CHEVROLET CAMARO 1982 Repair Guide

Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 751 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 751

13. Lubricate a new outlet tube 0-ring and in

stall it on the end of the tube.

14. Connect the regulator base to the fuel outlet tube, then to the fuel rail.

15. Finger-tighten the base-to-rail screw.

16. Install the pressure regulator br acket. Finger-tighten the screws only.

17. Lubricate a new rear crossover tube O-ring and install it on the end of the

tube.

18. Install the rear crossover tube to the regulator base.

19. Install the crossover tube reta iner and finger-tighten the screw.

20. Tighten all attaching screws to 44 inch lbs. (5 Nm).

21. Install the fuel rail assembly.

22. Temporarily connect the negative battery cable. a. With the engine OFF and the igniti on ON, check for fuel leaks.

b. Disconnect the negative battery cable.

23. Install the intake plenum and runners.

24. Connect the negative battery cable.

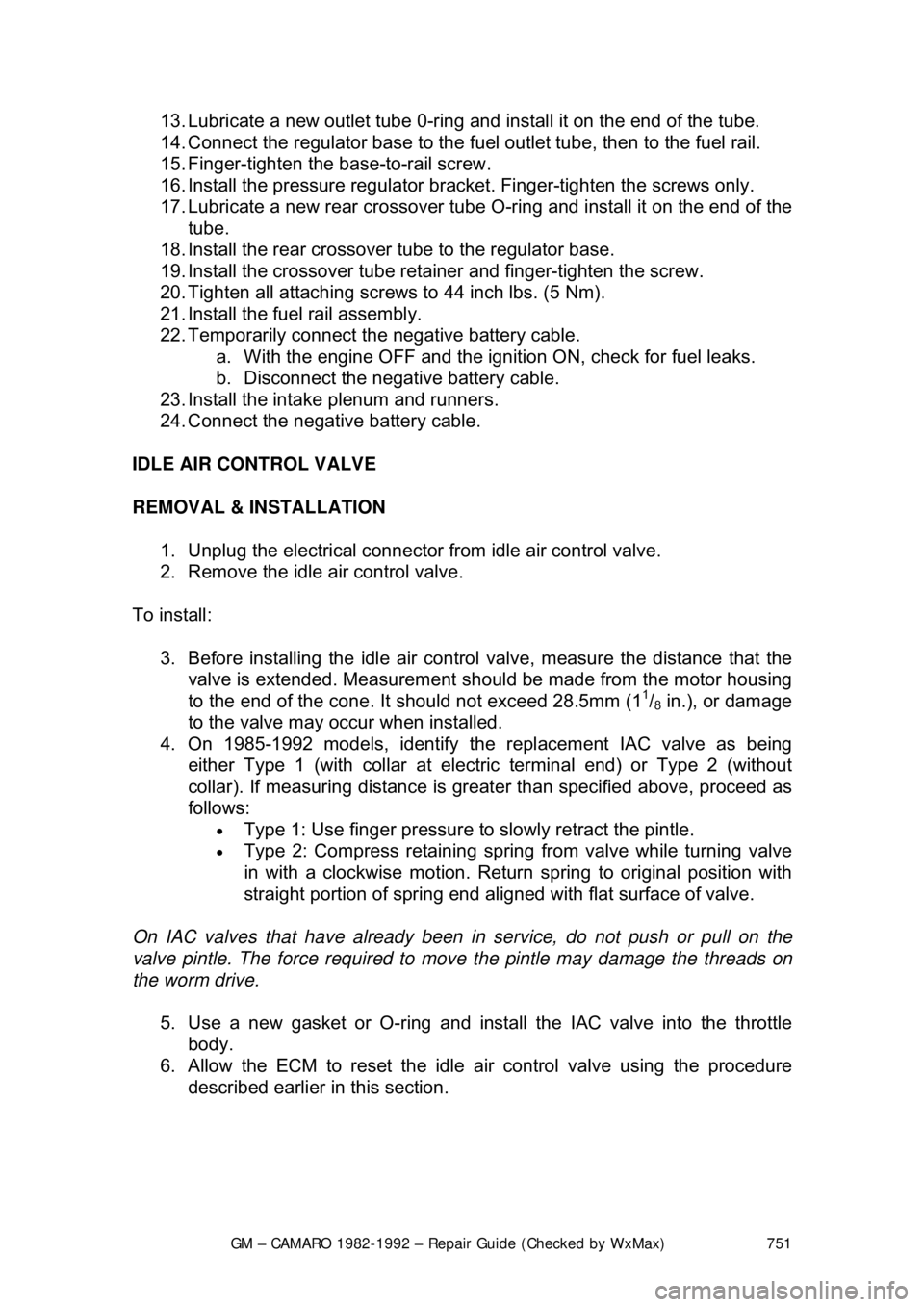

IDLE AIR CONTROL VALVE

REMOVAL & INSTALLATION 1. Unplug the electrical connector from idle air control valve.

