CHERY TIGGO 2009 Service Repair Manual

Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 711 of 1903

Downloaded from www.Manualslib.com manuals search engine ON-VEHICLE SERVICE

Engine Coolant Temperature (ECT) Sensor

Description

The Engine Coolant Temperature (ECT) sensor threads into the coolant outlet connector. The ECT is a negative

thermal coefficient sensor.

Operation

The ECT provides an input to the Engine Control Module (ECM). As temperature increases, resistance of the sensor

decreases. As coolant temperature varies, the ECT sensor resistance changes resulting in a different voltage value

at the ECT sensor signal circuit. The ECM uses the input to control air-fuel mixture, timing, A/C compressor and

radiator fan on/off times.

Removal & Installation

1. Disconnect the negative battery cable.

2. Drain the cooling system (See Cooling System Draining Procedure in Section 06 Cooling System).

WARNING!

Never remove the pressure relief cap under any conditions while the engine is operating or hot. Failure to follow

these instructions could result in personal injury or damage to the cooling system or engine. To avoid having

scalding hot coolant or steam blow out of the cooling system, use extreme care when removing the pressure

relief cap. Wait until the engine has cooled, then wrap a thick cloth around the pressure relief cap and turn it

slowly one turn (counterclockwise). Step back while the pressure is released from the cooling system. When you

are certain all the pressure has been released, (with a cloth) turn and remove the pressure relief cap. Failure to

follow these instructions may result in series personal injury.

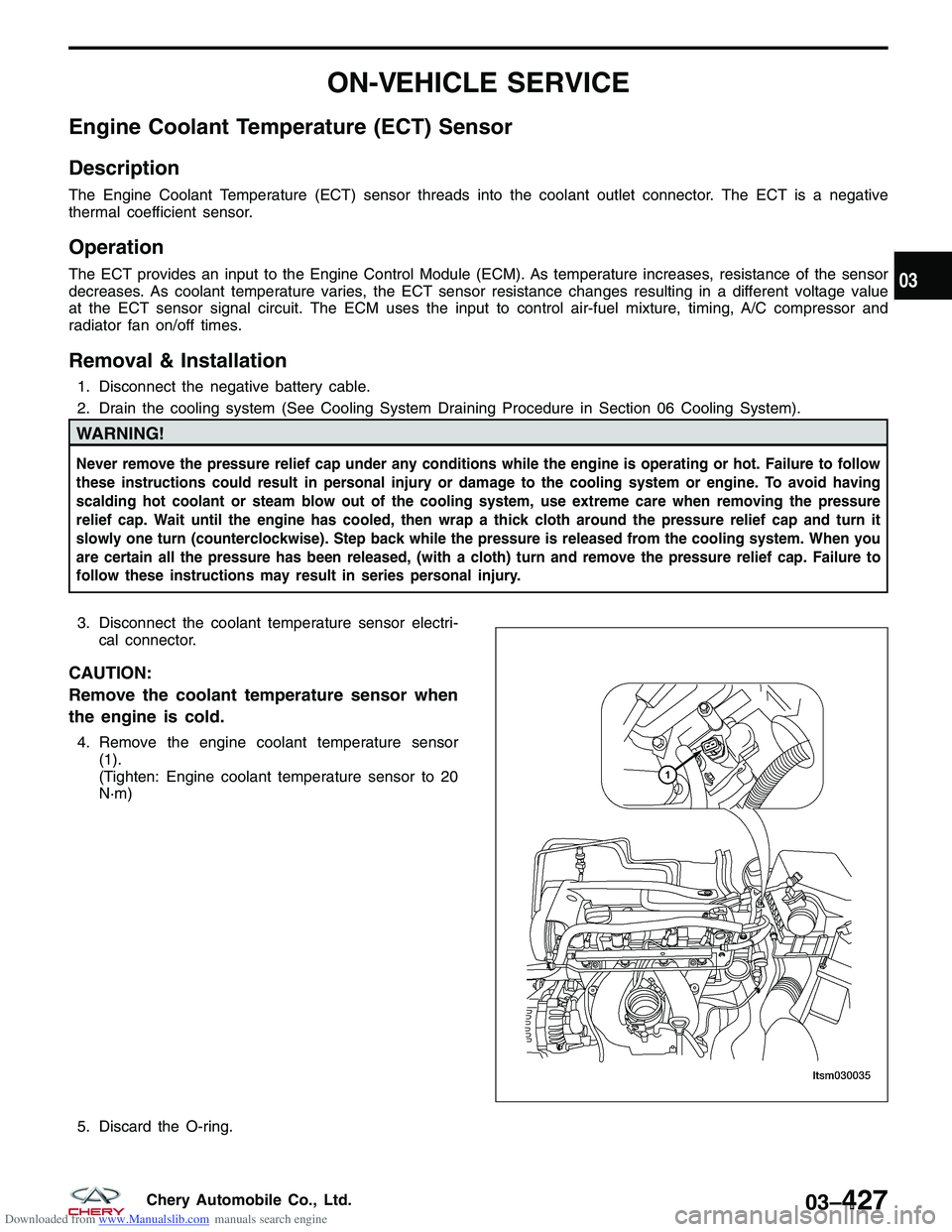

3. Disconnect the coolant temperature sensor electri-cal connector.

CAUTION:

Remove the coolant temperature sensor when

the engine is cold.

4. Remove the engine coolant temperature sensor(1).

(Tighten: Engine coolant temperature sensor to 20

N·m)

5. Discard the O-ring.

LTSM030035

03

03–427Chery Automobile Co., Ltd.

Page 712 of 1903

Downloaded from www.Manualslib.com manuals search engine 6. Installation is in the reverse order of removal.

NOTE :

After installing the engine coolant temperature sensor, check the coolant level.

Knock Sensor

Description

The knock sensor is attached to the cylinder block. The knock sensor is designed to detect engine vibration that is

caused by detonation.

Operation

When the knock sensor detects a knock in one of the cylinders, it sends an input signal to the Engine Control Module

(ECM). In response, the ECM retards ignition timing for all cylinders by a specified amount.

The knock sensor contains a piezoelectric material which constantly vibrates and sends an input voltage (signal) to

the ECM while the engine operates. As the intensity of the vibration increases, the knock sensor output voltage also

increases.

