clock CHRYSLER VOYAGER 1996 Manual PDF

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 995 of 1938

CONNECTOR/GROUND LOCATIONS

For items not shown in this section a N/S is placed

in the Fig. column.

Component/

GroundColor Location Fig.

A/C

Compressor

ClutchBK Top of A/C

Compressor5, 6, 7,

8, 9

A/C-Heater

Control Module

C1NAT Rear of Control 11

A/C-Heater

Control Module

C2BK Rear of Control 11

A/C Pressure

TransducerGY RT Side Cowl 3

A/C Zone Door

ActuatorNAT LT Side of

HVAC15

Airbag Control

Module C1YL Rear of I.P.

Center Stack12

Airbag Contol

Module C2BK Rear of I.P.

Center Stack12

All Wheel Drive

SolenoidBK Near Fuel Tank 20

Ambient

Temperature

SensorGY On Radiator

Closure Panel4

Ash Receiver

LampRD At Lamp 10

Automatic

Day/Night MirrorBK At Mirror 17

B01 BK RT Kick Panel 18

B02 BK RT Kick Panel 18

B03 BK LT Kick Panel 18

B09 BK Under Seat 16

B17 BK LT Quarter

Panel21

B23 BK RT of Steering

Column13

B33 BK LT Frame Rail 2

B56 BK Under Seat 16

B70 LT/GY LT Frame Rail 2

B75 BL Bottom of RT

B-Pillar14

B98 BK Rear of RT Tail

LampN/SComponent/

GroundColor Location Fig.

B99 BK Rear of LT Tail

LampN/S

B120 BK LT Kick Panel N/S

Backup Lamp

Switch (M/T)BK On

Transmission5, 6, 8

Blend Door

ActuatorNAT LT Side of

HVAC15

Body Control

Module C1NAT On Junction

Block12

Body Control

Module C2NAT On Junction

Block12

Brake Pressure

SwitchBK On Master

Cylinder2

C19 At Top Center

of Windshield17

C20 Bottom of RT

B-PillarN/S

Camshaft

Position Sensor

2.4LBK Rear of

Cylinder Head6, 7

Camshaft

Position Sensor

3.3L, 3.8LBK RT Side of

Engine9

Center Dome

LampBK At Lamp N/S

CHMSL RD Rear of CHMSL 23

Clockspring C1 YL Rear of

Clockspring11

Clockspring C2 NAT Rear of

Clockspring11

Clutch Switch BK Top of Clutch

Pedal13

Controller

Anti-Lock BrakeBK LT Side of

Engine

CompartmentN/S

Crankshaft

Position SensorBK Rear of Engine 5, 6, 7,

9

D01 BK On Kick Panel 19

D02 BK On Kick Panel 19

Data Link

ConnectorBK LT of Steering

Column12

NS/GS8W - 90 CONNECTOR/GROUND LOCATIONS 8W - 90 - 31

DESCRIPTION AND OPERATION (Continued)

Page 1082 of 1938

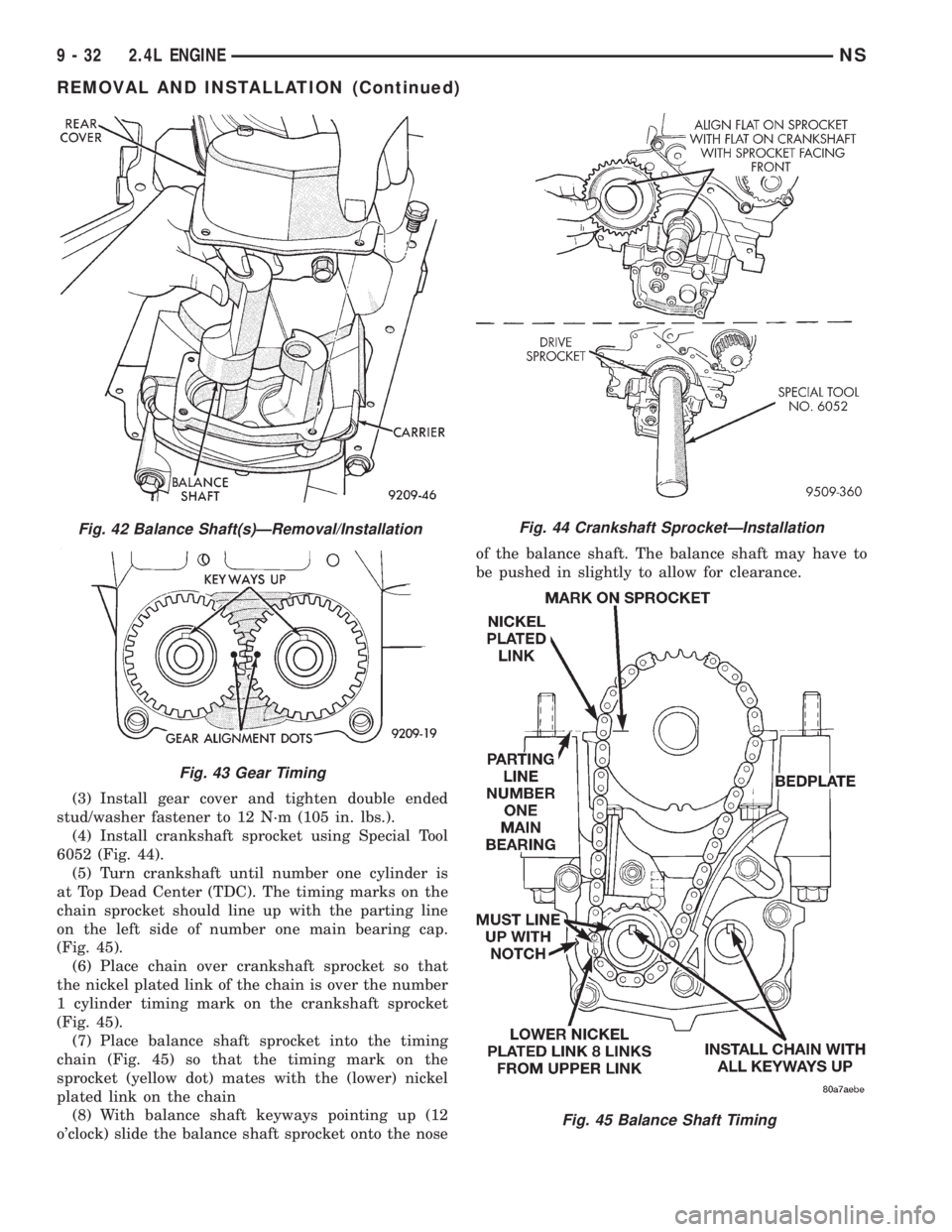

(3) Install gear cover and tighten double ended

stud/washer fastener to 12 N´m (105 in. lbs.).