2. Remove the idle air control valve.

To install: 3. Before installing the idle air contro l valve, measure the distance that the

valve is extended. Measurement s hould be made from the motor housing

to the end of the cone. It should not exceed 28.5mm (1

1/8 in.), or damage

to the valve may occur when installed.

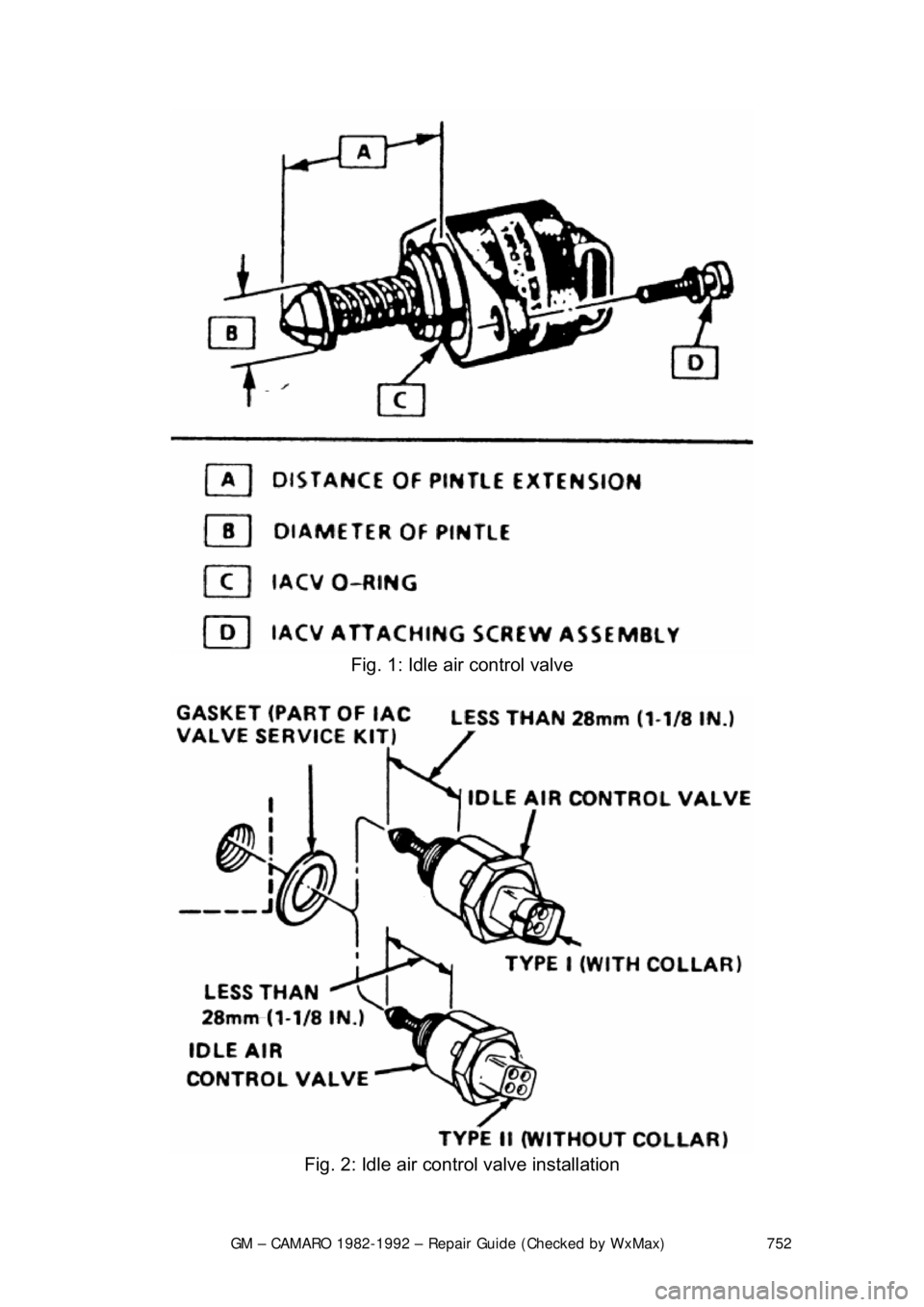

4. On 1985-1992 models, identify the replacement IAC valve as being

either Type 1 (with collar at electric terminal end) or Type 2 (without

collar). If measuring distance is great er than specified above, proceed as

follows:

• Type 1: Use finger pressure to slowly retract the pintle.

• Type 2: Compress retaining spring from valve while turning valve

in with a clockwise motion. Return spring to original position with

straight portion of spring end aligned with flat surface of valve.

On IAC valves that have already been in service, do not push or pull on the

valve pintle. The force required to move the pintle may damage the threads on

the worm drive.

5. Use a new gasket or O-ring and install the IAC valve into the throttle body.

6. Allow the ECM to reset the idle air control valve using the procedure

described earlier in this section.