The ECM ignores knock sensor input during engine idle conditions. Once the engine speed exceeds a specified

value, knock retard is allowed.

Removal & Installation

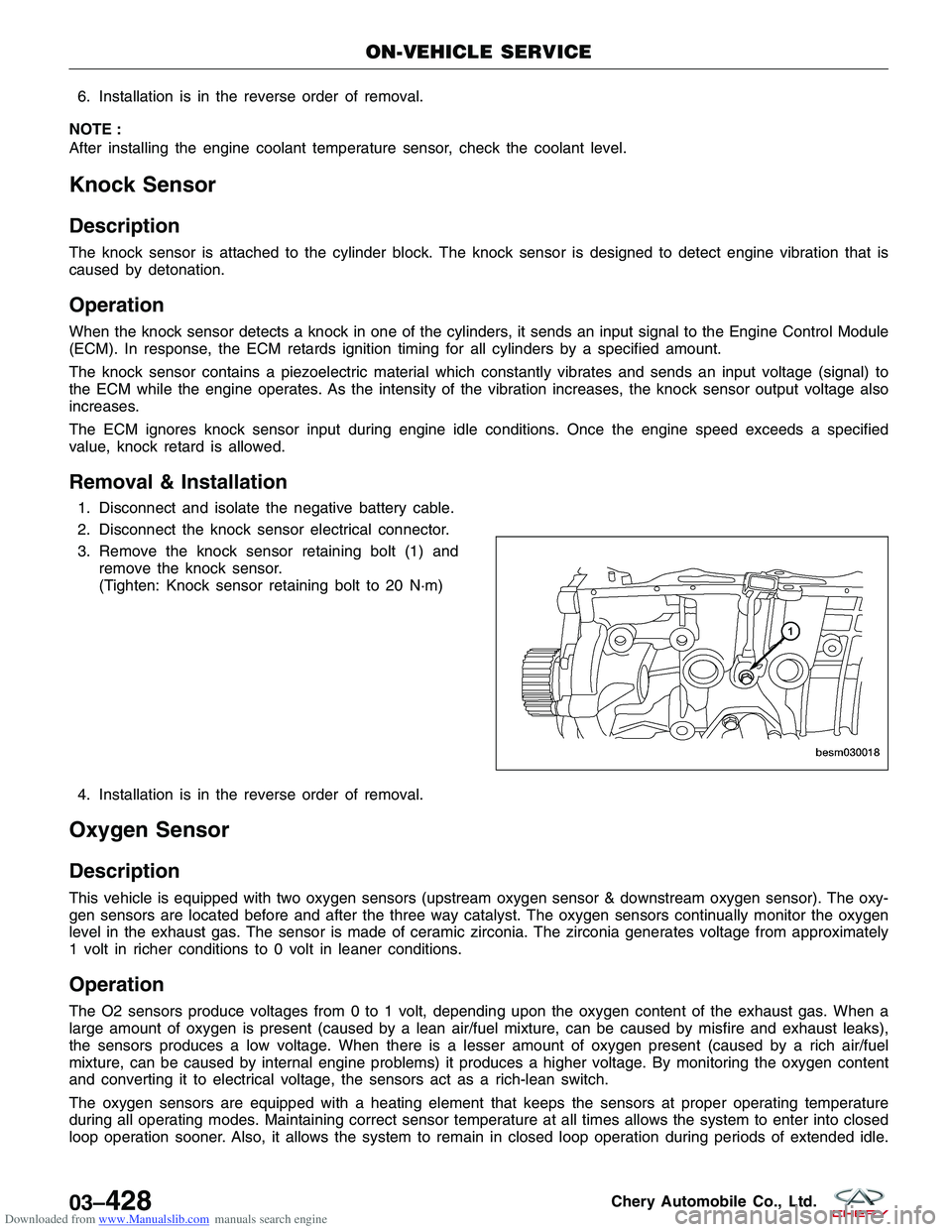

1. Disconnect and isolate the negative battery cable.

2. Disconnect the knock sensor electrical connector.

3. Remove the knock sensor retaining bolt (1) and

remove the knock sensor.

(Tighten: Knock sensor retaining bolt to 20 N·m)

4. Installation is in the reverse order of removal.

Oxygen Sensor

Description

This vehicle is equipped with two oxygen sensors (upstream oxygen sensor & downstream oxygen sensor). The oxy-

gen sensors are located before and after the three way catalyst. The oxygen sensors continually monitor the oxygen

level in the exhaust gas. The sensor is made of ceramic zirconia. The zirconia generates voltage from approximately

1 volt in richer conditions to 0 volt in leaner conditions.

Operation

The O2 sensors produce voltages from 0 to 1 volt, depending upon the oxygen content of the exhaust gas. When a

large amount of oxygen is present (caused by a lean air/fuel mixture, can be caused by misfire and exhaust leaks),

the sensors produces a low voltage. When there is a lesser amount of oxygen present (caused by a rich air/fuel

mixture, can be caused by internal engine problems) it produces a higher voltage. By monitoring the oxygen content

and converting it to electrical voltage, the sensors act as a rich-lean switch.

The oxygen sensors are equipped with a heating element that keeps the sensors at proper operating temperature

during all operating modes. Maintaining correct sensor temperature at all times allows the system to enter into closed

loop operation sooner. Also, it allows the system to remain in closed loop operation during periods of extended idle.

ON-VEHICLE SERVICE

BESM030018

03–428Chery Automobile Co., Ltd.

Page 713 of 1903

Downloaded from www.Manualslib.com manuals search engine Upstream Oxygen Sensor

The input from the upstream heated oxygen sensor tells the Engine Control Module (ECM) the oxygen content of the

exhaust gas. Based on this input, the ECM fine tunes the air-fuel ratio by adjusting injector pulse width.

Downstream Oxygen Sensor

The downstream heated oxygen sensor signal is used to detect catalytic convertor deterioration. As the convertor

deteriorates, the signal from the downstream sensor begins to match the upstream sensor signal except for a slight

time delay. By comparing the downstream heated oxygen sensor signal to the signal from the upstream sensor, the

ECM calculates catalytic convertor efficiency. This calculation is also used to establish the upstream O2 goal voltage

(switching point).

