check engine CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1312 of 1938

INSTALLATION

(1) Position fuel tank on transmission jack. Con-

nect pressure relief/rollover valve hose. Connect fuel

filler tube vent hose and replace clamp.

(2) Raise tank into position and carefully work

filler tube into tank. A light coating of clean engine

oil on the tube end may be used to aid assembly.

(3) Feed filler vent line thru frame rail. Careful

not to cross lines.

(4) Tighten strap bolts to 54 N´m (40 ft. lbs.)

torque. Remove transmission jack.

(5) Tighten filler hose clamp to 3.3 N´m (30 in.

lbs.).

CAUTION: Ensure straps are not twisted or bent

before or after tightening strap nuts.

(6) Connect fuel pump/module electrical connector.

Place retainer in locked position.

(7) Lubricate the fuel supply line with clean 30

weight engine oil, install the quick connect fuel fit-

ting. Refer to Tube/Fitting Assembly in the Fuel

Delivery section of this Group.

(8) Attach filler line to filler tube. Pull on connec-

tor to make sure of connection.

(9) Fill fuel tank, replace cap, and connect battery

negative cable.

CAUTION: When using the ASD Fuel System Test,

the ASD relay and fuel pump relay remain energized

for 7 minutes or until the test is stopped, or until

the ignition switch is turned to the Off position.

(10) Use the DRB scan tool ASD Fuel System Test

to pressurize the fuel system. Check for leaks.

FUEL INJECTOR RAILÐ2.4L

REMOVAL

(1) Perform fuel system pressure release procedure

before servicing or starting repairs.Refer to

Fuel System Pressure Release Procedure in this sec-

tion.

(2) Disconnect negative cable from battery.

(3) Remove air cleaner inlet hose from throttle

body.

(4) Remove throttle cable and speed control cable

(if equipped) from throttle lever.

(5) Remove throttle cables from bracket by com-

pressing retaining tabs.

(6) Remove connector from throttle position sensor.

(7) Remove connector from idle air control motor.

