service CHERY TIGGO 2009 Service Repair Manual

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 1334 of 1903

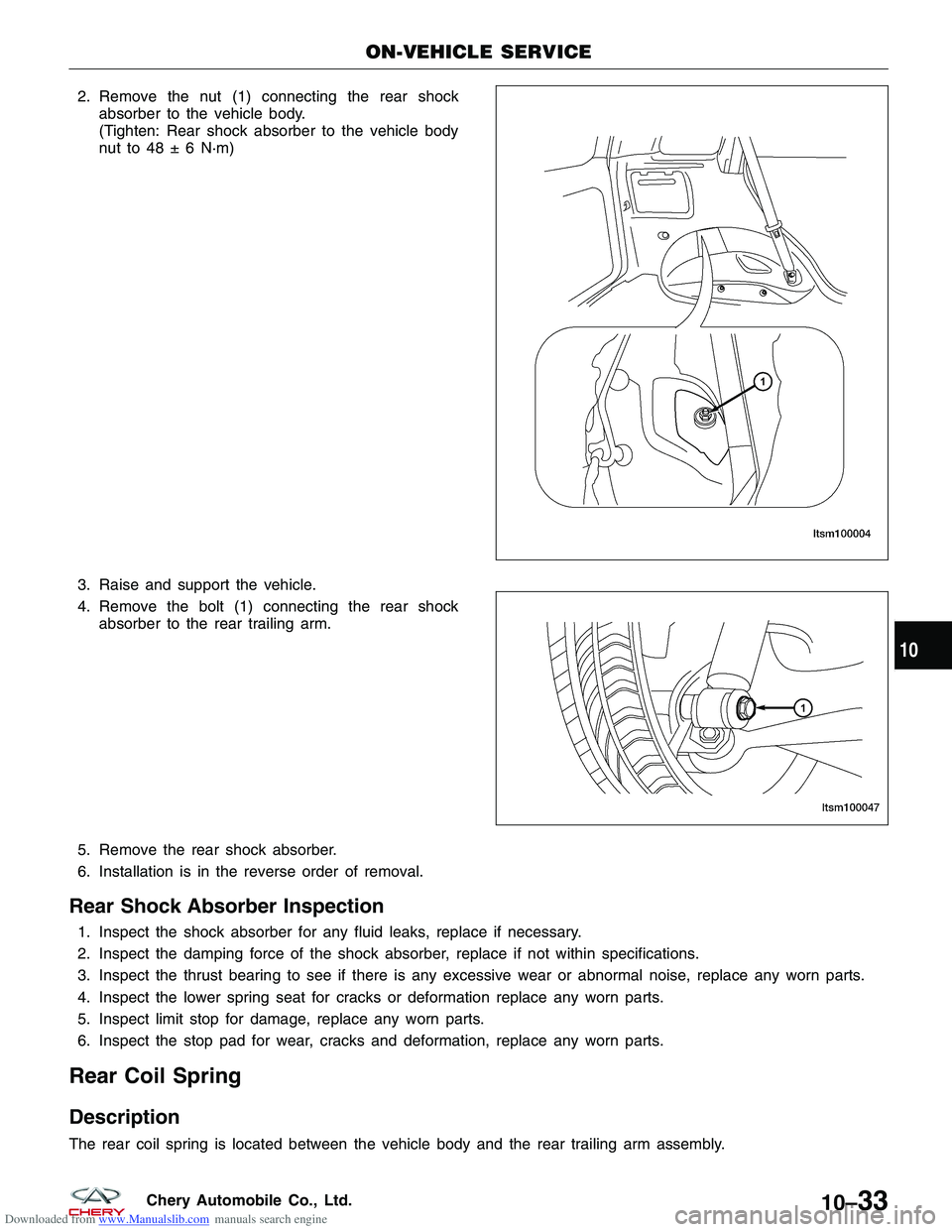

Downloaded from www.Manualslib.com manuals search engine 2. Remove the nut (1) connecting the rear shockabsorber to the vehicle body.

(Tighten: Rear shock absorber to the vehicle body

nut to 48 ± 6 N·m)

