torque CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1410 of 1938

(a) Remove the throttle body from engine.

(b) While holding the throttle open, spray the

entire throttle body bore and the manifold side of

the throttle plate with Mopar Parts Cleaner.Only

use Mopar Parts Cleaner to clean the throttle

body.

(c) Using a soft scuff pad, clean the top and bot-

tom of throttle body bore and the edges and mani-

fold side of the throttle blade.The edges of the

throttle blade and portions of the throttle

bore that are closest to the throttle blade

when closed, must be free of deposits.

(d) Use compressed air to dry the throttle body.

(e) Inspect throttle body for foreign material.

(f) Install throttle body on manifold.

(g) Repeat steps 1 through 14. If the minimum

air flow is still not within specifications, the prob-

lem is not caused by the throttle body.

(12) Shut off engine.

(13) Remove Air Metering Orifice 6457. Install

purge hose.

(14) Remove cap from PCV valve. Connect hose to

PCV valve.

(15) Remove DRB scan tool.SPECIFICATIONS

TORQUE

DESCRIPTION TORQUE

Air Cleaner Wingnut.........1.5N´m(15in.lbs.)

Air Cleaner Mount. Stud-To-Thrott. Body . . 10 N´m

(90 in. lbs.)

Crankshaft Position Sensor Mounting Bolts . . 8 N´m

(70 in. lbs.)

Engine Coolant Temperature Sensor......18N´m

(165 in. lbs.)

IAC Motor-To-Throttle Body Bolts.........7N´m

(60 in. lbs.)

MAP/IAT Sensor.............2N´m(20in.lbs.)

MAP/IAT Sensor.............3N´m(30in.lbs.)

Oxygen Sensor..............28N´m(20ft.lbs.)

Powertrain Control Module

(PCM) Mounting Screws.....4N´m(35in.lbs.)

Throttle Cable Cover........4.5N´m(40in.lbs.).

Throttle Body Mounting Bolts...........23N´m

(200 in. lbs.)

Throttle Position Sensor Mounting Screws . . . 2 N´m

(20 in. lbs.)

Vehicle Speed Sensor Mounting Bolt......2.2N´m

(20 in. lbs.)

14 - 42 FUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINENS/GS

DIAGNOSIS AND TESTING (Continued)

Page 1411 of 1938

FUEL INJECTION SYSTEMÐ2.5L DIESEL ENGINE

INDEX

page page

GENERAL INFORMATION

INTRODUCTION....................... 43

DESCRIPTION AND OPERATION

AIR CONDITIONING (A/C) CONTROLSÐ

PCM INPUTS........................ 47

AIR CONDITIONING RELAYÐPCM OUTPUT . . 48

BATTERY VOLTAGEÐPCM INPUT.......... 45

BOOST PRESSURE SENSOR............. 45

BRAKE SWITCHÐPCM INPUT............. 47

DATA LINK CONNECTORÐ

PCM INPUT AND OUTPUT.............. 47

DIESEL PCM RELAYÐPCM INPUT......... 48

ENGINE COOLANT GAUGEÐPCM OUTPUT . . 48

ENGINE COOLANT TEMPERATURE SENSORÐ

PCM INPUT......................... 46

ENGINE OIL PRESSURE GAUGEÐ

PCM OUTPUT........................ 48

ENGINE SPEED SENSORÐPCM INPUT..... 46

EXHAUST GAS RECIRCULATION (EGR)

