fuel pump CHEVROLET DYNASTY 1993 Owner's Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1592 of 2438

valve spring retainer locks to become dislocated

when depressing the valve spring. Check and make

sure the locks are in their proper location. (3) Install valve cover as previously outlined in

this section.

VALVE SPRINGS AND VALVE STEM SEALS

REMOVAL

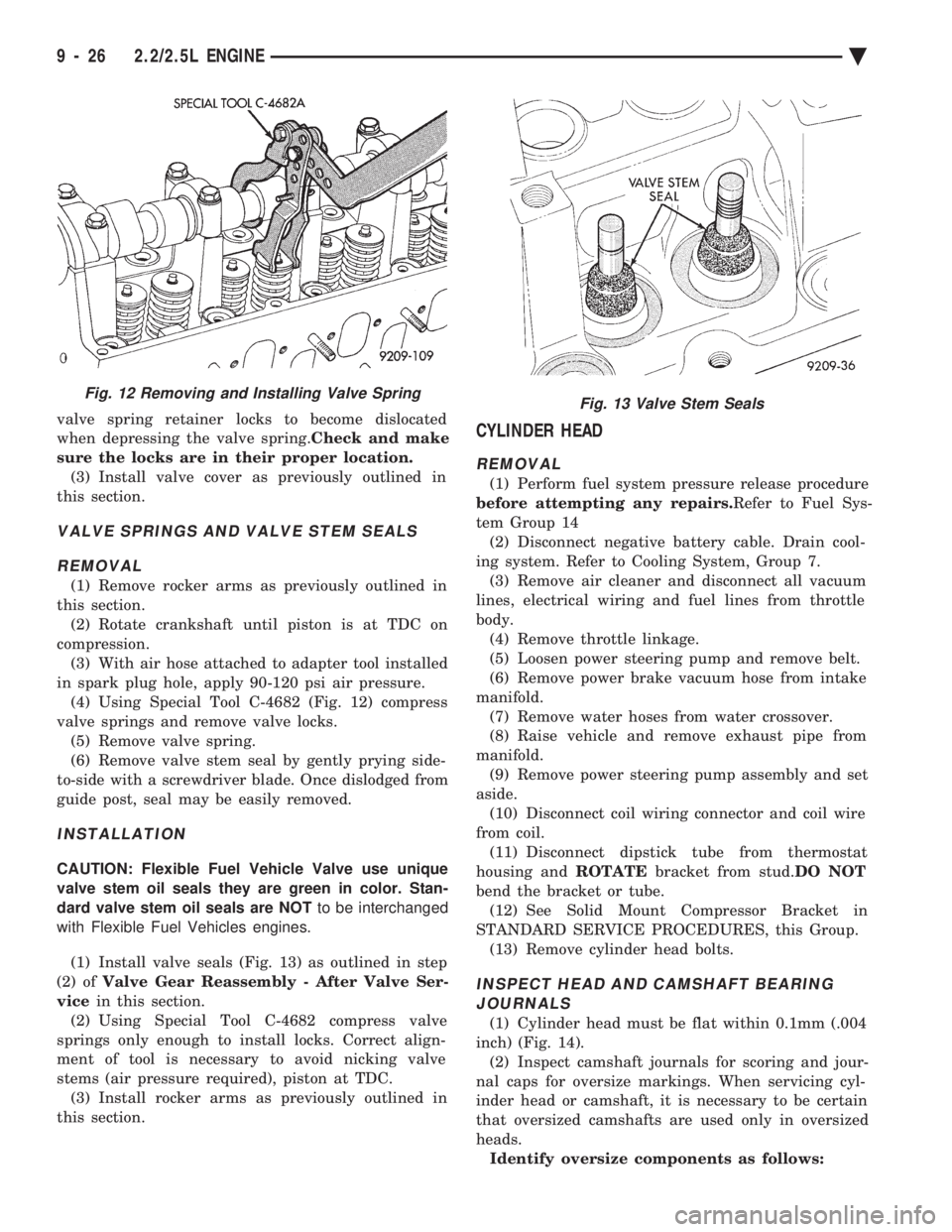

(1) Remove rocker arms as previously outlined in

this section. (2) Rotate crankshaft until piston is at TDC on

compression. (3) With air hose attached to adapter tool installed

in spark plug hole, apply 90-120 psi air pressure. (4) Using Special Tool C-4682 (Fig. 12) compress

valve springs and remove valve locks. (5) Remove valve spring.

(6) Remove valve stem seal by gently prying side-

to-side with a screwdriver blade. Once dislodged from

guide post, seal may be easily removed.

INSTALLATION

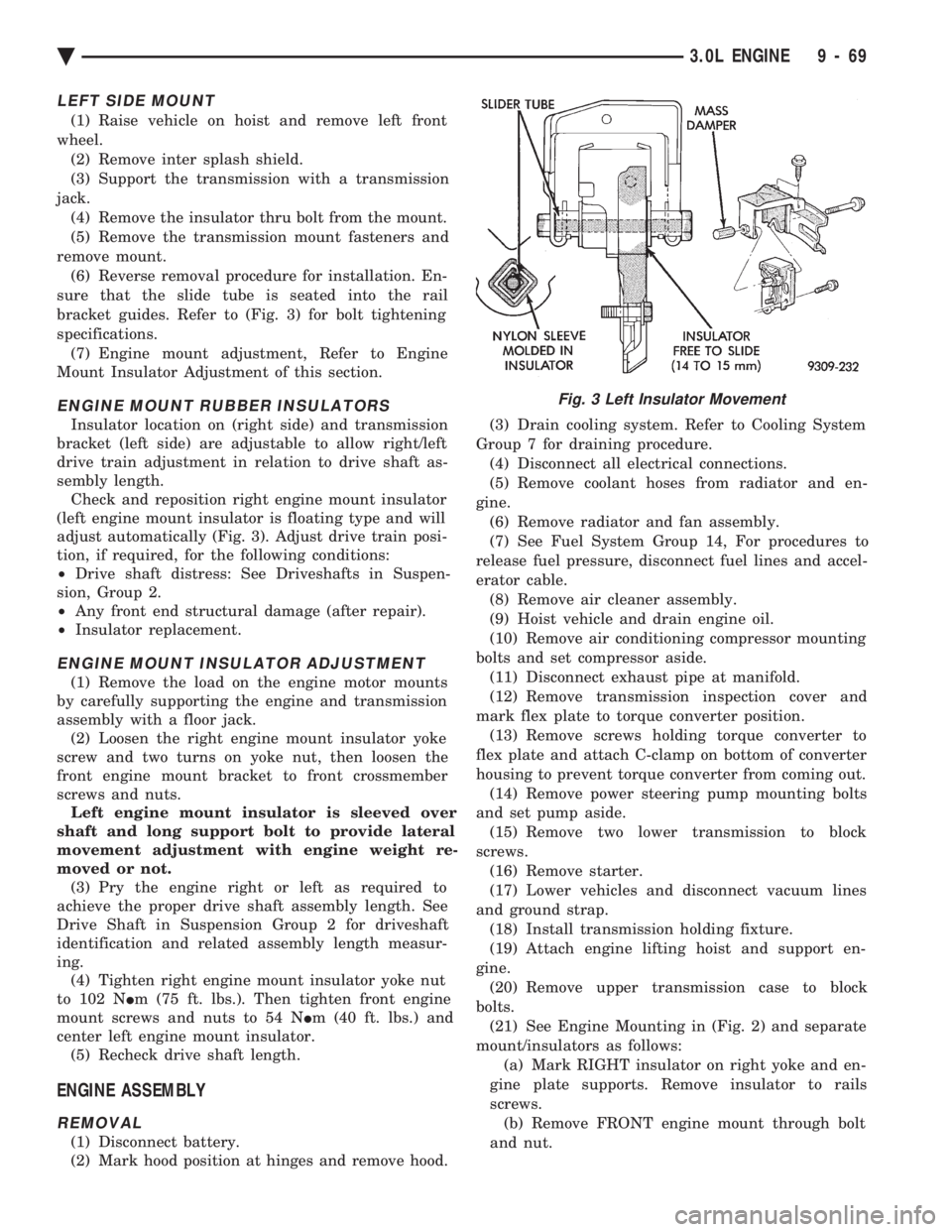

CAUTION: Flexible Fuel Vehicle Valve use unique

valve stem oil seals they are green in color. Stan-

dard valve stem oil seals are NOT to be interchanged

with Flexible Fuel Vehicles engines.

