CHEVROLET CAMARO 1982 Repair Guide

Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 41 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 41

1. Determine the rear view mirror suppor

t position on the windshield. Support is

to be located at the center of the glass 271/8 in. (69cm) from the base of the

glass to the base of the support.

2. Mark the location on the outside of the glass with wax pencil or crayon.

Make a larger diameter circle around t he mirror support circle on the outside

of the glass surface.

3. On the inside of the glass surface, clean the large circle with a paper towel

and domestic scouring cleanser, gla ss cleaning solution or polishing

compound. Rub until the area is comple tely clean and dry. When dry, clean

the area with an alcohol saturated paper towel to remove any traces of

scouring powder or cleaning solution from this area.

4. With a piece of fine grit (No. 320 or No. 360) emery cloth or sandpaper, sand

the bonding surface of the new rear view mirror support or factory installed

support. If original rear view mirror support is to be reused, all traces of the

factory installed adhesive must be re moved prior to reinstallation.

5. Wipe the sanded mirror support with a clean paper towel saturated with alcohol and allow it to dry.

6. Follow the directions on the manufac turer's kit to prepare the rear view

mirror support prior to inst allation on the glass.

7. Properly position the support to it s premarked location, with rounded end

pointed upward, press the support agai nst the glass for 30-60 seconds,

exerting steady pressure against the gla ss. After five minutes, any excess

adhesive may be removed with an alcohol moistened paper towel or glass

cleaning solution.

8. Install the mirror.

SEATS

REMOVAL & INSTALLATION

1. Operate the seat to the full-forwar d position. If a six-way power seat is

operable, operate the seat to the full-forward and up positions. Where

necessary to gain access to the adjuste r-to-floor pan attaching nuts, remove

the adjuster rear foot covers and/or carpet retainers.

2. Remove the track covers where nec essary; then remove the adjuster-to-

floor pan rear attaching nuts. Operate t he seat to the full-rearward position.

Remove the adjuster front foot covers ; then remove the adjuster-to-floor pan

front attaching nuts.

3. Remove the seat assembly from the car.

4. Check that both seat adjusters ar e parallel and in phase with each other.

5. Install the adjuster-to- floor pan attaching nuts by moving the seat forward

and rearward and torque nuts to 15-21 ft. lbs. (20-28 Nm).

