clock CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1699 of 1938

INSTALLATION

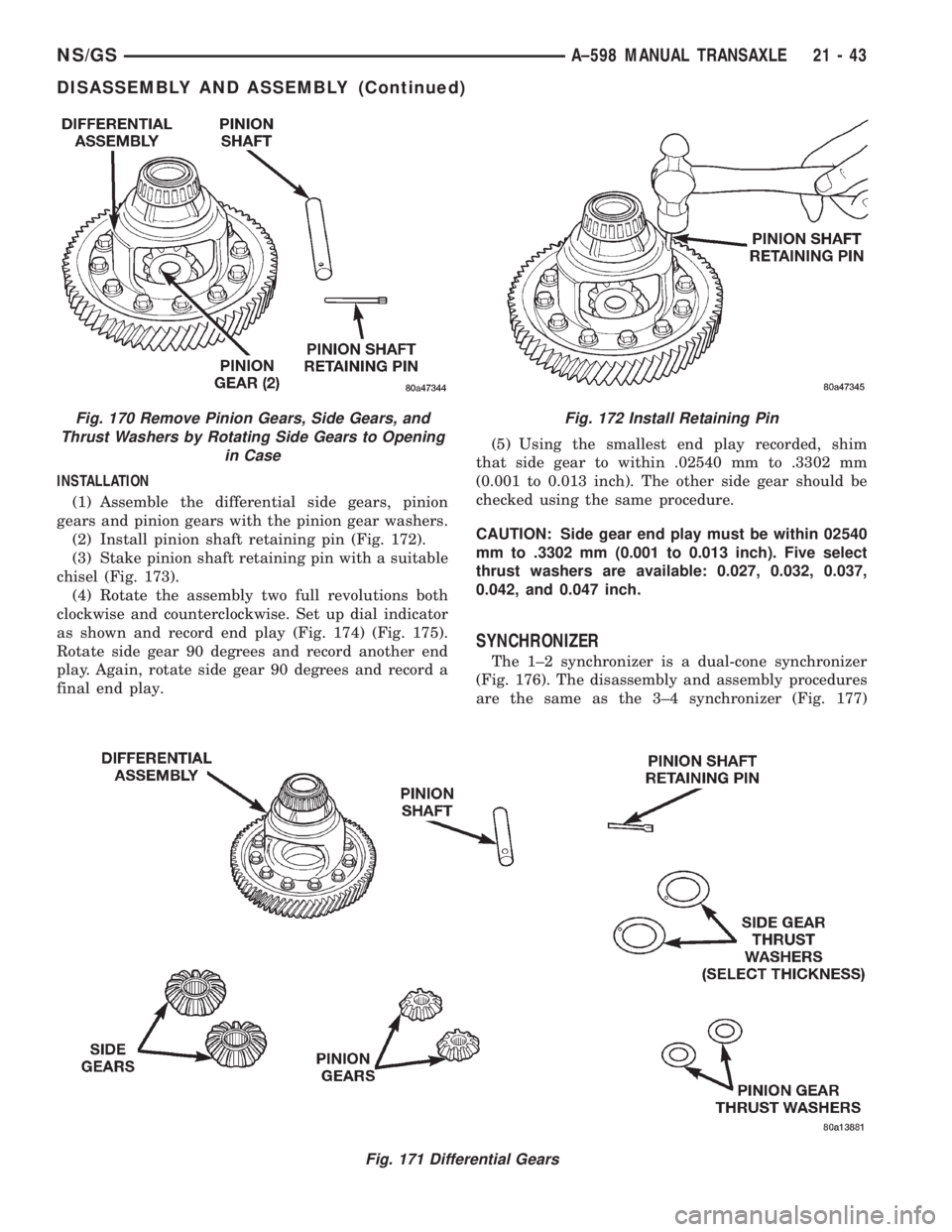

(1) Assemble the differential side gears, pinion

gears and pinion gears with the pinion gear washers.

(2) Install pinion shaft retaining pin (Fig. 172).

