CHEVROLET PLYMOUTH ACCLAIM 1993 Service Manual

PLYMOUTH ACCLAIM 1993

CHEVROLET

CHEVROLET

https://www.carmanualsonline.info/img/24/56861/w960_56861-0.png

CHEVROLET PLYMOUTH ACCLAIM 1993 Service Manual

Trending: wiper blades, inflation pressure, oil change, heating, transmission oil, parking brake, transmission fluid

Page 1981 of 2438

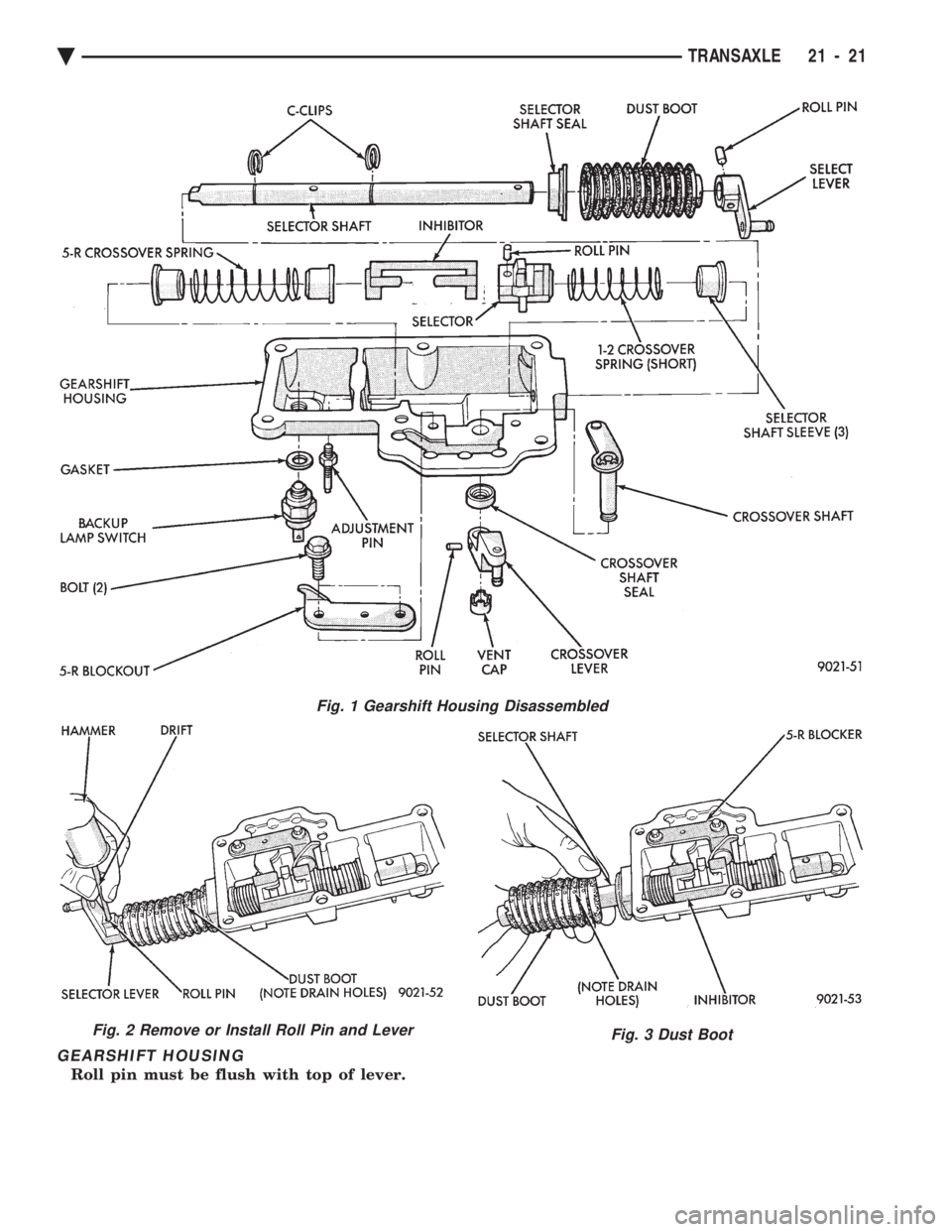

GEARSHIFT HOUSING

Roll pin must be flush with top of lever.

