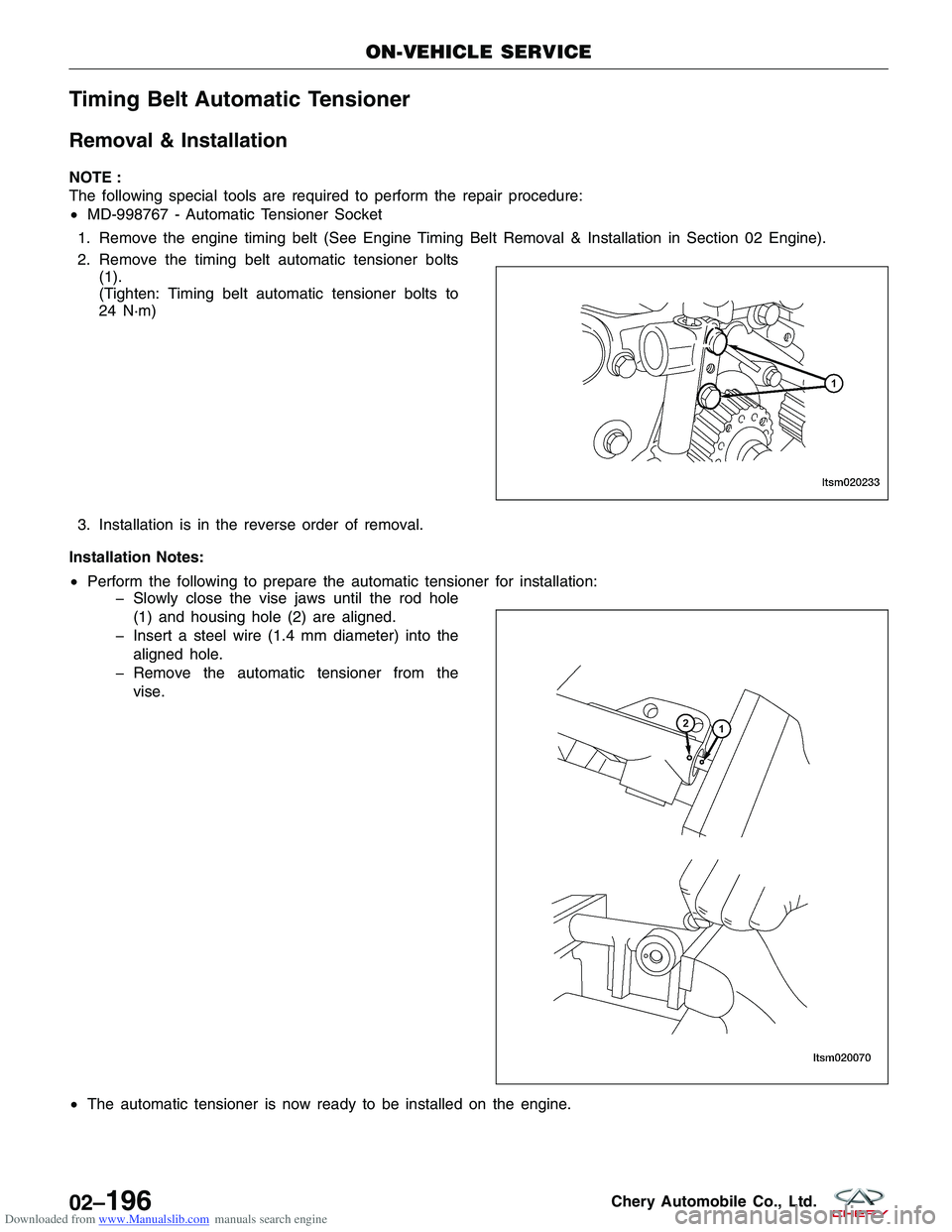

Downloaded from www.Manualslib.com manuals search engine Timing Belt Automatic Tensioner

Removal & Installation

NOTE :

The following special tools are required to perform the repair procedure:

