relay CHEVROLET CAMARO 1967 1.G Chassis Repair Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 564 of 659

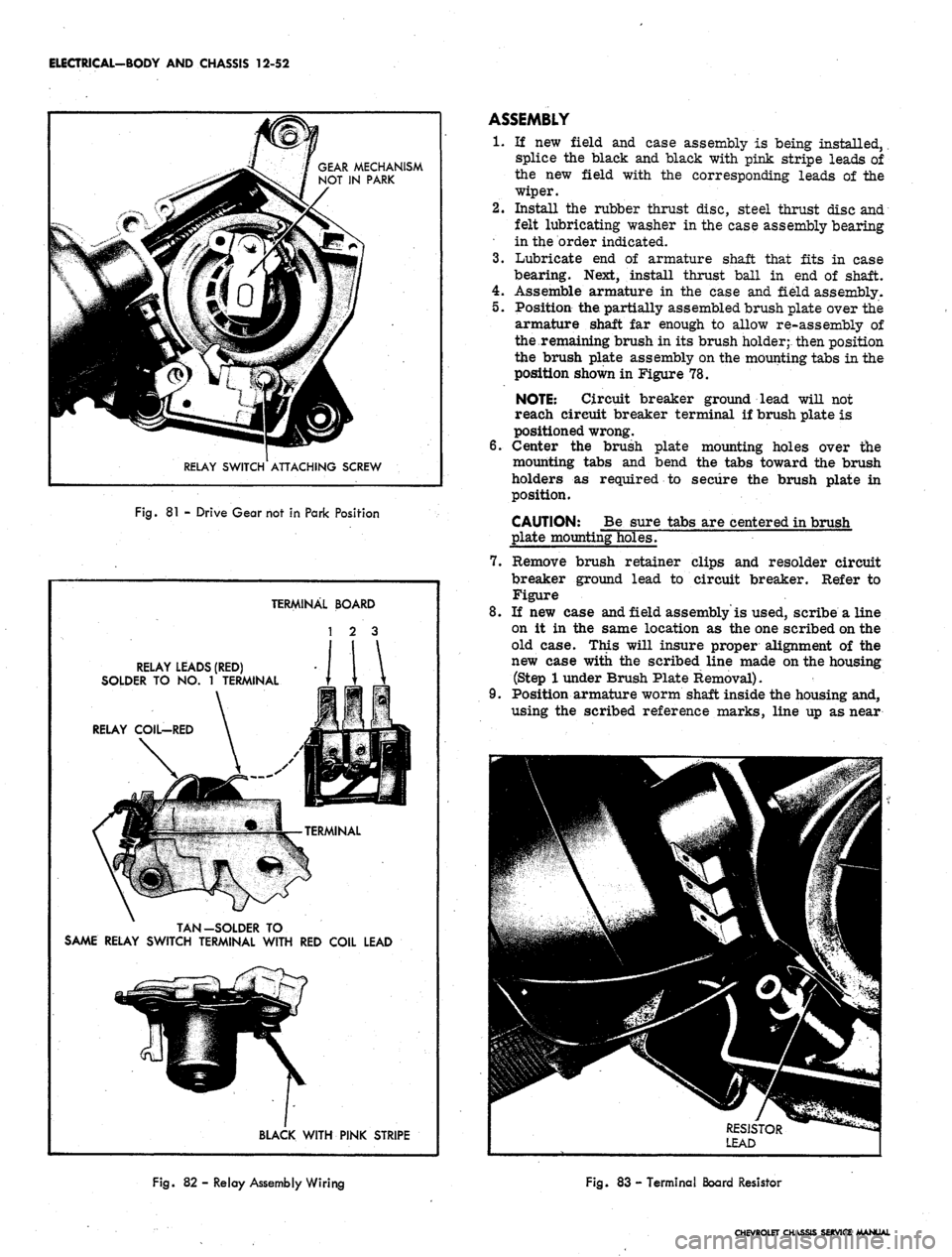

ELECTRICAL-BODY AND CHASSIS 12-52

GEAR MECHANISM

NOT IN PARK

RELAY SWITCH ATTACHING SCREW

Fig.

81 -

Drive Gear not

in

Park Position

TERMINAL BOARD

1 2 3

RELAY LEADS (RED)

SOLDER TO NO. 1 TERMINAL

RELAY

COIL-RED

TAN-SOLDER TO

SAME RELAY SWITCH TERMINAL WITH RED COIL LEAD

BLACK WITH PINK STRIPE

ASSEMBLY

1.

