CHRYSLER VOYAGER 1996 Service Manual

Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1451 of 1938

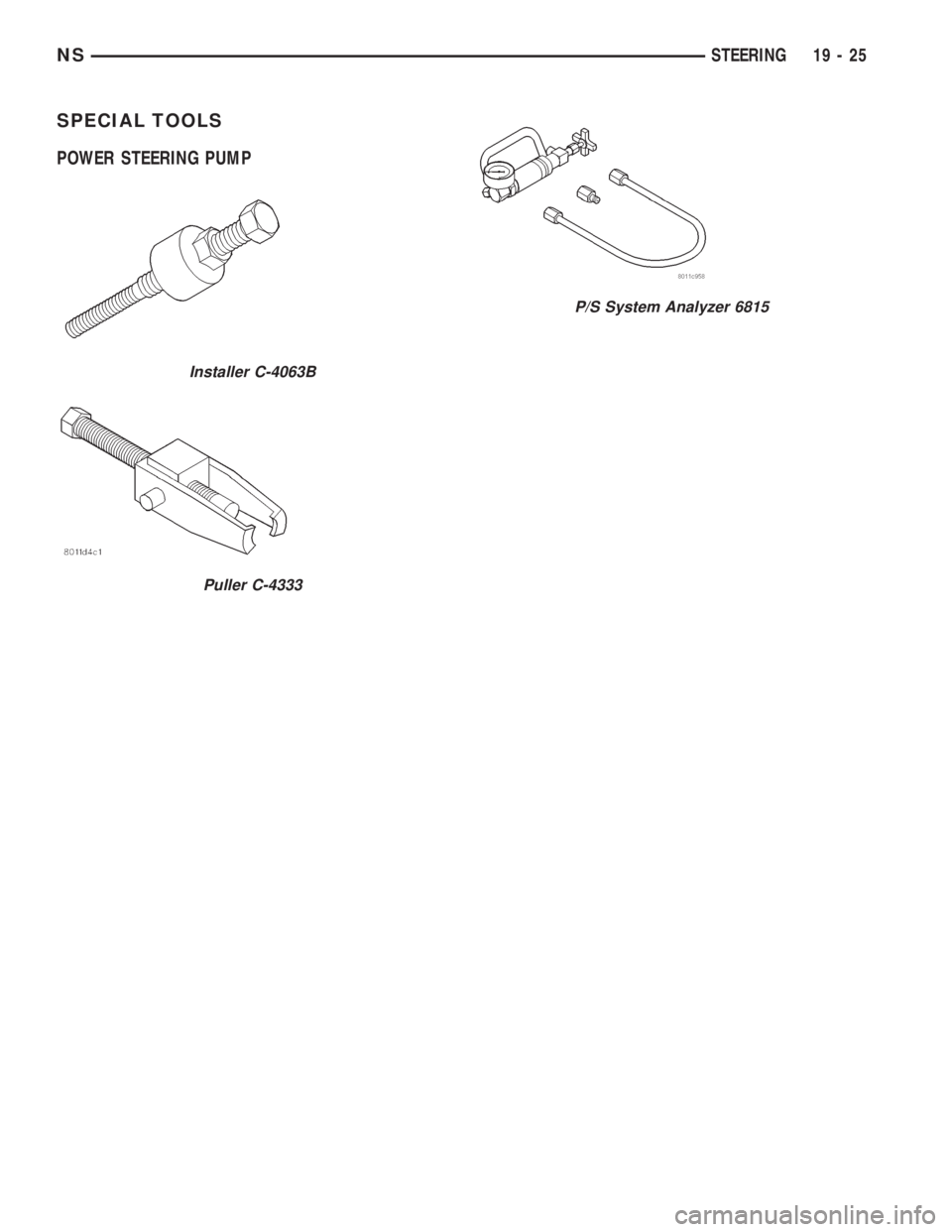

SPECIAL TOOLS

POWER STEERING PUMP

Installer C-4063B

Puller C-4333

P/S System Analyzer 6815

NSSTEERING 19 - 25

Page 1452 of 1938

POWER STEERING GEAR

INDEX

page page

DESCRIPTION AND OPERATION

STEERING GEAR OPERATION DESCRIPTION . 26

DIAGNOSIS AND TESTING

POWER STEERING GEAR................. 27

REMOVAL AND INSTALLATION

STEERING GEAR....................... 27

DISASSEMBLY AND ASSEMBLY

OUTER TIE ROD END................... 33STEERING GEAR INNER TIE ROD BOOT..... 31

SPECIFICATIONS

STEERING GEAR FASTENER TORQUE

SPECIFICATIONS...................... 34

SPECIAL TOOLS

POWER STEERING GEAR................. 35

DESCRIPTION AND OPERATION

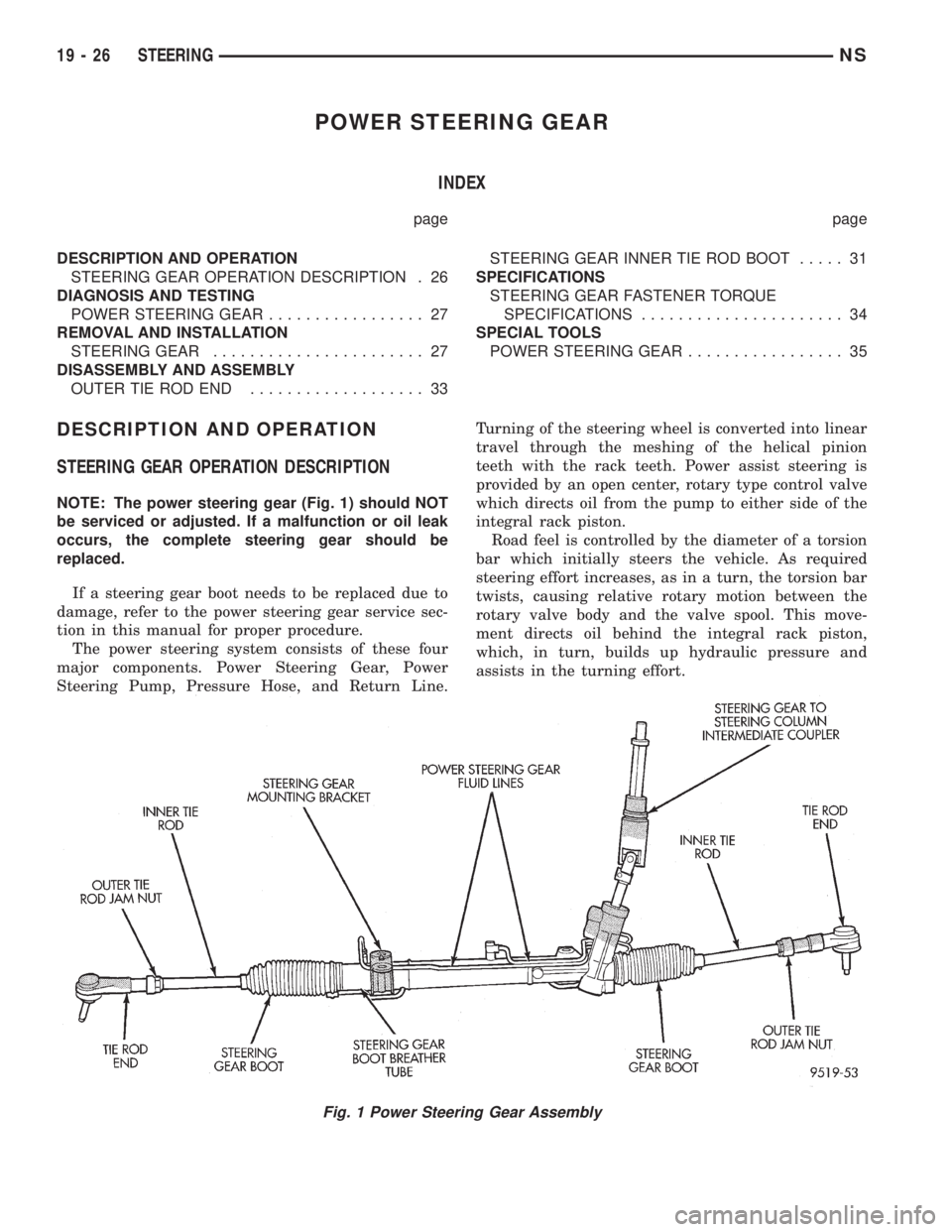

STEERING GEAR OPERATION DESCRIPTION

NOTE: The power steering gear (Fig. 1) should NOT

be serviced or adjusted. If a malfunction or oil leak

occurs, the complete steering gear should be

replaced.

If a steering gear boot needs to be replaced due to

damage, refer to the power steering gear service sec-

tion in this manual for proper procedure.

The power steering system consists of these four

major components. Power Steering Gear, Power

Steering Pump, Pressure Hose, and Return Line.Turning of the steering wheel is converted into linear

travel through the meshing of the helical pinion

teeth with the rack teeth. Power assist steering is

provided by an open center, rotary type control valve

which directs oil from the pump to either side of the

integral rack piston.

Road feel is controlled by the diameter of a torsion

