CHEVROLET PLYMOUTH ACCLAIM 1993 Service Manual

PLYMOUTH ACCLAIM 1993

CHEVROLET

CHEVROLET

https://www.carmanualsonline.info/img/24/56861/w960_56861-0.png

CHEVROLET PLYMOUTH ACCLAIM 1993 Service Manual

Trending: trunk, horn, ABS, dead battery, oil, automatic transmission, wheel bolt torque

Page 1971 of 2438

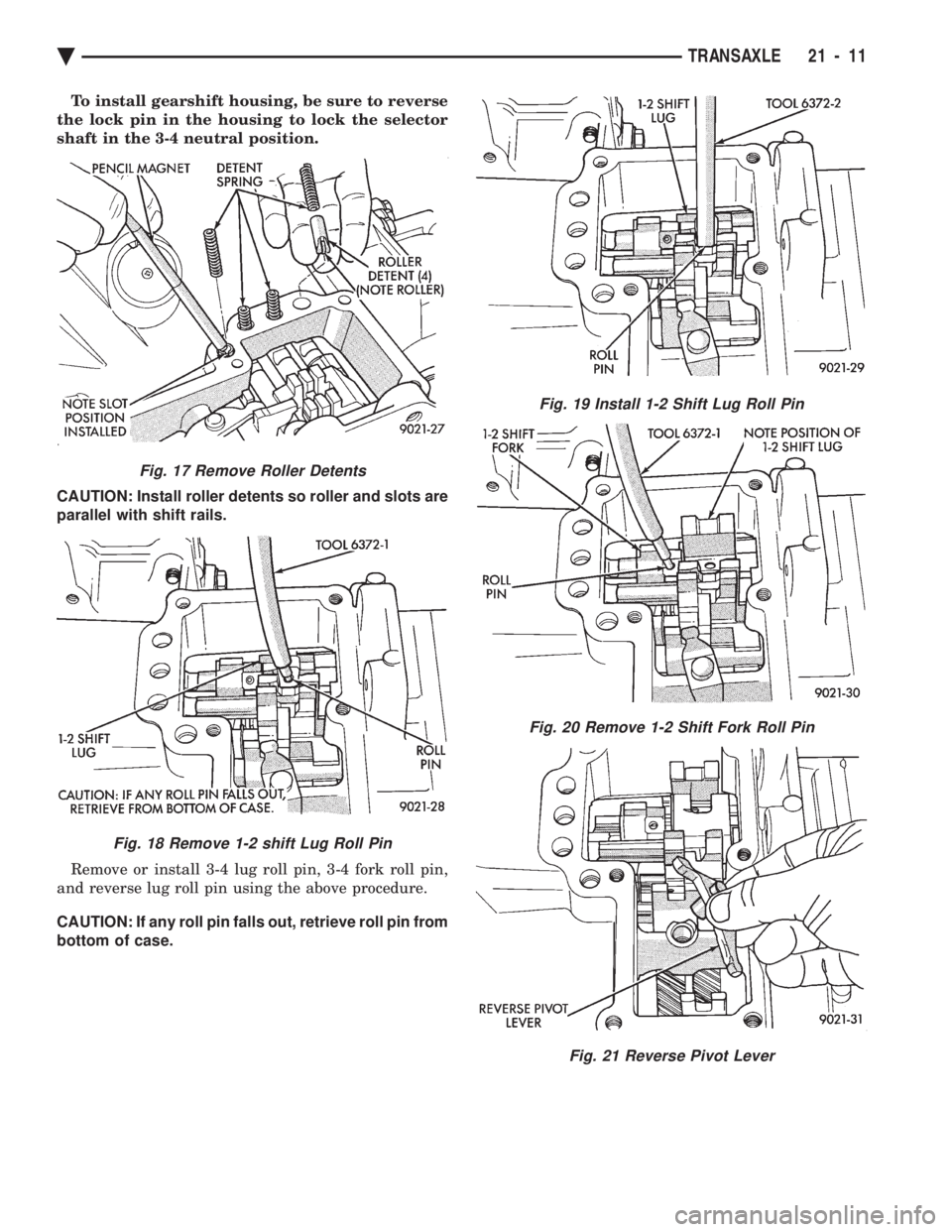

To install gearshift housing, be sure to reverse

the lock pin in the housing to lock the selector

shaft in the 3-4 neutral position.

CAUTION: Install roller detents so roller and slots are

parallel with shift rails.

Remove or install 3-4 lug roll pin, 3-4 fork roll pin,

and reverse lug roll pin using the above procedure.

CAUTION: If any roll pin falls out, retrieve roll pin from

bottom of case.