If new field and case assembly is being installed,

splice the black and black with pink stripe leads of

the new field with the corresponding leads of the

wiper.

2.

Install the rubber thrust disc, steel thrust disc and

felt lubricating washer in the case assembly bearing

in the order indicated.

3.

Lubricate end of armature shaft that fits in case

bearing. Next, install thrust ball in end of shaft.

4.

Assemble armature in the case and field assembly.

5.

Position the partially assembled brush plate over the

armature shaft far enough to allow re-assembly of

the remaining brush in its brush holder;- then position

the brush plate assembly on the mounting tabs in the

position shown in Figure 78.

NOTE: Circuit breaker ground lead will not

reach circuit breaker terminal if brush plate is

positioned wrong.

6. Center the brush plate mounting holes over the

mounting tabs and bend the tabs toward the brush

holders as required to secure the brush plate in

position.

CAUTION: Be sure tabs are centered in brush

plate mounting holes.

7.

Remove brush retainer clips and resolder circuit

breaker ground lead to circuit breaker. Refer to

Figure

8. If new case and field assembly'is used, scribe a line

on it in the same location as the one scribed on the

old case. This will insure proper alignment of the

new case with the scribed line made on the housing

(Step

1

under Brush Plate Removal).

9. Position armature worm shaft inside the housing and,

using the scribed reference marks, line up as near

Fig.

82 - Relay Assembly Wiring

Fig.

83 -

Terminal Board Resistor

CHEVROLET CHASSIS SERVICE MANUAL

Page 565 of 659

ELECTRICAL-BODY AND CHASSIS 12-53

13

10 11

Fig.

84- Drive Gear Mechanism Assembly

1.

Drive Gear Shaft

2.

Drive Pawl

3. Lock Pawl

4.

Coil Spring

5. Drive Gear

6. Relay Assembly

7. Spacer

8. Shield

9. Seal

10.

Washer

11.

Snap Ring

12.

Crank Arm

13.

Nut

10.

1

NOTE:

VIEW SHOWS RELAY SWITCH ASSEMBLY

AND TERMINAL BOARD REMOVED.

GEAR MAY BE REMOVED WITHOUT

DISTURBING RELAY SWITCH

OR TERMINAL BOARD. f* ;<^ / t

\ MAINTAIN GEAR

J ASSEMBLY IN

V POSITION

^^ SHOWN

FT"

DURING

* & REASSEMBLY

WM IN HOUSING

f

INNER SPACER

J WASHER

ft

as possible the case and field assembly with the

housing.

Maintaining the armature in its assembled position

in the case, start the armature worm shaft through

the field and housing bearing until it starts to mesh

with the worm gear. At the same time carefully pull

the excess black and black with pink stripe leads

thru the housing grommet.

DRIVE

PAWL

DRIVE SHAFT AND

PLATE ASSEMBLY

LOCK

PAWL

Fig.

85 - Removing Gear Assembly

Fig.

86 - Lock and Drive Pawl Assembly

CHEVROLET CHASSIS SERVICE MANUAL

Page 566 of 659

ELECTRICAL-BODY AND CHASSIS 12-54

INNER

SPACER

WASHER

LOCK

PAWL

COIL

SPRING

DRIVE,

PAWL

DRIVE

SHAFT

AND

PLATE

ASSEMBLY

DRIVE

AND

LOCK

PAWL

GUIDE

PINS

IN

GEAR

POCKETS

7

DURING

NORMAL

OPERATION

RELAY

LATCH

ARM

IS

HELD

OUT OF

PATH

OF

GEAR

BY

RELAY

MAGNET

11.

12.

Fig. 87 - Drive Gear and Shaft Assembly

CAUTION: It may be necessary at this point to

rotate armature slightly before the armature

worm will engage with worm gear teeth.

Rotate the case as required to align the bolt holes in

the case with those in the housing.

Secure the case to the housing with the two tie bolts.

GEAR BOX SECTION

Fig. 88 - Drive and Lock Pawl Guide Pins in Pockets

(drive pawl away from latch arm, fig. 81), proceed

to Step 3.