bar which initially steers the vehicle. As required

steering effort increases, as in a turn, the torsion bar

twists, causing relative rotary motion between the

rotary valve body and the valve spool. This move-

ment directs oil behind the integral rack piston,

which, in turn, builds up hydraulic pressure and

assists in the turning effort.

Fig. 1 Power Steering Gear Assembly

19 - 26 STEERINGNS

Page 1453 of 1938

The drive tangs on the pinion mate loosely with a

stub shaft to permit manual steering control to be

maintained if the drive belt on the power steering

pump should break. However, under these conditions,

steering effort will be increased.

DIAGNOSIS AND TESTING

POWER STEERING GEAR

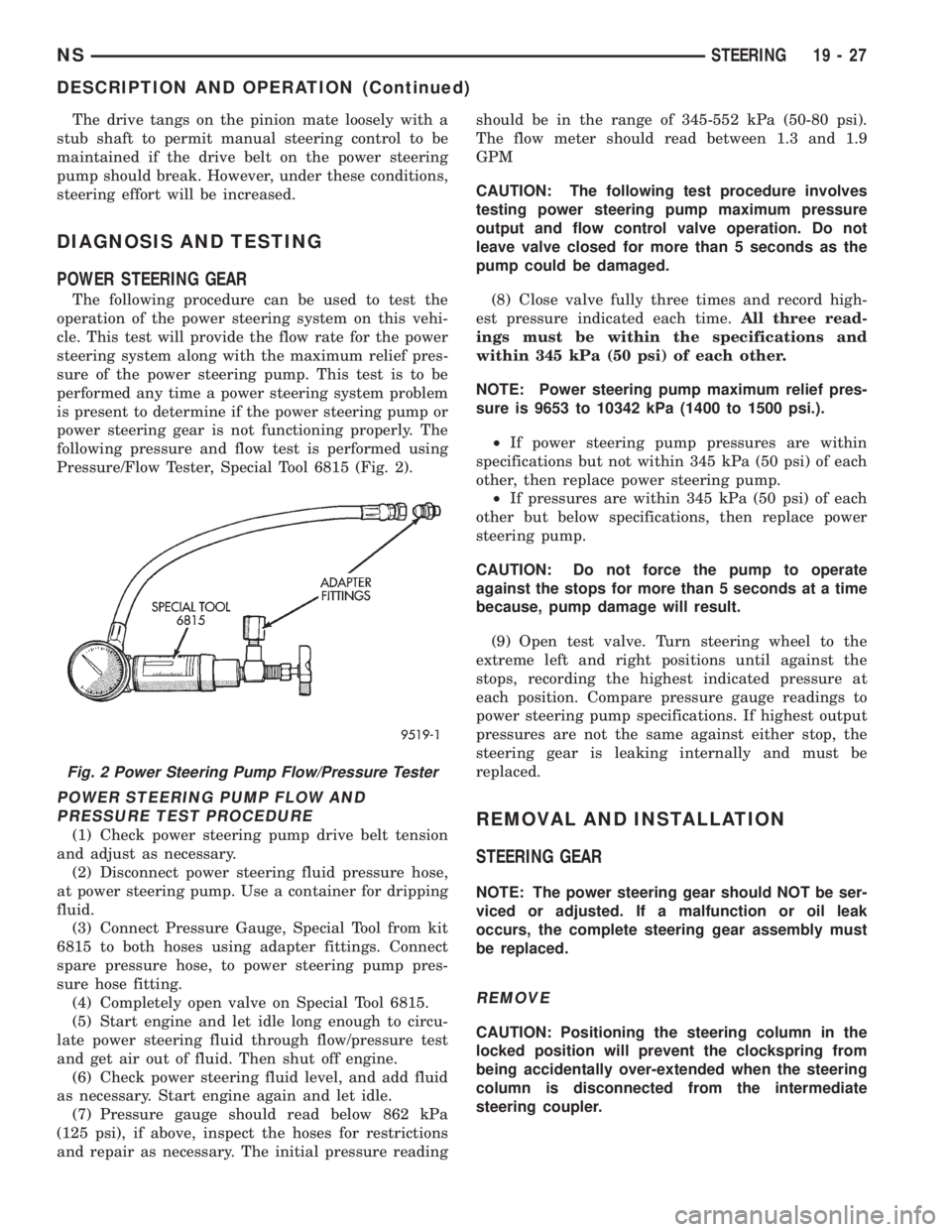

The following procedure can be used to test the

operation of the power steering system on this vehi-

cle. This test will provide the flow rate for the power

steering system along with the maximum relief pres-

sure of the power steering pump. This test is to be

performed any time a power steering system problem

is present to determine if the power steering pump or

power steering gear is not functioning properly. The

following pressure and flow test is performed using

Pressure/Flow Tester, Special Tool 6815 (Fig. 2).

POWER STEERING PUMP FLOW AND

PRESSURE TEST PROCEDURE

(1) Check power steering pump drive belt tension

and adjust as necessary.

(2) Disconnect power steering fluid pressure hose,

at power steering pump. Use a container for dripping

fluid.

(3) Connect Pressure Gauge, Special Tool from kit

6815 to both hoses using adapter fittings. Connect

spare pressure hose, to power steering pump pres-

sure hose fitting.

