wheel CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1903 of 2438

line. However, these could result in a rich or lean

condition causing an oxygen sensor fault to be stored in

the PCM. Secondary Ignition Circuit - The PCM cannot

detect an inoperative ignition coil, fouled or worn spark

plugs, ignition cross firing, or open spark plug cables. Engine Timing - The PCM cannot detect an incor-

rectly indexed timing chain, camshaft sprocket and

crankshaft sprocket. However, these could result in a

rich or lean condition causing an oxygen sensor fault to

be stored in the PCM. Cylinder Compression - The PCM cannot detect

uneven, low, or high engine cylinder compression. Exhaust System - The PCM cannot detect a

plugged, restricted or leaking exhaust system. Fuel Injector Malfunctions - The PCM cannot

determine if a fuel injector is clogged, the needle is

sticking or the wrong injector is installed. However,

these could result in a rich or lean condition causing an

oxygen sensor fault to be stored in the PCM. Excessive Oil Consumption - Although the PCM

monitors exhaust stream oxygen content when the

system is in closed loop, it cannot determine excessive

oil consumption. Throttle Body Air Flow - The PCM cannot detect a

clogged or restricted air cleaner inlet or filter element. Evaporative System - The PCM will not detect a

restricted, plugged or loaded evaporative purge canis-

ter. Vacuum Assist - Leaks or restrictions in the

vacuum circuits of vacuum assisted engine control

system devices are not monitored by the PCM. How-

ever, these could result in a MAP sensor fault being

stored in the PCM. PCM System Ground - The PCM cannot determine

a poor system ground. However, a diagnostic trouble

code may be generated as a result of this condition. PCM Connector Engagement - The PCM cannot

determine spread or damaged connector pins. How-

ever, a diagnostic trouble code may be generated as a

result of this condition.

HIGH AND LOW LIMITS

The powertrain control module (PCM) compares in-

put signal voltages from each input device with estab-

lished high and low limits for the device. If the input

voltage is not within limits and other diagnostic

trouble code criteria are met, a diagnostic trouble code

will be stored in memory. Other diagnostic trouble code

criteria might include engine RPM limits or input

voltages from other sensors or switches that must be

present before a fault condition can be verified.

DIAGNOSTIC TROUBLE CODE DESCRIPTION

A diagnostic trouble code indicates that the power-

train control module (PCM) has recognized an abnor- mal condition in the system. Diagnostic trouble codes

can be obtained from the malfunction indicator lamp

(Check Engine lamp on the instrument panel) or from

the DRBII scan tool. Diagnostic trouble codes indicate

the results of a failure but do not identify the failed

component directly.

SYSTEM TESTS

WARNING: APPLY PARKING BRAKE AND/OR BLOCK

WHEELS BEFORE PERFORMING ANY TEST ON AN

OPERATING ENGINE.

OBTAINING DIAGNOSTIC TROUBLE CODES

(1) Connect the DRBII scan tool to the data link

connector located in the engine compartment near the

driver side strut tower (Fig. 1). (2) Start the engine if possible, cycle the transaxle

selector and the A/Cswitch if applicable. Shut off the

engine. (3) Turn the ignition switch on, access Read Fault

Screen. Record all the fault messages shown on the

DRBII scan tool. Observe the malfunction indicator

lamp (check engine lamp on the instrument panel). The

lamp should light for 2 seconds then go out (bulb

check). Diagnostic trouble code erasure; access erase

diagnostic trouble code data

STATE DISPLAY TEST MODE

The switch inputs used by the powertrain control

module (PCM) have only two recognized states, HIGH

and LOW. For this reason, the PCM cannot recognize

the difference between a selected switch position ver-

sus an open circuit, a short circuit, or a defective

switch. If the change is displayed, it can be assumed

that the entire switch circuit to the PCM is functional.

From the state display screen access either State

Display Inputs and Outputs or State Display Sensors.

STATE DISPLAY INPUTS AND OUTPUTS

Connect the DRBII scan tool to the vehicle and access

the State Display screen. Then access Inputs and

Outputs. The following is a list of the engine control

system functions accessible through the Inputs and

Outputs screen. Park/Neutral Switch

Speed Control Resume

Brake Switch

Speed Control On/Off

Speed Control Set

A/C Switch Sense

S/C Vent Solenoid

Ä FUEL SYSTEMS 14 - 163

Page 1919 of 2438

STEERING

CONTENTS

page page

ACUSTAR STANDARD AND TILT STEERING COLUMN ............................ 28

AUTOMATIC TRANSMISSION SHIFTER/IGNITION INTERLOCK .......................... 36

GENERAL INFORMATION .................. 1 POWER STEERING GEAR

................ 25

POWER STEERING PUMPS ................ 1

SPECIFICATIONS AND TIGHTENING REFERENCE .......................... 42

GENERAL INFORMATION

Safety goggles should be worn at all times

when working on any steering gear or pump. Throughout this group, references may be made to

a particular vehicle by letter or number designation.

A chart showing the breakdown of these designations

is included in the Introduction Section at the front of

this service manual. The power steering system consists of these four

major components. Power Steering Pump, Power

Steering Gear, Pressure Hose, and Return Line.

Turning of the steering wheel is converted into lin-

ear travel through the meshing of the helical pinion teeth with the rack teeth. Power assist steering is

provided by an open center, rotary type control valve.

It is used to direct oil from the power steering pump

to either side of the integral steering rack piston. Road feel is controlled by the diameter of a torsion

bar which initially steers the vehicle. As steering ef-

fort increases as in a turn, the torsion bar twists,

causing relative rotary motion between the rotary

valve body and valve spool. This movement directs

oil behind the integral rack piston, which in turn,

builds up hydraulic pressure and assists in the turn-

ing effort.

POWER STEERING PUMPS

INDEX

page page

Checking Power Steering Fluid Level .......... 9

Flow Control Valve Fitting O-Ring Seal ........ 23

General Information ........................ 1

Power Steering Hoses ..................... 11

Power Steering Pressure Switch ............. 10

Power Steering Pump Fluid Reservoirs ........ 22 Power Steering Pump Pressure Test

........... 9

Power Steering Pump Pulley Service .......... 20

Power Steering Pump Removal .............. 12

Power Steering Pump Service ................ 2

Power Steering PumpÐInitial Operation ....... 24

Steering Components Service Diagnosis ........ 2

GENERAL INFORMATION

Hydraulic pressure for operation of the power

steering gear is provided by a belt driven power

steering pump. The power steering pump is a con-

stant flow rate and displacement, vane type pump.