6. Check the operation of the seat a ssembly to full limits of travel.

Page 42 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 42

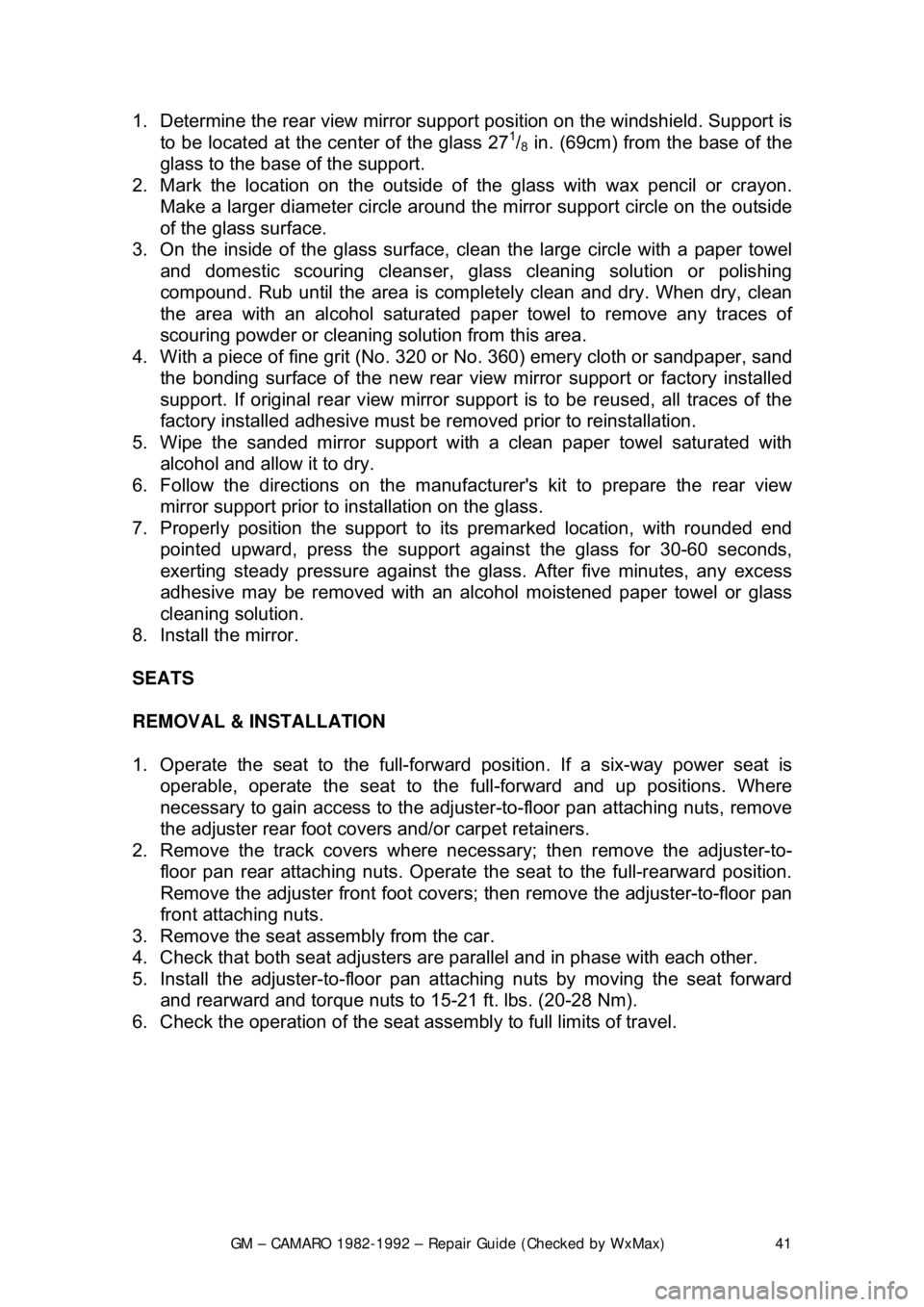

SEAT BELT SYSTEM

REMOVAL & INSTALLATION

Fig. 1: Front seat belt - coupe