(4) Install crankshaft sprocket using Special Tool

6052 (Fig. 44).

(5) Turn crankshaft until number one cylinder is

at Top Dead Center (TDC). The timing marks on the

chain sprocket should line up with the parting line

on the left side of number one main bearing cap.

(Fig. 45).

(6) Place chain over crankshaft sprocket so that

the nickel plated link of the chain is over the number

1 cylinder timing mark on the crankshaft sprocket

(Fig. 45).

(7) Place balance shaft sprocket into the timing

chain (Fig. 45) so that the timing mark on the

sprocket (yellow dot) mates with the (lower) nickel

plated link on the chain

(8) With balance shaft keyways pointing up (12

o'clock) slide the balance shaft sprocket onto the noseof the balance shaft. The balance shaft may have to

be pushed in slightly to allow for clearance.

Fig. 42 Balance Shaft(s)ÐRemoval/Installation

Fig. 43 Gear Timing

Fig. 44 Crankshaft SprocketÐInstallation

Fig. 45 Balance Shaft Timing

9 - 32 2.4L ENGINENS

REMOVAL AND INSTALLATION (Continued)

Page 1088 of 1938

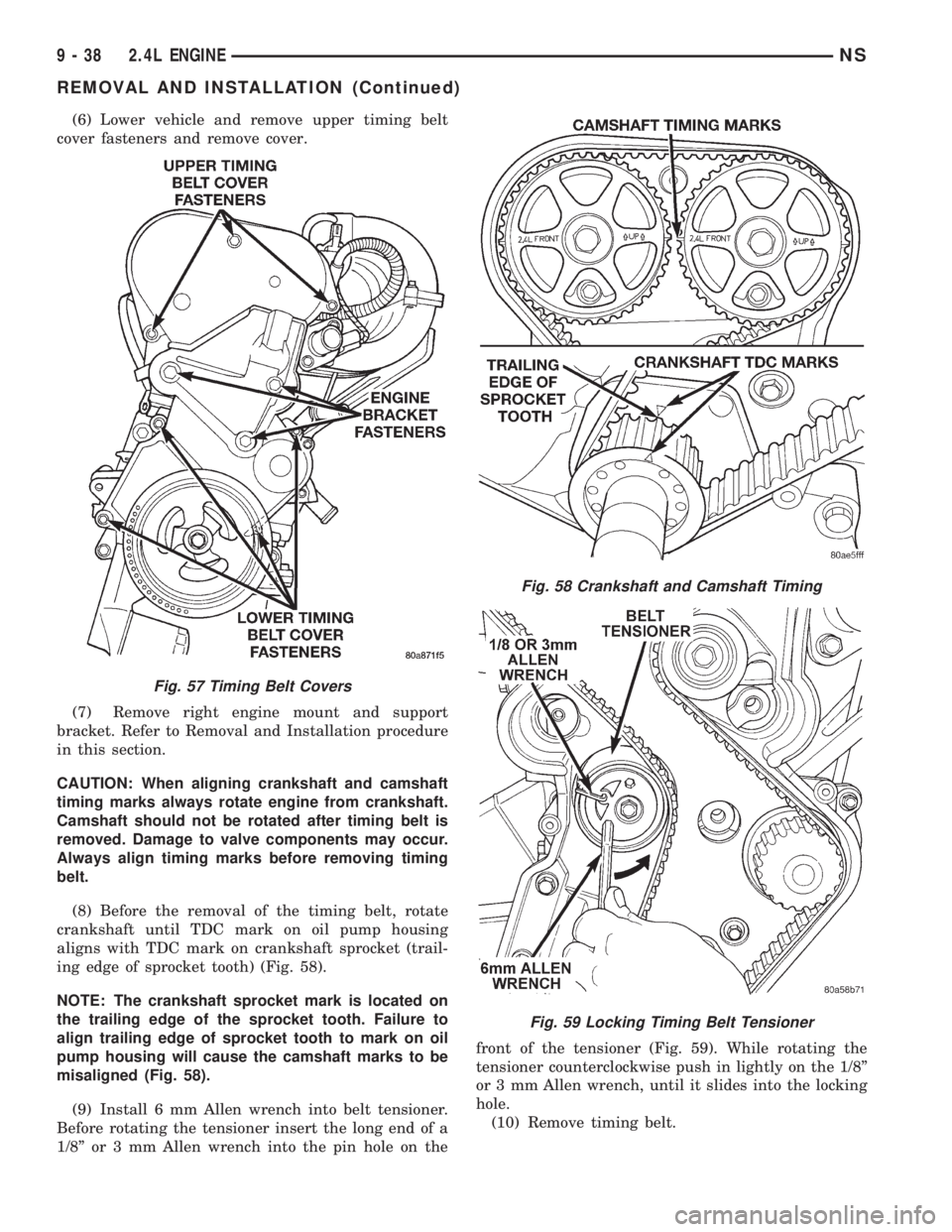

(6) Lower vehicle and remove upper timing belt

cover fasteners and remove cover.

(7) Remove right engine mount and support

bracket. Refer to Removal and Installation procedure

in this section.

CAUTION: When aligning crankshaft and camshaft

timing marks always rotate engine from crankshaft.

Camshaft should not be rotated after timing belt is

removed. Damage to valve components may occur.

Always align timing marks before removing timing

belt.

(8) Before the removal of the timing belt, rotate

crankshaft until TDC mark on oil pump housing

aligns with TDC mark on crankshaft sprocket (trail-

ing edge of sprocket tooth) (Fig. 58).

NOTE: The crankshaft sprocket mark is located on

the trailing edge of the sprocket tooth. Failure to

align trailing edge of sprocket tooth to mark on oil

pump housing will cause the camshaft marks to be

misaligned (Fig. 58).

(9) Install 6 mm Allen wrench into belt tensioner.

Before rotating the tensioner insert the long end of a

1/8º or 3 mm Allen wrench into the pin hole on thefront of the tensioner (Fig. 59). While rotating the

tensioner counterclockwise push in lightly on the 1/8º

or 3 mm Allen wrench, until it slides into the locking

hole.

(10) Remove timing belt.

Fig. 57 Timing Belt Covers

Fig. 58 Crankshaft and Camshaft Timing

Fig. 59 Locking Timing Belt Tensioner

9 - 38 2.4L ENGINENS

REMOVAL AND INSTALLATION (Continued)

Page 1089 of 1938

CAUTION: If timing belt was damaged due to incor-

rect tracking (alignment), the belt tensioner assem-

bly must be replace. Refer to Timing Belt Tensioner

Assembly Removal and Installation procedure out-

lined in this section.

