CHEVROLET CAMARO 1982 Repair Guide

Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 721 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 721

8. The idle speed should be 450-500 rpm, adjust as necessary.

WARNING - Correct minimum idle speed adj ustment is critical to vehicle

performance and component durability. Incorrect minimum idle speed

adjustment (too high) will caus e the IAC valve pintle to constantly bottom in it's

seat and result in early valve failure. If minimum idle speed is adjusted too low,

the vehicle may not start in cold weather or may stall during warm-up.

Turn the ignition OFF and reconnect the IAC motor connector.

9. Reconnect the distributor set-timing connector.

10. Use silicone sealant to co ver the throttle stop screw.

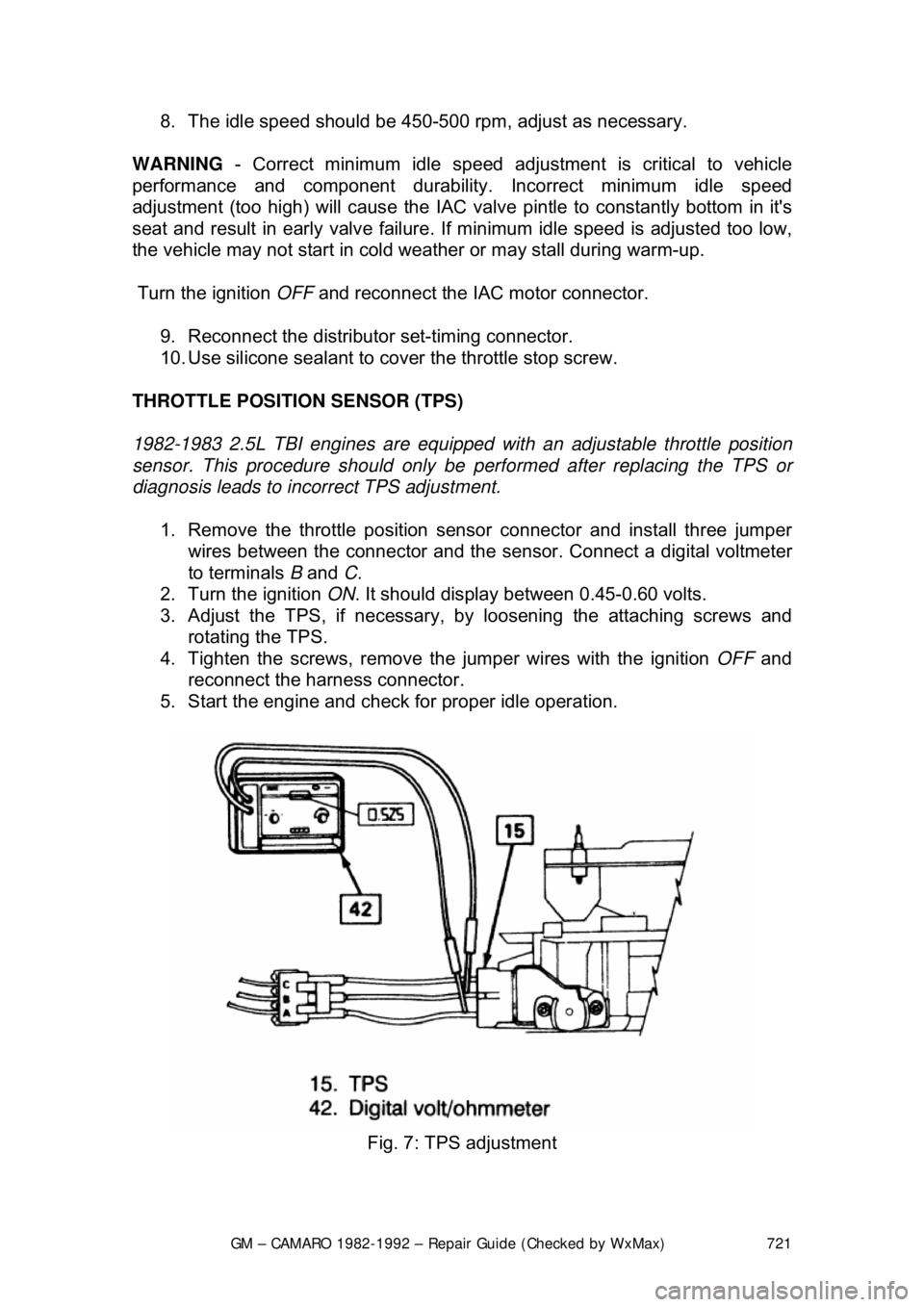

THROTTLE POSITION SENSOR (TPS)

1982-1983 2.5L TBI engines ar e equipped with an adjustable throttle position

sensor. This procedure should only be performed after replacing the TPS or

diagnosis leads to incorrect TPS adjustment.

1. Remove the throttle position sensor connector and install three jumper wires between the connector and the s ensor. Connect a digital voltmeter

to terminals B and C.

2. Turn the ignition ON. It should display bet ween 0.45-0.60 volts.

3. Adjust the TPS, if necessary, by loosening the attaching screws and

rotating the TPS.

4. Tighten the screws, remove the jumper wires with the ignition OFF and

reconnect the harness connector.

