relay CHEVROLET CAMARO 1967 1.G Chassis Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 474 of 659

STEERING 9-34

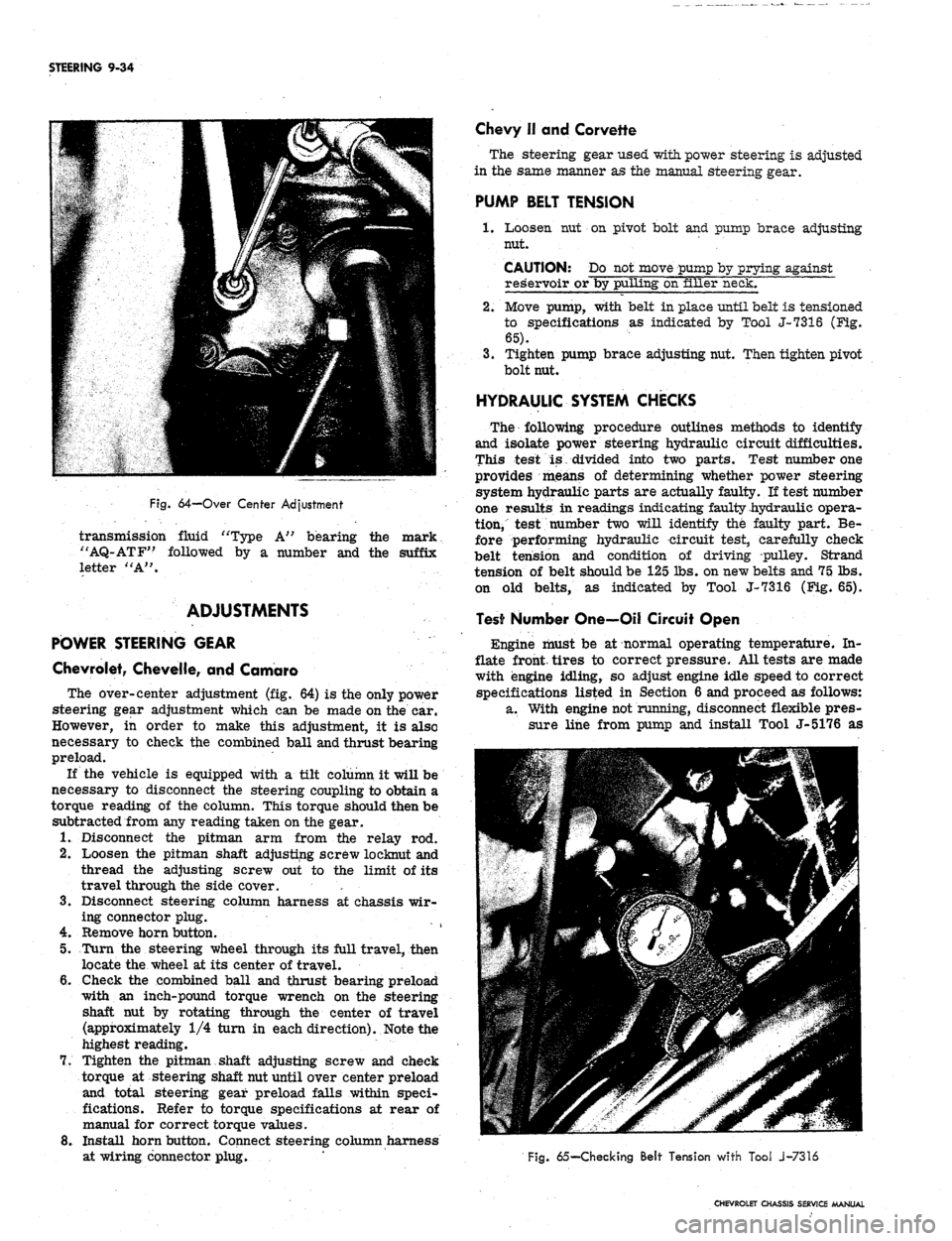

Fig.

64-Over Center Adjustment

transmission fluid "Type A" bearing the mark

"AQ-ATF" followed by a number and the suffix

letter "A".

ADJUSTMENTS

POWER STEERING GEAR

Chevrolet, Chevelle, and Camaro

The over-center adjustment (fig. 64) is the only power

steering gear adjustment which can be made on the car.

However, in order to make this adjustment, it is also

necessary to check the combined ball and thrust bearing

preload.

If the vehicle is equipped with a tilt column it will be

necessary to disconnect the steering coupling to obtain a

torque reading of the column. This torque should then be

subtracted from any reading taken on the gear.

1.

Disconnect the pitman arm from the relay rod.

2.

Loosen the pitman shaft adjusting screw loeknut and

thread the adjusting screw out to the limit of its

travel through the side cover. '. •

3.

Disconnect steering column harness at chassis wir-

ing connector plug.

4.

Remove horn button.

5.

Turn the steering wheel through its full travel, then

locate the wheel at its center of travel.

6. Gheck the combined ball and thrust bearing preload

with an inch-pound torque wrench on the steering

shaft nut by rotating through the center of travel

(approximately 1/4 turn in each direction). Note the

highest reading.

7.

Tighten the pitman shaft adjusting screw and check

torque at steering shaft nut until over center preload

and total steering gear preload falls within speci-

fications. Refer to torque specifications at rear of

manual for correct torque values.

8. Install horn button. Connect steering column harness

at wiring connector plug.

Chevy II and Corvette

The steering gear used with power steering is adjusted

in the same manner as the manual steering gear.

PUMP BELT TENSION

1.

Loosen nut on pivot bolt and pump brace adjusting

nut.