(4) Completely open valve on Special Tool 6815.

(5) Start engine and let idle long enough to circu-

late power steering fluid through flow/pressure test

and get air out of fluid. Then shut off engine.

(6) Check power steering fluid level, and add fluid

as necessary. Start engine again and let idle.

(7) Pressure gauge should read below 862 kPa

(125 psi), if above, inspect the hoses for restrictions

and repair as necessary. The initial pressure readingshould be in the range of 345-552 kPa (50-80 psi).

The flow meter should read between 1.3 and 1.9

GPM

CAUTION: The following test procedure involves

testing power steering pump maximum pressure

output and flow control valve operation. Do not

leave valve closed for more than 5 seconds as the

pump could be damaged.

(8) Close valve fully three times and record high-

est pressure indicated each time.All three read-

ings must be within the specifications and

within 345 kPa (50 psi) of each other.

NOTE: Power steering pump maximum relief pres-

sure is 9653 to 10342 kPa (1400 to 1500 psi.).

²If power steering pump pressures are within

specifications but not within 345 kPa (50 psi) of each

other, then replace power steering pump.

²If pressures are within 345 kPa (50 psi) of each

other but below specifications, then replace power

steering pump.

CAUTION: Do not force the pump to operate

against the stops for more than 5 seconds at a time

because, pump damage will result.

(9) Open test valve. Turn steering wheel to the

extreme left and right positions until against the

stops, recording the highest indicated pressure at

each position. Compare pressure gauge readings to

power steering pump specifications. If highest output

pressures are not the same against either stop, the

steering gear is leaking internally and must be

replaced.REMOVAL AND INSTALLATION

STEERING GEAR

NOTE: The power steering gear should NOT be ser-

viced or adjusted. If a malfunction or oil leak

occurs, the complete steering gear assembly must

be replaced.

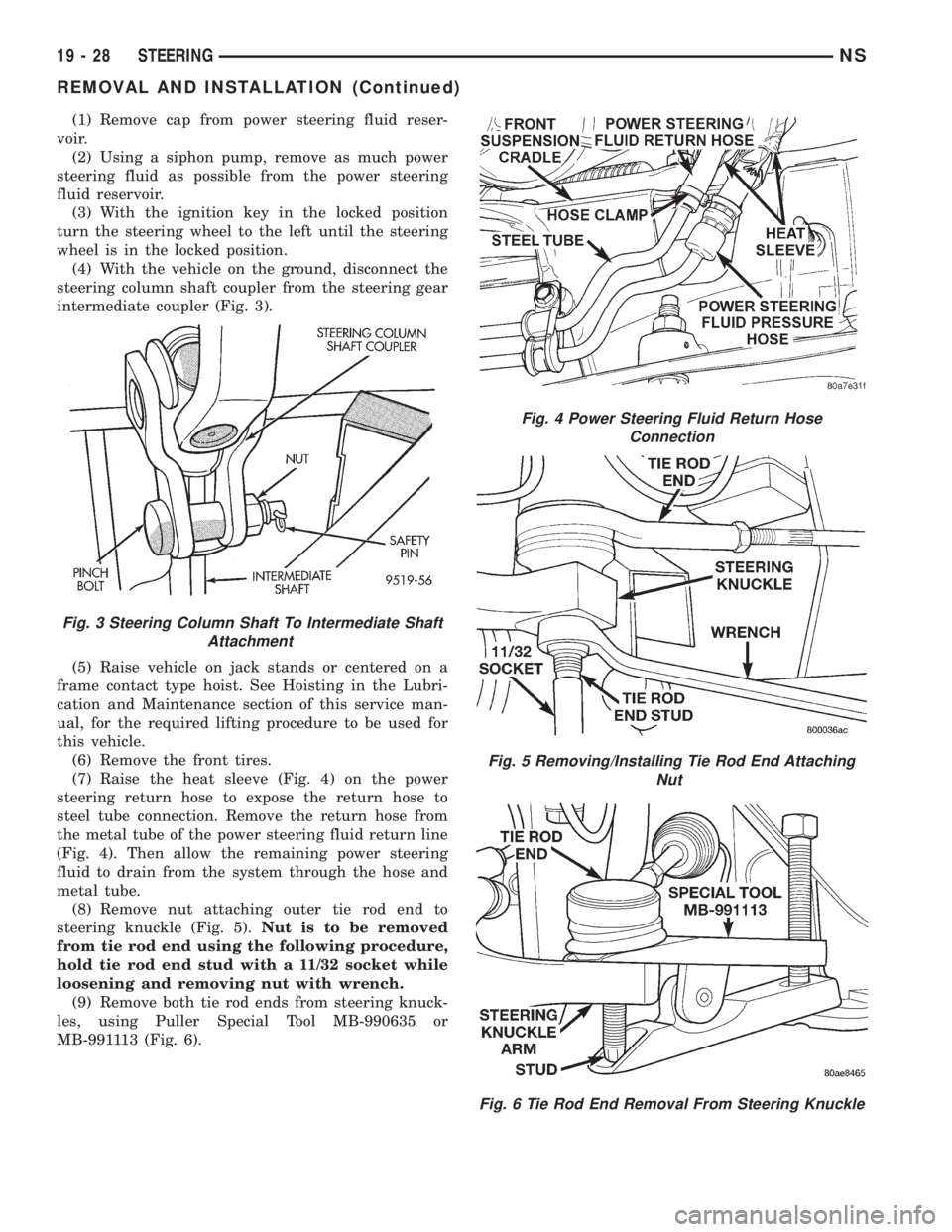

REMOVE

CAUTION: Positioning the steering column in the

locked position will prevent the clockspring from

being accidentally over-extended when the steering

column is disconnected from the intermediate

steering coupler.

Fig. 2 Power Steering Pump Flow/Pressure Tester

NSSTEERING 19 - 27

DESCRIPTION AND OPERATION (Continued)

Page 1454 of 1938

(1) Remove cap from power steering fluid reser-

voir.

(2) Using a siphon pump, remove as much power

steering fluid as possible from the power steering

fluid reservoir.

(3) With the ignition key in the locked position

turn the steering wheel to the left until the steering

wheel is in the locked position.

(4) With the vehicle on the ground, disconnect the

steering column shaft coupler from the steering gear

intermediate coupler (Fig. 3).

(5) Raise vehicle on jack stands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this service man-

ual, for the required lifting procedure to be used for

this vehicle.

(6) Remove the front tires.

(7) Raise the heat sleeve (Fig. 4) on the power

steering return hose to expose the return hose to

steel tube connection. Remove the return hose from

the metal tube of the power steering fluid return line

(Fig. 4). Then allow the remaining power steering

fluid to drain from the system through the hose and

metal tube.

(8) Remove nut attaching outer tie rod end to

steering knuckle (Fig. 5).Nut is to be removed

from tie rod end using the following procedure,

hold tie rod end stud with a 11/32 socket while

loosening and removing nut with wrench.

(9) Remove both tie rod ends from steering knuck-

les, using Puller Special Tool MB-990635 or

MB-991113 (Fig. 6).