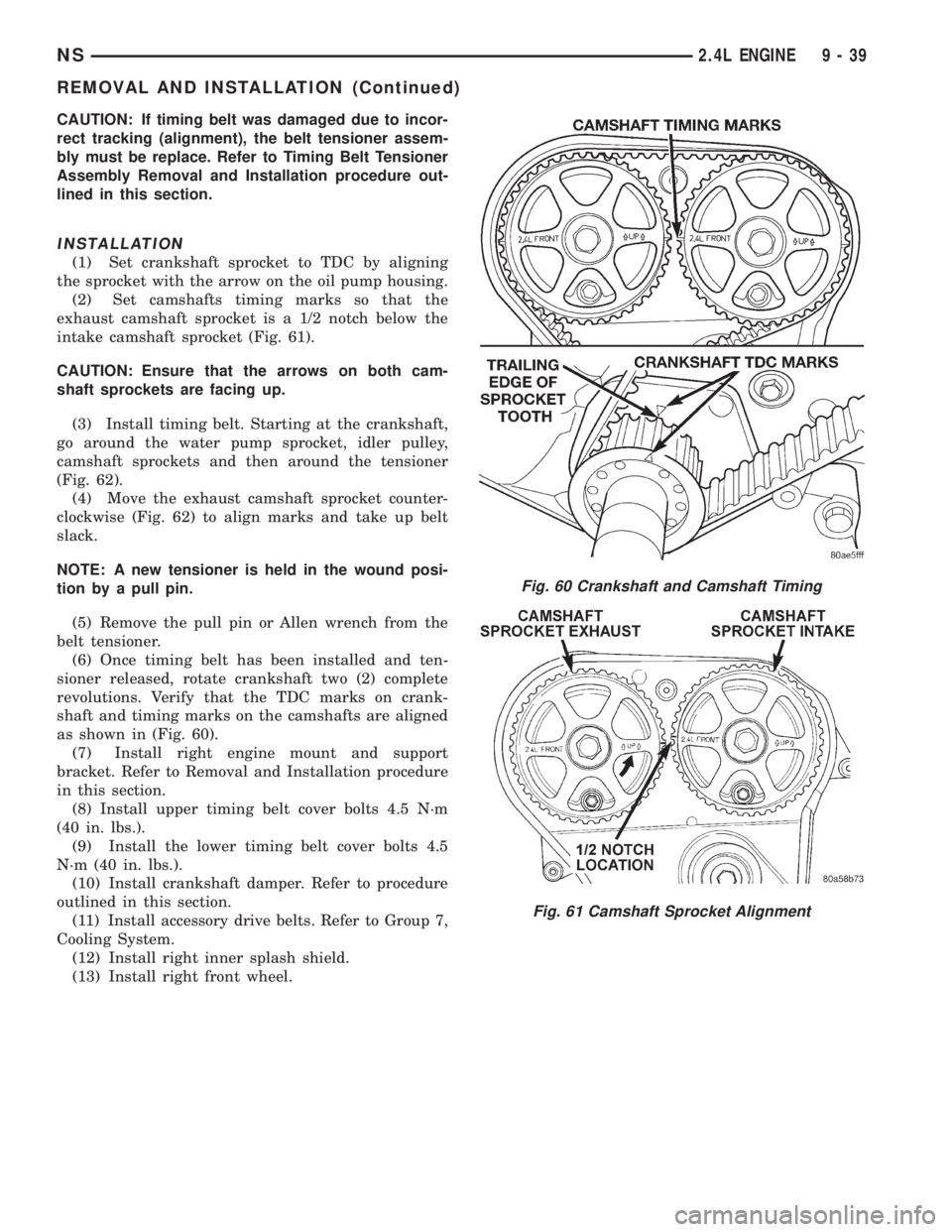

INSTALLATION

(1) Set crankshaft sprocket to TDC by aligning

the sprocket with the arrow on the oil pump housing.

(2) Set camshafts timing marks so that the

exhaust camshaft sprocket is a 1/2 notch below the

intake camshaft sprocket (Fig. 61).

CAUTION: Ensure that the arrows on both cam-

shaft sprockets are facing up.

(3) Install timing belt. Starting at the crankshaft,

go around the water pump sprocket, idler pulley,

camshaft sprockets and then around the tensioner

(Fig. 62).

(4) Move the exhaust camshaft sprocket counter-

clockwise (Fig. 62) to align marks and take up belt

slack.

NOTE: A new tensioner is held in the wound posi-

tion by a pull pin.

(5) Remove the pull pin or Allen wrench from the

belt tensioner.

(6) Once timing belt has been installed and ten-

sioner released, rotate crankshaft two (2) complete

revolutions. Verify that the TDC marks on crank-

shaft and timing marks on the camshafts are aligned

as shown in (Fig. 60).

(7) Install right engine mount and support

bracket. Refer to Removal and Installation procedure

in this section.

(8) Install upper timing belt cover bolts 4.5 N´m

(40 in. lbs.).

(9) Install the lower timing belt cover bolts 4.5

N´m (40 in. lbs.).

(10) Install crankshaft damper. Refer to procedure

outlined in this section.

(11) Install accessory drive belts. Refer to Group 7,

Cooling System.

(12) Install right inner splash shield.

(13) Install right front wheel.

Fig. 60 Crankshaft and Camshaft Timing

Fig. 61 Camshaft Sprocket Alignment

NS2.4L ENGINE 9 - 39

REMOVAL AND INSTALLATION (Continued)

Page 1097 of 1938

(7) Install main bearing bedplate to engine block

bolts 11, 17 and 20 finger tight. Tighten these bolts

down together until the bedplate contacts the cylin-

der block.

(8) To ensure correct thrust bearing alignment per-

form the following steps:

²Step 1: Rotate crankshaft until number 4 pis-

ton is at TDC.

²Step 2: Move crankshaft rearward to limits of

travel.

²Step 3: Then, move crankshaft forward to lim-

its of travel.

²Step 4: Wedge an appropraite tool between the

rear of the cylinder block(NOT BED PLATE)and

the rear crankshaft counterweight. This will hold the

crankshaft in it's furthest forward position.

²Step 5: Install and tighten bolts (1-10) in

sequence shown in (Fig. 84) to 41 Nzm (30 ft. lbs.).

²Step 6: Remove wedge tool used to hold crank-

shaft.

(9) Tighten bolts (1-10) again to 41 Nzm (30 ft. lbs)

+ 1/4 turn in sequence shown in (Fig. 84).

(10) Install main bearing bedplate to engine block

bolts (11-20), and torque each bolt to 28 Nzm (20 ft.

lbs.) in sequence shown in (Fig. 84).

(11) After the main bearing bedplate is installed,

check the crankshaft turning torque. The turning

torque should not exceed 5.6 Nzm (50 in. lbs.).