(3) Stake pinion shaft retaining pin with a suitable

chisel (Fig. 173).

(4) Rotate the assembly two full revolutions both

clockwise and counterclockwise. Set up dial indicator

as shown and record end play (Fig. 174) (Fig. 175).

Rotate side gear 90 degrees and record another end

play. Again, rotate side gear 90 degrees and record a

final end play.(5) Using the smallest end play recorded, shim

that side gear to within .02540 mm to .3302 mm

(0.001 to 0.013 inch). The other side gear should be

checked using the same procedure.

CAUTION: Side gear end play must be within 02540

mm to .3302 mm (0.001 to 0.013 inch). Five select

thrust washers are available: 0.027, 0.032, 0.037,

0.042, and 0.047 inch.

SYNCHRONIZER

The 1±2 synchronizer is a dual-cone synchronizer

(Fig. 176). The disassembly and assembly procedures

are the same as the 3±4 synchronizer (Fig. 177)

Fig. 171 Differential Gears

Fig. 170 Remove Pinion Gears, Side Gears, and

Thrust Washers by Rotating Side Gears to Opening

in CaseFig. 172 Install Retaining Pin

NS/GSA±598 MANUAL TRANSAXLE 21 - 43

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1749 of 1938

INSTALLATION

(1) Place heated seat module in position on seat

pan.

(2) Install module attaching screws.

(3) Connect module wire connectors.

(4) Install seat.

HEATED SEAT SWITCH

Diagnostic information for heated seat switch is

located in Group 8R, Power Seats.