Fig. 1 Gearshift Housing Disassembled

Fig. 2 Remove or Install Roll Pin and LeverFig. 3 Dust Boot

Ä TRANSAXLE 21 - 21

Page 1982 of 2438

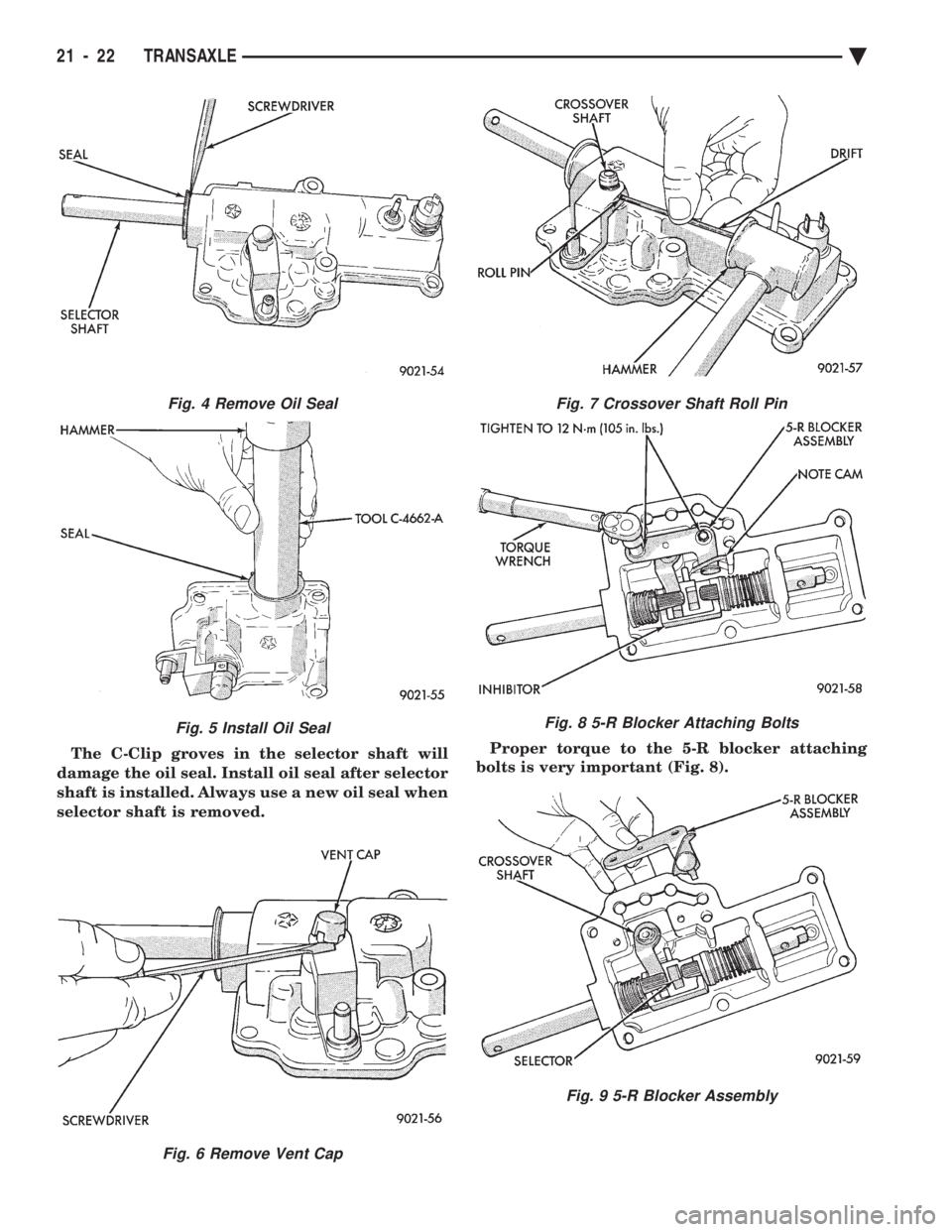

The C-Clip groves in the selector shaft will

damage the oil seal. Install oil seal after selector

shaft is installed. Always use a new oil seal when

selector shaft is removed. Proper torque to the 5-R blocker attaching

bolts is very important (Fig. 8).