Remove relay-switch attaching screw (fig. 80) and

carefully lift the relay-switch assembly out of the

gear box. Unsolder leads from switch terminals as

required. Refer to Figure when resoldering leads.

To remove terminal board assembly simply slide it

out of housing and unsolder leads as required.

The gear box section is subdivided into two areas, (A)

the relay control and latching mechanism and (B) the

drive gear mechanism.

A—Relay Switch and Latch Assembly-

Terminal Board Removal

1.

Remove screws retaining washer pump assembly to

wiper unit.

2.

If wiper pawl is in full park position (drive pawl lo-

cated in magnetic switch assembly slot, fig. 79), it

becomes necessary to remove gear assembly first

(see Gear Assembly Removal).

If wiper gear mechanism is not in park position

VALVE

ASSEMBLY—j

RATCHET ->Mmk

LATC

SPR

HOUT

ING

RELAY COIL

/PAWL SPRING

/ /'

^L / PAWL

|j^»i It

RATCHET

WHEEL

Fig. 89 - Washer Pump Assembly

CHEVROLET CHASSIS SERVICE MANUAL

Page 567 of 659

ELECTRICAL-BODY

AND

CHASSIS

12-55

COVER RELAY COIL

ASSEMBLY

PAWL SPRING

a=-

VALVE ASSEMBLY

RATCHET DOG AND _/_ f1

LATCHOUT SPRING ^—-»*

PAWL

RATCHET WHEEL

J

Fig.

SO

-

Exploded View

of

Pump

Relay Switch—Latch and Terminal Board Assembly

1.

Resolder leads

to

wiper terminal board as required

(fig. 82).

2.

Slide terminal board into wiper housing being careful

to position the terminal board resistor lead as shown

in Figure 83.

3.

Resolder leads

to

relay switch assembly

as

required

(fig. 82).

4.

Position relay-switch assembly

in

housing.

CAUTION:

Be

very careful

to

route leads

in

such

a

manner

as to

avoid having them pinched

between relay and wiper housing.

5. Install relay-switch mounting screw.

6. Assemble gear box cover and washer pump assembly

to wiper being careful that the ground strap

is

prop-

erly connected. Refer

to

Figure 75 for assembly

of

washer pump

to

gear housing.

B-Drive Gear Disassembly (Fig.

84)

1.

Remove washer pump assembly.

2.

Remove crank

arm

retaining nut, crank arm, rubber

seal

cap,

retaining ring, shim washers, shield

and

spacer washer in the order indicated.

3.

Slide gear assembly out

of

housing (fig. 85).

4.

Slide drive plate and shaft out

of

gear and remove the

drive pawl, lock pawl

and

coil spring

as

required.

Drive Gear—Assembly

1.

Position drive pawl

on

drive plate

as

shown

in

Fig.

ure 86.

2.

Assemble lock pawl over drive pawl

as

shown

in

Figure

86.

3.

Slide gear

and

tube over

the

drive shaft (fig. 87).

(Move drive and lock pawls

as

required to allow their

respective pins

to fit in the

gear guide channel,

fig.

88).

4.

Holding

the

gear, manually rotate

the

drive plate

until

the

drive

and

lock pawl guide pins snap into

their respective pockets in the gear (fig. 88).

5. Reinstall coil spring between lock

and

drive pawls

(fig. 88).

IMPORTANT: Be very careful

to

maintain lock

and drive pawl guide pins

in

their respective

pockets during Step

6.

6. Assemble inner spacer washer over gear shaft

and

assemble gear mechanism

in

housing

so

that

it is

positioned with respect to the housing in the approxi-

mate location shown

in

Figure 85.

7. Reassemble

the

outer spacer washer, shield, shim

washers

as

required

to

obtain .005"

max.

end play,

snap ring and rubber seal cap in the order indicated.

Refer to Figure 84.

8. Operate wiper

to

"park"

or

"off" position and install

crank arm.

9. Reassemble washer pump

to

wiper (fig. 75).

WASHER PUMP UNIT

The washer pump and/or valve assembly

may be re-

moved from the wiper assembly

as a

unit; therefore,

it is

not necessary

to

remove

the

wiper assembly irom

the

vehicle

if

only

the

washer pump and/or valve assembly

required service.

When

the

pump

is

removed from

the

wiper assembly,

all working parts

are

readily accessible and may easily

be serviced

as

necessary

(fig. 89).

An exploded view

of

the washer pump

is

shown in Figure 90.