Page 43 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 43

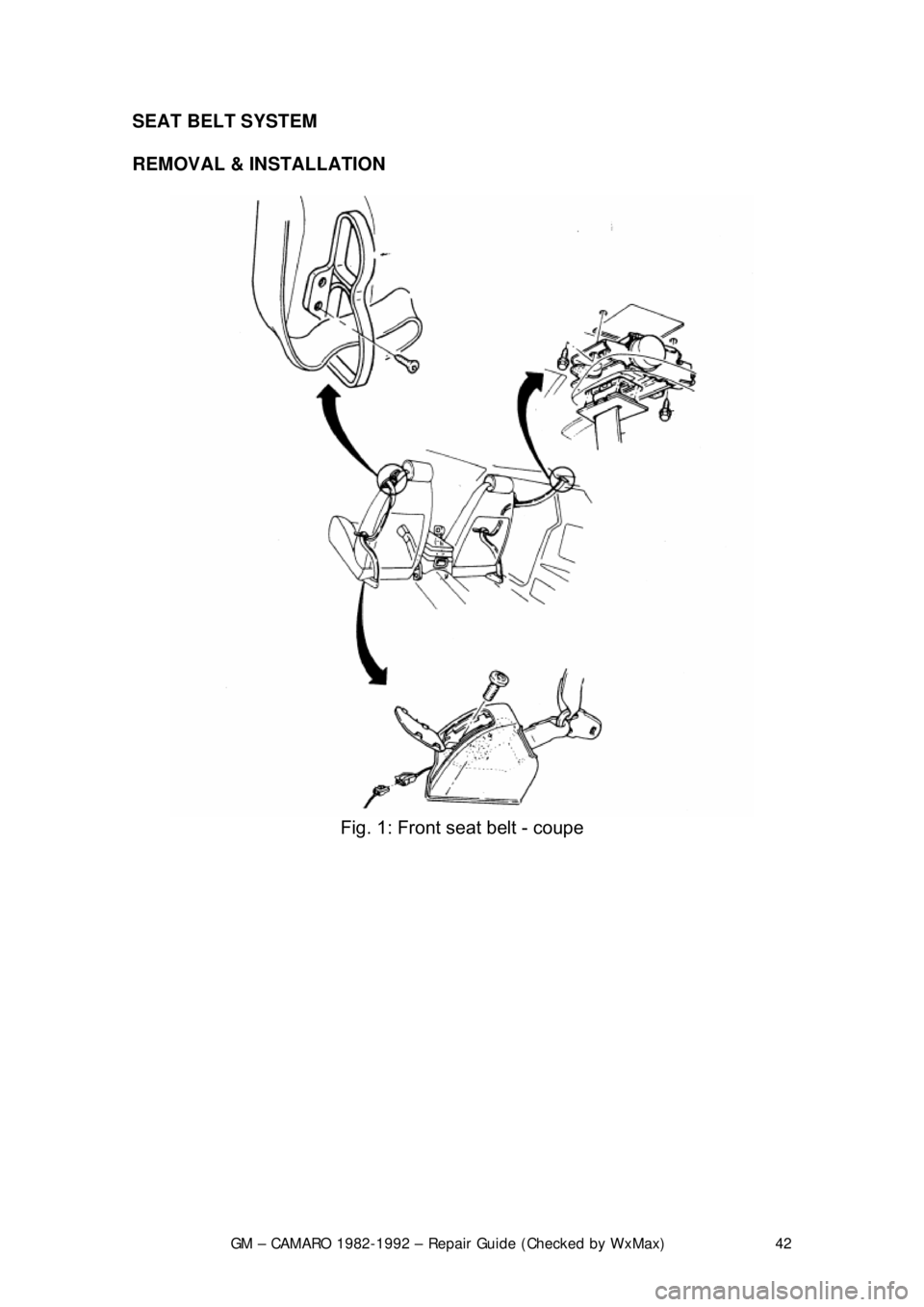

Fig. 2: Rear seat belt - coupe

Fig. 3: Front seat belt - convertible

Page 44 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 44