Different styles of Saginaw power steering pumps are

used depending on the engine application of the ve-

hicle. On all four cylinder and 3.0-liter V-6 applications

the Saginaw Ham Can power steering pump is used

(Fig. 1). On the 3.3 & 3.8-liter V-6 and Turbo III applica-

tions, different versions of the Saginaw T/C style

power steering pump is used (Fig. 2). The 3.3 & 3.8 liter V-6 engine application uses the T/C style power

steering pump with a remote mounted reservoir for

the power steering fluid. On the Turbo III application

of the T/C style power steering pump, the power

steering fluid reservoir is integral to the power steer-

ing pump. On the integral reservoir type pump (Fig. 1) the

pump housing and internal components are combined

with the reservoir to form a one-piece mechanism. The Saginaw T/C style power steering pump (Fig.

2), consists of the power steering pump internal com-

ponents and pump housing. The Saginaw T/C style

power steering pump though has no internal reser-

voir for the power steering fluid. Depending on vehi-

Ä STEERING 19 - 1

Page 1927 of 2438

When steering conditions exceed maximum pres-

sure requirements, such as when the wheels are

turned against the stops. The pressure built up in

the steering gear exerts pressure on the spring end of

the flow control valve. The high pressure lifts the re-

lief valve ball from its seat and allows oil to flow

through a trigger orifice located in the outlet fitting.

This reduces pressure on the spring end of the flow

control valve which then opens and allows the oil to

return to the intake side of the pump. This action

limits maximum pressure output of the pump to a

safe level. Under normal power steering pump operating con-

ditions, pressure requirements of the pump are below

maximum, causing the pressure relief valve to re-

main closed.

CHECKING POWER STEERING FLUID LEVEL

WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH ENGINE OFF TO PREVENT INJURY FROM

MOVING PARTS. DO NOT USE AUTOMATIC TRANS-

MISSION FLUID IN THE POWER STEERING SYS-

TEM. DO NOT OVERFILL THE POWER STEERING

SYSTEM.

Wipe reservoir filler cap free of dirt, before check-

ing power steering fluid level. The dipstick should in- dicate FULL COLD when fluid is at normal ambient

temperature, approximately 21ÉC to 27ÉC (70ÉF to

80ÉF). In all pumps add fluid as necessary to obtain

proper level, using only MopartPower Steering

Fluid, or equivalent. DO NOT USE ANY TYPE

OF AUTOMATIC TRANSMISSION FLUID.

POWER STEERING PUMP PRESSURE TEST

The following procedure can be used to test the op-

eration of the power steering system on the vehicle. (1) Check power steering pump drive belt tension

and adjust as necessary. (2) Disconnect power steering fluid pressure hose,

at steering gear or power steering pump. Use a con-

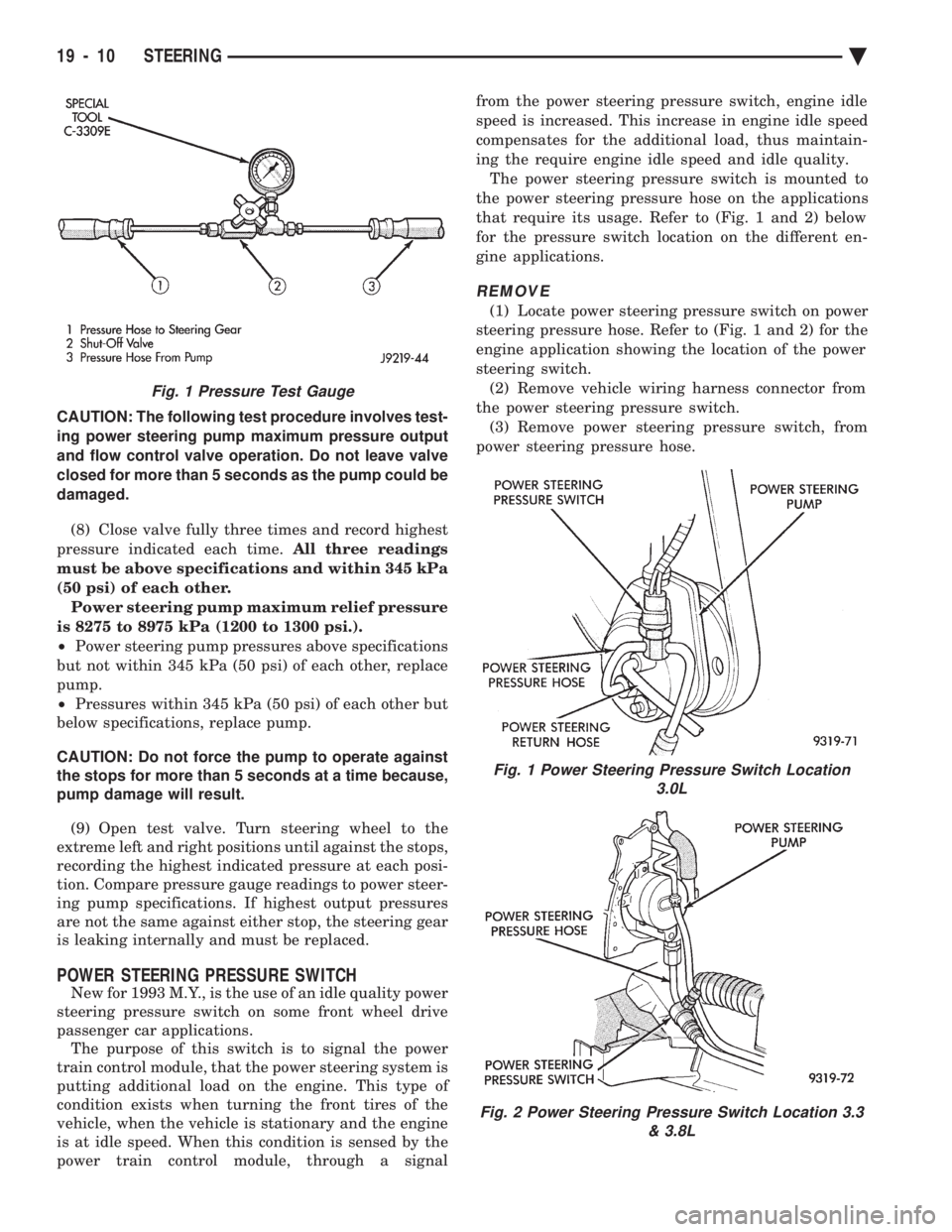

tainer for dripping fluid. (3) Connect Pressure Gauge, Special Tool C-3309-E

(Fig. 1) to both hoses using adapter fittings. Connect

spare pressure hose to gear or pump. (4) Completely open valve on Special Tool

C-3309-E (Fig. 1). (5) Start engine and let idle.

