CHEVROLET PLYMOUTH ACCLAIM 1993 Service Manual

PLYMOUTH ACCLAIM 1993

CHEVROLET

CHEVROLET

https://www.carmanualsonline.info/img/24/56861/w960_56861-0.png

CHEVROLET PLYMOUTH ACCLAIM 1993 Service Manual

Trending: ECU, snow chains, radiator cap, parking sensors, open hood, AUX, buttons

Page 2011 of 2438

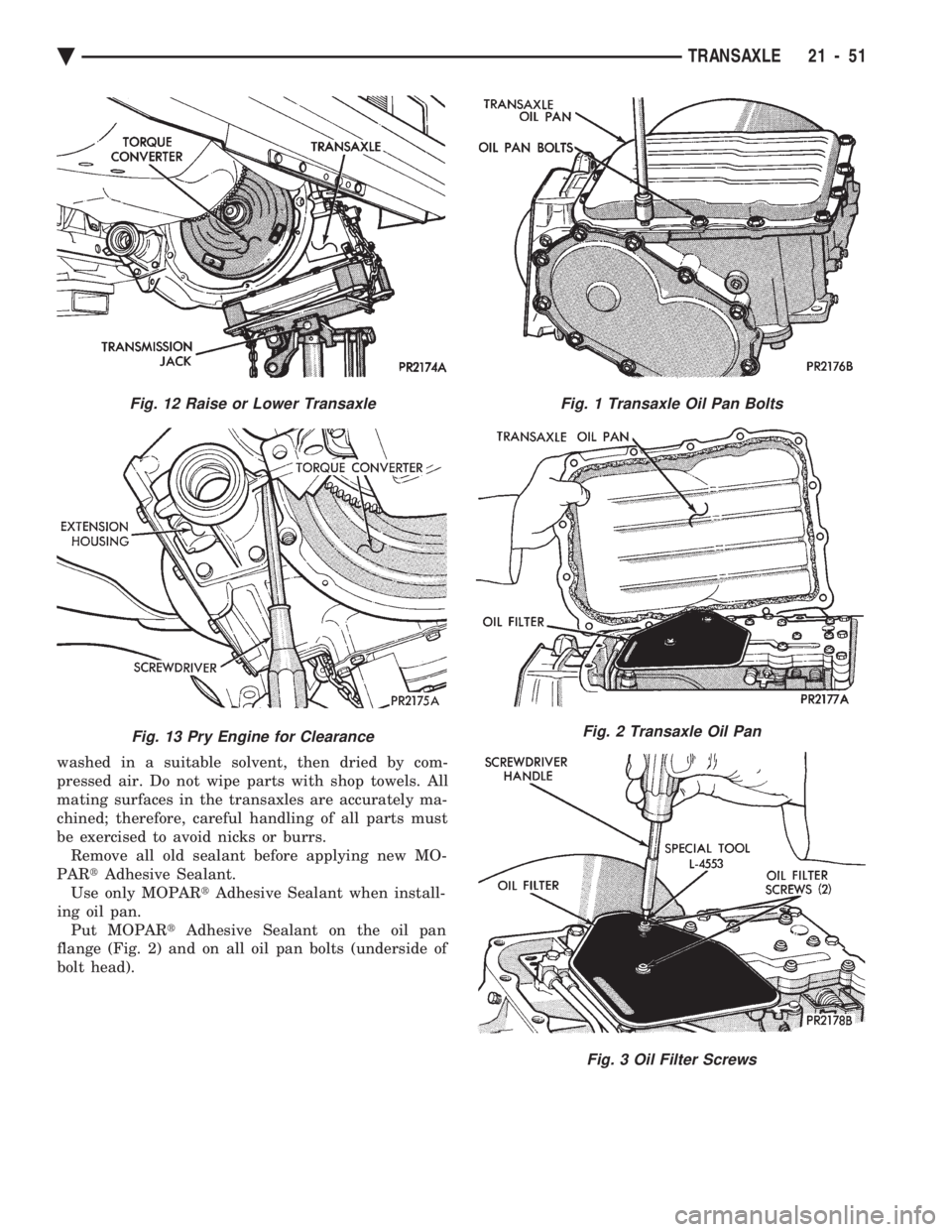

washed in a suitable solvent, then dried by com-

pressed air. Do not wipe parts with shop towels. All

mating surfaces in the transaxles are accurately ma-

chined; therefore, careful handling of all parts must

be exercised to avoid nicks or burrs. Remove all old sealant before applying new MO-

PAR tAdhesive Sealant.

Use only MOPAR tAdhesive Sealant when install-

ing oil pan. Put MOPAR tAdhesive Sealant on the oil pan

flange (Fig. 2) and on all oil pan bolts (underside of

bolt head).