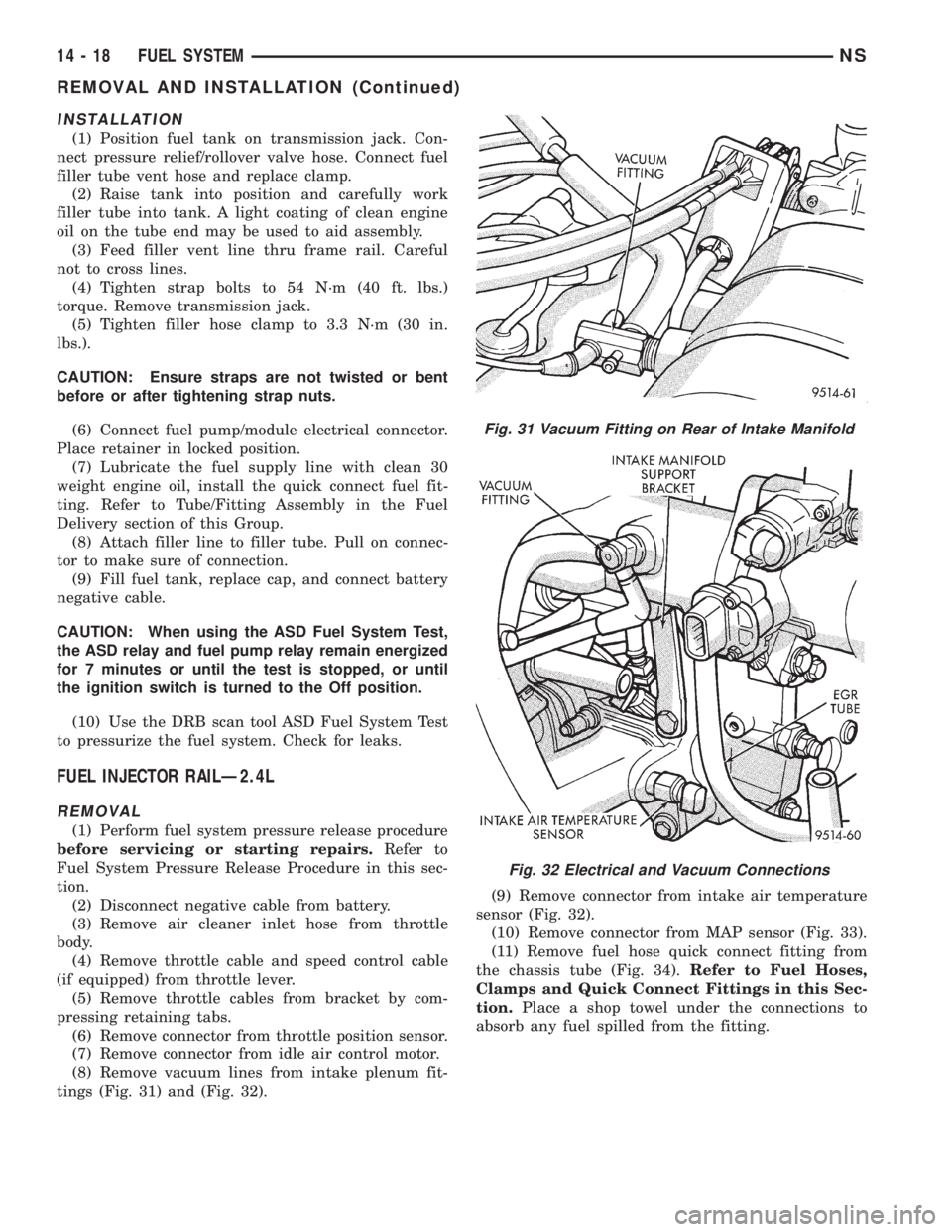

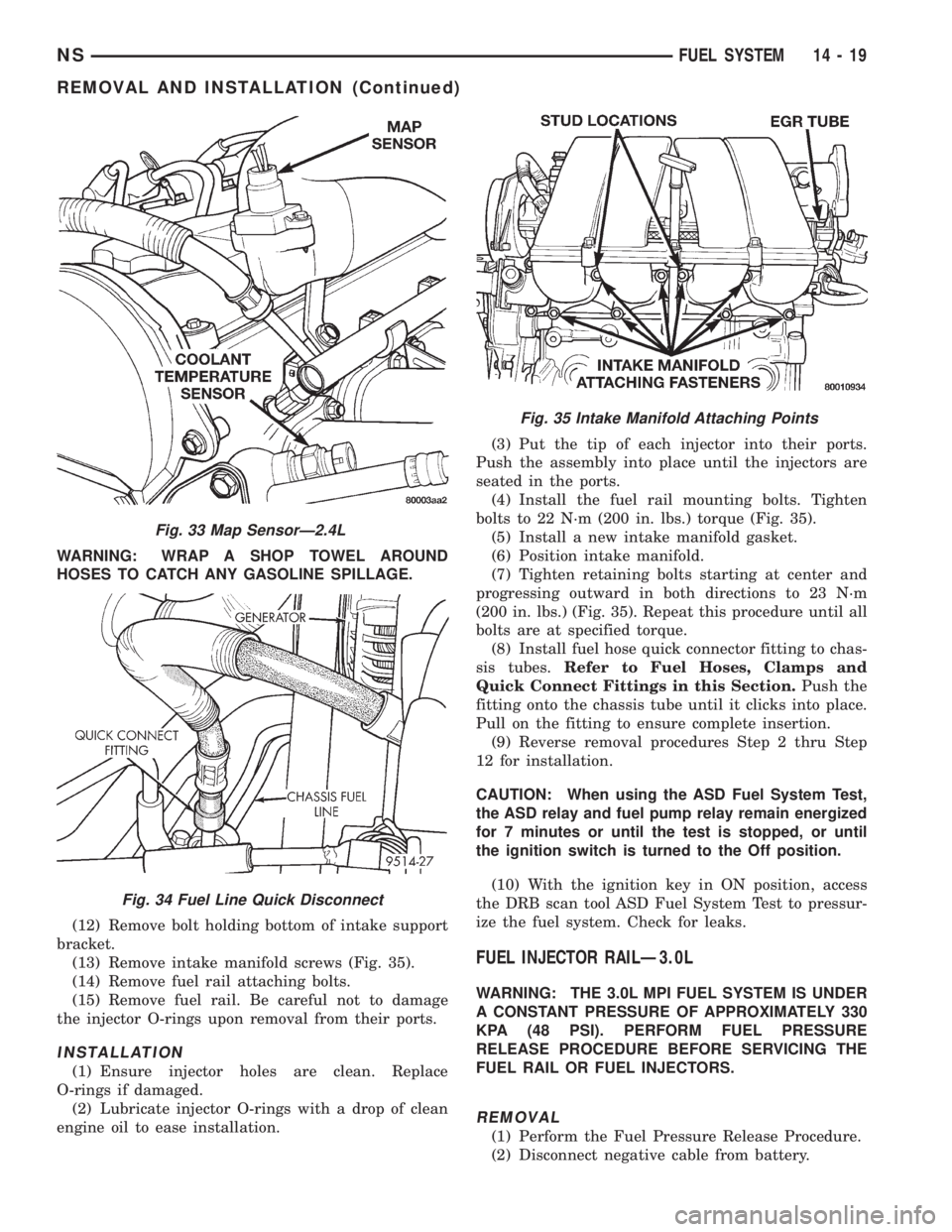

(8) Remove vacuum lines from intake plenum fit-

tings (Fig. 31) and (Fig. 32).(9) Remove connector from intake air temperature

sensor (Fig. 32).

(10) Remove connector from MAP sensor (Fig. 33).

(11) Remove fuel hose quick connect fitting from

the chassis tube (Fig. 34).Refer to Fuel Hoses,

Clamps and Quick Connect Fittings in this Sec-

tion.Place a shop towel under the connections to

absorb any fuel spilled from the fitting.

Fig. 31 Vacuum Fitting on Rear of Intake Manifold

Fig. 32 Electrical and Vacuum Connections

14 - 18 FUEL SYSTEMNS

REMOVAL AND INSTALLATION (Continued)

Page 1313 of 1938

WARNING: WRAP A SHOP TOWEL AROUND

HOSES TO CATCH ANY GASOLINE SPILLAGE.

(12) Remove bolt holding bottom of intake support

bracket.

(13) Remove intake manifold screws (Fig. 35).

(14) Remove fuel rail attaching bolts.

(15) Remove fuel rail. Be careful not to damage

the injector O-rings upon removal from their ports.

INSTALLATION

(1) Ensure injector holes are clean. Replace

O-rings if damaged.

(2) Lubricate injector O-rings with a drop of clean

engine oil to ease installation.(3) Put the tip of each injector into their ports.

Push the assembly into place until the injectors are

seated in the ports.

(4) Install the fuel rail mounting bolts. Tighten

bolts to 22 N´m (200 in. lbs.) torque (Fig. 35).

(5) Install a new intake manifold gasket.

(6) Position intake manifold.

(7) Tighten retaining bolts starting at center and

progressing outward in both directions to 23 N´m

(200 in. lbs.) (Fig. 35). Repeat this procedure until all

bolts are at specified torque.

(8) Install fuel hose quick connector fitting to chas-

sis tubes.Refer to Fuel Hoses, Clamps and

Quick Connect Fittings in this Section.Push the

fitting onto the chassis tube until it clicks into place.

Pull on the fitting to ensure complete insertion.

(9) Reverse removal procedures Step 2 thru Step

12 for installation.

CAUTION: When using the ASD Fuel System Test,

the ASD relay and fuel pump relay remain energized

for 7 minutes or until the test is stopped, or until

the ignition switch is turned to the Off position.

(10) With the ignition key in ON position, access

the DRB scan tool ASD Fuel System Test to pressur-

ize the fuel system. Check for leaks.

FUEL INJECTOR RAILÐ3.0L

WARNING: THE 3.0L MPI FUEL SYSTEM IS UNDER

A CONSTANT PRESSURE OF APPROXIMATELY 330

KPA (48 PSI). PERFORM FUEL PRESSURE

RELEASE PROCEDURE BEFORE SERVICING THE

FUEL RAIL OR FUEL INJECTORS.

REMOVAL

(1) Perform the Fuel Pressure Release Procedure.

(2) Disconnect negative cable from battery.

Fig. 33 Map SensorÐ2.4L

Fig. 34 Fuel Line Quick Disconnect

Fig. 35 Intake Manifold Attaching Points

NSFUEL SYSTEM 14 - 19

REMOVAL AND INSTALLATION (Continued)

Page 1315 of 1938

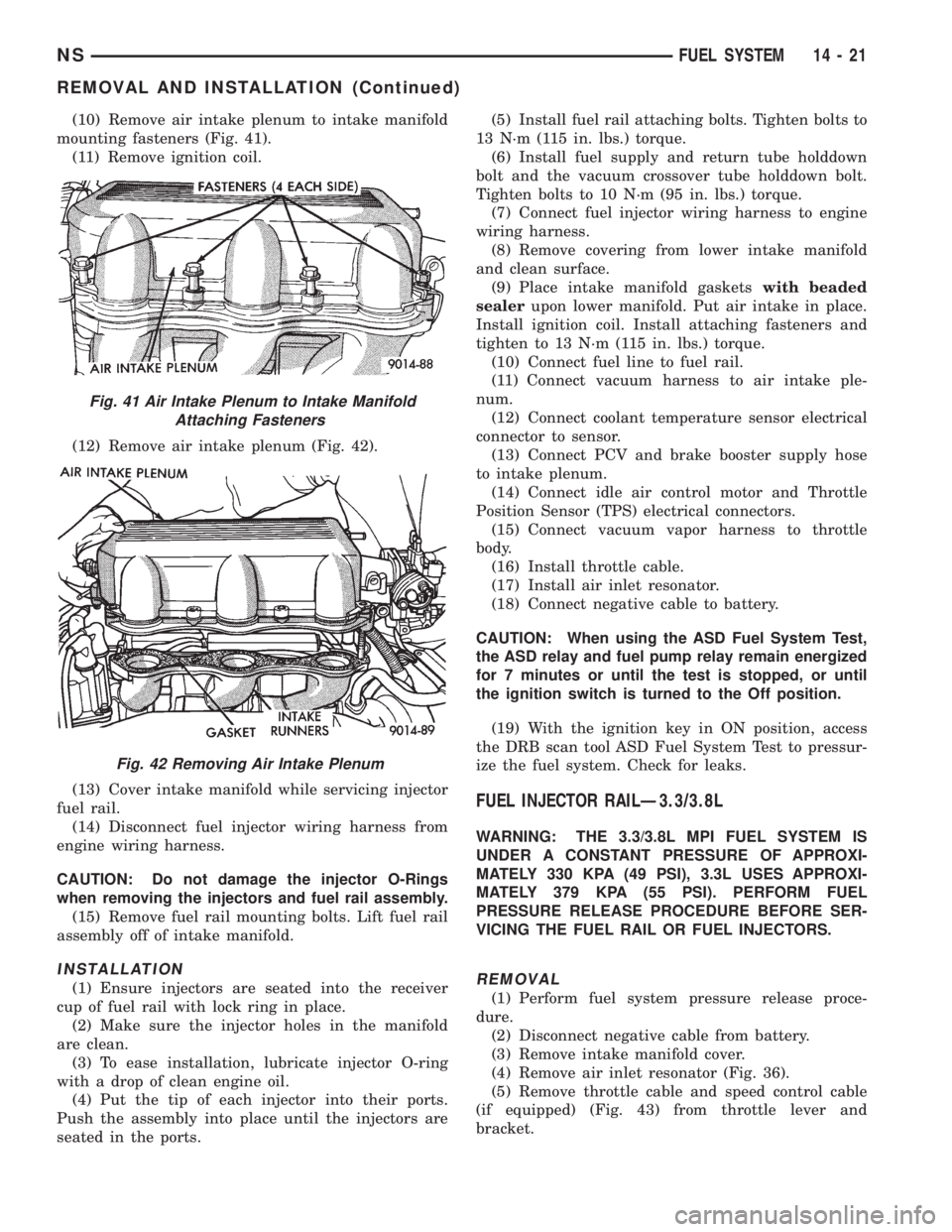

(10) Remove air intake plenum to intake manifold

mounting fasteners (Fig. 41).