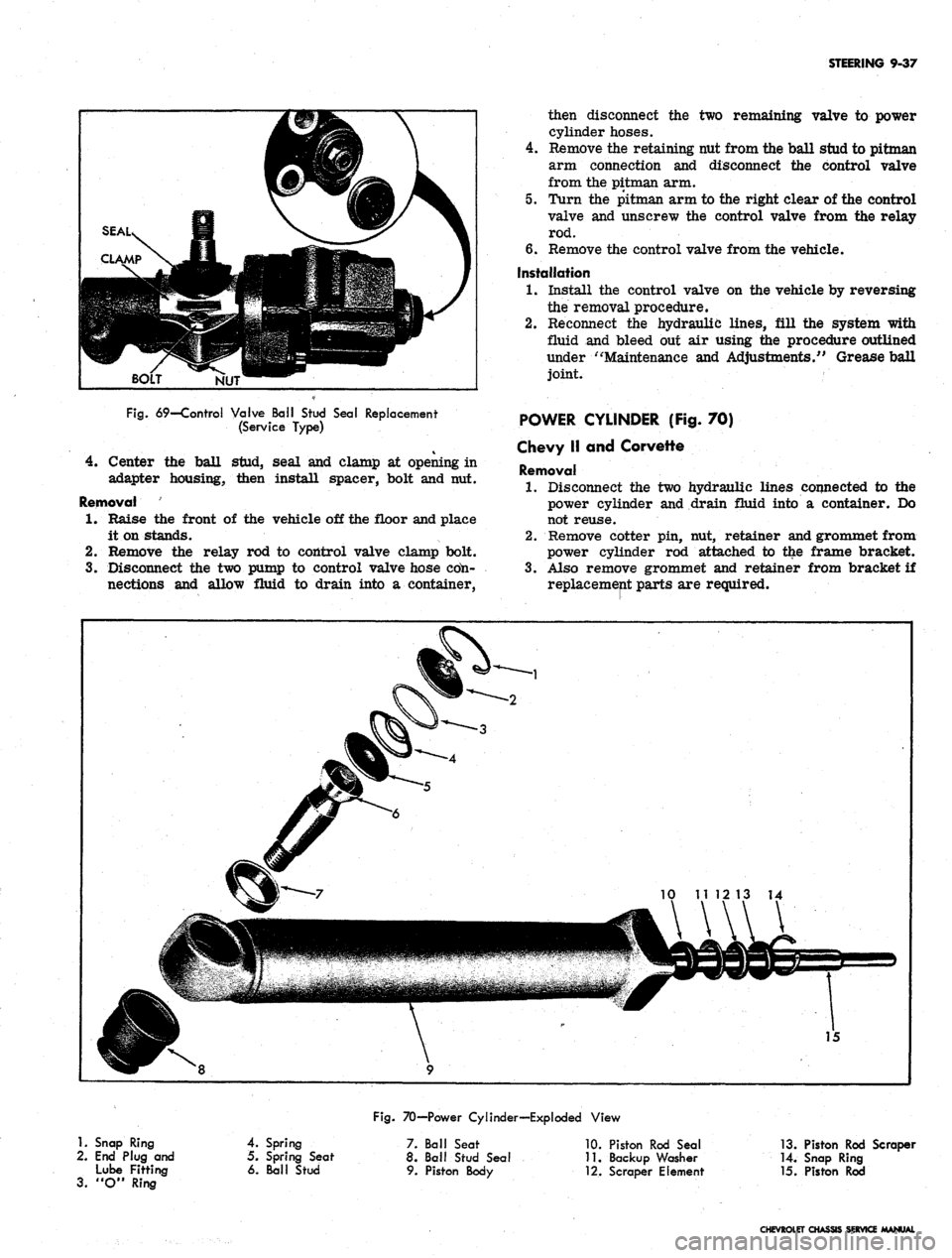

CAUTION: Do not move pump by prying against

reservoir or by pulling on filler neck.

2.

Move pump, with belt in place until belt is tensioned

to specifications as indicated by Tool J-7316 (Fig-.

65).

3.

Tighten pump brace adjusting nut. Then tighten pivot

bolt nut.

HYDRAULIC SYSTEM CHECKS

The following procedure outlines methods to identify

and isolate power steering hydraulic circuit difficulties.

This test is divided into two parts. Test number one

provides means of determining whether power steering

system hydraulic parts are actually faulty. If test number

one results in readings indicating faulty hydraulic opera-

tion, test number two will identify the faulty part. Be-

fore performing hydraulic circuit test, carefully check

belt tension and condition of driving pulley. Strand

tension of belt should be 125 lbs. on new belts and 75 lbs.

on old belts, as indicated by Tool J-7316 (Fig. 65).

Test Number One—Oil Circuit Open

Engine must be at normal operating temperature. In-

flate front, tires to correct pressure. All tests are made

with engine idling, so adjust engine idle speed to correct

specifications listed in Section 6 and proceed as follows:

a. With engine not running, disconnect flexible pres-

sure line from pump and install Tool J-5176 as

Fig.

65— Checking Belt Tension with Tool J-7316

CHEVROLET CHASSIS SERVICE MANUAL

Page 477 of 659

STEERING 9-37

NUT

Fig.

69—Control Valve Ball Stud Seal Replacement

(Service Type)

4.

Center the ball stud, seal and clamp at opening in

adapter housing, then install spacer, bolt and nut.

Removal

1.

Raise the front of the vehicle off the floor and place

it on stands.

2.

Remove the relay rod to control valve clamp bolt.

3.

Disconnect the two pump to control valve hose cdn-

nections and allow fluid to drain into a container,

then disconnect the two remaining valve to power

cylinder hoses.

4.

Remove the retaining nut from the ball stud to pitman

arm connection and disconnect the control valve

from the pitman arm.

5. Turn the pitman arm to the right clear of the control

valve and unscrew the control valve from the relay

rod.

6. Remove the control valve from the vehicle.

Installation

1.

Install the control valve on the vehicle by reversing

the removal procedure.

2.

Reconnect the hydraulic lines, fill the system with

fluid and bleed out air using the procedure outlined

under "Maintenance and Adjustments/' Grease ball

joint.