(6) Check power steering fluid level, and add fluid

as necessary. (7) Gauge should read below 862 kPa (125 psi), if

above, inspect the hoses for restrictions and repair as

necessary. The initial pressure should be in the

range of 345-552 kPa (50-80 psi).

PUMP LEAKAGE DIAGNOSIS

Ä STEERING 19 - 9

Page 1928 of 2438

CAUTION: The following test procedure involves test-

ing power steering pump maximum pressure output

and flow control valve operation. Do not leave valve

closed for more than 5 seconds as the pump could be

damaged.

(8) Close valve fully three times and record highest

pressure indicated each time. All three readings

must be above specifications and within 345 kPa

(50 psi) of each other. Power steering pump maximum relief pressure

is 8275 to 8975 kPa (1200 to 1300 psi.).

² Power steering pump pressures above specifications

but not within 345 kPa (50 psi) of each other, replace

pump.

² Pressures within 345 kPa (50 psi) of each other but

below specifications, replace pump.

CAUTION: Do not force the pump to operate against

the stops for more than 5 seconds at a time because,

pump damage will result.

(9) Open test valve. Turn steering wheel to the

extreme left and right positions until against the stops,

recording the highest indicated pressure at each posi-

tion. Compare pressure gauge readings to power steer-

ing pump specifications. If highest output pressures

are not the same against either stop, the steering gear

is leaking internally and must be replaced.

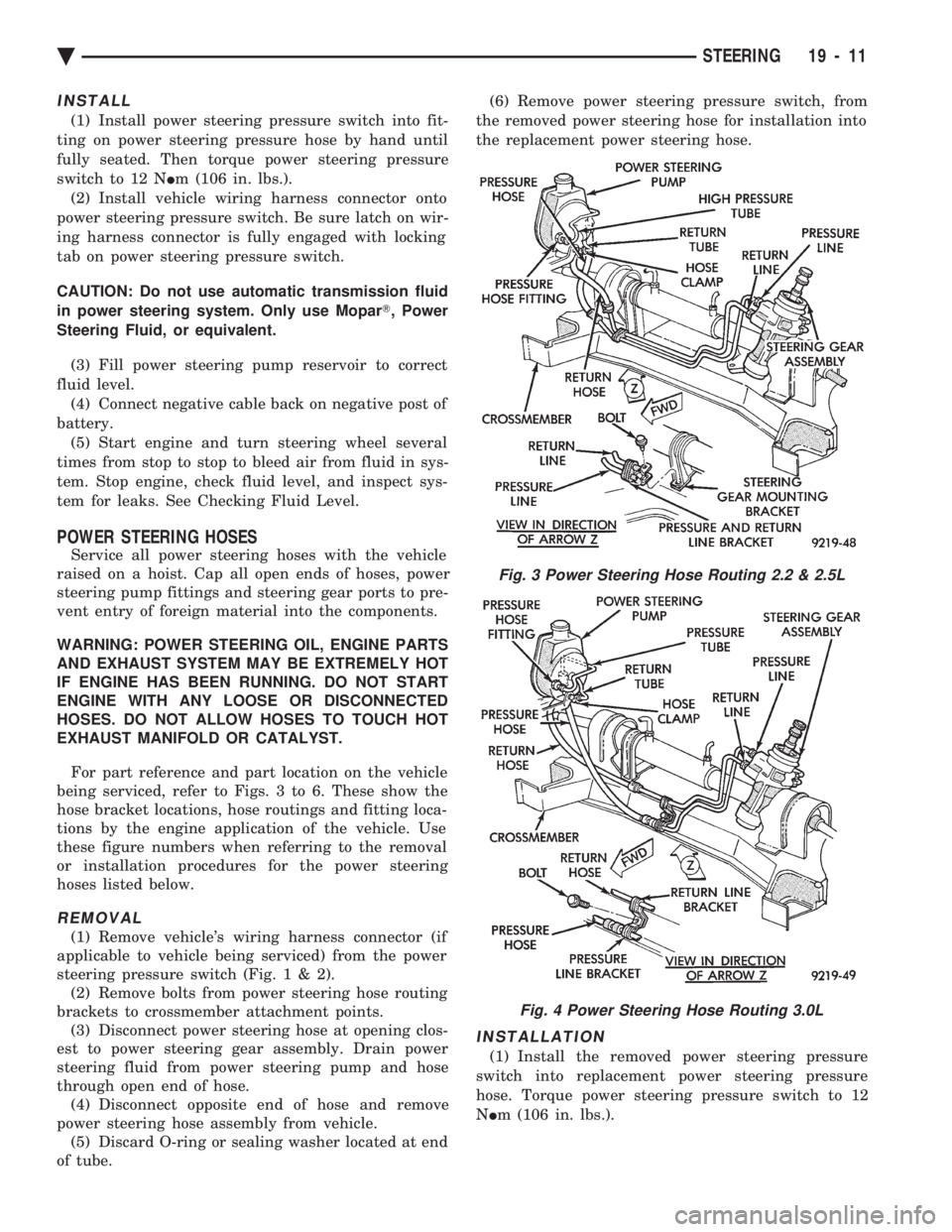

POWER STEERING PRESSURE SWITCH

New for 1993 M.Y., is the use of an idle quality power

steering pressure switch on some front wheel drive

passenger car applications. The purpose of this switch is to signal the power

train control module, that the power steering system is

putting additional load on the engine. This type of

condition exists when turning the front tires of the

vehicle, when the vehicle is stationary and the engine

is at idle speed. When this condition is sensed by the

power train control module, through a signal from the power steering pressure switch, engine idle

speed is increased. This increase in engine idle speed

compensates for the additional load, thus maintain-

ing the require engine idle speed and idle quality.