Fig. 19 Install 1-2 Shift Lug Roll Pin

Fig. 20 Remove 1-2 Shift Fork Roll Pin

Fig. 21 Reverse Pivot Lever

Fig. 17 Remove Roller Detents

Fig. 18 Remove 1-2 shift Lug Roll Pin

Ä TRANSAXLE 21 - 11

Page 1972 of 2438

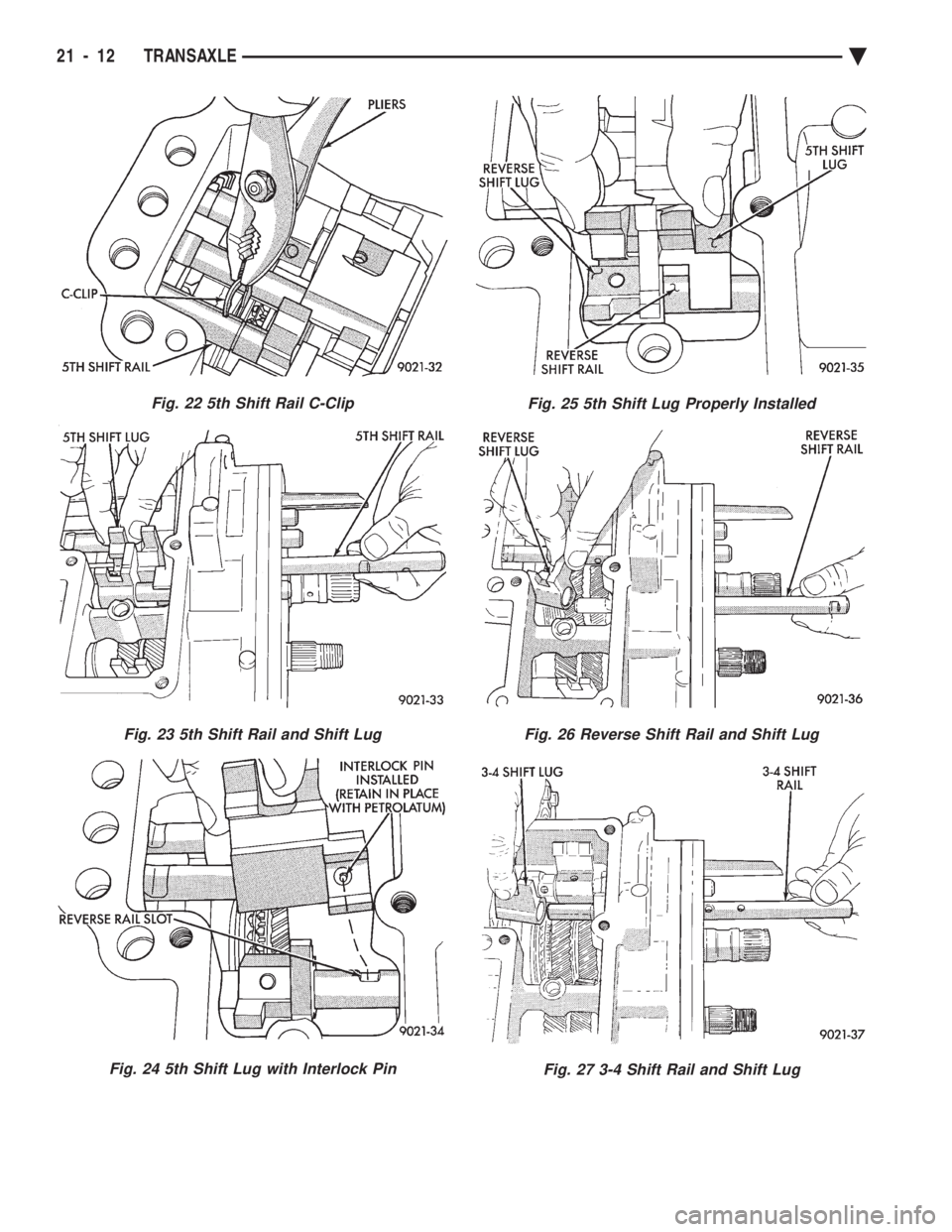

Fig. 22 5th Shift Rail C-Clip

Fig. 23 5th Shift Rail and Shift Lug