Removal and Installation

1.

Raise vehicle hood.

2.

Disconnect washer hoses

and

electrical connections

from assembly.

3.

Remove

3

screws securing washer pump

and

cover

to wiper assembly. Remove pump from wiper gear

box.

4.

Position pump

and

cover assembly

to

the wiper and

install retaining screws.

5. Connect washer hoses

to

valve assembly and wiring

leads

to

pump and wiper terminals.

6. Check operation

of

unit.

CHEVROLET CHASSIS SERVICE MANUAL

Page 568 of 659

ELECTRICAL-BODY

AND

CHASSIS

12-56

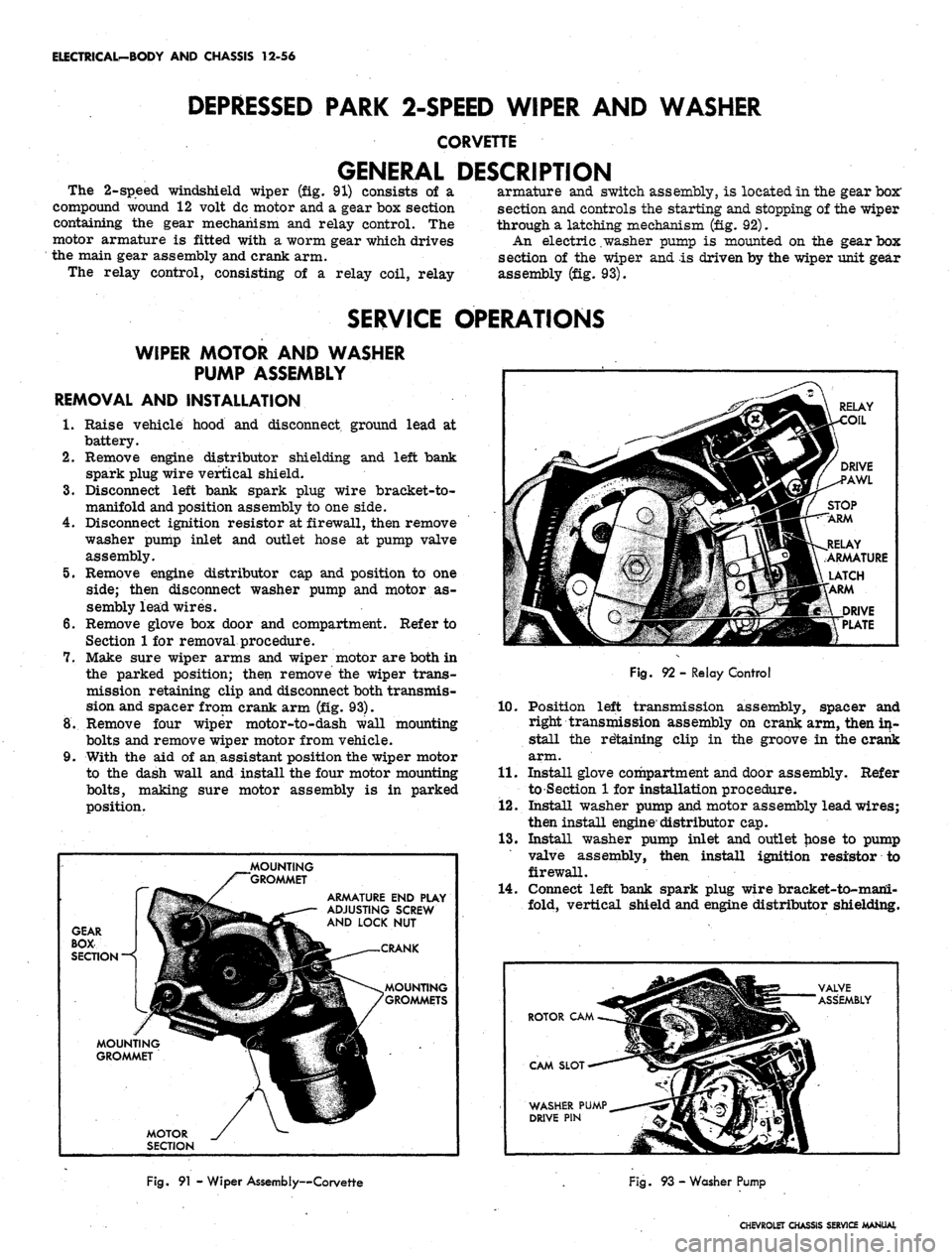

DEPRESSED PARK 2-SPEED WIPER

AND

WASHER

CORVETTE

GENERAL DESCRIPTION

The 2-speed windshield wiper

(fig. 91)

consists

of a

compound wound

12

volt dc motor and

a

gear box section

containing

the

gear mechanism

and

relay control.