(11) Remove ignition coil.

(12) Remove air intake plenum (Fig. 42).

(13) Cover intake manifold while servicing injector

fuel rail.

(14) Disconnect fuel injector wiring harness from

engine wiring harness.

CAUTION: Do not damage the injector O-Rings

when removing the injectors and fuel rail assembly.

(15) Remove fuel rail mounting bolts. Lift fuel rail

assembly off of intake manifold.

INSTALLATION

(1) Ensure injectors are seated into the receiver

cup of fuel rail with lock ring in place.

(2) Make sure the injector holes in the manifold

are clean.

(3) To ease installation, lubricate injector O-ring

with a drop of clean engine oil.

(4) Put the tip of each injector into their ports.

Push the assembly into place until the injectors are

seated in the ports.(5) Install fuel rail attaching bolts. Tighten bolts to

13 N´m (115 in. lbs.) torque.

(6) Install fuel supply and return tube holddown

bolt and the vacuum crossover tube holddown bolt.

Tighten bolts to 10 N´m (95 in. lbs.) torque.

(7) Connect fuel injector wiring harness to engine

wiring harness.

(8) Remove covering from lower intake manifold

and clean surface.

(9) Place intake manifold gasketswith beaded

sealerupon lower manifold. Put air intake in place.

Install ignition coil. Install attaching fasteners and

tighten to 13 N´m (115 in. lbs.) torque.

(10) Connect fuel line to fuel rail.

(11) Connect vacuum harness to air intake ple-

num.

(12) Connect coolant temperature sensor electrical

connector to sensor.

(13) Connect PCV and brake booster supply hose

to intake plenum.

(14) Connect idle air control motor and Throttle

Position Sensor (TPS) electrical connectors.

(15) Connect vacuum vapor harness to throttle

body.

(16) Install throttle cable.

(17) Install air inlet resonator.

(18) Connect negative cable to battery.

CAUTION: When using the ASD Fuel System Test,

the ASD relay and fuel pump relay remain energized

for 7 minutes or until the test is stopped, or until

the ignition switch is turned to the Off position.

(19) With the ignition key in ON position, access

the DRB scan tool ASD Fuel System Test to pressur-

ize the fuel system. Check for leaks.

FUEL INJECTOR RAILÐ3.3/3.8L

WARNING: THE 3.3/3.8L MPI FUEL SYSTEM IS

UNDER A CONSTANT PRESSURE OF APPROXI-

MATELY 330 KPA (49 PSI), 3.3L USES APPROXI-

MATELY 379 KPA (55 PSI). PERFORM FUEL

PRESSURE RELEASE PROCEDURE BEFORE SER-

VICING THE FUEL RAIL OR FUEL INJECTORS.

REMOVAL

(1) Perform fuel system pressure release proce-

dure.

(2) Disconnect negative cable from battery.

(3) Remove intake manifold cover.

(4) Remove air inlet resonator (Fig. 36).

(5) Remove throttle cable and speed control cable

(if equipped) (Fig. 43) from throttle lever and

bracket.

Fig. 41 Air Intake Plenum to Intake Manifold

Attaching Fasteners

Fig. 42 Removing Air Intake Plenum

NSFUEL SYSTEM 14 - 21

REMOVAL AND INSTALLATION (Continued)

Page 1318 of 1938

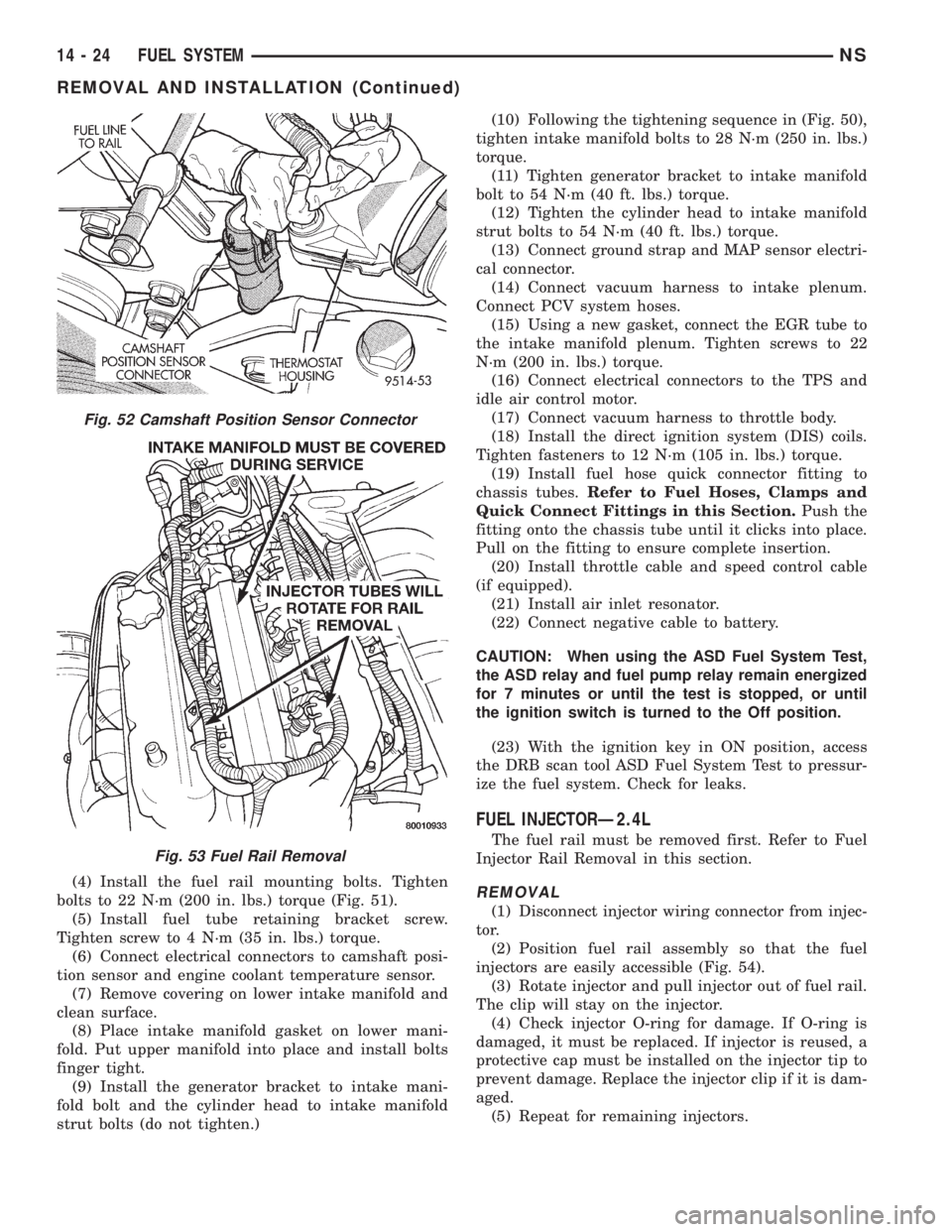

(4) Install the fuel rail mounting bolts. Tighten

bolts to 22 N´m (200 in. lbs.) torque (Fig. 51).

(5) Install fuel tube retaining bracket screw.

Tighten screw to 4 N´m (35 in. lbs.) torque.

(6) Connect electrical connectors to camshaft posi-

tion sensor and engine coolant temperature sensor.

(7) Remove covering on lower intake manifold and

clean surface.