Fig. 12 Raise or Lower Transaxle

Fig. 13 Pry Engine for Clearance

Fig. 1 Transaxle Oil Pan Bolts

Fig. 2 Transaxle Oil Pan

Fig. 3 Oil Filter Screws

Ä TRANSAXLE 21 - 51

Page 2012 of 2438

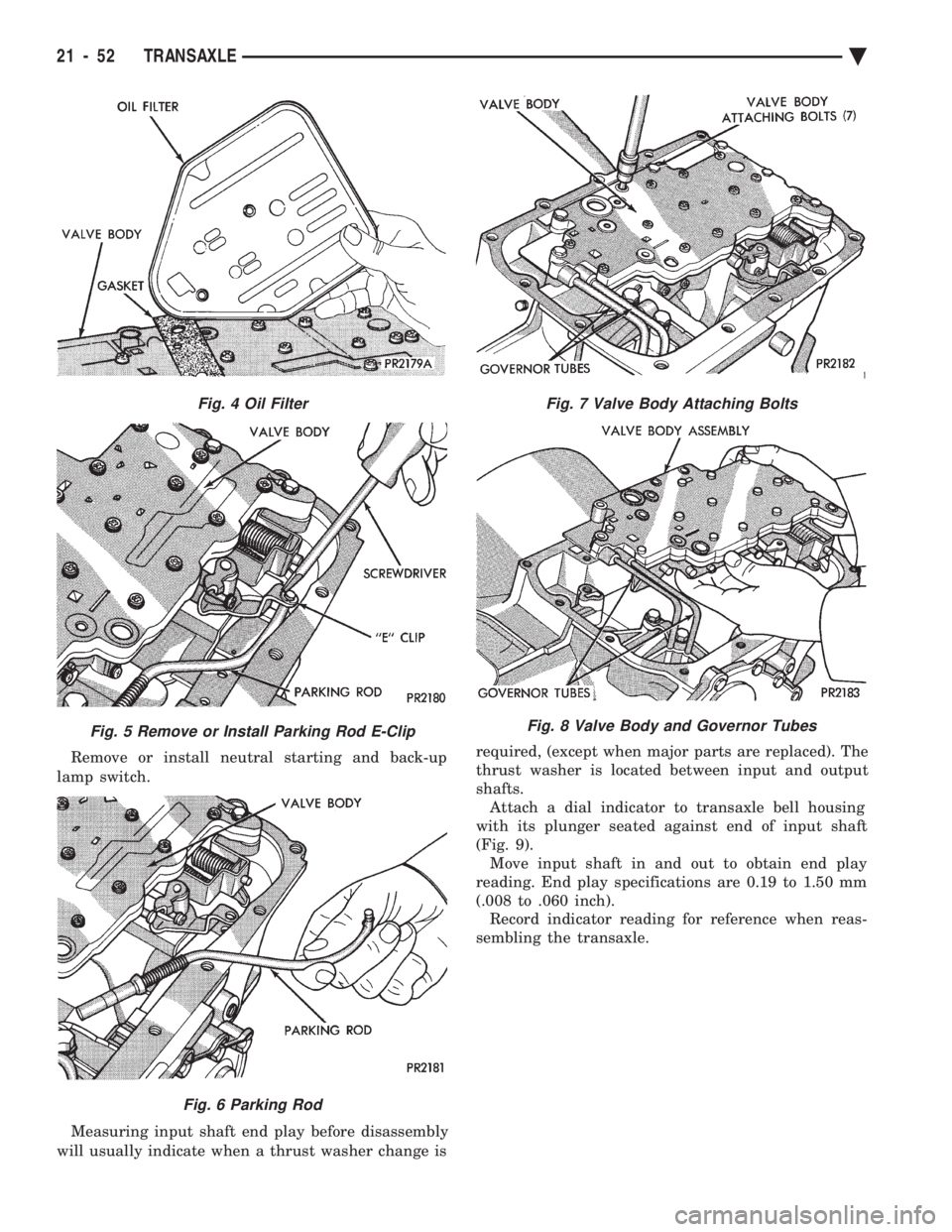

Remove or install neutral starting and back-up

lamp switch.

Measuring input shaft end play before disassembly

will usually indicate when a thrust washer change is required, (except when major parts are replaced). The

thrust washer is located between input and output

shafts. Attach a dial indicator to transaxle bell housing

with its plunger seated against end of input shaft

(Fig. 9). Move input shaft in and out to obtain end play

reading. End play specifications are 0.19 to 1.50 mm

(.008 to .060 inch). Record indicator reading for reference when reas-

sembling the transaxle.