Fig. 4 Remove Oil Seal

Fig. 5 Install Oil Seal

Fig. 6 Remove Vent Cap

Fig. 7 Crossover Shaft Roll Pin

Fig. 8 5-R Blocker Attaching Bolts

Fig. 9 5-R Blocker Assembly

21 - 22 TRANSAXLE Ä

Page 1983 of 2438

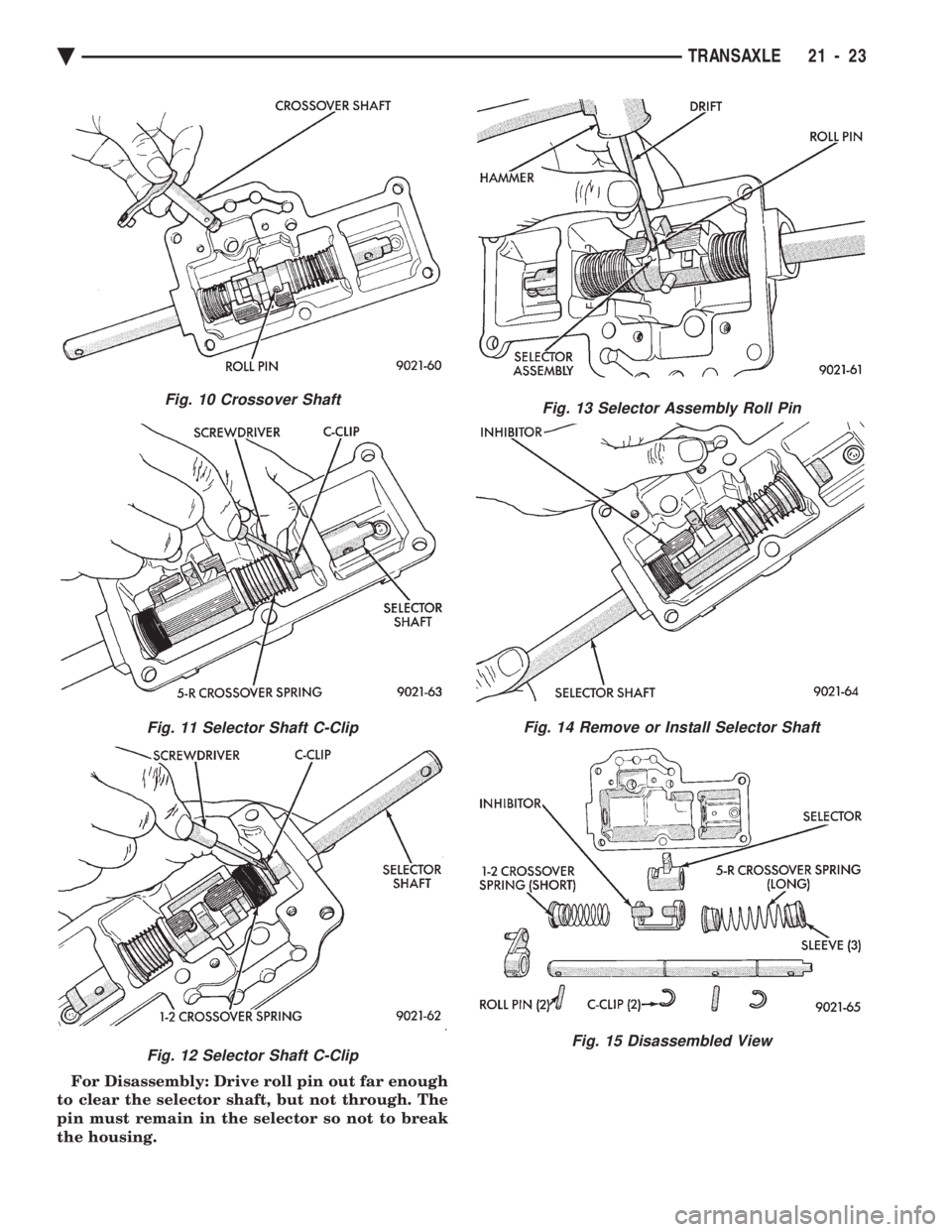

For Disassembly: Drive roll pin out far enough

to clear the selector shaft, but not through. The

pin must remain in the selector so not to break

the housing.