The

motor armature

is

fitted with

a

worm gear which drives

the main gear assembly and crank arm.

The relay control, consisting

of a

relay coil, relay

armature

and

switch assembly,

is

located in the gear

box"

section and controls the starting and stopping of the wiper

through

a

latching mechanism (fig. 92).

An electric .washer pump

is

mounted

on the

gear box

section

of the

wiper

and is

driven by the wiper unit gear

assembly (fig. 93).

SERVICE OPERATIONS

WIPER MOTOR

AND

WASHER

PUMP ASSEMBLY

REMOVAL AND INSTALLATION

1.

Raise vehicle hood

and

disconnect, ground lead

at

battery.

2.

Remove engine distributor shielding

and

left bank

spark plug wire vertical shield.

3.

Disconnect left bank spark plug wire bracket-to-

manifold and position assembly to one side.

4.

Disconnect ignition resistor at firewall, then remove

washer pump inlet

and

outlet hose

at

pump valve

assembly.

5.

Remove engine distributor

cap

and position

to one

side;

then disconnect washer pump

and

motor

as-

sembly lead wires.

6. Remove glove

box

door

and

compartment. Refer

to

Section

1

for

removal procedure.

7.

Make sure wiper arms

and

wiper motor are both

in

the parked position; then remove

the

wiper trans-

mission retaining clip and disconnect both transmis-

sion and spacer from crank arm (fig. 93).

8. Remove four wiper motor-to-dash wall mounting

bolts and remove wiper motor from vehicle.

9. With

the aid of

an assistant position the wiper motor

to

the

dash wall

and

install the four motor mounting

bolts,

making sure motor assembly

is in

parked

position.

GEAR

BOX

SECTION

—<

MOUNTING

^*^

GROMMET

MOTOR

_/

SECTION

MOUNTING

/"""GROMMET

ARMATURE

END

PLAY

ADJUSTING SCREW

AND LOCK

NUT

P

^

CRANK

^_ /GROMMETS

RELAY

Fig.

92 -

Relay Control

10.

Position left transmission assembly, spacer

and

right transmission assembly

on

crank arm, then in-

stall

the

retaining clip

in the

groove

in

the crank

arm.

11.

Install glove compartment and door assembly. Refer

to Section

1

for

installation procedure.

12.

Install washer pump and motor assembly lead wires;

then install engine-distributor cap.

13.

Install washer pump inlet

and

outlet hose

to

pump

valve assembly, then install ignition resistor

to

firewall.

14.

Connect left bank spark plug wire bracket-to-mani-

fold, vertical shield and engine distributor shielding.

ROTOR

CAM. ^

CAM SLOT-~-*"'-*

WASHER PUMP^.

DRIVE

PIN

m

M

VALVE

— ASSEMBLY

i

Fig.

91 - Wiper Assembly—Corvette

Fig.