Fig. 24 5th Shift Lug with Interlock Pin

Fig. 25 5th Shift Lug Properly Installed

Fig. 26 Reverse Shift Rail and Shift Lug

Fig. 27 3-4 Shift Rail and Shift Lug

21 - 12 TRANSAXLE Ä

Page 1973 of 2438

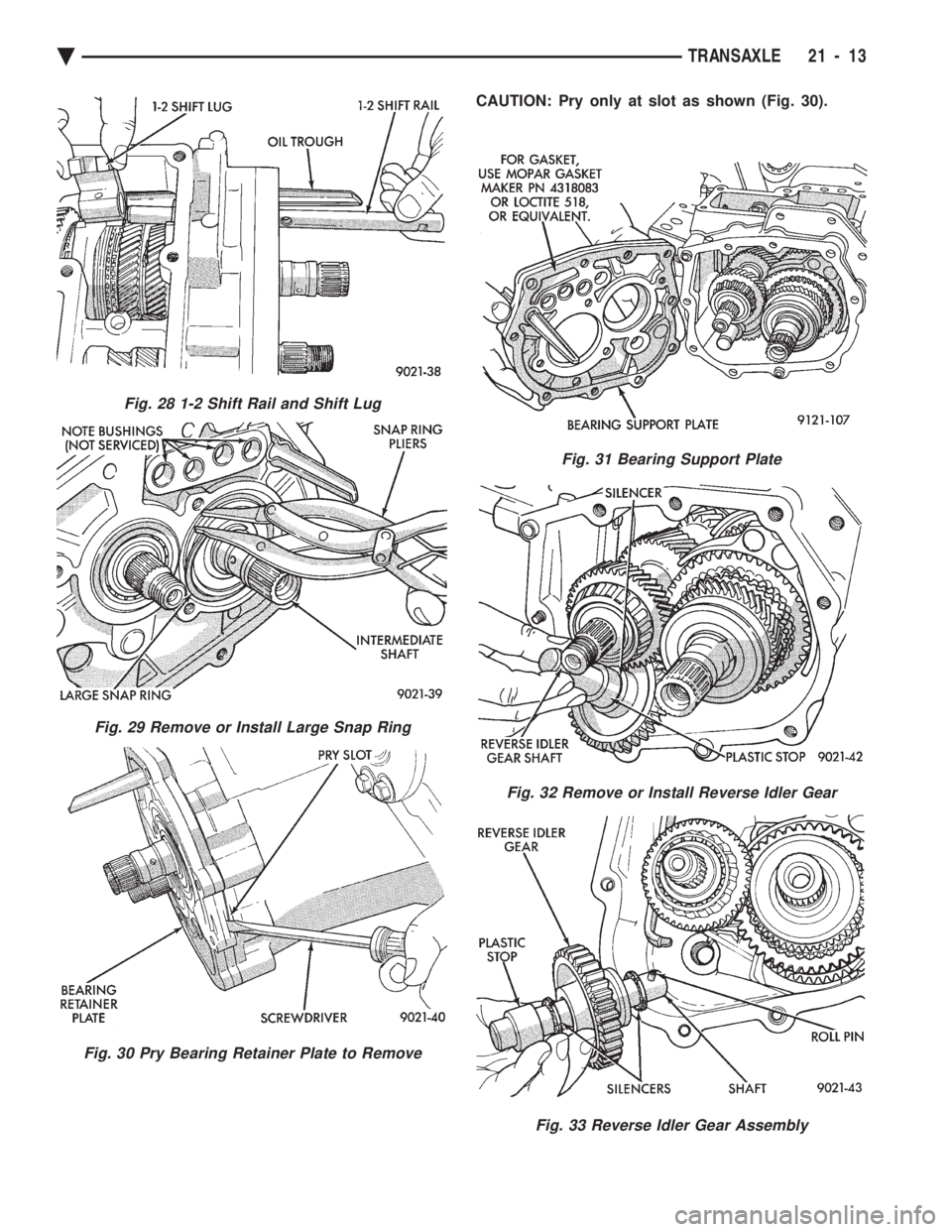

CAUTION: Pry only at slot as shown (Fig. 30).