Fig. 10 Crossover Shaft

Fig. 11 Selector Shaft C-Clip

Fig. 12 Selector Shaft C-Clip

Fig. 13 Selector Assembly Roll Pin

Fig. 14 Remove or Install Selector Shaft

Fig. 15 Disassembled View

Ä TRANSAXLE 21 - 23

Page 1984 of 2438

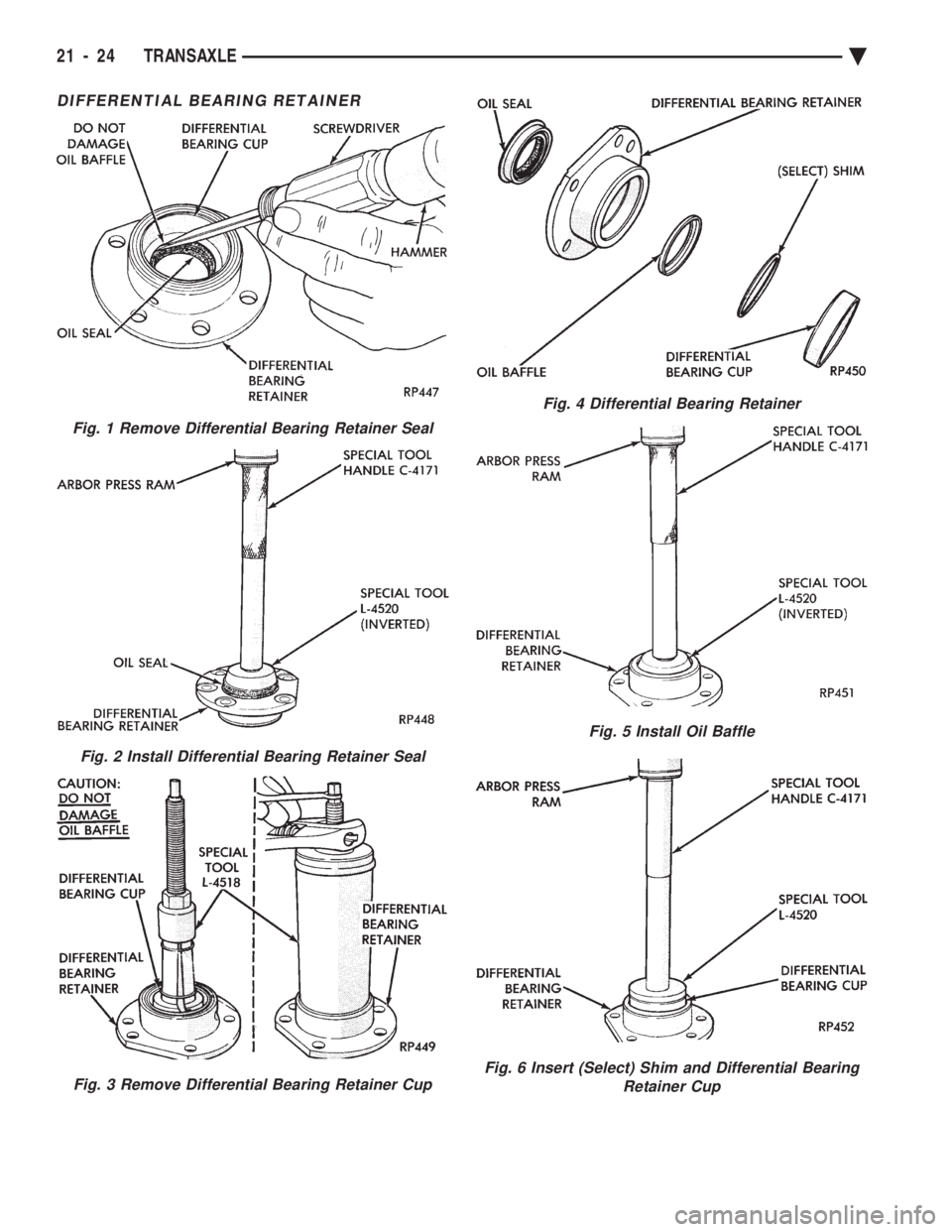

DIFFERENTIAL BEARING RETAINER

Fig. 1 Remove Differential Bearing Retainer Seal

Fig. 2 Install Differential Bearing Retainer Seal

Fig. 3 Remove Differential Bearing Retainer Cup

Fig. 4 Differential Bearing Retainer

Fig. 5 Install Oil Baffle

Fig. 6 Insert (Select) Shim and Differential Bearing Retainer Cup

21 - 24 TRANSAXLE Ä

Page 1985 of 2438

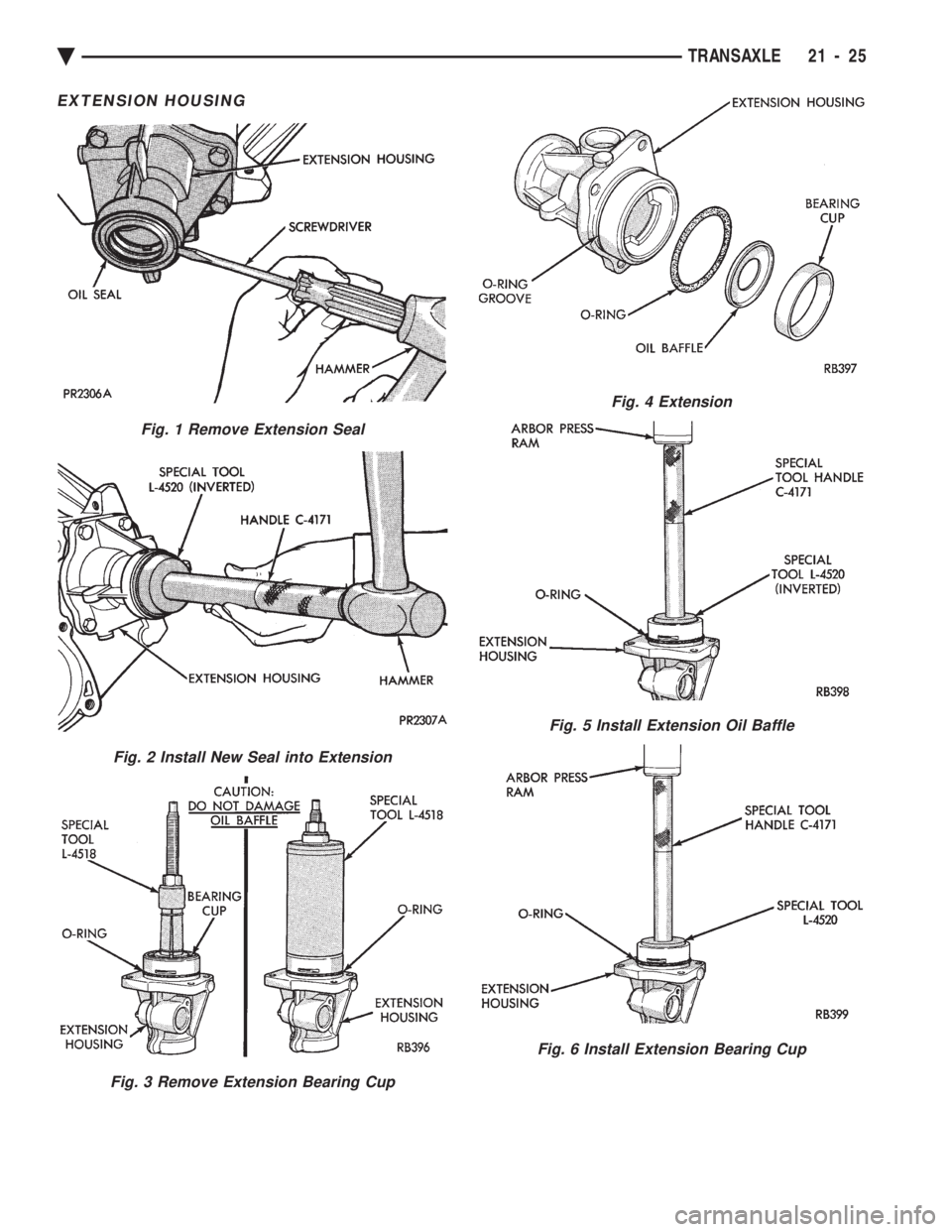