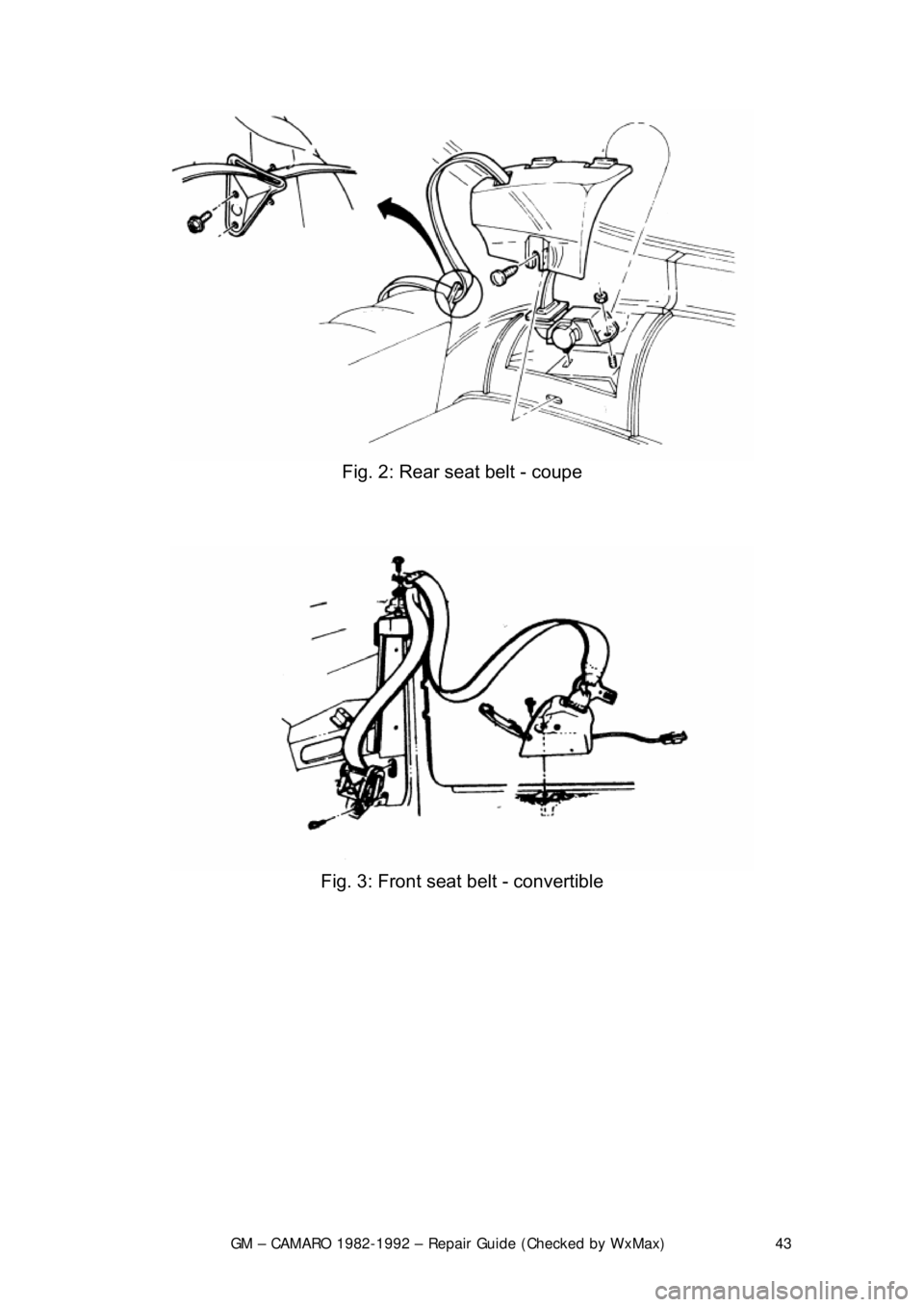

Fig. 4: Rear seat belt - convertible

Page 45 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 45

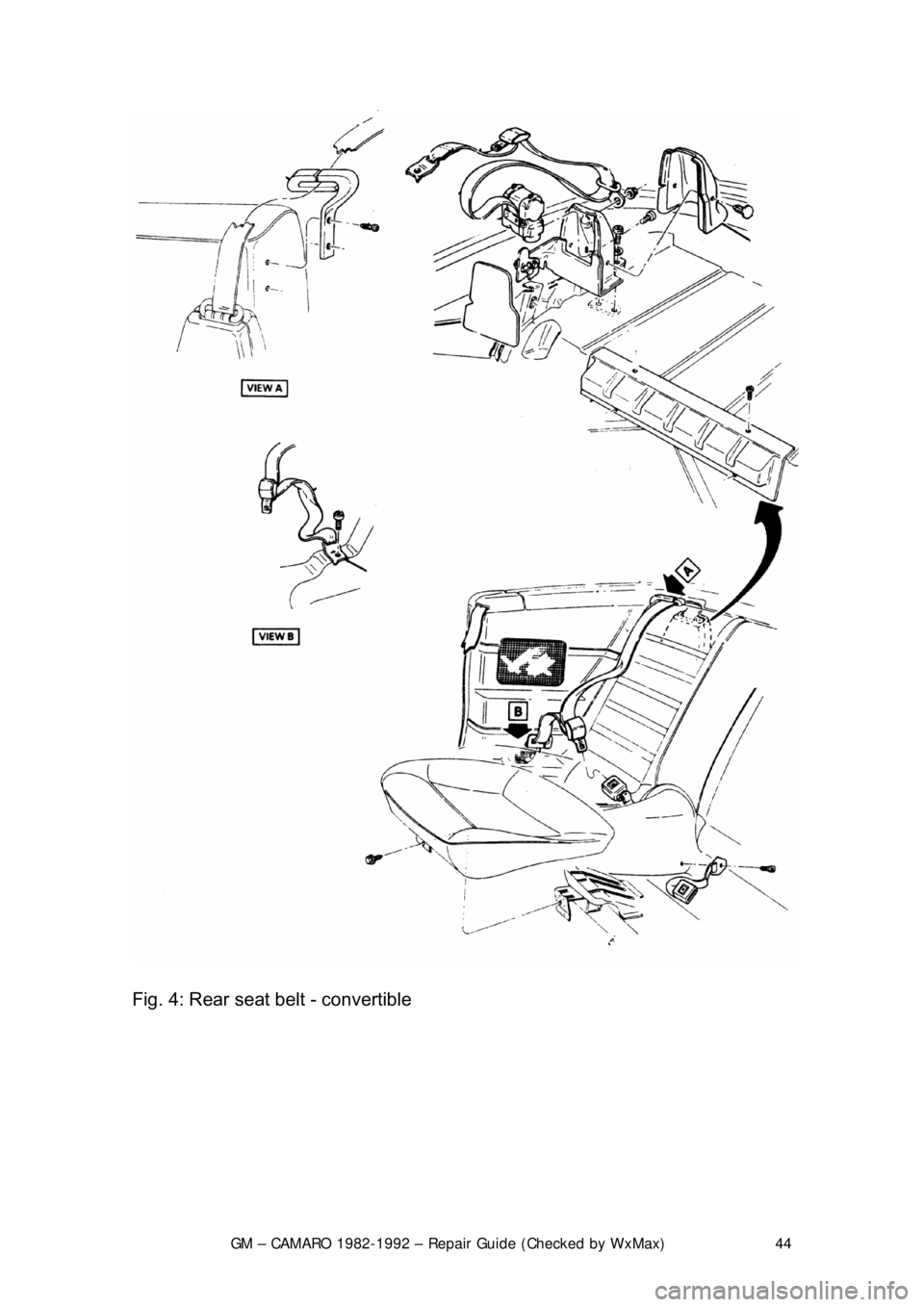

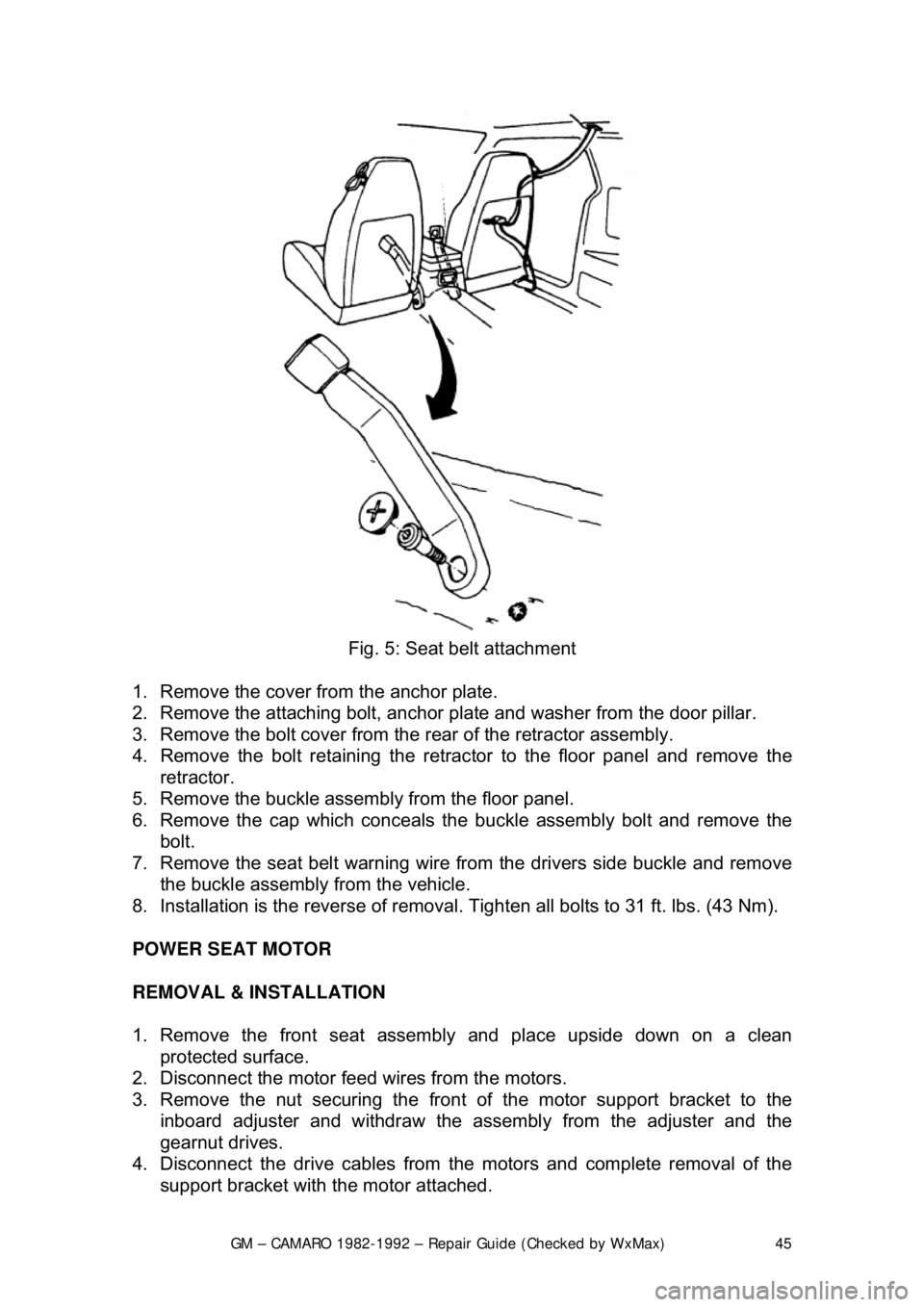

Fig. 5: Seat belt attachment

1. Remove the cover from the anchor plate.

2. Remove the attaching bolt, anchor pl ate and washer from the door pillar.

3. Remove the bolt cover from the rear of the retractor assembly.

4. Remove the bolt retaining the retrac tor to the floor panel and remove the

retractor.