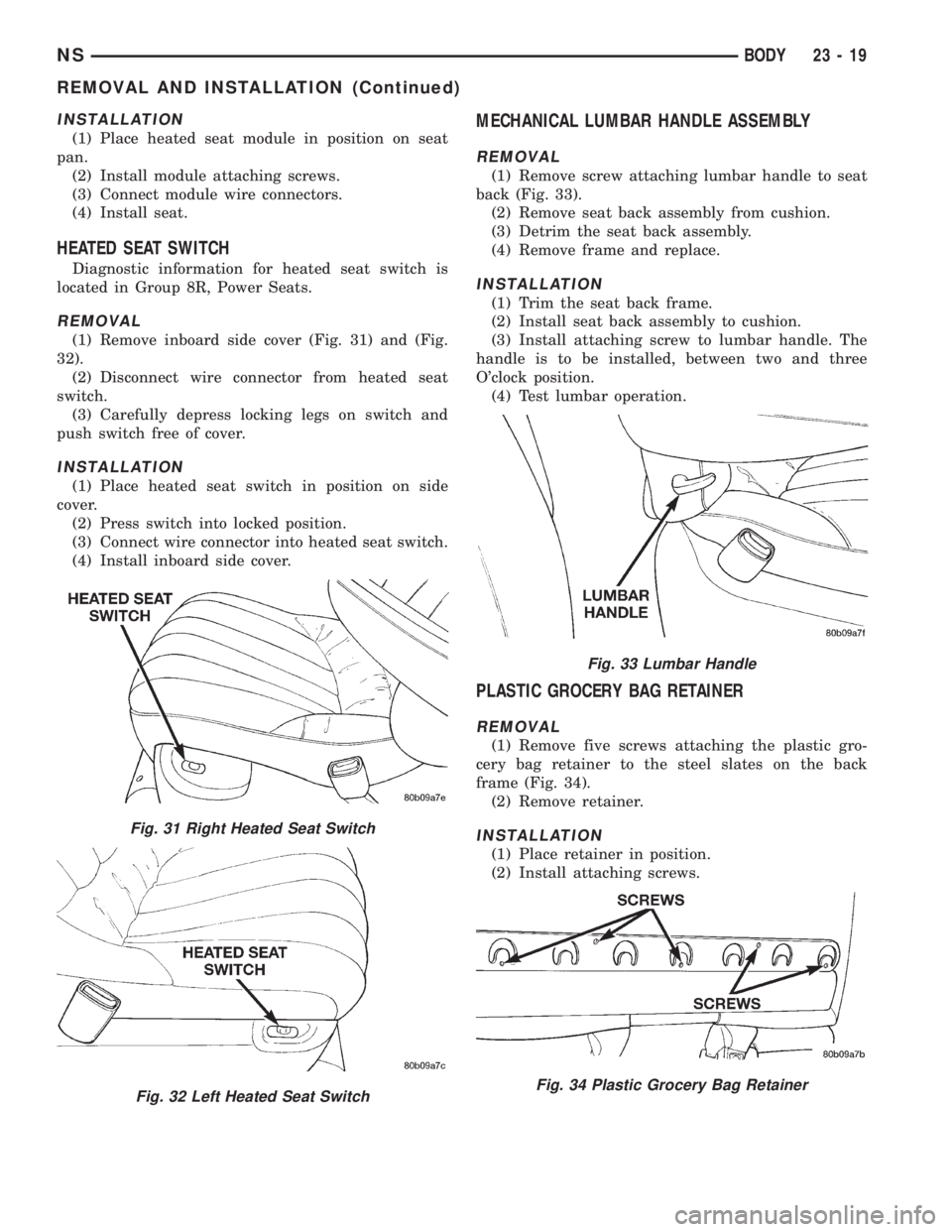

REMOVAL

(1) Remove inboard side cover (Fig. 31) and (Fig.

32).

(2) Disconnect wire connector from heated seat

switch.

(3) Carefully depress locking legs on switch and

push switch free of cover.

INSTALLATION

(1) Place heated seat switch in position on side

cover.

(2) Press switch into locked position.

(3) Connect wire connector into heated seat switch.

(4) Install inboard side cover.

MECHANICAL LUMBAR HANDLE ASSEMBLY

REMOVAL

(1) Remove screw attaching lumbar handle to seat

back (Fig. 33).

(2) Remove seat back assembly from cushion.

(3) Detrim the seat back assembly.

(4) Remove frame and replace.

INSTALLATION

(1) Trim the seat back frame.

(2) Install seat back assembly to cushion.

(3) Install attaching screw to lumbar handle. The

handle is to be installed, between two and three

O'clock position.

(4) Test lumbar operation.

PLASTIC GROCERY BAG RETAINER

REMOVAL

(1) Remove five screws attaching the plastic gro-

cery bag retainer to the steel slates on the back

frame (Fig. 34).

(2) Remove retainer.

INSTALLATION

(1) Place retainer in position.

(2) Install attaching screws.

Fig. 31 Right Heated Seat Switch

Fig. 32 Left Heated Seat Switch

Fig. 33 Lumbar Handle

Fig. 34 Plastic Grocery Bag Retainer

NSBODY 23 - 19

REMOVAL AND INSTALLATION (Continued)