Fig. 28 1-2 Shift Rail and Shift Lug

Fig. 29 Remove or Install Large Snap Ring

Fig. 30 Pry Bearing Retainer Plate to Remove

Fig. 31 Bearing Support Plate

Fig. 32 Remove or Install Reverse Idler Gear

Fig. 33 Reverse Idler Gear Assembly

Ä TRANSAXLE 21 - 13

Page 1974 of 2438

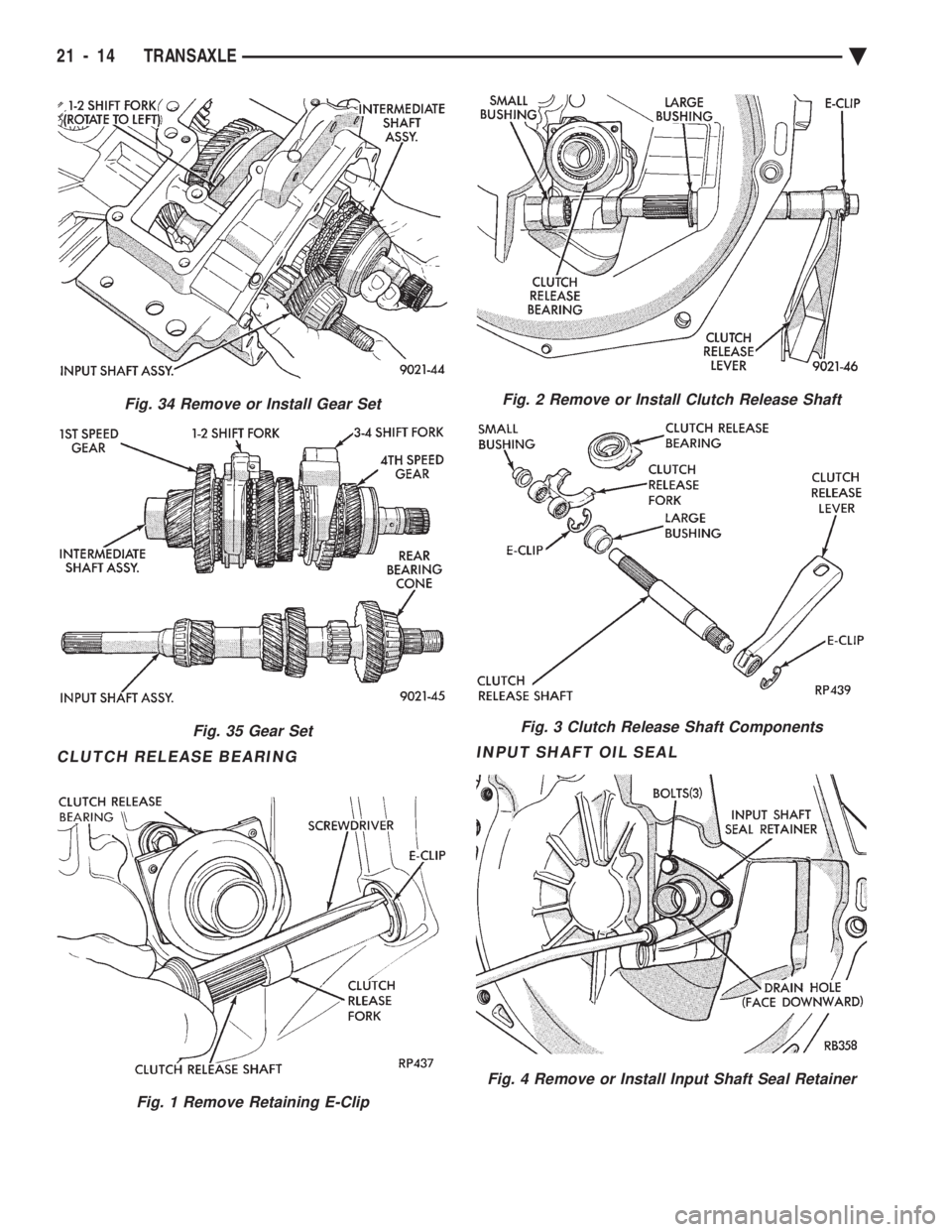

CLUTCH RELEASE BEARING INPUT SHAFT OIL SEAL

Fig. 34 Remove or Install Gear Set

Fig. 35 Gear Set

Fig. 1 Remove Retaining E-Clip

Fig. 2 Remove or Install Clutch Release Shaft

Fig. 3 Clutch Release Shaft Components

Fig. 4 Remove or Install Input Shaft Seal Retainer

21 - 14 TRANSAXLE

Ä

Page 1975 of 2438

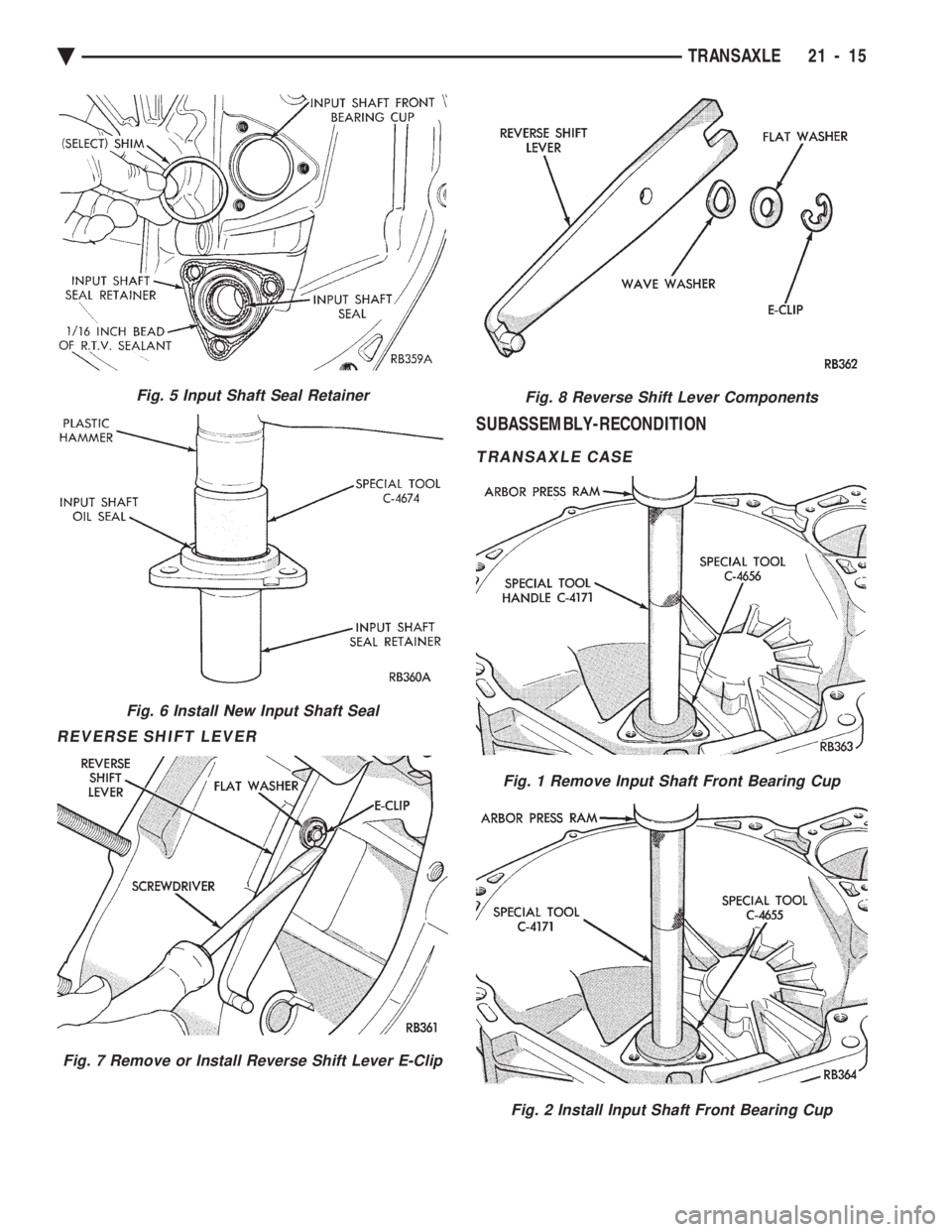