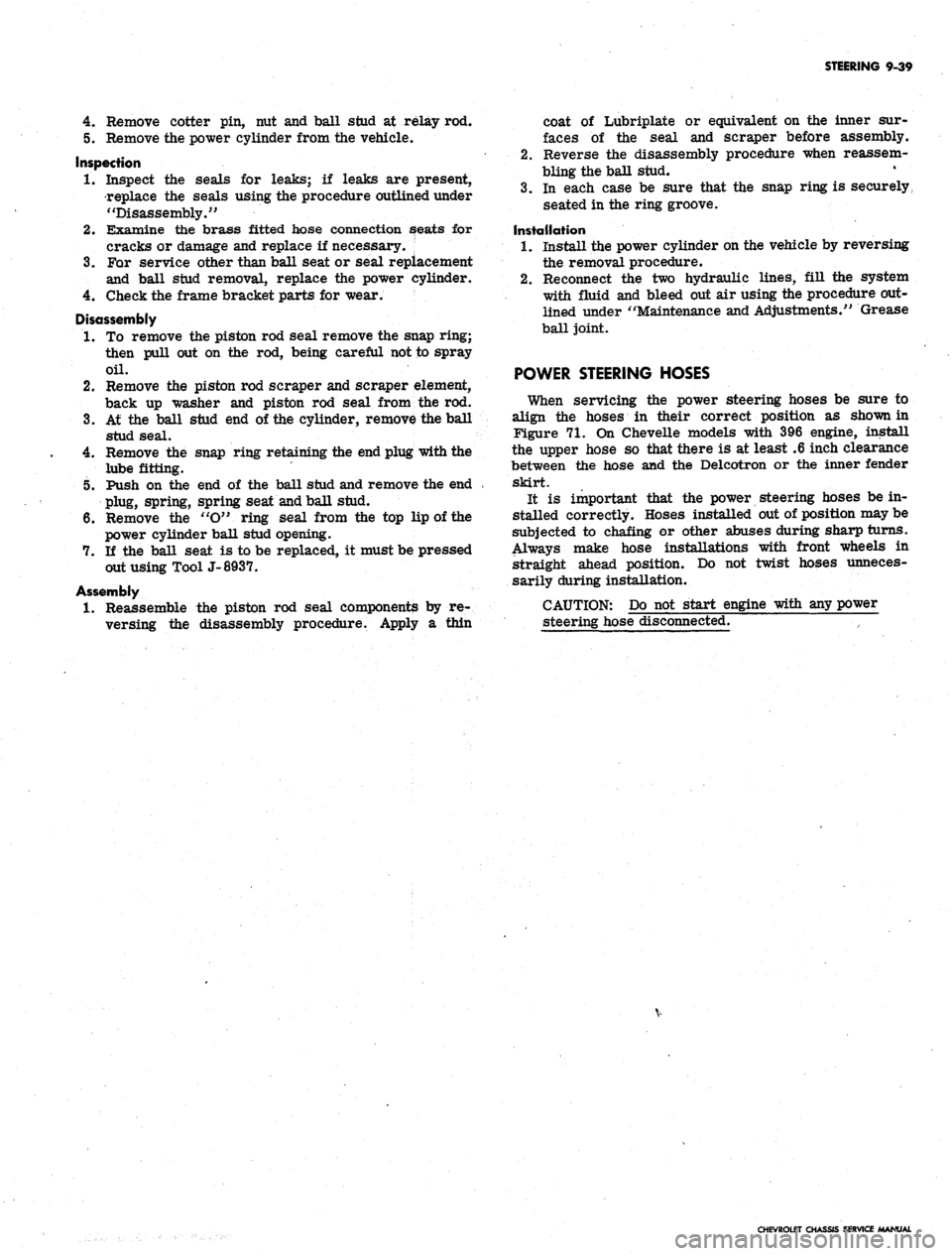

POWER CYLINDER (Fig. 70)

Chevy II and Corvette

Removal

1.

Disconnect the two hydraulic lines connected to the

power cylinder and drain fluid into a container. Do

not reuse.

2.

Remove cotter pin, nut, retainer and grommet from

power cylinder rod attached to the frame bracket.

3.

Also remove grommet and retainer from bracket if

replacement parts are required.

1.

Snap Ring

2.

End Plug and

Lube Fitting

3.

"O" Ring

Fig.

70—Power Cylinder—Exploded View

4.

Spring

5. Spring Seat

6. Ball Stud

7. Ball Seat

8. Ball Stud Seal

9. Piston Body

10.

Piston Rod Seal

11.

Backup Washer

•12.

Scraper Element

13.

Piston Rod Scraper

14.

Snap Ring

15.

Piston Rod

CHEVROLET CHASSIS SERVICE MANUAL

Page 479 of 659

STEERING 9-39

4.

Remove cotter pin, nut and ball stud at relay rod.

5. Remove the power cylinder from the vehicle.

Inspection

1.

Inspect the seals for leaks; if leaks are present,

replace the seals using the procedure outlined under

"Disassembly."

2.

Examine the brass fitted hose connection seats for

cracks or damage and replace if necessary.

3.

For service other than ball seat or seal replacement

and ball stud removal, replace the power cylinder.

4.

Check the frame bracket parts for wear.

Disassembly

1.

To remove the piston rod seal remove the snap ring;

then pull out on the rod, being careful not to spray

oil.

2.

Remove the piston rod scraper and scraper element,

back up washer and piston rod seal from the rod.

3.

At the ball stud end of the cylinder, remove the ball

stud seal.

4.

Remove the snap ring retaining the end plug with the

lube fitting.

5. Push on the end of the ball stud and remove the end

plug, spring, spring seat and ball stud.

6. Remove the "O" ring seal from the top lip of the

power cylinder ball stud opening.

7. If the ball seat is to be replaced, it must be pressed

out using Tool J-8937.

Assembly

1.

Reassemble the piston rod seal components by re-

versing the disassembly procedure. Apply a thin

coat of Lubriplate or equivalent on the inner sur-

faces of the seal and scraper before assembly.

2.

Reverse the disassembly procedure when reassem-

bling the ball stud.

3.

In each case be sure that the snap ring is securely,

seated in the ring groove.

Installation

1.

Install the power cylinder on the vehicle by reversing

the removal procedure.

2.

Reconnect the two hydraulic lines, fill the system

with fluid and bleed out air using the procedure out-

lined under "Maintenance and Adjustments." Grease

ball joint.

POWER STEERING HOSES

When servicing the power steering hoses be sure to

align the hoses in their correct position as shown in

Figure 71. On Chevelle models with 396 engine, install

the upper hose so that there is at least .6 inch clearance

between the hose and the Delcotron or the inner fender

skirt.

It is important that the power steering hoses be in-

stalled correctly. Hoses installed out of position may be

subjected to chafing or other abuses during sharp turns.

Always make hose installations with front wheels in

straight ahead position. Do not twist hoses unneces-

sarily during installation.

CAUTION: Do not start engine with any power

steering hose disconnected.

CHEVROLET CHASSIS SERVICE MANUAL

Page 501 of 659

CHASSIS SHEET METAL 11-14

location is shimmed; thus keeping the fender mount-

ing bolts from crushing in the fender mounting

flange.

