CHRYSLER VOYAGER 1996 Service Manual

Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1491 of 1938

(2) To perform the dipstick tube fluid suction

method, use a suitable fluid suction device (Vaculay

or equivalent).

(3) Insert the fluid suction line into the dipstick

tube.

NOTE: Verify that the suction line is inserted to the

lowest point of the transaxle oil pan. This will

ensure complete evacuation of the fluid in the pan.

(4) Follow the manufacturers recommended proce-

dure and evacuate the fluid from the transaxle.

(5) Remove the suction line from the dipstick tube.

(6) Add 4 Quarts of Mopar ATF Plus 3 Type 7176

transaxle fluid.

(7) Start the engine and allow it to idle for a min-

imum of one minute. With the parking brake applied,

press your foot on the service brake and cycle the

transaxle from park to all gear positions ending in

neutral or park.

(8) Check the transaxle fluid level and add an

appropriate amount to bring the transaxle fluid level

to 3mm (1/8 in.) below the ADD mark on the dip-

stick.

(9) Recheck the fluid level after the transaxle is at

normal operating temperature. The level should be in

the HOT range.

TRANSAXLE OIL PAN DROP METHOD

This procedure involves removing the transaxle oil

pan to drain the transaxle fluid.

(1) Bring the vehicle up to normal operating tem-

perature. Drive the vehicle a minimum of 10 miles.

(2) Raise the vehicle on the hoist.

(3) Loosen the transaxle oil pan and drain the

fluid into a suitable container.

(4) Remove the pan and clean all sealant from the

pan and transaxle mating surfaces. Clean the mag-

net and the inside of the pan.

(5) Apply a 1/8 inch bead of Mopar RTV Sealant to

the mounting flange of the transaxle oil pan. Apply

RTV Sealant to the underside of the attaching bolts.

Attach the oil pan to the transaxle. Tighten the bolts

to 19 N²m (165 in. lbs.).

(6) Lower the vehicle and add 4 Quarts of Mopar

ATF Plus 3 Type 7176 transaxle fluid.

(7) Start the engine and allow it to idle for a min-

imum of one minute. With the parking brake applied,

press your foot on the service brake and cycle the

transaxle from park to all gear positions ending in

neutral or park.

(8) Check the transaxle fluid level and add an

appropriate amount to bring the transaxle fluid level

to 3mm (1/8 in.) below the ADD mark on the dip-

stick.

(9) Recheck the fluid level after the transaxle is at

normal operating temperature. The level should be inthe HOT range. Drive the vehicle a minimum of 10

miles.

(10) Raise the vehicle on the hoist.

(11) Check for leaks around the transaxle oil pan

sealing surfaces.

(12) Recheck the fluid level. The level should be in

the HOT range.

SEVERE USAGE SERVICE

If the vehicle exhibits any of the following symp-

toms, it is recommended that the transaxle oil and

filter be replaced.

²Transaxle oil discolored

²Transaxle oil has high mileage

²Oil feels grimy when rubbed between fingertips

²Poor shift quality

²Delayed gear engagement

²Vehicle shudder between shifts

TRANSAXLE OIL AND FILTER REPLACEMENT

This procedure involves changing the transaxle

fluid and filter, driving the vehicle for 10 miles and

changing the transaxle fluid a second time.

(1) Bring the vehicle up to normal operating tem-

perature. Drive the vehicle a minimum of 10 miles.

(2) Raise the vehicle on the hoist.

(3) Loosen the transaxle oil pan and drain the

fluid into a suitable container.

(4) Remove the pan and clean all sealant from the

pan and transaxle mating surfaces. Clean the mag-

net and the inside of the pan.

(5) Separate the filter and O-ring from the valve

body. Inspect the O-ring for cuts or improper instal-

lation. This could lead to delayed garage shifts.

(6) Install a new filter. Replace the O-ring as nec-

essary.

(7) Apply a 1/8 inch bead of Mopar RTV Sealant to

the mounting flange of the transaxle oil pan. Apply

RTV Sealant to the underside of the attaching bolts.

Attach the oil pan to the transaxle. Tighten the bolts

to 19 N²m (165 in. lbs.).

(8) Lower the vehicle and add 4 Quarts of Mopar

ATF Plus 3 Type 7176 transaxle fluid.

(9) Start the engine and allow it to idle for a min-

imum of one minute. With the parking brake applied,

press your foot on the service brake and cycle the

transaxle from park to all gear positions ending in

neutral or park.

(10) Check the transaxle fluid level and add an

appropriate amount to bring the transaxle fluid level

to 3mm (1/8 in.) below the ADD mark on the dip-

stick.

(11) Recheck the fluid level after the transaxle is

at normal operating temperature. The level should be

in the HOT range. Drive the vehicle a minimum of

10 miles.

(12) Raise the vehicle on the hoist.

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 17

SERVICE PROCEDURES (Continued)

Page 1492 of 1938

(13) Remove the pan and clean all sealant from

the pan and transaxle mating surfaces. Clean the

magnet and the inside of the pan.

(14) Separate the filter from the valve body to

allow additional fluid to drain from the transaxle.

Inspect the filter O-ring for any damage and replace

as necessary.

(15) After the transaxle has stopped draining,

reinstall the filter and O-ring.

(16) Apply a 1/8 inch bead of Mopar RTV Sealant

to the mounting flange of the transaxle oil pan.

Apply RTV Sealant to the underside of the attaching

bolts. Attach the oil pan to the transaxle. Tighten the

bolts to 19 N²m (165 in. lbs.).

(17) Lower the vehicle and add 4 Quarts of Mopar

ATF Plus 3 Type 7176 transaxle fluid.

(18) Start the engine and allow it to idle for a min-

imum of one minute. With the parking brake applied,

press your foot on the service brake and cycle the

transaxle from park to all gear positions ending in

neutral or park.

(19) Check the transaxle fluid level and add an

appropriate amount to bring the transaxle fluid level

to 3mm (1/8 in.) below the ADD mark on the dip-

stick.