EXTENSION HOUSING

Fig. 1 Remove Extension Seal

Fig. 2 Install New Seal into Extension

Fig. 3 Remove Extension Bearing Cup

Fig. 4 Extension

Fig. 5 Install Extension Oil Baffle

Fig. 6 Install Extension Bearing Cup

Ä TRANSAXLE 21 - 25

Page 1986 of 2438

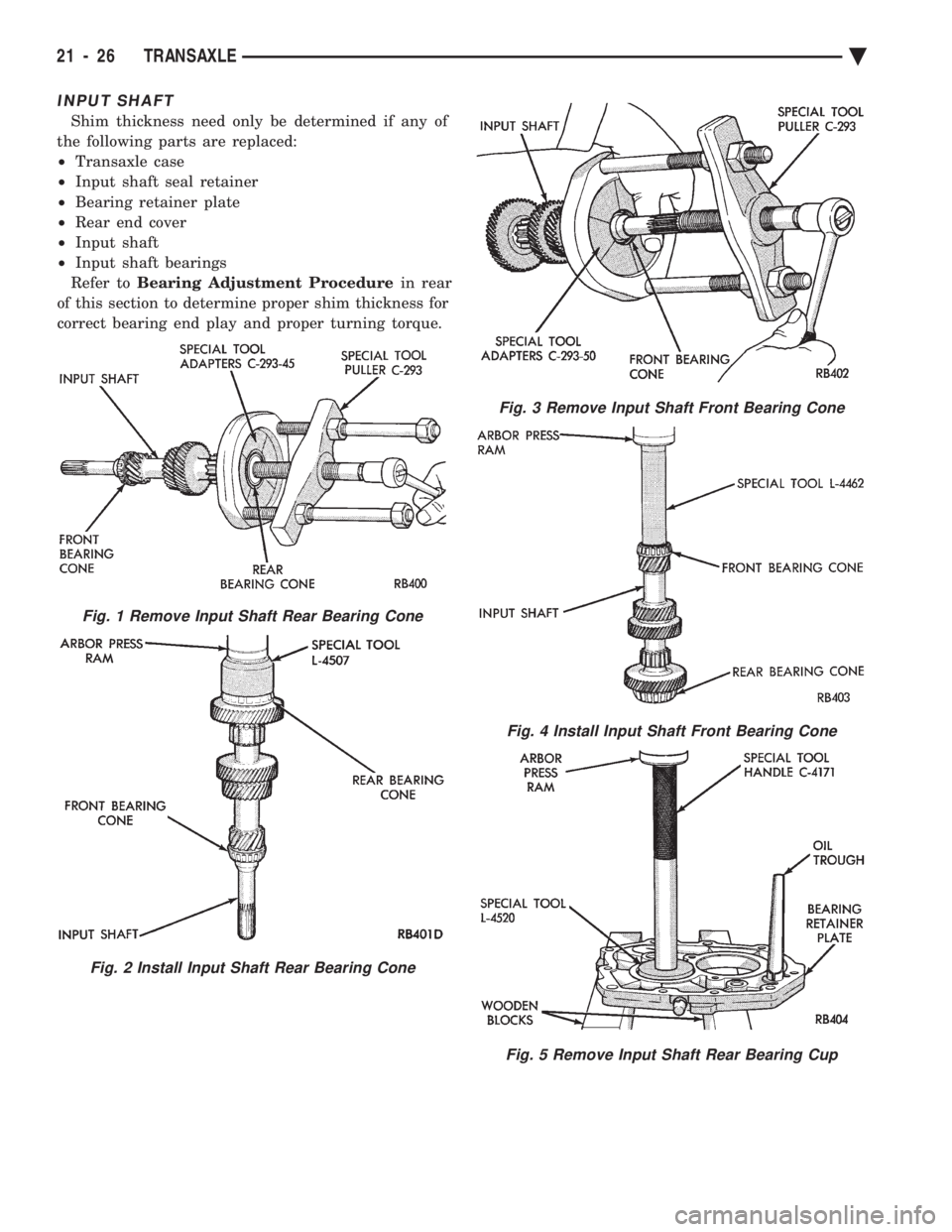

INPUT SHAFT

Shim thickness need only be determined if any of

the following parts are replaced:

² Transaxle case

² Input shaft seal retainer

² Bearing retainer plate

² Rear end cover

² Input shaft

² Input shaft bearings

Refer to Bearing Adjustment Procedure in rear

of this section to determine proper shim thickness for

correct bearing end play and proper turning torque.