SOLENOIDÐPCM OUTPUT............. 50

FIVE VOLT POWERÐPCM OUTPUT........ 48

FUEL INJECTOR SENSORÐGROUND...... 46

FUEL TIMING SOLENOIDÐPCM OUTPUT.... 48

GLOW PLUG LAMPÐPCM OUTPUT........ 48

GLOW PLUG RELAYÐPCM OUTPUT....... 49

GLOW PLUGS......................... 49

IGNITION CIRCUIT SENSEÐPCM INPUT.... 45

NEEDLE MOVEMENT OR INSTRUMENTED

FIRST INJECTORÐPCM INPUT.......... 45

POWER GROUND...................... 45

POWERTRAIN CONTROL MODULE (PCM) . . . 44

SENSOR RETURNÐPCM INPUT (ANALOG

GROUND)........................... 45SIGNAL GROUNDÐPCM INPUT........... 45

SPEED CONTROLÐPCM INPUTS.......... 48

SPEED CONTROLÐPCM OUTPUTS........ 48

START SIGNALÐPCM INPUT............. 45

TACHOMETERÐPCM OUTPUT............ 49

VEHICLE SPEED SENSORÐPCM INPUT.... 47

VEHICLE THEFT ALARM................. 45

DIAGNOSIS AND TESTING

BOOST PRESSURE SENSOR............. 53

DIAGNOSTIC TROUBLE CODES........... 53

DIESEL DIAGNOSTICS.................. 50

DIESEL PCM RELAY TEST............... 50

ENGINE COOLANT TEMPERATURE

SENSOR TEST....................... 50

ENGINE SPEED SENSOR TEST........... 50

GLOW PLUG RELAY TEST............... 51

GLOW PLUG TEST..................... 51

RELAYSÐOPERATION/TESTING........... 52

VEHICLE SPEED SENSOR TEST........... 53

REMOVAL AND INSTALLATION

A/C CLUTCH RELAY.................... 53

DIESEL PCM RELAY.................... 53

ENGINE COOLANT TEMPERATURE

SENSOR............................ 54

ENGINE SPEED SENSOR................ 53

GLOW PLUG RELAY.................... 55

GLOW PLUGS......................... 54

POWERTRAIN CONTROL MODULE (PCM) . . . 55

VEHICLE SPEED SENSOR............... 55

SPECIFICATIONS

GLOW PLUG CURRENT DRAW............ 56

TORQUE CHARTÐ2.5L DIESEL............ 57

GENERAL INFORMATION

INTRODUCTION

This section will cover components either regulated

or controlled by the Powertrain Control Module

(PCM). The fuel heater relay, fuel heater and fuel

gauge are not operated by the PCM. These compo-

nents are controlled by the ignition (key) switch. All

other fuel system electrical components necessary to

operate the engine are controlled or regulated by the

PCM. Refer to the following PCM description for

more information.

Certain fuel system component failures may cause

a no start, or prevent the engine from running. It is

important to know that the PCM has a featurewhere, if possible, it will ignore the failed sensor, set

a code related to the sensor, and operate the engine

in a ªLimp Homeº mode. When the PCM is operating

in a ªLimp Homeº mode, the Diesel Glow Plug lamp

on the instrument panel will be constantly illumi-

nated, and the engine will most likely have a notice-

able loss of performance. An example of this would be

an Accelerator Pedal Position Sensor failure, and in

that situation, the engine would run at a constant

1100 RPM, regardless of the actual position of the

pedal. This is the most extreme of the three ªLimp

Homeº modes.

In addition to indicating that the glow plugs are

hot enough to start combustion, the Glow Plug Lamp

is also used in the diagnosis of the PCM, and when

NS/GSFUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE 14 - 43

Page 1422 of 1938

(2) Remove the sensor mounting bolts.

(3) Remove the sensor.

INSTALLATION

(1) Install the sensor flush against the opening in

the transmission housing.

(2) Install and tighten the sensor mounting bolt to

19 N´m (14 ft. lbs.) torque.

(3) Connect the electrical connector to the sensor.

ENGINE COOLANT TEMPERATURE SENSOR

The sensor is located on the side of cylinder head

near the rear of fuel injection pump (Fig. 19).

REMOVAL

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING. COOLING SYSTEM

MUST BE PARTIALLY DRAINED BEFORE REMOV-

ING THE COOLANT TEMPERATURE SENSOR.

REFER TO GROUP 7, COOLING.

(1) Partially drain cooling system. Refer to Group

7, Cooling.

(2) Disconnect electrical connector from sensor.

(3) Remove sensor from cylinder head.

INSTALLATION

(1) Install a new copper gasket to sensor.

(2) Install sensor to cylinder head.

(3) Tighten sensor to 18 N´m (13 ft. lbs.) torque.

(4) Connect electrical connector to sensor.

(5) Replace any lost engine coolant. Refer to Group

7, Cooling System.

GLOW PLUGS

The glow plugs are located above each fuel injector

(Fig. 20). Four individual plugs are used.

REMOVAL

(1) Disconnect the negative battery cable at the

battery.

(2) Clean the area around the glow plug with com-

pressed air before removal.

(3) Disconnect electrical connector (Fig. 21) at glow

plug.

(4) Remove the glow plug (Fig. 20) from cylinder

head.

Fig. 18 Engine Speed SensorFig. 19 Engine Coolant Temperature Sensor

Location

Fig. 20 Glow Plug

14 - 54 FUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINENS/GS

REMOVAL AND INSTALLATION (Continued)

Page 1423 of 1938

INSTALLATION

(1) Apply high±temperature anti±seize compound

to glow plug threads before installation

(2) Install the glow plug into the cylinder head.

Tighten to 23 N´m (203 in. lbs.) torque.

(3) Connect battery cable to battery.

GLOW PLUG RELAY

The glow plug relay is located in the engine com-

partment on the left±inner fender (Fig. 22).

REMOVAL

(1) Disconnect the negative battery cable at the

battery.

(2) Remove relay mounting bolt.(3) Disconnect electrical connector at relay and

remove relay.

INSTALLATION

(1) Check condition of electrical connector for dam-

age or corrosion. Repair as necessary.

(2) Install electrical connector to relay.

(3) Install relay to inner fender.

(4) Connect battery cable to battery.

POWERTRAIN CONTROL MODULE (PCM)

The PCM is mounted to a bracket located in the

center consule in front of the air bag module (Fig.

23).