Removal & Installation - Upstream Oxygen Sensor

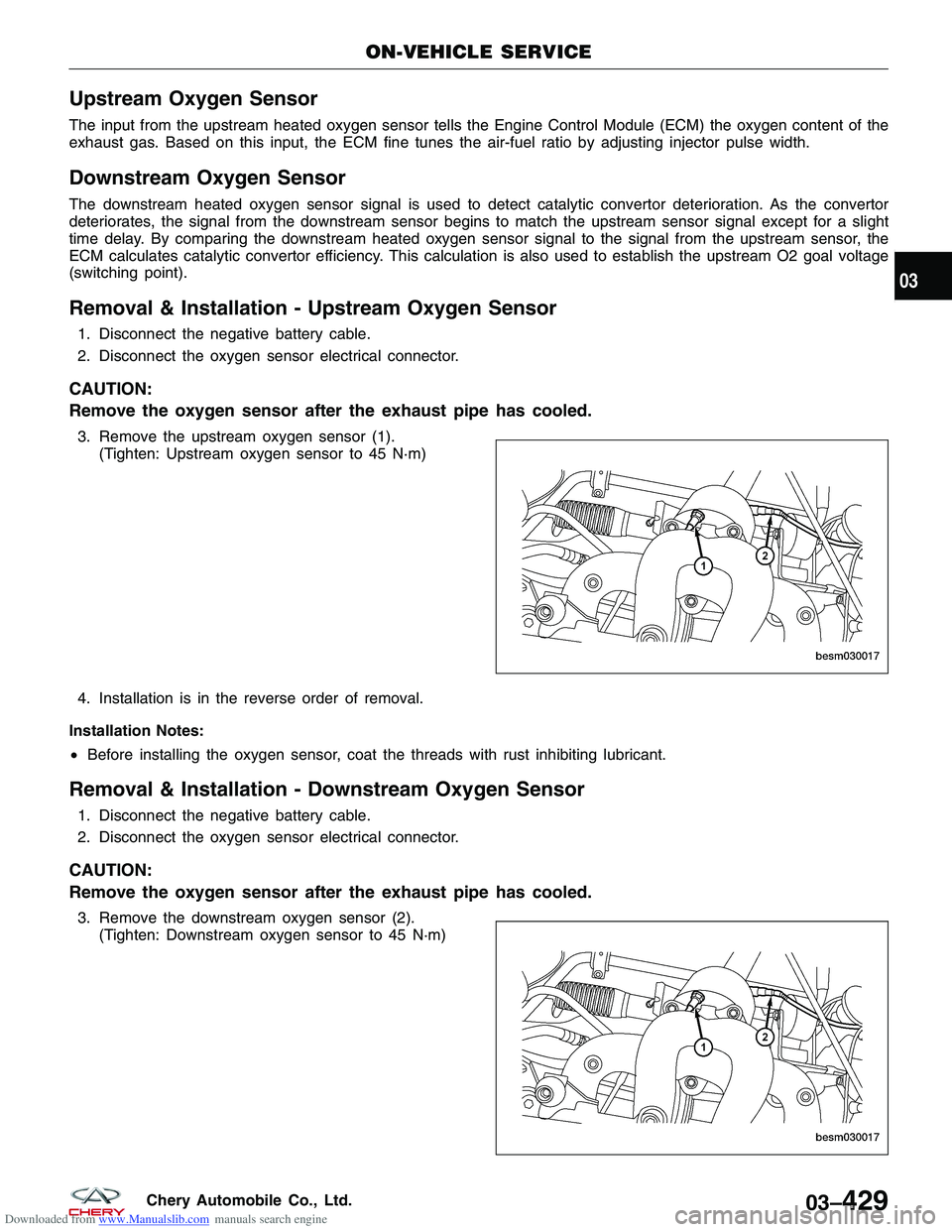

1. Disconnect the negative battery cable.

2. Disconnect the oxygen sensor electrical connector.

CAUTION:

Remove the oxygen sensor after the exhaust pipe has cooled.

3. Remove the upstream oxygen sensor (1).(Tighten: Upstream oxygen sensor to 45 N·m)

4. Installation is in the reverse order of removal.

Installation Notes:

• Before installing the oxygen sensor, coat the threads with rust inhibiting lubricant.

Removal & Installation - Downstream Oxygen Sensor

1. Disconnect the negative battery cable.

2. Disconnect the oxygen sensor electrical connector.

CAUTION:

Remove the oxygen sensor after the exhaust pipe has cooled.

3. Remove the downstream oxygen sensor (2).

(Tighten: Downstream oxygen sensor to 45 N·m)

ON-VEHICLE SERVICE

BESM030017

BESM030017

03

03–429Chery Automobile Co., Ltd.

Page 714 of 1903

Downloaded from www.Manualslib.com manuals search engine 4. Installation is in the reverse order of removal.

Installation Notes:

• Before installing the oxygen sensor, coat the threads with rust inhibiting lubricant.

Crankshaft Position (CKP) Sensor

Description

The Crankshaft Position (CKP) sensor is located on the flywheel shell facing the gear teeth of the signal plate. It

detects the fluctuation of the engine revolution. The sensor consists of a permanent magnet and Induction coil.

Operation

When the engine is running, the high and low parts of the teeth cause the gap with the sensor to change. The

changing gap causes the magnetic field near the sensor to change. Due to the changing magnetic field, the voltage

from the sensor changes. The Engine Control Module (ECM) receives the voltage signal and detects the fluctuation

of the engine revolution.