•MD-998767 - Automatic Tensioner Socket

1. Remove the engine timing belt (See Engine Timing Belt Removal & Installation in Section 02 Engine).

2. Remove the timing belt automatic tensioner bolts (1).

(Tighten: Timing belt automatic tensioner bolts to

24 N·m)

3. Installation is in the reverse order of removal.

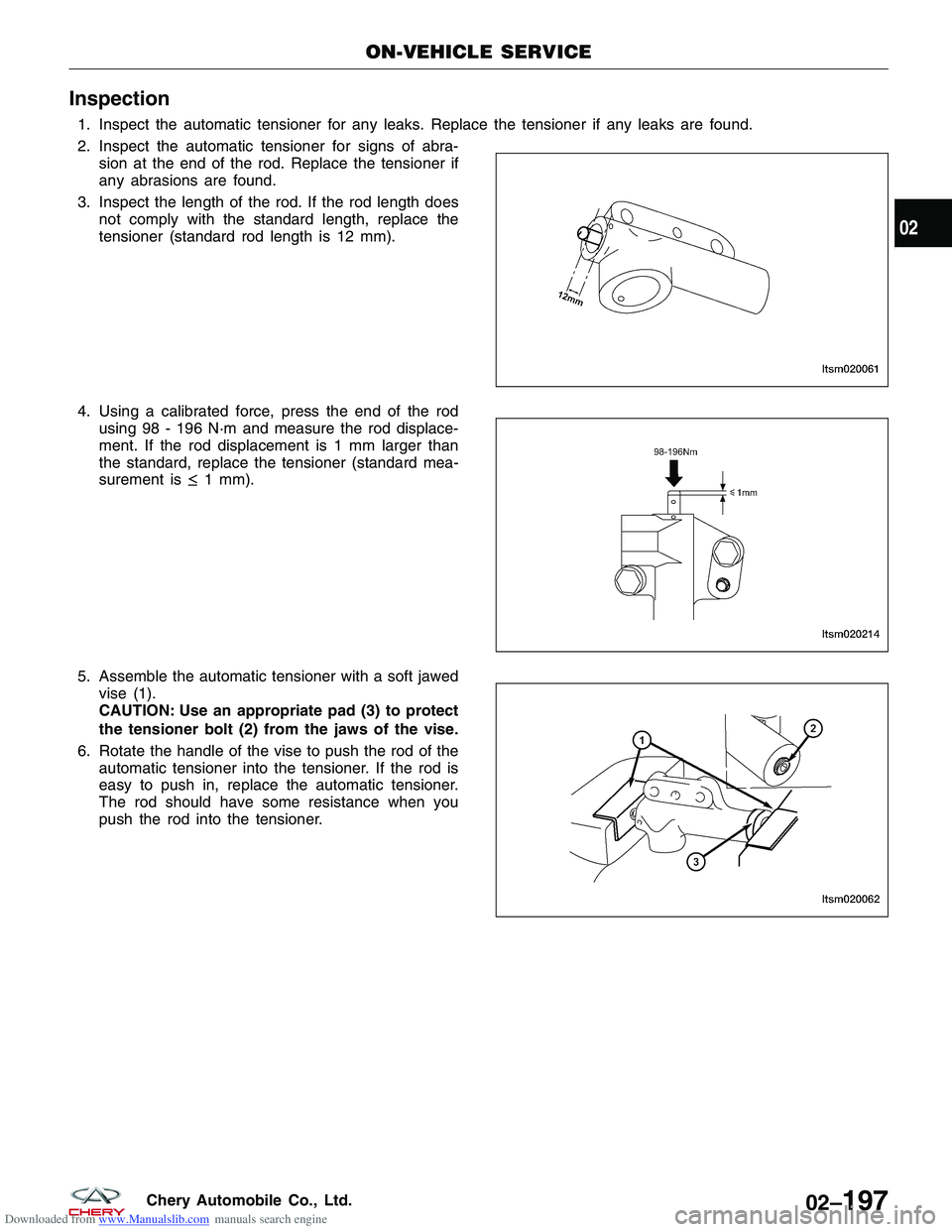

Installation Notes:

• Perform the following to prepare the automatic tensioner for installation:

� Slowly close the vise jaws until the rod hole

(1) and housing hole (2) are aligned.