5. Remove the buckle assemb ly from the floor panel.

6. Remove the cap which conceals t he buckle assembly bolt and remove the

bolt.

7. Remove the seat belt warning wire from the drivers side buckle and remove

the buckle assembly from the vehicle.

8. Installation is the reverse of removal. Tighten all bolts to 31 ft. lbs. (43 Nm).

POWER SEAT MOTOR

REMOVAL & INSTALLATION

1. Remove the front seat assemb ly and place upside down on a clean

protected surface.

2. Disconnect the motor feed wires from the motors.

3. Remove the nut securing the front of the motor support bracket to the

inboard adjuster and withdraw the asse mbly from the adjuster and the

gearnut drives.

4. Disconnect the drive cables from t he motors and complete removal of the

support bracket with the motor attached.

Page 46 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 46

5. Grind off the peened ov

er end(s) of the grommet assembly securing the

motor to the support and separate the moto r(s) as required from the support.

To install:

6. Drill out the top end of the grommet assembly using a

3/16 in. (5mm) drill.

7. Install the grommet assembly to the motor support bracket and secure the

motor to the grommet using

3/16 in. (5mm) rivet.

8. Install the support bra cket with the motor attached and connect the drive

cables to the motors.

9. Install the support bracket nuts secu ring the front of the motor support

bracket to the inboard adjuster.