Page 752 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 752

Fig. 1: Idle air control valve

Fig. 2: Idle air control valve installation

Page 753 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 753

THROTTLE POSITION SENSOR (TPS)

REMOVAL & INSTALLATION

1. Disconnect the negative battery cable.

2. Detach the electrical connector from the sensor.

3. Remove the attaching screws, lockw ashers and retainers. Some models

use a seal between the throttle body and the sensor, do not lose this! \

4. Remove the throttle position sensor.

To install: 5. Install the throttle position sensor seal, if applicable.

6. With the throttle valve in the norma l closed idle position, install the

sensor on the throttle body assembly. Make sure the sensor pickup lever

is properly located on the th rottle actuator lever.

7. Install the retainers, screws and lockwashers using a thread locking

compound. On models up to 1989, DO NOT tighten the screws until the

sensor is adjusted. Follow the procedures outlined earli er in this section.

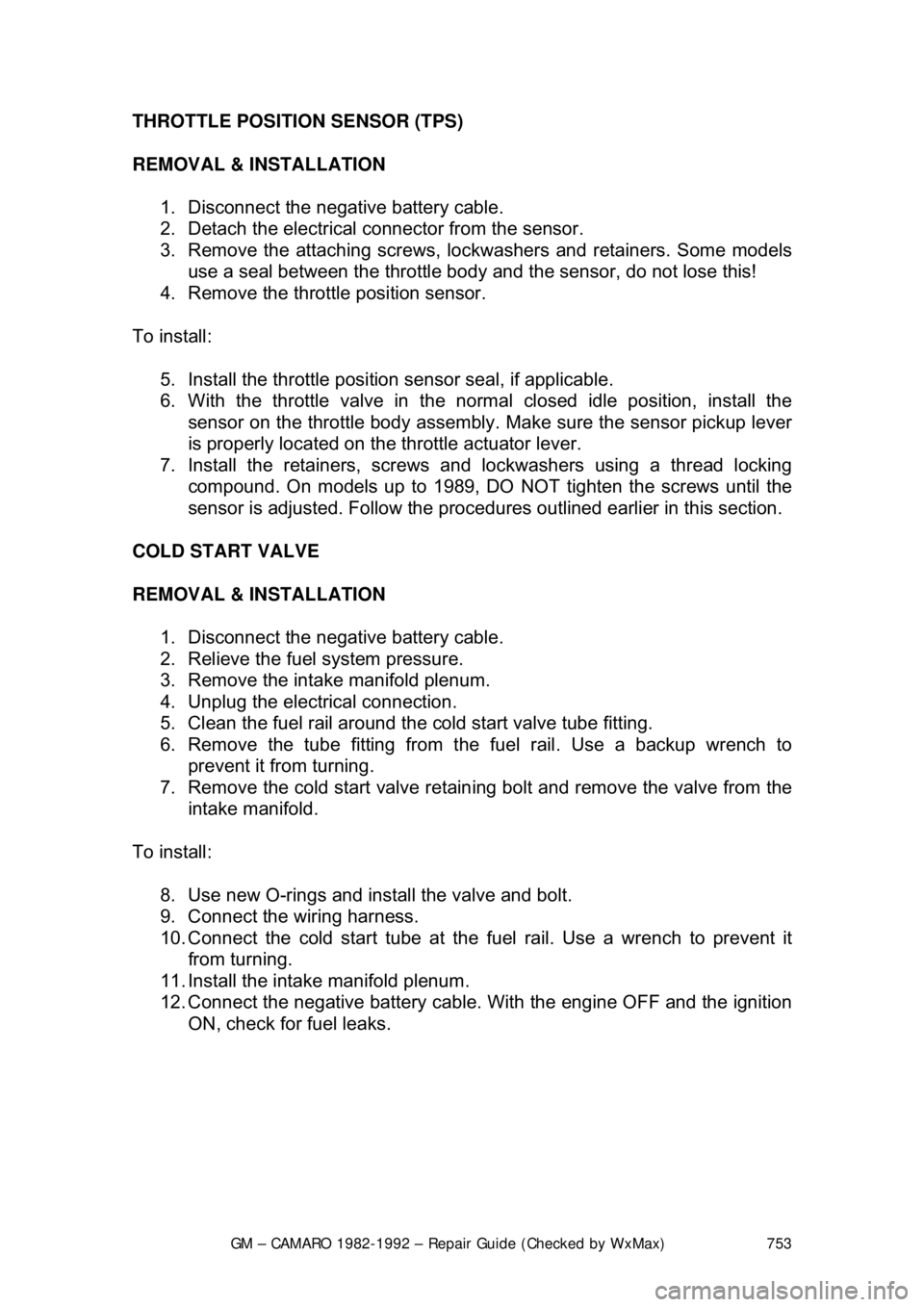

COLD START VALVE

REMOVAL & INSTALLATION 1. Disconnect the negative battery cable.

2. Relieve the fuel system pressure.

3. Remove the intake manifold plenum.

4. Unplug the electrical connection.

5. Clean the fuel rail around the cold start valve tube fitting.

6. Remove the tube fitting from t he fuel rail. Use a backup wrench to

prevent it from turning.