Fig. 4 Oil Filter

Fig. 5 Remove or Install Parking Rod E-Clip

Fig. 6 Parking Rod

Fig. 7 Valve Body Attaching Bolts

Fig. 8 Valve Body and Governor Tubes

21 - 52 TRANSAXLE Ä

Page 2013 of 2438

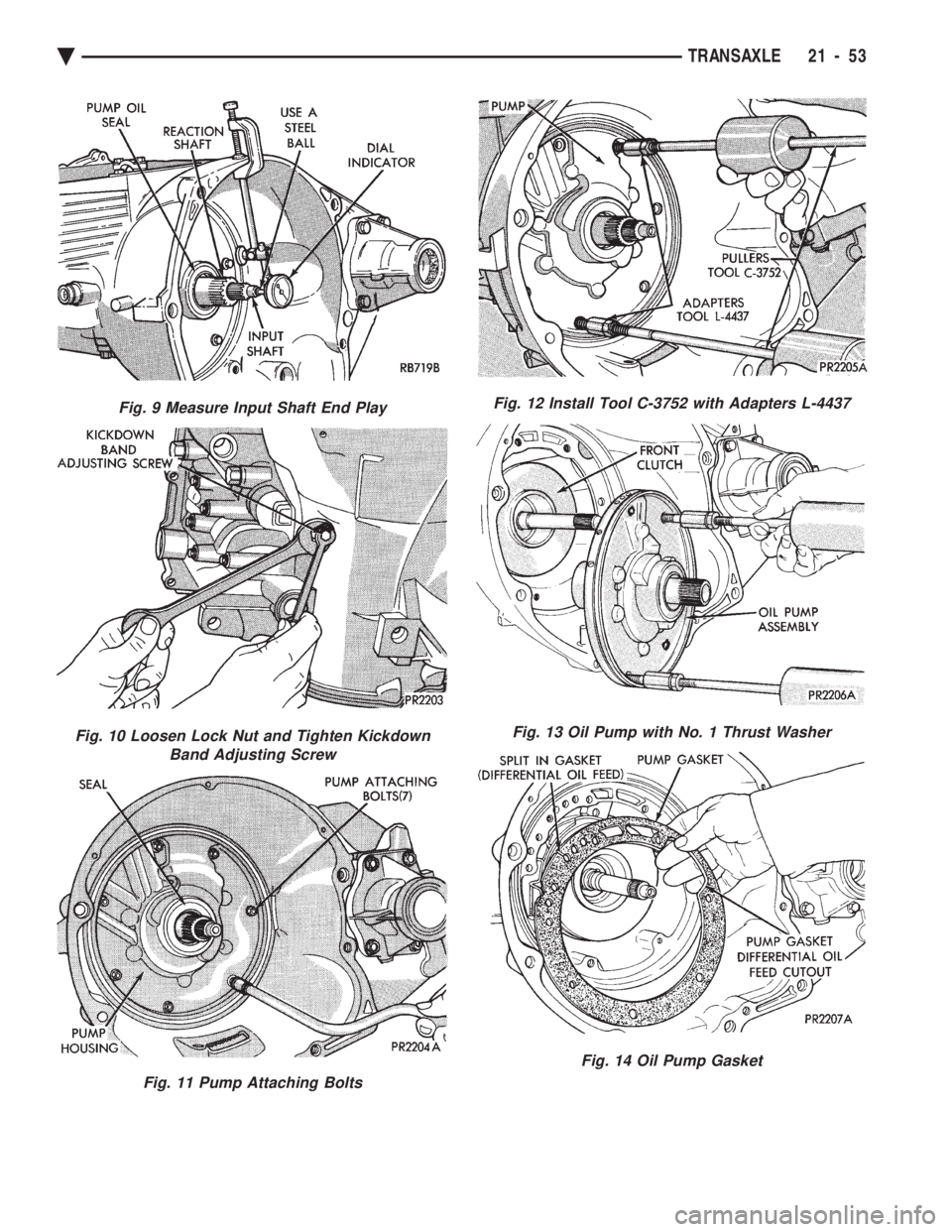

Fig. 9 Measure Input Shaft End Play

Fig. 10 Loosen Lock Nut and Tighten Kickdown Band Adjusting Screw

Fig. 11 Pump Attaching Bolts

Fig. 12 Install Tool C-3752 with Adapters L-4437

Fig. 13 Oil Pump with No. 1 Thrust Washer

Fig. 14 Oil Pump Gasket

Ä TRANSAXLE 21 - 53

Page 2014 of 2438

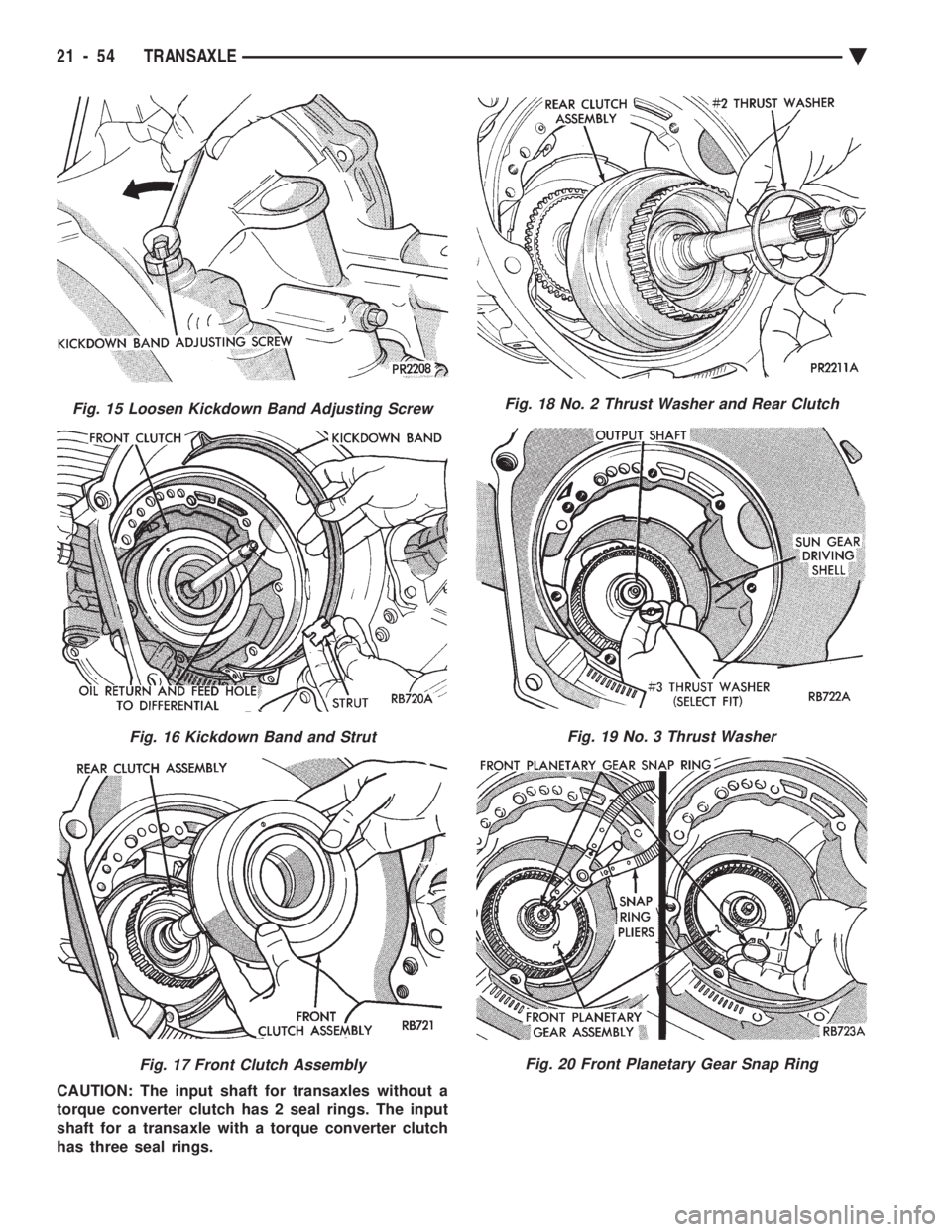

CAUTION: The input shaft for transaxles without a

torque converter clutch has 2 seal rings. The input

shaft for a transaxle with a torque converter clutch

has three seal rings.