The power steering pressure switch is mounted to

the power steering pressure hose on the applications

that require its usage. Refer to (Fig. 1 and 2) below

for the pressure switch location on the different en-

gine applications.

REMOVE

(1) Locate power steering pressure switch on power

steering pressure hose. Refer to (Fig. 1 and 2) for the

engine application showing the location of the power

steering switch. (2) Remove vehicle wiring harness connector from

the power steering pressure switch. (3) Remove power steering pressure switch, from

power steering pressure hose.

Fig. 1 Power Steering Pressure Switch Location 3.0L

Fig. 2 Power Steering Pressure Switch Location 3.3 & 3.8L

Fig. 1 Pressure Test Gauge

19 - 10 STEERING Ä

Page 1929 of 2438

INSTALL

(1) Install power steering pressure switch into fit-

ting on power steering pressure hose by hand until

fully seated. Then torque power steering pressure

switch to 12 N Im (106 in. lbs.).

(2) Install vehicle wiring harness connector onto

power steering pressure switch. Be sure latch on wir-

ing harness connector is fully engaged with locking

tab on power steering pressure switch.

CAUTION: Do not use automatic transmission fluid

in power steering system. Only use Mopar T, Power

Steering Fluid, or equivalent.

(3) Fill power steering pump reservoir to correct

fluid level. (4) Connect negative cable back on negative post of

battery. (5) Start engine and turn steering wheel several

times from stop to stop to bleed air from fluid in sys-

tem. Stop engine, check fluid level, and inspect sys-

tem for leaks. See Checking Fluid Level.

POWER STEERING HOSES

Service all power steering hoses with the vehicle

raised on a hoist. Cap all open ends of hoses, power

steering pump fittings and steering gear ports to pre-

vent entry of foreign material into the components.

WARNING: POWER STEERING OIL, ENGINE PARTS

AND EXHAUST SYSTEM MAY BE EXTREMELY HOT

IF ENGINE HAS BEEN RUNNING. DO NOT START

ENGINE WITH ANY LOOSE OR DISCONNECTED

HOSES. DO NOT ALLOW HOSES TO TOUCH HOT

EXHAUST MANIFOLD OR CATALYST.

For part reference and part location on the vehicle

being serviced, refer to Figs. 3 to 6. These show the

hose bracket locations, hose routings and fitting loca-

tions by the engine application of the vehicle. Use

these figure numbers when referring to the removal

or installation procedures for the power steering

hoses listed below.

REMOVAL

(1) Remove vehicle's wiring harness connector (if

applicable to vehicle being serviced) from the power

steering pressure switch (Fig .1&2).

(2) Remove bolts from power steering hose routing

brackets to crossmember attachment points. (3) Disconnect power steering hose at opening clos-

est to power steering gear assembly. Drain power

steering fluid from power steering pump and hose

through open end of hose. (4) Disconnect opposite end of hose and remove

power steering hose assembly from vehicle. (5) Discard O-ring or sealing washer located at end

of tube. (6) Remove power steering pressure switch, from

the removed power steering hose for installation into

the replacement power steering hose.

INSTALLATION

(1) Install the removed power steering pressure

switch into replacement power steering pressure

hose. Torque power steering pressure switch to 12

N Im (106 in. lbs.).

Fig. 3 Power Steering Hose Routing 2.2 & 2.5L

Fig. 4 Power Steering Hose Routing 3.0L

Ä STEERING 19 - 11

Page 1932 of 2438

(10) Connect negative cable back on negative post

of battery. (11) Start engine and turn steering wheel several

times from stop to stop to bleed air from fluid in sys-

tem. Stop engine, check fluid level, and inspect sys-

tem for leaks. See Checking Fluid Level.

3.0 LITER

REMOVE

(1) REMOVE THE (-) NEGATIVE BATTERY CA-

BLE FROM THE BATTERY AND ISOLATE CA-

BLE. (2) Remove the serpentine accessory drive belt

from engine (Fig. 4). See Cooling, Group 7 for de-

tailed removal procedure.