OIL FILTER

CAUTION: When servicing the oil filter avoid

deforming the filter can by installing the remove/in-

stall tool band strap against the can to base lock

seam. The lock seam joining the can to the base is

reinforced by the base plate.(1) Turn counterclockwise to remove.

(2) To install, lubricate new filter gasket. Check

filter mounting surface. The surface must be smooth,

flat and free of debris or old pieces of rubber. Screw

filter on until the gasket contacts base. Tighten to 21

N´m (15 ft. lbs.).

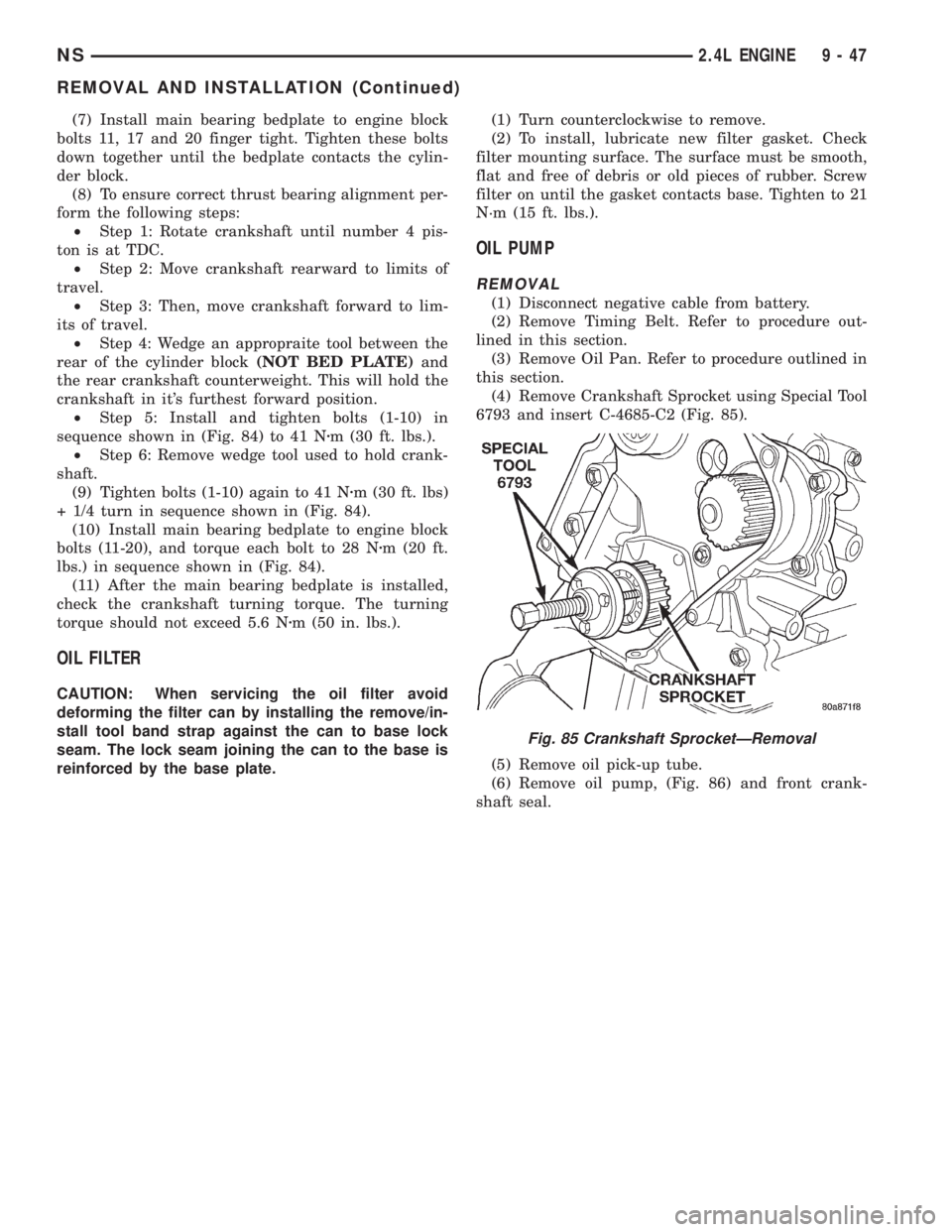

OIL PUMP

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove Timing Belt. Refer to procedure out-

lined in this section.

(3) Remove Oil Pan. Refer to procedure outlined in

this section.

(4) Remove Crankshaft Sprocket using Special Tool

6793 and insert C-4685-C2 (Fig. 85).

(5) Remove oil pick-up tube.

(6) Remove oil pump, (Fig. 86) and front crank-

shaft seal.

Fig. 85 Crankshaft SprocketÐRemoval

NS2.4L ENGINE 9 - 47

REMOVAL AND INSTALLATION (Continued)