Fig. 15 Loosen Kickdown Band Adjusting Screw

Fig. 16 Kickdown Band and Strut

Fig. 17 Front Clutch Assembly

Fig. 18 No. 2 Thrust Washer and Rear Clutch

Fig. 19 No. 3 Thrust Washer

Fig. 20 Front Planetary Gear Snap Ring

21 - 54 TRANSAXLE Ä

Page 2015 of 2438

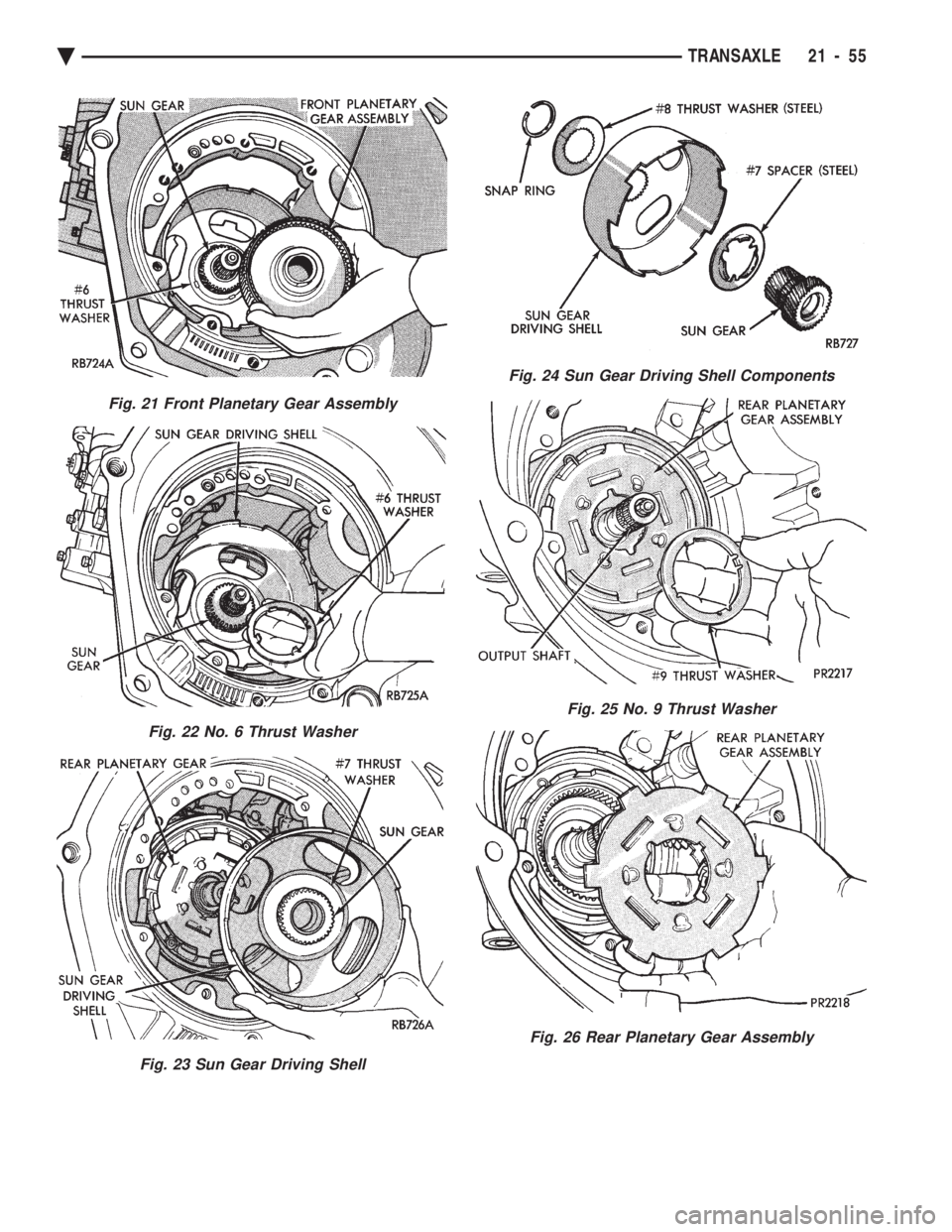

Fig. 21 Front Planetary Gear Assembly

Fig. 22 No. 6 Thrust Washer

Fig. 23 Sun Gear Driving Shell

Fig. 24 Sun Gear Driving Shell Components

Fig. 25 No. 9 Thrust Washer

Fig. 26 Rear Planetary Gear Assembly

Ä TRANSAXLE 21 - 55

Page 2016 of 2438

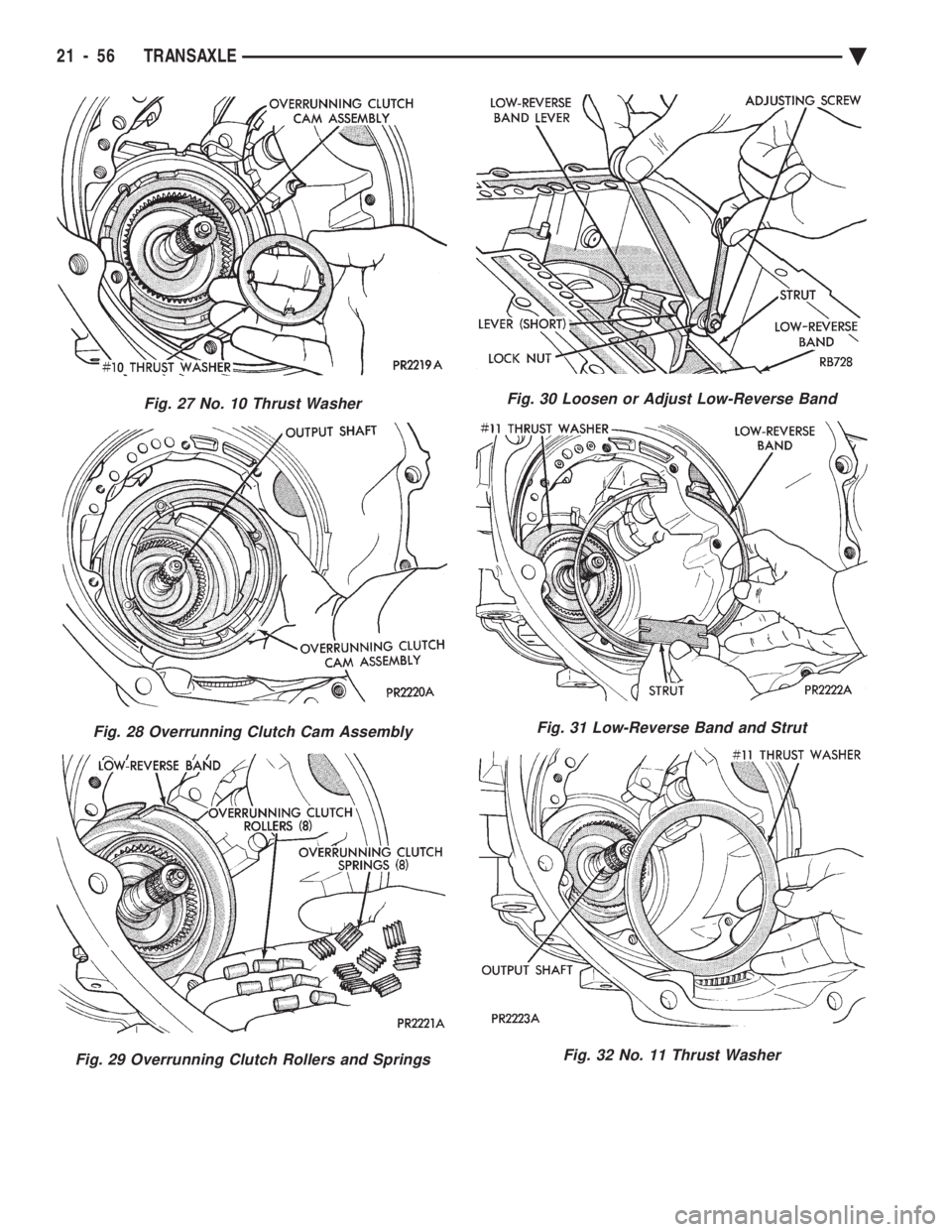