Fig. 1 Remove Input Shaft Rear Bearing Cone

Fig. 2 Install Input Shaft Rear Bearing Cone

Fig. 3 Remove Input Shaft Front Bearing Cone

Fig. 4 Install Input Shaft Front Bearing Cone

Fig. 5 Remove Input Shaft Rear Bearing Cup

21 - 26 TRANSAXLE Ä

Page 1987 of 2438

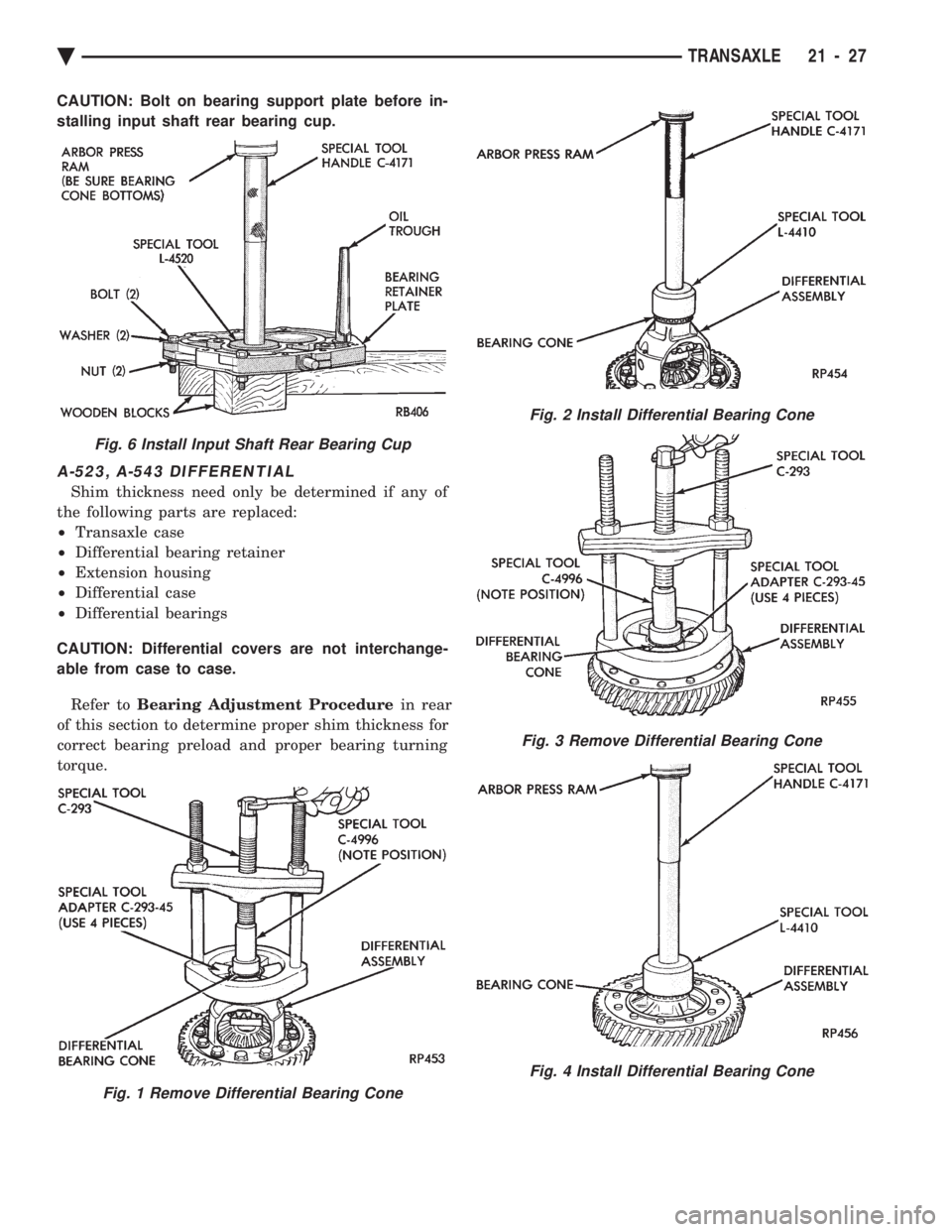

CAUTION: Bolt on bearing support plate before in-

stalling input shaft rear bearing cup.

A-523, A-543 DIFFERENTIAL

Shim thickness need only be determined if any of

the following parts are replaced:

² Transaxle case

² Differential bearing retainer

² Extension housing

² Differential case

² Differential bearings

CAUTION: Differential covers are not interchange-

able from case to case.

Refer to Bearing Adjustment Procedure in rear

of this section to determine proper shim thickness for

correct bearing preload and proper bearing turning

torque.