Fig. 3 Steering Column Shaft To Intermediate Shaft

Attachment

Fig. 4 Power Steering Fluid Return Hose

Connection

Fig. 5 Removing/Installing Tie Rod End Attaching

Nut

Fig. 6 Tie Rod End Removal From Steering Knuckle

19 - 28 STEERINGNS

REMOVAL AND INSTALLATION (Continued)

Page 1455 of 1938

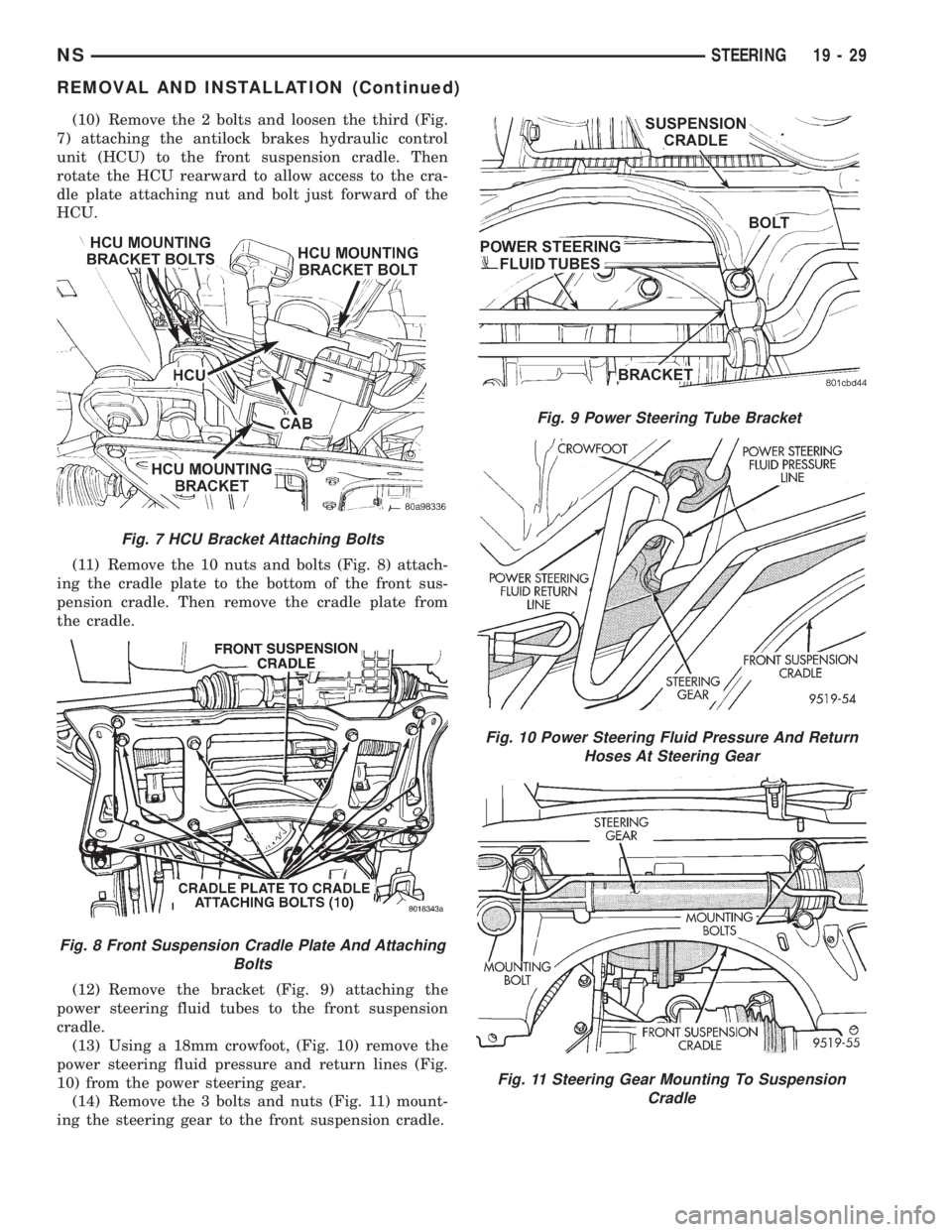

(10) Remove the 2 bolts and loosen the third (Fig.

7) attaching the antilock brakes hydraulic control

unit (HCU) to the front suspension cradle. Then

rotate the HCU rearward to allow access to the cra-

dle plate attaching nut and bolt just forward of the

HCU.

(11) Remove the 10 nuts and bolts (Fig. 8) attach-

ing the cradle plate to the bottom of the front sus-

pension cradle. Then remove the cradle plate from

the cradle.

(12) Remove the bracket (Fig. 9) attaching the

power steering fluid tubes to the front suspension

cradle.

(13) Using a 18mm crowfoot, (Fig. 10) remove the

power steering fluid pressure and return lines (Fig.

10) from the power steering gear.

(14) Remove the 3 bolts and nuts (Fig. 11) mount-

ing the steering gear to the front suspension cradle.

Fig. 7 HCU Bracket Attaching Bolts

Fig. 8 Front Suspension Cradle Plate And Attaching

Bolts

Fig. 9 Power Steering Tube Bracket

Fig. 10 Power Steering Fluid Pressure And Return

Hoses At Steering Gear

Fig. 11 Steering Gear Mounting To Suspension

Cradle

NSSTEERING 19 - 29

REMOVAL AND INSTALLATION (Continued)