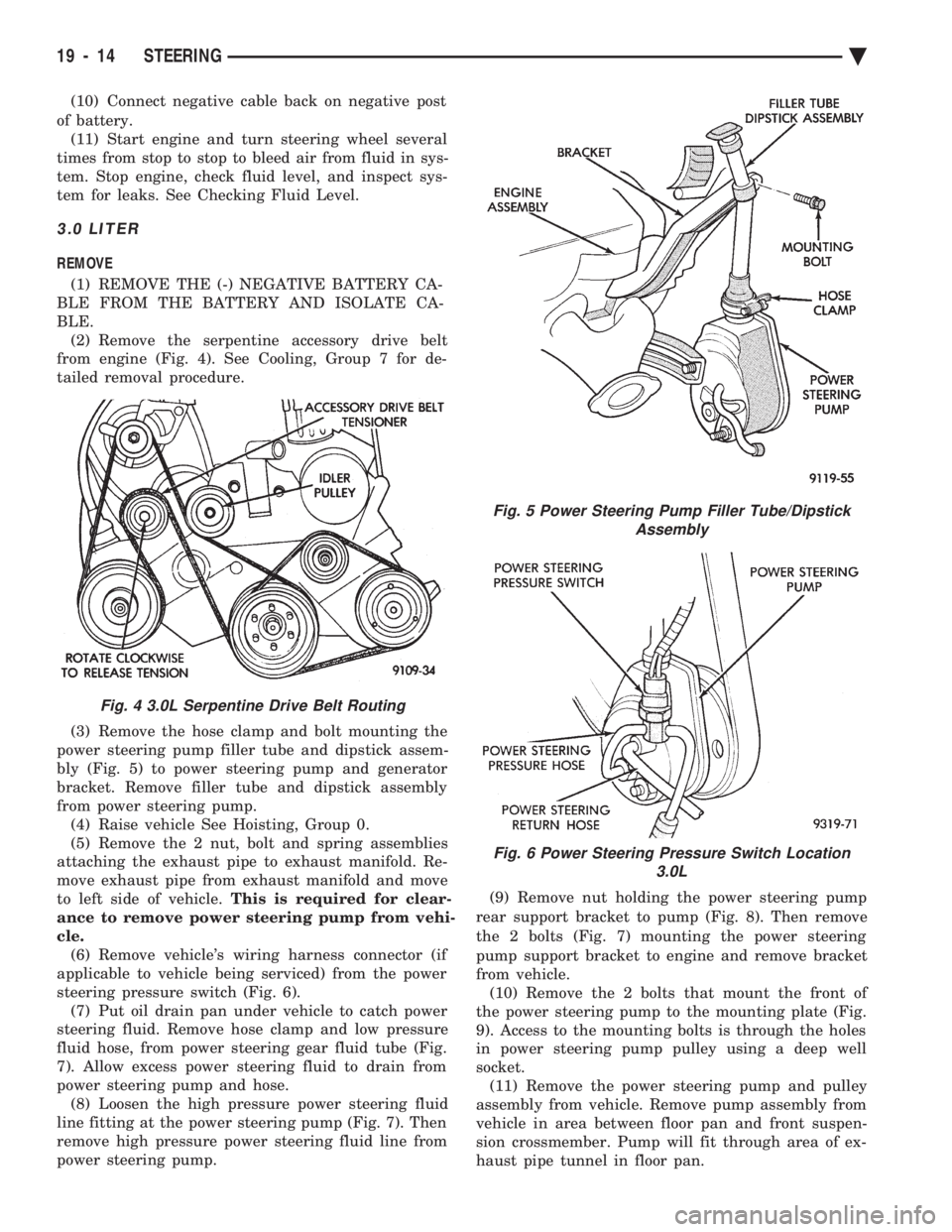

(3) Remove the hose clamp and bolt mounting the

power steering pump filler tube and dipstick assem-

bly (Fig. 5) to power steering pump and generator

bracket. Remove filler tube and dipstick assembly

from power steering pump. (4) Raise vehicle See Hoisting, Group 0.

(5) Remove the 2 nut, bolt and spring assemblies

attaching the exhaust pipe to exhaust manifold. Re-

move exhaust pipe from exhaust manifold and move

to left side of vehicle. This is required for clear-

ance to remove power steering pump from vehi-

cle. (6) Remove vehicle's wiring harness connector (if

applicable to vehicle being serviced) from the power

steering pressure switch (Fig. 6). (7) Put oil drain pan under vehicle to catch power

steering fluid. Remove hose clamp and low pressure

fluid hose, from power steering gear fluid tube (Fig.

7). Allow excess power steering fluid to drain from

power steering pump and hose. (8) Loosen the high pressure power steering fluid

line fitting at the power steering pump (Fig. 7). Then

remove high pressure power steering fluid line from

power steering pump. (9) Remove nut holding the power steering pump

rear support bracket to pump (Fig. 8). Then remove

the 2 bolts (Fig. 7) mounting the power steering

pump support bracket to engine and remove bracket

from vehicle. (10) Remove the 2 bolts that mount the front of

the power steering pump to the mounting plate (Fig.

9). Access to the mounting bolts is through the holes

in power steering pump pulley using a deep well

socket. (11) Remove the power steering pump and pulley

assembly from vehicle. Remove pump assembly from

vehicle in area between floor pan and front suspen-

sion crossmember. Pump will fit through area of ex-

haust pipe tunnel in floor pan.

Fig. 4 3.0L Serpentine Drive Belt Routing

Fig. 5 Power Steering Pump Filler Tube/Dipstick Assembly

Fig. 6 Power Steering Pressure Switch Location 3.0L

19 - 14 STEERING Ä

Page 1934 of 2438

(15) Start engine and turn steering wheel several

times from stop to stop to bleed air from fluid in sys-

tem. Stop engine, check fluid level, and inspect sys-

tem for leaks. See Checking Fluid Level.

3.3 & 3.8 LITER

REMOVE

(1) Remove the (-) negative battery cable from the

battery and isolate cable. (2) Remove the serpentine accessory drive belt

from engine (Fig. 10). See Cooling, Group 7 for de-

tailed removal procedure.

(3) Raise vehicle See Hoisting, Group 0.