93 - Washer Pump

CHEVROLET CHASSIS SERVICE MANUAL

Page 570 of 659

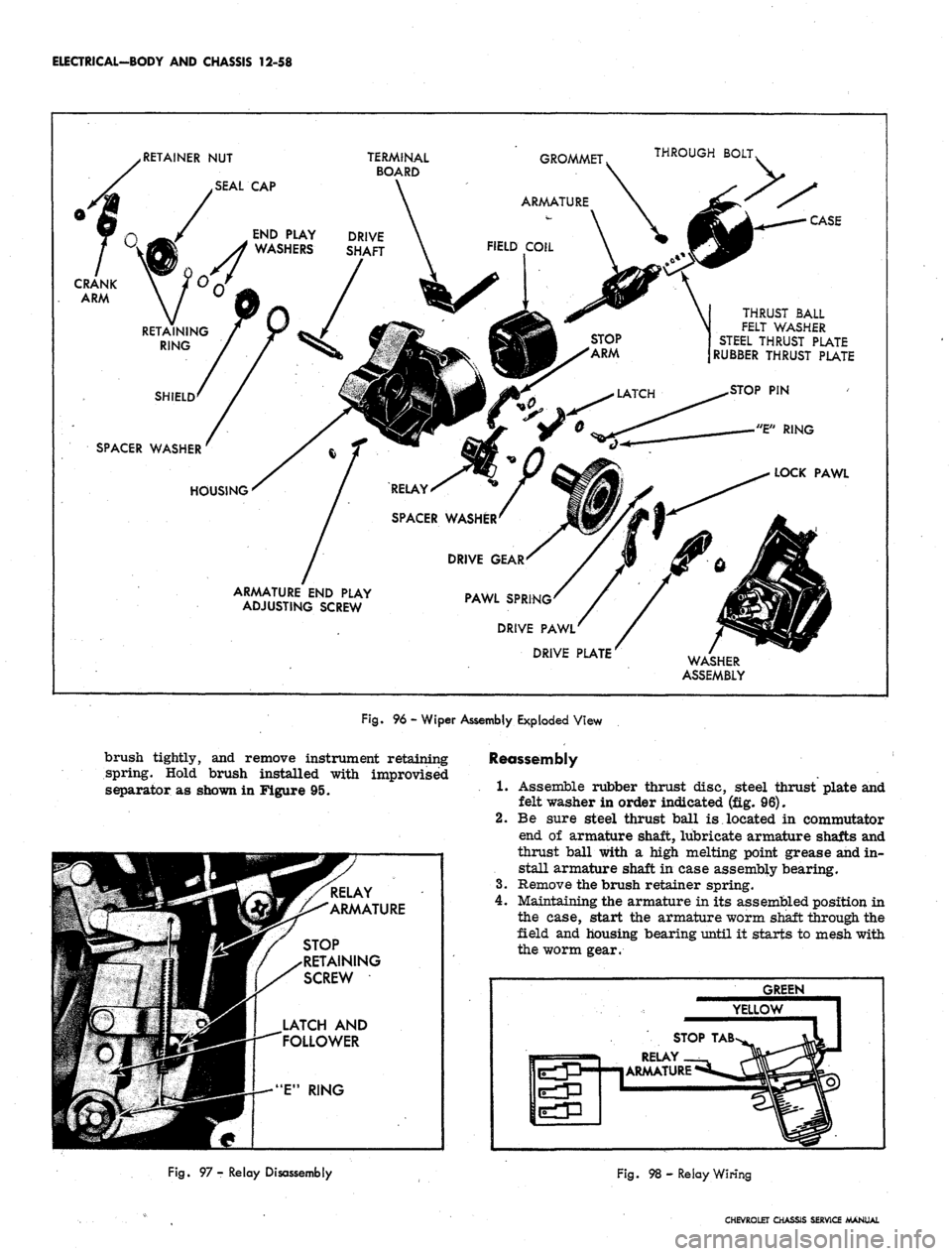

ELECTRICAL-BODY AND CHASSIS 12-58

RETAINER NUT

.SEAL CAP

THROUGH

BOLT,

CASE

CRANK

ARM

THRUST

BALL

FELT

WASHER

STEEL THRUST PLATE

RUBBER THRUST PLATE

SPACER WASHER

HOUSING

ARMATURE END PLAY

ADJUSTING SCREW

PAWL SPRING'

DRIVE

PAWL'

DRIVE PLATE

WASHER

ASSEMBLY

Fig.

96 - Wiper Assembly Exploded View

brush tightly, and remove instrument retaining

spring. Hold brush installed with improvised

separator as shown in Figure 95.

STOP

RETAINING

SCREW

LATCH AND

FOLLOWER

Reassembly

1.

Assemble rubber thrust disc, steel thrust plate and

felt washer in order indicated (fig. 96).

2.

Be sure steel thrust ball is located in commutator

end of armature shaft, lubricate armature shafts and

thrust ball with a high melting point grease and in-

stall armature shaft in case assembly bearing.

3.

Remove the brush retainer spring.

4.

Maintaining the armature in its assembled position in

the case, start the armature worm shaft through the

field and housing bearing until it starts to mesh with

the worm gear.

GREEN

YELLOW

STOP

TAB

RELAY

ARMATURE

Fig.