If shimming is done without the fenders being disas-

asembled, it is suggested that fender mounting bolts

rearward of radiator support be loosened while shims

are inserted and sheet metal fit is checked. Tighten

shimmed mounting bolts first, then all others.

COMPONENT PART REPLACEMENT

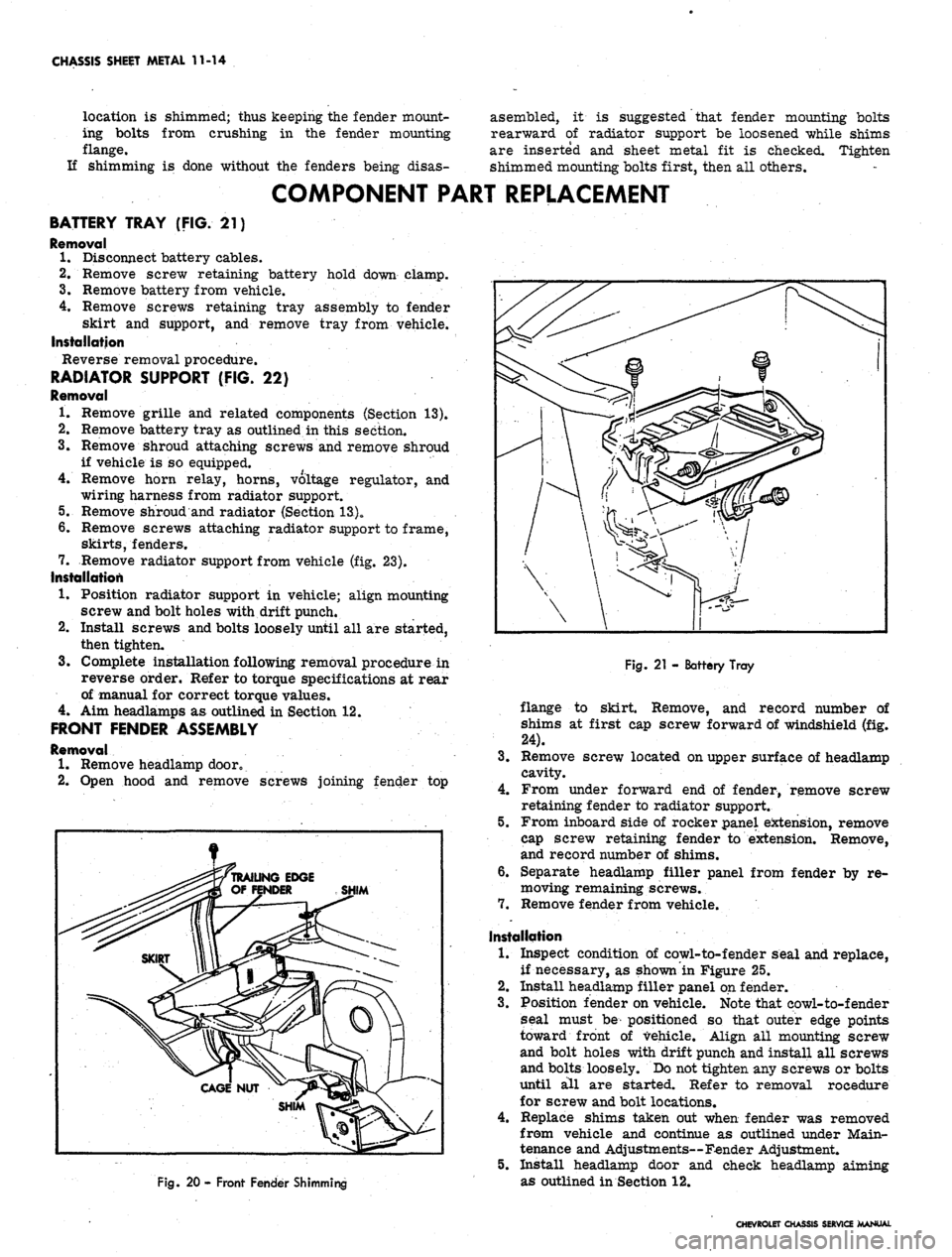

BATTERY TRAY (FIG. 21)

Removal

1.

Disconnect battery cables.

2.

Remove screw retaining battery hold down clamp.

3.

Remove battery from vehicle.

4.

Remove screws retaining tray assembly to fender

skirt and support, and remove tray from vehicle.

Installation

Reverse removal procedure.

RADIATOR SUPPORT (FIG. 22)

Removal

1.

Remove grille and related components (Section 13).

Remove battery tray as outlined in this section.

Remove shroud attaching screws and remove shroud

if vehicle is so equipped.

Remove horn relay, horns, voltage regulator, and

wiring harness from radiator support.

Remove shroud and radiator (Section 13)o

Remove screws attaching radiator support to frame,

skirts,

fenders.

Remove radiator support from vehicle (fig. 23).

Installation

1.

Position radiator support in vehicle; align mounting

screw and bolt holes with drift punch.

Install screws and bolts loosely until all are started,

then tighten.

3.

Complete installation following removal procedure in

reverse order. Refer to torque specifications at rear

of manual for correct torque values.

4.

Aim headlamps as outlined in Section 12.

FRONT FENDER ASSEMBLY

Removal

1*

Remove headlamp dooro

2.

Open hood and remove screws joining fender top

2.

Fig. 20 - Front Fender Shimming

Fig.

21 - Battery Tray

flange to skirt. Remove, and record number of

shims at first cap screw forward of windshield (fig.

24).

3.

Remove screw located on upper surface of headlamp

cavity.

4.

From under forward end of fender, remove screw

retaining fender to radiator support.

5.

From inboard side of rocker panel extension, remove

cap screw retaining fender to extension. Remove,

and record number of shims.

6. Separate headlamp filler panel from fender by re-

moving remaining screws.

7.

Remove fender from vehicle.

Installation

1.

Inspect condition of cowl-to-fender seal and replace,

if necessary, as shown in Figure 25.

2.

Install headlamp filler panel on fender.

3.

Position fender on vehicle. Note that eowl-to-fender

seal must be positioned so that outer edge points

toward front of vehicle. Align all mounting screw

and bolt holes with drift punch and install all screws

and bolts loosely. Do not tighten any screws or bolts

until all are started. Refer to removal rocedure

for screw and bolt locations.