� Insert a steel wire (1.4 mm diameter) into the aligned hole.

� Remove the automatic tensioner from the vise.

• The automatic tensioner is now ready to be installed on the engine.

ON-VEHICLE SERVICE

LTSM020233

LTSM020070

02–196Chery Automobile Co., Ltd.

Page 226 of 1903

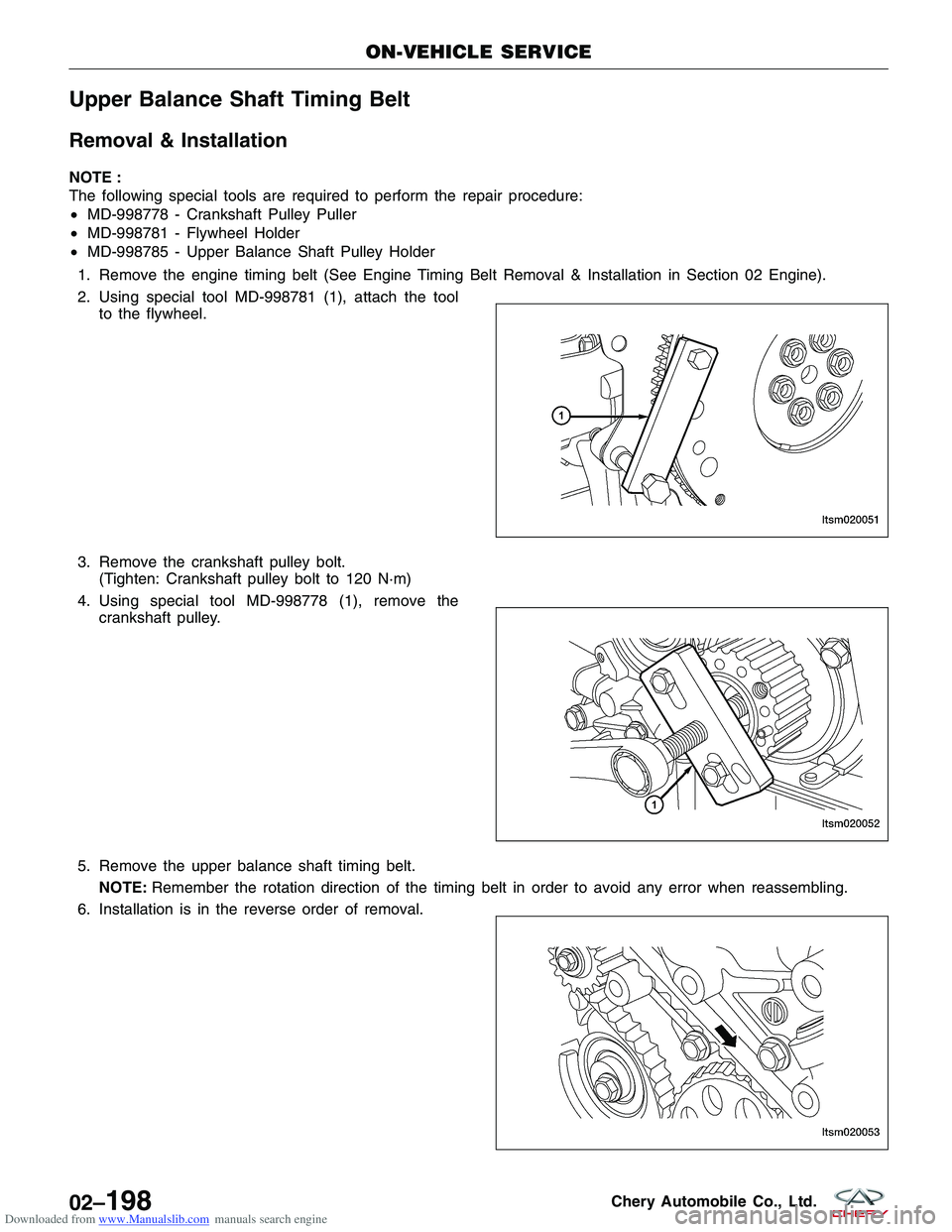

Downloaded from www.Manualslib.com manuals search engine Inspection

1. Inspect the automatic tensioner for any leaks. Replace the tensioner if any leaks are found.

2. Inspect the automatic tensioner for signs of abra-sion at the end of the rod. Replace the tensioner if

any abrasions are found.