REVERSE SHIFT LEVER

SUBASSEMBLY-RECONDITION

TRANSAXLE CASE

Fig. 6 Install New Input Shaft Seal

Fig. 7 Remove or Install Reverse Shift Lever E-Clip

Fig. 8 Reverse Shift Lever Components

Fig. 1 Remove Input Shaft Front Bearing Cup

Fig. 2 Install Input Shaft Front Bearing Cup

Fig. 5 Input Shaft Seal Retainer

Ä TRANSAXLE 21 - 15

Page 1976 of 2438

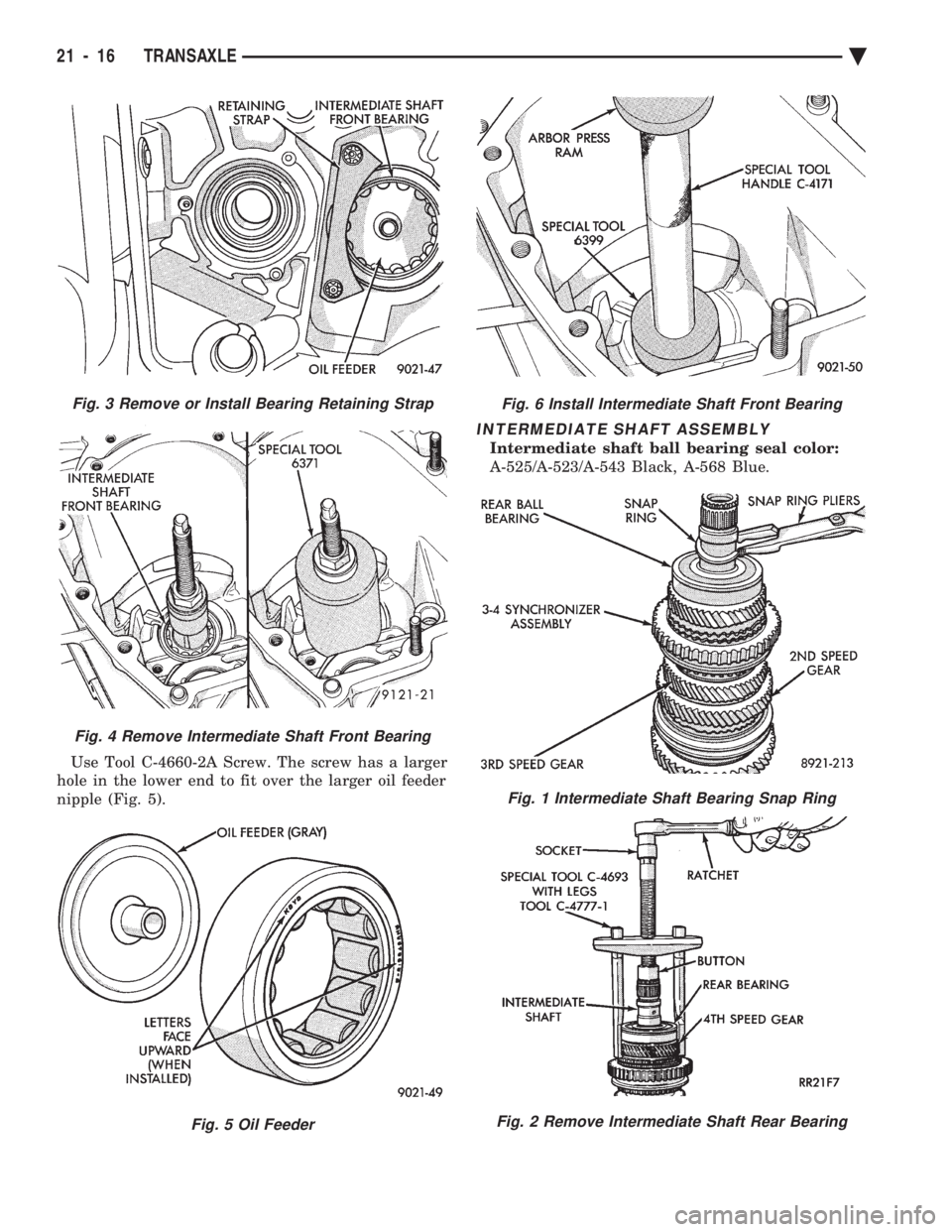

Use Tool C-4660-2A Screw. The screw has a larger

hole in the lower end to fit over the larger oil feeder

nipple (Fig. 5).

INTERMEDIATE SHAFT ASSEMBLY

Intermediate shaft ball bearing seal color:

A-525/A-523/A-543 Black, A-568 Blue.