Page 1456 of 1938

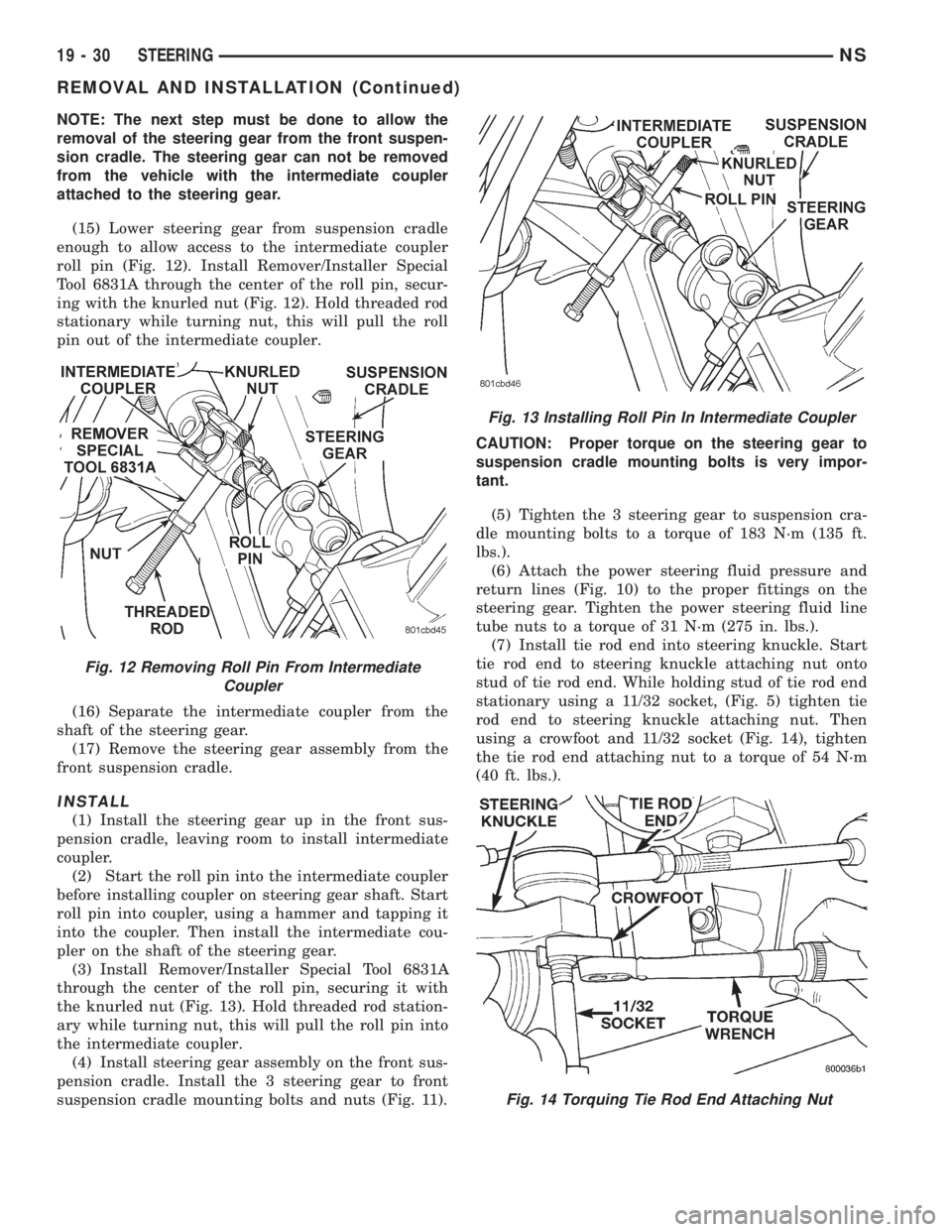

NOTE: The next step must be done to allow the

removal of the steering gear from the front suspen-

sion cradle. The steering gear can not be removed

from the vehicle with the intermediate coupler

attached to the steering gear.

(15) Lower steering gear from suspension cradle

enough to allow access to the intermediate coupler

roll pin (Fig. 12). Install Remover/Installer Special

Tool 6831A through the center of the roll pin, secur-

ing with the knurled nut (Fig. 12). Hold threaded rod

stationary while turning nut, this will pull the roll

pin out of the intermediate coupler.

(16) Separate the intermediate coupler from the

shaft of the steering gear.

(17) Remove the steering gear assembly from the

front suspension cradle.

INSTALL

(1) Install the steering gear up in the front sus-

pension cradle, leaving room to install intermediate

coupler.

(2) Start the roll pin into the intermediate coupler

before installing coupler on steering gear shaft. Start

roll pin into coupler, using a hammer and tapping it

into the coupler. Then install the intermediate cou-

pler on the shaft of the steering gear.

(3) Install Remover/Installer Special Tool 6831A

through the center of the roll pin, securing it with

the knurled nut (Fig. 13). Hold threaded rod station-

ary while turning nut, this will pull the roll pin into

the intermediate coupler.

(4) Install steering gear assembly on the front sus-

pension cradle. Install the 3 steering gear to front

suspension cradle mounting bolts and nuts (Fig. 11).CAUTION: Proper torque on the steering gear to

suspension cradle mounting bolts is very impor-

tant.

(5) Tighten the 3 steering gear to suspension cra-

dle mounting bolts to a torque of 183 N´m (135 ft.

lbs.).

(6) Attach the power steering fluid pressure and

return lines (Fig. 10) to the proper fittings on the

steering gear. Tighten the power steering fluid line

tube nuts to a torque of 31 N´m (275 in. lbs.).

(7) Install tie rod end into steering knuckle. Start

tie rod end to steering knuckle attaching nut onto

stud of tie rod end. While holding stud of tie rod end

stationary using a 11/32 socket, (Fig. 5) tighten tie

rod end to steering knuckle attaching nut. Then

using a crowfoot and 11/32 socket (Fig. 14), tighten

the tie rod end attaching nut to a torque of 54 N´m

(40 ft. lbs.).

Fig. 12 Removing Roll Pin From Intermediate

Coupler

Fig. 13 Installing Roll Pin In Intermediate Coupler

Fig. 14 Torquing Tie Rod End Attaching Nut

19 - 30 STEERINGNS

REMOVAL AND INSTALLATION (Continued)

Page 1457 of 1938

CAUTION: Proper torque on the cradle plate to

suspension cradle mounting bolts is very impor-

tant.

(8) Install cradle plate on front suspension cradle

and install the 10 cradle plate to cradle attaching

bolts and nuts (Fig. 8). Tighten all attaching bolts to

a torque of 165 N´m (123 ft. lbs.).

(9) Install the bracket (Fig. 9) attaching the power

steering fluid tubes to the front suspension cradle.

CAUTION:

(10) Install the power steering fluid return hose on

the steel tube at the front suspension cradle (Fig. 4).

(11) Install a screw type hose clamp on the power

steering hose to steel tube connection.Be sure hose

clamp is installed on return tube past the upset

bead on the tube.Tighten the screw clamp to a

torque of 2 N´m (18 in. lbs.).

CAUTION: The protective heat shield sleeves must

cover the entire rubber hose and hose to tube con-

nection portion of both the power steering fluid

pressure and return hoses (Fig. 4). This is required

to prevent the power steering hoses from being

overheated.

(12) When used, properly position the protective

heat sleeves on the power steering hoses. Then, tie

strap the heat sleeves to the power steering hoses to

keep them in their proper position.

(13) Install the front tire and wheel assemblies on

vehicle. Install the wheel lug nuts and torque to 129

N´m (95 ft. lbs.).

(14) Lower the vehicle to a level were the interior

of vehicle is accessible.

(15) Using the intermediate coupler, turn the front

wheels of the vehicle to the left until the intermedi-

ate coupler shaft is properly aligned with the steer-

ing column coupler. Assemble the steering column

shaft coupler (Fig. 3) onto the steering gear interme-

diate coupler. Install steering column coupler to

intermediate shaft retaining pinch bolt (Fig. 3).

Tighten the pinch bolt nut to a torque of 28 N´m (250

in. lbs.).

CAUTION: Do not use automatic transmission fluid

in the power steering system. Only use Mopar,

Power Steering Fluid or an exact equivalent prod-

uct.

(16) Fill power steering pump fluid reservoir to the

proper level.

(17) Start the engine and let run for a few seconds.

Then turn the engine off.(18) Add fluid if necessary. Repeat the above pro-

cedure until the fluid level remains constant after

running the engine.

(19) Raise front wheels of vehicle off the ground.

(20) Start the engine. Slowly turn the steering

wheel right and left, lightly contacting the wheel

stops. Then turn the engine off.

(21) Add power steering fluid if necessary.

(22) Lower the vehicle and turn the steering wheel

slowly from lock to lock.

(23) Stop the engine. Check the fluid level and

refill as required.

(24) If the fluid is extremely foamy, allow the vehi-

cle to stand a few minutes and repeat the above pro-

cedure.