(8) Place intake manifold gasket on lower mani-

fold. Put upper manifold into place and install bolts

finger tight.

(9) Install the generator bracket to intake mani-

fold bolt and the cylinder head to intake manifold

strut bolts (do not tighten.)(10) Following the tightening sequence in (Fig. 50),

tighten intake manifold bolts to 28 N´m (250 in. lbs.)

torque.

(11) Tighten generator bracket to intake manifold

bolt to 54 N´m (40 ft. lbs.) torque.

(12) Tighten the cylinder head to intake manifold

strut bolts to 54 N´m (40 ft. lbs.) torque.

(13) Connect ground strap and MAP sensor electri-

cal connector.

(14) Connect vacuum harness to intake plenum.

Connect PCV system hoses.

(15) Using a new gasket, connect the EGR tube to

the intake manifold plenum. Tighten screws to 22

N´m (200 in. lbs.) torque.

(16) Connect electrical connectors to the TPS and

idle air control motor.

(17) Connect vacuum harness to throttle body.

(18) Install the direct ignition system (DIS) coils.

Tighten fasteners to 12 N´m (105 in. lbs.) torque.

(19) Install fuel hose quick connector fitting to

chassis tubes.Refer to Fuel Hoses, Clamps and

Quick Connect Fittings in this Section.Push the

fitting onto the chassis tube until it clicks into place.

Pull on the fitting to ensure complete insertion.

(20) Install throttle cable and speed control cable

(if equipped).

(21) Install air inlet resonator.

(22) Connect negative cable to battery.

CAUTION: When using the ASD Fuel System Test,

the ASD relay and fuel pump relay remain energized

for 7 minutes or until the test is stopped, or until

the ignition switch is turned to the Off position.

(23) With the ignition key in ON position, access

the DRB scan tool ASD Fuel System Test to pressur-

ize the fuel system. Check for leaks.

FUEL INJECTORÐ2.4L

The fuel rail must be removed first. Refer to Fuel

Injector Rail Removal in this section.

REMOVAL

(1) Disconnect injector wiring connector from injec-

tor.

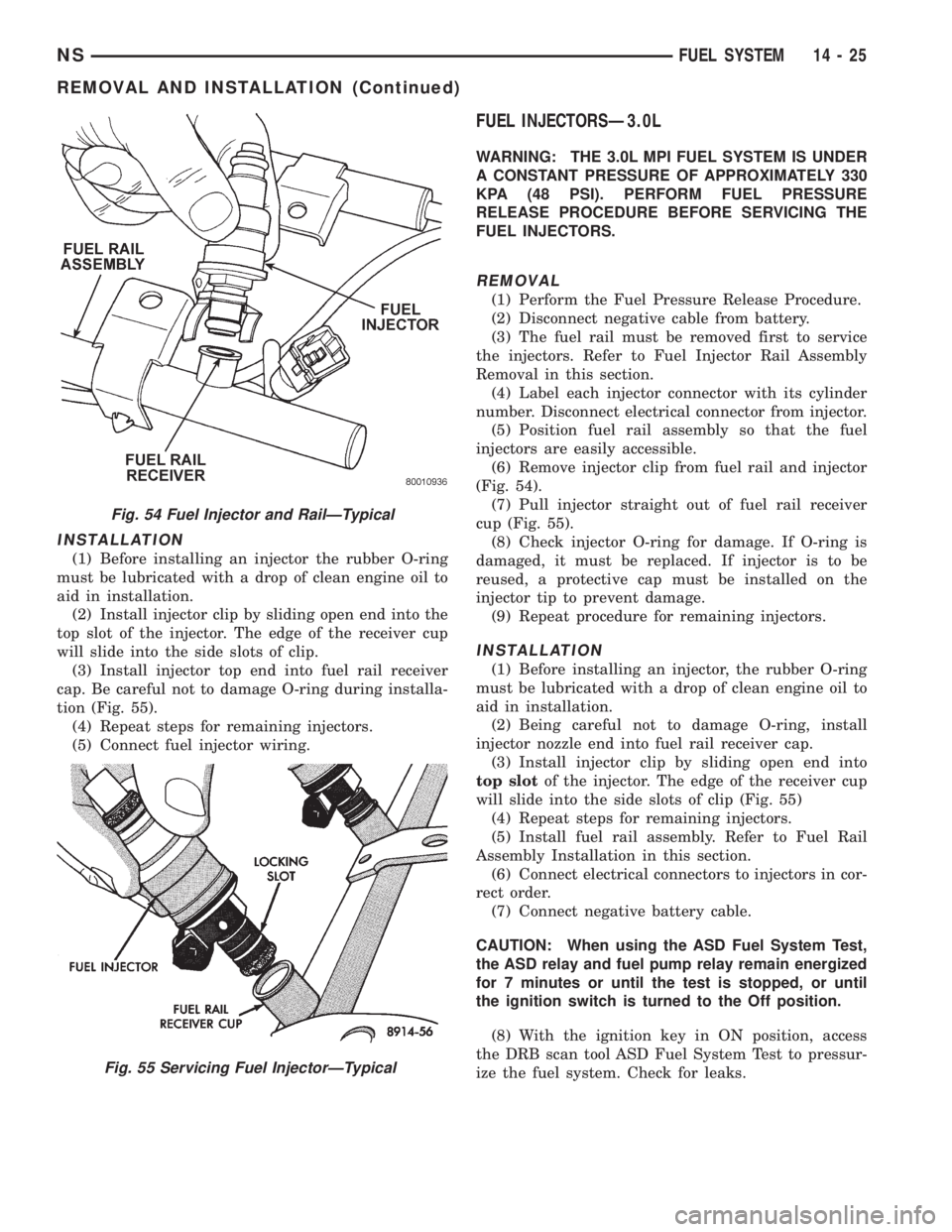

(2) Position fuel rail assembly so that the fuel

injectors are easily accessible (Fig. 54).

(3) Rotate injector and pull injector out of fuel rail.

The clip will stay on the injector.

(4) Check injector O-ring for damage. If O-ring is

damaged, it must be replaced. If injector is reused, a

protective cap must be installed on the injector tip to

prevent damage. Replace the injector clip if it is dam-

aged.

(5) Repeat for remaining injectors.

Fig. 52 Camshaft Position Sensor Connector

Fig. 53 Fuel Rail Removal

14 - 24 FUEL SYSTEMNS

REMOVAL AND INSTALLATION (Continued)

Page 1319 of 1938

INSTALLATION

(1) Before installing an injector the rubber O-ring

must be lubricated with a drop of clean engine oil to

aid in installation.

(2) Install injector clip by sliding open end into the

top slot of the injector. The edge of the receiver cup

will slide into the side slots of clip.

(3) Install injector top end into fuel rail receiver

cap. Be careful not to damage O-ring during installa-

tion (Fig. 55).

(4) Repeat steps for remaining injectors.

(5) Connect fuel injector wiring.

FUEL INJECTORSÐ3.0L

WARNING: THE 3.0L MPI FUEL SYSTEM IS UNDER

A CONSTANT PRESSURE OF APPROXIMATELY 330

KPA (48 PSI). PERFORM FUEL PRESSURE

RELEASE PROCEDURE BEFORE SERVICING THE

FUEL INJECTORS.

REMOVAL

(1) Perform the Fuel Pressure Release Procedure.

(2) Disconnect negative cable from battery.

(3) The fuel rail must be removed first to service

the injectors. Refer to Fuel Injector Rail Assembly

Removal in this section.

(4) Label each injector connector with its cylinder

number. Disconnect electrical connector from injector.

(5) Position fuel rail assembly so that the fuel

injectors are easily accessible.

(6) Remove injector clip from fuel rail and injector

(Fig. 54).

(7) Pull injector straight out of fuel rail receiver

cup (Fig. 55).

(8) Check injector O-ring for damage. If O-ring is

damaged, it must be replaced. If injector is to be

reused, a protective cap must be installed on the

injector tip to prevent damage.