(1) Install valve seals (Fig. 13) as outlined in step

(2) of Valve Gear Reassembly - After Valve Ser-

vice in this section.

(2) Using Special Tool C-4682 compress valve

springs only enough to install locks. Correct align-

ment of tool is necessary to avoid nicking valve

stems (air pressure required), piston at TDC. (3) Install rocker arms as previously outlined in

this section.

CYLINDER HEAD

REMOVAL

(1) Perform fuel system pressure release procedure

before attempting any repairs. Refer to Fuel Sys-

tem Group 14 (2) Disconnect negative battery cable. Drain cool-

ing system. Refer to Cooling System, Group 7. (3) Remove air cleaner and disconnect all vacuum

lines, electrical wiring and fuel lines from throttle

body. (4) Remove throttle linkage.

(5) Loosen power steering pump and remove belt.

(6) Remove power brake vacuum hose from intake

manifold. (7) Remove water hoses from water crossover.

(8) Raise vehicle and remove exhaust pipe from

manifold. (9) Remove power steering pump assembly and set

aside. (10) Disconnect coil wiring connector and coil wire

from coil. (11) Disconnect dipstick tube from thermostat

housing and ROTATEbracket from stud. DO NOT

bend the bracket or tube. (12) See Solid Mount Compressor Bracket in

STANDARD SERVICE PROCEDURES, this Group. (13) Remove cylinder head bolts.

INSPECT HEAD AND CAMSHAFT BEARINGJOURNALS

(1) Cylinder head must be flat within 0.1mm (.004

inch) (Fig. 14). (2) Inspect camshaft journals for scoring and jour-

nal caps for oversize markings. When servicing cyl-

inder head or camshaft, it is necessary to be certain

that oversized camshafts are used only in oversized

heads. Identify oversize components as follows:

Fig. 12 Removing and Installing Valve SpringFig. 13 Valve Stem Seals

9 - 26 2.2/2.5L ENGINE Ä

Page 1635 of 2438

LEFT SIDE MOUNT

(1) Raise vehicle on hoist and remove left front

wheel. (2) Remove inter splash shield.

(3) Support the transmission with a transmission

jack. (4) Remove the insulator thru bolt from the mount.

(5) Remove the transmission mount fasteners and

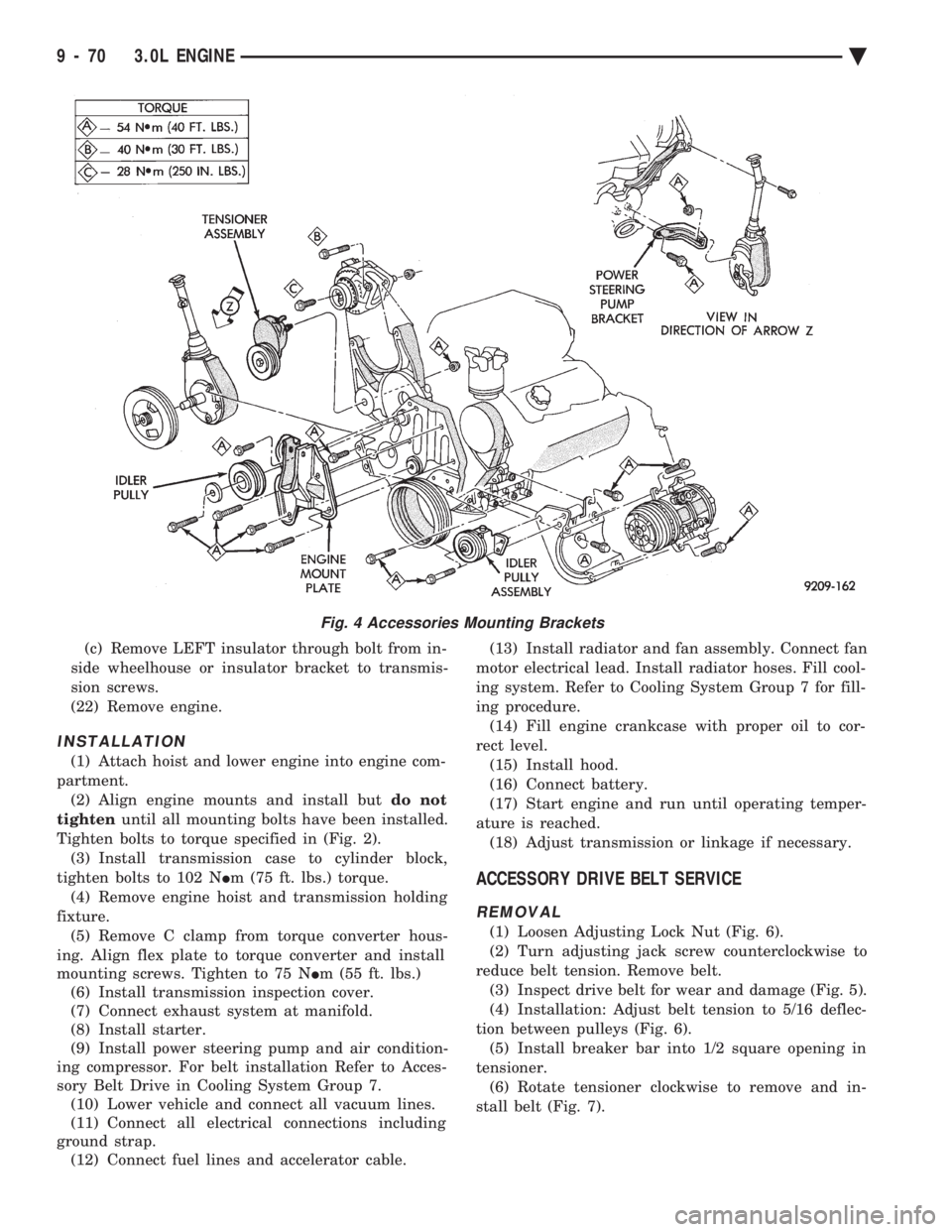

remove mount. (6) Reverse removal procedure for installation. En-

sure that the slide tube is seated into the rail

bracket guides. Refer to (Fig. 3) for bolt tightening

specifications. (7) Engine mount adjustment, Refer to Engine

Mount Insulator Adjustment of this section.

ENGINE MOUNT RUBBER INSULATORS

Insulator location on (right side) and transmission

bracket (left side) are adjustable to allow right/left

drive train adjustment in relation to drive shaft as-

sembly length. Check and reposition right engine mount insulator

(left engine mount insulator is floating type and will

adjust automatically (Fig. 3). Adjust drive train posi-

tion, if required, for the following conditions:

² Drive shaft distress: See Driveshafts in Suspen-

sion, Group 2.

² Any front end structural damage (after repair).