Fig. 6 Install Input Shaft Rear Bearing Cup

Fig. 1 Remove Differential Bearing Cone

Fig. 2 Install Differential Bearing Cone

Fig. 3 Remove Differential Bearing Cone

Fig. 4 Install Differential Bearing Cone

Ä TRANSAXLE 21 - 27

Page 1988 of 2438

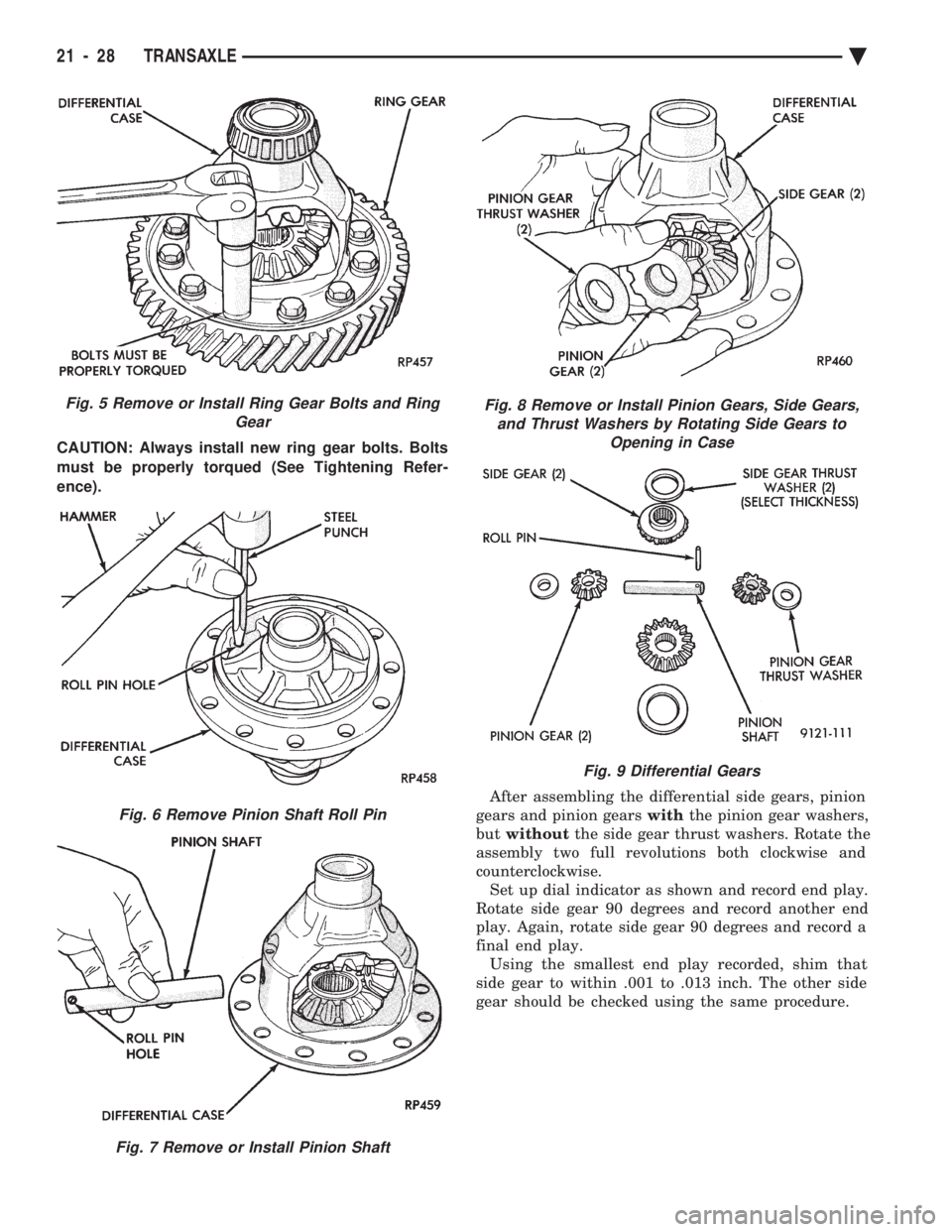

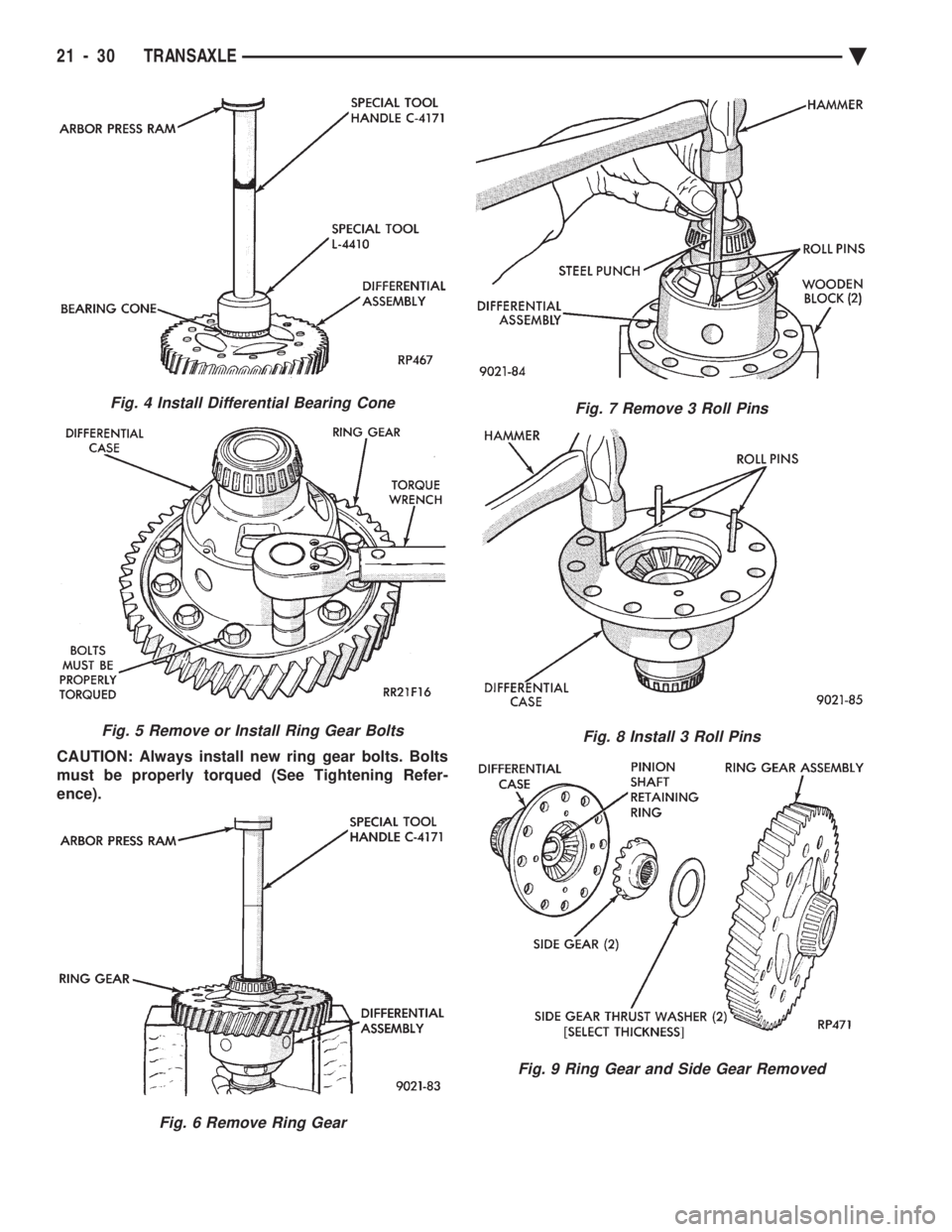

CAUTION: Always install new ring gear bolts. Bolts

must be properly torqued (See Tightening Refer-

ence). After assembling the differential side gears, pinion

gears and pinion gears withthe pinion gear washers,

but without the side gear thrust washers. Rotate the

assembly two full revolutions both clockwise and

counterclockwise. Set up dial indicator as shown and record end play.

Rotate side gear 90 degrees and record another end

play. Again, rotate side gear 90 degrees and record a

final end play. Using the smallest end play recorded, shim that

side gear to within .001 to .013 inch. The other side

gear should be checked using the same procedure.