(25) Fill power steering reservoir to correct level

with Mopart, Power Steering Fluid, or equivalent.

(26) Adjust toe (Refer to Group 2 Suspension).

DISASSEMBLY AND ASSEMBLY

STEERING GEAR INNER TIE ROD BOOT

DISASSEMBLE

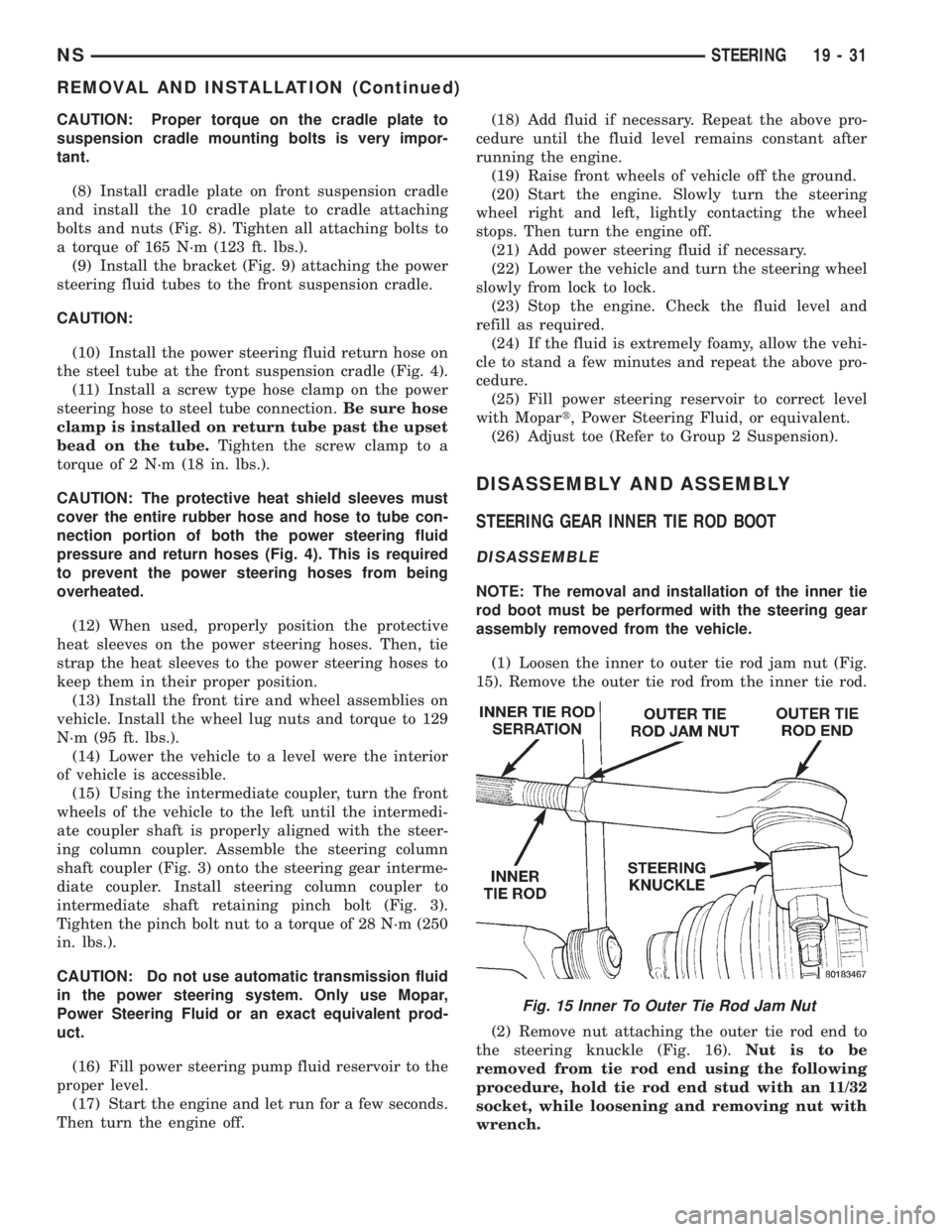

NOTE: The removal and installation of the inner tie

rod boot must be performed with the steering gear

assembly removed from the vehicle.

(1) Loosen the inner to outer tie rod jam nut (Fig.

15). Remove the outer tie rod from the inner tie rod.

(2) Remove nut attaching the outer tie rod end to

the steering knuckle (Fig. 16).Nut is to be

removed from tie rod end using the following

procedure, hold tie rod end stud with an 11/32

socket, while loosening and removing nut with

wrench.

Fig. 15 Inner To Outer Tie Rod Jam Nut

NSSTEERING 19 - 31

REMOVAL AND INSTALLATION (Continued)