² Insulator replacement.

ENGINE MOUNT INSULATOR ADJUSTMENT

(1) Remove the load on the engine motor mounts

by carefully supporting the engine and transmission

assembly with a floor jack. (2) Loosen the right engine mount insulator yoke

screw and two turns on yoke nut, then loosen the

front engine mount bracket to front crossmember

screws and nuts. Left engine mount insulator is sleeved over

shaft and long support bolt to provide lateral

movement adjustment with engine weight re-

moved or not. (3) Pry the engine right or left as required to

achieve the proper drive shaft assembly length. See

Drive Shaft in Suspension Group 2 for driveshaft

identification and related assembly length measur-

ing. (4) Tighten right engine mount insulator yoke nut

to 102 N Im (75 ft. lbs.). Then tighten front engine

mount screws and nuts to 54 N Im (40 ft. lbs.) and

center left engine mount insulator. (5) Recheck drive shaft length.

ENGINE ASSEMBLY

REMOVAL

(1) Disconnect battery.

(2) Mark hood position at hinges and remove hood. (3) Drain cooling system. Refer to Cooling System

Group 7 for draining procedure. (4) Disconnect all electrical connections.

(5) Remove coolant hoses from radiator and en-

gine. (6) Remove radiator and fan assembly.

(7) See Fuel System Group 14, For procedures to

release fuel pressure, disconnect fuel lines and accel-

erator cable. (8) Remove air cleaner assembly.

(9) Hoist vehicle and drain engine oil.

(10) Remove air conditioning compressor mounting

bolts and set compressor aside. (11) Disconnect exhaust pipe at manifold.

(12) Remove transmission inspection cover and

mark flex plate to torque converter position. (13) Remove screws holding torque converter to

flex plate and attach C-clamp on bottom of converter

housing to prevent torque converter from coming out. (14) Remove power steering pump mounting bolts

and set pump aside. (15) Remove two lower transmission to block

screws. (16) Remove starter.

(17) Lower vehicles and disconnect vacuum lines

and ground strap. (18) Install transmission holding fixture.

(19) Attach engine lifting hoist and support en-

gine. (20) Remove upper transmission case to block

bolts. (21) See Engine Mounting in (Fig. 2) and separate

mount/insulators as follows: (a) Mark RIGHT insulator on right yoke and en-

gine plate supports. Remove insulator to rails

screws. (b) Remove FRONT engine mount through bolt

and nut.

Fig. 3 Left Insulator Movement

Ä 3.0L ENGINE 9 - 69

Page 1636 of 2438

(c) Remove LEFT insulator through bolt from in-

side wheelhouse or insulator bracket to transmis-

sion screws.

(22) Remove engine.

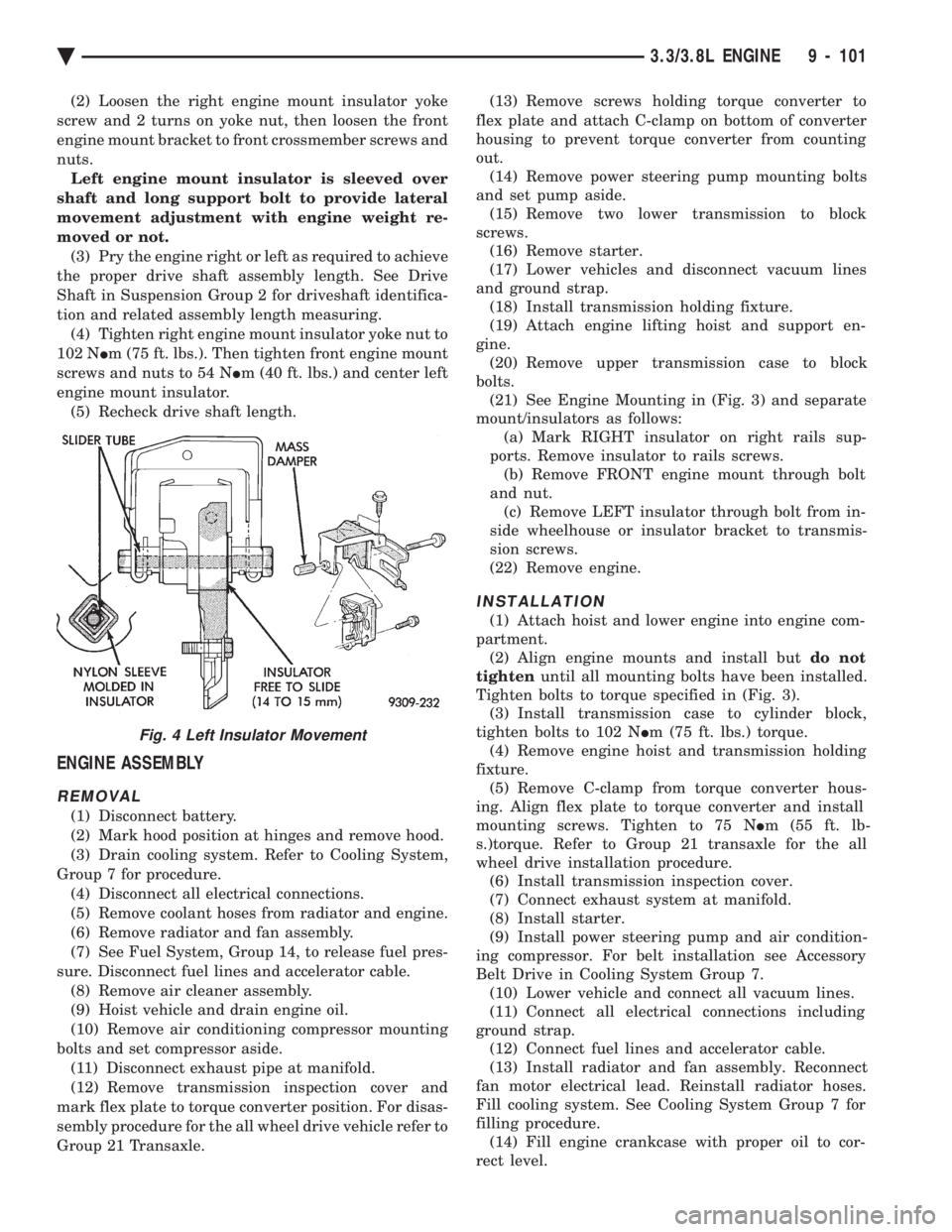

INSTALLATION

(1) Attach hoist and lower engine into engine com-

partment. (2) Align engine mounts and install but do not

tighten until all mounting bolts have been installed.

Tighten bolts to torque specified in (Fig. 2). (3) Install transmission case to cylinder block,

tighten bolts to 102 N Im (75 ft. lbs.) torque.

(4) Remove engine hoist and transmission holding

fixture. (5) Remove C clamp from torque converter hous-

ing. Align flex plate to torque converter and install

mounting screws. Tighten to 75 N Im (55 ft. lbs.)

(6) Install transmission inspection cover.

(7) Connect exhaust system at manifold.

(8) Install starter.

(9) Install power steering pump and air condition-

ing compressor. For belt installation Refer to Acces-

sory Belt Drive in Cooling System Group 7. (10) Lower vehicle and connect all vacuum lines.

(11) Connect all electrical connections including

ground strap. (12) Connect fuel lines and accelerator cable. (13) Install radiator and fan assembly. Connect fan

motor electrical lead. Install radiator hoses. Fill cool-

ing system. Refer to Cooling System Group 7 for fill-

ing procedure. (14) Fill engine crankcase with proper oil to cor-

rect level. (15) Install hood.

(16) Connect battery.