Fig. 5 Remove or Install Ring Gear Bolts and Ring Gear

Fig. 6 Remove Pinion Shaft Roll Pin

Fig. 7 Remove or Install Pinion Shaft

Fig. 8 Remove or Install Pinion Gears, Side Gears,and Thrust Washers by Rotating Side Gears to Opening in Case

Fig. 9 Differential Gears

21 - 28 TRANSAXLE Ä

Page 1989 of 2438

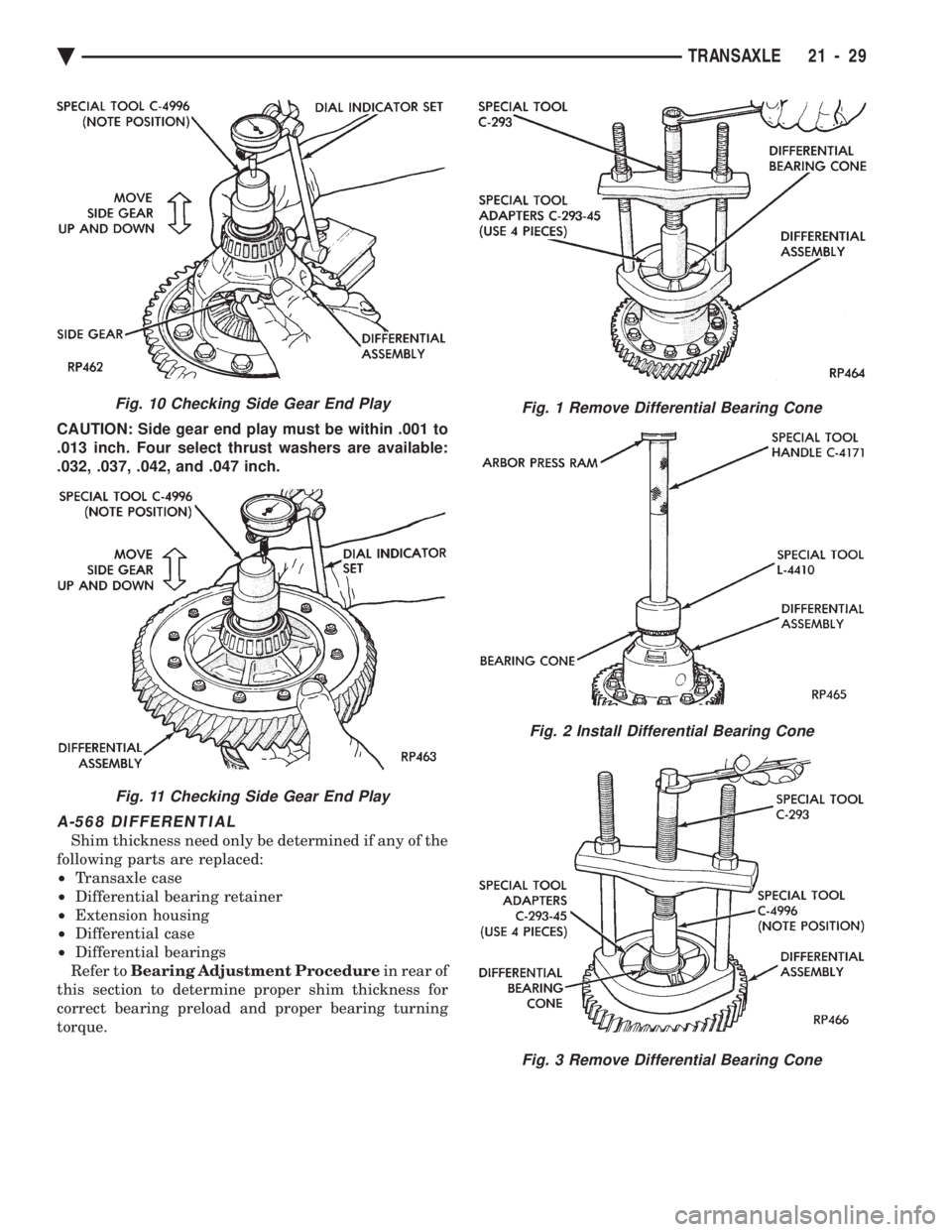

CAUTION: Side gear end play must be within .001 to

.013 inch. Four select thrust washers are available:

.032, .037, .042, and .047 inch.

A-568 DIFFERENTIAL

Shim thickness need only be determined if any of the

following parts are replaced:

² Transaxle case

² Differential bearing retainer

² Extension housing

² Differential case

² Differential bearings

Refer to Bearing Adjustment Procedure in rear of

this section to determine proper shim thickness for

correct bearing preload and proper bearing turning

torque.

Fig. 1 Remove Differential Bearing Cone

Fig. 2 Install Differential Bearing Cone

Fig. 3 Remove Differential Bearing Cone

Fig. 10 Checking Side Gear End Play

Fig. 11 Checking Side Gear End Play

Ä TRANSAXLE 21 - 29

Page 1990 of 2438

CAUTION: Always install new ring gear bolts. Bolts

must be properly torqued (See Tightening Refer-

ence).

Fig. 4 Install Differential Bearing Cone

Fig. 5 Remove or Install Ring Gear Bolts

Fig. 6 Remove Ring Gear

Fig. 7 Remove 3 Roll Pins

Fig. 8 Install 3 Roll Pins

Fig. 9 Ring Gear and Side Gear Removed

21 - 30 TRANSAXLE Ä

Trending: length, suspension, fold seats, check oil, Transaxle, radiator, deactivate airbag