(20) Recheck the fluid level after the transaxle is

at normal operating temperature. The level should be

in the HOT range.

FLUID DRAIN AND REFILL

(1) Raise vehicle on a hoist (See Group 0, Lubrica-

tion). Place a drain container with a large opening,

under transaxle oil pan.

(2) Loosen pan bolts and tap the pan at one corner

to break it loose allowing fluid to drain, then remove

the oil pan.

(3) Install a new filter and gasket on bottom of the

valve body and tighten retaining screws to 5 N´m (40

inch-pounds).

(4) Clean the oil pan and magnet. Reinstall pan

using new sealant. Tighten oil pan bolts to 19 N´m

(165 in. lbs.).

(5) Pour four quarts of Mopar ATF PLUS 3 (Auto-

matic Transmission Fluid) Type 7176 through the

dipstick opening.

(6) Start engine and allow to idle for at least one

minute. Then, with parking and service brakes

applied, move selector lever momentarily to each

position, ending in the park or neutral position.

(7) Add sufficient fluid to bring level to 1/8 inch

below the ADD mark.

(8) Recheck fluid level after transaxle is at normal

operating temperature. The level should be in the

HOT region.

ALUMINUM THREAD REPAIR

Damaged or worn threads in the aluminum transaxle

case and valve body can be repaired by the use of Heli-

Coils, or equivalent. This repair consists of drilling out

the worn-out damaged threads. Then tapping the hole

with a Heli-Coil tap, or equivalent, and installing a

Heli-Coil insert, or equivalent, into the hole. This

brings the hole back to its original thread size.

Heli-Coil, or equivalent, tools and inserts are readily

available from most automotive parts suppliers.

FLUSHING COOLERS AND TUBES

When a transaxle failure has contaminated the

fluid, the oil cooler(s) must be flushed. The cooler

bypass valve in the transaxle must be replaced also.

The torque converter must also be replaced with an

exchange unit. This will ensure that metal particles

or sludged oil are not later transferred back into the

reconditioned (or replaced) transaxle.

The recommended procedure for flushing the cool-

ers and tubes is to use Tool 6906A Cooler Flusher.

WARNING: WEAR PROTECTIVE EYEWEAR THAT

MEETS THE REQUIREMENTS OF OSHA AND ANSI

Z87.1±1968. WEAR STANDARD INDUSTRIAL RUB-

BER GLOVES.

KEEP LIGHTED CIGARETTES, SPARKS, FLAMES,

AND OTHER IGNITION SOURCES AWAY FROM THE

AREA TO PREVENT THE IGNITION OF COMBUSTI-

BLE LIQUIDS AND GASES. KEEP A CLASS (B) FIRE

EXTINGUISHER IN THE AREA WHERE THE

FLUSHER WILL BE USED.

KEEP THE AREA WELL VENTILATED.

DO NOT LET FLUSHING SOLVENT COME IN CON-

TACT WITH YOUR EYES OR SKIN: IF EYE CONTAM-

INATION OCCURS, FLUSH EYES WITH WATER FOR

15 TO 20 SECONDS. REMOVE CONTAMINATED

CLOTHING AND WASH AFFECTED SKIN WITH

SOAP AND WATER. SEEK MEDICAL ATTENTION.

COOLER FLUSH USING TOOL 6906A

(1) Remove cover plate filler plug on Tool 6906A.

Fill reservoir 1/2 to 3/4 full of fresh flushing solution.

Flushing solvents are petroleum based solutions gen-

erally used to clean automatic transmission compo-

nents.DO NOTuse solvents containing acids, water,

gasoline, or any other corrosive liquids.

(2) Reinstall filler plug on Tool 6906A.

(3) Verify pump power switch is turned OFF. Con-

nect red alligator clip to positive (+) battery post.

Connect black (-) alligator clip to a good ground.

(4) Disconnect the cooler lines at the transmission.

NOTE: When flushing transmission cooler and

lines, ALWAYS reverse flush.

21 - 18 TRANSAXLE AND POWER TRANSFER UNITNS

SERVICE PROCEDURES (Continued)

Page 1493 of 1938

(5) Connect the BLUE pressure line to the OUT-

LET (From) cooler line.

(6) Connect the CLEAR return line to the INLET

(To) cooler line

(7) Turn pump ON for two to three minutes to

flush cooler(s) and lines. Monitor pressure readings

and clear return lines. Pressure readings should sta-

bilize below 20 psi. for vehicles equipped with a sin-

gle cooler and 30 psi. for vehicles equipped with dual

coolers. If flow is intermittent or exceeds these pres-

sures, replace cooler.

(8) Turn pump OFF.

(9) Disconnect CLEAR suction line from reservoir

at cover plate. Disconnect CLEAR return line at

cover plate, and place it in a drain pan.

(10) Turn pump ON for 30 seconds to purge flush-

ing solution from cooler and lines. Turn pump OFF.

(11) Place CLEAR suction line into a one quart

container of Mopar ATF Plus 3ttype 7176 automatic

transmission fluid.

(12) Turn pump ON until all transmission fluid is

removed from the one quart container and lines. This

purges any residual cleaning solvent from the trans-

mission cooler and lines. Turn pump OFF.

(13) Disconnect alligator clips from battery. Recon-

nect flusher lines to cover plate, and remove flushing

adapters from cooler lines.

OIL PUMP VOLUME CHECK

After the new or repaired transmission has been

installed, fill to the proper level with MopartAT F

PLUS 3 (Type 7176) automatic transmission fluid.

The volume should be checked using the following

procedure:

(1) Disconnect theFrom coolerline at the trans-

mission and place a collecting container under the

disconnected line.

CAUTION: With the fluid set at the proper level,

fluid collection should not exceed (1) quart or inter-

nal damage to the transmission may occur.

(2) Run the engineat curb idle speed, with the

shift selector in neutral.