(17) Start engine and run until operating temper-

ature is reached. (18) Adjust transmission or linkage if necessary.

ACCESSORY DRIVE BELT SERVICE

REMOVAL

(1) Loosen Adjusting Lock Nut (Fig. 6).

(2) Turn adjusting jack screw counterclockwise to

reduce belt tension. Remove belt. (3) Inspect drive belt for wear and damage (Fig. 5).

(4) Installation: Adjust belt tension to 5/16 deflec-

tion between pulleys (Fig. 6). (5) Install breaker bar into 1/2 square opening in

tensioner. (6) Rotate tensioner clockwise to remove and in-

stall belt (Fig. 7).

Fig. 4 Accessories Mounting Brackets

9 - 70 3.0L ENGINE Ä

Page 1667 of 2438

(2) Loosen the right engine mount insulator yoke

screw and 2 turns on yoke nut, then loosen the front

engine mount bracket to front crossmember screws and

nuts. Left engine mount insulator is sleeved over

shaft and long support bolt to provide lateral

movement adjustment with engine weight re-

moved or not. (3) Pry the engine right or left as required to achieve

the proper drive shaft assembly length. See Drive

Shaft in Suspension Group 2 for driveshaft identifica-

tion and related assembly length measuring. (4) Tighten right engine mount insulator yoke nut to

102 N Im (75 ft. lbs.). Then tighten front engine mount

screws and nuts to 54 N Im (40 ft. lbs.) and center left

engine mount insulator. (5) Recheck drive shaft length.

ENGINE ASSEMBLY

REMOVAL

(1) Disconnect battery.

(2) Mark hood position at hinges and remove hood.

(3) Drain cooling system. Refer to Cooling System,

Group 7 for procedure. (4) Disconnect all electrical connections.

(5) Remove coolant hoses from radiator and engine.

(6) Remove radiator and fan assembly.

(7) See Fuel System, Group 14, to release fuel pres-

sure. Disconnect fuel lines and accelerator cable. (8) Remove air cleaner assembly.

(9) Hoist vehicle and drain engine oil.

(10) Remove air conditioning compressor mounting

bolts and set compressor aside. (11) Disconnect exhaust pipe at manifold.

(12) Remove transmission inspection cover and

mark flex plate to torque converter position. For disas-

sembly procedure for the all wheel drive vehicle refer to

Group 21 Transaxle. (13) Remove screws holding torque converter to

flex plate and attach C-clamp on bottom of converter

housing to prevent torque converter from counting

out. (14) Remove power steering pump mounting bolts

and set pump aside. (15) Remove two lower transmission to block

screws. (16) Remove starter.

(17) Lower vehicles and disconnect vacuum lines

and ground strap. (18) Install transmission holding fixture.

(19) Attach engine lifting hoist and support en-

gine. (20) Remove upper transmission case to block

bolts. (21) See Engine Mounting in (Fig. 3) and separate

mount/insulators as follows: (a) Mark RIGHT insulator on right rails sup-

ports. Remove insulator to rails screws. (b) Remove FRONT engine mount through bolt

and nut. (c) Remove LEFT insulator through bolt from in-

side wheelhouse or insulator bracket to transmis-

sion screws.

(22) Remove engine.

INSTALLATION

(1) Attach hoist and lower engine into engine com-

partment. (2) Align engine mounts and install but do not

tighten until all mounting bolts have been installed.

Tighten bolts to torque specified in (Fig. 3). (3) Install transmission case to cylinder block,

tighten bolts to 102 N Im (75 ft. lbs.) torque.

(4) Remove engine hoist and transmission holding

fixture. (5) Remove C-clamp from torque converter hous-

ing. Align flex plate to torque converter and install

mounting screws. Tighten to 75 N Im (55 ft. lb-

s.)torque. Refer to Group 21 transaxle for the all

wheel drive installation procedure. (6) Install transmission inspection cover.

(7) Connect exhaust system at manifold.

(8) Install starter.

(9) Install power steering pump and air condition-

ing compressor. For belt installation see Accessory

Belt Drive in Cooling System Group 7. (10) Lower vehicle and connect all vacuum lines.

(11) Connect all electrical connections including

ground strap. (12) Connect fuel lines and accelerator cable.

(13) Install radiator and fan assembly. Reconnect

fan motor electrical lead. Reinstall radiator hoses.

Fill cooling system. See Cooling System Group 7 for

filling procedure. (14) Fill engine crankcase with proper oil to cor-

rect level.

Fig. 4 Left Insulator Movement

Ä 3.3/3.8L ENGINE 9 - 101

Page 1702 of 2438

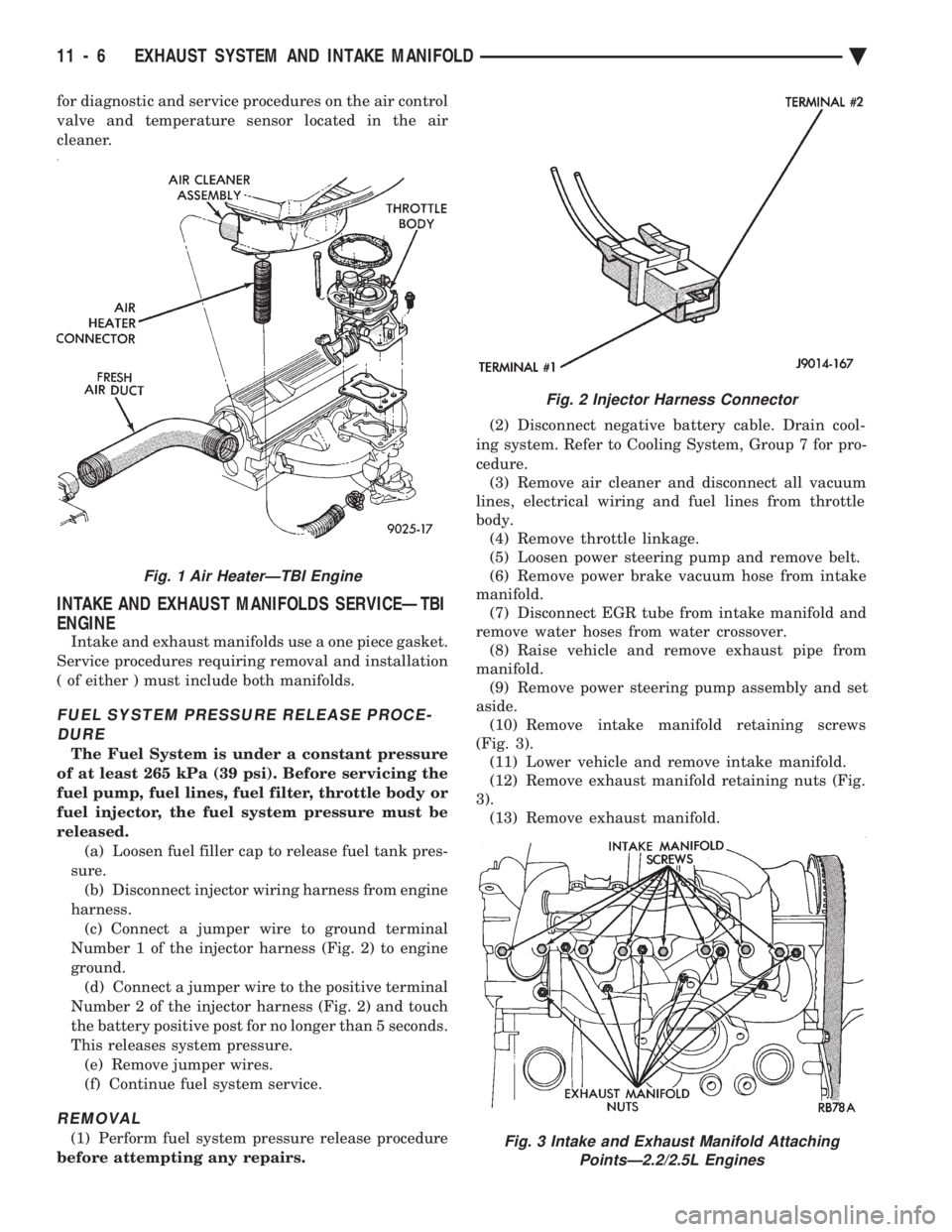

for diagnostic and service procedures on the air control

valve and temperature sensor located in the air

cleaner.