Fig. 3 Remove or Install Bearing Retaining Strap

Fig. 4 Remove Intermediate Shaft Front Bearing

Fig. 5 Oil Feeder

Fig. 6 Install Intermediate Shaft Front Bearing

Fig. 1 Intermediate Shaft Bearing Snap Ring

Fig. 2 Remove Intermediate Shaft Rear Bearing

21 - 16 TRANSAXLE Ä

Page 1977 of 2438

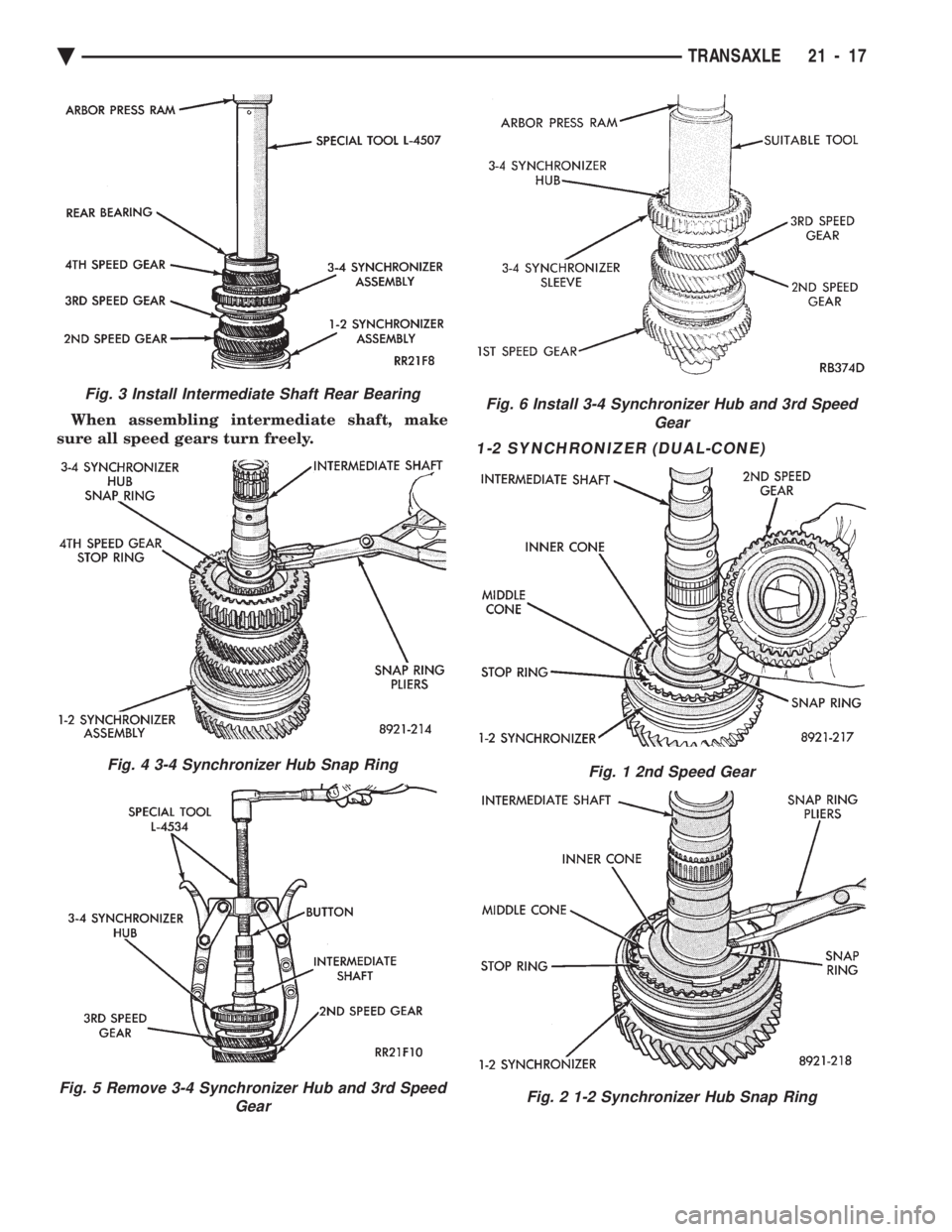

When assembling intermediate shaft, make

sure all speed gears turn freely.

1-2 SYNCHRONIZER (DUAL-CONE)