Page 1126 of 1938

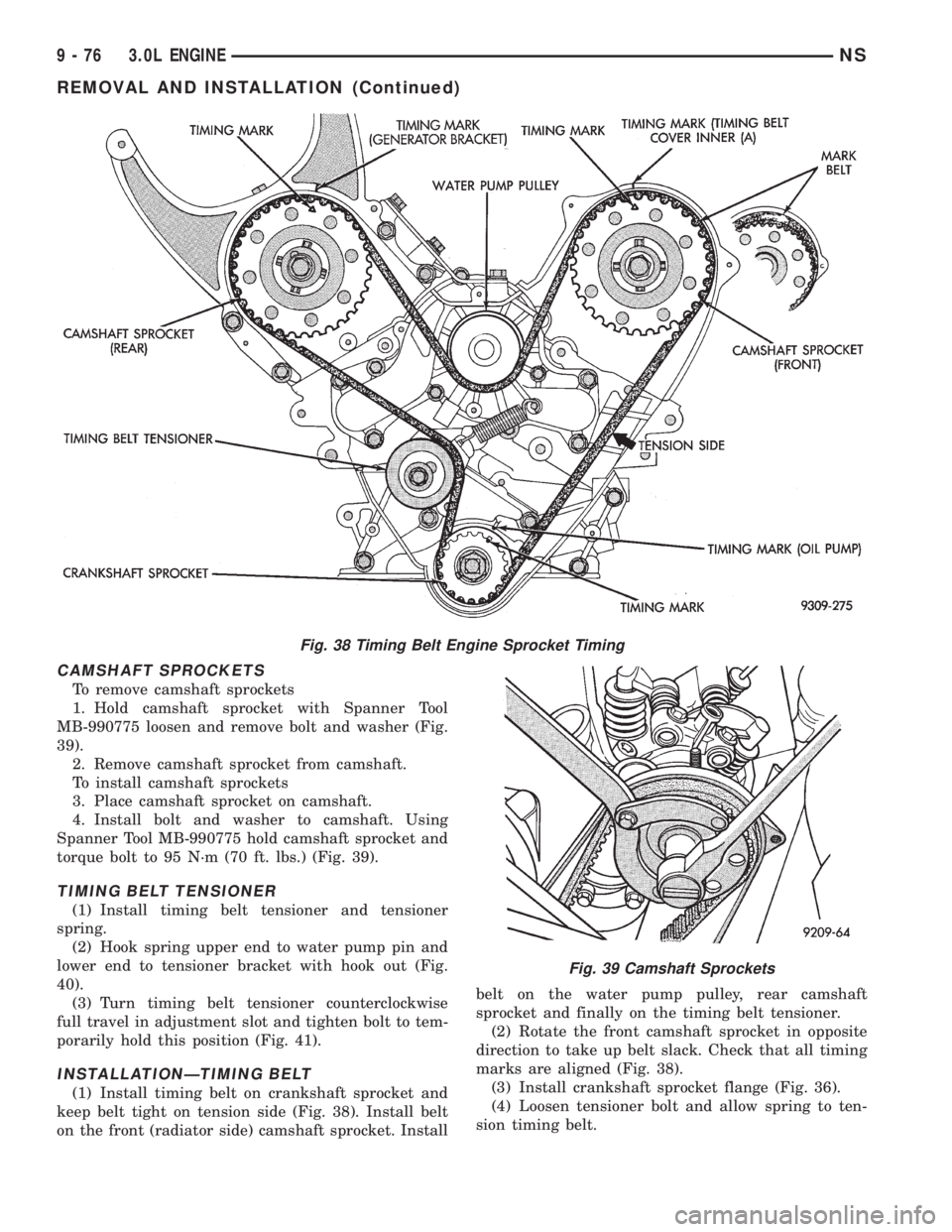

CAMSHAFT SPROCKETS

To remove camshaft sprockets

1. Hold camshaft sprocket with Spanner Tool

MB-990775 loosen and remove bolt and washer (Fig.

39).

2. Remove camshaft sprocket from camshaft.

To install camshaft sprockets

3. Place camshaft sprocket on camshaft.

4. Install bolt and washer to camshaft. Using

Spanner Tool MB-990775 hold camshaft sprocket and

torque bolt to 95 N´m (70 ft. lbs.) (Fig. 39).

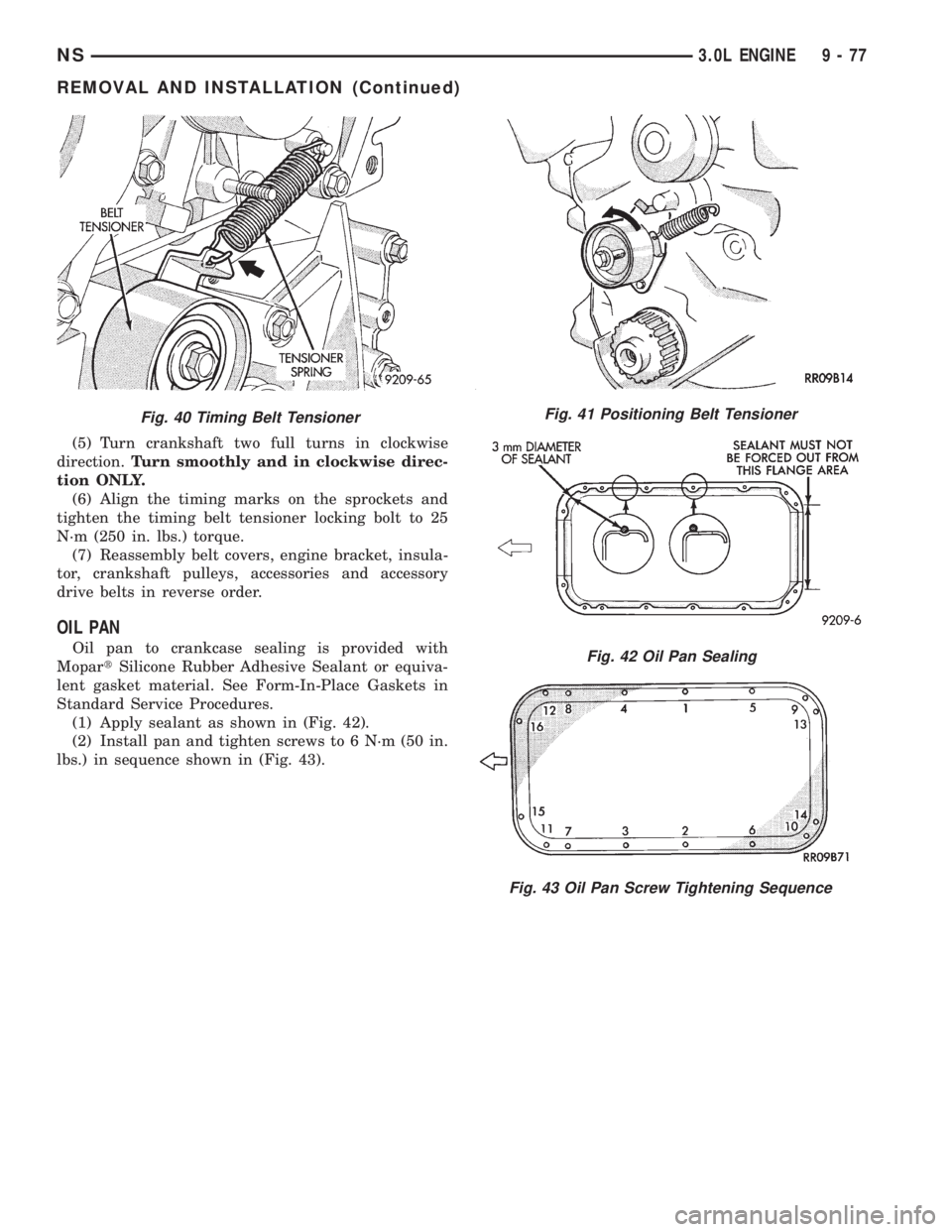

TIMING BELT TENSIONER

(1) Install timing belt tensioner and tensioner

spring.

(2) Hook spring upper end to water pump pin and

lower end to tensioner bracket with hook out (Fig.

40).

(3) Turn timing belt tensioner counterclockwise

full travel in adjustment slot and tighten bolt to tem-

porarily hold this position (Fig. 41).

INSTALLATIONÐTIMING BELT

(1) Install timing belt on crankshaft sprocket and

keep belt tight on tension side (Fig. 38). Install belt

on the front (radiator side) camshaft sprocket. Installbelt on the water pump pulley, rear camshaft

sprocket and finally on the timing belt tensioner.