(9) Repeat procedure for remaining injectors.

INSTALLATION

(1) Before installing an injector, the rubber O-ring

must be lubricated with a drop of clean engine oil to

aid in installation.

(2) Being careful not to damage O-ring, install

injector nozzle end into fuel rail receiver cap.

(3) Install injector clip by sliding open end into

top slotof the injector. The edge of the receiver cup

will slide into the side slots of clip (Fig. 55)

(4) Repeat steps for remaining injectors.

(5) Install fuel rail assembly. Refer to Fuel Rail

Assembly Installation in this section.

(6) Connect electrical connectors to injectors in cor-

rect order.

(7) Connect negative battery cable.

CAUTION: When using the ASD Fuel System Test,

the ASD relay and fuel pump relay remain energized

for 7 minutes or until the test is stopped, or until

the ignition switch is turned to the Off position.

(8) With the ignition key in ON position, access

the DRB scan tool ASD Fuel System Test to pressur-

ize the fuel system. Check for leaks.

Fig. 54 Fuel Injector and RailÐTypical

Fig. 55 Servicing Fuel InjectorÐTypical

NSFUEL SYSTEM 14 - 25

REMOVAL AND INSTALLATION (Continued)

Page 1320 of 1938

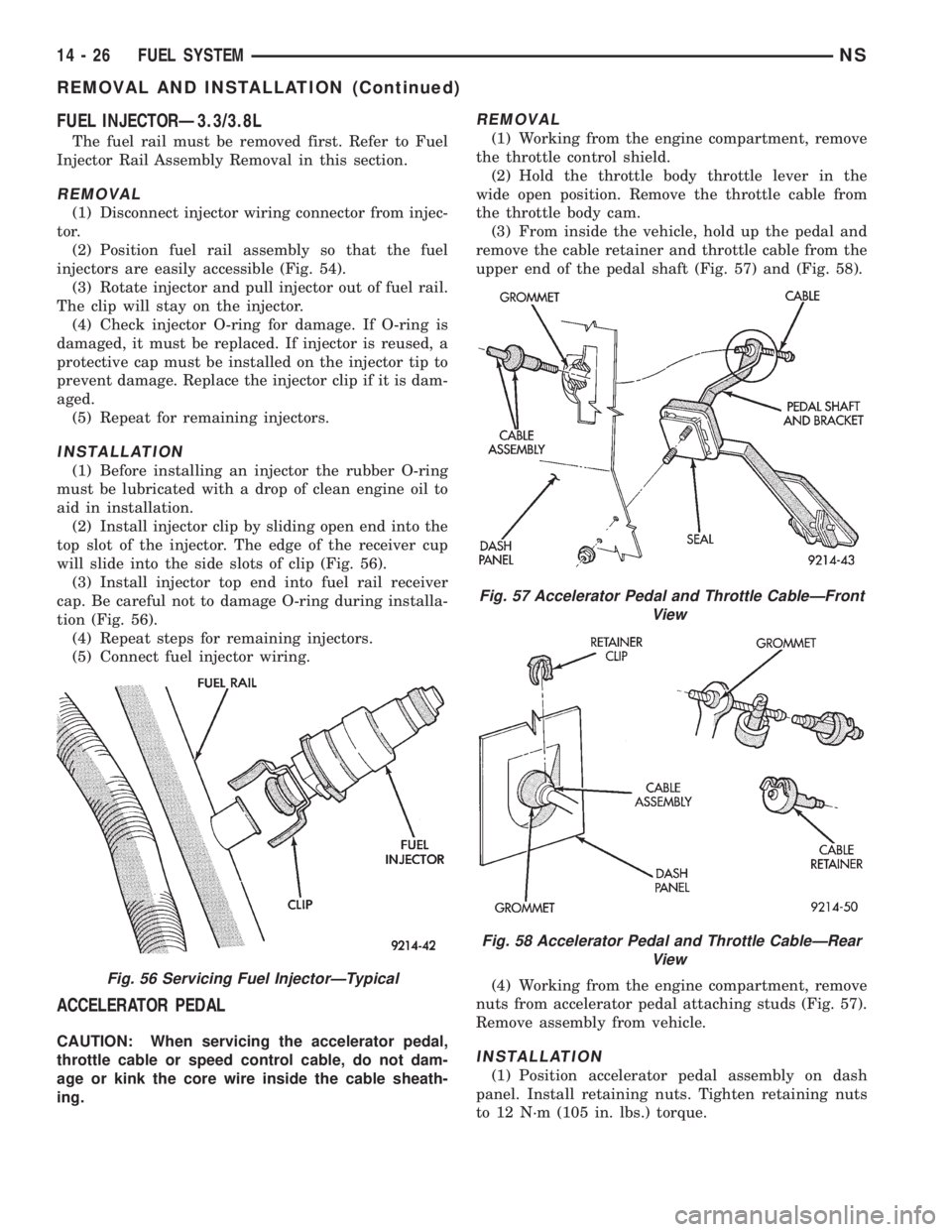

FUEL INJECTORÐ3.3/3.8L

The fuel rail must be removed first. Refer to Fuel

Injector Rail Assembly Removal in this section.

REMOVAL

(1) Disconnect injector wiring connector from injec-

tor.

(2) Position fuel rail assembly so that the fuel

injectors are easily accessible (Fig. 54).

(3) Rotate injector and pull injector out of fuel rail.

The clip will stay on the injector.

(4) Check injector O-ring for damage. If O-ring is

damaged, it must be replaced. If injector is reused, a

protective cap must be installed on the injector tip to

prevent damage. Replace the injector clip if it is dam-

aged.

(5) Repeat for remaining injectors.

INSTALLATION

(1) Before installing an injector the rubber O-ring

must be lubricated with a drop of clean engine oil to

aid in installation.

(2) Install injector clip by sliding open end into the

top slot of the injector. The edge of the receiver cup

will slide into the side slots of clip (Fig. 56).

(3) Install injector top end into fuel rail receiver

cap. Be careful not to damage O-ring during installa-

tion (Fig. 56).

(4) Repeat steps for remaining injectors.

(5) Connect fuel injector wiring.

ACCELERATOR PEDAL

CAUTION: When servicing the accelerator pedal,

throttle cable or speed control cable, do not dam-

age or kink the core wire inside the cable sheath-

ing.

REMOVAL

(1) Working from the engine compartment, remove

the throttle control shield.

(2) Hold the throttle body throttle lever in the

wide open position. Remove the throttle cable from

the throttle body cam.

(3) From inside the vehicle, hold up the pedal and

remove the cable retainer and throttle cable from the

upper end of the pedal shaft (Fig. 57) and (Fig. 58).

(4) Working from the engine compartment, remove

nuts from accelerator pedal attaching studs (Fig. 57).

Remove assembly from vehicle.

INSTALLATION

(1) Position accelerator pedal assembly on dash

panel. Install retaining nuts. Tighten retaining nuts

to 12 N´m (105 in. lbs.) torque.