5. Start the engine and check fo r proper idle operation.

Fig. 7: TPS adjustment

Page 722 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 722

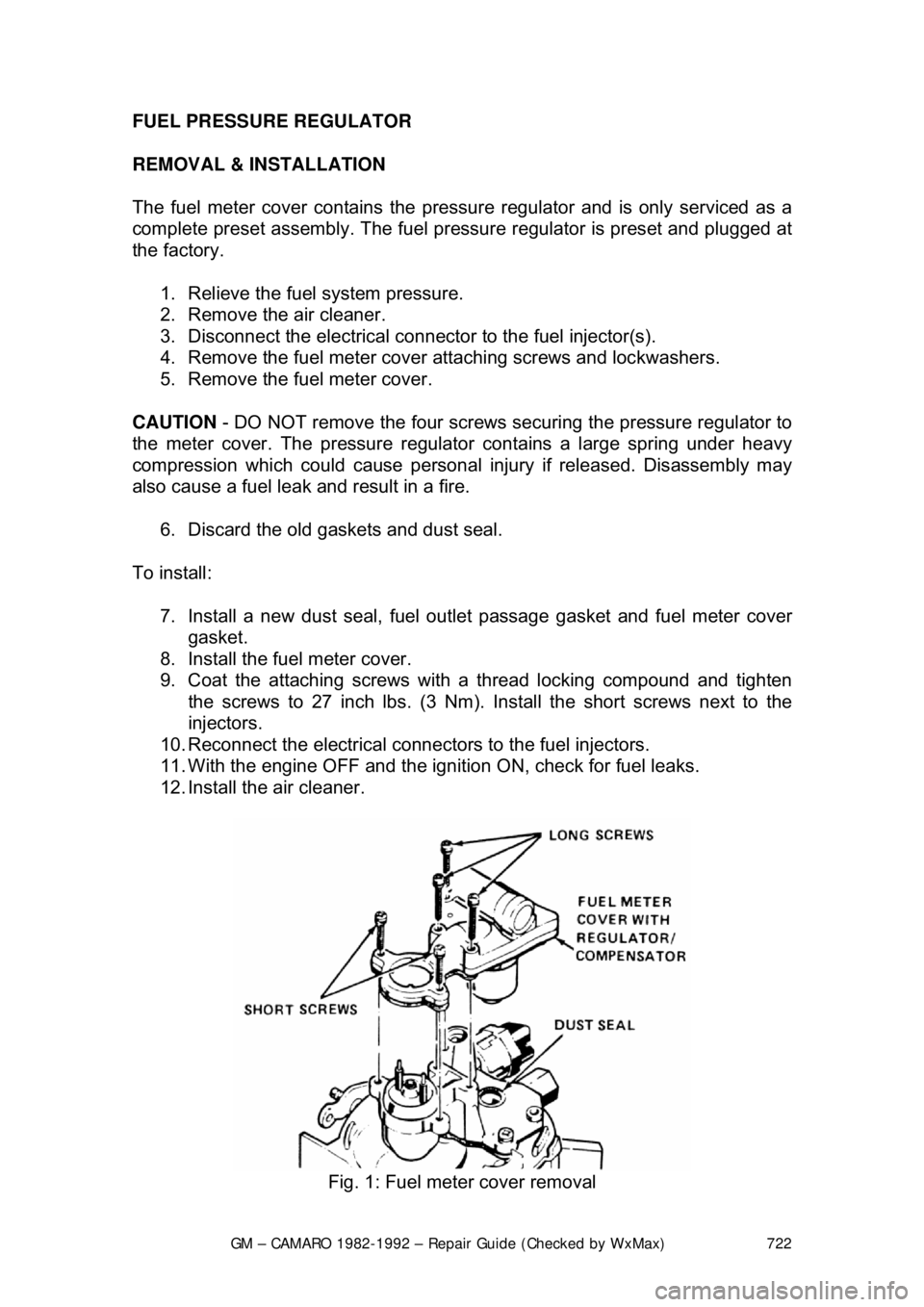

FUEL PRESSURE REGULATOR

REMOVAL & INSTALLATION

The fuel meter cover contains the pressu

re regulator and is only serviced as a

complete preset assembly. The fuel pressu re regulator is preset and plugged at

the factory.

1. Relieve the fuel system pressure.

2. Remove the air cleaner.

3. Disconnect the electrical connec tor to the fuel injector(s).

4. Remove the fuel meter cover attaching screws and lockwashers.

5. Remove the fuel meter cover.

CAUTION - DO NOT remove the four screws se curing the pressure regulator to

the meter cover. The pressure regulat or contains a large spring under heavy

compression which could cause personal injury if released. Disassembly may

also cause a fuel leak and result in a fire.

6. Discard the old gaskets and dust seal.

To install: 7. Install a new dust seal, fuel outlet passage gasket and fuel meter cover\

gasket.

8. Install the fuel meter cover.

9. Coat the attaching screws with a thread locking compound and tighten the screws to 27 inch lbs. (3 Nm). Install the short screws next to the

injectors.