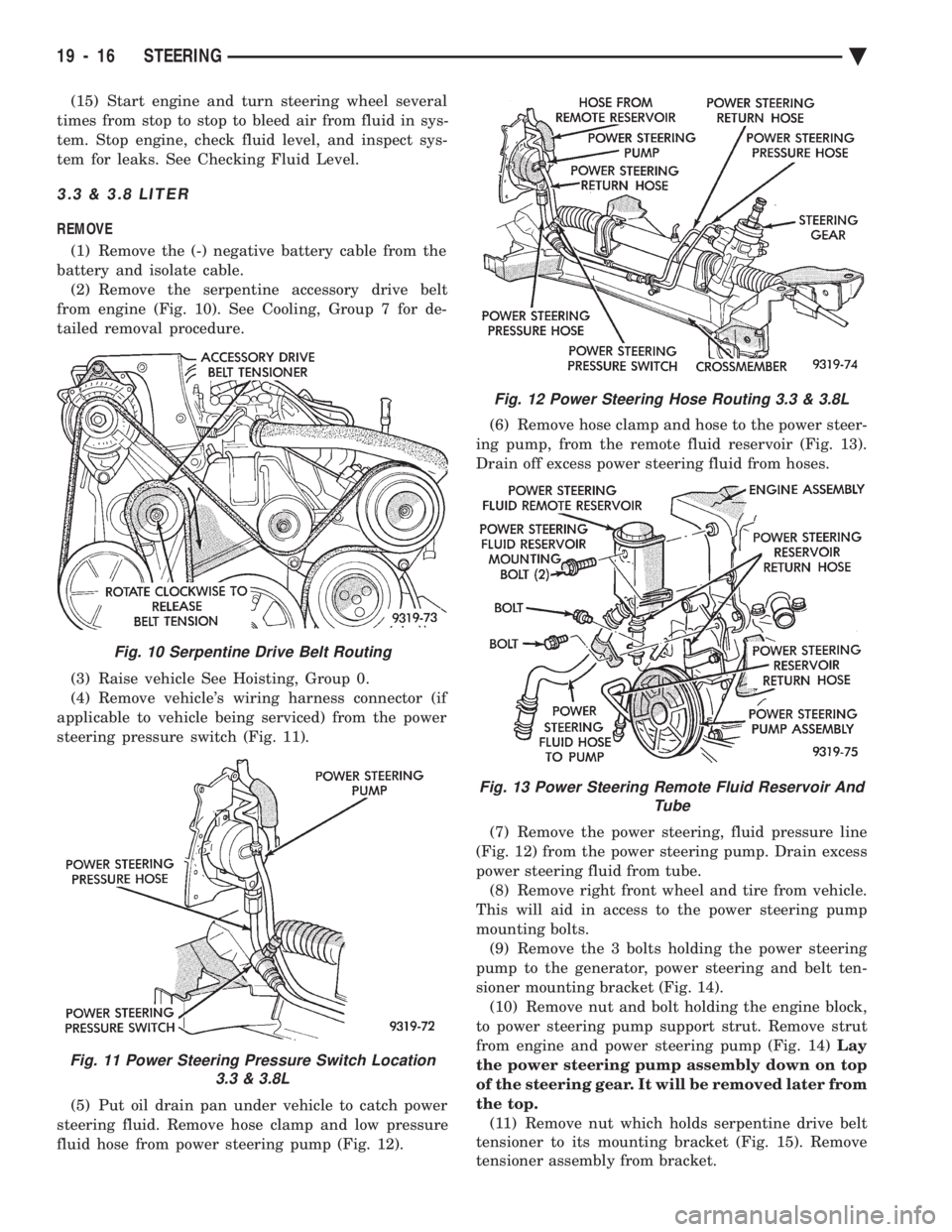

(4) Remove vehicle's wiring harness connector (if

applicable to vehicle being serviced) from the power

steering pressure switch (Fig. 11).

(5) Put oil drain pan under vehicle to catch power

steering fluid. Remove hose clamp and low pressure

fluid hose from power steering pump (Fig. 12). (6) Remove hose clamp and hose to the power steer-

ing pump, from the remote fluid reservoir (Fig. 13).

Drain off excess power steering fluid from hoses.

(7) Remove the power steering, fluid pressure line

(Fig. 12) from the power steering pump. Drain excess

power steering fluid from tube. (8) Remove right front wheel and tire from vehicle.

This will aid in access to the power steering pump

mounting bolts. (9) Remove the 3 bolts holding the power steering

pump to the generator, power steering and belt ten-

sioner mounting bracket (Fig. 14). (10) Remove nut and bolt holding the engine block,

to power steering pump support strut. Remove strut

from engine and power steering pump (Fig. 14) Lay

the power steering pump assembly down on top

of the steering gear. It will be removed later from

the top. (11) Remove nut which holds serpentine drive belt

tensioner to its mounting bracket (Fig. 15). Remove

tensioner assembly from bracket.

Fig. 10 Serpentine Drive Belt Routing

Fig. 11 Power Steering Pressure Switch Location 3.3 & 3.8L

Fig. 12 Power Steering Hose Routing 3.3 & 3.8L

Fig. 13 Power Steering Remote Fluid Reservoir And Tube

19 - 16 STEERING Ä

Page 1936 of 2438

INSTALL (1) Install power steering pump back in vehicle,

laying it on the steering gear. Do not mount it to the

power steering pump bracket. (2) Install generator back on the lower generator

bracket and install bolt and nut (Fig. 19). Do not

tighten bolt at this time. (3) Install the generator bracket back on engine and

intake manifold. Loosely install the 4 generator

bracket to engine attaching bolts (Fig. 19). Be sure

the SPACER (Fig. 18) is installed between the

engine mounting strut and the generator

bracket. (4) Temporarily install the serpentine belt tensioner

bolt through both generator brackets. This will align

all generator bracket mounting holes (Fig. 15). Then

torque the 4 generator bracket to engine and intake manifold mounting bolts to 54 N

Im (40 ft.

lbs.). Then remove the serpentine belt tensioner from

bracket. It will be installed on the bracket in a

later step. (5) Tighten the bolt holding the engine bracket as-

sembly to the engine support assembly (Fig. 18) to 150

N Im (110 ft. lbs.).

(6) Attach the engine wiring harness routing clip to

the generator bracket. (7) Install the generator to generator bracket attach-

ing bolt (Fig. 19). Torque bolt to 54 N Im (40 ft. lbs.).

Tighten the lower generator pivot bolt to 54 N Im (40 ft.

lbs.). (8) Install the power steering pump fluid reservoir

and tube/hose assembly onto the power steering pump

bracket and generator bracket (Fig. 17). Torque the 2

bolts holding the reservoir to the generator bracket to

5N Im (45 in. lbs.). Torque the 1 bolt holding the

tube/hose assembly to the power steering pump

bracket to 12 N Im (105 in. lbs.).

(9) Raise vehicle See Hoisting, Group 0.

(10) Install the strut assembly power

steering/generator bracket to engine (Fig. 16). Torque

the nut and bolt holding the strut assembly to bracket

and the exhaust manifold stud to 54 N Im (40 ft. lbs).

(11) Install the serpentine drive belt tensioner onto

the power steering/generator bracket (Fig. 15). Install

the tensioner to bracket retaining nut and torque to 54

N Im (40 ft. lbs.).

(12) Install the power steering pump on bracket, by

aligning the 3 mounting holes in pump with mounting

holes in bracket (Fig. 14). Install the 3 power steering

pump to bracket mounting bolts. Torque power steer-

ing pump mounting bolts to 54 N Im (40 ft. lbs.).

(13) Install the support strut, engine block to power

steering pump on pump stud (Fig. 14). Install the nut

and bolt holding the strut to the power steering pump

and engine block and torque to 54 N Im (40 ft. lbs.).

(14) Install the power steering fluid pressure line

onto the output fitting of the power steering pump (Fig.

12). Torque the pressure line pump fitting nut to 31

N Im (275 in. lbs.). Before connecting the pressure

line to power steering pump inspect the O-ring

on the pressure line for damage. (15) Install vehicle's wiring harness connector (if

applicable to vehicle being serviced) onto the power

steering pressure switch (Fig. 11). (16) Install the power steering fluid, low pressure

return hose on the power steering pump low pressure

fitting (Fig. 12). Then install the hose from the remote

reservoir onto the power steering pump (Fig. 13). Be

sure all hose clamps are properly reinstalled. (17) Install right front tire and wheel on vehicle.