(2) Rotate the front camshaft sprocket in opposite

direction to take up belt slack. Check that all timing

marks are aligned (Fig. 38).

(3) Install crankshaft sprocket flange (Fig. 36).

(4) Loosen tensioner bolt and allow spring to ten-

sion timing belt.

Fig. 38 Timing Belt Engine Sprocket Timing

Fig. 39 Camshaft Sprockets

9 - 76 3.0L ENGINENS

REMOVAL AND INSTALLATION (Continued)

Page 1127 of 1938

(5) Turn crankshaft two full turns in clockwise

direction.Turn smoothly and in clockwise direc-

tion ONLY.

(6) Align the timing marks on the sprockets and

tighten the timing belt tensioner locking bolt to 25

N´m (250 in. lbs.) torque.

(7) Reassembly belt covers, engine bracket, insula-

tor, crankshaft pulleys, accessories and accessory

drive belts in reverse order.

OIL PAN

Oil pan to crankcase sealing is provided with

MopartSilicone Rubber Adhesive Sealant or equiva-

lent gasket material. See Form-In-Place Gaskets in

Standard Service Procedures.

(1) Apply sealant as shown in (Fig. 42).

(2) Install pan and tighten screws to 6 N´m (50 in.

lbs.) in sequence shown in (Fig. 43).

Fig. 41 Positioning Belt Tensioner

Fig. 42 Oil Pan Sealing

Fig. 43 Oil Pan Screw Tightening Sequence

Fig. 40 Timing Belt Tensioner

NS3.0L ENGINE 9 - 77

REMOVAL AND INSTALLATION (Continued)

Page 1134 of 1938

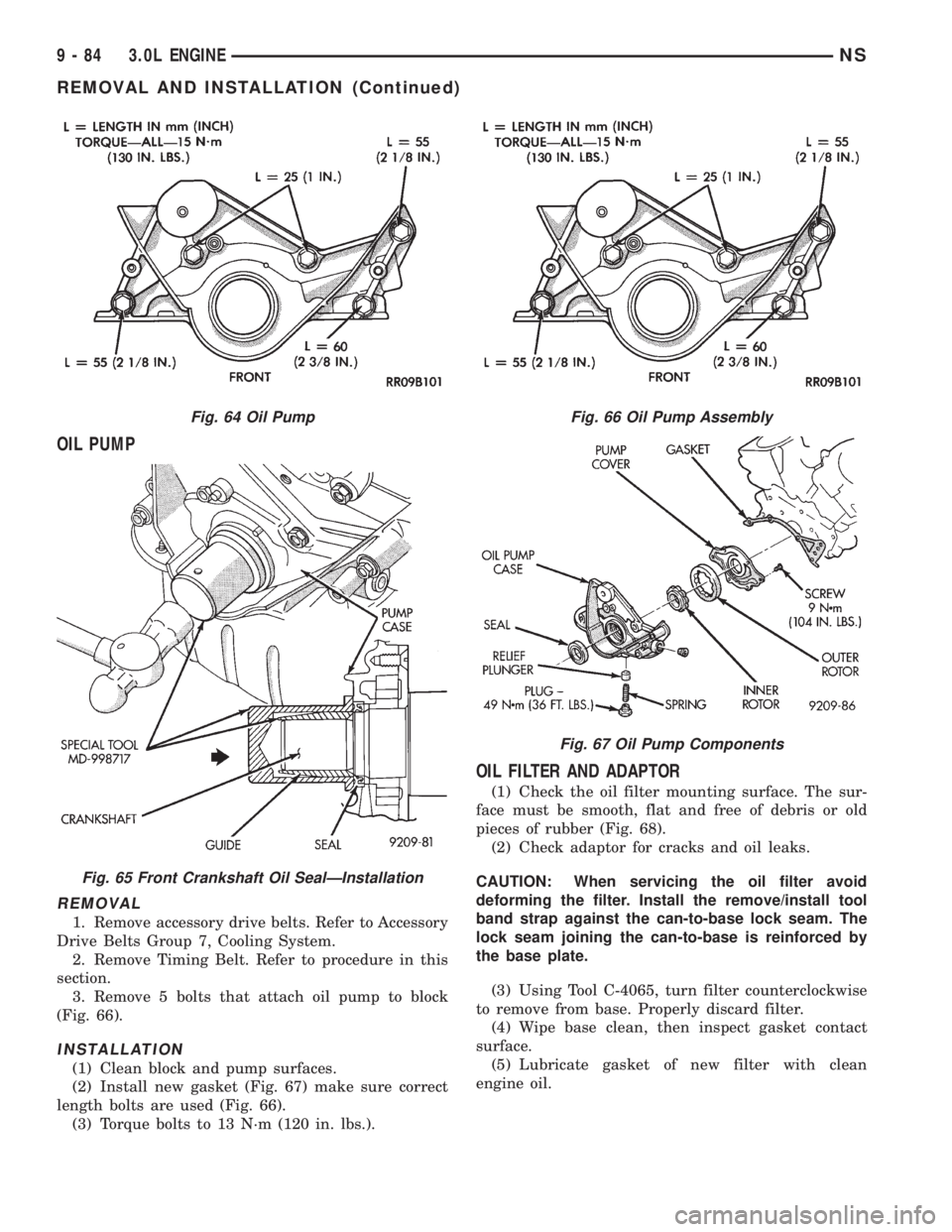

OIL PUMP

REMOVAL

1. Remove accessory drive belts. Refer to Accessory

Drive Belts Group 7, Cooling System.

2. Remove Timing Belt. Refer to procedure in this

section.

3. Remove 5 bolts that attach oil pump to block

(Fig. 66).

INSTALLATION

(1) Clean block and pump surfaces.

(2) Install new gasket (Fig. 67) make sure correct

length bolts are used (Fig. 66).

(3) Torque bolts to 13 N´m (120 in. lbs.).

OIL FILTER AND ADAPTOR

(1) Check the oil filter mounting surface. The sur-

face must be smooth, flat and free of debris or old

pieces of rubber (Fig. 68).

(2) Check adaptor for cracks and oil leaks.

CAUTION: When servicing the oil filter avoid

deforming the filter. Install the remove/install tool

band strap against the can-to-base lock seam. The

lock seam joining the can-to-base is reinforced by

the base plate.

(3) Using Tool C-4065, turn filter counterclockwise

to remove from base. Properly discard filter.

(4) Wipe base clean, then inspect gasket contact

surface.

(5) Lubricate gasket of new filter with clean

engine oil.