4.

Replace shims taken out when fender was removed

from vehicle and continue as outlined under Main-

tenance and Adjustments—Fender Adjustment.

5.

Install headlamp door and cheek headlamp aiming

as outlined in Section 12.

CHEVROLET CHASSIS SERVICE MANUAL

Page 507 of 659

CHASSIS SHEET METAL 11-20

GENERAL DESCRIPTION

The Camaro sheet metal components are much the

same as other Chevrolet passenger models as shown in

Figure 32. The front end design is such that servicing

of the fenders and skirts is most efficiently performed

by removing the fender and skirt as an assembly. Refer

to Section 14 for bumper service procedures, Section 13

for radiator and grille, and Section 1A for air condition-

ing components.

MAINTENANCE AND ADJUSTMENTS

HOOD ADJUSTMENT

The Camaro hood is adjusted in the conventional man-

ner, by adjustment of the hood bumpers and hinges. The

two hood bumpers are located on each side at the top of

the radiator support. Do not attempt hood latch adjust-

ments until the hinges and bumpers are correctly ad-

justed. Latch adjustments are made so that effort re-

quired to open and close the hood is reasonable, and

hood alignment obtained by hinge and bumper adjust-

ment is maintained when the hood is closed. Note that

the hood latch is not designed to correct basic hood mis-

alignment.

HOOD HINGE (Fig. 33)

NOTE: The body mounted portion of the hood

hinges are slotted to provide up and down move-

ment. The hood mounted end is slotted to pro-

vide forward and rearward movement.

1.

Scribe a. line around the entire. hinge plate to be

repositioned.

2.

Loosen the appropriate screws and shift the position

of the hood into correct alignment using the scribe

marks to check amount of movement. Check align-

ment by tightening screws and closing the hood.

HOOD BUMPERS

Adjust hood bumpers so that hood top surface is flush

with fender and header panel top surfaces. See Figure

34 for correct sheet metal adjustment dimensions.

HOOD CATCH AND LOCK (Fig. 35)

Adjust hood lock bolt so that top surface of hood is

flush with top surface'of header panel. The distance that

the lock bolt protrudes out of the lock plate should be

adjusted so that the hood bumpers are slightly com-

pressed by the fully latched hood, and effort required

to release the hood catch is reasonable. Close the hood

and insure catch engages securely.

FENDERS

Fenders are adjustable with shims at the cowl and

rocker panel. To add or remove shims, loosen bolts

Fig. 33 - Hood Hinge - Camaro

at shim locations (fig. 36) and carefully apply force with

pry bar to provide clearance for shim removal or in-

stallation.

SHEET METAL

For proper operation of doors and hood, and for pre-

sentable appearance, adjust front sheet metal to the di-

mensions shown in Figure 34.

COMPONENT PART REPLACEMENT

NOTE: When replacing sheet metal compo-

nents on Camaro, note position and attachment

of all seals and dust shielding and replace if

necessary.

BATTERY TRAY

Removal

1.

Disconnect battery cables and remove battery from

vehicle.

2.

Remove screws securing battery tray to fender skirt

and radiator support.

3.

Remove battery tray from vehicle.

Installation

Install battery tray following removal procedure in

reverse order.

RADIATOR SUPPORT

Removal

1.

Raise hood, disconnect battery cables, and remove

battery.

2.

Remove front bumper (Section 14).

3.

Remove grille and related components (Section 13).

4.