Page 1810 of 1938

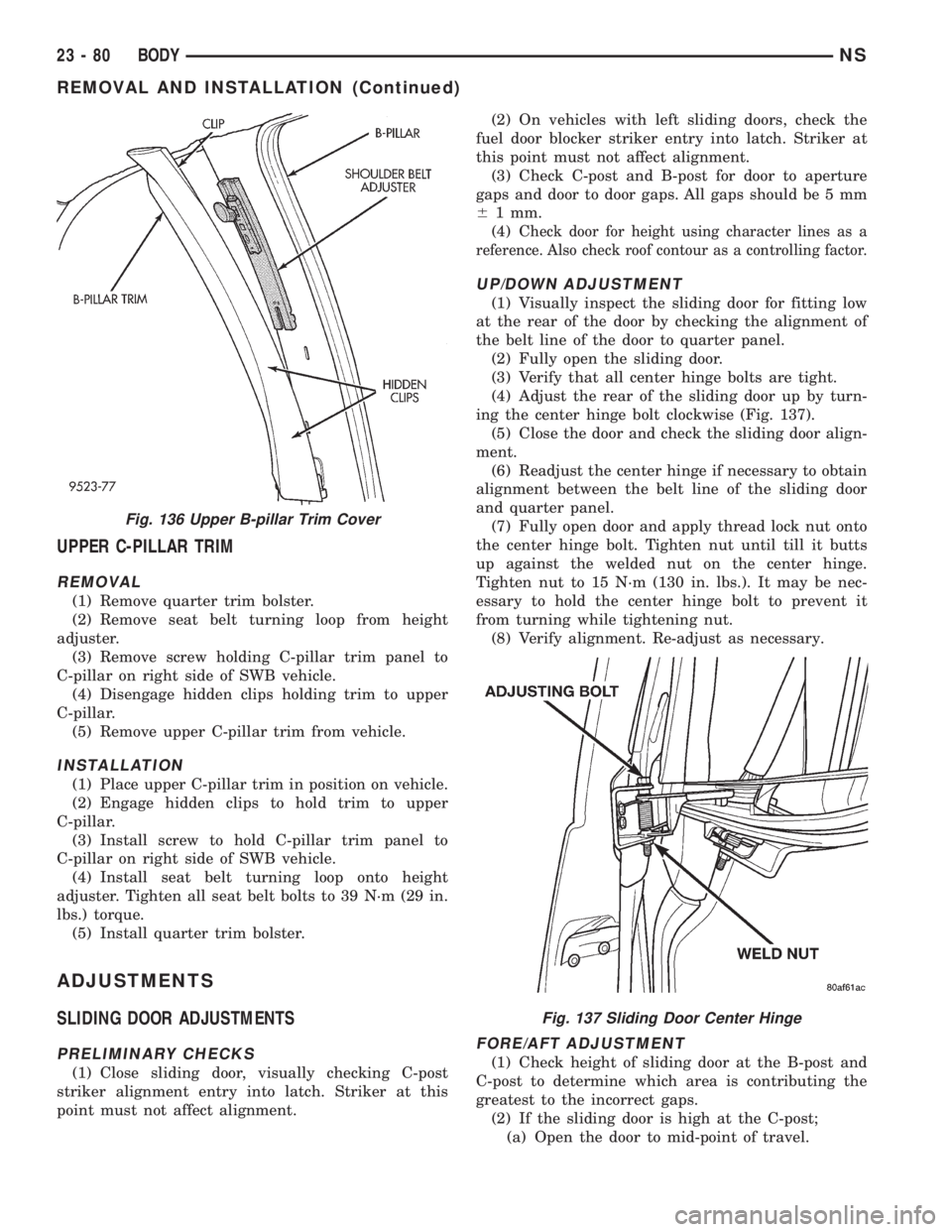

UPPER C-PILLAR TRIM

REMOVAL

(1) Remove quarter trim bolster.

(2) Remove seat belt turning loop from height

adjuster.

(3) Remove screw holding C-pillar trim panel to

C-pillar on right side of SWB vehicle.

(4) Disengage hidden clips holding trim to upper

C-pillar.

(5) Remove upper C-pillar trim from vehicle.

INSTALLATION

(1) Place upper C-pillar trim in position on vehicle.

(2) Engage hidden clips to hold trim to upper

C-pillar.

(3) Install screw to hold C-pillar trim panel to

C-pillar on right side of SWB vehicle.

(4) Install seat belt turning loop onto height

adjuster. Tighten all seat belt bolts to 39 N´m (29 in.

lbs.) torque.

(5) Install quarter trim bolster.

ADJUSTMENTS

SLIDING DOOR ADJUSTMENTS

PRELIMINARY CHECKS

(1) Close sliding door, visually checking C-post

striker alignment entry into latch. Striker at this

point must not affect alignment.(2) On vehicles with left sliding doors, check the

fuel door blocker striker entry into latch. Striker at

this point must not affect alignment.

(3) Check C-post and B-post for door to aperture

gaps and door to door gaps. All gaps should be 5 mm

61 mm.