10. Reconnect the electrical connec tors to the fuel injectors.

11. With the engine OFF and the igniti on ON, check for fuel leaks.

12. Install the air cleaner.

Fig. 1: Fuel meter cover removal

Page 723 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 723

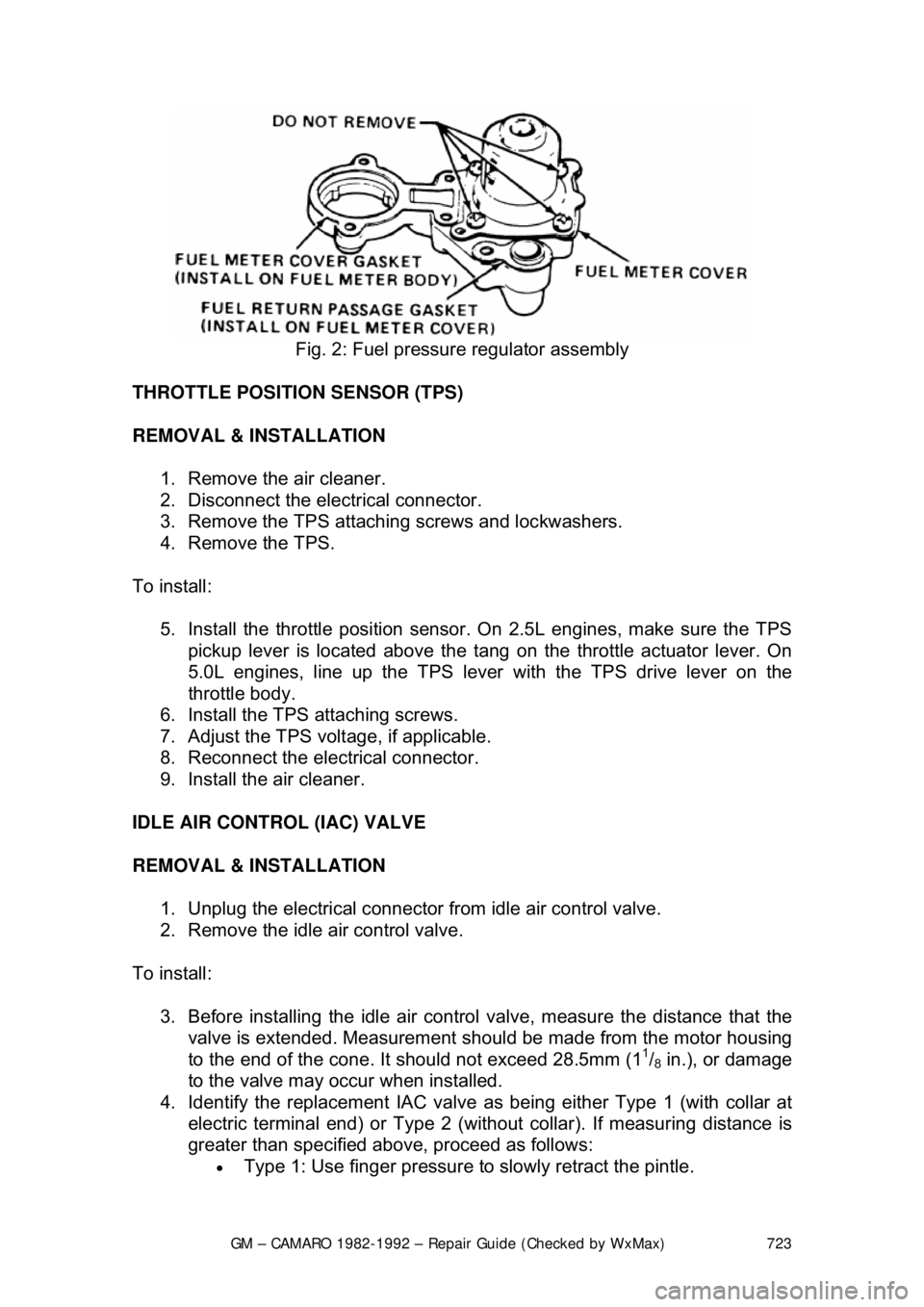

Fig. 2: Fuel pressure regulator assembly

THROTTLE POSITION SENSOR (TPS)

REMOVAL & INSTALLATION 1. Remove the air cleaner.

2. Disconnect the electrical connector.

3. Remove the TPS attaching screws and lockwashers.

4. Remove the TPS.

To install: 5. Install the throttle position sensor. On 2.5L engines, make sure the TPS pickup lever is located above the tang on the throttle actuator lever. On

5.0L engines, line up the TPS lever with the TPS drive lever on the

throttle body.

6. Install the TPS attaching screws.

7. Adjust the TPS volt age, if applicable.

8. Reconnect the electrical connector.

9. Install the air cleaner.

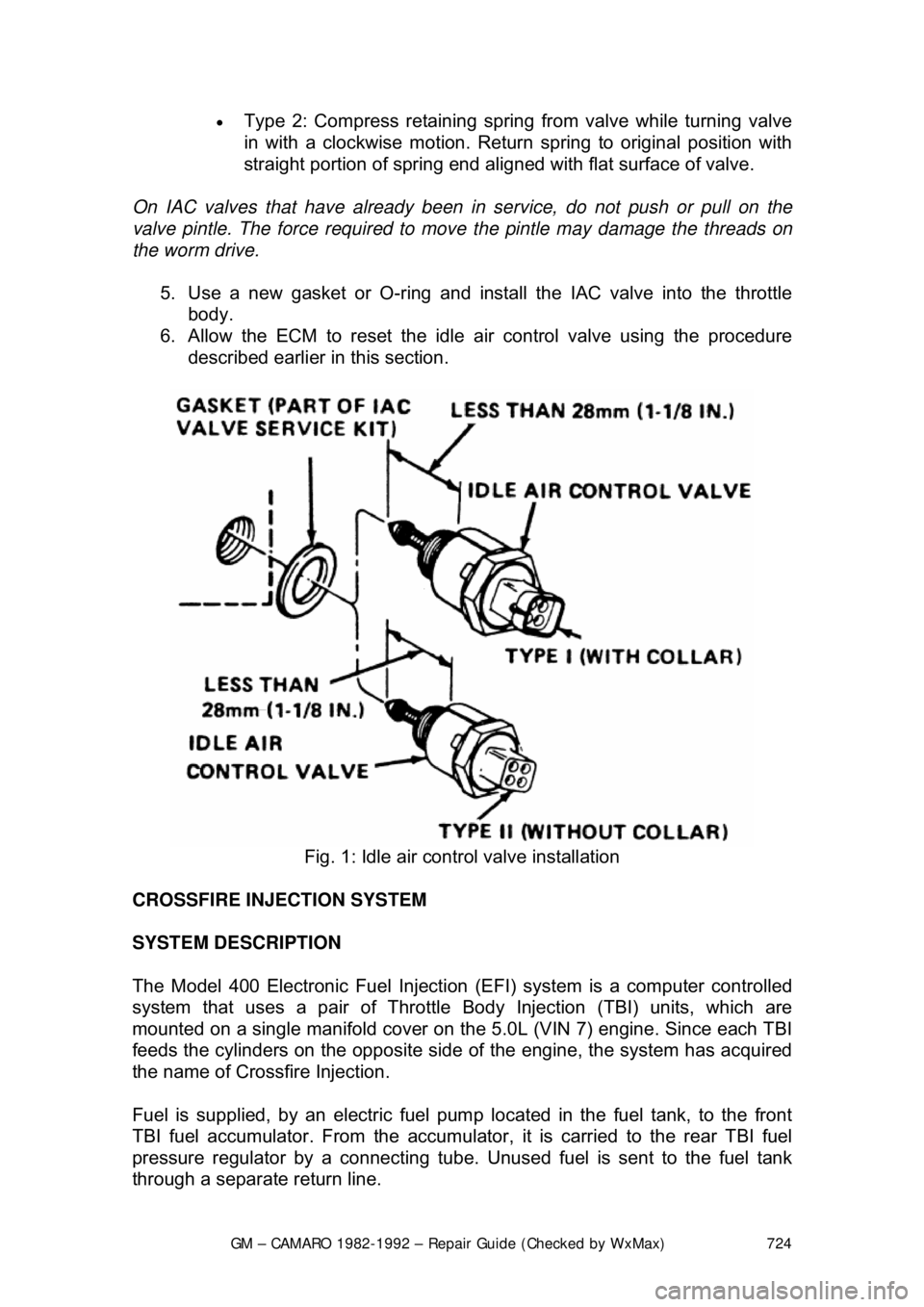

IDLE AIR CONTROL (IAC) VALVE

REMOVAL & INSTALLATION 1. Unplug the electrical connector from idle air control valve.

2. Remove the idle air control valve.

To install: 3. Before installing the idle air contro l valve, measure the distance that the

valve is extended. Measurement s hould be made from the motor housing

to the end of the cone. It should not exceed 28.5mm (1

1/8 in.), or damage

to the valve may occur when installed.

4. Identify the replacement IAC valve as being either Type 1 (with collar at

electric terminal end) or Type 2 (without collar). If measuring distance is

greater than specified abov e, proceed as follows:

• Type 1: Use finger pressure to slowly retract the pintle.

Page 724 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 724

•

Type 2: Compress retaining spring from valve while turning valve

in with a clockwise motion. Return spring to original position with

straight portion of spring end aligned with flat surface of valve.

On IAC valves that have already been in service, do not push or pull on the

valve pintle. The force required to move the pintle may damage the threads on

the worm drive.