7. Remove the cold start valve retain ing bolt and remove the valve from the

intake manifold.

To install: 8. Use new O-rings and install the valve and bolt.

9. Connect the wiring harness.

10. Connect the cold start tube at the f uel rail. Use a wrench to prevent it

from turning.

11. Install the intake manifold plenum.

12. Connect the negative battery cable. With the engine OFF and the ignition

ON, check for fuel leaks.

Page 754 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 754

Fig. 1: Cold start valve assembly

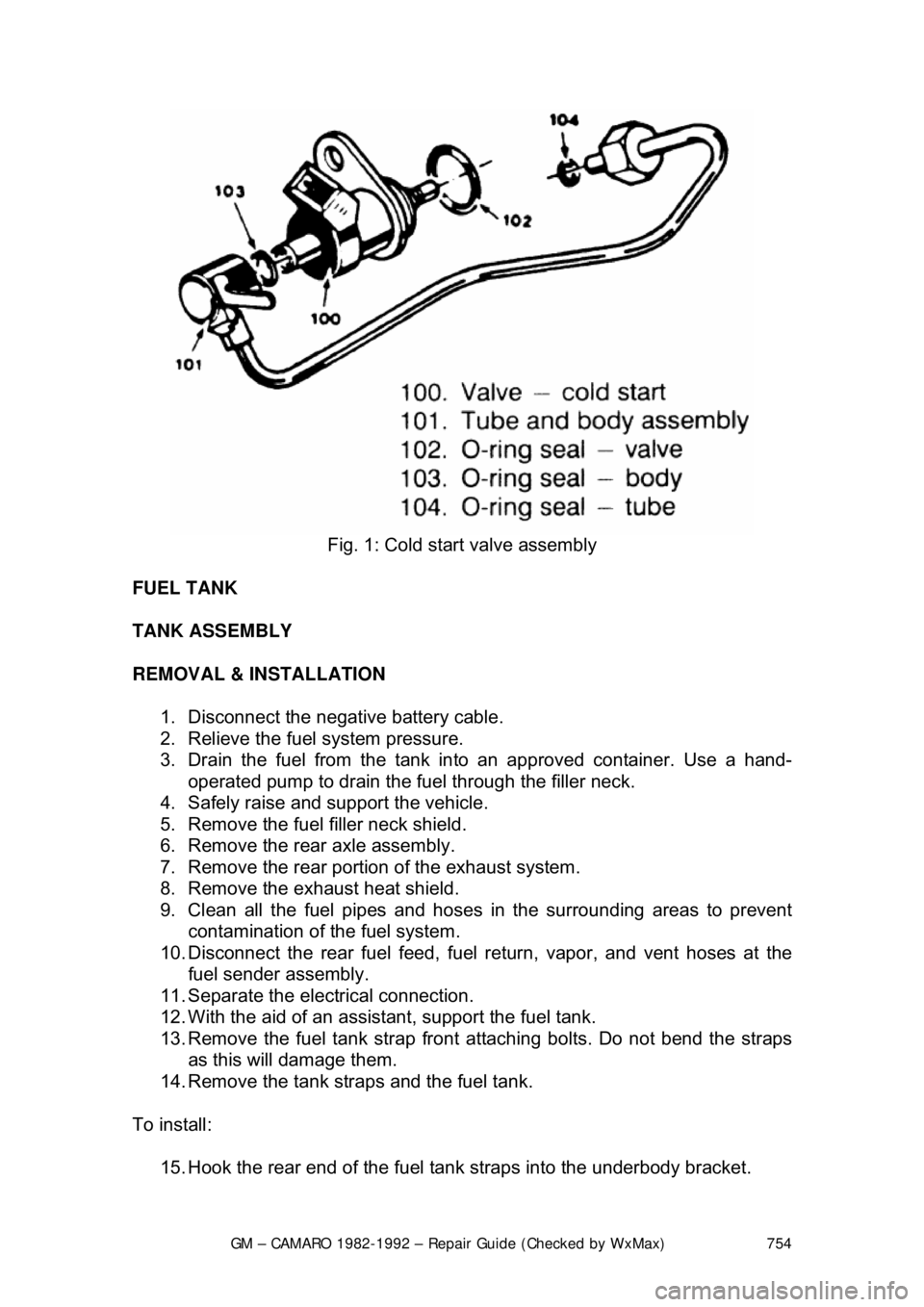

FUEL TANK

TANK ASSEMBLY

REMOVAL & INSTALLATION 1. Disconnect the negative battery cable.

2. Relieve the fuel system pressure.

3. Drain the fuel from the tank in to an approved container. Use a hand-

operated pump to drain the fuel through the filler neck.

4. Safely raise and support the vehicle.

5. Remove the fuel filler neck shield.

6. Remove the rear axle assembly.

7. Remove the rear portion of the exhaust system.

8. Remove the exhaust heat shield.

9. Clean all the fuel pipes and hoses in the surrounding areas to prevent

contamination of the fuel system.