3. Inspect the length of the rod. If the rod length does not comply with the standard length, replace the

tensioner (standard rod length is 12 mm).

4. Using a calibrated force, press the end of the rod using 98 - 196 N·m and measure the rod displace-

ment. If the rod displacement is 1 mm larger than

the standard, replace the tensioner (standard mea-

surement is ≤1 mm).

5. Assemble the automatic tensioner with a soft jawed vise (1).

CAUTION: Use an appropriate pad (3) to protect

the tensioner bolt (2) from the jaws of the vise.

6. Rotate the handle of the vise to push the rod of the automatic tensioner into the tensioner. If the rod is

easy to push in, replace the automatic tensioner.

The rod should have some resistance when you

push the rod into the tensioner.

ON-VEHICLE SERVICE

LTSM020061

LTSM020214

LTSM020062

02

02–197Chery Automobile Co., Ltd.

Page 227 of 1903

Downloaded from www.Manualslib.com manuals search engine Upper Balance Shaft Timing Belt

Removal & Installation

NOTE :

The following special tools are required to perform the repair procedure:

•MD-998778 - Crankshaft Pulley Puller

• MD-998781 - Flywheel Holder

• MD-998785 - Upper Balance Shaft Pulley Holder

1. Remove the engine timing belt (See Engine Timing Belt Removal & Installation in Section 02 Engine).

2. Using special tool MD-998781 (1), attach the tool to the flywheel.

3. Remove the crankshaft pulley bolt. (Tighten: Crankshaft pulley bolt to 120 N·m)

4. Using special tool MD-998778 (1), remove the crankshaft pulley.

5. Remove the upper balance shaft timing belt. NOTE: Remember the rotation direction of the timing belt in order to avoid any error when reassembling.

6. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM020051

LTSM020052

LTSM020053

02–198Chery Automobile Co., Ltd.