(4) C

heck door for height using character lines as a

reference. Also check roof contour as a controlling factor.

UP/DOWN ADJUSTMENT

(1) Visually inspect the sliding door for fitting low

at the rear of the door by checking the alignment of

the belt line of the door to quarter panel.

(2) Fully open the sliding door.

(3) Verify that all center hinge bolts are tight.

(4) Adjust the rear of the sliding door up by turn-

ing the center hinge bolt clockwise (Fig. 137).

(5) Close the door and check the sliding door align-

ment.

(6) Readjust the center hinge if necessary to obtain

alignment between the belt line of the sliding door

and quarter panel.

(7) Fully open door and apply thread lock nut onto

the center hinge bolt. Tighten nut until till it butts

up against the welded nut on the center hinge.

Tighten nut to 15 N´m (130 in. lbs.). It may be nec-

essary to hold the center hinge bolt to prevent it

from turning while tightening nut.

(8) Verify alignment. Re-adjust as necessary.

FORE/AFT ADJUSTMENT

(1) Check height of sliding door at the B-post and

C-post to determine which area is contributing the

greatest to the incorrect gaps.

(2) If the sliding door is high at the C-post;

(a) Open the door to mid-point of travel.

Fig. 136 Upper B-pillar Trim Cover

Fig. 137 Sliding Door Center Hinge

23 - 80 BODYNS

REMOVAL AND INSTALLATION (Continued)