(3) If fluid flow is intermittent or it takes more

than 20 seconds to collect one quart of ATF PLUS 3,

disconnect theTo Coolerline at the transaxle.

(4) Refill the transaxle to proper level and recheck

pump volume.

(5) If flow is found to be within acceptable limits,

replace the cooler. Then fill transmission to the

proper level, using MopartATF PLUS 3 (Type 7176)

automatic transmission fluid.

(6) If fluid flow is still found to be inadequate,

check the line pressure using the Transaxle Hydrau-

lic Pressure Test procedure.

REMOVAL AND INSTALLATION

VEHICLE SPEED SENSOR PINION GEAR

When the sensor is removed for any reason, a

NEW O-ring must be installed on its outside diame-

ter.

REMOVAL

(1) Remove harness connector from sensor. Make

sure weatherseal stays on harness connector.

(2) Remove bolt securing the sensor in the exten-

sion housing.

(3) Carefully pull sensor and pinion gear assembly

out of extension housing.

(4) Remove pinion gear from sensor.

INSTALLATION

(1) To install, reverse the above procedure. Make

sure extension housing and sensor flange are clean

prior to installation. Always use a NEW sensor

O-ring.

(2) Tighten bolt to 7 N´m (60 in. lbs.). Tighten

speedometer cable to 4 N´m (35 in. lbs.).

PARK/NEUTRAL STARTING AND BACK-UP LAMP

SWITCH

TEST

The park/neutral starting switch is the center ter-

minal of the 3 terminal switch. It provides ground for

the starter solenoid circuit through the selector lever

in only Park and Neutral positions.

(1) To test switch, remove wiring connector from

switch and test for continuity between center pin of

switch and transaxle case. Continuity should exist

only when transaxle is in Park or Neutral.

(2) Check gearshift cable adjustment before replac-

ing a switch which tests bad.

REMOVAL

(1) Unscrew switch from transaxle case allowing

fluid to drain into a container. Move selector lever to

Park, then to Neutral position, and inspect to see the

switch operating lever fingers are centered in switch

opening.

INSTALLATION

(1) Screw the switch with a new seal into tran-

saxle case and tighten to 33 N´m (24 ft. lbs.). Retest

switch with the test lamp.

(2) Add fluid to transaxle to bring up to proper

level.

(3) The back-up lamp switch circuit is through the

two outside terminals of the 3 terminal switch.

(4) To test switch, remove wiring connector from

switch and test for continuity between the two out-

side pins.

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 19

SERVICE PROCEDURES (Continued)

Page 1494 of 1938

(5) Continuity should exist only with transaxle in

Reverse position.

(6) No continuity should exist from either pin to

the case.

TRANSAXLE AND TORQUE CONVERTER REMOVAL

NOTE: Transaxle removal does NOT require engine

removal.

The transaxle and torque converter must be

removed as an assembly; otherwise, the torque con-

verter drive plate, pump bushing, or oil seal may be

damaged. The drive plate will not support a load;

therefore, none of the weight of the transaxle should

be allowed to rest on the plate during removal.

REMOVAL

(1) Disconnect negative battery cable.

(2) Remove air cleaner and hoses.

(3) Disconnect throttle linkage and shift linkage

from transaxle.

(4) Unplug torque converter clutch connector,

located near the dipstick. Unplug the gear position

switch.

(5) Remove transaxle dipstick tube.

(6) Remove the transaxle cooler lines and plug.