Install the wheel stud nuts and torque to 129 N Im (95

ft. lbs.).

Fig. 18 Engine Bracket Support Assembly

Fig. 19 Generator Mounting

19 - 18 STEERING Ä

Page 1937 of 2438

(18) Lower vehicle.

(19) Install the serpentine drive belt. Refer to (Fig.

10) for correct serpentine belt routing. See Cooling,

Group 7 for detailed installation procedure.

CAUTION: Do not use automatic transmission fluid

in power steering system. Only use Mopar T, Power

Steering Fluid, or equivalent.

(20) Fill power steering pump reservoir to correct

fluid level. (21) Connect the negative battery cable on the

negative battery post. (22) Start engine and turn steering wheel several

times from stop to stop to bleed air from fluid in sys-

tem. Stop engine, check fluid level, and inspect sys-

tem for leaks. See Checking Fluid Level.

TURBO III

REMOVE

(1) Disconnect the battery (-) negative cable from

the battery and isolate cable. (2) Raise vehicle See Hoisting, Group 0. Put oil

drain pan under vehicle to catch power steering

fluid. (3) Remove the right front underhood splash shield

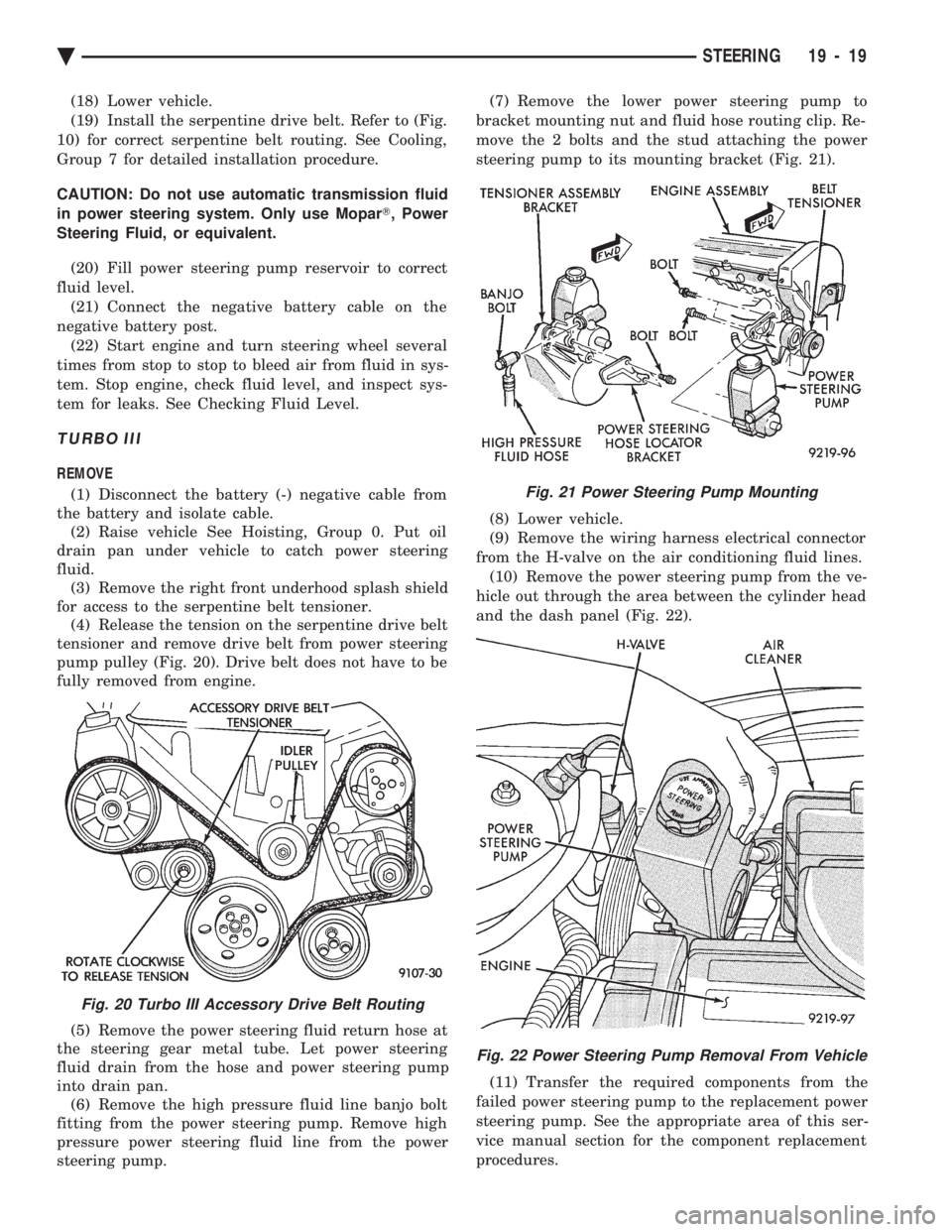

for access to the serpentine belt tensioner. (4) Release the tension on the serpentine drive belt

tensioner and remove drive belt from power steering

pump pulley (Fig. 20). Drive belt does not have to be

fully removed from engine.

(5) Remove the power steering fluid return hose at

the steering gear metal tube. Let power steering

fluid drain from the hose and power steering pump

into drain pan. (6) Remove the high pressure fluid line banjo bolt

fitting from the power steering pump. Remove high

pressure power steering fluid line from the power

steering pump. (7) Remove the lower power steering pump to

bracket mounting nut and fluid hose routing clip. Re-

move the 2 bolts and the stud attaching the power

steering pump to its mounting bracket (Fig. 21).

(8) Lower vehicle.

(9) Remove the wiring harness electrical connector

from the H-valve on the air conditioning fluid lines. (10) Remove the power steering pump from the ve-

hicle out through the area between the cylinder head

and the dash panel (Fig. 22).

(11) Transfer the required components from the

failed power steering pump to the replacement power

steering pump. See the appropriate area of this ser-

vice manual section for the component replacement

procedures.

Fig. 20 Turbo III Accessory Drive Belt Routing

Fig. 21 Power Steering Pump Mounting

Fig. 22 Power Steering Pump Removal From Vehicle

Ä STEERING 19 - 19

Page 1938 of 2438

INSTALL (1) Install the power steering pump back into the

vehicle in the reverse order of removal, between cyl-

inder head and dash panel (Fig. 20). (2) Install the wiring harness connector back on

the H-valve located on the air conditioning fluid

lines (Fig. 20). (3) Raise vehicle See Hoisting, Group 0.