Page 1862 of 1938

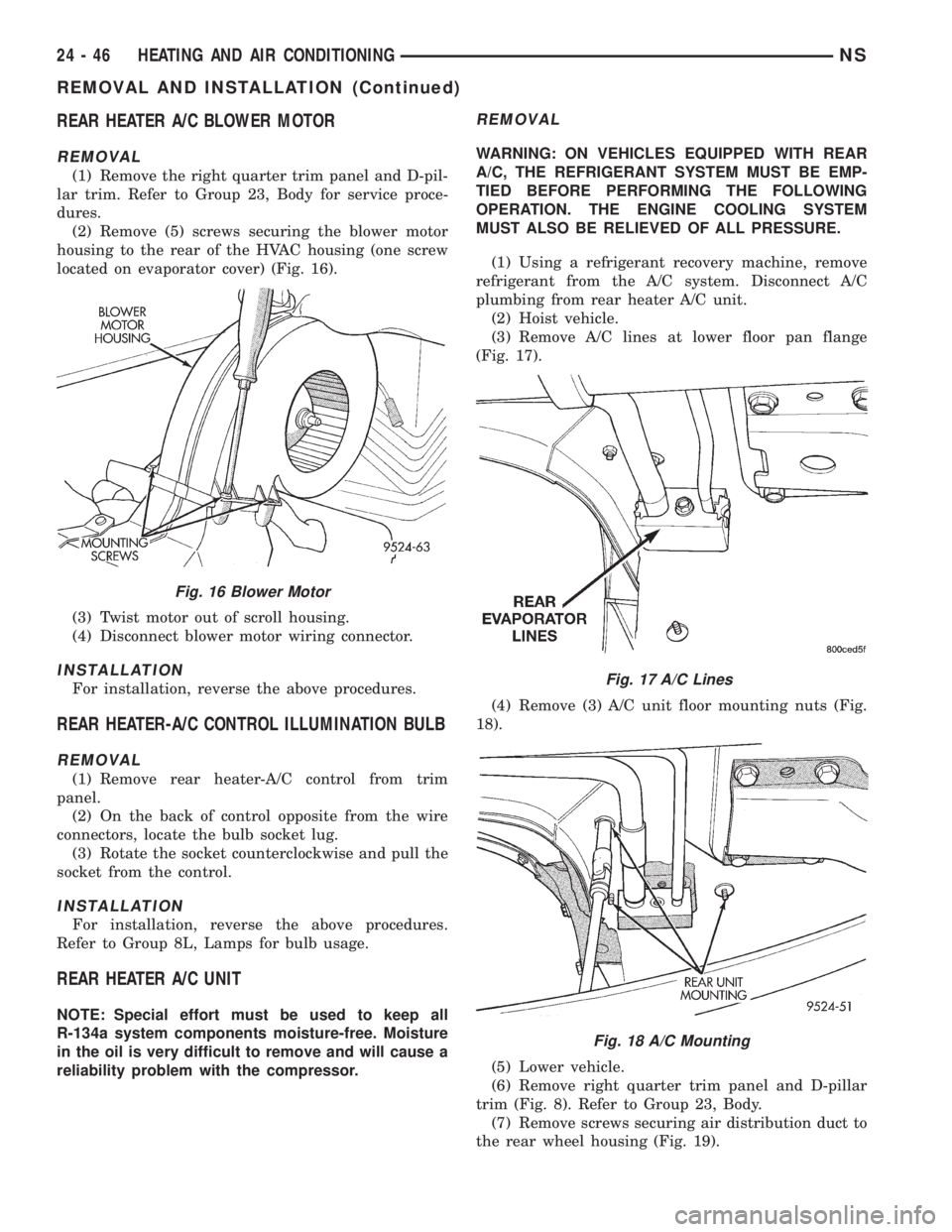

REAR HEATER A/C BLOWER MOTOR

REMOVAL

(1) Remove the right quarter trim panel and D-pil-

lar trim. Refer to Group 23, Body for service proce-

dures.

(2) Remove (5) screws securing the blower motor

housing to the rear of the HVAC housing (one screw

located on evaporator cover) (Fig. 16).

(3) Twist motor out of scroll housing.

(4) Disconnect blower motor wiring connector.

INSTALLATION

For installation, reverse the above procedures.

REAR HEATER-A/C CONTROL ILLUMINATION BULB

REMOVAL

(1) Remove rear heater-A/C control from trim

panel.

(2) On the back of control opposite from the wire

connectors, locate the bulb socket lug.

(3) Rotate the socket counterclockwise and pull the

socket from the control.

INSTALLATION

For installation, reverse the above procedures.

Refer to Group 8L, Lamps for bulb usage.

REAR HEATER A/C UNIT

NOTE: Special effort must be used to keep all

R-134a system components moisture-free. Moisture

in the oil is very difficult to remove and will cause a

reliability problem with the compressor.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH REAR

A/C, THE REFRIGERANT SYSTEM MUST BE EMP-

TIED BEFORE PERFORMING THE FOLLOWING

OPERATION. THE ENGINE COOLING SYSTEM

MUST ALSO BE RELIEVED OF ALL PRESSURE.

(1) Using a refrigerant recovery machine, remove

refrigerant from the A/C system. Disconnect A/C

plumbing from rear heater A/C unit.

(2) Hoist vehicle.

(3) Remove A/C lines at lower floor pan flange

(Fig. 17).

(4) Remove (3) A/C unit floor mounting nuts (Fig.

18).

(5) Lower vehicle.

(6) Remove right quarter trim panel and D-pillar

trim (Fig. 8). Refer to Group 23, Body.

(7) Remove screws securing air distribution duct to

the rear wheel housing (Fig. 19).

Fig. 16 Blower Motor

Fig. 17 A/C Lines

Fig. 18 A/C Mounting

24 - 46 HEATING AND AIR CONDITIONINGNS

REMOVAL AND INSTALLATION (Continued)

Page 1914 of 1938

The primary components within the assembly are:

A three port solenoid that activates both of the func-

tions listed above; a pump which contains a switch,

two check valves and a spring/diaphragm, a canister

vent valve (CVV) seal which contains a spring loaded

vent seal valve.