3. Raise and support the vehicle.

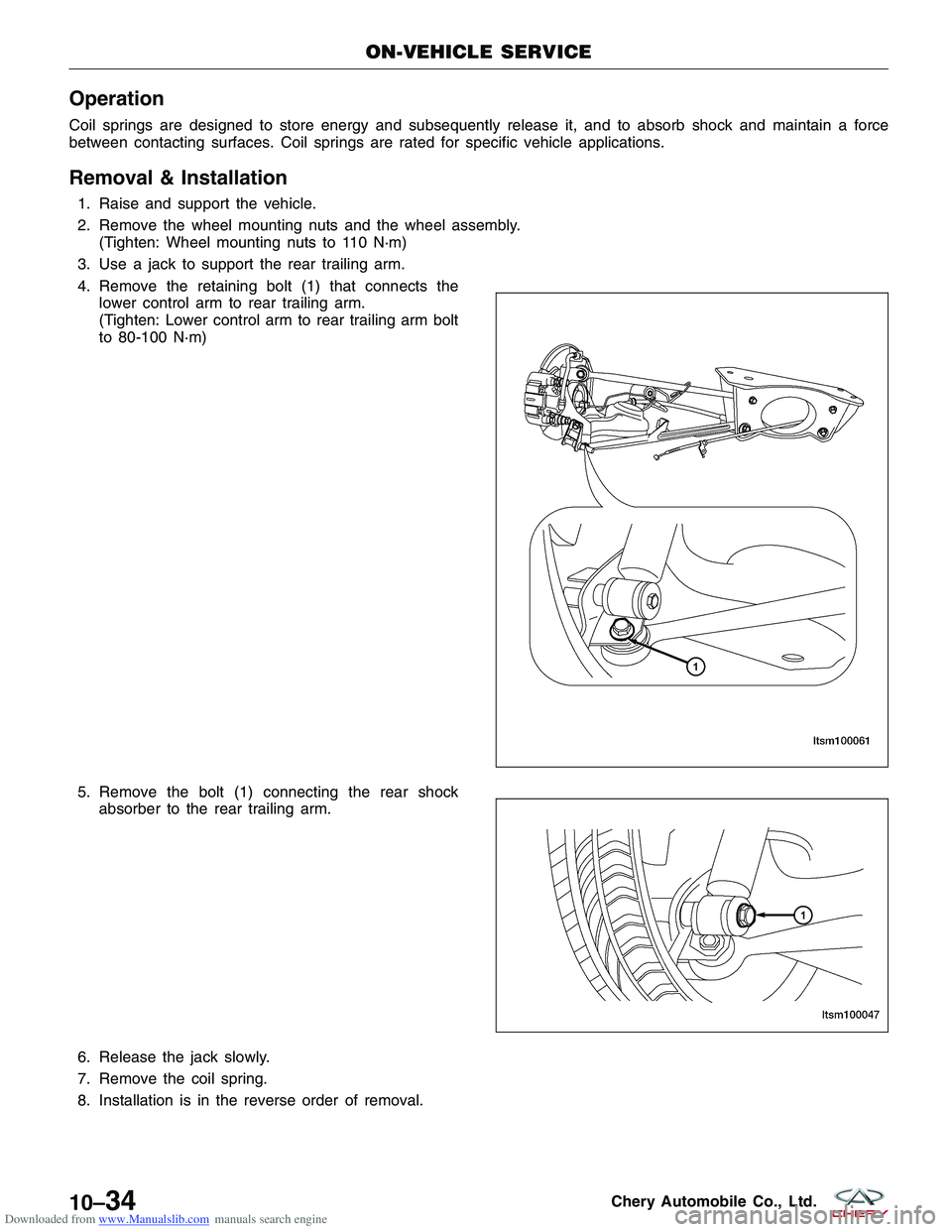

4. Remove the bolt (1) connecting the rear shock absorber to the rear trailing arm.

5. Remove the rear shock absorber.

6. Installation is in the reverse order of removal.

Rear Shock Absorber Inspection

1. Inspect the shock absorber for any fluid leaks, replace if necessary.

2. Inspect the damping force of the shock absorber, replace if not within specifications.

3. Inspect the thrust bearing to see if there is any excessive wear or abnormal noise, replace any worn parts.

4. Inspect the lower spring seat for cracks or deformation replace any worn parts.

5. Inspect limit stop for damage, replace any worn parts.

6. Inspect the stop pad for wear, cracks and deformation, replace any worn parts.

Rear Coil Spring

Description

The rear coil spring is located between the vehicle body and the rear trailing arm assembly.

ON-VEHICLE SERVICE

LTSM100004

LTSM100047

10

10–33Chery Automobile Co., Ltd.

Page 1335 of 1903

Downloaded from www.Manualslib.com manuals search engine Operation

Coil springs are designed to store energy and subsequently release it, and to absorb shock and maintain a force

between contacting surfaces. Coil springs are rated for specific vehicle applications.