5. Use a new gasket or O-ring and install the IAC valve into the throttle body.

6. Allow the ECM to reset the idle air control valve using the procedure

described earlier in this section.

Fig. 1: Idle air control valve installation

CROSSFIRE INJECTION SYSTEM

SYSTEM DESCRIPTION

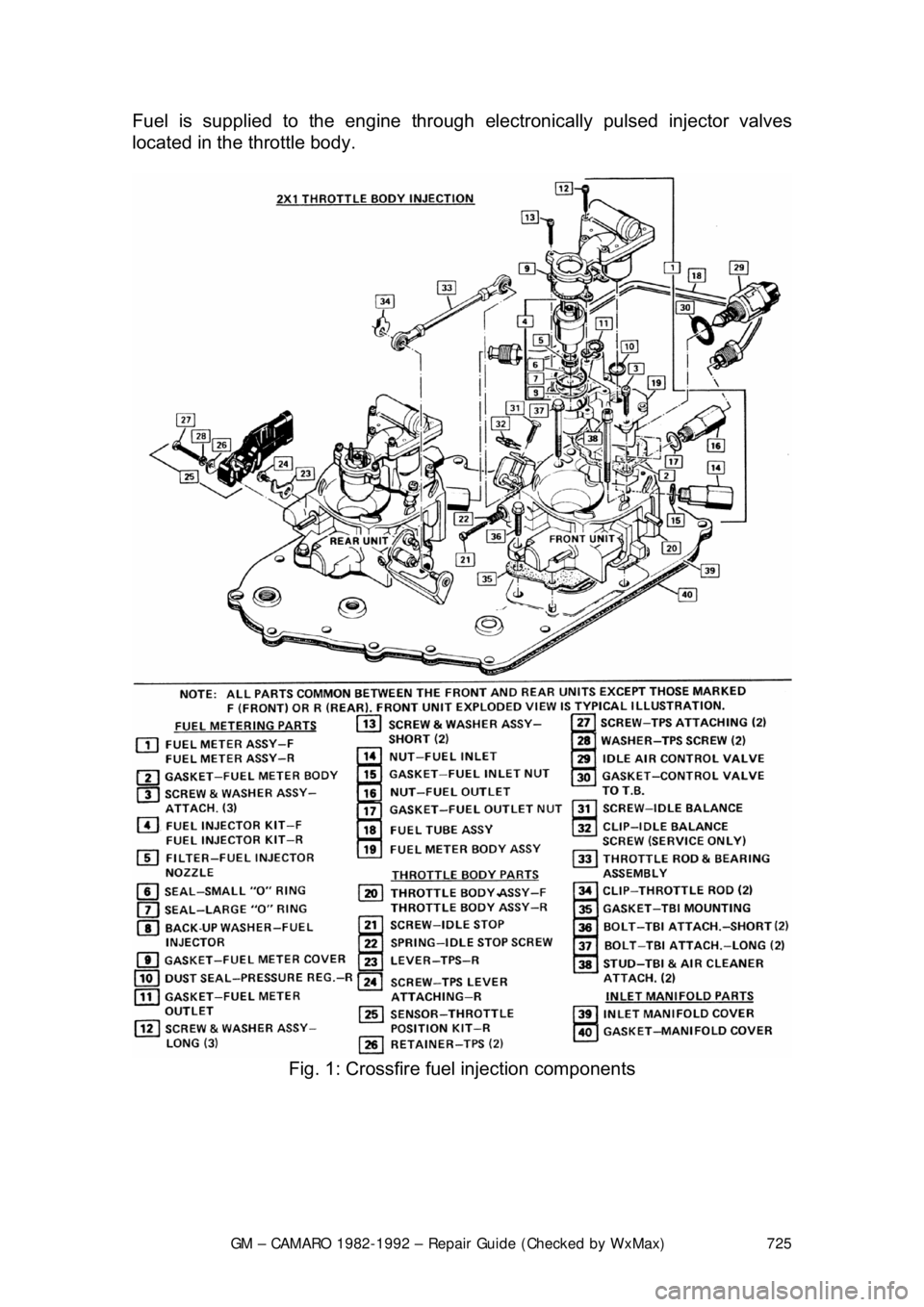

The Model 400 Electronic Fuel Injection (EFI) system is a computer controlled

system that uses a pair of Throttle Body Injection (TBI) units, which are

mounted on a single manifold cover on t he 5.0L (VIN 7) engine. Since each TBI

feeds the cylinders on the opposite side of the engine, the system has acquired

the name of Crossf ire Injection.

Fuel is supplied, by an electric fuel pum p located in the fuel tank, to the front

TBI fuel accumulator. From the accumulator, it is carried to the rear TBI fuel

pressure regulator by a c onnecting tube. Unused fuel is sent to the fuel tank

through a separate return line.

Page 725 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 725

Fuel is supplied to the engine through

electronically pulsed injector valves

located in the throttle body.