Fig. 27 No. 10 Thrust Washer

Fig. 28 Overrunning Clutch Cam Assembly

Fig. 29 Overrunning Clutch Rollers and Springs

Fig. 30 Loosen or Adjust Low-Reverse Band

Fig. 31 Low-Reverse Band and Strut

Fig. 32 No. 11 Thrust Washer

21 - 56 TRANSAXLE Ä

Page 2017 of 2438

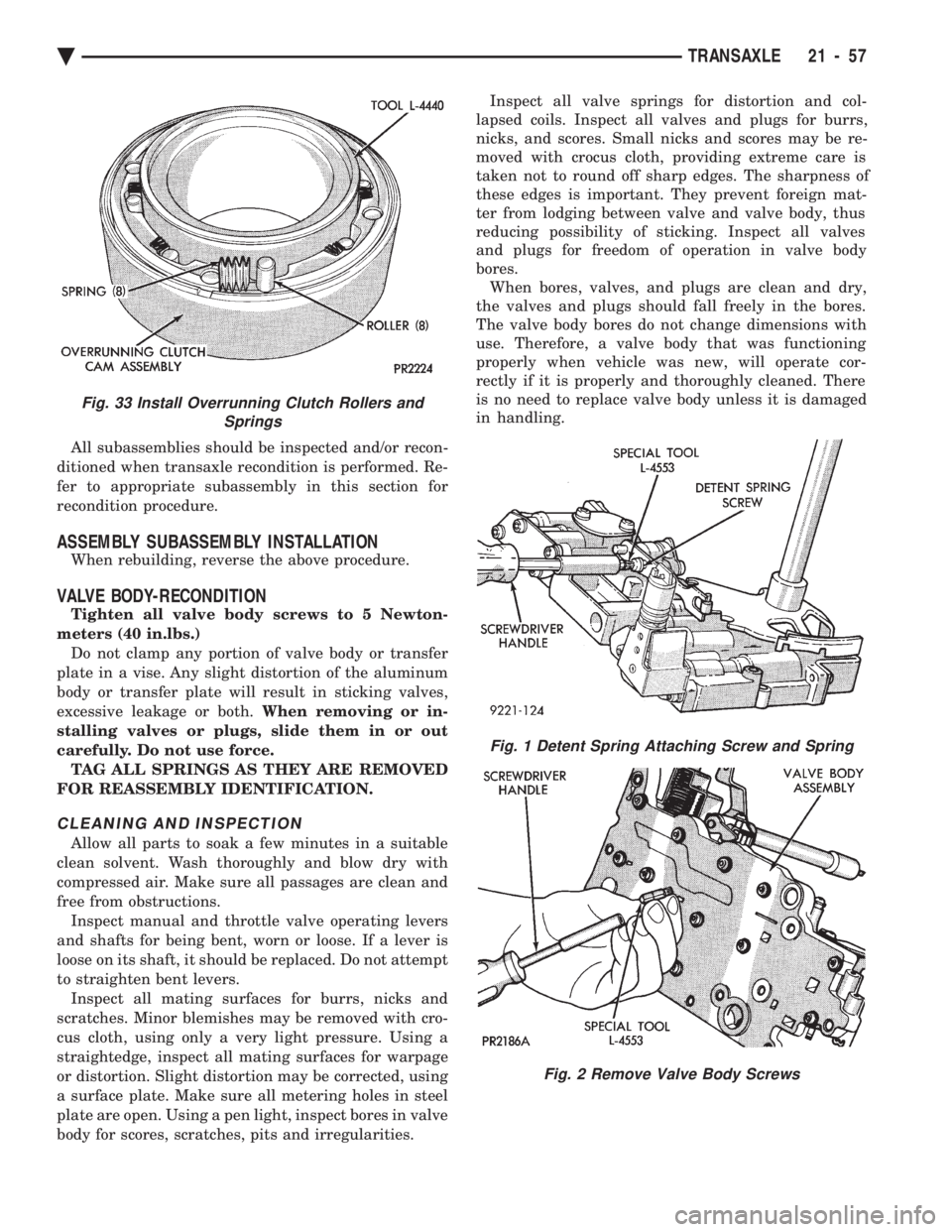

All subassemblies should be inspected and/or recon-

ditioned when transaxle recondition is performed. Re-

fer to appropriate subassembly in this section for

recondition procedure.

ASSEMBLY SUBASSEMBLY INSTALLATION

When rebuilding, reverse the above procedure.