INTAKE AND EXHAUST MANIFOLDS SERVICEÐTBI

ENGINE

Intake and exhaust manifolds use a one piece gasket.

Service procedures requiring removal and installation

( of either ) must include both manifolds.

FUEL SYSTEM PRESSURE RELEASE PROCE- DURE

The Fuel System is under a constant pressure

of at least 265 kPa (39 psi). Before servicing the

fuel pump, fuel lines, fuel filter, throttle body or

fuel injector, the fuel system pressure must be

released. (a) Loosen fuel filler cap to release fuel tank pres-

sure. (b) Disconnect injector wiring harness from engine

harness. (c) Connect a jumper wire to ground terminal

Number 1 of the injector harness (Fig. 2) to engine

ground. (d) Connect a jumper wire to the positive terminal

Number 2 of the injector harness (Fig. 2) and touch

the battery positive post for no longer than 5 seconds.

This releases system pressure. (e) Remove jumper wires.

(f) Continue fuel system service.

REMOVAL

(1) Perform fuel system pressure release procedure

before attempting any repairs. (2) Disconnect negative battery cable. Drain cool-

ing system. Refer to Cooling System, Group 7 for pro-

cedure. (3) Remove air cleaner and disconnect all vacuum

lines, electrical wiring and fuel lines from throttle

body. (4) Remove throttle linkage.

(5) Loosen power steering pump and remove belt.

(6) Remove power brake vacuum hose from intake

manifold. (7) Disconnect EGR tube from intake manifold and

remove water hoses from water crossover. (8) Raise vehicle and remove exhaust pipe from

manifold. (9) Remove power steering pump assembly and set

aside. (10) Remove intake manifold retaining screws

(Fig. 3). (11) Lower vehicle and remove intake manifold.

(12) Remove exhaust manifold retaining nuts (Fig.

3). (13) Remove exhaust manifold.

Fig. 2 Injector Harness Connector

Fig. 3 Intake and Exhaust Manifold Attaching PointsÐ2.2/2.5L Engines

Fig. 1 Air HeaterÐTBI Engine

11 - 6 EXHAUST SYSTEM AND INTAKE MANIFOLD Ä

Page 1710 of 2438

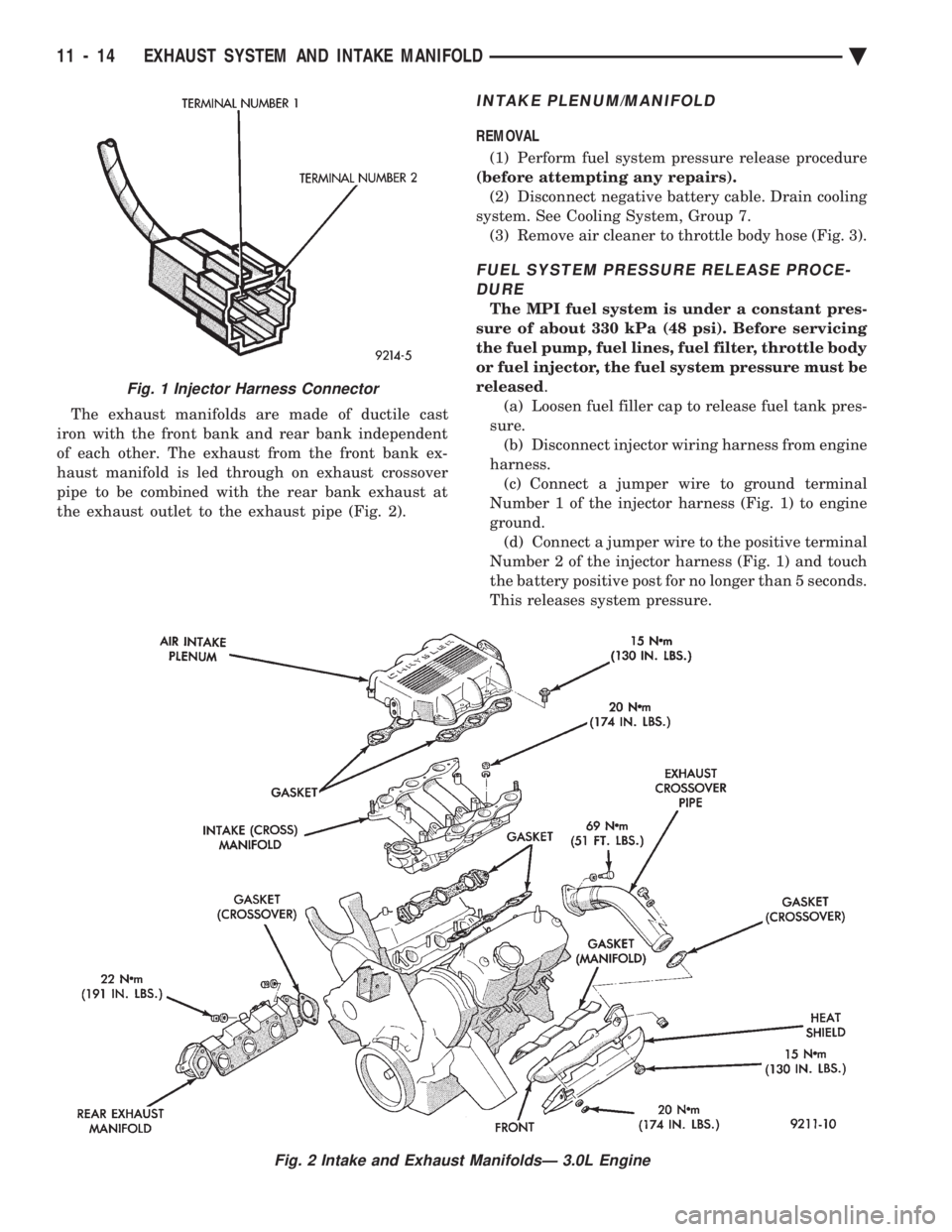

The exhaust manifolds are made of ductile cast

iron with the front bank and rear bank independent

of each other. The exhaust from the front bank ex-

haust manifold is led through on exhaust crossover

pipe to be combined with the rear bank exhaust at

the exhaust outlet to the exhaust pipe (Fig. 2).

INTAKE PLENUM/MANIFOLD

REMOVAL

(1) Perform fuel system pressure release procedure

(before attempting any repairs). (2) Disconnect negative battery cable. Drain cooling

system. See Cooling System, Group 7. (3) Remove air cleaner to throttle body hose (Fig. 3).

FUEL SYSTEM PRESSURE RELEASE PROCE-DURE

The MPI fuel system is under a constant pres-

sure of about 330 kPa (48 psi). Before servicing

the fuel pump, fuel lines, fuel filter, throttle body

or fuel injector, the fuel system pressure must be

released .