10. Connect the motor feed wires to the motors.

11. Install the front seat assembly.

Page 47 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 47

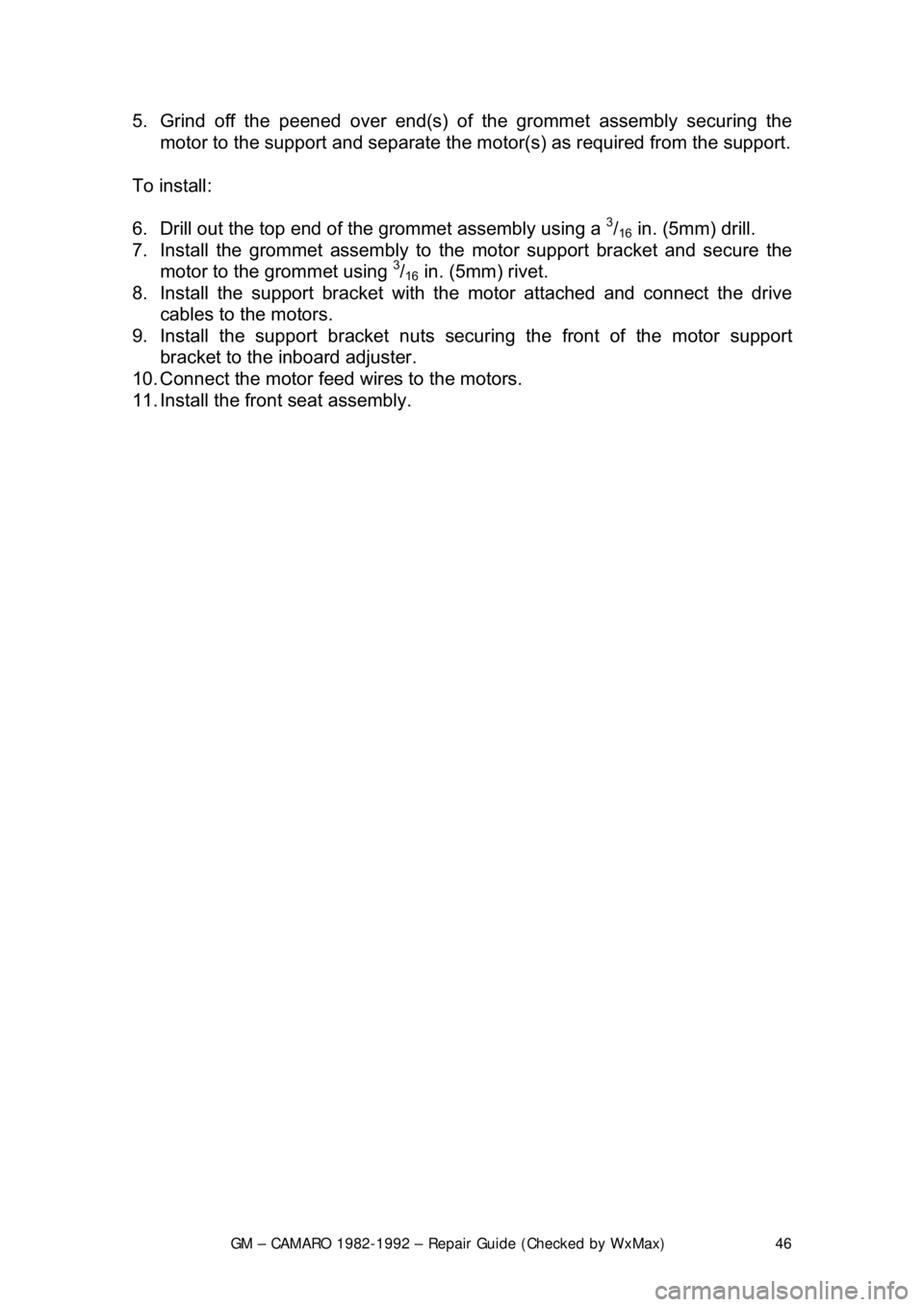

Fig. 1

Page 48 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 48

BRAKES

BASIC OPERATING PRINCIPLES

Hydraulic systems are used to actuate t he brakes of all modern automobiles.

The system transports the power required to force the frictional surfaces of the

braking system together from the pedal to the individual brake units at each

wheel. A hydraulic system is used for two reasons.

First, fluid under pressure can be carried to all parts of an automobile by small

pipes and flexible hoses without taking up a significant amount of room or

posing routing problems.

Second, a great mechanical advantage can be given to the brake pedal end of

the system, and the foot pressure requi red to actuate the brakes can be

reduced by making the surface area of t he master cylinder pistons smaller than

that of any of the pistons in t he wheel cylinders or calipers.

The master cylinder consists of a flui d reservoir along with a double cylinder

and piston assembly. Double type master cylinders are designed to separate

the front and rear braking systems hydraulic ally in case of a leak. The master

cylinder coverts mechanical motion from t he pedal into hydraulic pressure within

the lines. This pressure is translated back into mechanical motion at th\

e wheels

by either the wheel cylinder (drum brak es) or the caliper (disc brakes).

Steel lines carry the brake fluid to a po int on the vehicle's frame near each of

the vehicle's wheels. The fluid is then ca rried to the calipers and wheel cylinders

by flexible tubes in order to allow for suspension and steering movements.

In drum brake systems, each wheel cylinde r contains two pistons, one at either

end, which push outward in opposite direct ions and force the brake shoe into

contact with the drum.

In disc brake systems, the cylinders ar e part of the calipers. At least one

cylinder in each caliper is used to fo rce the brake pads against the disc.

All pistons employ some type of seal, us ually made of rubber, to minimize fluid

leakage. A rubber dust boot seals the outer end of the cylinder against dust and

dirt. The boot fits around the outer end of the piston on disc brake calipers, and

around the brake actuating rod on wheel cylinders.

The hydraulic system operates as follows : When at rest, the entire system, from

the piston(s) in the master cylinder to t hose in the wheel cylinders or calipers, is

full of brake fluid. Upon app lication of the brake pedal, fluid trapped in front of

the master cylinder piston(s) is forced through the lines to the wheel cylinders.

Here, it forces the pistons outward, in the case of drum brakes, and inward

toward the disc, in the case of disc brakes. The motion of the pistons is

opposed by return springs mounted outside the cylinders in drum brakes, and

by spring seals, in disc brakes.

Page 49 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 49

Upon release of the brake pedal, a spri

ng located inside the master cylinder

immediately returns the master cylinder pistons to the normal position. The

pistons contain check valv es and the master cylinder has compensating ports

drilled in it. These are uncovered as the pistons reach their normal position. The

piston check valves allow fluid to flow to ward the wheel cylinders or calipers as

the pistons withdraw. Then, as the return springs force the brake pads or shoes

into the released position, the excess fluid reservoir through the compensating

ports. It is during the time the pedal is in the released position that any fluid that

has leaked out of the syst em will be replaced through the compensating ports.