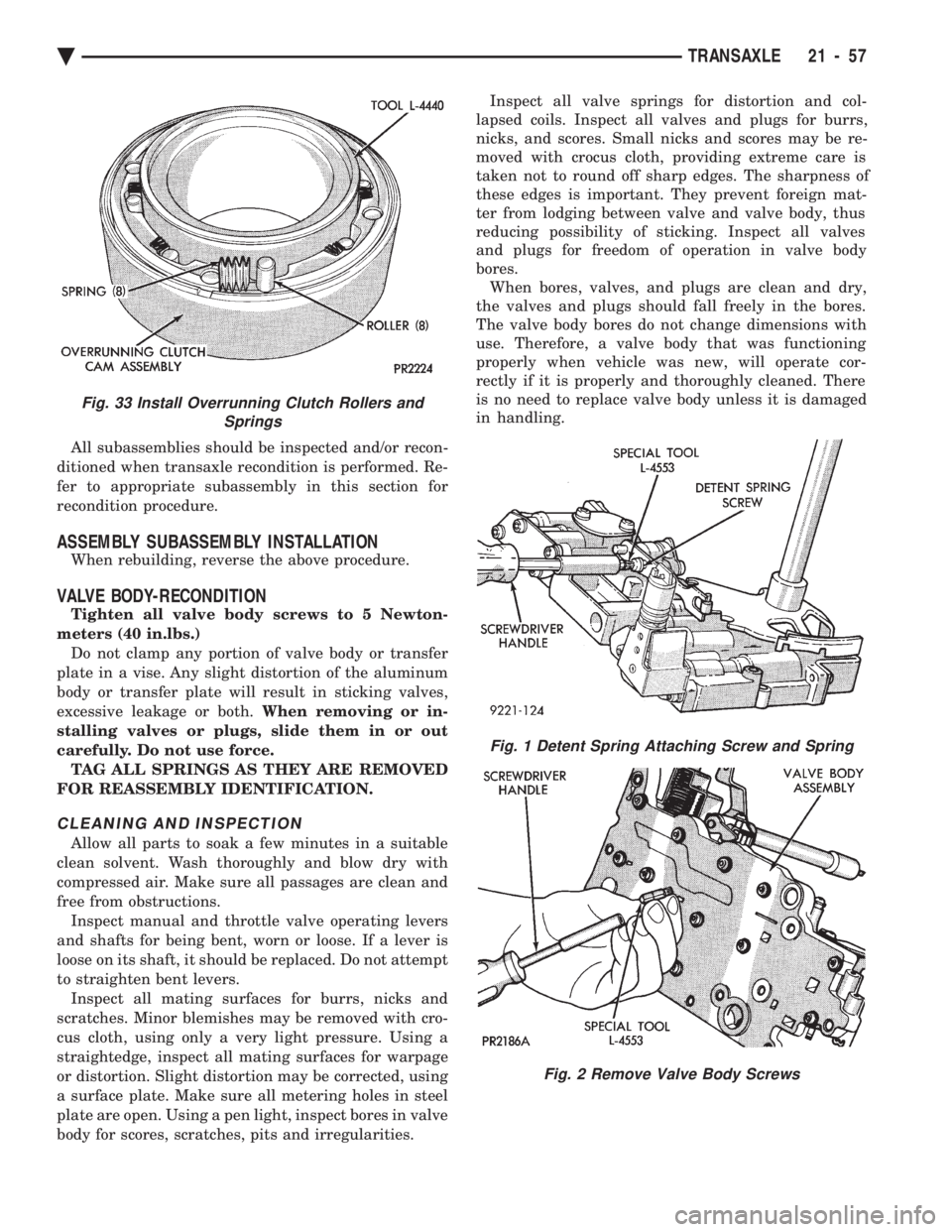

VALVE BODY-RECONDITION

Tighten all valve body screws to 5 Newton-

meters (40 in.lbs.) Do not clamp any portion of valve body or transfer

plate in a vise. Any slight distortion of the aluminum

body or transfer plate will result in sticking valves,

excessive leakage or both. When removing or in-

stalling valves or plugs, slide them in or out

carefully. Do not use force. TAG ALL SPRINGS AS THEY ARE REMOVED

FOR REASSEMBLY IDENTIFICATION.

CLEANING AND INSPECTION

Allow all parts to soak a few minutes in a suitable

clean solvent. Wash thoroughly and blow dry with

compressed air. Make sure all passages are clean and

free from obstructions. Inspect manual and throttle valve operating levers

and shafts for being bent, worn or loose. If a lever is

loose on its shaft, it should be replaced. Do not attempt

to straighten bent levers. Inspect all mating surfaces for burrs, nicks and

scratches. Minor blemishes may be removed with cro-

cus cloth, using only a very light pressure. Using a

straightedge, inspect all mating surfaces for warpage

or distortion. Slight distortion may be corrected, using

a surface plate. Make sure all metering holes in steel

plate are open. Using a pen light, inspect bores in valve

body for scores, scratches, pits and irregularities. Inspect all valve springs for distortion and col-

lapsed coils. Inspect all valves and plugs for burrs,

nicks, and scores. Small nicks and scores may be re-

moved with crocus cloth, providing extreme care is

taken not to round off sharp edges. The sharpness of

these edges is important. They prevent foreign mat-

ter from lodging between valve and valve body, thus

reducing possibility of sticking. Inspect all valves

and plugs for freedom of operation in valve body

bores. When bores, valves, and plugs are clean and dry,

the valves and plugs should fall freely in the bores.

The valve body bores do not change dimensions with

use. Therefore, a valve body that was functioning

properly when vehicle was new, will operate cor-

rectly if it is properly and thoroughly cleaned. There

is no need to replace valve body unless it is damaged

in handling.