(a) Loosen fuel filler cap to release fuel tank pres-

sure. (b) Disconnect injector wiring harness from engine

harness. (c) Connect a jumper wire to ground terminal

Number 1 of the injector harness (Fig. 1) to engine

ground. (d) Connect a jumper wire to the positive terminal

Number 2 of the injector harness (Fig. 1) and touch

the battery positive post for no longer than 5 seconds.

This releases system pressure.

Fig. 1 Injector Harness Connector

Fig. 2 Intake and Exhaust ManifoldsÐ 3.0L Engine

11 - 14 EXHAUST SYSTEM AND INTAKE MANIFOLD Ä

Page 1715 of 2438

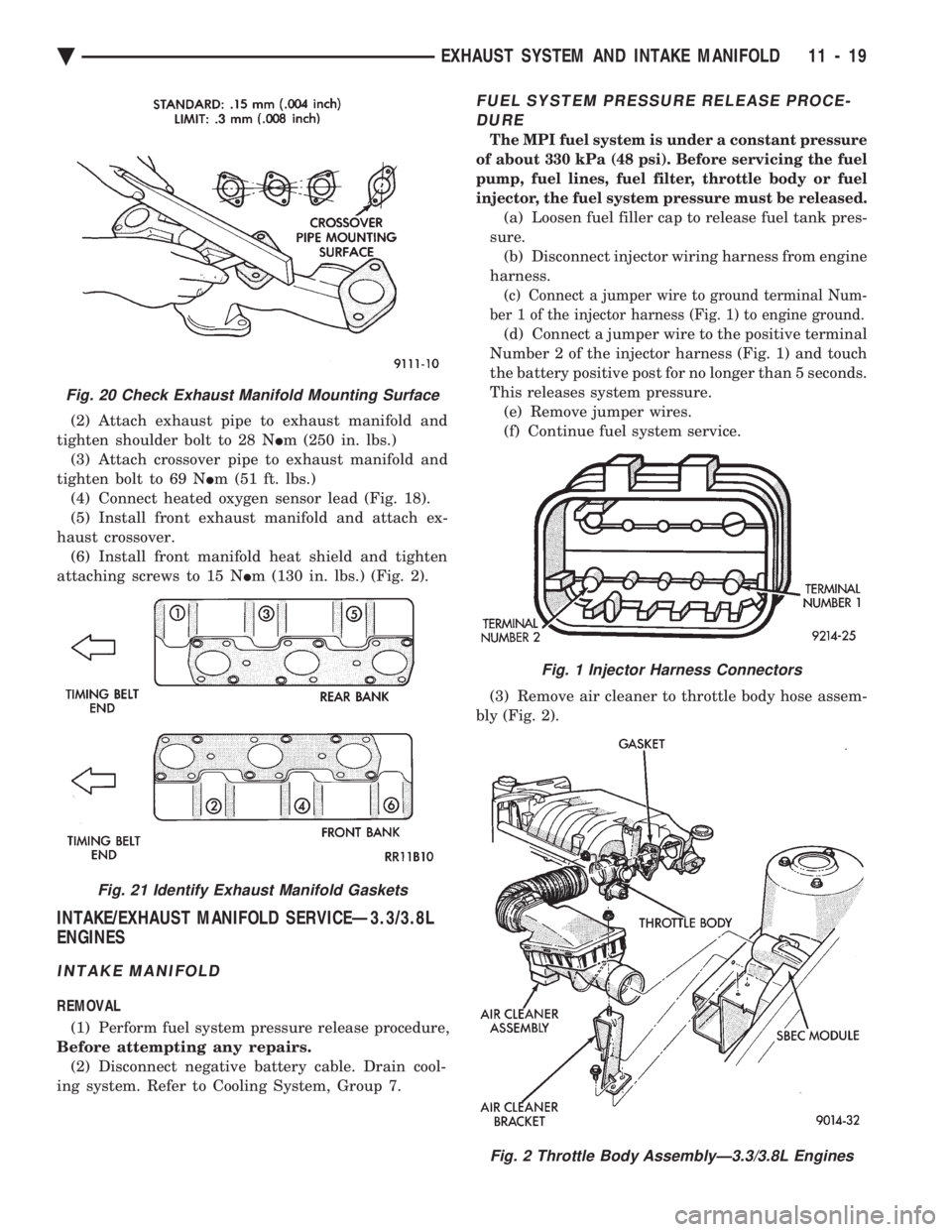

(2) Attach exhaust pipe to exhaust manifold and

tighten shoulder bolt to 28 N Im (250 in. lbs.)

(3) Attach crossover pipe to exhaust manifold and

tighten bolt to 69 N Im (51 ft. lbs.)

(4) Connect heated oxygen sensor lead (Fig. 18).

(5) Install front exhaust manifold and attach ex-

haust crossover. (6) Install front manifold heat shield and tighten

attaching screws to 15 N Im (130 in. lbs.) (Fig. 2).

INTAKE/EXHAUST MANIFOLD SERVICEÐ3.3/3.8L

ENGINES

INTAKE MANIFOLD

REMOVAL

(1) Perform fuel system pressure release procedure,

Before attempting any repairs. (2) Disconnect negative battery cable. Drain cool-

ing system. Refer to Cooling System, Group 7.

FUEL SYSTEM PRESSURE RELEASE PROCE- DURE

The MPI fuel system is under a constant pressure

of about 330 kPa (48 psi). Before servicing the fuel

pump, fuel lines, fuel filter, throttle body or fuel

injector, the fuel system pressure must be released.

(a) Loosen fuel filler cap to release fuel tank pres-

sure. (b) Disconnect injector wiring harness from engine

harness.

(c) Connect a jumper wire to ground terminal Num-

ber 1 of the injector harness (Fig. 1) to engine ground.

(d) Connect a jumper wire to the positive terminal

Number 2 of the injector harness (Fig. 1) and touch

the battery positive post for no longer than 5 seconds.

This releases system pressure. (e) Remove jumper wires.

(f) Continue fuel system service.

(3) Remove air cleaner to throttle body hose assem-

bly (Fig. 2).