Fig. 6 Install 3-4 Synchronizer Hub and 3rd Speed Gear

Fig. 1 2nd Speed Gear

Fig. 2 1-2 Synchronizer Hub Snap Ring

Fig. 3 Install Intermediate Shaft Rear Bearing

Fig. 4 3-4 Synchronizer Hub Snap Ring

Fig. 5 Remove 3-4 Synchronizer Hub and 3rd Speed Gear

Ä TRANSAXLE 21 - 17

Page 1978 of 2438

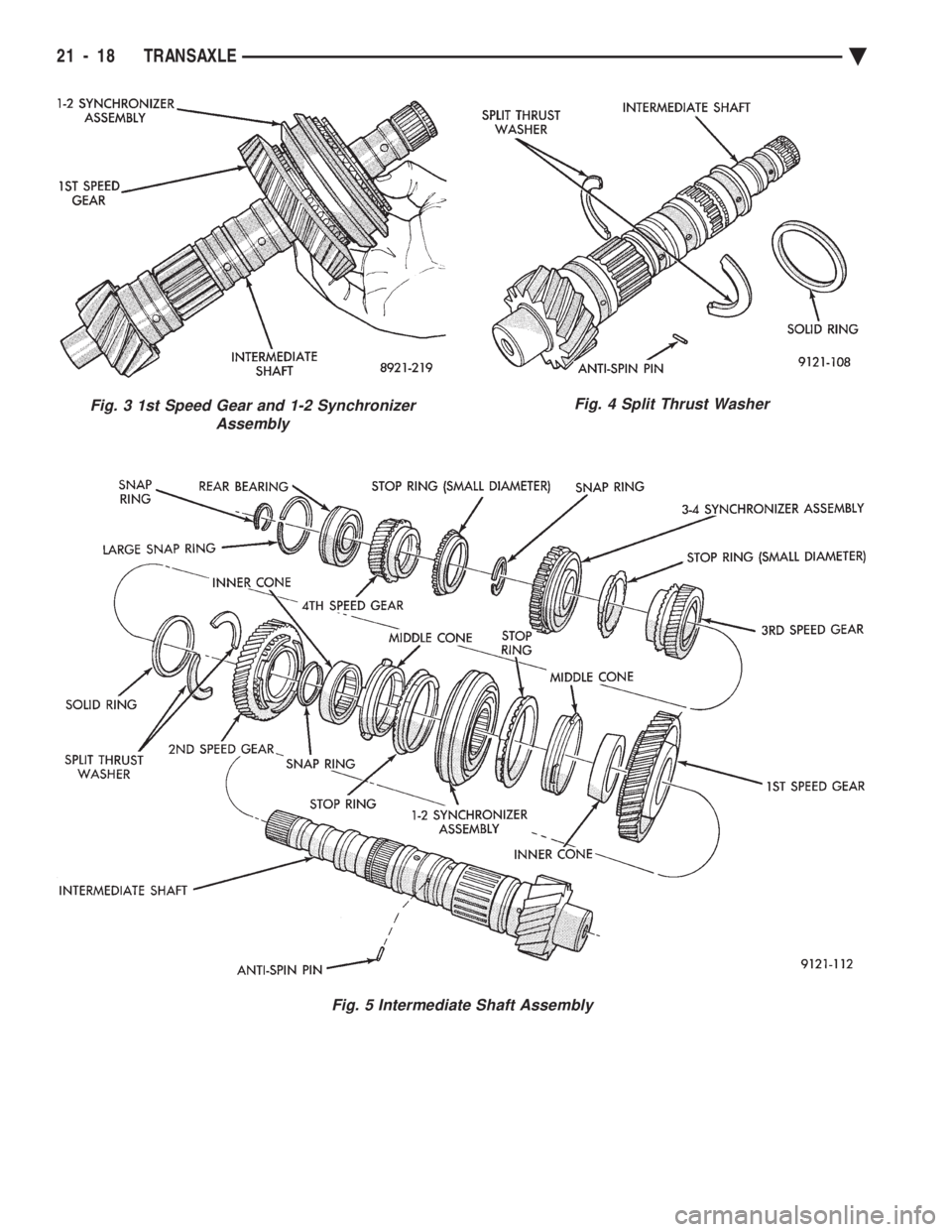

Fig. 3 1st Speed Gear and 1-2 Synchronizer AssemblyFig. 4 Split Thrust Washer

Fig. 5 Intermediate Shaft Assembly

21 - 18 TRANSAXLE Ä

Page 1979 of 2438

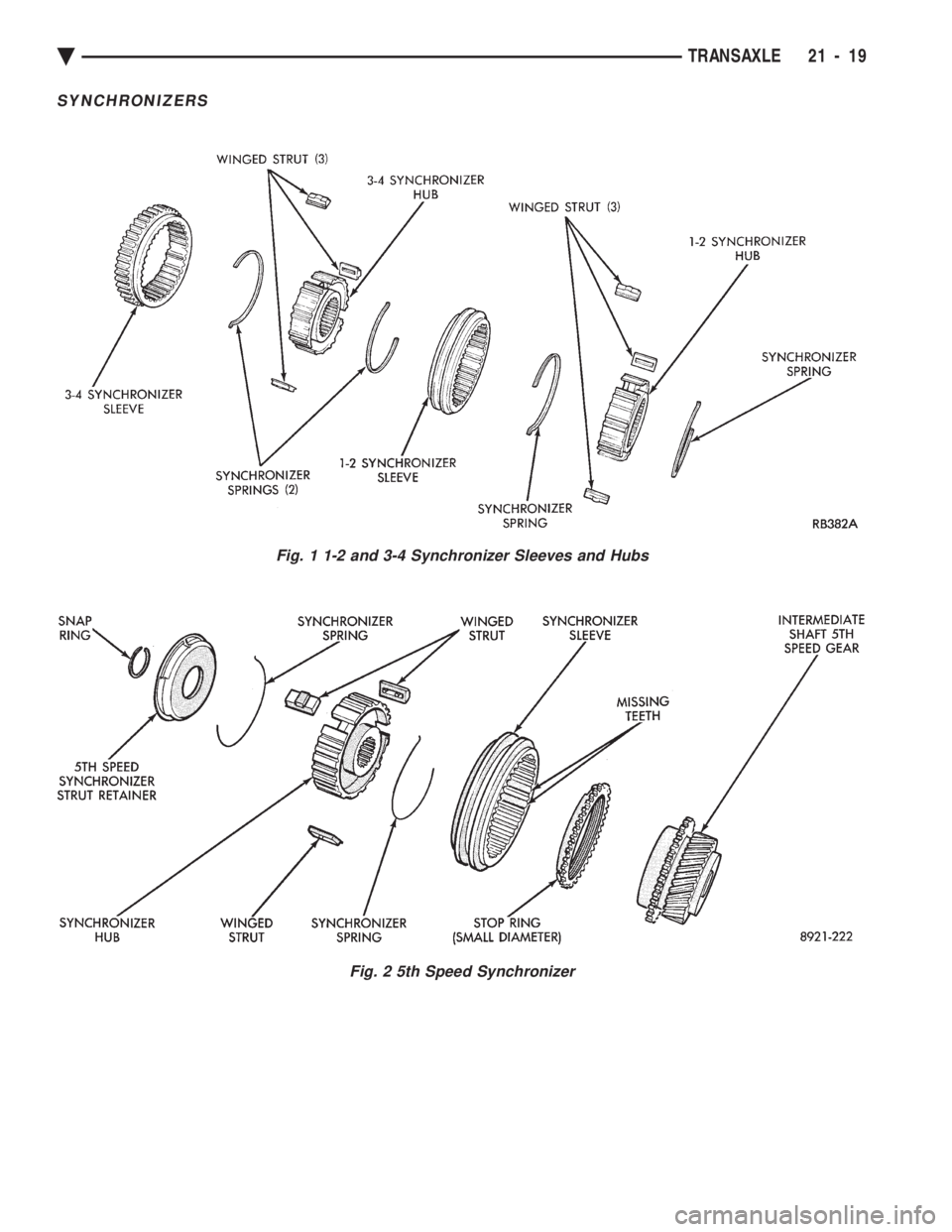