Fig. 1 Detent Spring Attaching Screw and Spring

Fig. 2 Remove Valve Body Screws

Fig. 33 Install Overrunning Clutch Rollers and Springs

Ä TRANSAXLE 21 - 57

Page 2018 of 2438

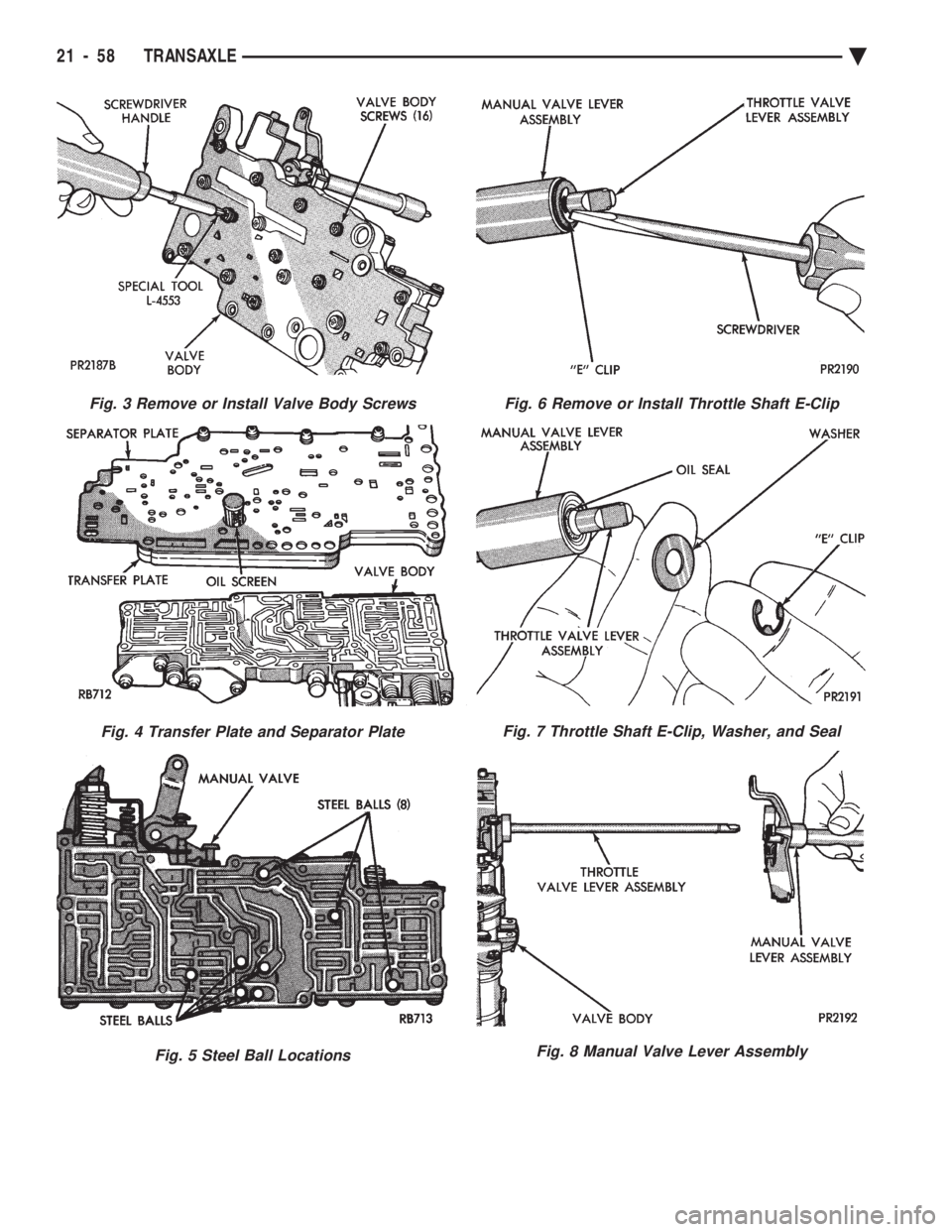

Fig. 3 Remove or Install Valve Body Screws

Fig. 4 Transfer Plate and Separator Plate

Fig. 5 Steel Ball Locations

Fig. 6 Remove or Install Throttle Shaft E-Clip

Fig. 7 Throttle Shaft E-Clip, Washer, and Seal

Fig. 8 Manual Valve Lever Assembly

21 - 58 TRANSAXLE Ä