97 - Relay Disassembly

Fig. 98 - Relay Wiring

CHEVROLET CHASSIS SERVICE MANUAL

Page 571 of 659

ELECTRICAL-BODY AND CHASSIS 12-59

NOTE: it may be necessary at this point to

rotate the armature slightly before the worm

will engage with the worm gear.

5.

Rotate the case as required to align the holes in the

case with those in the housing.

6. Being very careful not to pinch any of the motor

leads between the case and edge of the field, push the

case onto the field until it butts against the housing.

7.

Secure case to housing with two tie bolts.

8. Install end-play adjusting screws and locknut and

adjust end-play by tightening adjusting screw finger

tight; then back off screw 1/4 turn and tighten

locknut.

GEAR BOX SECTION

The gear box section is subdivided into two areas, (A)

the relay control and latching mechanism and (B) the

drive gear mechanism.

A—Relay Control and Latching Mechanism:

Disassembly

1.

Remove four screws which secure the washer pump

assembly to gear box.

2.

Refer to Figure 97. Disconnect coil spring, remove

"E"

ring and lift the latch and follower assembly off

the pivot pin and relay armature.

3.

Remove the stop assembly retaining screw. This

will permit the stop assembly to be moved as neces-

sary to allow clearance for removing the relay con-

trol assembly.

Fig.

100 - Assembly Gear and Eccentric Shaft

4.

Remove the two screws that secure the relay control

assembly.

5.

Lift the relay control assembly out of the gearbox

and unsolder leads as required.

Reassembly

1.

Solder existing green and yellow wiper leads to relay

control switch and solder the relay coil Iea4 to the

wiper unit terminal board as shown in Figure

B—Drive Gear Mechanism:

Disassembly

Refer to Figure 84 unless other wise specified.

1.

Remove the crank arm retaining nut (No. 1).

2.

Remove crank arm (No. 2), snap ring (No. 3) and

rubber seal (No. 4).

3.

Remove the retaining ring (No. 5), end play washers

(No.

6), shield (No. 7) and spacer washer (No. 8).

4.

Follow Steps 1 through 3 under relay control and

latch mechanism disassembly.

Fig.

99 - Lock and Drive Pawi Mechanism

Fig.

101 - Drive Gear Mechanism Installed

CHEVROLET CHASSIS SER\

Page 641 of 659

SPECIFICATIONS 14

REGULATOR

Regulator Model

Application

Field Relay: Air Gap

Point Opening

Closing Voltage

Voltage Regulator: Air Gap

Point Opening

Voltage Setting

1119515

Base

All Except

with Generator

1117765 and

1100742

.015

.030

1.5-3.2

.067

.014

13.8-14.8

@

85°F.

1119519

Base

with Generator

1100742

.015

.030

1.5-3.2

.067

.014

13.8-14.8

@

85°F.

1116378

Base

with Generator

1117754

.011-.018

.020-.030

2.5-3.5

—.

—

13.7-14.4

@

85°F.

"O"

Position of

Adjusting Screw

STARTING MOTOR

Starting Motor Model

Application

Brush Spring Tension, oz.

Free

Speed

Volts

Amperes

RPM

Resistance Test

Armature

Locked

Volts

Amperes

1107399

153L-4

194L-6 &

230L-6

w/Mariual

Trans.

230L-6

w/Auto.

Trans.

250L-6

All Trans.

35

10.6

49-87*

6200-10700

4.2

290-425*

1107400

153L-4 &.

194L-6

w/Auto.

Trans.

35

10.6

49-87*

6200-10700

4.2

290-425*

1107496

283 Cu. In.

V-8

All Trans.

35

10.6

49-87*

6200-10700

4.2

290-425*

1107320

327 Cu. In.

V-8

Auto.-

Trans.

35

io.6

65-100*

3600-5100

3.5

300-360*

1107372

250L-6

Hvy. Duty

& Taxi

Chevrolet

35

10.6

55-95*

3800-6000

3.5

300-360

1107365

396 & 427

Cu-In.

V-8

All Trans.

Chevelle,

Chevrolet

& Corvette

w/14"

Ring

Gear

35

10.6

70-99*

7800-12000

3.0

410-480*

1107388

283 & 327

V-8 w/H.D.

Clutch,

350

Cu.

In.