Removal & Installation

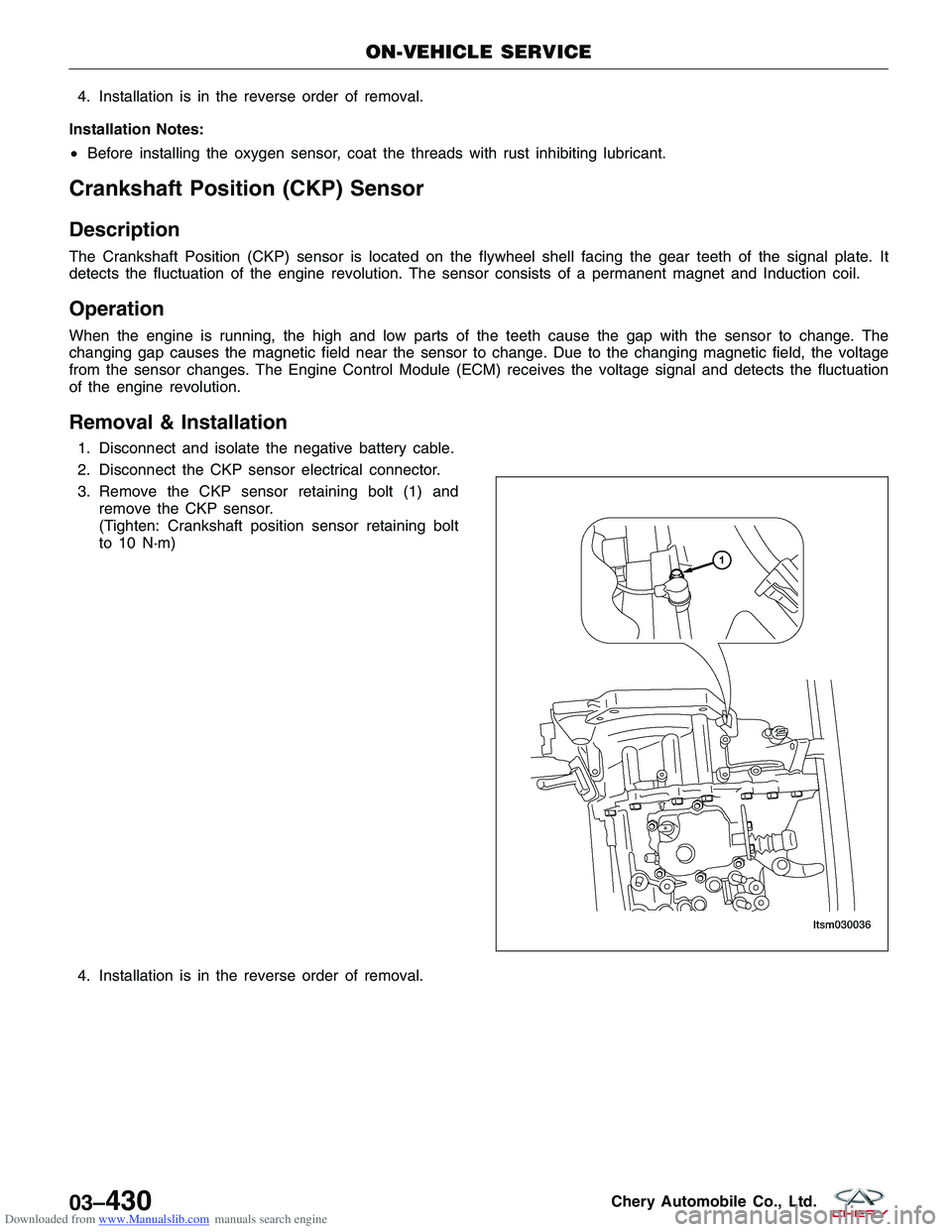

1. Disconnect and isolate the negative battery cable.

2. Disconnect the CKP sensor electrical connector.

3. Remove the CKP sensor retaining bolt (1) and

remove the CKP sensor.

(Tighten: Crankshaft position sensor retaining bolt

to 10 N·m)

4. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM030036

03–430Chery Automobile Co., Ltd.