Page 2019 of 2438

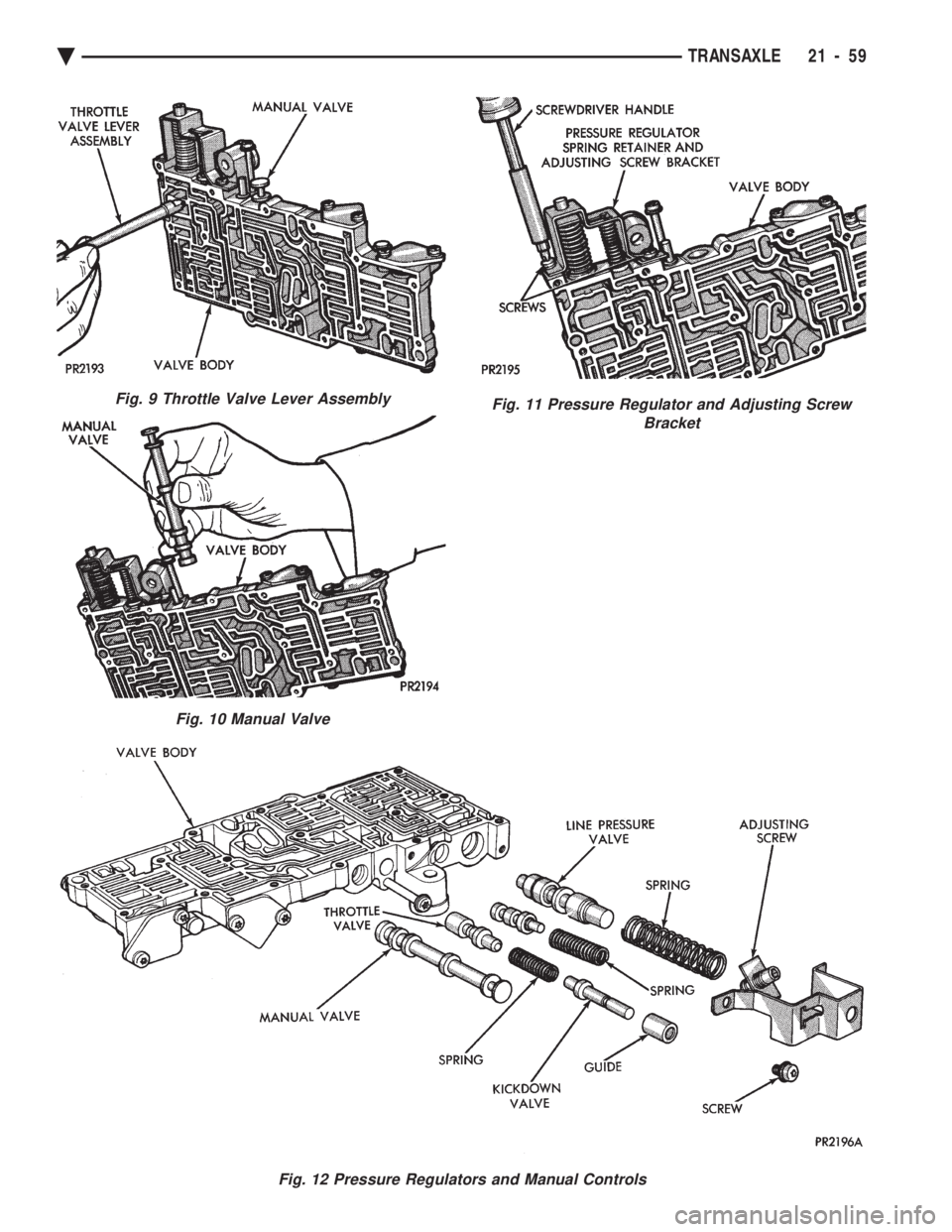

Fig. 9 Throttle Valve Lever Assembly

Fig. 10 Manual Valve

Fig. 11 Pressure Regulator and Adjusting Screw Bracket

Fig. 12 Pressure Regulators and Manual Controls

Ä TRANSAXLE 21 - 59

Page 2020 of 2438

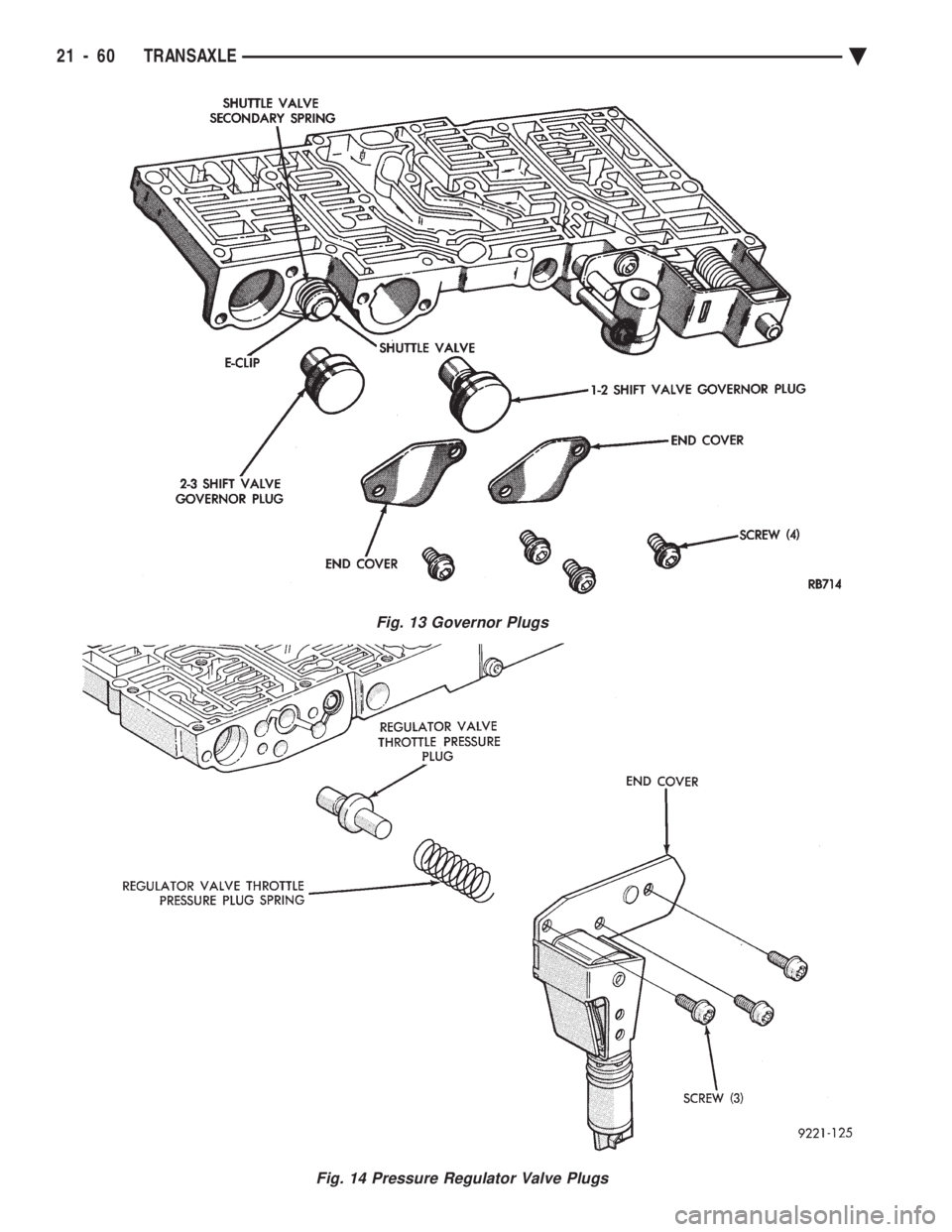

Fig. 13 Governor Plugs

Fig. 14 Pressure Regulator Valve Plugs

21 - 60 TRANSAXLE Ä

Trending: sunroof, diagram, hood release, headlight bulb, brake sensor, service schedule, fuel reserve