Fig. 56 Servicing Fuel InjectorÐTypical

Fig. 57 Accelerator Pedal and Throttle CableÐFront

View

Fig. 58 Accelerator Pedal and Throttle CableÐRear

View

14 - 26 FUEL SYSTEMNS

REMOVAL AND INSTALLATION (Continued)

Page 1323 of 1938

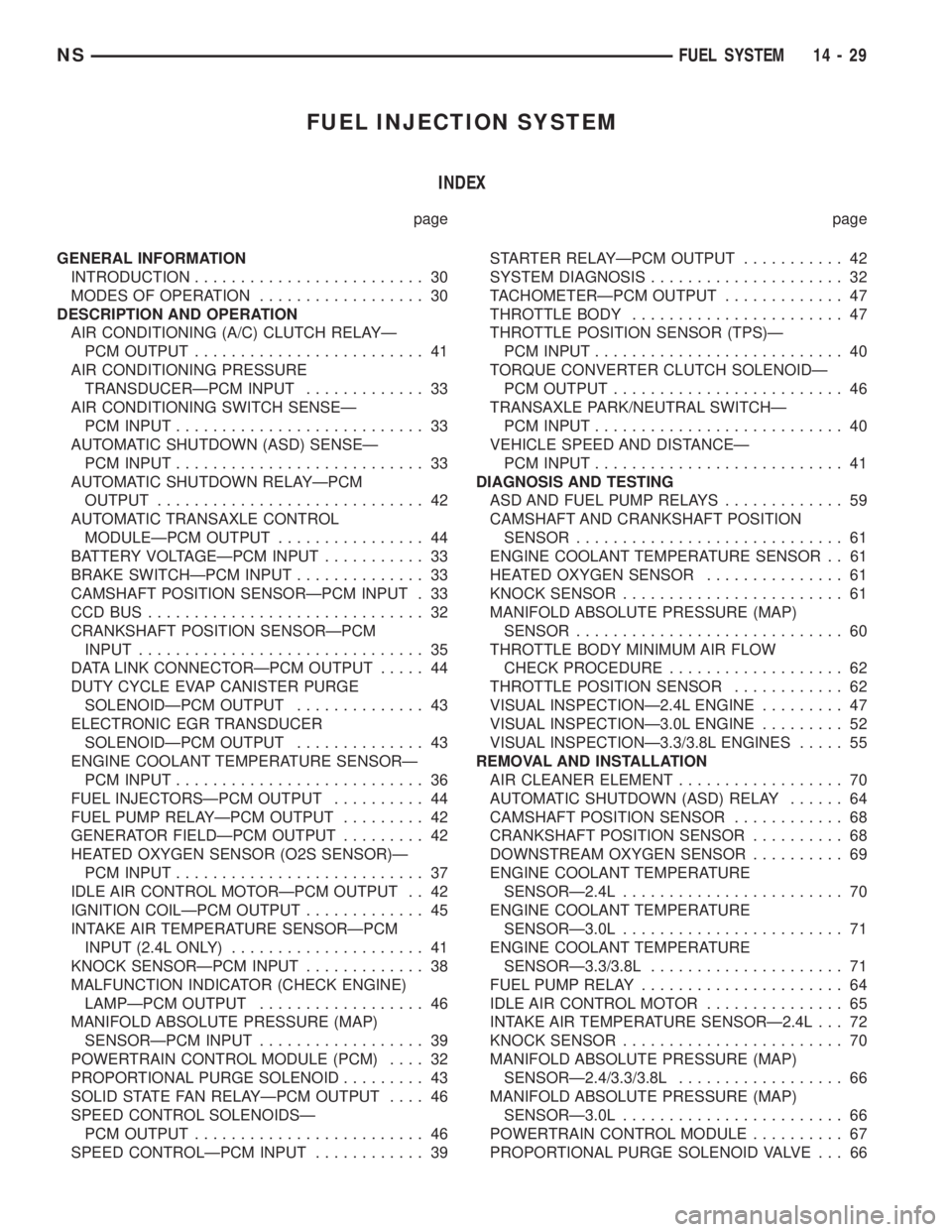

FUEL INJECTION SYSTEM

INDEX

page page

GENERAL INFORMATION

INTRODUCTION......................... 30

MODES OF OPERATION.................. 30

DESCRIPTION AND OPERATION

AIR CONDITIONING (A/C) CLUTCH RELAYÐ

PCM OUTPUT......................... 41

AIR CONDITIONING PRESSURE

TRANSDUCERÐPCM INPUT............. 33

AIR CONDITIONING SWITCH SENSEÐ

PCM INPUT........................... 33

AUTOMATIC SHUTDOWN (ASD) SENSEÐ

PCM INPUT........................... 33

AUTOMATIC SHUTDOWN RELAYÐPCM

OUTPUT............................. 42

AUTOMATIC TRANSAXLE CONTROL

MODULEÐPCM OUTPUT................ 44

BATTERY VOLTAGEÐPCM INPUT........... 33

BRAKE SWITCHÐPCM INPUT.............. 33

CAMSHAFT POSITION SENSORÐPCM INPUT . 33

CCDBUS .............................. 32

CRANKSHAFT POSITION SENSORÐPCM

INPUT............................... 35

DATA LINK CONNECTORÐPCM OUTPUT..... 44

DUTY CYCLE EVAP CANISTER PURGE

SOLENOIDÐPCM OUTPUT.............. 43

ELECTRONIC EGR TRANSDUCER

SOLENOIDÐPCM OUTPUT.............. 43

ENGINE COOLANT TEMPERATURE SENSORÐ

PCM INPUT........................... 36

FUEL INJECTORSÐPCM OUTPUT.......... 44

FUEL PUMP RELAYÐPCM OUTPUT......... 42

GENERATOR FIELDÐPCM OUTPUT......... 42

HEATED OXYGEN SENSOR (O2S SENSOR)Ð

PCM INPUT........................... 37

IDLE AIR CONTROL MOTORÐPCM OUTPUT . . 42

IGNITION COILÐPCM OUTPUT............. 45

INTAKE AIR TEMPERATURE SENSORÐPCM

INPUT (2.4L ONLY)..................... 41

KNOCK SENSORÐPCM INPUT............. 38

MALFUNCTION INDICATOR (CHECK ENGINE)

LAMPÐPCM OUTPUT.................. 46

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSORÐPCM INPUT.................. 39

POWERTRAIN CONTROL MODULE (PCM).... 32

PROPORTIONAL PURGE SOLENOID......... 43

SOLID STATE FAN RELAYÐPCM OUTPUT.... 46

SPEED CONTROL SOLENOIDSÐ

PCM OUTPUT......................... 46

SPEED CONTROLÐPCM INPUT............ 39STARTER RELAYÐPCM OUTPUT........... 42

SYSTEM DIAGNOSIS..................... 32

TACHOMETERÐPCM OUTPUT............. 47

THROTTLE BODY....................... 47

THROTTLE POSITION SENSOR (TPS)Ð

PCM INPUT........................... 40

TORQUE CONVERTER CLUTCH SOLENOIDÐ

PCM OUTPUT......................... 46

TRANSAXLE PARK/NEUTRAL SWITCHÐ

PCM INPUT........................... 40

VEHICLE SPEED AND DISTANCEÐ

PCM INPUT........................... 41

DIAGNOSIS AND TESTING

ASD AND FUEL PUMP RELAYS............. 59

CAMSHAFT AND CRANKSHAFT POSITION

SENSOR............................. 61

ENGINE COOLANT TEMPERATURE SENSOR . . 61

HEATED OXYGEN SENSOR............... 61

KNOCK SENSOR........................ 61

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSOR............................. 60

THROTTLE BODY MINIMUM AIR FLOW

CHECK PROCEDURE................... 62

THROTTLE POSITION SENSOR............ 62

VISUAL INSPECTIONÐ2.4L ENGINE......... 47

VISUAL INSPECTIONÐ3.0L ENGINE......... 52

VISUAL INSPECTIONÐ3.3/3.8L ENGINES..... 55

REMOVAL AND INSTALLATION

AIR CLEANER ELEMENT.................. 70

AUTOMATIC SHUTDOWN (ASD) RELAY...... 64

CAMSHAFT POSITION SENSOR............ 68

CRANKSHAFT POSITION SENSOR.......... 68

DOWNSTREAM OXYGEN SENSOR.......... 69

ENGINE COOLANT TEMPERATURE

SENSORÐ2.4L........................ 70

ENGINE COOLANT TEMPERATURE

SENSORÐ3.0L........................ 71

ENGINE COOLANT TEMPERATURE

SENSORÐ3.3/3.8L..................... 71

FUEL PUMP RELAY...................... 64

IDLE AIR CONTROL MOTOR............... 65

INTAKE AIR TEMPERATURE SENSORÐ2.4L . . . 72

KNOCK SENSOR........................ 70

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSORÐ2.4/3.3/3.8L.................. 66

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSORÐ3.0L........................ 66

POWERTRAIN CONTROL MODULE.......... 67

PROPORTIONAL PURGE SOLENOID VALVE . . . 66

NSFUEL SYSTEM 14 - 29

Page 1326 of 1938

IGNITION SWITCH OFF MODE

When the ignition switch is turned to the OFF

position, the following occurs:

²All outputs are turned off.