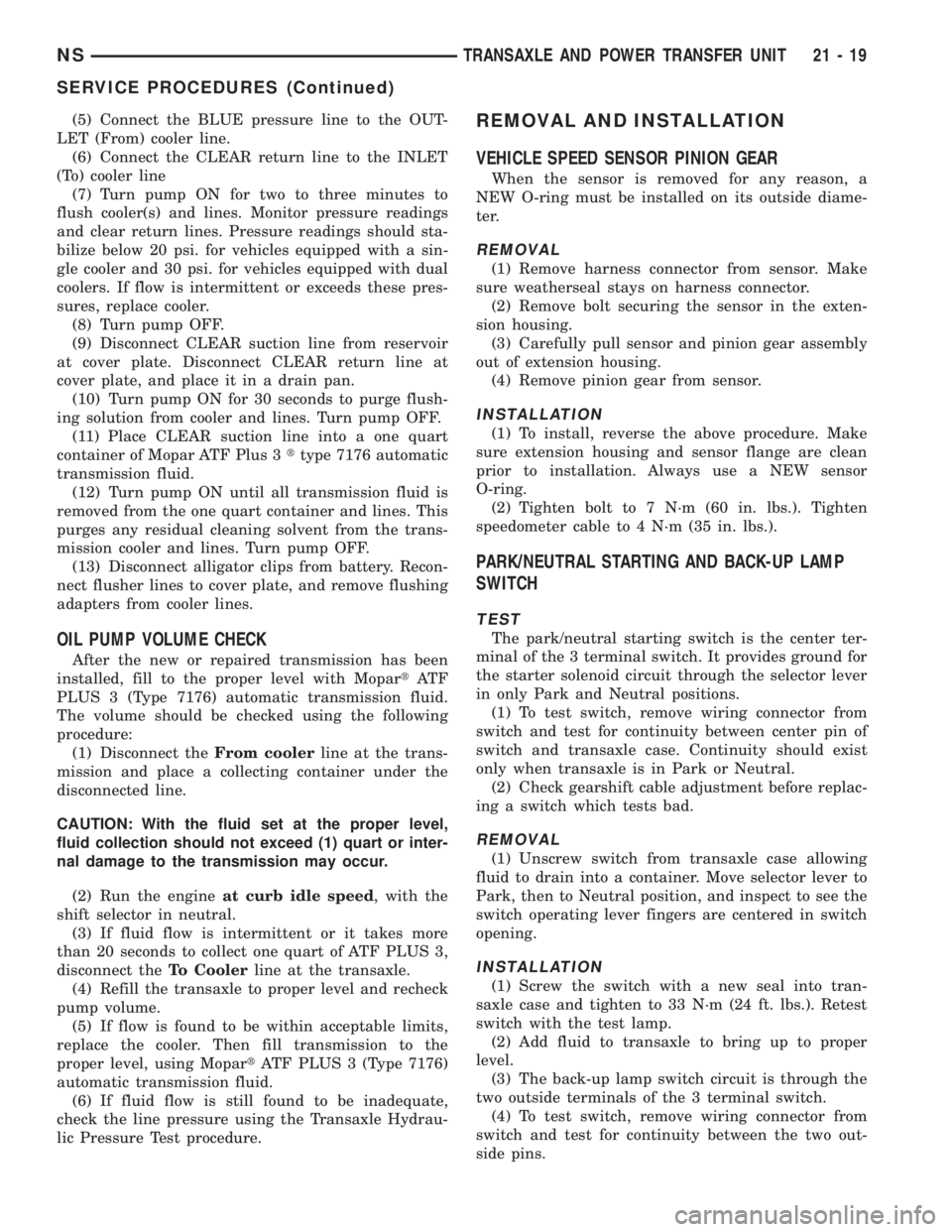

(7) Install engine support fixture (Fig. 5) .

(8) Remove bell housing upper bolts.

(9) Raise vehicle. Remove front wheels. Refer to

Group 2, Suspension to remove or install wheel hub

nut and both drive shafts.

CAUTION: The exhaust flex joint must be discon-

nected from the exhaust manifold anytime the

engine is lowered. If the engine is lowered while the

flex pipe is attached, damage will occur.(10) Remove bolts securing exhaust flex joint to

exhaust manifold. Disconnect exhaust pipe from

manifold.

(11) Remove torque converter dust cover. Mark

torque converter and drive plate with chalk, for reas-

sembly. Rotate engine clockwise and remove torque

converter mounting bolts.

(12) Remove engine mount bracket from front

crossmember.

(13) Remove front mount insulator through-bolt

and bellhousing bolts.

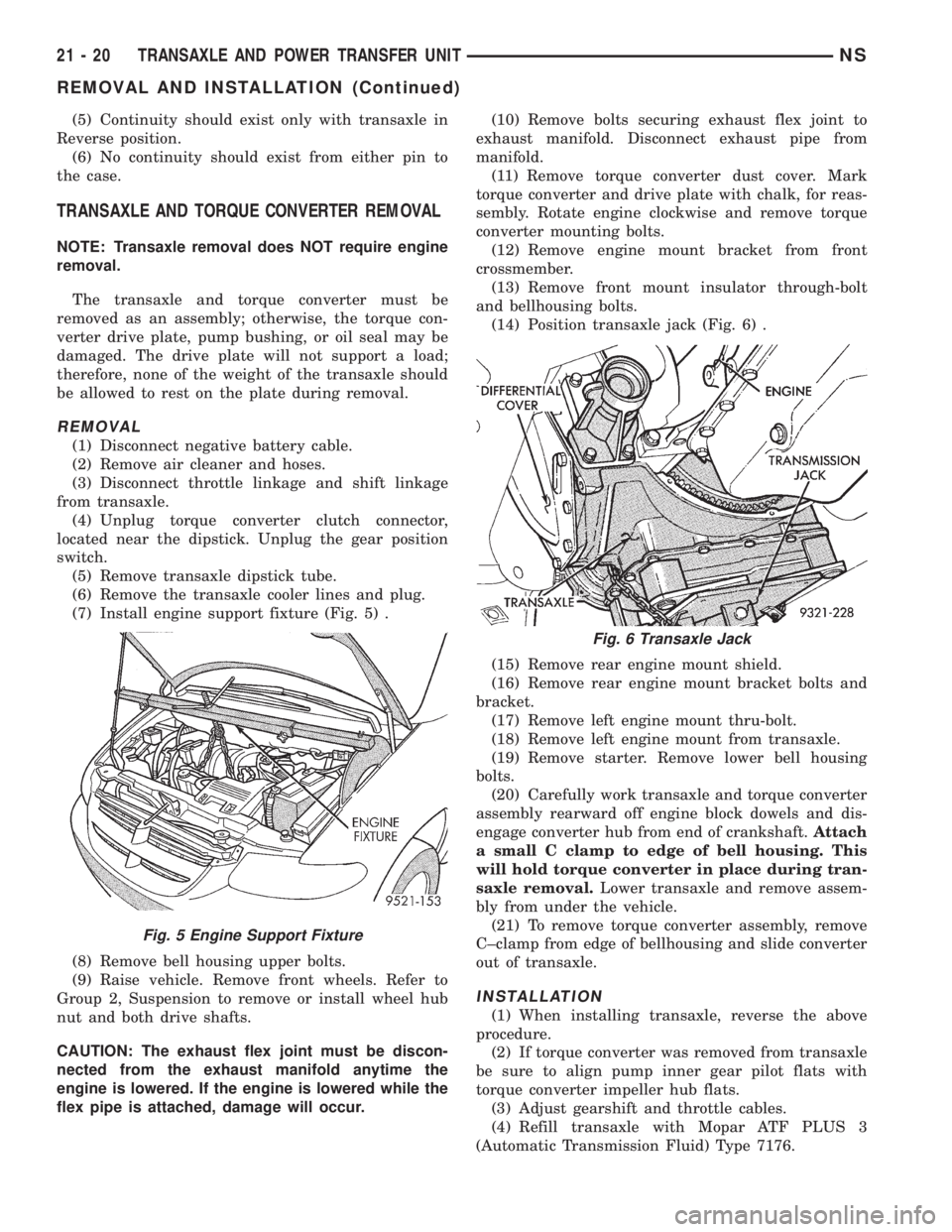

(14) Position transaxle jack (Fig. 6) .

(15) Remove rear engine mount shield.

(16) Remove rear engine mount bracket bolts and

bracket.

(17) Remove left engine mount thru-bolt.

(18) Remove left engine mount from transaxle.