10. Disconnect the rear fuel feed, fuel return, vapor, and vent hoses at the

fuel sender assembly.

11. Separate the electrical connection.

12. With the aid of an assist ant, support the fuel tank.

13. Remove the fuel tank strap front attaching bolts. Do not bend the straps

as this will damage them.

14. Remove the tank straps and the fuel tank.

To install: 15. Hook the rear end of the fuel t ank straps into the underbody bracket.

Page 755 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 755

16. With the aid of an assistant, posit

ion and support the fuel tank with the

straps. Loosely install the front fuel tank attaching bolts.

17. Engage the electrical connection.

18. Connect the fuel hoses and li nes separated during removal.

19. Install the muffler heat sh ield and the exhaust system.

20. Install the rear axle and the fuel filler neck shield.

21. Lower the vehicle.

22. Add fuel and install the filler cap.

23. Connect the negative battery cable.

24. With the engine OFF, turn the igni tion switch to the ON position for 2

seconds, then turn it to the OFF positi on for 10 seconds. Again turn it to

the ON position and check for fuel leaks.

SENDING UNIT REPLACEMENT 1. Remove the fuel tank.

2. Clean the area surrounding t he sender assembly to prevent

contamination of the fuel system.

3. Using tool J-24187 or equivalent, re move the sending unit retaining cam.

Remove the fuel sender and O-rings fr om the tank. Discard the O-rings.

4. If necessary, separate the fuel pum p from the sending unit assembly.

To install: 5. If removed, install the fuel pump to the sending unit. If the strainer was

removed, it must be re placed with a new one.

6. Inspect and clean the O-ring mating surfaces.

7. Install a new O-ring in the groove around the tank opening. If applicable,

install a new O-ring on t he fuel sender feed tube.

8. Install the fuel sender assembly as follows: a. The fuel pump strainer must be in a horizontal position, and when

installed, must not block the travel of the float arm. Gently fold the

strainer over itself an d slowly position the sending assembly in the

tank so the strainer is not dam aged or trapped by the sump walls.