Page 715 of 1903

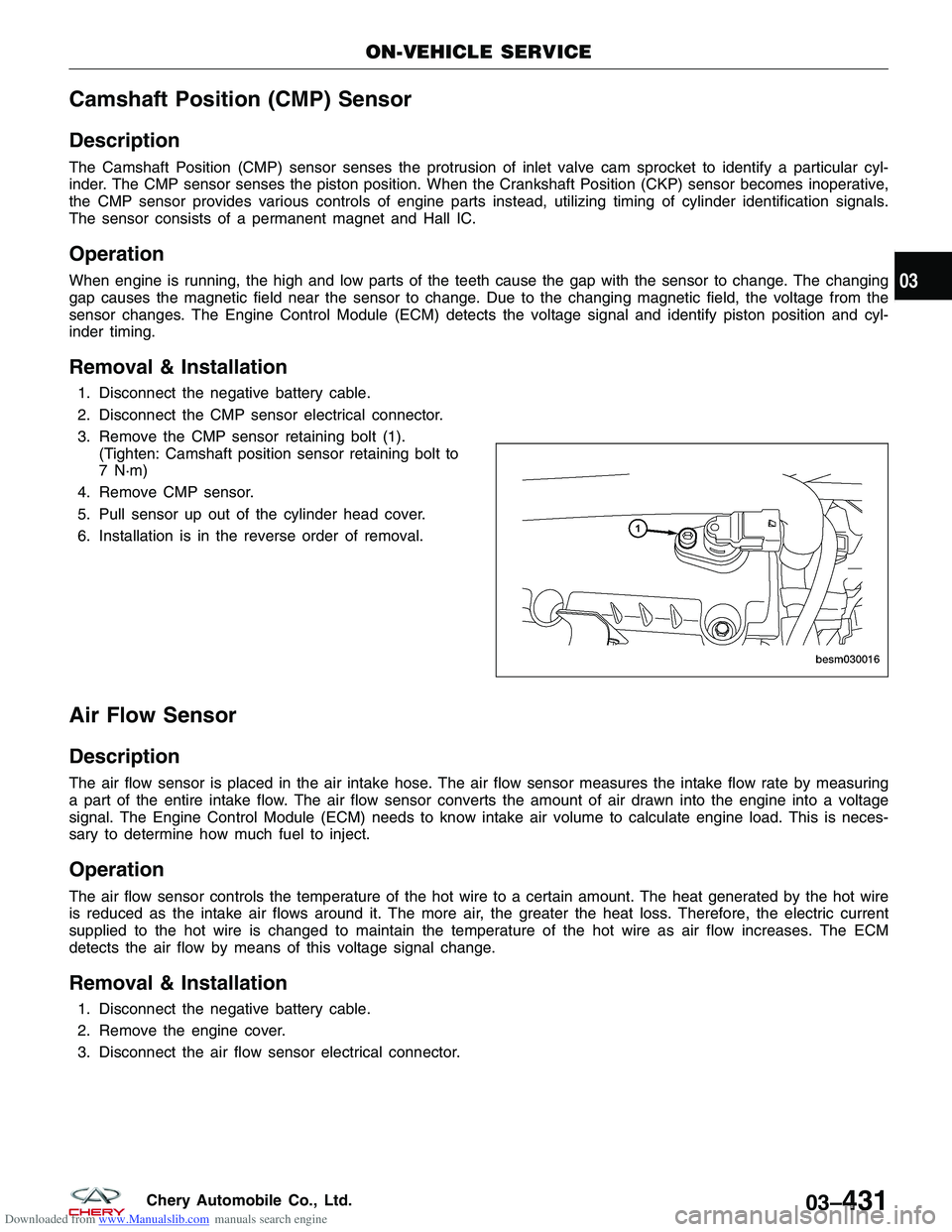

Downloaded from www.Manualslib.com manuals search engine Camshaft Position (CMP) Sensor

Description

The Camshaft Position (CMP) sensor senses the protrusion of inlet valve cam sprocket to identify a particular cyl-

inder. The CMP sensor senses the piston position. When the Crankshaft Position (CKP) sensor becomes inoperative,

the CMP sensor provides various controls of engine parts instead, utilizing timing of cylinder identification signals.

The sensor consists of a permanent magnet and Hall IC.

Operation

When engine is running, the high and low parts of the teeth cause the gap with the sensor to change. The changing

gap causes the magnetic field near the sensor to change. Due to the changing magnetic field, the voltage from the

sensor changes. The Engine Control Module (ECM) detects the voltage signal and identify piston position and cyl-

inder timing.

Removal & Installation

1. Disconnect the negative battery cable.

2. Disconnect the CMP sensor electrical connector.

3. Remove the CMP sensor retaining bolt (1).(Tighten: Camshaft position sensor retaining bolt to

7 N·m)

4. Remove CMP sensor.

5. Pull sensor up out of the cylinder head cover.

6. Installation is in the reverse order of removal.

Air Flow Sensor

Description

The air flow sensor is placed in the air intake hose. The air flow sensor measures the intake flow rate by measuring

a part of the entire intake flow. The air flow sensor converts the amount of air drawn into the engine into a voltage

signal. The Engine Control Module (ECM) needs to know intake air volume to calculate engine load. This is neces-

sary to determine how much fuel to inject.

Operation

The air flow sensor controls the temperature of the hot wire to a certain amount. The heat generated by the hot wire

is reduced as the intake air flows around it. The more air, the greater the heat loss. Therefore, the electric current

supplied to the hot wire is changed to maintain the temperature of the hot wire as air flow increases. The ECM

detects the air flow by means of this voltage signal change.

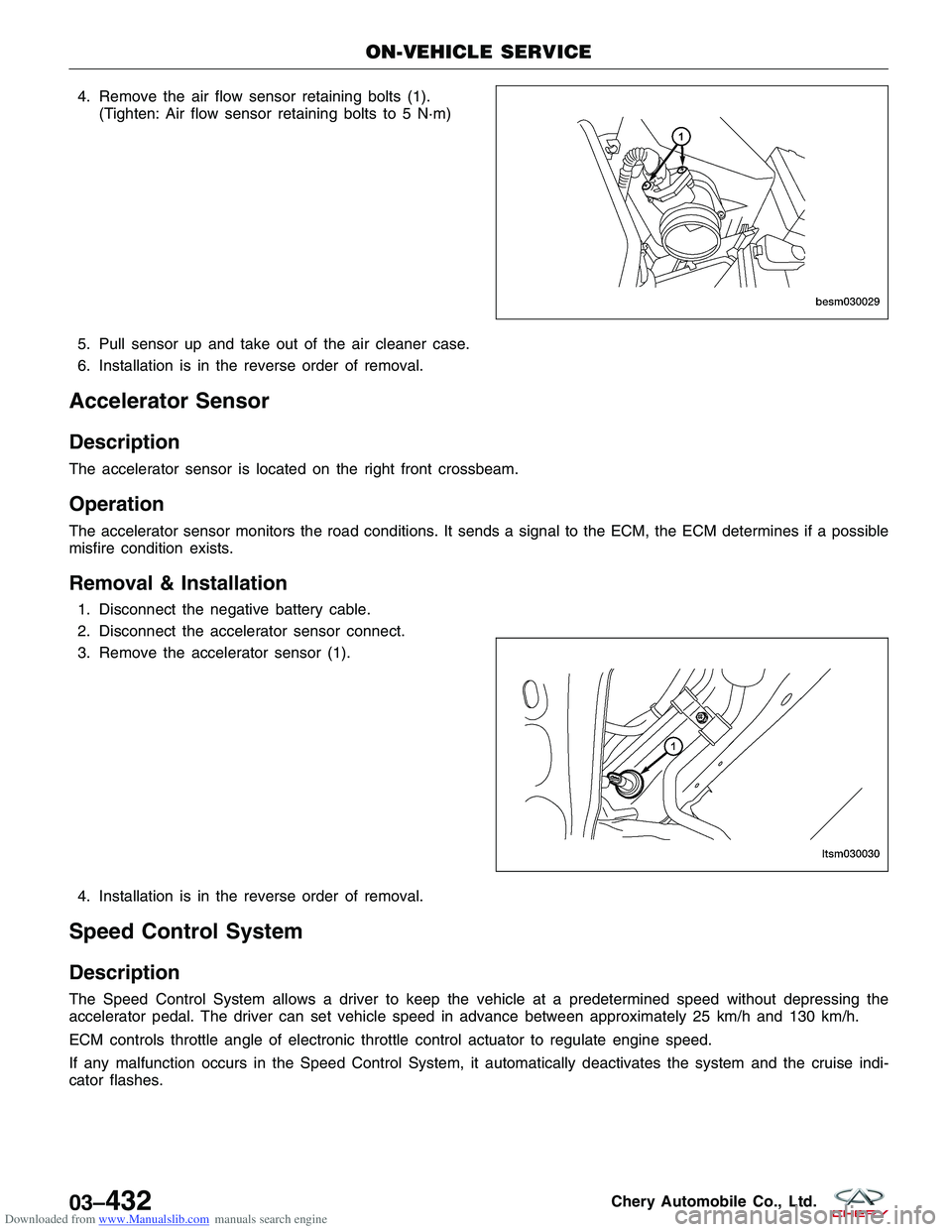

Removal & Installation

1. Disconnect the negative battery cable.

2. Remove the engine cover.

3. Disconnect the air flow sensor electrical connector.

ON-VEHICLE SERVICE

BESM030016

03

03–431Chery Automobile Co., Ltd.