Fig. 1: Crossfire fuel injection components

Page 726 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 726

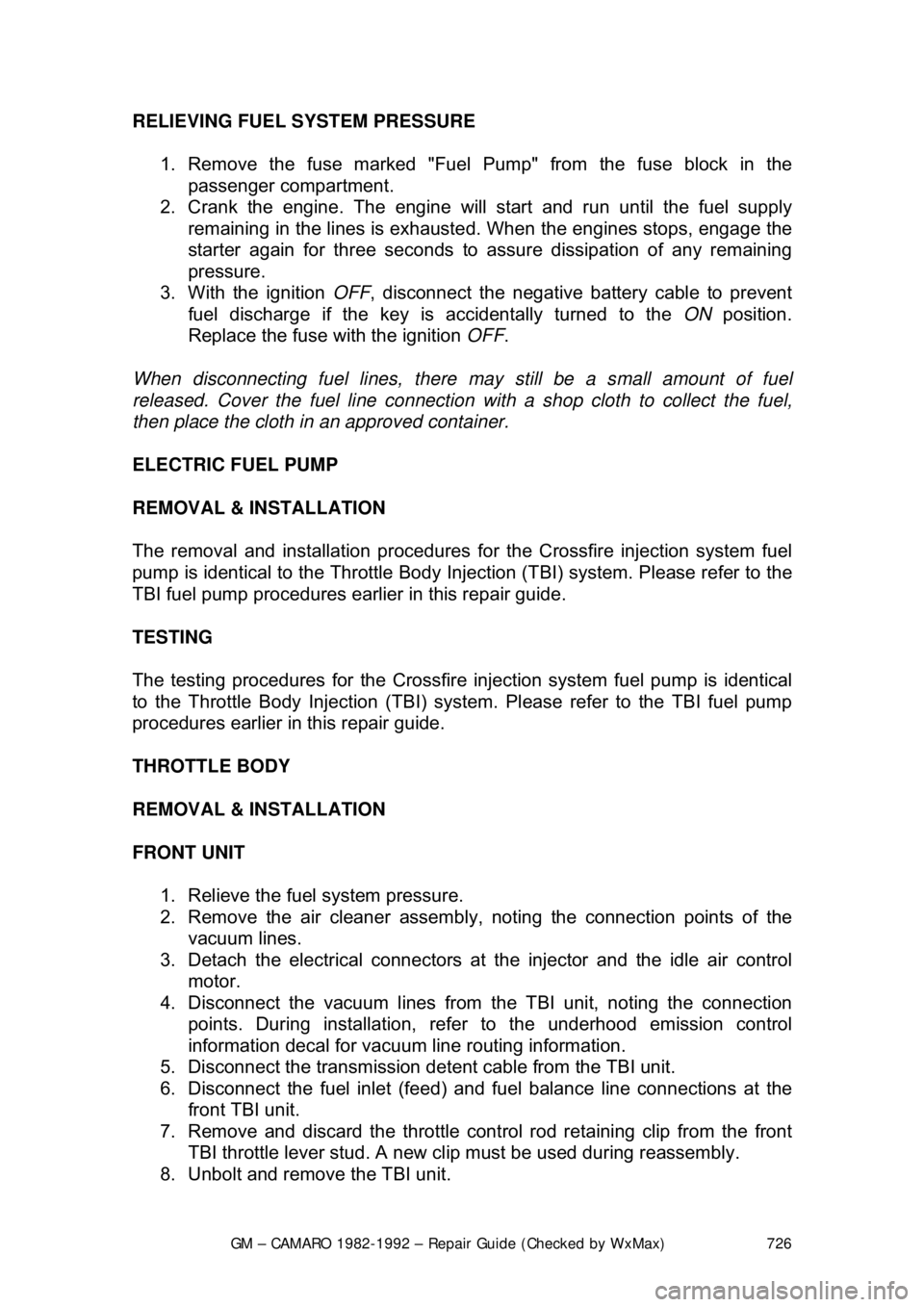

RELIEVING FUEL SYSTEM PRESSURE

1. Remove the fuse marked "Fuel Pu mp" from the fuse block in the

passenger compartment.

2. Crank the engine. Th e engine will start and run until the fuel supply

remaining in the lines is exhauste d. When the engines stops, engage the

starter again for three seconds to a ssure dissipation of any remaining

pressure.

3. With the ignition OFF, disconnect the negative battery cable to prevent

fuel discharge if the key is accidentally turned to the ON position.

Replace the fuse with the ignition OFF.

When disconnecting fuel lines, there ma y still be a small amount of fuel

released. Cover the fuel line connection wi th a shop cloth to collect the fuel,

then place the cloth in an approved container.

ELECTRIC FUEL PUMP

REMOVAL & INSTALLATION

The removal and installation procedures fo r the Crossfire injection system fuel

pump is identical to the Throttle Body In jection (TBI) system. Please refer to the

TBI fuel pump procedures earlier in this repair guide.

TESTING

The testing procedures for the Crossfire in jection system fuel pump is identical

to the Throttle Body Injection (TBI) syst em. Please refer to the TBI fuel pump

procedures earlier in this repair guide.

THROTTLE BODY

REMOVAL & INSTALLATION

FRONT UNIT

1. Relieve the fuel system pressure.

2. Remove the air cleaner assembly, noting the connection points of the

vacuum lines.

3. Detach the electrical connectors at the injector and the idle air control

motor.

4. Disconnect the vacuum lines from the TBI unit, noting the connection

points. During installation, refer to the underhood emission control

information decal for vacuum line routing information.

5. Disconnect the transmission det ent cable from the TBI unit.

6. Disconnect the fuel inlet (feed) and fuel balance line connections at the

front TBI unit.

7. Remove and discard the throttle cont rol rod retaining clip from the front

TBI throttle lever stud. A new clip must be used during reassembly.

8. Unbolt and remove the TBI unit.

Page 727 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 727

To install:

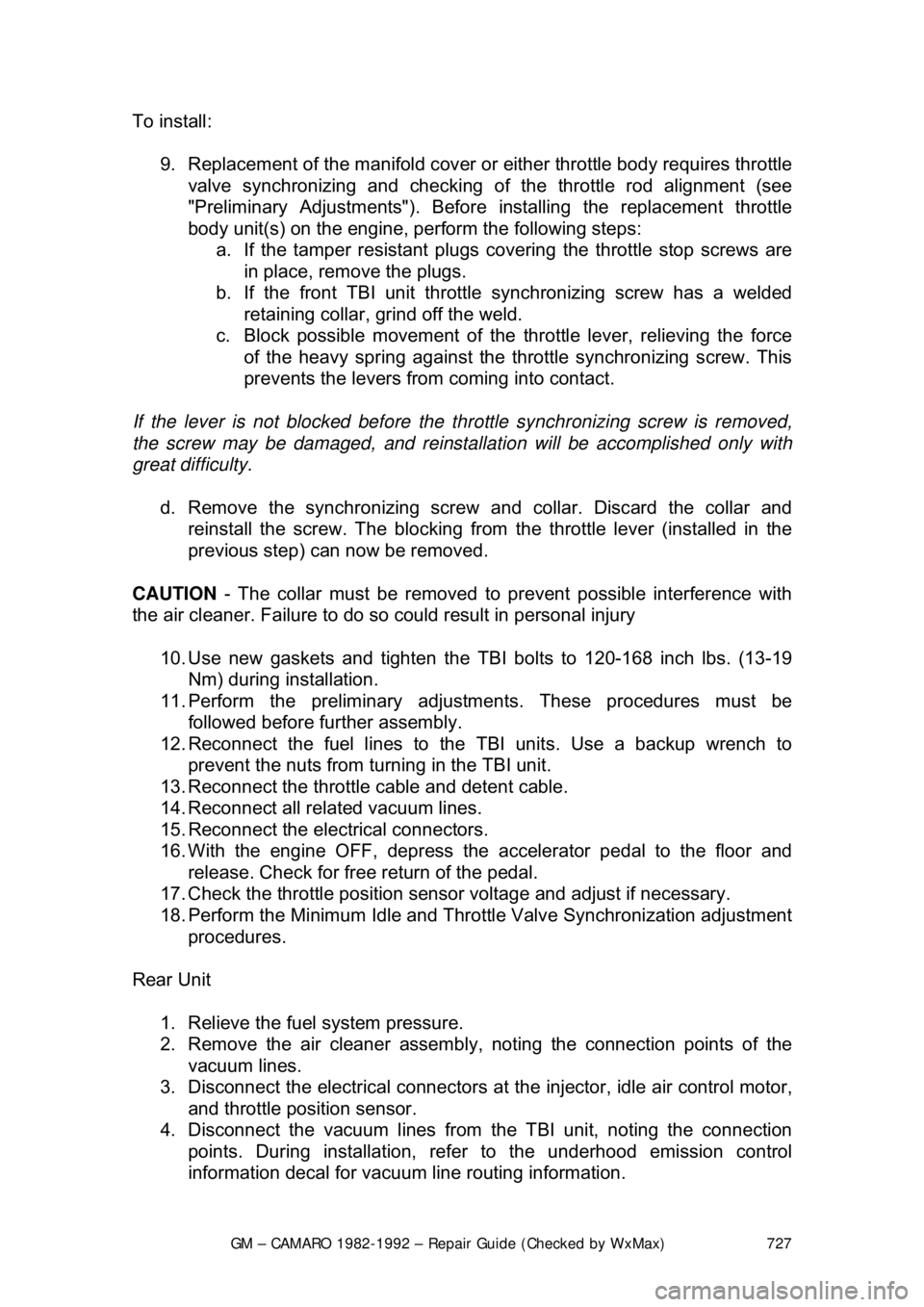

9. Replacement of the manifold cover or either throttle body requires throttle

valve synchronizing and checking of the throttle rod alignment (see

"Preliminary Adjustments"). Before installing the replacement throttle

body unit(s) on the engine, perform the following steps:

a. If the tamper resistant plugs co vering the throttle stop screws are

in place, remove the plugs.

b. If the front TBI unit throttle syn chronizing screw has a welded

retaining collar, grind off the weld.

c. Block possible movement of the throttle lever, relieving the force

of the heavy spring against the throttle synchronizing screw. This

prevents the levers from coming into contact.

If the lever is not blocked before the thro ttle synchronizing screw is removed,

the screw may be damaged, and reinstallation will be accomplished only with

great difficulty.

d. Remove the synchronizing screw and collar. Discard the collar and reinstall the screw. The blocking from the throttle lever (installed in the

previous step) can now be removed.

CAUTION - The collar must be removed to prevent possible interference with

the air cleaner. Failure to do so c ould result in personal injury

10. Use new gaskets and tighten the TB I bolts to 120-168 inch lbs. (13-19

Nm) during installation.

11. Perform the preliminary adjustm ents. These procedures must be

followed before further assembly.

12. Reconnect the fuel lines to the TBI units. Use a backup wrench to

prevent the nuts from tu rning in the TBI unit.

13. Reconnect the throttle cable and detent cable.

14. Reconnect all related vacuum lines.

15. Reconnect the electrical connectors.

16. With the engine OFF, depress the accelerator pedal to the floor and

release. Check for free return of the pedal.

17. Check the throttle position sensor voltage and adjust if necessary.

18. Perform the Minimum Idle and Thro ttle Valve Synchronization adjustment

procedures.

Rear Unit 1. Relieve the fuel system pressure.

2. Remove the air cleaner assembly, noting the connection points of the

vacuum lines.

3. Disconnect the electrical connectors at the injector, idle air control motor,

and throttle position sensor.

4. Disconnect the vacuum lines from the TBI unit, noting the connection

points. During installation, refer to the underhood emission control

information decal for vacuum line routing information.

Page 728 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 728

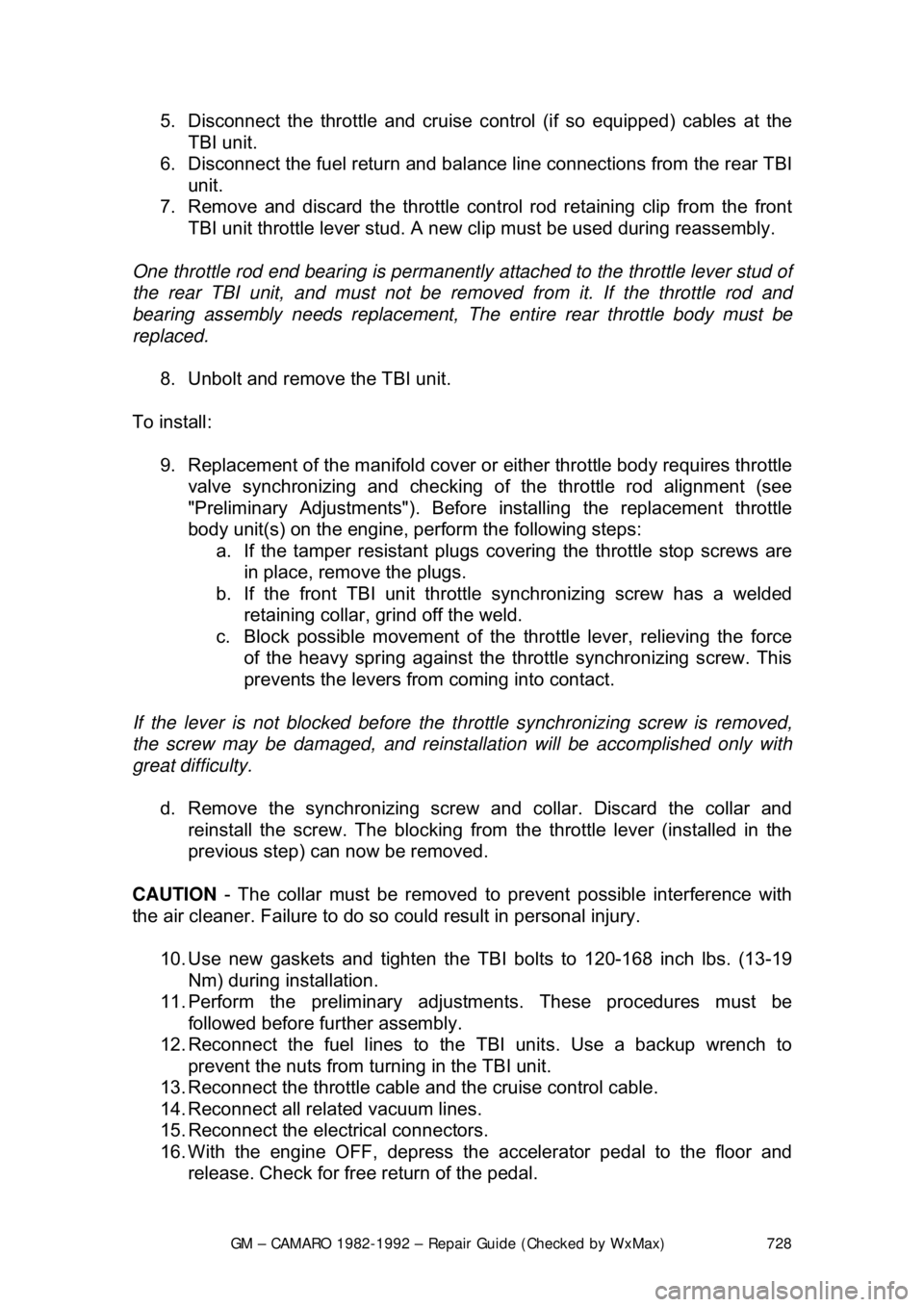

5. Disconnect the throttle and cruise c

ontrol (if so equipped) cables at the

TBI unit.