Dual circuit master cylinders employ tw o pistons, located one behind the other,

in the same cylinder. The primary pist on is actuated directly by mechanical

linkage from the brake peda l through the power booster. The secondary piston

is actuated by fluid tra pped between the two pistons. If a leak develops in front

of the secondary piston, it moves forward until it bottoms against the front of the

master cylinder, and the fluid trapped betw een the pistons will operate the rear

brakes. If the rear brakes develop a l eak, the primary piston will move forward

until direct contact with the secondary pi ston takes place, and it will force the

secondary piston to actuate the front brakes. In either case, the brake pedal

moves farther when the brakes are applied, and less braking power is available.

All dual circuit systems use a switch to wa rn the driver when only half of the

brake system is operational. This switch is usually located in a valve body which

is mounted on the firewall or the frame below the master cylinder. A hydraulic

piston receives pressure from both circui ts, each circuit's pressure being applied

to one end of the piston. When the pressures are in balance, the piston remains

stationary. When one circuit has a leak, however, the greater pressure in that

circuit during application of the brakes will push the piston to one side, closing

the switch and activating the brake warning light.

In disc brake systems, this valve body also contains a metering valve and, in

some cases, a proportioning valve. The metering valve keeps pressure fro\

m

traveling to the disc brakes on the front wheels until the brake shoes on the rear

wheels have contacted the drums, ensuri ng that the front brakes will never be

used alone. The proportioning va lve controls the pressure to the rear brakes to

lessen the chance of rear wheel lo ck-up during very hard braking.

Warning lights may be tested by depressi ng the brake pedal and holding it while

opening one of the wheel cyli nder bleeder screws. If this does not cause the

light to go on, substitute a new lamp , make continuity checks, and, finally,

replace the switch as necessary.

The hydraulic system may be checked for leaks by applying pressure to the

pedal gradually and steadily. If the pedal sinks very slowly to the floor, the

system has a leak. This is not to be conf used with a springy or spongy feel due

to the compression of air within the lin es. If the system leaks, there will be a

gradual change in the position of the pedal with a constant pressure.

Check for leaks along all lines and at wheel cylinders. If no external leaks are

apparent, the problem is inside the master cylinder.

Page 50 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 50

DISC BRAKES

Instead of the traditional ex

panding brakes that press out ward against a circular

drum, disc brake systems utilize a disc (rotor) with brake pads positioned on

either side of it. An easily-seen analog y is the hand brake arrangement on a

bicycle. The pads squeeze onto the rim of the bike wheel, slowing its motion.

Automobile disc brakes use the identical principle but apply the braking effort to

a separate disc instead of the wheel.

The disc (rotor) is a casting, usually eq uipped with cooling fins between the two

braking surfaces. This enables air to ci rculate between the braking surfaces

making them less sensitive to heat bui ldup and more resistant to fade. Dirt and

water do not drastically affect braking ac tion since contaminants are thrown off

by the centrifugal action of the rotor or scraped off the by the pads. Also, the

equal clamping action of the two brake pad s tends to ensure uniform, straight

line stops. Disc brakes are inherently se lf-adjusting. There are three general

types of disc brake:

1. A fixed caliper.

2. A floating caliper.

3. A sliding caliper.

The fixed caliper design uses two pistons mounted on either side of the rotor (in

each side of the caliper). The caliper is mounted rigidly and does not move.

The sliding and floating designs are quite similar. In fact, these two types are

often lumped together. In both designs, the pad on the inside of the rotor is

moved into contact with the rotor by hy draulic force. The caliper, which is not

held in a fixed position, moves slightly, bringing the outside pad into contact with

the rotor. There are various methods of attaching floating calipers. Some pivot

at the bottom or top, and some slide on mounting bolts. In any event, the end

result is the same.

DRUM BRAKES

Drum brakes employ two brake shoes mounted on a st ationary backing plate.

These shoes are positioned inside a circul ar drum which rotates with the wheel

assembly. The shoes are held in place by springs. This allows them to slide

toward the drums (when they are applied) while keeping the linings and drums

in alignment. The shoes are actuated by a wheel cylinder which is mounted at

the top of the backing plat e. When the brakes are app lied, hydraulic pressure

forces the wheel cylinder's actuating links outward. Since these links bear

directly against the top of the brake s hoes, the tops of the shoes are then forced

against the inner side of the drum. This action forces the bottoms of the two

shoes to contact the brake drum by rotati ng the entire assembly slightly (known

as servo action). When pressure within the wheel cylinder is relaxed, return

springs pull the shoes back away from the drum.

Most modern drum brakes are designed to self-adjust themselves during

application when the vehicle is moving in reverse. This motion causes both