Disconnect horns, horn relay, voltage regulator,

CHEVROLET CHASSIS SERVICE MANUAL

Page 514 of 659

ELECTRICAL-BODY AND CHASSIS 12-2

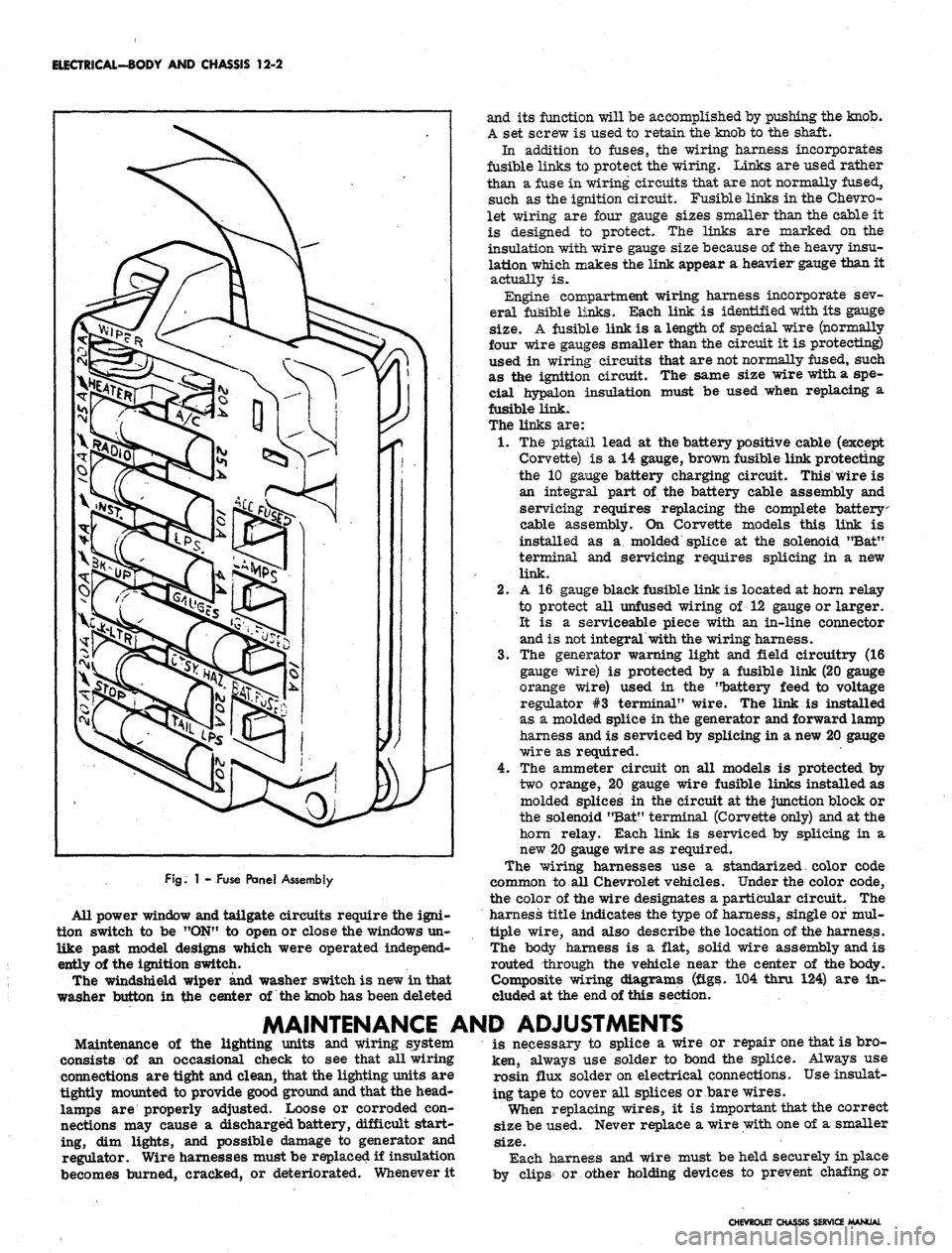

FJg.

1 - Fuse Panel Assembly

All power window and tailgate circuits require the igni-

tion switch to be "ON" to open or close the windows un-

like past model designs which were operated independ-

ently of the ignition switch.

The windshield wiper and washer switch is new in that

washer button in the center of the knob has been deleted

and its function will be accomplished by pushing the knob.

A set screw is used to retain the knob to the shaft.

In addition to fuses, the wiring harness incorporates

fusible links to protect the wiring. Links are used rather

than a fuse in wiring circuits that are not normally fused,

such as the ignition circuit. Fusible links in the Chevro-

let wiring are four gauge sizes smaller than the cable it

is designed to protect. The links are marked on the

insulation with wire gauge size because of the heavy insu-

lation which makes the link appear a heavier gauge than it

actually is.

Engine compartment wiring harness incorporate sev-

eral fusible links. Each link is identified with its gauge

size.

A fusible link is a length of special wire (normally

four wire gauges smaller than the circuit it is protecting)

used in wiring circuits that are not normally fused, such

as the ignition circuit. The same size wire with a spe-

cial hypalon insulation must be used when replacing a

fusible link.

The links are:

1.

The pigtail lead at the battery positive cable (except

Corvette) is a 14 gauge, brown fusible link protecting

the 10 gange battery charging circuit. This wire is

an integral part of the battery cable assembly and

servicing requires replacing the complete battery

cable assembly. On Corvette models this link is

installed as a molded splice at the solenoid "Bat"

terminal and servicing requires splicing in a new

link.

2.

A 16 gauge black fusible link is located at horn relay

to protect all unfused wiring of 12 gauge or larger.

It is a serviceable piece with an in-line connector

and is not integral with the wiring harness.

3.

The generator warning light and field circuitry (16

gauge wire) is protected by a fusible link (20 gauge

orange wire) used in the "battery feed to voltage

regulator #3 terminal" wire. The link is installed

as a molded splice in the generator and forward lamp

harness and is serviced by splicing in a new 20 gauge

wire as required.

4.

The ammeter circuit on all models is protected by

two orange, 20 gauge wire fusible links installed as

molded splices in the circuit at the junction block or

the solenoid "Bat" terminal (Corvette only) and at the

horn relay. Each link is serviced by splicing in a

new 20 gauge wire as required.

The wiring harnesses use a standarized. color code

common to all Chevrolet vehicles. Under the color code,

the color of the wire designates a particular circuit. The

harness title indicates the type of harness, single of mul-

tiple wire, and also describe the location of the harness.

The body harness is a flat, solid wire assembly and is

routed through the vehicle near the center of the body.

Composite wiring diagrams (figs. 104 thru 124) are in-

cluded at the end of this section.

MAINTENANCE AND ADJUSTMENTS

Maintenance of the lighting units and wiring system

consists of an occasional check to see that all wiring

connections are tight and clean, that the lighting units are

tightly mounted to provide good ground and that the head-

lamps are properly adjusted. Loose or corroded con-

nections may cause a discharged battery, difficult start-

ing, dim lights, and possible damage to generator and

regulator. Wire harnesses must be replaced if insulation

becomes burned, cracked, or deteriorated. Whenever it

is necessary to splice a wire or repair one that is bro-

ken, always use solder to bond the splice. Always use

rosin flux solder on electrical connections. Use insulat-

ing tape to cover all splices or bare wires.

When replacing wires, it is important that the correct

size be used. Never replace a wire with one of a smaller

size.

Each harness and wire must be held securely in place

by clips or other holding devices to prevent chafing or

CHEVROLET CHASSIS SERVICE MANUAL

Page 560 of 659

ELECTRICAL-BODY

AND CHASSIS 12-48

NOTE:

Screws, nuts and lock washers for re-

assembling cover to wiper are contained in a

service repair package.

6. Remove output gear and shaft assembly, then slide

,

intermediate gear and pinion assembly off shaft.

7. If necessary, remove terminal board and park switch

assembly as follows:

a. Unsolder motor leads from terminals. Coding of

motor leads is not necessary on single-speed

wipers.

b.

Drill out rivets securing terminal board and park

switch ground strap to mounting plate.

NOTE:

Screws, nuts and washers for attaching

a replacement terminal board-park switch as-

sembly are included with the replacement

assembly.

Motor

(Fig. 65)

1.

Follow Steps 1 through 7b under gear box

disassembly.

2.

Remove, motor through bolts, tap motor frame

lightly, and remove motor from mounting plate.

3.

Remove brush spring tension (fig. 68), slide arma-

ture and end plate from motor frame. Pull end

plate from armature.

NOTE:

Thrust plug located between armature

shaft and end plate.

4.

Remove end play adjusting washers from armature,

noting arrangement for proper reinstallation.

INSPECTION

Check and inspect all parts for serviceability, replace

as necessary. All parts can be replaced individually

except motor frame and field, which is serviced as an

assembly. Service kits also provide screws, nuts and

washers to replace gear cpver and terminal board rivets.

ASSEMBLY

Refer to Figure 65 for exploded view of motor and gear

train.

Motor

Reassemble motor using reverse of disassembly

procedures.