Page 716 of 1903

Downloaded from www.Manualslib.com manuals search engine 4. Remove the air flow sensor retaining bolts (1).(Tighten: Air flow sensor retaining bolts to 5 N·m)

5. Pull sensor up and take out of the air cleaner case.

6. Installation is in the reverse order of removal.

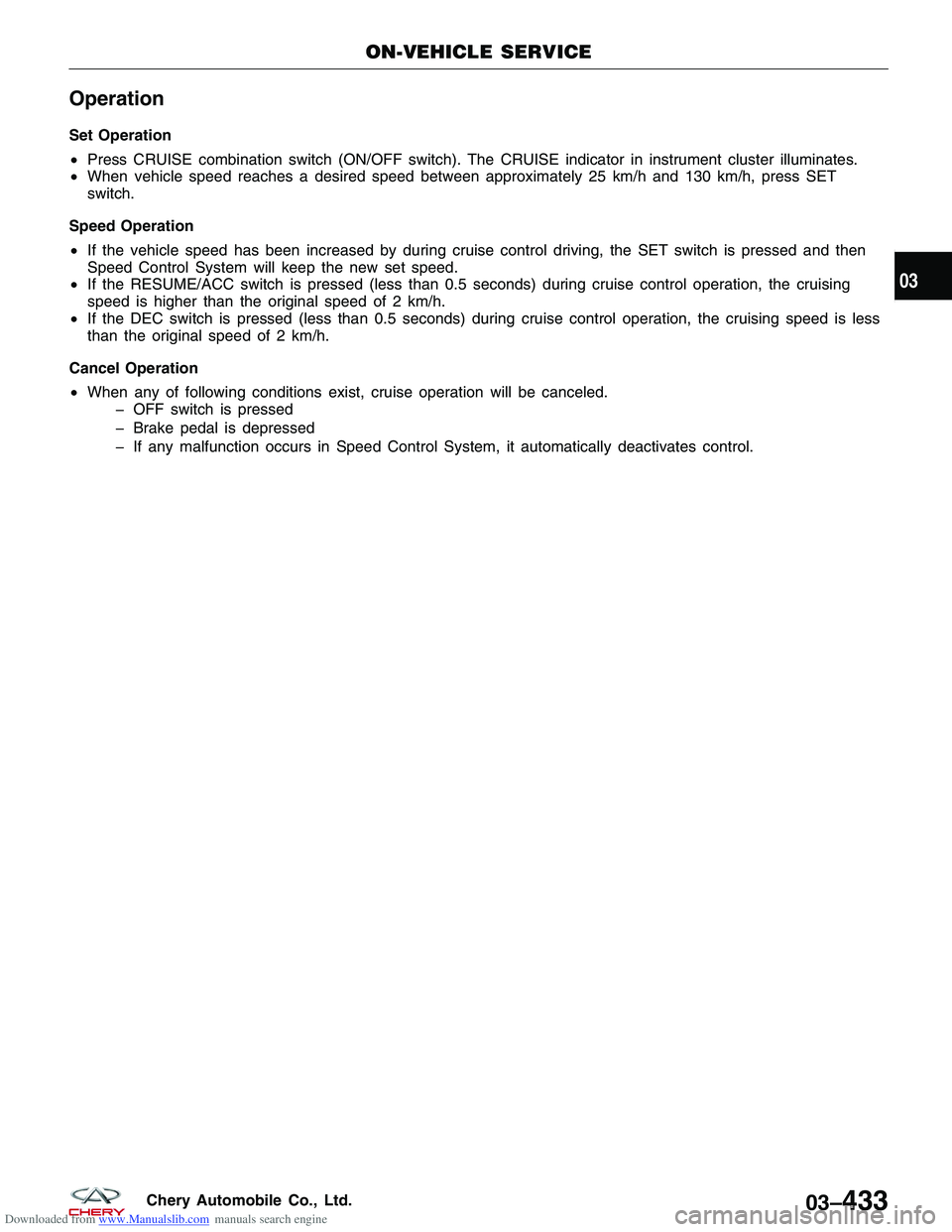

Accelerator Sensor

Description

The accelerator sensor is located on the right front crossbeam.

Operation

The accelerator sensor monitors the road conditions. It sends a signal to the ECM, the ECM determines if a possible

misfire condition exists.

Removal & Installation

1. Disconnect the negative battery cable.

2. Disconnect the accelerator sensor connect.

3. Remove the accelerator sensor (1).

4. Installation is in the reverse order of removal.

Speed Control System

Description

The Speed Control System allows a driver to keep the vehicle at a predetermined speed without depressing the

accelerator pedal. The driver can set vehicle speed in advance between approximately 25 km/h and 130 km/h.

ECM controls throttle angle of electronic throttle control actuator to regulate engine speed.

If any malfunction occurs in the Speed Control System, it automatically deactivates the system and the cruise indi-

cator flashes.

ON-VEHICLE SERVICE

BESM030029

LTSM030030

03–432Chery Automobile Co., Ltd.

Page 717 of 1903

Downloaded from www.Manualslib.com manuals search engine Operation

Set Operation

•Press CRUISE combination switch (ON/OFF switch). The CRUISE indicator in instrument cluster illuminates.

• When vehicle speed reaches a desired speed between approximately 25 km/h and 130 km/h, press SET

switch.

Speed Operation

• If the vehicle speed has been increased by during cruise control driving, the SET switch is pressed and then

Speed Control System will keep the new set speed.

• If the RESUME/ACC switch is pressed (less than 0.5 seconds) during cruise control operation, the cruising

speed is higher than the original speed of 2 km/h.