Immediately after a cold start, between predeter-

mined temperature thresholds limits, the three port

solenoid is briefly energized. This initializes the

pump by drawing air into the pump cavity and also

closes the vent seal. During non test conditions the

vent seal is held open by the pump diaphragm

assembly which pushes it open at the full travel posi-

tion. The vent seal will remain closed while the

pump is cycling due to the reed switch triggering of

the three port solenoid that prevents the diaphragm

assembly from reaching full travel. After the brief

initialization period, the solenoid is de-energized

allowing atmospheric pressure to enter the pump

cavity, thus permitting the spring to drive the dia-

phragm which forces air out of the pump cavity and

into the vent system. When the solenoid is energized

and de energized, the cycle is repeated creating flow

in typical diaphragm pump fashion. The pump is con-

trolled in 2 modes:

Pump Mode:The pump is cycled at a fixed rate to

achieve a rapid pressure build in order to shorten the

overall test length.

Test Mode:The solenoid is energized with a fixed

duration pulse. Subsequent fixed pulses occur when

the diaphragm reaches the Switch closure point.

The spring in the pump is set so that the system

will achieve an equalized pressure of about 7.5º H20.

The cycle rate of pump strokes is quite rapid as the

system begins to pump up to this pressure. As the

pressure increases, the cycle rate starts to drop off. If

there is no leak in the system, the pump would even-

tually stop pumping at the equalized pressure. If

there is a leak, it will continue to pump at a rate rep-

resentative of the flow characteristic of the size of the

leak. From this information we can determine if the

leak is larger than the required detection limit (cur-

rently set at .020º orifice by CARB). If a leak is

revealed during the leak test portion of the test, the

test is terminated at the end of the test mode and no

further system checks will be performed.

After passing the leak detection phase of the test,

system pressure is maintained by turning on the

LDP's solenoid until the purge system is activated.

Purge activation in effect creates a leak. The cycle

rate is again interrogated and when it increases due

to the flow through the purge system, the leak check

portion of the diagnostic is complete.

The canister vent valve will unseal the system

after completion of the test sequence as the pumpdiaphragm assembly moves to the full travel position.

Evaporative system functionality will be verified by

using the stricter evap purge flow monitor. At an

appropriate warm idle the LDP will be energized to

seal the canister vent. The purge flow will be clocked

up from some small value in an attempt to see a

shift in the 02 control system. If fuel vapor, indicated

by a shift in the 02 control, is present the test is

passed. If not, it is assumed that the purge system is

not functioning in some respect. The LDP is again

turned off and the test is ended.

TRIP DEFINITION

A ªTripº means vehicle operation (following an

engine-off period) of duration and driving mode such

that all components and systems are monitored at

least once by the diagnostic system. The monitors

must successfully pass before the PCM can verify

that a previously malfunctioning component is meet-

ing the normal operating conditions of that compo-

nent. For misfire or fuel system malfunction, the

MIL may be extinguished if the fault does not recur

when monitored during three subsequent sequential

driving cycles in which conditions are similar to

those under which the malfunction was first deter-

mined.

Anytime the MIL is illuminated, a DTC is stored.

The DTC can self erase only when the MIL has been

extinguished. Once the MIL is extinguished, the

PCM must pass the diagnostic test for the most

recent DTC for 40 warm-up cycles (80 warm-up

cycles for the Fuel System Monitor and the Misfire

Monitor). A warm-up cycle can best be described by

the following:

²The engine must be running

²A rise of 40ÉF in engine temperature must occur

from the time when the engine was started

²Engine coolant temperature must reach at least

160ÉF

²A ªdriving cycleº that consists of engine start up

and engine shut off.

Once the above conditions occur, the PCM is con-

sidered to have passed a warm-up cycle. Due to the

conditions required to extinguish the MIL and erase

the DTC, it is most important that after a repair has

been made, all DTC's be erased and the repair veri-

fied.

COMPONENT MONITORS

There are several components that will affect vehi-

cle emissions if they malfunction. If one of these com-

ponents malfunctions the Malfunction Indicator

Lamp (Check Engine) will illuminate.

Some of the component monitors are checking for

proper operation of the part. Electrically operated

25 - 10 EMISSION CONTROL SYSTEMSNS

DESCRIPTION AND OPERATION (Continued)