NOTE:

Armature end play is controlled by end

play washers. See Figure 69 for proper assem-

bly of end play washers. Lubricate armature

shaft bushings with light machine oil.

Gear Box

1.

Assemble gear box using reverse of disassembly

procedure.

NOTE:

Lubricate gear teeth with Delco Cam

and Ball Bearing lubricant or equivalent. Be

sure cover is properly located over dowel pins

and be sure to reinstall ground strap.

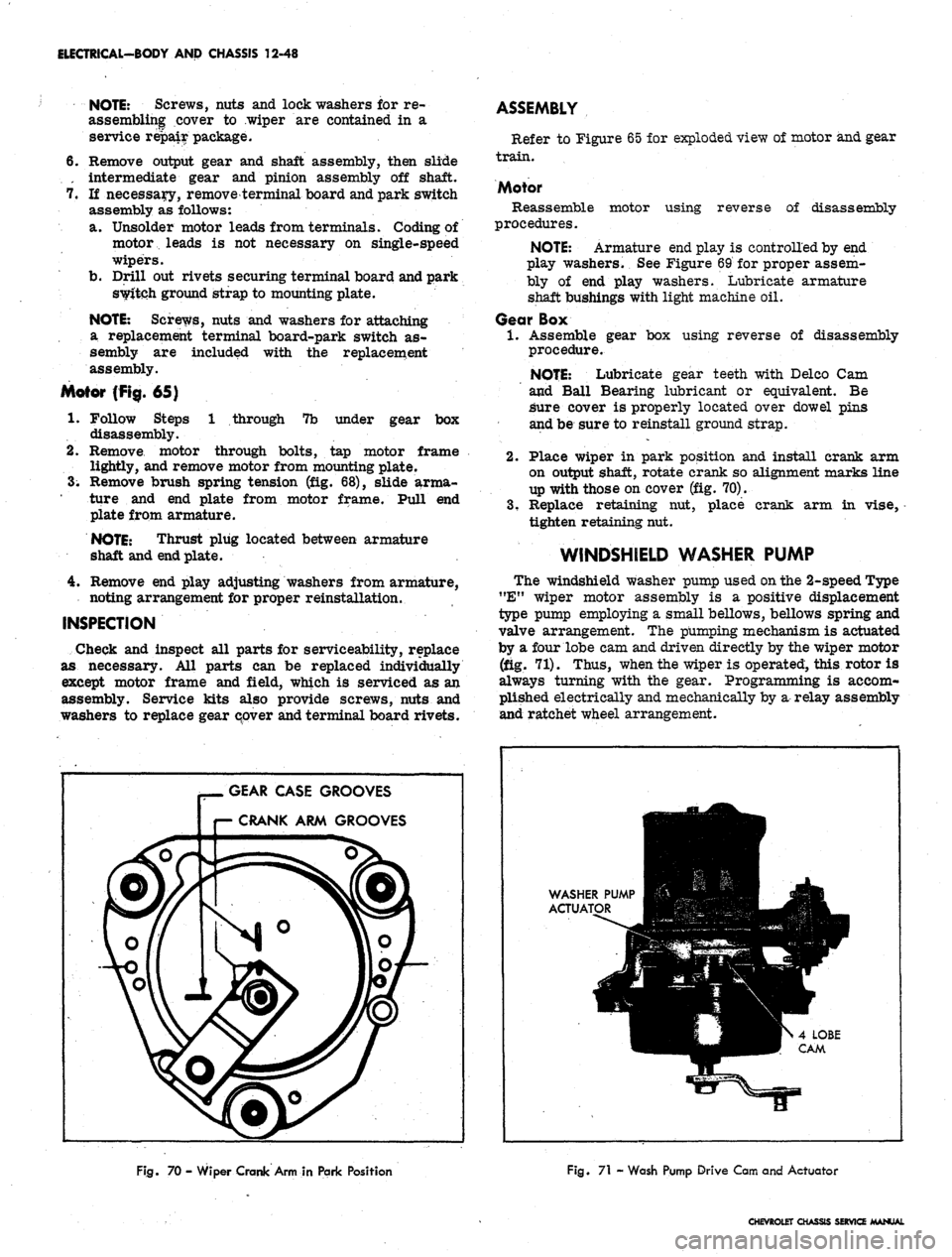

2.

Place wiper in park position and install crank arm

on output shaft, rotate crank so alignment marks line

up with those on cover (fig. 70).

3.

Replace retaining nut, place crank arm in vise,

tighten retaining nut.

WINDSHIELD

WASHER PUMP

The windshield washer pump used on the 2-speed Type

"E"

wiper motor assembly is a positive displacement

type pump employing a small bellows, bellows spring and

valve arrangement. The pumping mechanism is actuated

by a four lobe cam and driven directly by the wiper motor

(fig. 71). Thus, when the wiper is operated, this rotor is

always turning with the gear. Programming is accom-

plished electrically and mechanically by a relay assembly

and ratchet wheel arrangement.

GEAR

CASE GROOVES

r— CRANK ARM GROOVES

WASHER PUMP

Ha

ACTUATOR

IB

•

^^HTS4LOBE

•MMBW

CAM

Fig.

70 - Wiper Crank Arm in Park Position

Fig.

71 - Wash Pump Drive Cam and Actuator

CHEVROLET

CHASSIS SERVICE MANUAL

Page 561 of 659

ELECTRICAL-BODY

AND

CHASSIS

12-49

BELLOWS

AND

SPRING

HOUSING

COIL

AND

POLE

ASSEMBLY

VALVE

ASSEMBLY

RATCHET

PAWL

ASSEMBLY

RATCHET

WHEEL

ACTUATOR

PLUNGER

ARM

ACTUATOR

PIN

HOLDING CONTACTS

OPEN

RAMP TANG

PLUNGER

ARM

Fig.

73 -

Releasing

Pump from

Lockout Position

Fig.

72 -

Washer

Pump

Mechanism

REMOVAL AND INSTALLATION

Removal of the washer pump from the wiper motor

consists of:

1.

Disconnect wiring harness and washer hoses from

washer.

2.

Remove the two pump-to-wiper retaining screws and

remove washer from wiper (fig. 66).

3.

Reverse removal procedure to install assembly.

DISASSEMBLY-ASSEMBLY

Refer to Figure

1.

Remove washer pump cover.