Fig. 20 Check Exhaust Manifold Mounting Surface

Fig. 21 Identify Exhaust Manifold Gaskets

Fig. 1 Injector Harness Connectors

Fig. 2 Throttle Body AssemblyÐ3.3/3.8L Engines

Ä EXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 19

Page 1741 of 2438

FUEL SYSTEMS

CONTENTS

page page

2.2L TURBO III MULTI-PORT FUEL INJECTIONÐ GENERAL DIAGNOSIS ................. 95

2.2L TURBO III MULTI-PORT FUEL INJECTIONÐ ON-BOARD DIAGNOSTICS ............. 100

2.2L TURBO III MULTI-PORT FUEL INJECTIONÐ SERVICE PROCEDURES ............... 107

2.2L TURBO III MULTI-PORT FUEL INJECTIONÐ SYSTEM OPERATION .................. 83

2.2L/2.5L SINGLE POINT FUEL INJECTIONÐ GENERAL DIAGNOSIS .................. 35

2.2L/2.5L SINGLE POINT FUEL INJECTIONÐ ON-BOARD DIAGNOSTICS .............. 41

2.2L/2.5L SINGLE POINT FUEL INJECTIONÐ SERVICE PROCEDURES ................ 48

2.2L/2.5L SINGLE POINT FUEL INJECTIONÐ SYSTEM OPERATION .................. 24

2.5L FLEXIBLE FUEL MULTI-PORT FUEL INJECTIONÐGENERAL DIAGNOSIS ....... 66

2.5L FLEXIBLE FUEL MULTI-PORT FUEL INJECTIONÐON-BOARD DIAGNOSTICS . . . 70

2.5L FLEXIBLE FUEL MULTI-PORT FUEL INJECTIONÐSERVICE PROCEDURES ..... 77

2.5L FLEXIBLE FUEL MULTI-PORT FUEL INJECTIONÐSYSTEM OPERATION ....... 55 3.0L MULTI-PORT FUEL INJECTIONÐ

GENERAL DIAGNOSIS ................. 125

3.0L MULTI-PORT FUEL INJECTIONÐ ON-BOARD DIAGNOSTICS ............. 130

3.0L MULTI-PORT FUEL INJECTIONÐ SERVICE PROCEDURES ............... 138

3.0L MULTI-PORT FUEL INJECTIONÐ SYSTEM OPERATION ................. 113

3.3L AND 3.8L MULTI-PORT FUEL INJECTIONÐ GENERAL DIAGNOSIS ................. 157

3.3L AND 3.8L MULTI-PORT FUEL INJECTIONÐ ON-BOARD DIAGNOSTICS ............. 162

3.3L AND 3.8L MULTI-PORT FUEL INJECTIONÐ SERVICE PROCEDURES ............... 169

3.3L AND 3.8L MULTI-PORT FUEL INJECTIONÐ SYSTEM OPERATION ................. 145

ACCELERATOR PEDAL AND THROTTLE CABLE .............................. 21

FUEL DELIVERY SYSTEM ................. 3

FUEL TANKS .......................... 14

GENERAL INFORMATION .................. 1

SPECIFICATIONS ...................... 178

GENERAL INFORMATION

Throughout this group, references are made to a

particular vehicle by letter designation. A chart

showing the breakdown of these designations is in-

cluded in the Introduction Section at the front of this

service manual. The Fuel System consists of the fuel tank, fuel

pump, fuel filter, throttle body, fuel injectors, fuel

tubes and vacuum tubes. The Fuel Delivery System consists of the fuel

pump, fuel filter, fuel lines and fuel hoses. The Fuel Tank Assembly consists of the fuel tank,

filler tube, a fuel gauge sending unit assembly and a

pressure-vacuum filler cap. Also, the Evaporation Control System is part of the

fuel system. The evaporation control system is de-

signed to reduce the emission of fuel vapor into the

atmosphere. The description and function of the Evaporation

Control System is found in Group 25 of this manual.FUEL REQUIREMENTS

Your vehicle was designed to meet all emission

regulations and provide excellent fuel economy when

using high quality unleaded gasoline.

VEHICLES WITHOUT TURBOCHARGED ENGINES

Use unleaded gasoline having a minimum octane

rating of 87.

VEHICLES WITH TURBOCHARGED ENGINESÐEXCEPT 16 VALVE 2.2L ENGINES

These vehicles will operate satisfactorily on both

regular unleaded gasoline having a minimum octane

rating or 87, and premium unleaded gasoline having

a minimum octane rating of 91. The use of premium

unleaded gasoline will improve performance.

VEHICLES WITH 2.2L 16 VALVE ENGINES

The use of premium unleaded gasoline having a

minimum octane of 91 is recommended. If premium

unleaded is not available, then unleaded gasoline

Ä FUEL SYSTEMS 14 - 1

Page 1743 of 2438

FUEL DELIVERY SYSTEM INDEX

page page

Chassis Fuel Tubes ...................... 11

Flexible Fuel Components ................... 3

Fuel FilterÐAll Vehicles .................... 9

Fuel Hoses, Clamps, and Quick Connect Fittings . 10

Fuel Pump Assembly ...................... 5

Fuel Pump Module Installation ............... 9

Fuel Pump Module Removal ................. 8

Fuel Pump Pressure TestÐ2.2L/2.5L TBI and 3.0L MPI Engines ........................... 7

Fuel Pump Pressure TestÐAll Except 2.2L/2.5L TBI and 3.0L MPI ....................... 6

Fuel Pump Strainer Service .................. 9 Fuel System Pressure

...................... 6

Fuel System Pressure Release ProcedureÐ 2.2L/2.5L TBI ........................... 4

Fuel System Pressure Release ProcedureÐ3.0L . . 5

Fuel System Pressure Release ProcedureÐExcept 2.2L/2.5L TBI and 3.0L ................... 4

General Information ........................ 3

Identifying Flexible Fuel Components .......... 3

Mechanical Malfunctions .................... 8

Methanol Concentration SensorÐFlexible Fuel AA-Body .............................. 4

Service Precautions for Flexible Fuel Vehicles .... 3

GENERAL INFORMATION

Beginning this model year, Chrysler began produc-

ing AA-Body vehicles designed to operate on a mix-

ture of gasoline and methanol. These automobiles are

referred to as Flexible Fuel vehicles. Flexible fuel vehicles can operate on a mixture of

up to 85 percent methanol, 15 percent unleaded gas-

oline. These vehicles also operate on mixtures con-

taining a lower percentage of methanol or just pure

unleaded gasoline. In many cases, the procedures for servicing flexible

fuel components is identical to gasoline only compo-

nents. Refer to the particular Service Procedure in

this section. If the service procedure for flexible fuel

component differs from a gasoline only component,

the title of each service procedure identifies the ap-

plication.

SERVICE PRECAUTIONS FOR FLEXIBLE FUEL

VEHICLES

Methanol is more toxic than gasoline. Always re-

lease fuel system pressure before servicing fuel sys-

tem components and wear methanol resistant gloves

and eye protection. Avoid breathing methanol vapors or ingesting

methanol. Headaches, dizziness and even uncon-

sciousness could result from breathing these vapors.

Serious injury, blindness and even death could result

from ingesting methanol. Methanol vapors are extremely flammable and can

travel along the ground. Service vehicles in well ven-

tilated areas and avoid ignition sources. Never

smoke while servicing the vehicle. Do not allow methanol to contact skin. Prolonged

contact with methanol can cause dry skin or an al-

lergic skin reaction. Also, prolonged contact could re-

sult in absorption through the skin.

IDENTIFYING FLEXIBLE FUEL COMPONENTS

Flexible Fuel vehicles have unique methanol com-

patible fuel system components. Chrysler identifies

methanol compatible components that could be phys-

ically interchanged with gasoline only parts by color-

ing them green or applying a green label or tag to

them. Even though they may appear physically iden-

tical, components for gasoline only vehicles must not

be used on flexible fuel vehicles.

FLEXIBLE FUEL COMPONENTS

Flexible fuel AA-body vehicles uses many unique

fuel system components. The unique parts are green

in appearance or have a green tag or label attached

to them. While components used on gasoline only ve-

hicles may look similar or identical, they cannot be

used on flexible fuel vehicles. When servicing a com-

ponent, always use an original equipment or equiva-

lent flexible fuel replacement. The fuel system of flexible fuel AA-body vehicles

have the following unique components.

² Fuel pump module

² Fuel level sensor

² Fuel gauge (gauge cluster).

² Fuel tank

² Fuel pressure regulator (including O-rings)

² Fuel rail

² Fuel injectors (including O-rings)

² Fuel tubes

² Fuel filter

² EVAP canister

² Fuel filler cap

² Fuel filler tube

² Pressure relief/Rollover valve

² All fuel system and emission system hoses and

tubes

Ä FUEL SYSTEMS 14 - 3

Page 1744 of 2438

INSTRUMENT PANEL CLUSTER IDENTIFICATIONÐFLEXIBLE FUEL AA-BODY

Flexible fuel A-Body vehicles use a unique gauge

cluster. To identify the cluster, remove it from the

instrument panel and check the number on the tag

on the top. If the part number matches the number

in the parts book for flexible fuel A-bodies, the vehi-

cle was built with the correct cluster. Refer to Group

8E, Instrument Panel and Gauges, for cluster re-

moval and installation.