Page 228 of 1903

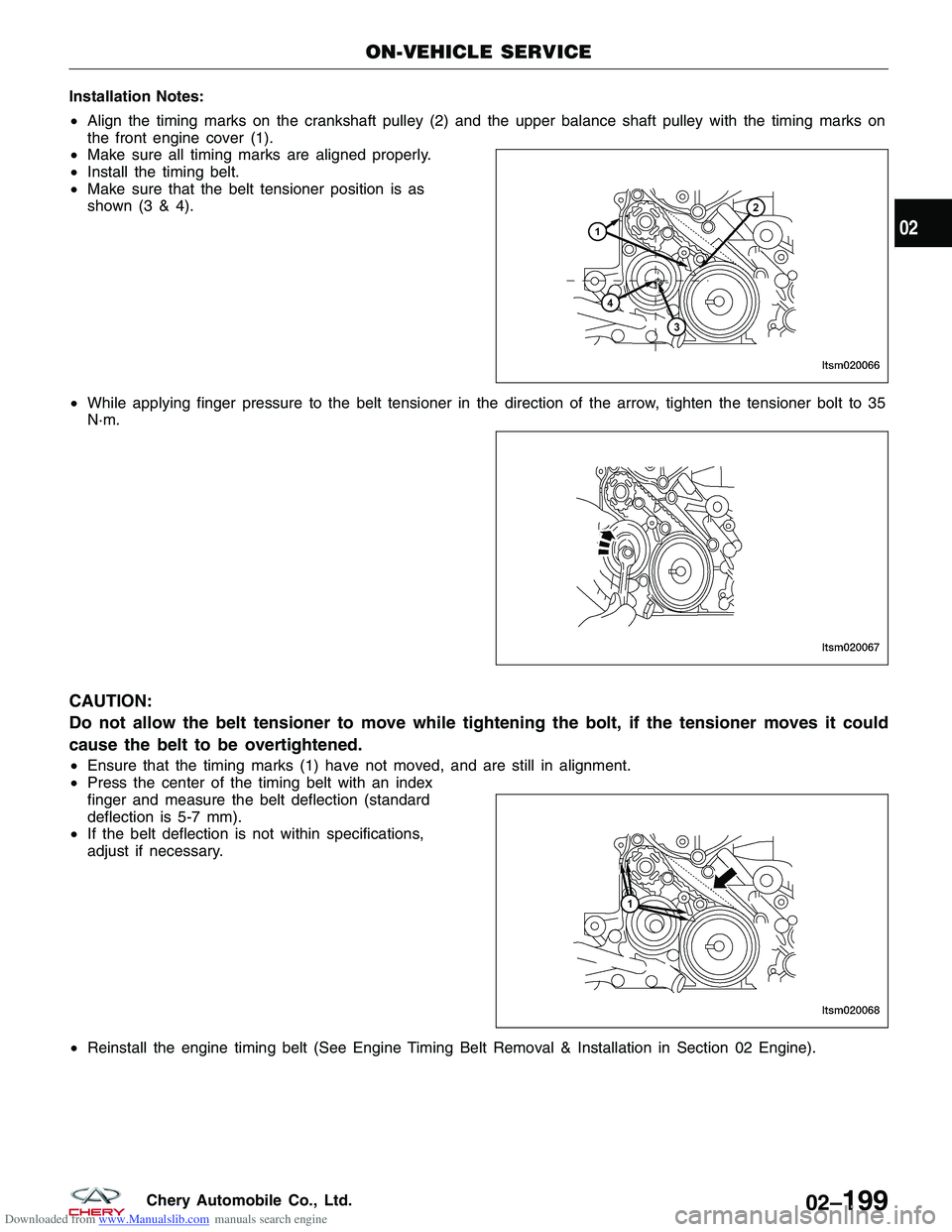

Downloaded from www.Manualslib.com manuals search engine Installation Notes:

•Align the timing marks on the crankshaft pulley (2) and the upper balance shaft pulley with the timing marks on

the front engine cover (1).

• Make sure all timing marks are aligned properly.

• Install the timing belt.

• Make sure that the belt tensioner position is as

shown (3 & 4).

• While applying finger pressure to the belt tensioner in the direction of the arrow, tighten the tensioner bolt to 35

N·m.

CAUTION:

Do not allow the belt tensioner to move while tightening the bolt, if the tensioner moves it could

cause the belt to be overtightened.

•Ensure that the timing marks (1) have not moved, and are still in alignment.

• Press the center of the timing belt with an index

finger and measure the belt deflection (standard

deflection is 5-7 mm).

• If the belt deflection is not within specifications,

adjust if necessary.

• Reinstall the engine timing belt (See Engine Timing Belt Removal & Installation in Section 02 Engine).

ON-VEHICLE SERVICE

LTSM020066

LTSM020067

LTSM020068

02

02–199Chery Automobile Co., Ltd.