6. Disconnect the fuel return and bal ance line connections from the rear TBI

unit.

7. Remove and discard the throttle cont rol rod retaining clip from the front

TBI unit throttle lever stud. A new clip must be used during reassembly.\

One throttle rod end bearing is permanently attached to the throttle lever stud of

the rear TBI unit, and must not be remov ed from it. If the throttle rod and

bearing assembly needs replacement, Th e entire rear throttle body must be

replaced.

8. Unbolt and remove the TBI unit.

To install: 9. Replacement of the manifold cover or either throttle body requires throttle

valve synchronizing and checking of the throttle rod alignment (see

"Preliminary Adjustments"). Before installing the replacement throttle

body unit(s) on the engine, perform the following steps:

a. If the tamper resistant plugs co vering the throttle stop screws are

in place, remove the plugs.

b. If the front TBI unit throttle syn chronizing screw has a welded

retaining collar, grind off the weld.

c. Block possible movement of the throttle lever, relieving the force

of the heavy spring against the throttle synchronizing screw. This

prevents the levers from coming into contact.

If the lever is not blocked before the thro ttle synchronizing screw is removed,

the screw may be damaged, and reinstallation will be accomplished only with

great difficulty.

d. Remove the synchronizing screw and collar. Discard the collar and reinstall the screw. The blocking from the throttle lever (installed in the

previous step) can now be removed.

CAUTION - The collar must be removed to prevent possible interference with

the air cleaner. Failure to do so c ould result in personal injury.

10. Use new gaskets and tighten the TB I bolts to 120-168 inch lbs. (13-19

Nm) during installation.

11. Perform the preliminary adjustm ents. These procedures must be

followed before further assembly.

12. Reconnect the fuel lines to the TBI units. Use a backup wrench to

prevent the nuts from tu rning in the TBI unit.

13. Reconnect the throttle cable and the cruise control cable.

14. Reconnect all related vacuum lines.

15. Reconnect the electrical connectors.

16. With the engine OFF, depress t he accelerator pedal to the floor and

release. Check for free return of the pedal.

Page 729 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 729

17. Check the throttle position sensor voltage and adjust if necessary.

18. Perform the Minimum Idle and Thro

ttle Valve Synchronization adjustment

procedures.

INJECTOR REPLACEMENT

The removal and installation procedures fo r the Crossfire injection system's fuel

injector is identical to the Throttle Bo dy Injection (TBI) system. Please refer to

the TBI fuel injector procedures earlier in this repair guide.

ADJUSTMENTS

PRELIMINARY ADJUSTMENTS

The preliminary adjustments are performed if tampering with the idle speed or

synchronization is evident and when either of the throttle bodies or the manifold

cover have been replaced. They must be performed BEFORE the Minimum Idle

and Throttle Valve Synchronizing procedure.