(19) Remove starter. Remove lower bell housing

bolts.

(20) Carefully work transaxle and torque converter

assembly rearward off engine block dowels and dis-

engage converter hub from end of crankshaft.Attach

a small C clamp to edge of bell housing. This

will hold torque converter in place during tran-

saxle removal.Lower transaxle and remove assem-

bly from under the vehicle.

(21) To remove torque converter assembly, remove

C±clamp from edge of bellhousing and slide converter

out of transaxle.

INSTALLATION

(1) When installing transaxle, reverse the above

procedure.

(2) If torque converter was removed from transaxle

be sure to align pump inner gear pilot flats with

torque converter impeller hub flats.

(3) Adjust gearshift and throttle cables.

(4) Refill transaxle with Mopar ATF PLUS 3

(Automatic Transmission Fluid) Type 7176.

Fig. 5 Engine Support Fixture

Fig. 6 Transaxle Jack

21 - 20 TRANSAXLE AND POWER TRANSFER UNITNS

REMOVAL AND INSTALLATION (Continued)

Page 1495 of 1938

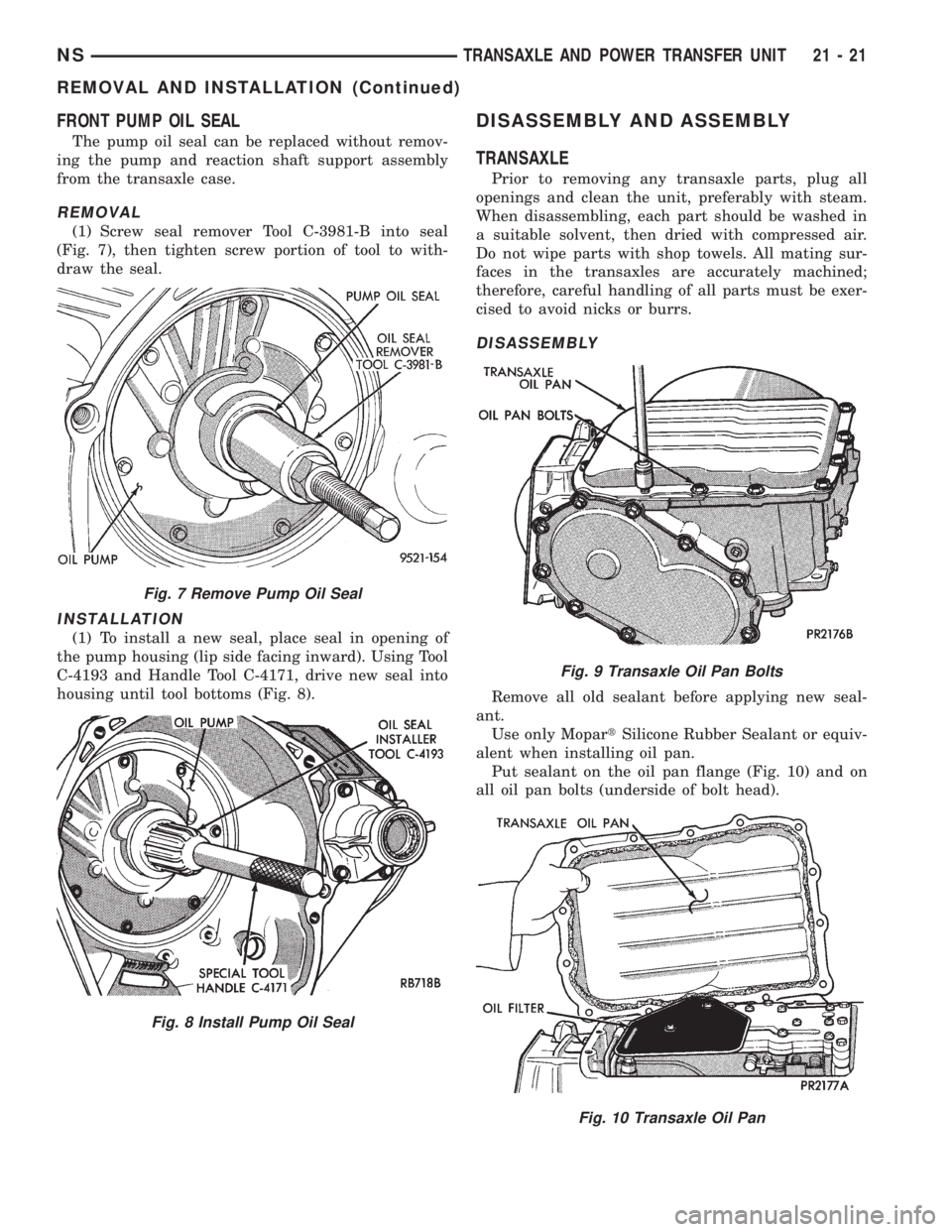

FRONT PUMP OIL SEAL

The pump oil seal can be replaced without remov-

ing the pump and reaction shaft support assembly

from the transaxle case.

REMOVAL

(1) Screw seal remover Tool C-3981-B into seal

(Fig. 7), then tighten screw portion of tool to with-

draw the seal.

INSTALLATION

(1) To install a new seal, place seal in opening of

the pump housing (lip side facing inward). Using Tool

C-4193 and Handle Tool C-4171, drive new seal into

housing until tool bottoms (Fig. 8).

DISASSEMBLY AND ASSEMBLY

TRANSAXLE

Prior to removing any transaxle parts, plug all

openings and clean the unit, preferably with steam.

When disassembling, each part should be washed in

a suitable solvent, then dried with compressed air.

Do not wipe parts with shop towels. All mating sur-

faces in the transaxles are accurately machined;

therefore, careful handling of all parts must be exer-

cised to avoid nicks or burrs.

DISASSEMBLY

Remove all old sealant before applying new seal-

ant.

Use only MopartSilicone Rubber Sealant or equiv-

alent when installing oil pan.

Put sealant on the oil pan flange (Fig. 10) and on

all oil pan bolts (underside of bolt head).