Removal & Installation

1. Raise and support the vehicle.

2. Remove the wheel mounting nuts and the wheel assembly.(Tighten: Wheel mounting nuts to 110 N·m)

3. Use a jack to support the rear trailing arm.

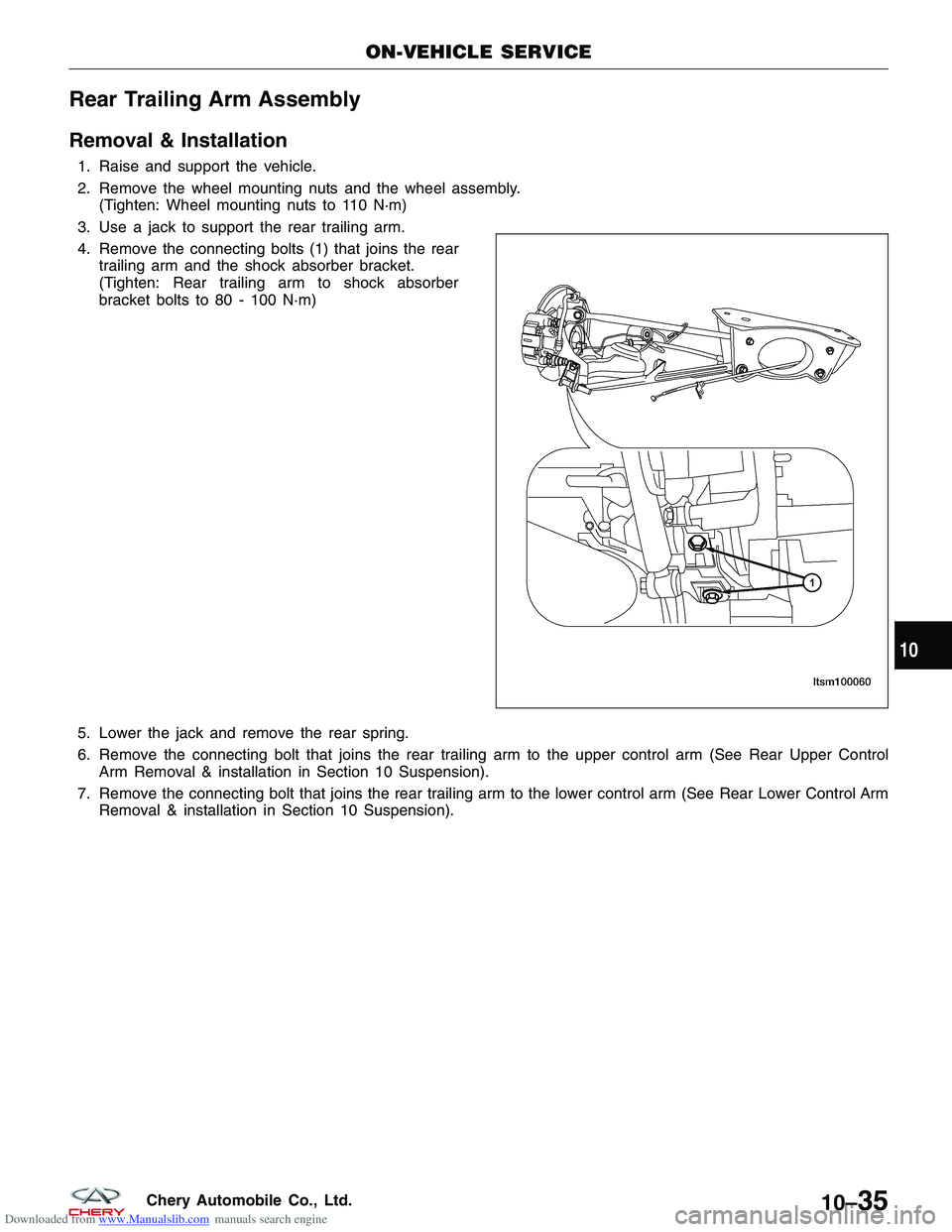

4. Remove the retaining bolt (1) that connects the lower control arm to rear trailing arm.

(Tighten: Lower control arm to rear trailing arm bolt

to 80-100 N·m)

5. Remove the bolt (1) connecting the rear shock absorber to the rear trailing arm.

6. Release the jack slowly.

7. Remove the coil spring.

8. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM100061

LTSM100047

10–34Chery Automobile Co., Ltd.

Page 1336 of 1903

Downloaded from www.Manualslib.com manuals search engine Rear Trailing Arm Assembly

Removal & Installation

1. Raise and support the vehicle.

2. Remove the wheel mounting nuts and the wheel assembly.(Tighten: Wheel mounting nuts to 110 N·m)

3. Use a jack to support the rear trailing arm.

4. Remove the connecting bolts (1) that joins the rear trailing arm and the shock absorber bracket.

(Tighten: Rear trailing arm to shock absorber

bracket bolts to 80 - 100 N·m)

5. Lower the jack and remove the rear spring.

6. Remove the connecting bolt that joins the rear trailing arm to the upper control arm (See Rear Upper Control Arm Removal & installation in Section 10 Suspension).

7. Remove the connecting bolt that joins the rear trailing arm to the lower control arm (See Rear Lower Control Arm Removal & installation in Section 10 Suspension).

ON-VEHICLE SERVICE

LTSM100060

10

10–35Chery Automobile Co., Ltd.