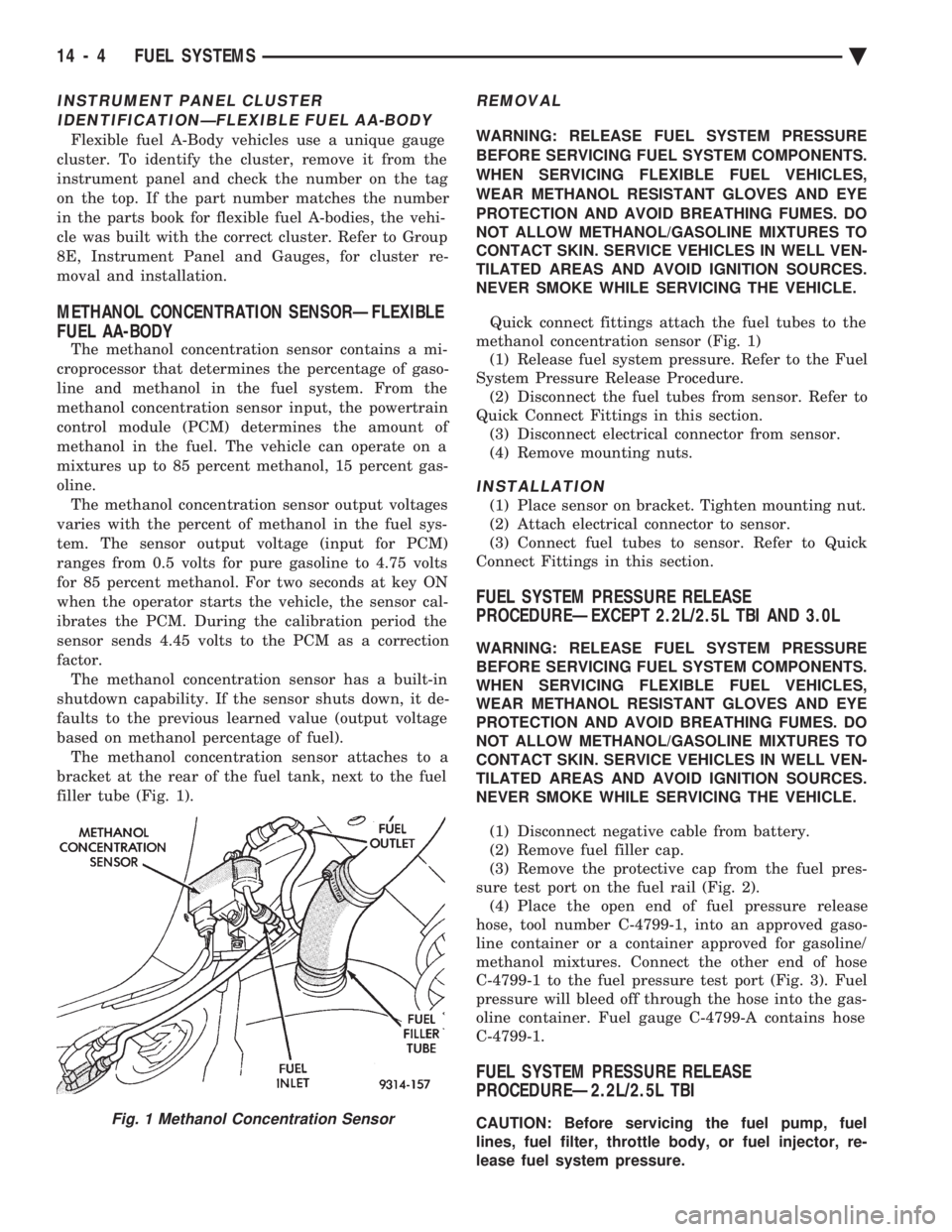

METHANOL CONCENTRATION SENSORÐFLEXIBLE

FUEL AA-BODY

The methanol concentration sensor contains a mi-

croprocessor that determines the percentage of gaso-

line and methanol in the fuel system. From the

methanol concentration sensor input, the powertrain

control module (PCM) determines the amount of

methanol in the fuel. The vehicle can operate on a

mixtures up to 85 percent methanol, 15 percent gas-

oline. The methanol concentration sensor output voltages

varies with the percent of methanol in the fuel sys-

tem. The sensor output voltage (input for PCM)

ranges from 0.5 volts for pure gasoline to 4.75 volts

for 85 percent methanol. For two seconds at key ON

when the operator starts the vehicle, the sensor cal-

ibrates the PCM. During the calibration period the

sensor sends 4.45 volts to the PCM as a correction

factor. The methanol concentration sensor has a built-in

shutdown capability. If the sensor shuts down, it de-

faults to the previous learned value (output voltage

based on methanol percentage of fuel). The methanol concentration sensor attaches to a

bracket at the rear of the fuel tank, next to the fuel

filler tube (Fig. 1).

REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

WHEN SERVICING FLEXIBLE FUEL VEHICLES,

WEAR METHANOL RESISTANT GLOVES AND EYE

PROTECTION AND AVOID BREATHING FUMES. DO

NOT ALLOW METHANOL/GASOLINE MIXTURES TO

CONTACT SKIN. SERVICE VEHICLES IN WELL VEN-

TILATED AREAS AND AVOID IGNITION SOURCES.

NEVER SMOKE WHILE SERVICING THE VEHICLE.

Quick connect fittings attach the fuel tubes to the

methanol concentration sensor (Fig. 1) (1) Release fuel system pressure. Refer to the Fuel

System Pressure Release Procedure. (2) Disconnect the fuel tubes from sensor. Refer to

Quick Connect Fittings in this section. (3) Disconnect electrical connector from sensor.

(4) Remove mounting nuts.

INSTALLATION

(1) Place sensor on bracket. Tighten mounting nut.

(2) Attach electrical connector to sensor.

(3) Connect fuel tubes to sensor. Refer to Quick

Connect Fittings in this section.

FUEL SYSTEM PRESSURE RELEASE

PROCEDUREÐEXCEPT 2.2L/2.5L TBI AND 3.0L

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

WHEN SERVICING FLEXIBLE FUEL VEHICLES,

WEAR METHANOL RESISTANT GLOVES AND EYE

PROTECTION AND AVOID BREATHING FUMES. DO

NOT ALLOW METHANOL/GASOLINE MIXTURES TO

CONTACT SKIN. SERVICE VEHICLES IN WELL VEN-

TILATED AREAS AND AVOID IGNITION SOURCES.

NEVER SMOKE WHILE SERVICING THE VEHICLE.

(1) Disconnect negative cable from battery.

(2) Remove fuel filler cap.

(3) Remove the protective cap from the fuel pres-

sure test port on the fuel rail (Fig. 2). (4) Place the open end of fuel pressure release

hose, tool number C-4799-1, into an approved gaso-

line container or a container approved for gasoline/

methanol mixtures. Connect the other end of hose

C-4799-1 to the fuel pressure test port (Fig. 3). Fuel

pressure will bleed off through the hose into the gas-

oline container. Fuel gauge C-4799-A contains hose

C-4799-1.

FUEL SYSTEM PRESSURE RELEASE

PROCEDUREÐ2.2L/2.5L TBI

CAUTION: Before servicing the fuel pump, fuel

lines, fuel filter, throttle body, or fuel injector, re-

lease fuel system pressure.Fig. 1 Methanol Concentration Sensor

14 - 4 FUEL SYSTEMS Ä