Fig. 7 Remove Pump Oil Seal

Fig. 8 Install Pump Oil Seal

Fig. 9 Transaxle Oil Pan Bolts

Fig. 10 Transaxle Oil Pan

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 21

REMOVAL AND INSTALLATION (Continued)

Page 1496 of 1938

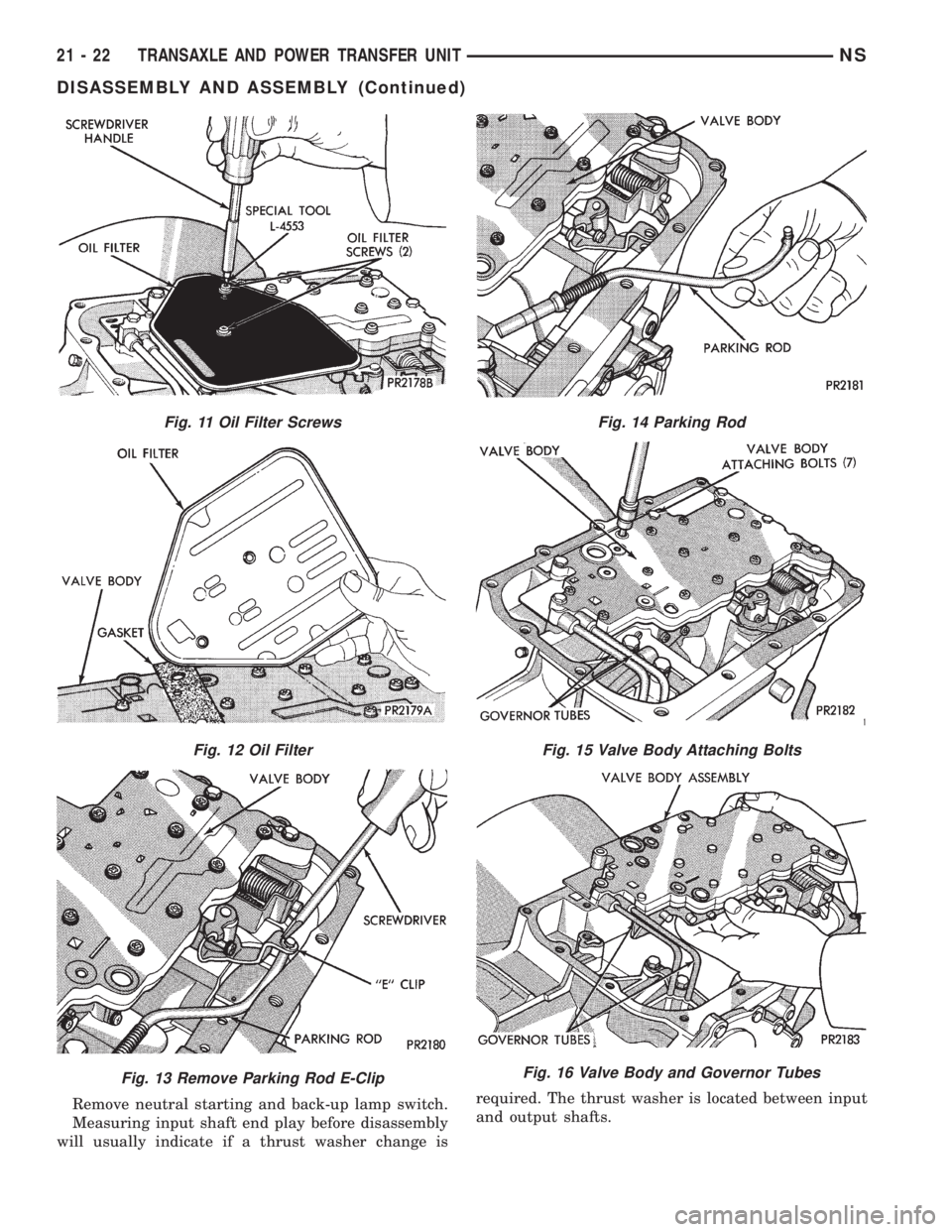

Remove neutral starting and back-up lamp switch.

Measuring input shaft end play before disassembly

will usually indicate if a thrust washer change isrequired. The thrust washer is located between input

and output shafts.

Fig. 11 Oil Filter Screws

Fig. 12 Oil Filter

Fig. 13 Remove Parking Rod E-Clip

Fig. 14 Parking Rod

Fig. 15 Valve Body Attaching Bolts

Fig. 16 Valve Body and Governor Tubes

21 - 22 TRANSAXLE AND POWER TRANSFER UNITNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1497 of 1938

Attach a dial indicator to transaxle bell housing

with its plunger seated against end of input shaft

(Fig. 17).

Move input shaft in and out to obtain end play

reading. End play specifications are 0.19 to 1.50 mm

(0.008 to 0.060 inch).

Record indicator reading for reference when reas-

sembling the transaxle.

Remove Number 6 thrust washer from sun

gear driving shell.