Page 229 of 1903

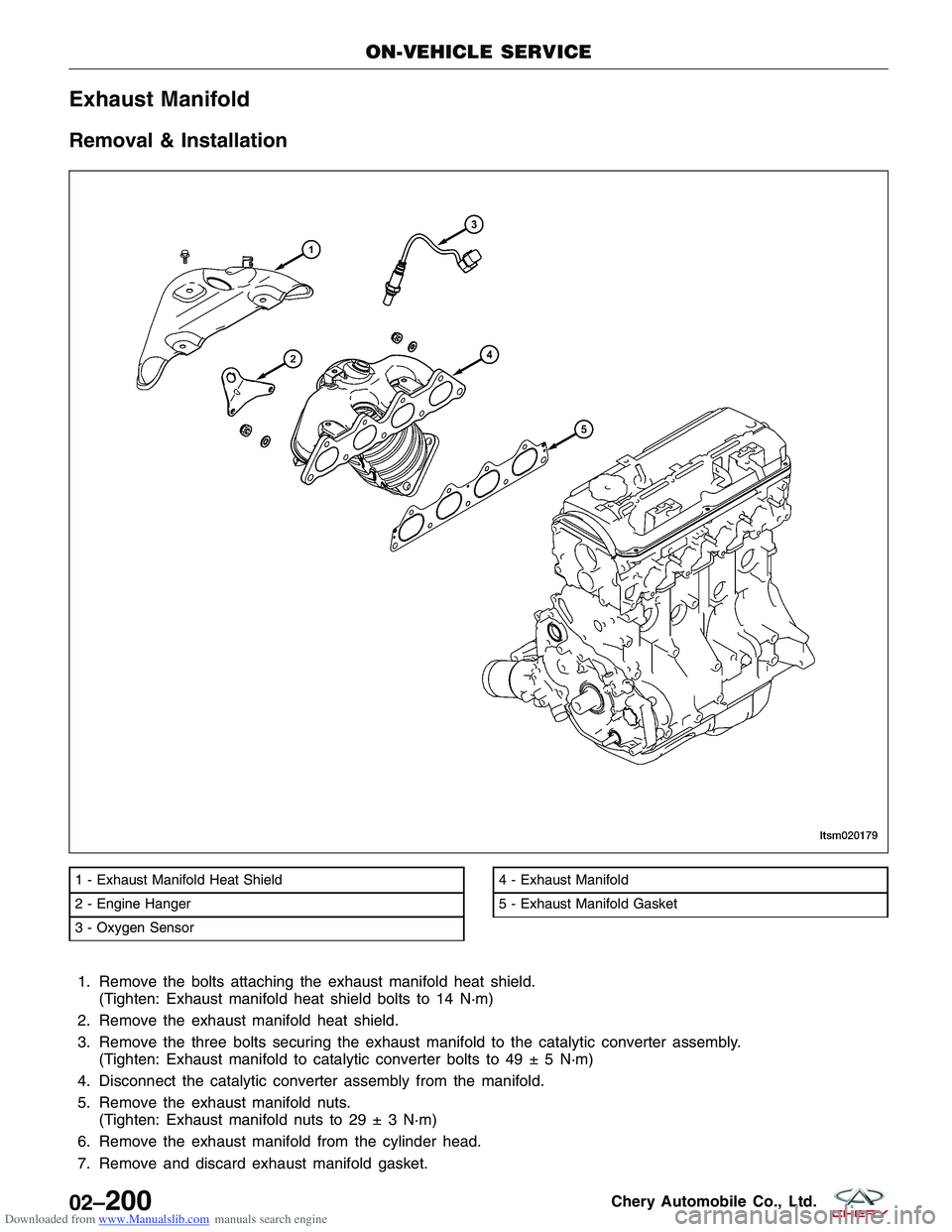

Downloaded from www.Manualslib.com manuals search engine Exhaust Manifold

Removal & Installation

1. Remove the bolts attaching the exhaust manifold heat shield.(Tighten: Exhaust manifold heat shield bolts to 14 N·m)

2. Remove the exhaust manifold heat shield.

3. Remove the three bolts securing the exhaust manifold to the catalytic converter assembly. (Tighten: Exhaust manifold to catalytic converter bolts to 49 ± 5 N·m)

4. Disconnect the catalytic converter assembly from the manifold.

5. Remove the exhaust manifold nuts. (Tighten: Exhaust manifold nuts to 29 ± 3 N·m)

6. Remove the exhaust manifold from the cylinder head.

7. Remove and discard exhaust manifold gasket.

1 - Exhaust Manifold Heat Shield

2 - Engine Hanger

3 - Oxygen Sensor4 - Exhaust Manifold

5 - Exhaust Manifold Gasket

ON-VEHICLE SERVICE

LTSM020179

02–200Chery Automobile Co., Ltd.

Page 230 of 1903

Downloaded from www.Manualslib.com manuals search engine 8. Installation is in the reverse order of removal.

Installation Notes:

• Clean all surfaces of manifold and cylinder head.

• Install a new exhaust manifold gasket during installation.