(4) Install the power steering pump on its mount-

ing bracket, and the hose locator bracket. Install the

bolt/stud and 2 bolts attaching the power steering

pump to its mounting bracket, and the bolts attach-

ing the hose locator bracket (Fig. 19). Torque all fas-

teners to 31 N Im (280 in. lbs.).

(5) Install the power steering fluid pressure hose,

banjo bolt and seal washer onto power steering pump

(Fig. 4). Pressure hose is to be installed so it is

routed to the left of the hose locator bracket (Fig.

19). Torque the banjo bolt to 31 N Im (275 in. lbs.).

Inspect the O-rings on the banjo bolt to ensure

they are not damaged and located correctly. (6) Install the low pressure fluid return hose from

the power steering pump back on the steel tube on

the steering gear (Fig. 4). Install hose clamp, be sure

the hose clamp is installed past the retaining bead

the steel tube. Install the hose routing clip on the

power steering pump bolt/stud, install clip retaining

nut and tighten. (7) Install the serpentine accessory drive belt (Fig.

18). Be sure the belt is correctly installed and

aligned on all pulleys before starting engine. (8) Install the right front underhood splash shield.

CAUTION: Do not use automatic transmission fluid

in power steering system. Only use Mopar T, Power

Steering Fluid, or equivalent.

(9) Fill power steering pump reservoir to correct

fluid level. (10) Connect the negative battery cable on the

negative battery post. (11) Start engine and turn steering wheel several

times from stop to stop to bleed air from fluid in sys-

tem. Stop engine, check fluid level, and inspect sys-

tem for leaks. See Checking Fluid Level.

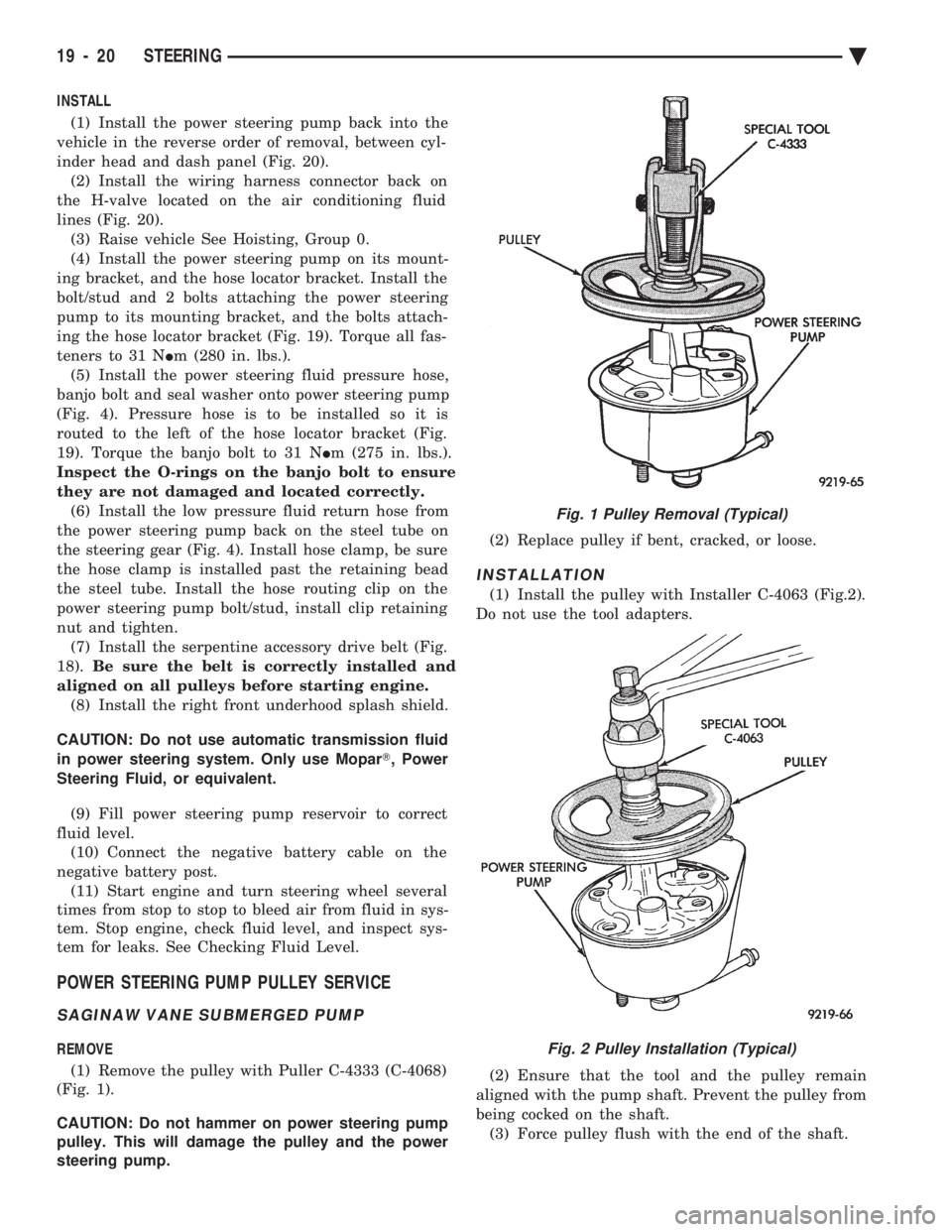

POWER STEERING PUMP PULLEY SERVICE

SAGINAW VANE SUBMERGED PUMP

REMOVE

(1) Remove the pulley with Puller C-4333 (C-4068)

(Fig. 1).

CAUTION: Do not hammer on power steering pump

pulley. This will damage the pulley and the power

steering pump. (2) Replace pulley if bent, cracked, or loose.

INSTALLATION

(1) Install the pulley with Installer C-4063 (Fig.2).

Do not use the tool adapters.

(2) Ensure that the tool and the pulley remain

aligned with the pump shaft. Prevent the pulley from

being cocked on the shaft. (3) Force pulley flush with the end of the shaft.

Fig. 1 Pulley Removal (Typical)

Fig. 2 Pulley Installation (Typical)

19 - 20 STEERING Ä