Page 1337 of 1903

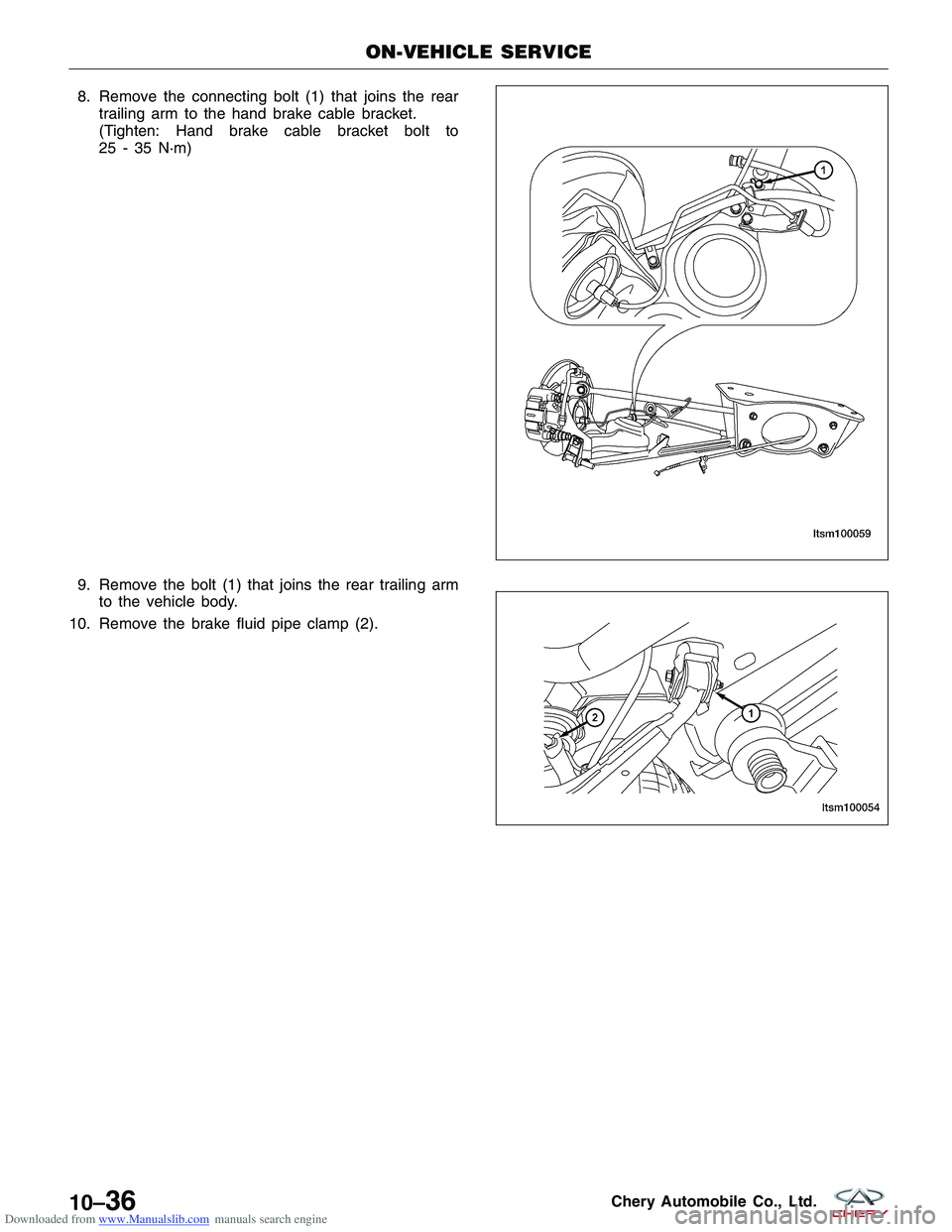

Downloaded from www.Manualslib.com manuals search engine 8. Remove the connecting bolt (1) that joins the reartrailing arm to the hand brake cable bracket.

(Tighten: Hand brake cable bracket bolt to

25 - 35 N·m)

9. Remove the bolt (1) that joins the rear trailing arm to the vehicle body.

10. Remove the brake fluid pipe clamp (2).

ON-VEHICLE SERVICE

LTSM100059

LTSM100054

10–36Chery Automobile Co., Ltd.