Fig. 17 Measure Input Shaft End Play

Fig. 18 Loosen Lock Nut and Tighten Kickdown

Band Adjusting Screw

Fig. 19 Pump Attaching Bolts

Fig. 20 Install Tool C-3752 with Adapters L-4437

Fig. 21 Oil Pump with No. 1 Thrust Washer

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 23

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1498 of 1938

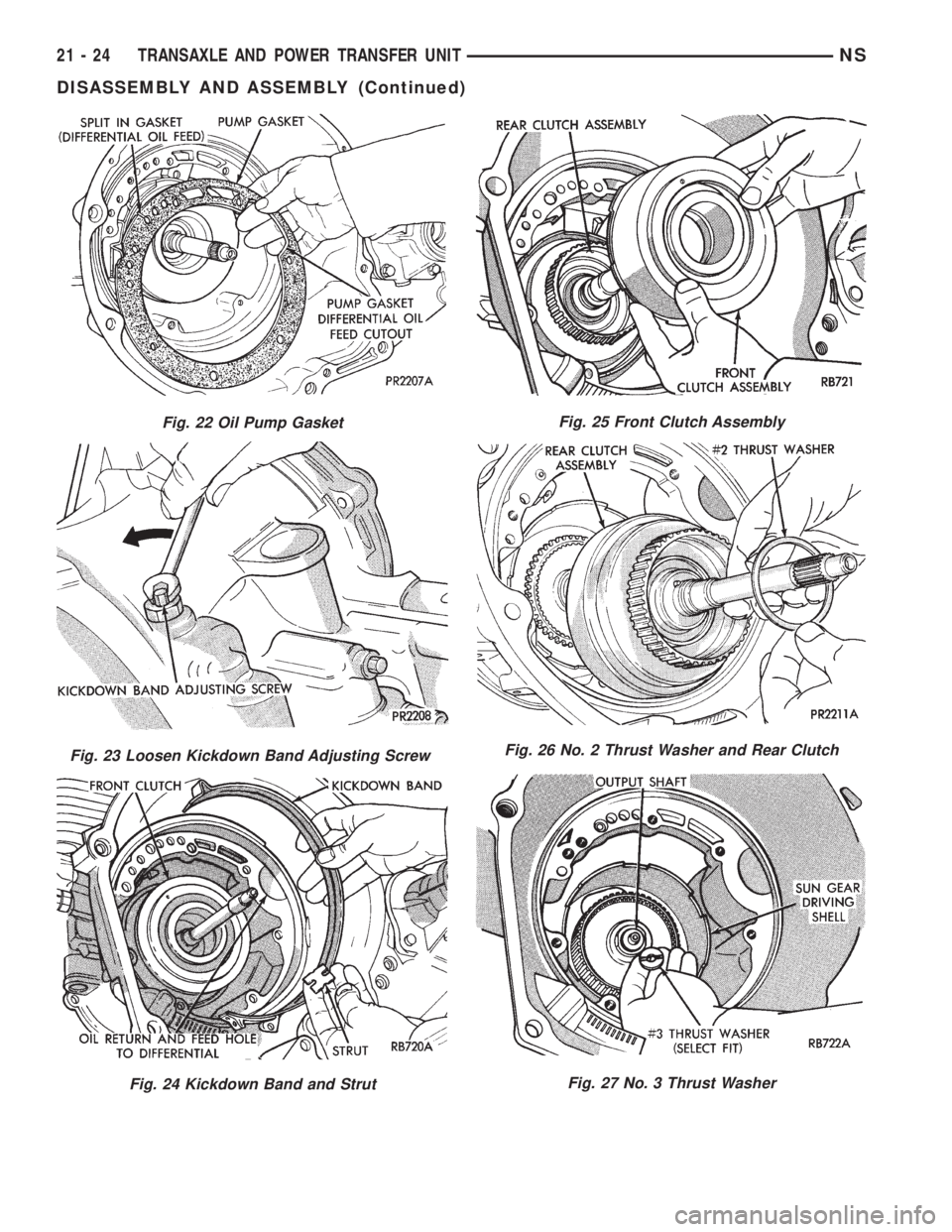

Fig. 22 Oil Pump Gasket

Fig. 23 Loosen Kickdown Band Adjusting Screw

Fig. 24 Kickdown Band and Strut

Fig. 25 Front Clutch Assembly

Fig. 26 No. 2 Thrust Washer and Rear Clutch

Fig. 27 No. 3 Thrust Washer

21 - 24 TRANSAXLE AND POWER TRANSFER UNITNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1499 of 1938