Page 1458 of 1938

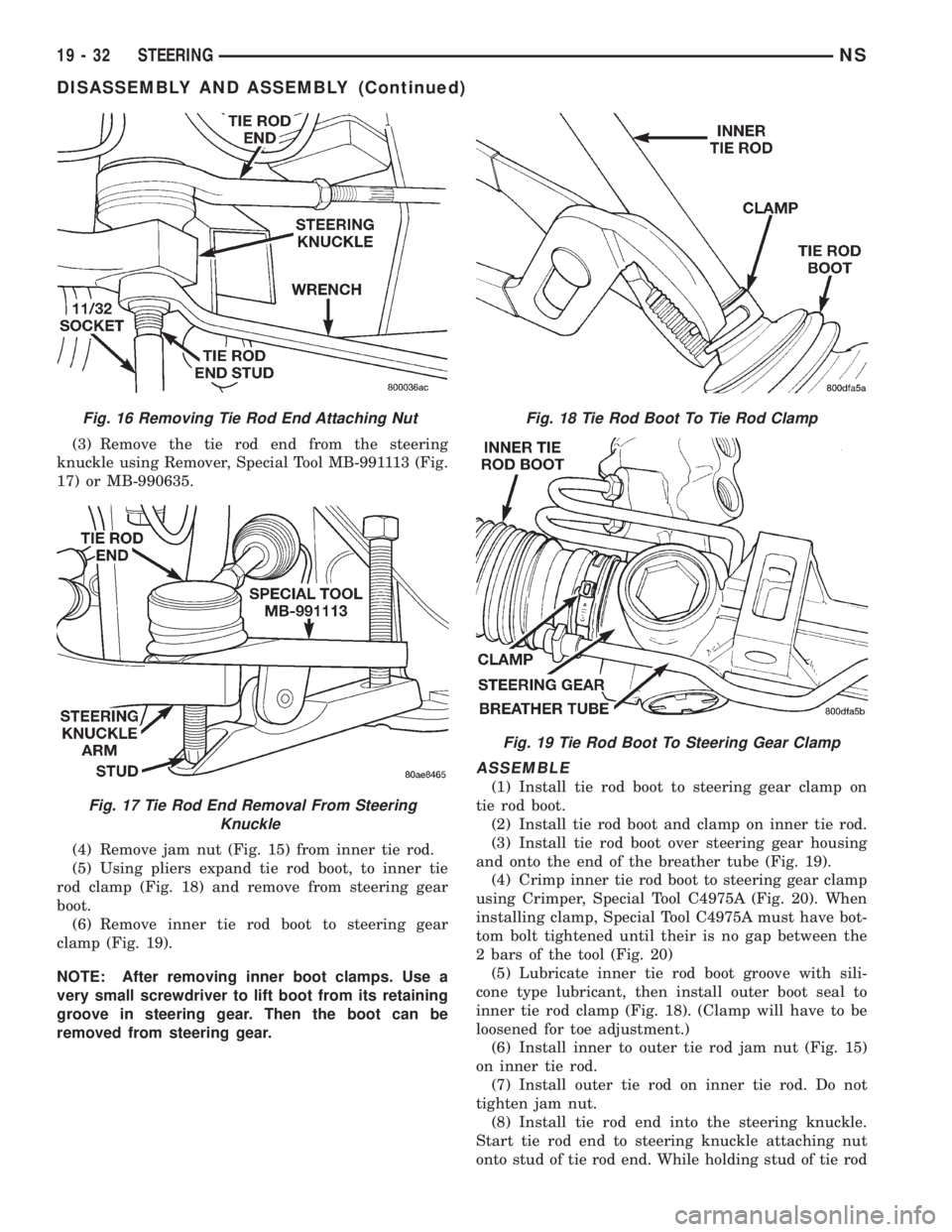

(3) Remove the tie rod end from the steering

knuckle using Remover, Special Tool MB-991113 (Fig.

17) or MB-990635.

(4) Remove jam nut (Fig. 15) from inner tie rod.

(5) Using pliers expand tie rod boot, to inner tie

rod clamp (Fig. 18) and remove from steering gear

boot.

(6) Remove inner tie rod boot to steering gear

clamp (Fig. 19).

NOTE: After removing inner boot clamps. Use a

very small screwdriver to lift boot from its retaining

groove in steering gear. Then the boot can be

removed from steering gear.

ASSEMBLE

(1) Install tie rod boot to steering gear clamp on

tie rod boot.

(2) Install tie rod boot and clamp on inner tie rod.

(3) Install tie rod boot over steering gear housing

and onto the end of the breather tube (Fig. 19).

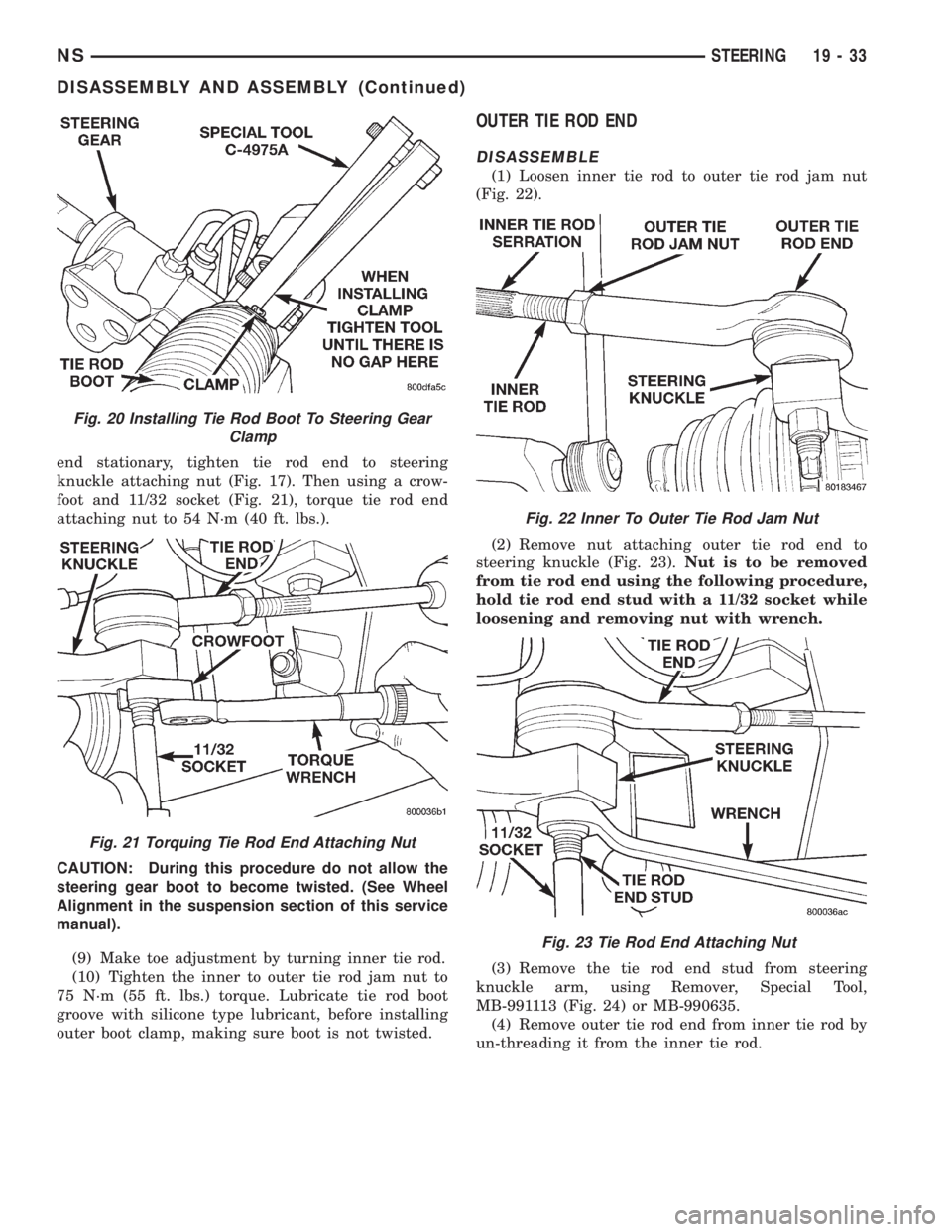

(4) Crimp inner tie rod boot to steering gear clamp

using Crimper, Special Tool C4975A (Fig. 20). When

installing clamp, Special Tool C4975A must have bot-

tom bolt tightened until their is no gap between the

2 bars of the tool (Fig. 20)

(5) Lubricate inner tie rod boot groove with sili-

cone type lubricant, then install outer boot seal to

inner tie rod clamp (Fig. 18). (Clamp will have to be

loosened for toe adjustment.)

(6) Install inner to outer tie rod jam nut (Fig. 15)

on inner tie rod.

(7) Install outer tie rod on inner tie rod. Do not

tighten jam nut.

(8) Install tie rod end into the steering knuckle.

Start tie rod end to steering knuckle attaching nut

onto stud of tie rod end. While holding stud of tie rod

Fig. 16 Removing Tie Rod End Attaching Nut

Fig. 17 Tie Rod End Removal From Steering

Knuckle

Fig. 18 Tie Rod Boot To Tie Rod Clamp

Fig. 19 Tie Rod Boot To Steering Gear Clamp

19 - 32 STEERINGNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1459 of 1938

end stationary, tighten tie rod end to steering

knuckle attaching nut (Fig. 17). Then using a crow-

foot and 11/32 socket (Fig. 21), torque tie rod end

attaching nut to 54 N´m (40 ft. lbs.).