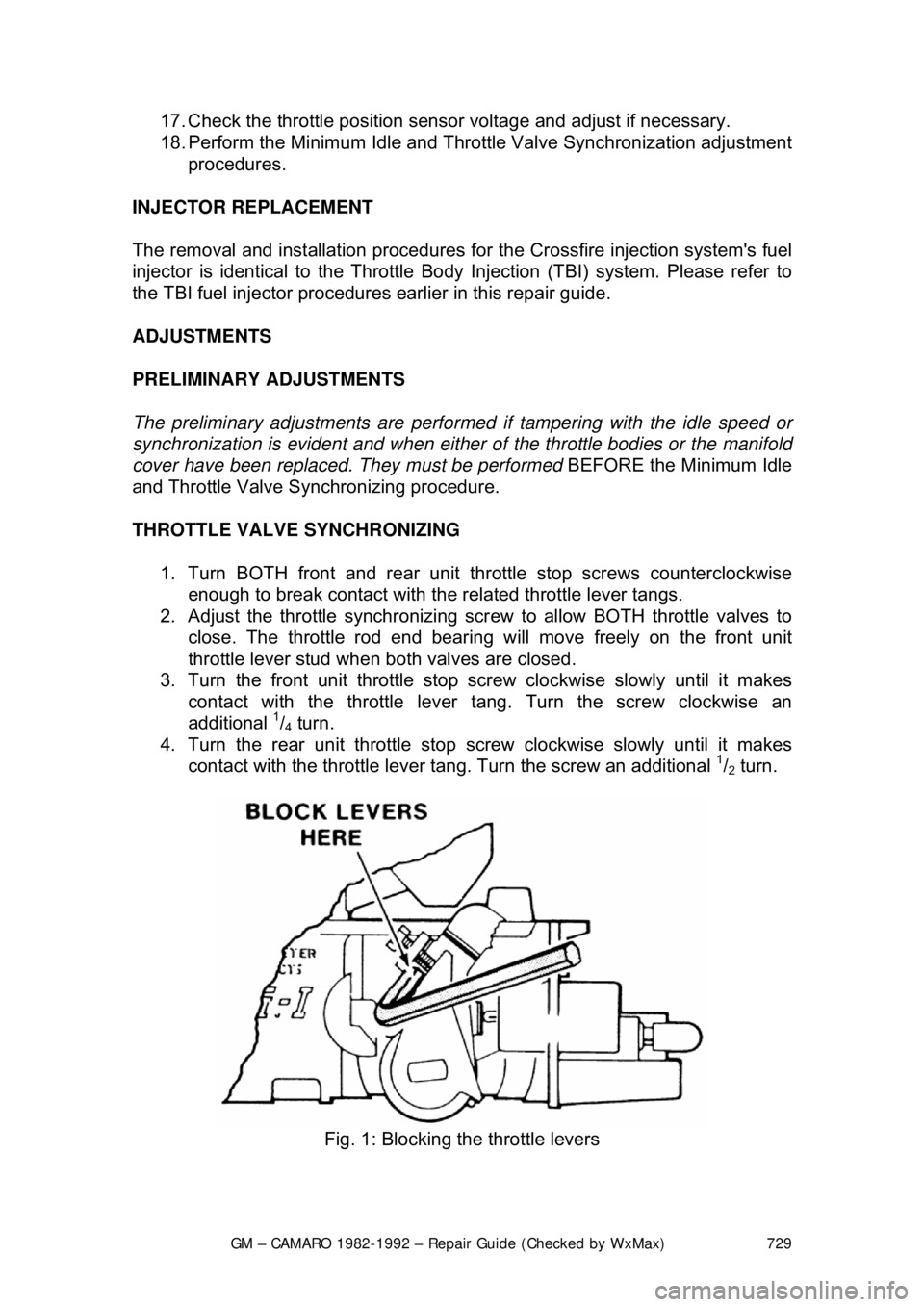

THROTTLE VALVE SYNCHRONIZING

1. Turn BOTH front and rear unit throttle stop screws counterclockwise enough to break contact with the related throttle lever tangs.

2. Adjust the throttle synchronizing scr ew to allow BOTH throttle valves to

close. The throttle rod end bearing w ill move freely on the front unit

throttle lever stud when both valves are closed.

3. Turn the front unit th rottle stop screw clockwise slowly until it makes

contact with the throttle lever tang. Turn the screw clockwise an

additional

1/4 turn.

4. Turn the rear unit throttle stop screw clockwise slowly until it makes

contact with the throttle lever t ang. Turn the screw an additional

1/2 turn.

Fig. 1: Blocking the throttle levers

Page 730 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 730

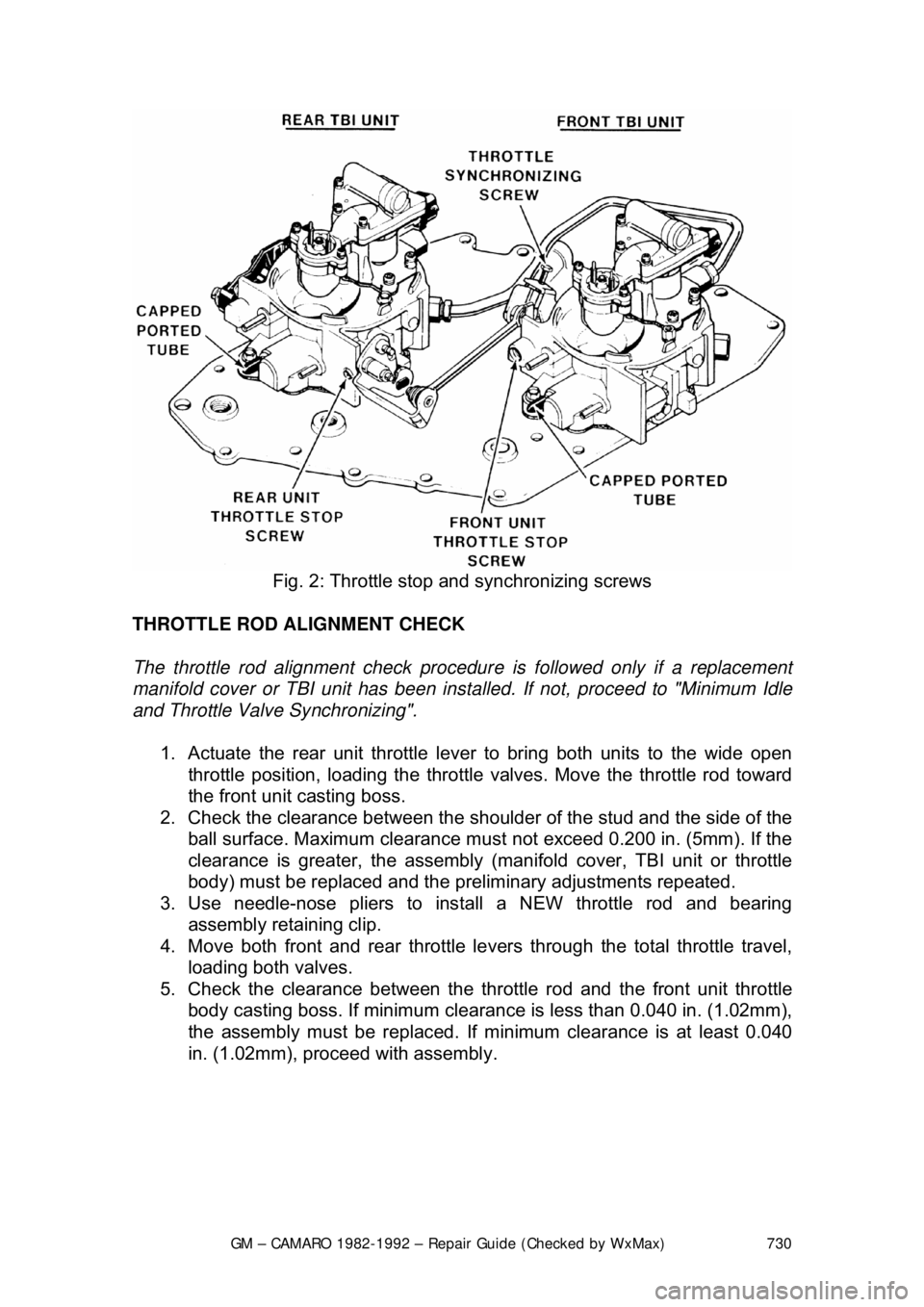

Fig. 2: Throttle stop and synchronizing screws

THROTTLE ROD ALIGNMENT CHECK

The throttle rod alignment check procedur e is followed only if a replacement

manifold cover or TBI unit has been inst alled. If not, proceed to "Minimum Idle

and Throttle Valve Synchronizing".

1. Actuate the rear unit throttle leve r to bring both units to the wide open

throttle position, loading the throttle valves. Move the throttle rod toward

the front unit casting boss.

2. Check the clearance bet ween the shoulder of the stud and the side of the

ball surface. Maximum clearance must not exceed 0.200 in. (5mm). If the

clearance is greater, the assembly (mani fold cover, TBI unit or throttle

body) must be replaced and the pr eliminary adjustments repeated.

3. Use needle-nose pliers to inst all a NEW throttle rod and bearing

assembly retaining clip.

4. Move both front and rear throttle le vers through the total throttle travel,

loading both valves.

5. Check the clearance bet ween the throttle rod and the front unit throttle

body casting boss. If minimum clearanc e is less than 0.040 in. (1.02mm),

the assembly must be replaced. If minimum clearance is at least 0.040

in. (1.02mm), proceed with assembly.