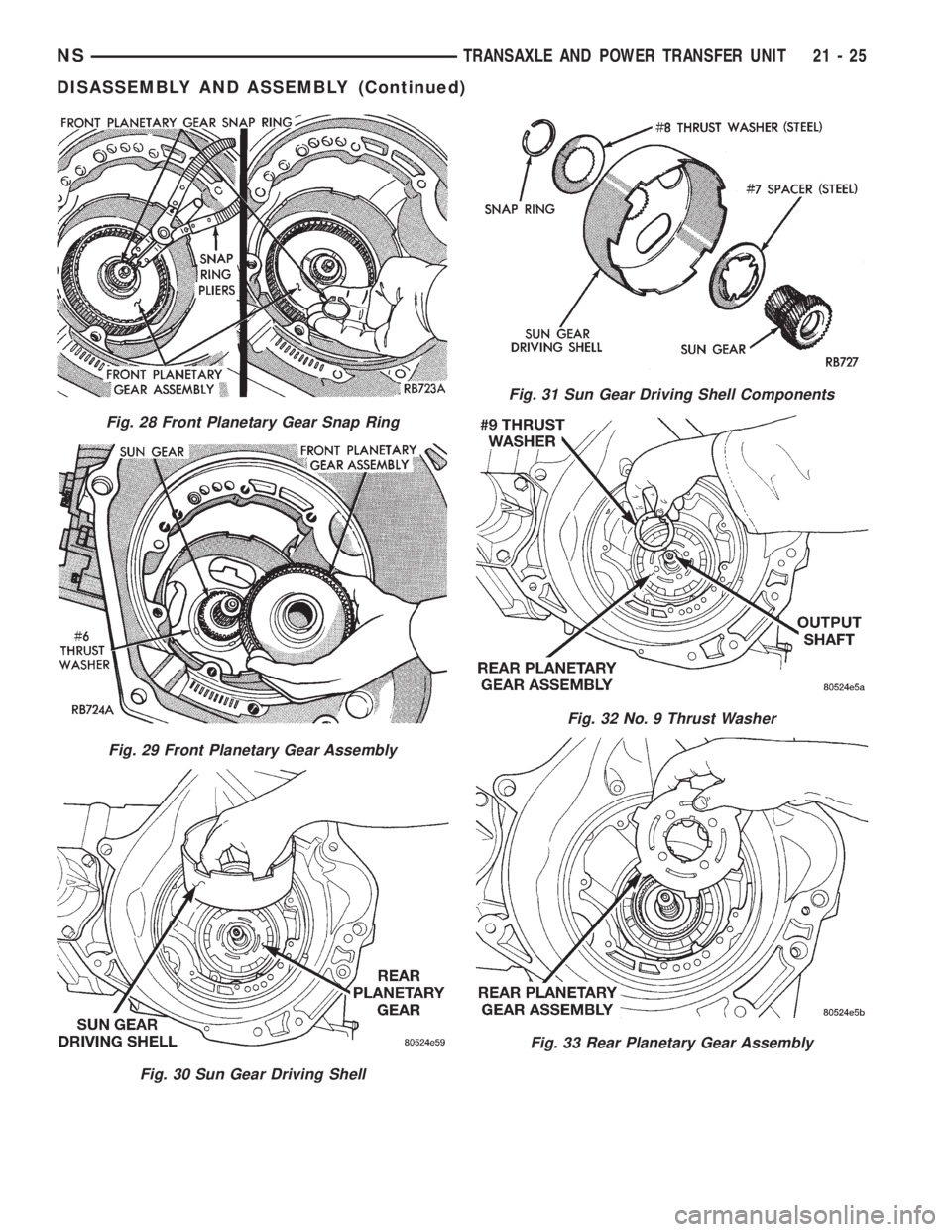

Fig. 28 Front Planetary Gear Snap Ring

Fig. 29 Front Planetary Gear Assembly

Fig. 30 Sun Gear Driving Shell

Fig. 31 Sun Gear Driving Shell Components

Fig. 32 No. 9 Thrust Washer

Fig. 33 Rear Planetary Gear Assembly

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 25

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1500 of 1938

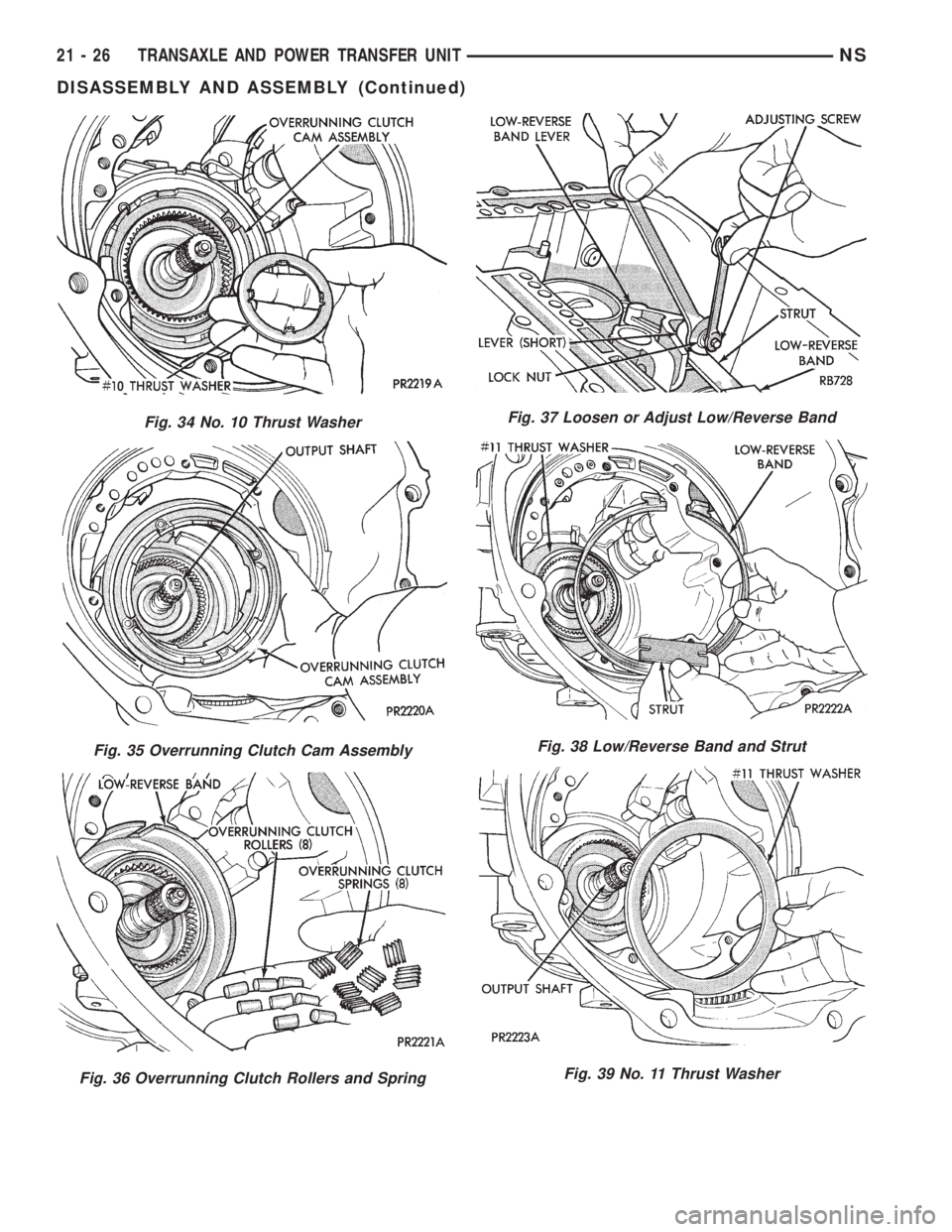

Fig. 34 No. 10 Thrust Washer

Fig. 35 Overrunning Clutch Cam Assembly

Fig. 36 Overrunning Clutch Rollers and Spring

Fig. 37 Loosen or Adjust Low/Reverse Band

Fig. 38 Low/Reverse Band and Strut

Fig. 39 No. 11 Thrust Washer

21 - 26 TRANSAXLE AND POWER TRANSFER UNITNS

DISASSEMBLY AND ASSEMBLY (Continued)