²No inputs are monitored.

²The PCM shuts down.

DESCRIPTION AND OPERATION

SYSTEM DIAGNOSIS

The PCM can test many of its own input and out-

put circuits. If the PCM senses a fault in a major

system, the PCM stores a Diagnostic Trouble Code

(DTC) in memory.

For DTC information, refer to Group 25, Emission

Control Systems. See On-Board Diagnostics.

CCD BUS

Various controllers and modules exchange informa-

tion through a communications port called the CCD

Bus. The PCM transmits the malfunction indicator

(check engine) lamp On/Off signal, engine RPM and

vehicle load information on the CCD Bus.

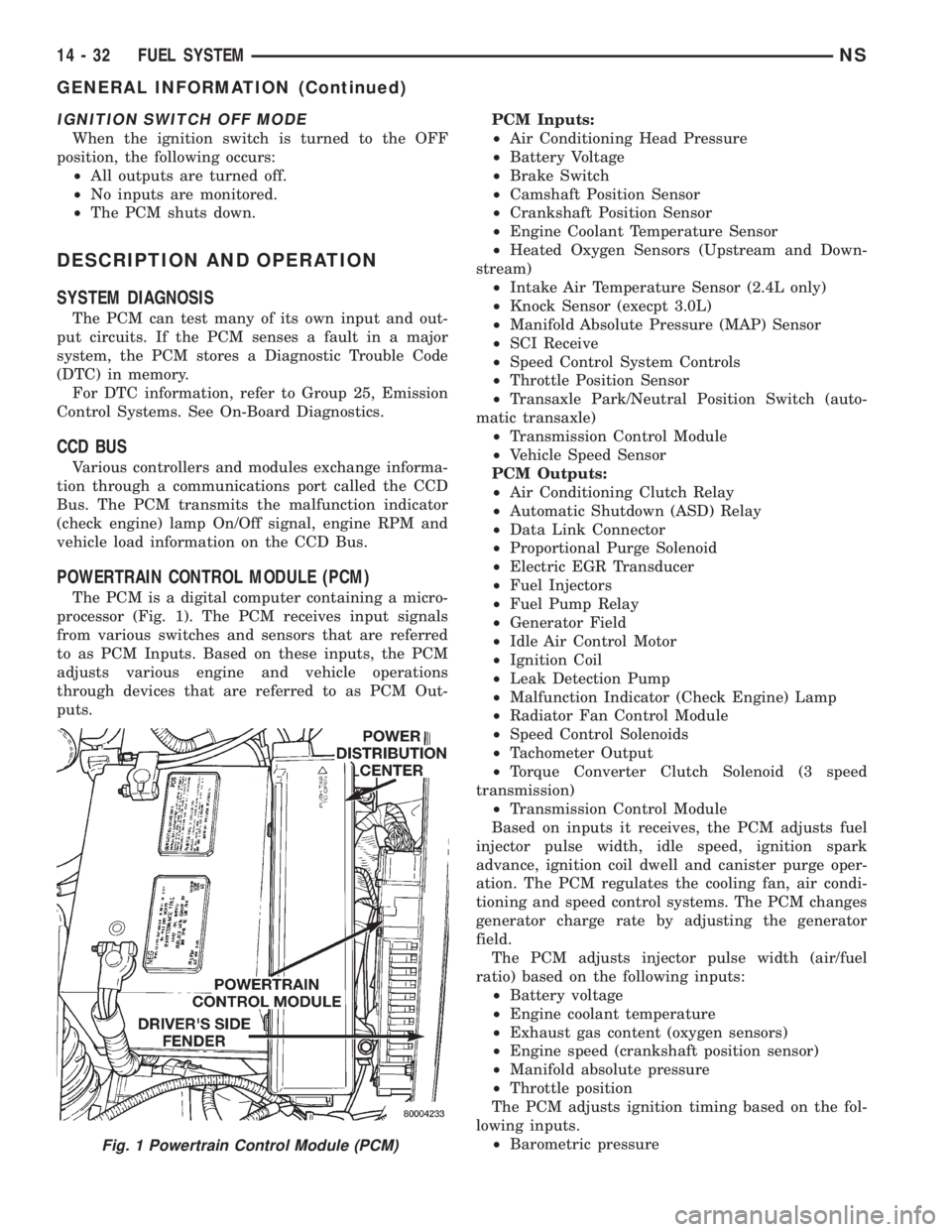

POWERTRAIN CONTROL MODULE (PCM)

The PCM is a digital computer containing a micro-

processor (Fig. 1). The PCM receives input signals

from various switches and sensors that are referred

to as PCM Inputs. Based on these inputs, the PCM

adjusts various engine and vehicle operations

through devices that are referred to as PCM Out-

puts.PCM Inputs:

²Air Conditioning Head Pressure

²Battery Voltage

²Brake Switch

²Camshaft Position Sensor

²Crankshaft Position Sensor

²Engine Coolant Temperature Sensor

²Heated Oxygen Sensors (Upstream and Down-

stream)

²Intake Air Temperature Sensor (2.4L only)

²Knock Sensor (execpt 3.0L)

²Manifold Absolute Pressure (MAP) Sensor

²SCI Receive

²Speed Control System Controls

²Throttle Position Sensor

²Transaxle Park/Neutral Position Switch (auto-

matic transaxle)

²Transmission Control Module

²Vehicle Speed Sensor

PCM Outputs:

²Air Conditioning Clutch Relay

²Automatic Shutdown (ASD) Relay

²Data Link Connector

²Proportional Purge Solenoid

²Electric EGR Transducer

²Fuel Injectors

²Fuel Pump Relay

²Generator Field

²Idle Air Control Motor

²Ignition Coil

²Leak Detection Pump

²Malfunction Indicator (Check Engine) Lamp

²Radiator Fan Control Module

²Speed Control Solenoids

²Tachometer Output

²Torque Converter Clutch Solenoid (3 speed

transmission)

²Transmission Control Module

Based on inputs it receives, the PCM adjusts fuel

injector pulse width, idle speed, ignition spark

advance, ignition coil dwell and canister purge oper-

ation. The PCM regulates the cooling fan, air condi-

tioning and speed control systems. The PCM changes

generator charge rate by adjusting the generator

field.

The PCM adjusts injector pulse width (air/fuel

ratio) based on the following inputs:

²Battery voltage

²Engine coolant temperature

²Exhaust gas content (oxygen sensors)

²Engine speed (crankshaft position sensor)

²Manifold absolute pressure

²Throttle position

The PCM adjusts ignition timing based on the fol-

lowing inputs.

²Barometric pressure

Fig. 1 Powertrain Control Module (PCM)

14 - 32 FUEL SYSTEMNS

GENERAL INFORMATION (Continued)

Page 1340 of 1938

Shutdown (ASD) RelayÐPCM Output in this section

for relay operation.

TORQUE CONVERTER CLUTCH SOLENOIDÐPCM

OUTPUT

Three-speed automatic transaxles use a torque con-

verter clutch solenoid. The PCM controls the engage-

ment of the torque converter clutch through the

solenoid. The torque converter clutch is engaged only

in direct drive mode. Refer to Group 21 for transaxle

information.

MALFUNCTION INDICATOR (CHECK ENGINE)

LAMPÐPCM OUTPUT

The PCM supplies the malfunction indicator (check

engine) lamp on/off signal to the instrument panel

through the CCD Bus. The CCD Bus is a communi-

cations port. Various modules use the CCD Bus to

exchange information.

The Check Engine lamp comes on each time the

ignition key is turned ON and stays on for 3 seconds

as a bulb test.