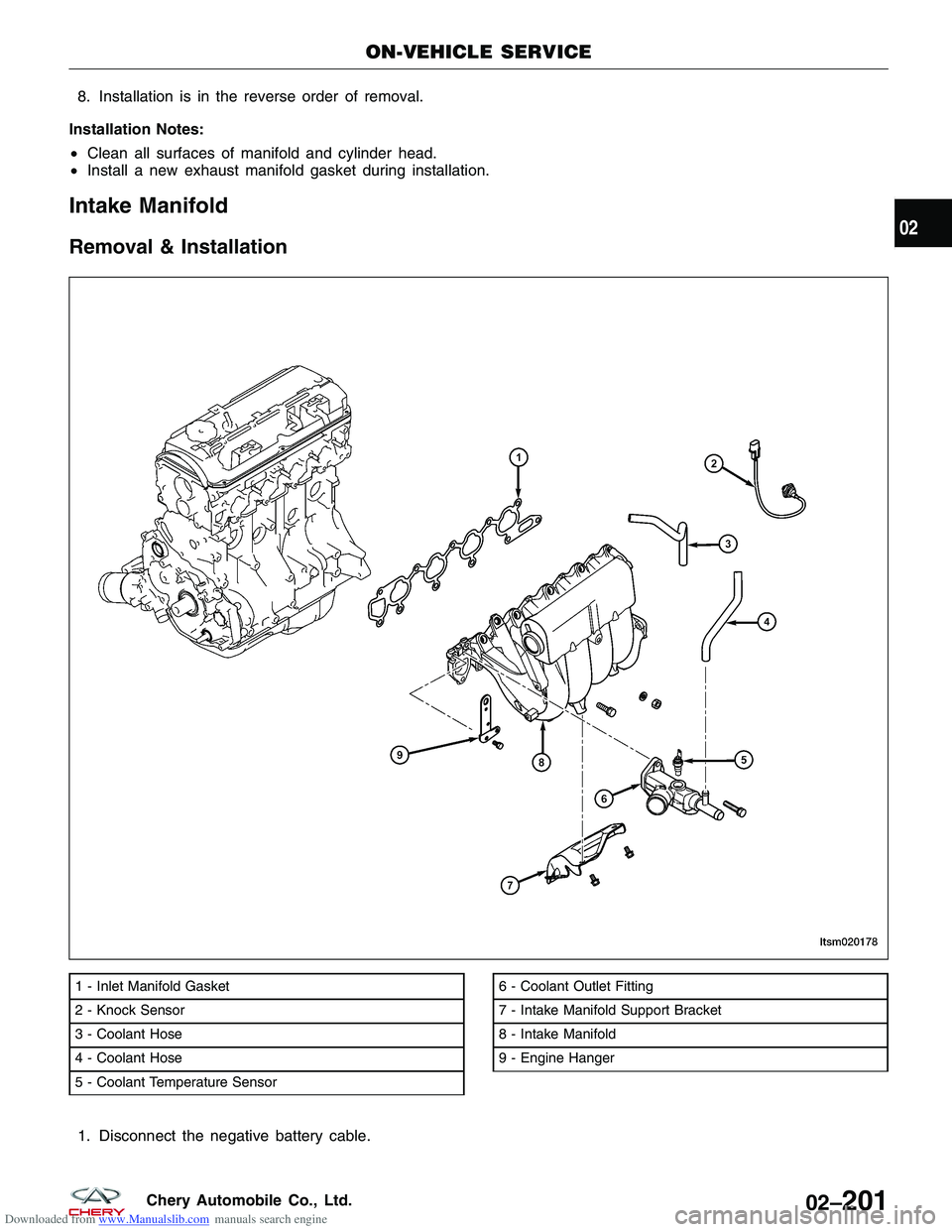

Intake Manifold

Removal & Installation

1. Disconnect the negative battery cable.

1 - Inlet Manifold Gasket

2 - Knock Sensor

3 - Coolant Hose

4 - Coolant Hose

5 - Coolant Temperature Sensor6 - Coolant Outlet Fitting

7 - Intake Manifold Support Bracket

8 - Intake Manifold

9 - Engine Hanger

ON-VEHICLE SERVICE

LTSM020178

02

02–201Chery Automobile Co., Ltd.