Fig. 64 Oil Pump

Fig. 65 Front Crankshaft Oil SealÐInstallation

Fig. 66 Oil Pump Assembly

Fig. 67 Oil Pump Components

9 - 84 3.0L ENGINENS

REMOVAL AND INSTALLATION (Continued)

Page 1146 of 1938

NOTE: Worn valve guides or cocked springs are

sometimes mistaken for noisy tappets. If such is

the case, noise may be dampened by applying side

thrust on the valve spring. If noise is not apprecia-

bly reduced, it can be assumed the noise is in the

tappet. Inspect the rocker arm push rod sockets

and push rod ends for wear.

Valve tappet noise ranges from light noise to a

heavy click. A light noise is usually caused by exces-

sive leak-down around the unit plunger which will

necessitate replacing the tappet, or by the plunger

partially sticking in the tappet body cylinder. A heavy

click is caused either by a tappet check valve not

seating, or by foreign particles becoming wedged

between the plunger and the tappet body causing the

plunger to stick in the down position. This heavy

click will be accompanied by excessive clearance

between the valve stem and rocker arm as valve

closes. In either case, tappet assembly should be

removed for inspection and cleaning.

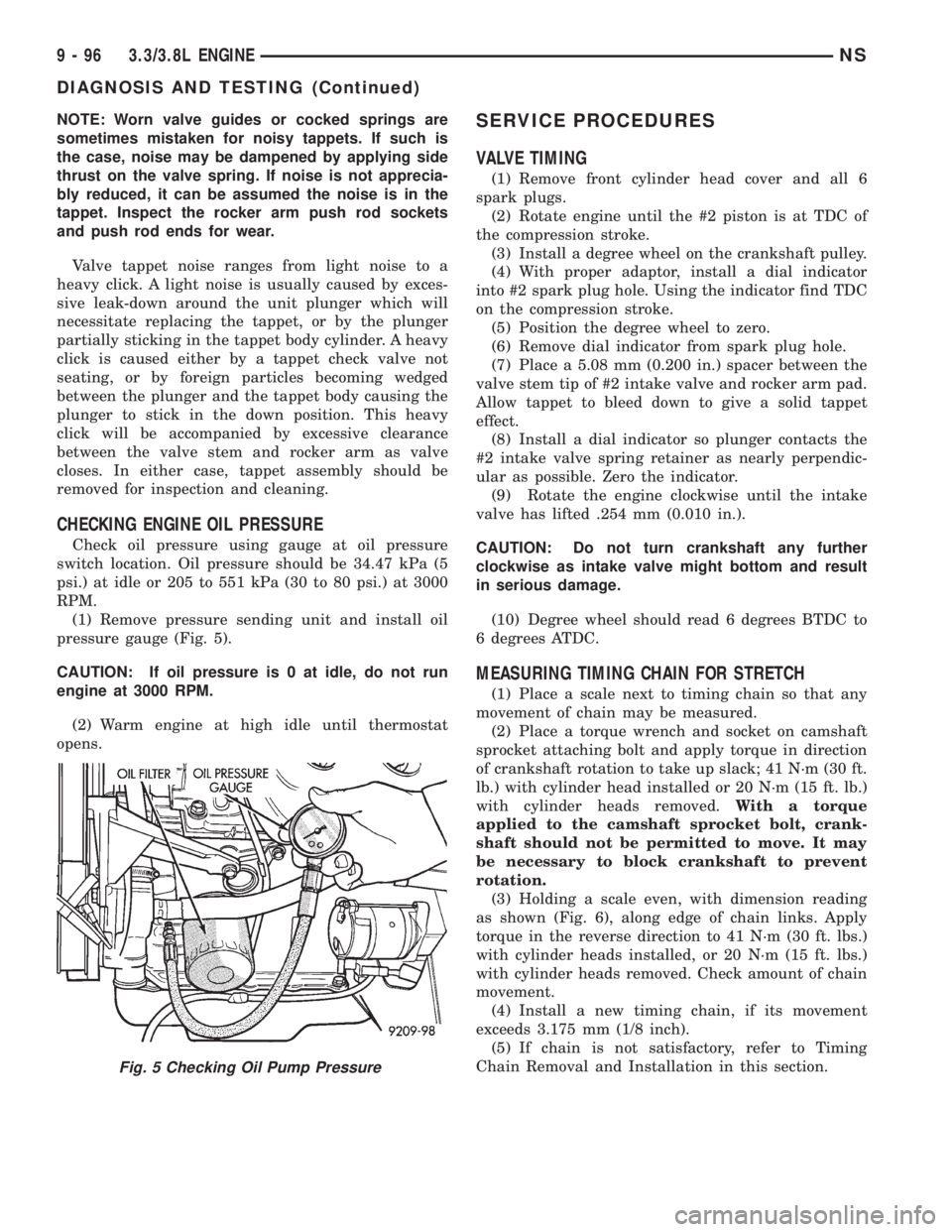

CHECKING ENGINE OIL PRESSURE

Check oil pressure using gauge at oil pressure

switch location. Oil pressure should be 34.47 kPa (5

psi.) at idle or 205 to 551 kPa (30 to 80 psi.) at 3000

RPM.

(1) Remove pressure sending unit and install oil

pressure gauge (Fig. 5).

CAUTION: If oil pressure is 0 at idle, do not run

engine at 3000 RPM.

(2) Warm engine at high idle until thermostat

opens.

SERVICE PROCEDURES

VALVE TIMING

(1) Remove front cylinder head cover and all 6

spark plugs.

(2) Rotate engine until the #2 piston is at TDC of

the compression stroke.

(3) Install a degree wheel on the crankshaft pulley.

(4) With proper adaptor, install a dial indicator

into #2 spark plug hole. Using the indicator find TDC

on the compression stroke.

(5) Position the degree wheel to zero.

(6) Remove dial indicator from spark plug hole.

(7) Place a 5.08 mm (0.200 in.) spacer between the

valve stem tip of #2 intake valve and rocker arm pad.

Allow tappet to bleed down to give a solid tappet

effect.

(8) Install a dial indicator so plunger contacts the

#2 intake valve spring retainer as nearly perpendic-

ular as possible. Zero the indicator.

(9) Rotate the engine clockwise until the intake

valve has lifted .254 mm (0.010 in.).

CAUTION: Do not turn crankshaft any further

clockwise as intake valve might bottom and result

in serious damage.

(10) Degree wheel should read 6 degrees BTDC to

6 degrees ATDC.

MEASURING TIMING CHAIN FOR STRETCH

(1) Place a scale next to timing chain so that any

movement of chain may be measured.

(2) Place a torque wrench and socket on camshaft

sprocket attaching bolt and apply torque in direction

of crankshaft rotation to take up slack; 41 N´m (30 ft.

lb.) with cylinder head installed or 20 N´m (15 ft. lb.)

with cylinder heads removed.With a torque

applied to the camshaft sprocket bolt, crank-

shaft should not be permitted to move. It may

be necessary to block crankshaft to prevent

rotation.