• If the DEC switch is pressed (less than 0.5 seconds) during cruise control operation, the cruising speed is less

than the original speed of 2 km/h.

Cancel Operation

• When any of following conditions exist, cruise operation will be canceled.

� OFF switch is pressed

� Brake pedal is depressed

� If any malfunction occurs in Speed Control System, it automatically deactivates control.

ON-VEHICLE SERVICE

03

03–433Chery Automobile Co., Ltd.

Page 718 of 1903

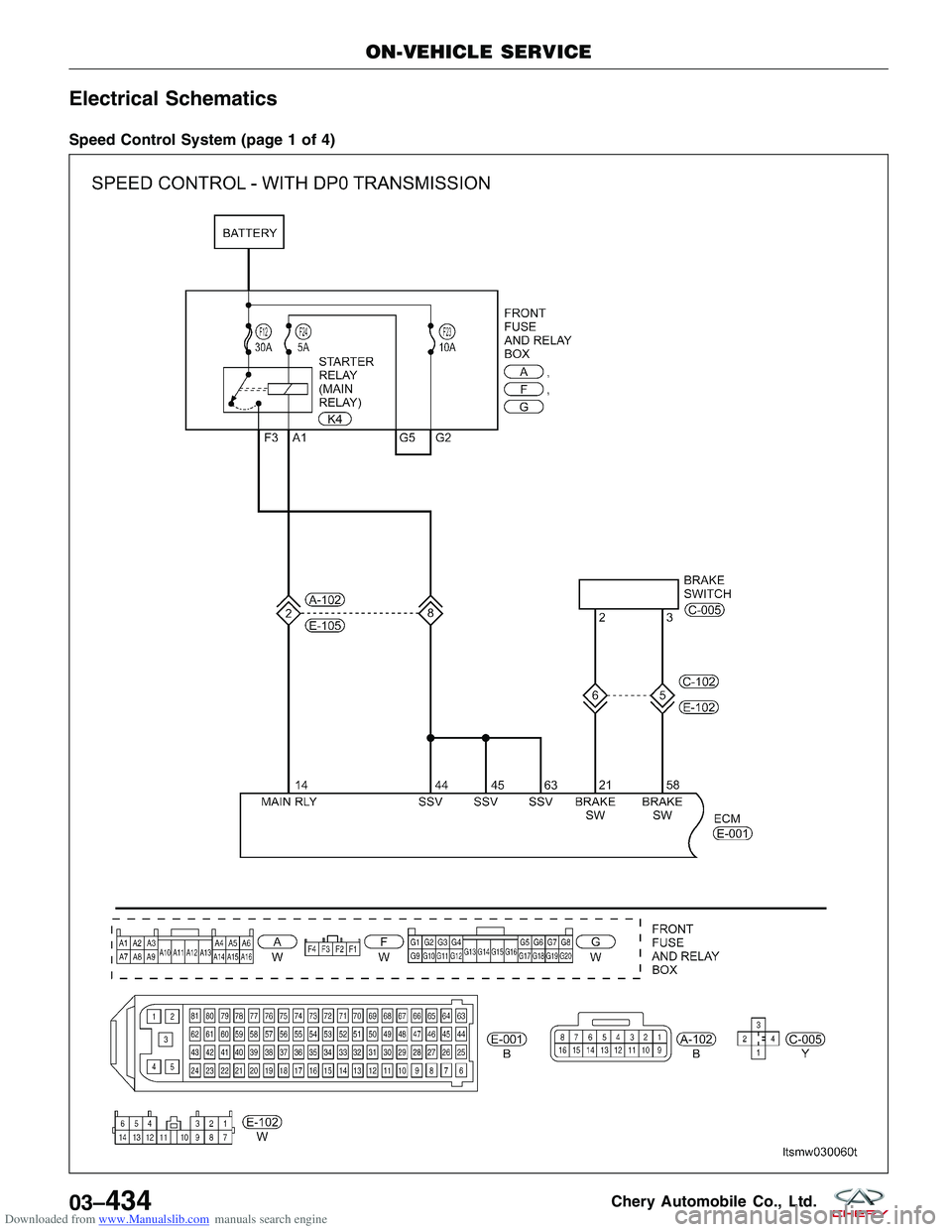

Downloaded from www.Manualslib.com manuals search engine Electrical Schematics

Speed Control System (page 1 of 4)

ON-VEHICLE SERVICE

LTSMW030060T

03–434Chery Automobile Co., Ltd.