9. Install the retaining cam us ing tool J-24187 or equivalent.

10. Install the fuel tank assembly.

Page 756 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 756

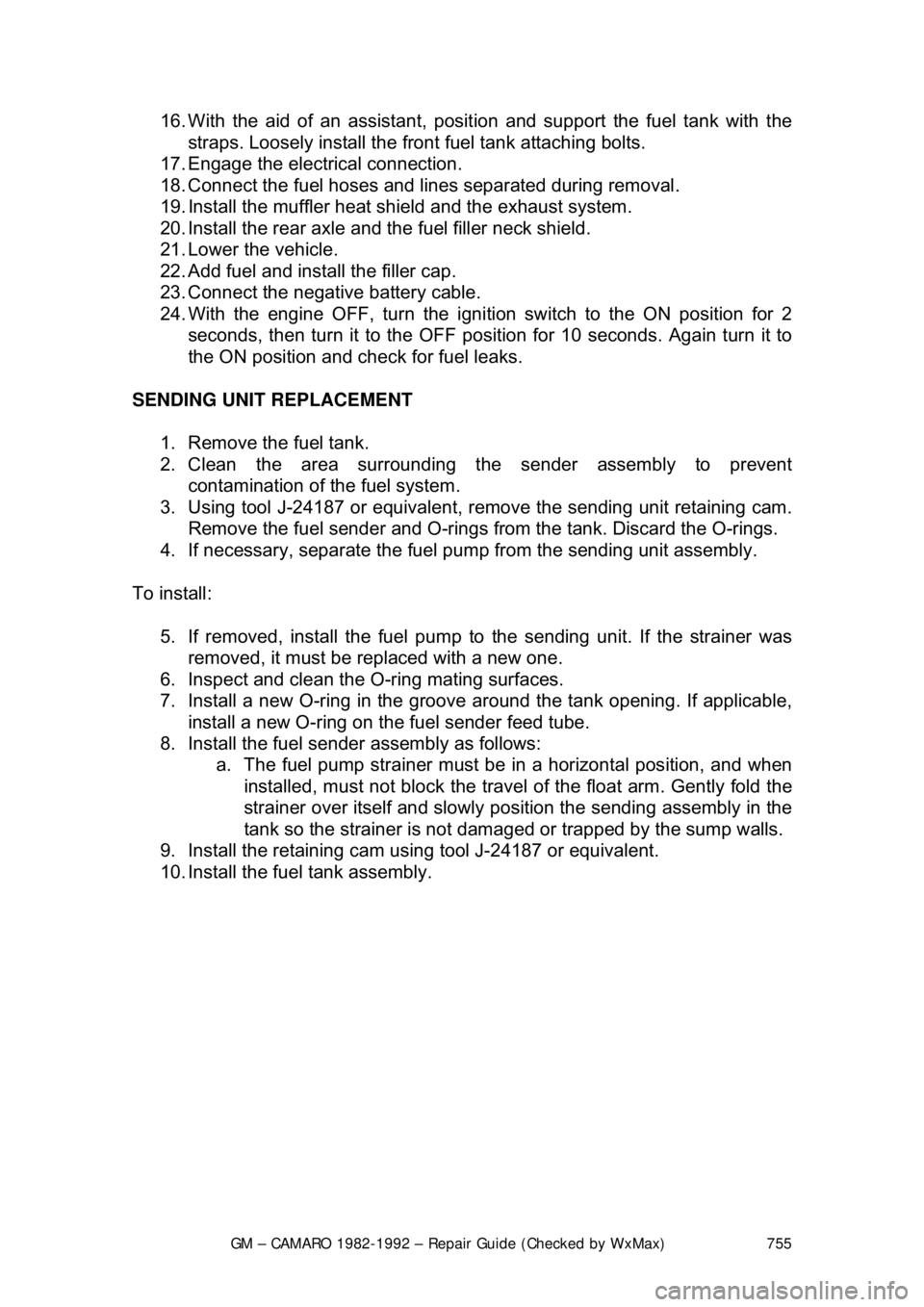

Fig. 1: Quick-connect fittings

Page 757 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 757

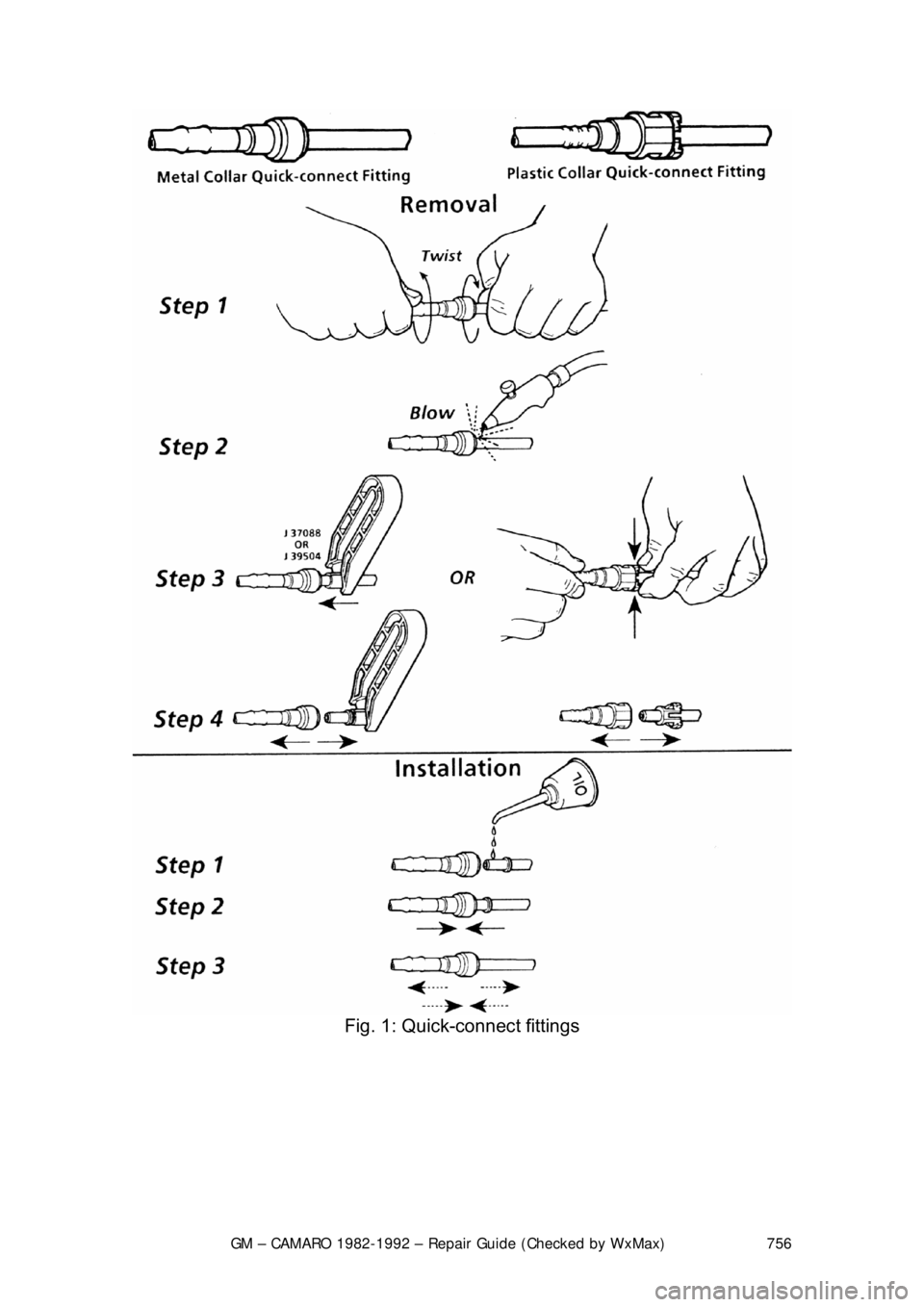

Fig. 2: Fuel tank removal

Page 758 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 758

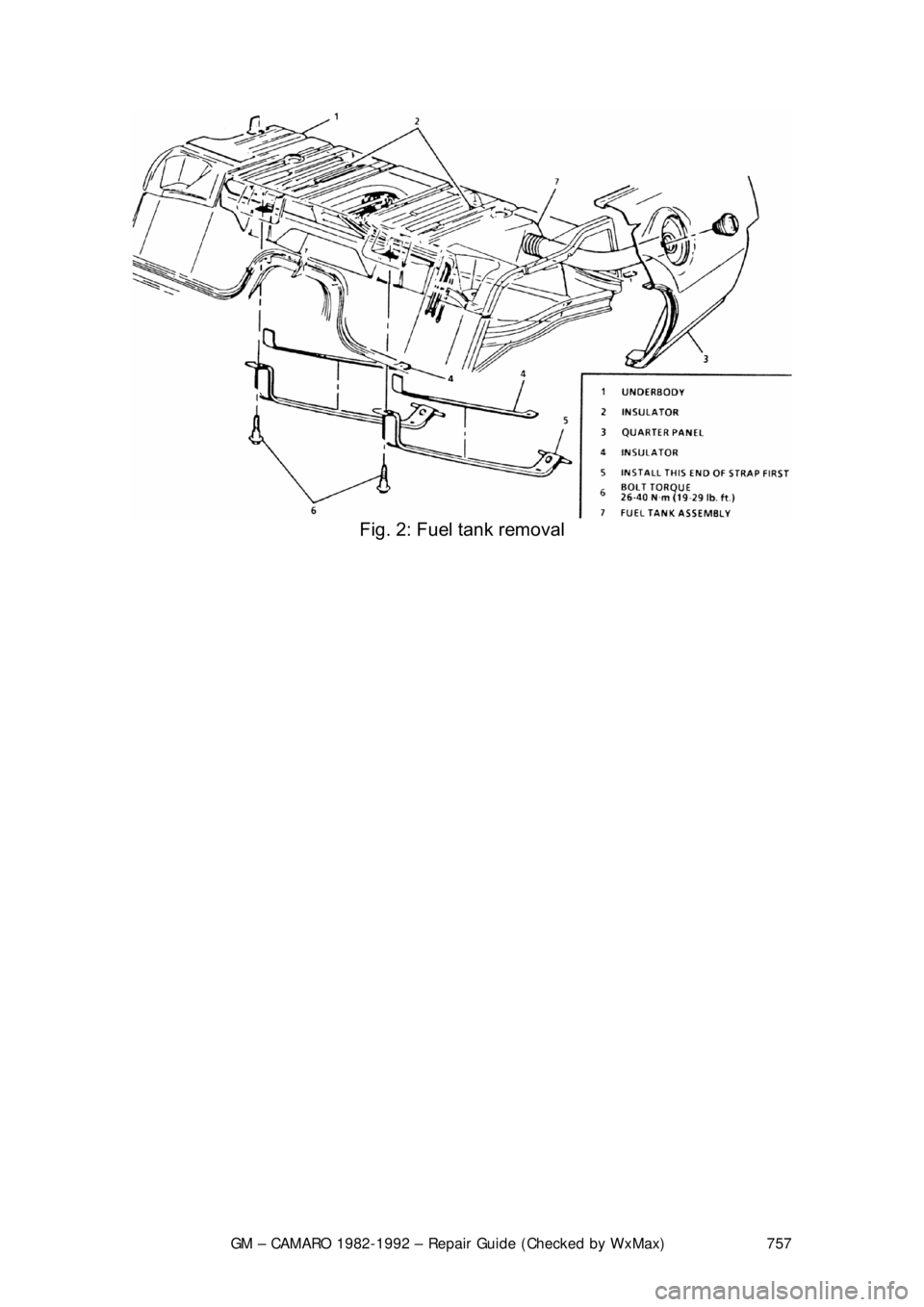

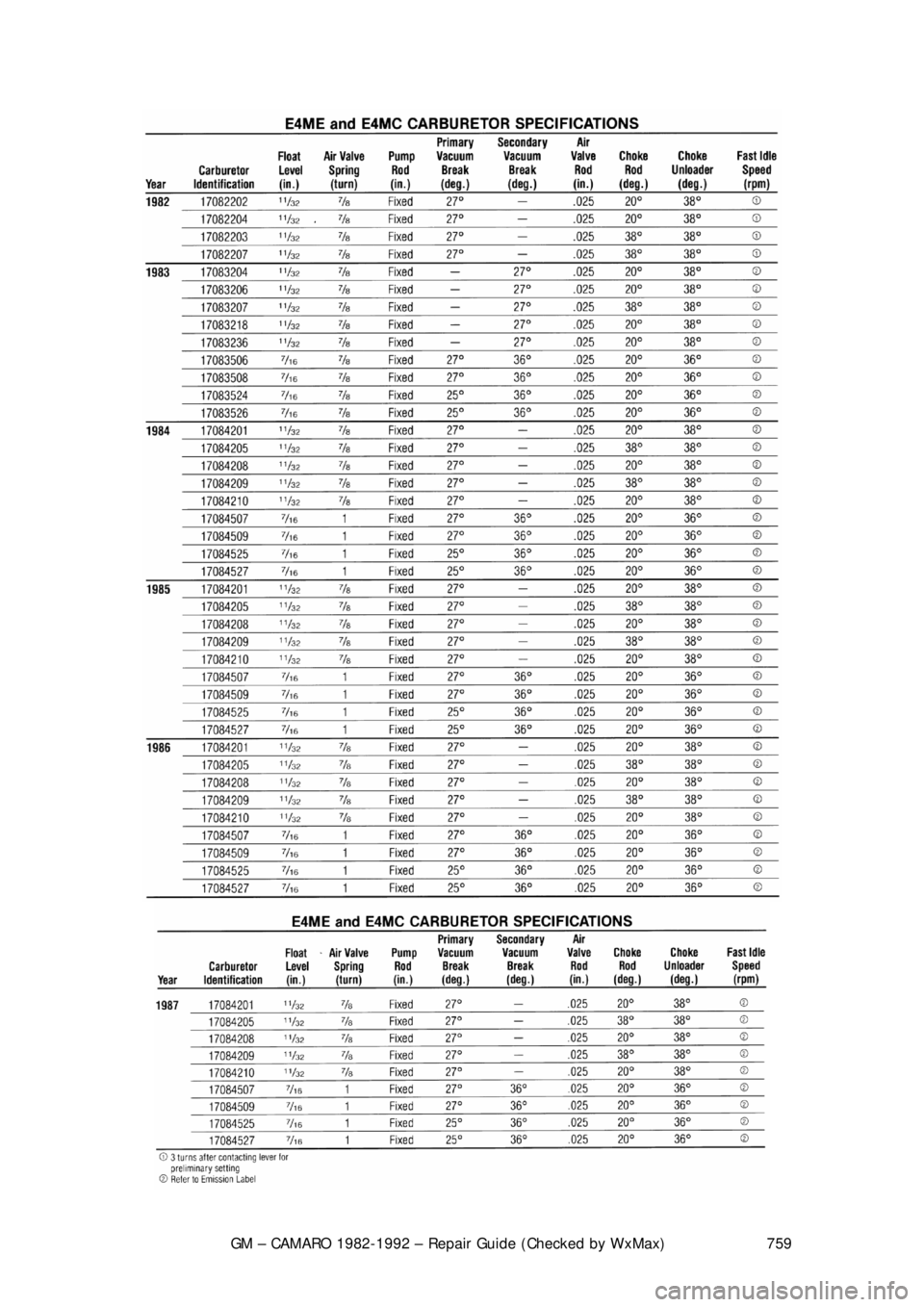

SPECIFICATIONS CHARTS

Page 759 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 759

Page 760 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 760

GENERAL INFORMATION & MAINTENANCE

HOW TO USE THIS INFORMATION

The introductory part of this repair gui de is intended to help you learn more

about the inner workings of your Camaro while saving you money on its upkeep

and operation.

The beginning of the repair guide will likely be referred to the most, since that is

where you will find information for maintenance and tune-up. The other