Page 1338 of 1903

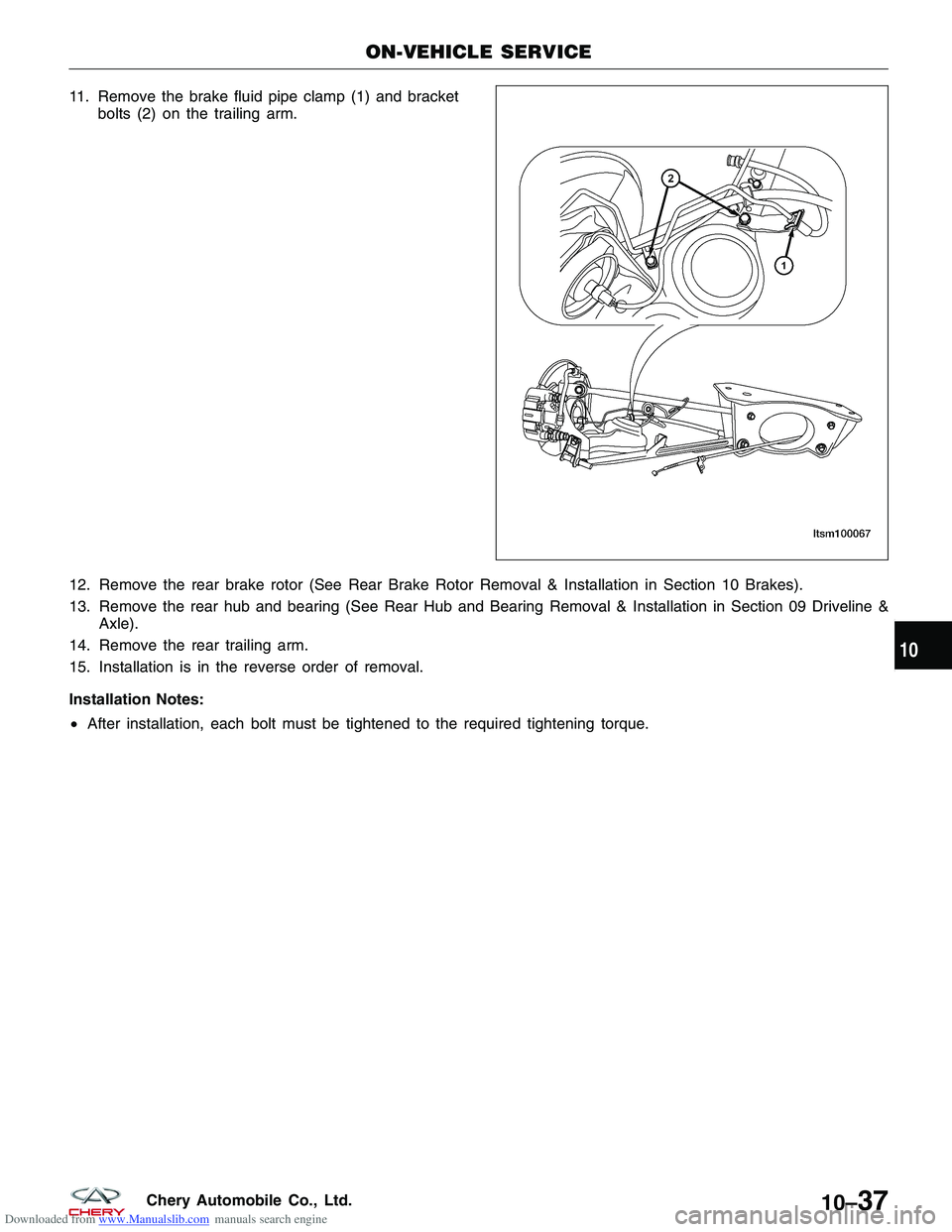

Downloaded from www.Manualslib.com manuals search engine 11. Remove the brake fluid pipe clamp (1) and bracketbolts (2) on the trailing arm.

12. Remove the rear brake rotor (See Rear Brake Rotor Removal & Installation in Section 10 Brakes).

13. Remove the rear hub and bearing (See Rear Hub and Bearing Removal & Installation in Section 09 Driveline & Axle).

14. Remove the rear trailing arm.

15. Installation is in the reverse order of removal.

Installation Notes:

• After installation, each bolt must be tightened to the required tightening torque.

ON-VEHICLE SERVICE

LTSM100067

10

10–37Chery Automobile Co., Ltd.

Page 1339 of 1903

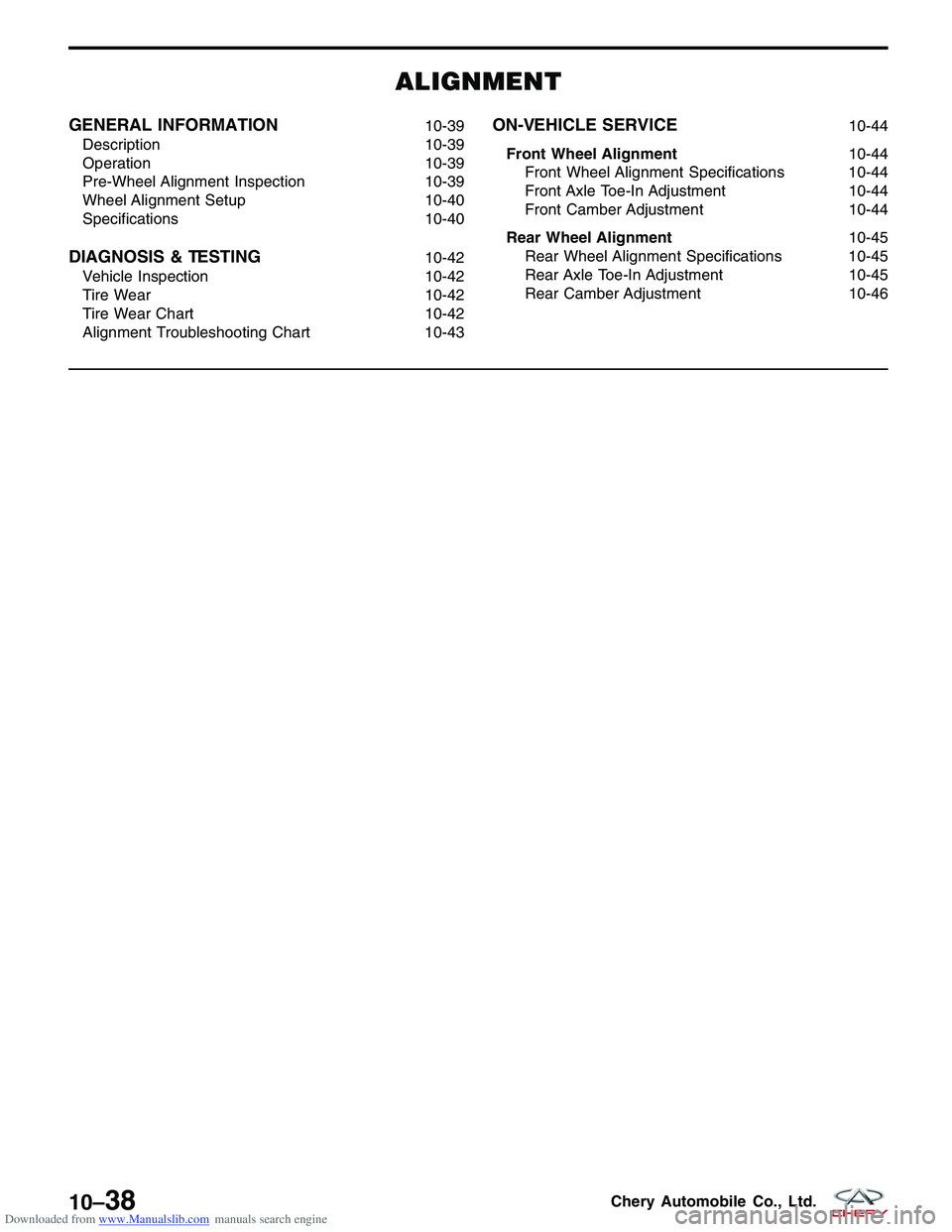

Downloaded from www.Manualslib.com manuals search engine ALIGNMENT

GENERAL INFORMATION10-39

Description 10-39

Operation 10-39

Pre-Wheel Alignment Inspection 10-39

Wheel Alignment Setup 10-40

Specifications 10-40

DIAGNOSIS & TESTING10-42

Vehicle Inspection 10-42

Tire Wear 10-42

Tire Wear Chart 10-42

Alignment Troubleshooting Chart 10-43

ON-VEHICLE SERVICE10-44

Front Wheel Alignment 10-44

Front Wheel Alignment Specifications 10-44

Front Axle Toe-In Adjustment 10-44

Front Camber Adjustment 10-44

Rear Wheel Alignment 10-45

Rear Wheel Alignment Specifications 10-45

Rear Axle Toe-In Adjustment 10-45

Rear Camber Adjustment 10-46

10–38Chery Automobile Co., Ltd.