SYNCHRONIZERS

Fig. 1 1-2 and 3-4 Synchronizer Sleeves and Hubs

Fig. 2 5th Speed Synchronizer

Ä TRANSAXLE 21 - 19

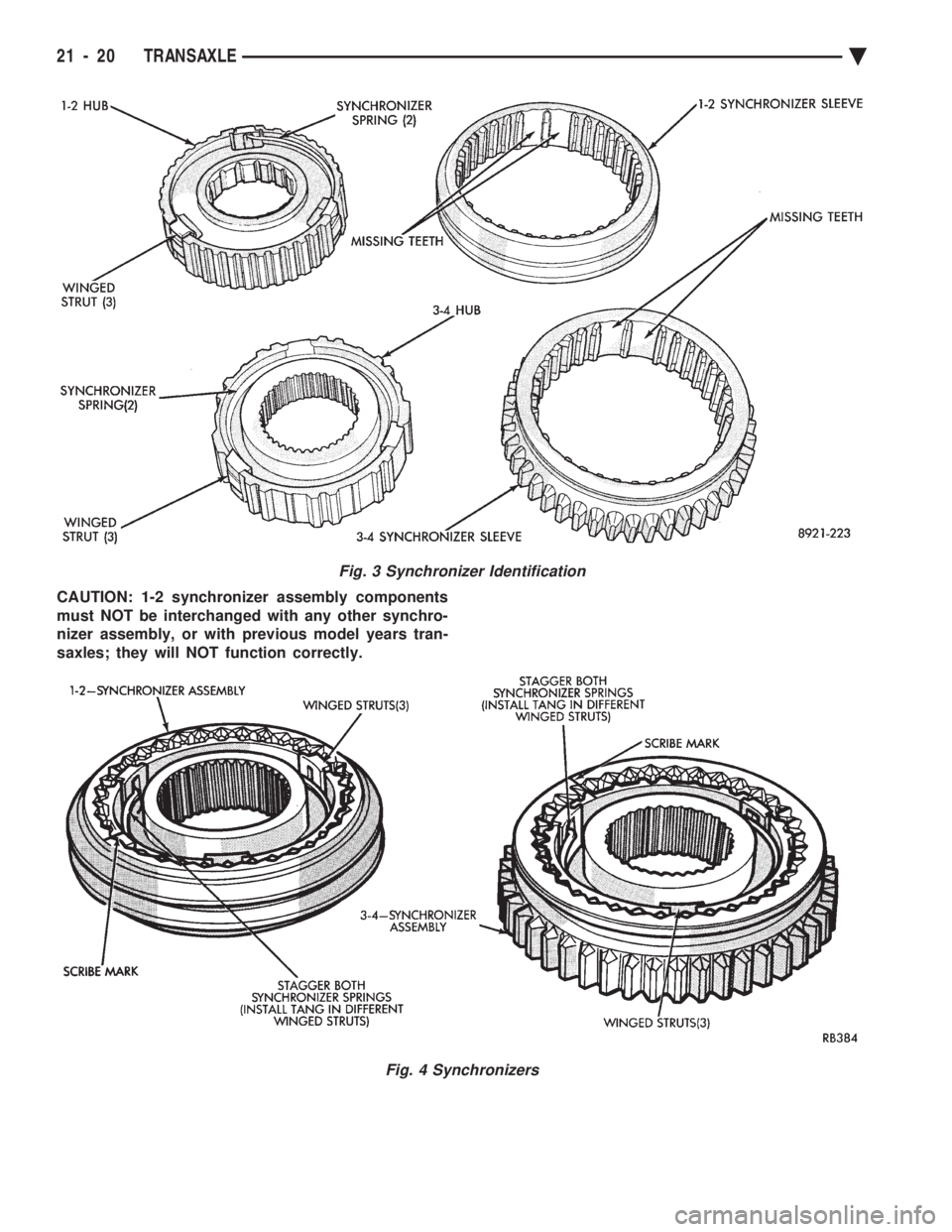

Page 1980 of 2438

CAUTION: 1-2 synchronizer assembly components

must NOT be interchanged with any other synchro-

nizer assembly, or with previous model years tran-

saxles; they will NOT function correctly.

Fig. 3 Synchronizer Identification

Fig. 4 Synchronizers

21 - 20 TRANSAXLE Ä

Trending: horn, cooling, wheel bolts, parking brake, Solenoid, fuel fill door release, brake sensor