information deals with the more complex systems of your vehicle. Systems

(from engine through brakes) are covered to the extent that the average do-it-

yourselfer can attempt. This repair guide will not explain such things as

rebuilding a differential because the ex pertise required and the special tools

necessary make this uneconomical. It will, however, give you detailed

instructions to help you change your own brake pads and shoes, replace spark

plugs, and perform many more jobs that can save you money and help avoid

expensive problems.

A secondary purpose of this repair guide is a reference for owners who want to

understand their vehicle and/or their mechanics better.

WHERE TO BEGIN

Before removing any bolts, read through t he entire procedure. This will give you

the overall view of what tools and supplies will be required. So read ahead and

plan ahead. Each operation should be approached logically and all procedures

thoroughly understood before attempting any work.

If repair of a component is not considered practical, we tell you how to remove

the part and then how to insta ll the new or rebuilt replacement. In this way, you

at least save labor costs.

AVOIDING TROUBLE

Many procedures in this repair guide r equire you to "label and disconnect ..." a

group of lines, hoses or wires. Don't be think you can remember where

everything goes - you won't. If you hook up va cuum or fuel lines incorrectly, the

vehicle may run poorly, if at all. If you hook up electrical wiring incorrectly, you

may instantly learn a very expensive lesson.

You don't need to know the proper name for each hose or line. A piece of

masking tape on the hose and a piece on its fitting will allow you to assign your

own label. As long as you remember your own code, the lines can be

reconnected by matching your tags. Re member that tape will dissolve in

gasoline or solvents; if a part is to be washed or cleaned, use another method

of identification. A permanent felt-tipped marker or a metal scribe can be very

handy for marking metal parts. Remove any tape or paper labels after

assembly.