Page 1345 of 1903

Downloaded from www.Manualslib.com manuals search engine ON-VEHICLE SERVICE

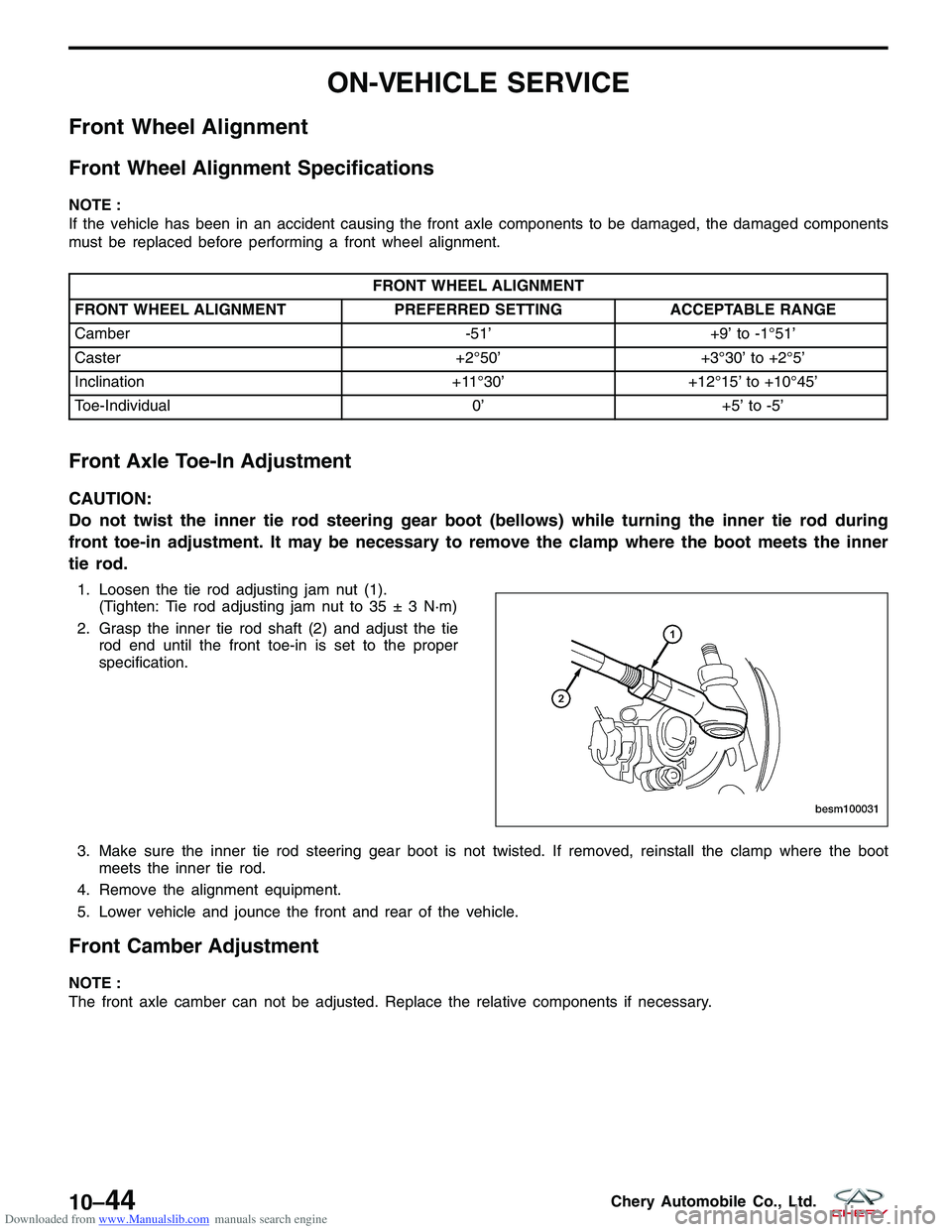

Front Wheel Alignment

Front Wheel Alignment Specifications

NOTE :

If the vehicle has been in an accident causing the front axle components to be damaged, the damaged components

must be replaced before performing a front wheel alignment.

FRONT WHEEL ALIGNMENT

FRONT WHEEL ALIGNMENT PREFERRED SETTINGACCEPTABLE RANGE

Camber -51’+9’ to -1°51’

Caster +2°50’+3°30’ to +2°5’

Inclination +11°30’+12°15’ to +10°45’

Toe-Individual 0’+5’ to -5’

Front Axle Toe-In Adjustment

CAUTION:

Do not twist the inner tie rod steering gear boot (bellows) while turning the inner tie rod during

front toe-in adjustment. It may be necessary to remove the clamp where the boot meets the inner

tie rod.