The Malfunction Indicator Lamp (MIL) stays on

continuously, when the PCM has entered a Limp-In

mode or identified a failed emission component. Dur-

ing Limp-in Mode, the PCM attempts to keep the

system operational. The MIL signals the need for

immediate service. In limp-in mode, the PCM com-

pensates for the failure of certain components that

send incorrect signals. The PCM substitutes for the

incorrect signals with inputs from other sensors.

If the PCM detects active engine misfire severe

enough to cause catalyst damage, it flashes the MIL.

At the same time the PCM also sets a Diagnostic

Trouble Code (DTC).

For signals that can trigger the MIL (Check

Engine Lamp) refer to Group 25, On-Board

Dianostics.

SOLID STATE FAN RELAYÐPCM OUTPUT

The radiator fan runs at a variable speed depend-

ing on coolant temperature and A/C system pressure.

The radiator fan circuit contains a Solid State Fan

Relay (SSFR). Refer to the Group 8W for a circuit

schematic.

A 5 volt signal is supplied to the SSFR. The PCM

provides a pulsed ground for the SSFR. Depending

upon the amount of pulse on time, the SSFR puts out

a proportional voltage to the fan motor at the lower

speed. For instance, if the on time is 30 percent, then

the voltage to the fan motor will be 3.6 volts.

When engine coolant reaches approximately 102ÉC

(215ÉF) the PCM grounds the SSFR relay. If engine

coolant reaches 207ÉC (225ÉF) the PCM grounds the

high speed ground relay and high speed fan relay. If

the fan operates at high speed, the PCM de-energizes

the high speed relay and high speed ground relay

when coolant temperature drops to approximately

101ÉC (214ÉF). When coolant temperature drops to

101ÉC (214ÉF) the fan operates at low speed. The

PCM de-energizes the low speed relay when coolant

temperature drops to approximately 93ÉC (199ÉF).

Also, when the air conditioning pressure switch

closes, the fan operates at high speed. The air condi-

tioning switch closes at 285 psi610 psi. When air

conditioning pressure drops approximately 40 psi, the

pressure switch opens and the fan operates at low

speed.

The SSFR relay is located on the left front inner

frame just behind the radiator (Fig. 42).

SPEED CONTROL SOLENOIDSÐPCM OUTPUT

The speed control vacuum and vent solenoids are

operated by the PCM. When the PCM supplies a

ground to the vacuum and vent solenoids, the speed

control system opens the throttle plate. When the

PCM removes the ground from the vacuum and vent

solenoids, the throttle blade closes. The PCM bal-

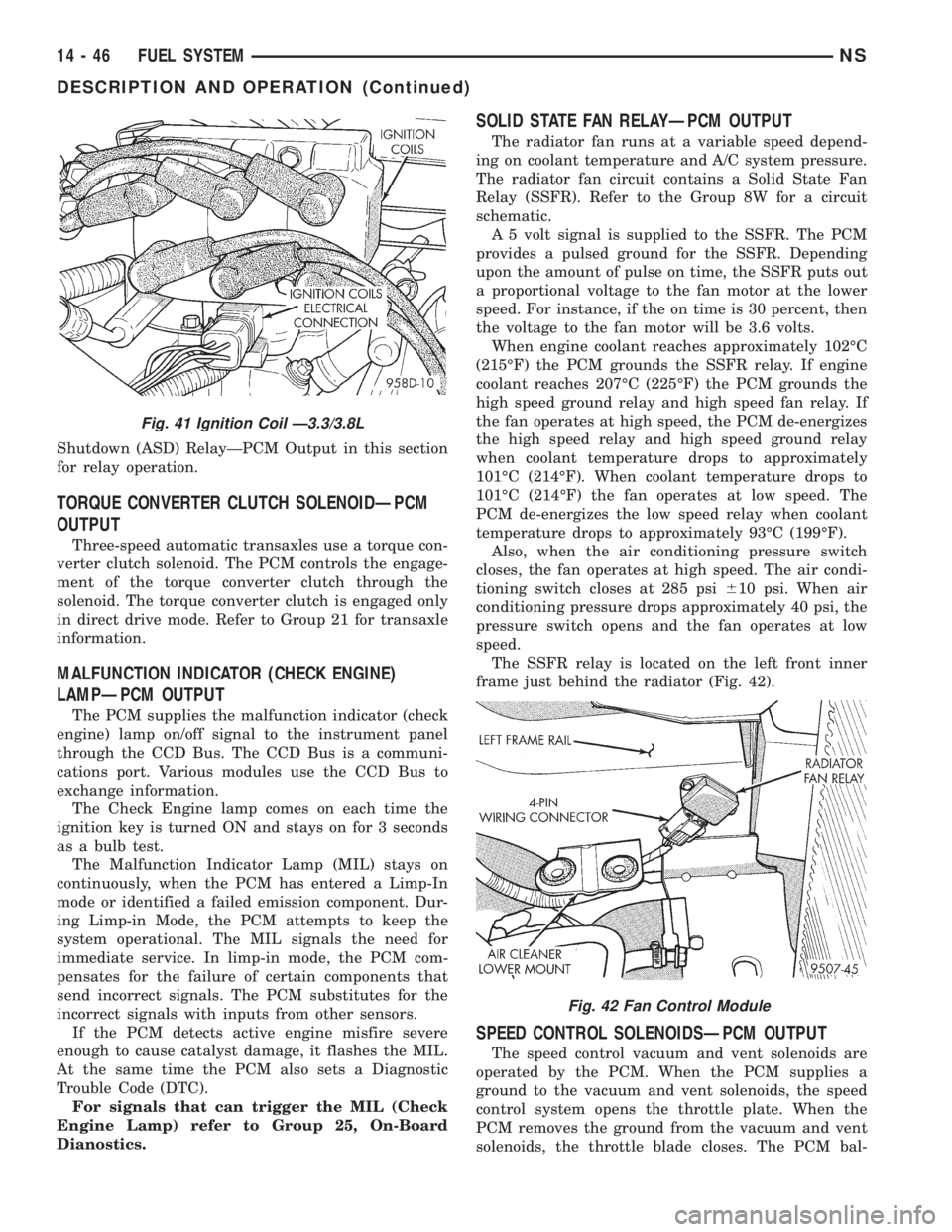

Fig. 41 Ignition Coil Ð3.3/3.8L

Fig. 42 Fan Control Module

14 - 46 FUEL SYSTEMNS

DESCRIPTION AND OPERATION (Continued)

Page 1341 of 1938

ances the two solenoids to maintain the set speed.

Refer to Group 8H for speed control information.

TACHOMETERÐPCM OUTPUT

The PCM supplies engine RPM to the instrument

panel tachometer through the CCD Bus. The CCD

Bus is a communications port. Various modules use

the CCD Bus to exchange information. Refer to

Group 8E for more information.

THROTTLE BODY

On all engine assemblies (2.4, 3.0, and 3.3/3.8L)

the throttle body's are located on the left side of the

intake manifold plenum. The throttle body houses

the throttle position sensor and the idle air control

motor. Air flow through the throttle body is con-

trolled by a cable operated throttle blade located in

the base of the throttle body (Fig. 43) or (Fig. 44) or

(Fig. 45).

DIAGNOSIS AND TESTING

VISUAL INSPECTIONÐ2.4L ENGINE

A visual inspection for loose, disconnected, or mis-

routed wires and hoses should be made before

attempting to diagnose or service the fuel injection

system. A visual check helps save unnecessary test

and diagnostic time. A thorough visual inspection will

include the following checks:

(1) Check ignition cable routing from the coil pack

to the spark plugs. Verify the cable are routed in the

correct order and are fully seated to the coil and

spark plug.

(2) Check direct ignition system (DIS) coil electri-

cal connection for damage and a complete connection

to the coil pack (Fig. 46).

Fig. 43 Throttle BodyÐ2.4L

Fig. 44 Throttle BodyÐ3.0L

NSFUEL SYSTEM 14 - 47

DESCRIPTION AND OPERATION (Continued)