Page 719 of 1903

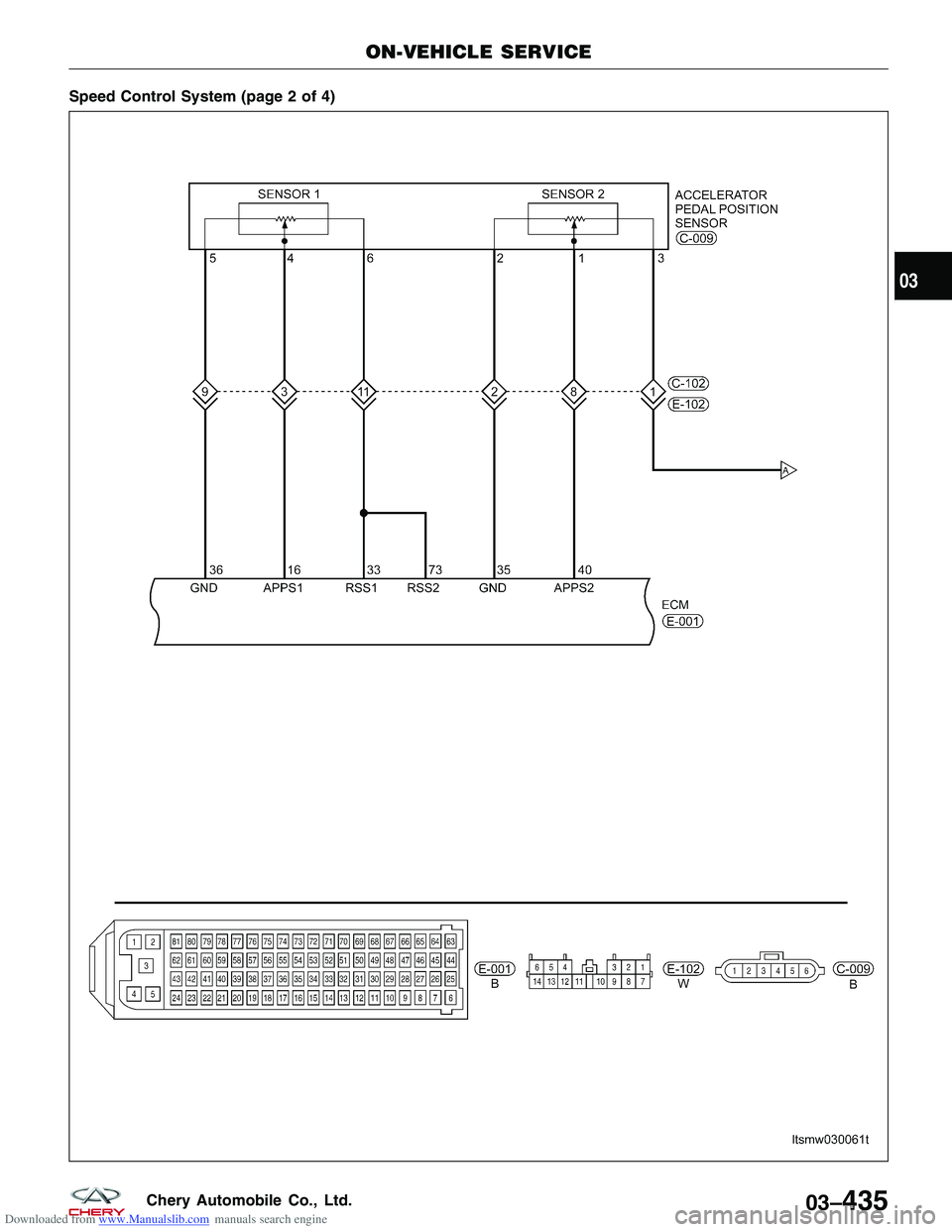

Downloaded from www.Manualslib.com manuals search engine Speed Control System (page 2 of 4)

ON-VEHICLE SERVICE

LTSMW030061T

03

03–435Chery Automobile Co., Ltd.

Page 720 of 1903

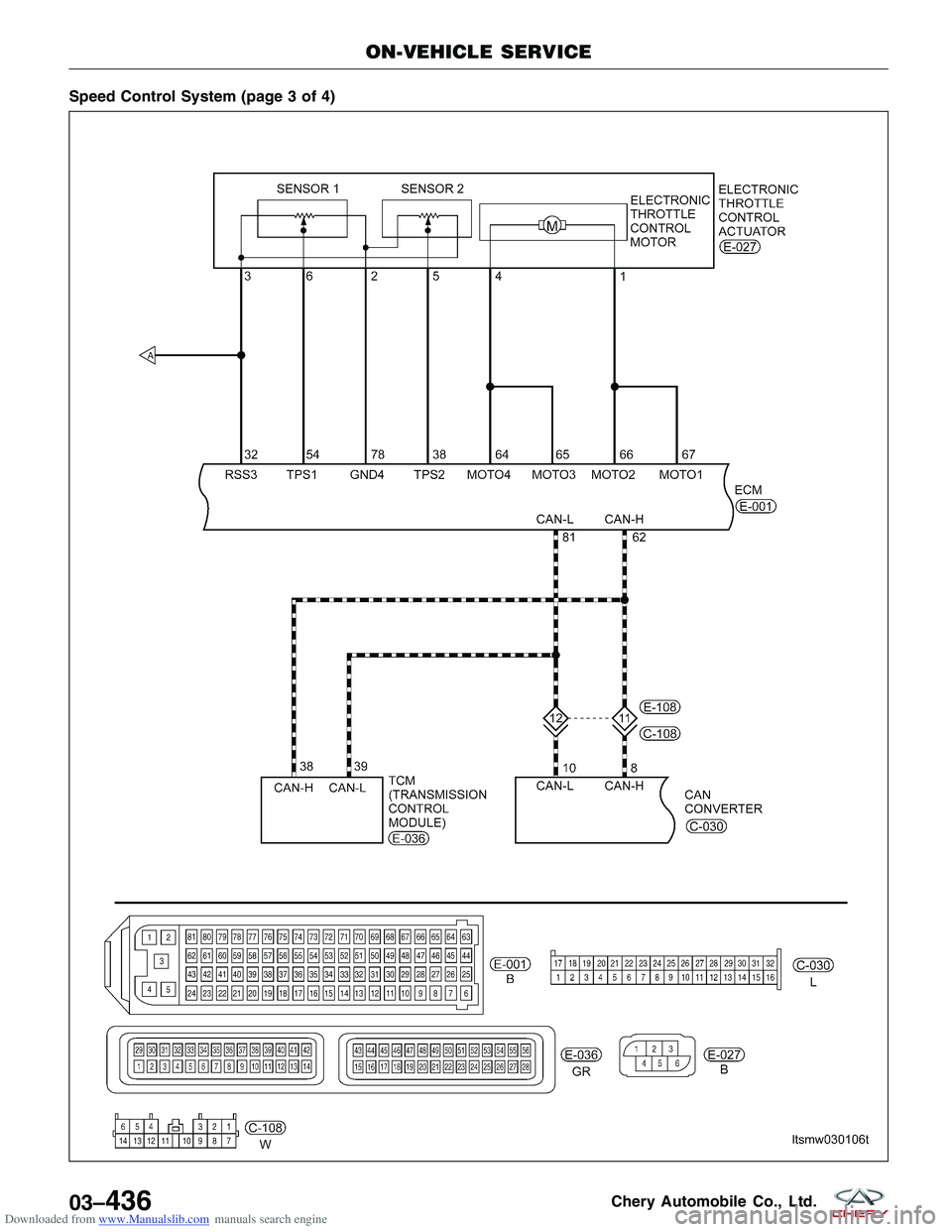

Downloaded from www.Manualslib.com manuals search engine Speed Control System (page 3 of 4)

ON-VEHICLE SERVICE

LTSMW030106T

03–436Chery Automobile Co., Ltd.