1. Loosen the tie rod adjusting jam nut (1).

(Tighten: Tie rod adjusting jam nut to 35 ± 3 N·m)

2. Grasp the inner tie rod shaft (2) and adjust the tie rod end until the front toe-in is set to the proper

specification.

3. Make sure the inner tie rod steering gear boot is not twisted. If removed, reinstall the clamp where the boot meets the inner tie rod.

4. Remove the alignment equipment.

5. Lower vehicle and jounce the front and rear of the vehicle.

Front Camber Adjustment

NOTE :

The front axle camber can not be adjusted. Replace the relative components if necessary.

BESM100031

10–44Chery Automobile Co., Ltd.

Page 1346 of 1903

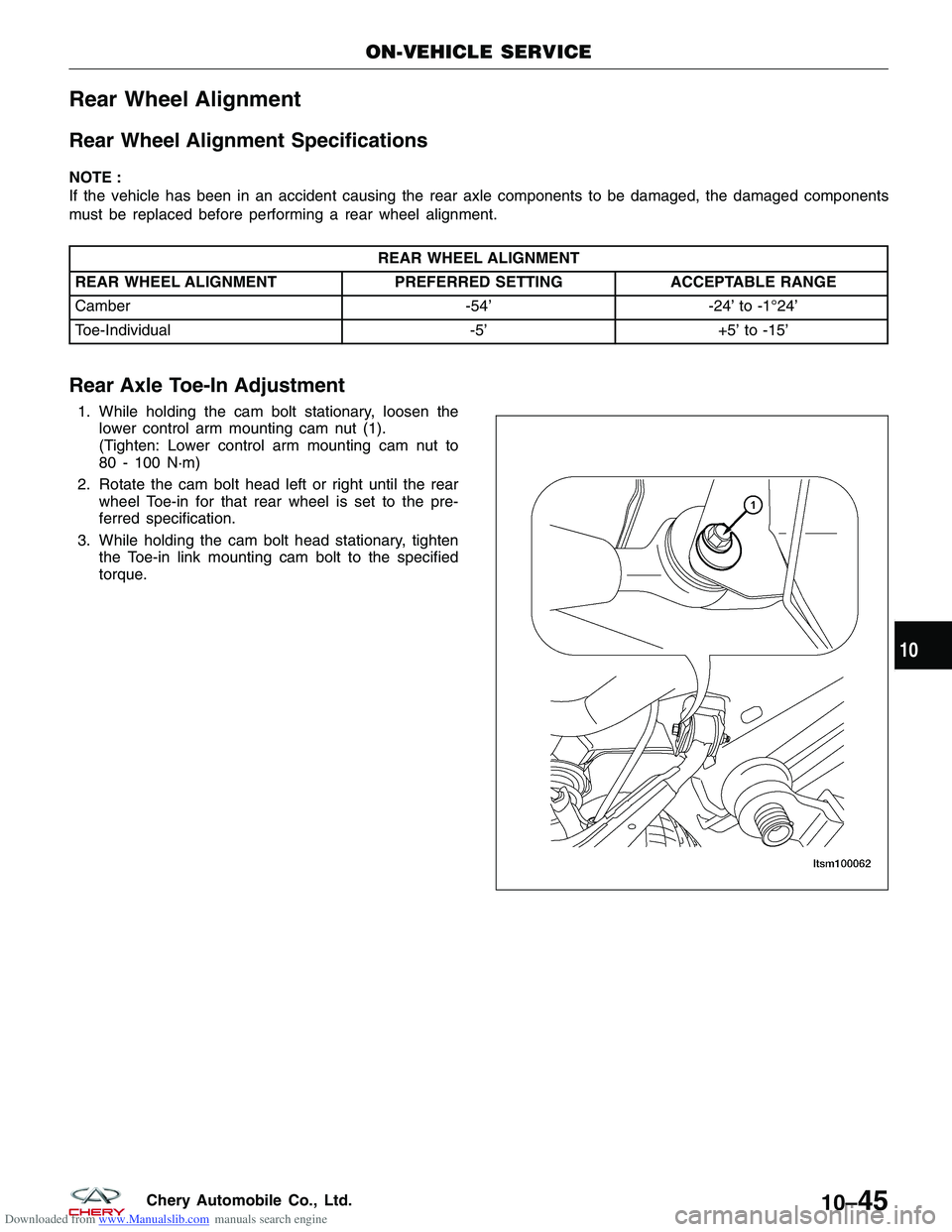

Downloaded from www.Manualslib.com manuals search engine Rear Wheel Alignment

Rear Wheel Alignment Specifications

NOTE :

If the vehicle has been in an accident causing the rear axle components to be damaged, the damaged components

must be replaced before performing a rear wheel alignment.

REAR WHEEL ALIGNMENT

REAR WHEEL ALIGNMENT PREFERRED SETTINGACCEPTABLE RANGE

Camber -54’-24’ to -1°24’

Toe-Individual -5’+5’ to -15’

Rear Axle Toe-In Adjustment

1. While holding the cam bolt stationary, loosen the

lower control arm mounting cam nut (1).

(Tighten: Lower control arm mounting cam nut to

80 - 100 N·m)

2. Rotate the cam bolt head left or right until the rear wheel Toe-in for that rear wheel is set to the pre-

ferred specification.