2.

Relay

a. To remove relay unsolder coil leads from

terminals.

NOTE:

No coil polarity is necessary when re-

soldering coil leads.

b.

Remove coil retainer clip and slip coil assembly

out of mounting bracket.

3.

Ratchet Pawl

a. To remove ratchet pawl disengage spring from

ratchet pawl and slide ratchet pawl from shaft.

CAUTION: Be sure spring is properly assem-

bled before replacing washer pump cover.

Terminal Board

a. Remove terminal board attaching screws, ratchet

dog and board from washer base.

Ratchet Wheel

a. Remove lock ring from shaft.

b.

Slide ratchet wheel from shaft.

Valve Assembly

a. To remove valve assembly remove screws that

secure valve assembly to bellows housing.

CAUTION: It may be necessary to carefully

pry bellows lip out of the valve body groove.

Bellows

a. To remove bellows first remove valve assembly.

b.

Manually operate pump clockwise to release pump

from 'lock-out" position (fig, 73).

c. Hold bellows plunger arm from moving, then push

in against bottom of bellows with thumb and twist

bellows spring from housing.

Actuator Pin

a. Remove actuator pin retaining spring and slide

pin from washer base.

Reverse disassembly procedure to assemble washer.

DEPRESSED PARK 2-SPEED WIPER

CHEVROLET

GENERAL DESCRIPTION

The Type "C" two speed electric wiper assembly (fig.

74) incorporates a depressed park type (blades park

against windshield lower molding when the motor is

turned off) motor and gear train. The wiper has a com-

pound wound 12 volt motor and a gear box section con-

taining the gear mechanism and relay control. The motor

armature is fitted with a worm gear which drives the

main gear assembly and crank arm.

The relay control, consisting of a relay coil, relay

armature and switch assembly, is located in the gear box

section bid controls the starting and stopping of the wiper

through a latching mechanism (fig. 75).

An electric washer pump is mounted on the gear box

section of the wiper and is driven by the wiper unit gear

assembly (fig* 75).

The overhaul procedures for the wiper are broken down

into three major areas: The motor section, gear box

section and washer pump section. Each section maybe

serviced independently of the other.

CHEVROLET CHASSIS SEftVKX

Page 562 of 659

ELECTRICAL-BODY AND CHASSIS 12-50

SERVICE OPERATIONS

MOTOR SECTION

DISASSEMBLY

NOTE:

Motor section

may be

disassembled

independently

of

the gear box.

Brush Plate and Circuit Breaker Removal

1.

Scribe

a

reference line along the side of the casting

and end cap to insure proper re-assembly.

2.

Remove the two motor thru bolts.

3.

Feed exposed excess length

of

motor leads thru the

casting grommet

and

carefully back

the

case

and

field assembly plus

the

armature away from

the

casting (fig. 76).

NOTE:

It may be

necessary

to

remove

the

armature end play adjusting screw and insert

a

rod thru

the

opening

in

order to apply pressure

against the end of the armature.

4.

Unsolder

the

black lead from circuit breaker

(fig.

77).

5.

Straighten

out the 4

tabs that secure the brush plate

to the field coil retainers (fig. 77).

CAUTION:

Be

careful

not to

break

any of

the

retainer tabs.

6. Install

"U"

shaped brush retainer clip over brush

holder that has brush lead attached to circuit breaker

(fig. 78).

7.

Holding

the

opposite brush from that retained in Step

6, carefully lift

the

brush holder

off the

mounting

tabs

far

enough

to

clear

the

armature commutator

(fig. 78).

8. Allow

the

brush, held

in

Step

7, to

move out

of its

holder. Remove

the

brush spring

and

lift the brush

holder

off

the armature shaft.

Armature Removal

1.

Follow Steps

1

thru

8

under brush plate removal.

2.

Lift armature out

of

case and field assembly.

3.

Remove thrust ball from

end of

armature shaft

as

PUMP

ASSEMBLY

CAM SLOT

DRIVE PLATE

AND

ASSEMBLY

RELAY SWITCH

ASSEMBLY

WASHER PUMP

DRIVE

PIN

Fig.

75

-

Wiper and Washer

Pump

Mechanism

required and save

for

reassembly.

NOTE: Thrust ball

may be

easily removed

with

a

magnet.

MOUNTING

GROMMET

WASHER PUMP COVER

RETAINING RING

STAKE MARKS -

CASE

TO

FIELD

LAMINA

(4

PLACES)

Fig. 74 - Depressed Park 2-Speed Wiper

Fig. 76 - Wiper Motor Separation

CHEVROLET CHASSIS SERVICE MANUAL

Page 563 of 659

ELECTRICAL-BODY

AND

CHASSIS

12-51

7^5

CUT MOTOR LEADS

GENERALAREA

FOR

in|i

BRUSH PLATE

ASSEMBIYI^^H

RETAINER TAB (4)__J^^H

BLACK

LEAD

TO §HH

CIRCUIT BREAKER»^^—

CIRCUIT

F^H^^^^^B

BREAKER)

^^SH^P

IN

THIS

m

•I

i

ii

ii ii H^MWii^A'

I^BRT^i"

BRUSH

•^^k RETAINER CLIP

•

SPUCENOTES:

•

1-SOLID

BLACK

TO

•

SHUNT FIELD COIL

5

2-SERIES

FIELD COIL

I

TO

BLACK WITH PINK

H STRIPE LEAD

w

Fig.

77

-

Circuit Breaker

Case and Field Assembly Removal

1.

Remove brush plate and armature.

2.

The end

case

and

field assembly

is

serviced

as

a

DRIVE PLATE

&*

ASSEMBLY

DRIVE PAWL

IN

PARK POSITION

IN

RELAY SWITCH SLOT

RELAY SWITCH ASSEMBLY

Fig.

79-

Drive Pawl

in

Full Park Position

unit.

To

free

the

field

and

case assembly,

cut the

solid black and black with pink stripe leads

in a

lo-

cation convenient

for

splicing

-

preferably near

the

wiper terminal board. Refer to Figure

76.

Remove steel thrust plate and rubber disc from case

bearing

as

required.

DRIVE

PAWL

ENGAGING

LATCH

ARM

Fig.

78

-

Removing Brush Holder

Fig.

80

-

Relay Assembly

CHEVROLET

CHASSIS SERVICE MANUAL