(3) Holding a scale even, with dimension reading

as shown (Fig. 6), along edge of chain links. Apply

torque in the reverse direction to 41 N´m (30 ft. lbs.)

with cylinder heads installed, or 20 N´m (15 ft. lbs.)

with cylinder heads removed. Check amount of chain

movement.

(4) Install a new timing chain, if its movement

exceeds 3.175 mm (1/8 inch).

(5) If chain is not satisfactory, refer to Timing

Chain Removal and Installation in this section.

Fig. 5 Checking Oil Pump Pressure

9 - 96 3.3/3.8L ENGINENS

DIAGNOSIS AND TESTING (Continued)

Page 1162 of 1938

(3) Rotate crankshaft so that the oil pump drive

flats are vertical.

(4) Position oil pump inner rotor so the mating

flats are in the same position as the crankshaft drive

flats (Fig. 47).

(5) Install cover onto crankshaft. Make sure the oil

pump is engaged on the crankshaft correctly or

severe damage may result.

(6) Install chain case cover screws and torque to

27 N´m (20 ft. lbs.).

(7) Install crankshaft oil seal (Fig. 48).

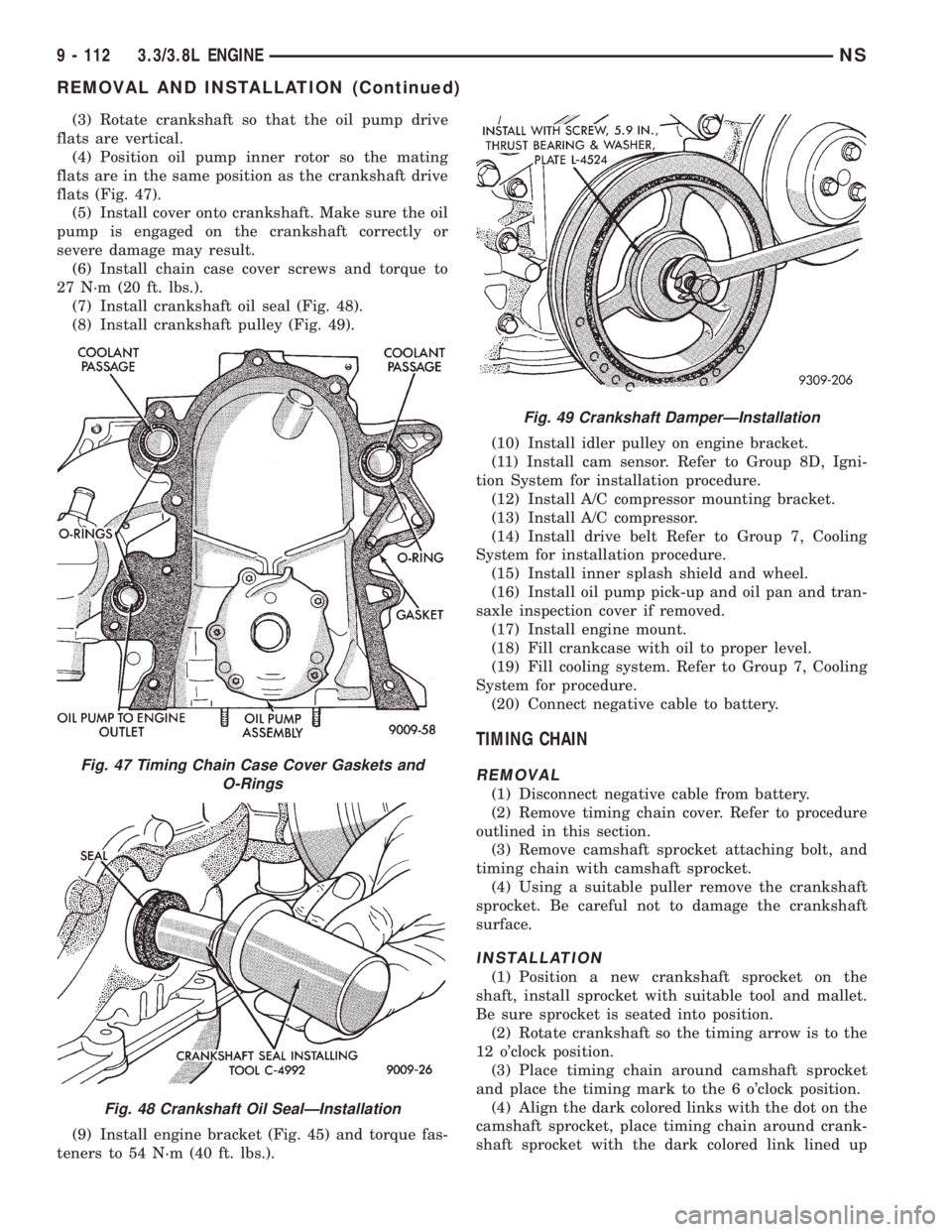

(8) Install crankshaft pulley (Fig. 49).

(9) Install engine bracket (Fig. 45) and torque fas-

teners to 54 N´m (40 ft. lbs.).(10) Install idler pulley on engine bracket.

(11) Install cam sensor. Refer to Group 8D, Igni-

tion System for installation procedure.

(12) Install A/C compressor mounting bracket.

(13) Install A/C compressor.

(14) Install drive belt Refer to Group 7, Cooling

System for installation procedure.

(15) Install inner splash shield and wheel.

(16) Install oil pump pick-up and oil pan and tran-

saxle inspection cover if removed.

(17) Install engine mount.

(18) Fill crankcase with oil to proper level.

(19) Fill cooling system. Refer to Group 7, Cooling

System for procedure.

(20) Connect negative cable to battery.

TIMING CHAIN

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove timing chain cover. Refer to procedure

outlined in this section.

(3) Remove camshaft sprocket attaching bolt, and

timing chain with camshaft sprocket.

(4) Using a suitable puller remove the crankshaft

sprocket. Be careful not to damage the crankshaft

surface.

INSTALLATION

(1) Position a new crankshaft sprocket on the

shaft, install sprocket with suitable tool and mallet.

Be sure sprocket is seated into position.

(2) Rotate crankshaft so the timing arrow is to the

12 o'clock position.

(3) Place timing chain around camshaft sprocket

and place the timing mark to the 6 o'clock position.

(4) Align the dark colored links with the dot on the

camshaft sprocket, place timing chain around crank-

shaft sprocket with the dark colored link lined up

Fig. 47 Timing Chain Case Cover Gaskets and

O-Rings

Fig. 48 Crankshaft Oil SealÐInstallation

Fig. 49 Crankshaft DamperÐInstallation

9 - 112 3.3/3.8L ENGINENS

REMOVAL AND INSTALLATION (Continued)