3. While holding the cam bolt head stationary, tighten the Toe-in link mounting cam bolt to the specified

torque.

ON-VEHICLE SERVICE

BESM100031

10

10–45Chery Automobile Co., Ltd.

Page 1347 of 1903

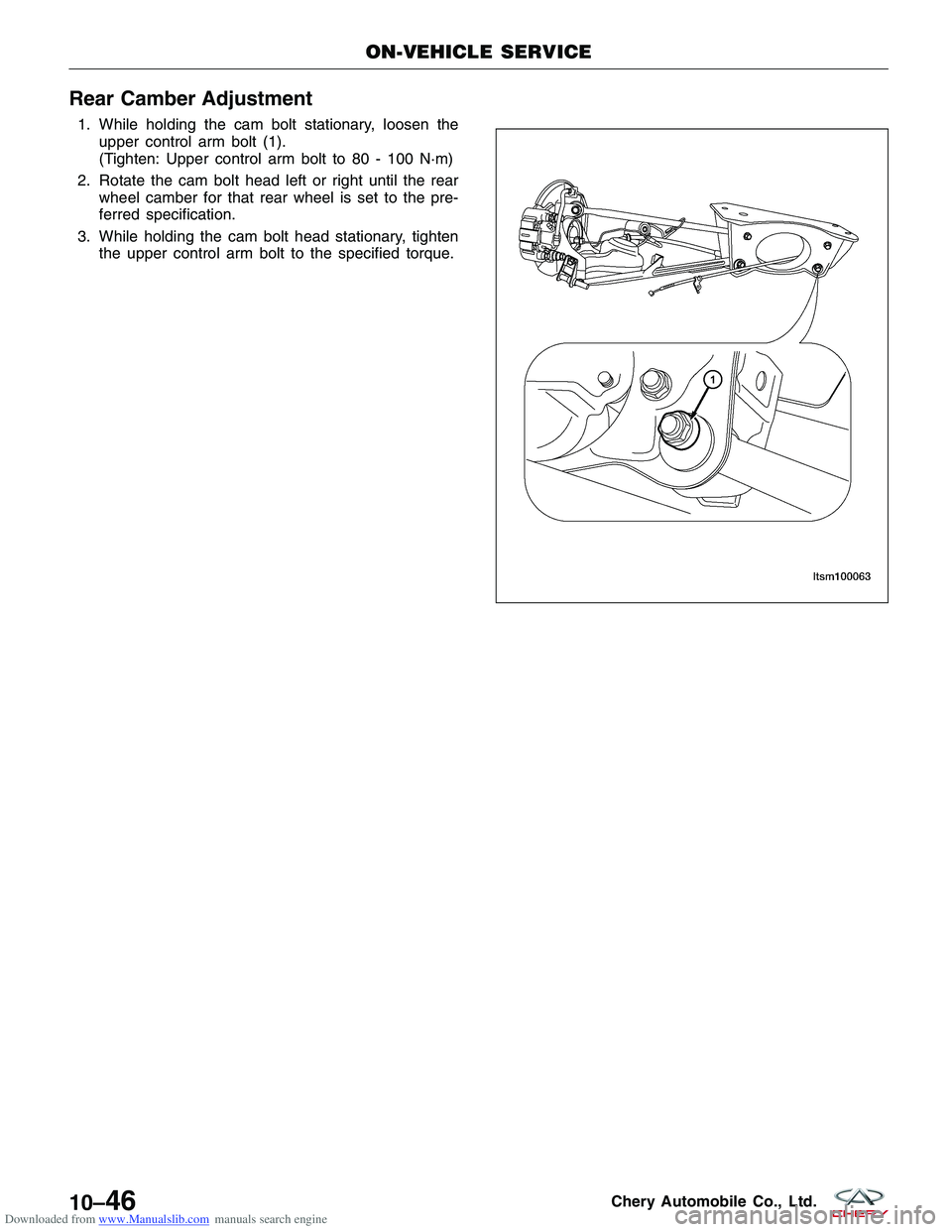

Downloaded from www.Manualslib.com manuals search engine Rear Camber Adjustment

1. While holding the cam bolt stationary, loosen theupper control arm bolt (1).

(Tighten: Upper control arm bolt to 80 - 100 N·m)

2. Rotate the cam bolt head left or right until the rear wheel camber for that rear wheel is set to the pre-

ferred specification.

3. While holding the cam bolt head stationary, tighten the upper control arm bolt to the specified torque.

ON-VEHICLE SERVICE

BESM100031

10–46Chery Automobile Co., Ltd.

Page 1348 of 1903

Downloaded from www.Manualslib.com manuals search engine WHEELS AND TIRES

GENERAL INFORMATION10-48

Description 10-48

Operation 10-48

Specifications 10-48

DIAGNOSIS & TESTING10-50

Vehicle Inspection 10-50

Tire and Wheel Vibration 10-50

Tire Wear Patterns 10-50

Wheel Out-Of-Round Inspection 10-50

ON-VEHICLE SERVICE10-51

Tire Repair 10-51

Description 10-51 Replacement Procedure 10-51

Repair Procedure 10-51

Wheel Assembly 10-52

Description 10-52

Removal & Installation 10-52

Wheel Balance 10-52

Description 10-52

Wheel Balance Procedure 10-53

Tire Rotation 10-53

Description 10-53

Non-Directional Tires 10-54

Directional Tires 10-54

10

10–47Chery Automobile Co., Ltd.