CAUTION: During this procedure do not allow the

steering gear boot to become twisted. (See Wheel

Alignment in the suspension section of this service

manual).

(9) Make toe adjustment by turning inner tie rod.

(10) Tighten the inner to outer tie rod jam nut to

75 N´m (55 ft. lbs.) torque. Lubricate tie rod boot

groove with silicone type lubricant, before installing

outer boot clamp, making sure boot is not twisted.

OUTER TIE ROD END

DISASSEMBLE

(1) Loosen inner tie rod to outer tie rod jam nut

(Fig. 22).

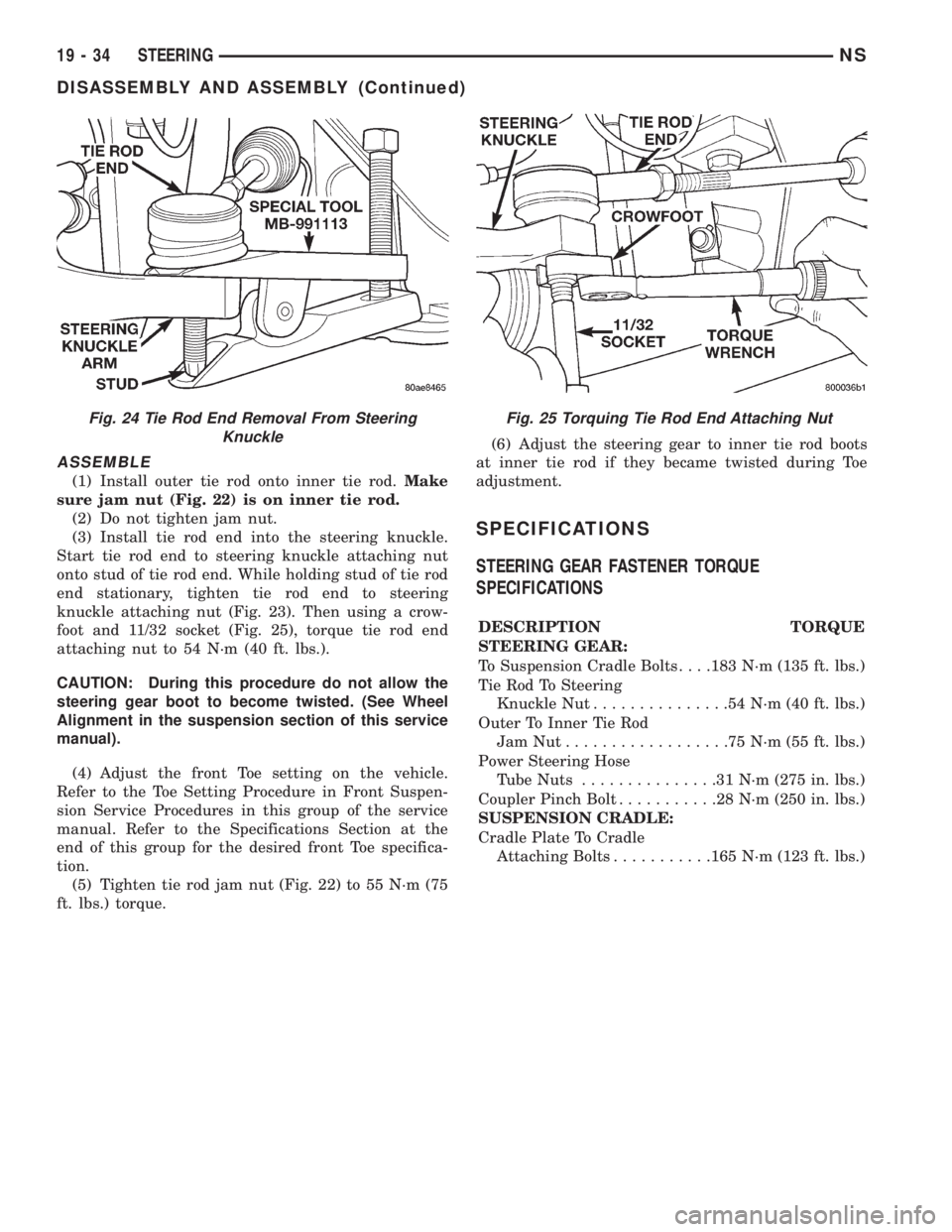

(2) Remove nut attaching outer tie rod end to

steering knuckle (Fig. 23).Nut is to be removed

from tie rod end using the following procedure,

hold tie rod end stud with a 11/32 socket while

loosening and removing nut with wrench.

(3) Remove the tie rod end stud from steering

knuckle arm, using Remover, Special Tool,

MB-991113 (Fig. 24) or MB-990635.

(4) Remove outer tie rod end from inner tie rod by

un-threading it from the inner tie rod.

Fig. 20 Installing Tie Rod Boot To Steering Gear

Clamp

Fig. 21 Torquing Tie Rod End Attaching Nut

Fig. 22 Inner To Outer Tie Rod Jam Nut

Fig. 23 Tie Rod End Attaching Nut

NSSTEERING 19 - 33

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1460 of 1938

ASSEMBLE

(1) Install outer tie rod onto inner tie rod.Make

sure jam nut (Fig. 22) is on inner tie rod.

(2) Do not tighten jam nut.

(3) Install tie rod end into the steering knuckle.

Start tie rod end to steering knuckle attaching nut

onto stud of tie rod end. While holding stud of tie rod

end stationary, tighten tie rod end to steering

knuckle attaching nut (Fig. 23). Then using a crow-

foot and 11/32 socket (Fig. 25), torque tie rod end

attaching nut to 54 N´m (40 ft. lbs.).

CAUTION: During this procedure do not allow the

steering gear boot to become twisted. (See Wheel

Alignment in the suspension section of this service

manual).

(4) Adjust the front Toe setting on the vehicle.

Refer to the Toe Setting Procedure in Front Suspen-

sion Service Procedures in this group of the service

manual. Refer to the Specifications Section at the

end of this group for the desired front Toe specifica-

tion.

(5) Tighten tie rod jam nut (Fig. 22) to 55 N´m (75

ft. lbs.) torque.(6) Adjust the steering gear to inner tie rod boots

at inner tie rod if they became twisted during Toe

adjustment.

SPECIFICATIONS

STEERING GEAR FASTENER TORQUE

SPECIFICATIONS

DESCRIPTION TORQUE

STEERING GEAR:

To Suspension Cradle Bolts. . . .183 N´m (135 ft. lbs.)

Tie Rod To Steering

Knuckle Nut...............54N´m(40ft.lbs.)

Outer To Inner Tie Rod

JamNut..................75N´m(55ft.lbs.)

Power Steering Hose

Tube Nuts...............31N´m(275 in. lbs.)

Coupler Pinch Bolt...........28N´m(250 in. lbs.)

SUSPENSION CRADLE:

Cradle Plate To Cradle

Attaching Bolts...........165 N´m (123 ft. lbs.)

Fig. 24 Tie Rod End Removal From Steering

KnuckleFig. 25 Torquing Tie Rod End Attaching Nut

19 - 34 STEERINGNS

DISASSEMBLY AND ASSEMBLY (Continued)