V-8

35

10.6

65-iOO*

3600-5100

3.5

300-360

•Includes Solenoid

CHEVROLET CHASSIS SERVICE MANUAL

Page 646 of 659

SPECIFICATIONS 19

STEERING

SECTION 9

STANDARD STEERING

Item

Steering

Gear

Linkage

Ratio

#

Type

Gear

Overall

Type

Location

Tie Rods

Chevrolet

24:1

31:4.1

Rear

Chevelle

24:1

28:1

Front

Chevy II

Recirculating Ball

20:1

25.4:1

Parallel Relay Rod

Rear

2

Camaro

(*)

Rear

Corvette

16:1

Road 20.2:1

Fast 17.6:1

Rear

Model and/or Option

L6-

All,

327

V-8 Sed., A/C

327V-,8 Cpe

350 V-8 All

Special Steering

Gear Ratio

28:1

24:1

24:1

24:1

Overall Ratio

28:1

24:1

24:1

21.6:1

POWER STEERING

Pump

Steering

Gear

Type

Pressure

Type

Ratio

Gear

Overall

Vane Impeller

1000-1100

870-1000

900-1000

Integral Recirculating Ball

17.5:1

21.3:1

17.5:1

20.4:1

870-1000

Recirculating

Ball

900-1000

Integ. Recirc. Ball

17.5:1

17.5:1

870-1000

Recirculating

Ball

17.6:1 Only

ADJUSTMENT SPECIFICATIONS- STANDARD STEERING

Adjustment

Worm Bearing Preload

Sector Lash Adjustment

Total Steering Gear Preload

Torque to Turn Worm Shaft

5 - 8 Lb. In.

4-10 Lb. In. in excess of above

16 Lb. In. Maximum

ADJUSTMENT SPECIFICATIONS-POWER STEERING

Ball Drag

Thrust Bearing Preload

Over Center Preload

Total Steering Gear Preload

Chevrolet, Chevelle, Camaro

3 Lb. In. Max.

1/2 - 2 Lb. In. in excess of valve assy, drag

3-6 Lb. In. in excess of above

14 Lb. In. Max.

Chevy n

Worm Bearing Preload

Sector Lash Adjustment

Total Steering Gear Preload

1-1/2 -5-1/2 Lb. In.

3 - 7 Lb. In. in excess of above

11 Lb. In. Max.

Corvette

Same as

Standard Steering

CHEVROLET CHi

SERVICE MANUAL

Page 647 of 659

SPECIFICATIONS 20

TORQUE CHART

Steering Gear Mounting

Bolts

Pitman Shaft Nut

Steering Wheel Nut

Steering Wheel Nut-Tilt

Steering Coupling Nuts

Steering Coupling Clamp

Bolts

Tie Rod End Nut

Tie Rod Clamp Nut

Idler Arm Mounting Nut

Steering Wheel to

Hub (Wood)

Steering Damper Bracket

Frame Nut

Steering Damper Bracket

Relay End Nut

Steering Damper to

Bracket Nut

Steering Damper Bracket

Relay Rod Bolt

Power Steering Pump

Pulley

Power Steering Mounting

Bolt

Power Steering Mounting

Nut

Power Cylinder to Relay

Rod Nut

Power Cylinder to Frame

Bracket

Control Valve to Pitman

Arm

Control Valve Clamp

Bolt

Steering Shaft to Gear

Clamp Nut

Chevrolet

70 lb. ft.

Chevelle'

70 lb. ft.

Chevy H

30 lb. ft.

Camaro

68 lb. ft.

Corvette

30 lb. ft.

140 lb. ft.

^ . 35 lb. ft.

1 lb. in.

1 lb. in.

18 lb. ft.

30 lb. ft.

—

—

1 lb. in.

—

18 lb. ft.

30 lb. ft.

—

35 lb. ft.

130 lb. in.

40 lb. ft.

25 lb. in.

—

— •

—

.—

—

—

v —

—

-

—

—

—

—

25 lb. in.

—

—

—

18 lb. ft.

25 lb. ft.

30 lb. ft.

25 lb. ft.

60 lb. ft.

20 lb. ft.

25 lb. ft.

— .

• ' —

, —

—

-

—

, .p-

—

-

45 lb. ft.

30 lb. ft.

45 lb. ft.

20 lb. ft.

35 lb. ft. .

—•

—

—

45 lb. ft.

25 lb. ft.

.

45 lb. ft.

20 lb. ft.

—

CHEVROLET CHASSIS SERVICE MANUAL