REMOVAL

(1) Disconnect the negative battery cable at the

battery.

(2) Loosen the 68±Way connector (Fig. 23). The

electrical connector has a sliding bar which moves

inward to lock or outward to unlock.

(3) Remove the electrical connector by pulling

straight out.

(4) Remove PCM.

INSTALLATION

(1) After the PCM electrical connector has been

separated from the PCM, inspect the pins for corro-

sion, being spread apart, bent or misaligned. Also

inspect the pin heights in the connector. If the pin

heights are different, this would indicate a pin has

separated from the connector. Repair as necessary.

(2) Engage 68±way connector into PCM. Move

slide bar to lock connector.

(3) Connect negative cable to battery.

VEHICLE SPEED SENSOR

The vehicle speed sensor (Fig. 24) is located on the

extension housing of the transmission.

Fig. 21 Glow Plug Electrical Connector

Fig. 22 Glow Plug Relay Location

Fig. 23 PCM Location

NS/GSFUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE 14 - 55

REMOVAL AND INSTALLATION (Continued)

Page 1425 of 1938

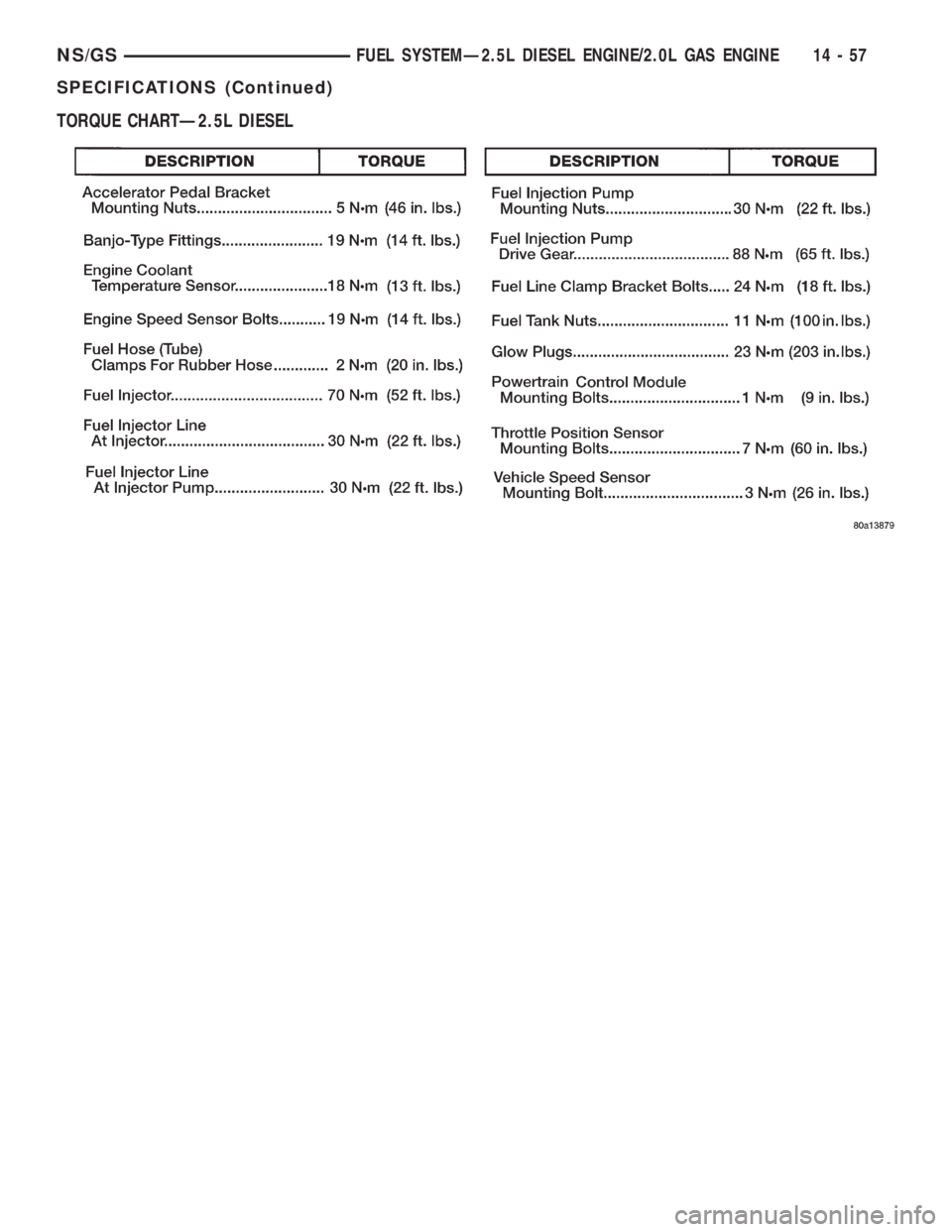

TORQUE CHARTÐ2.5L DIESEL

NS/GSFUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE 14 - 57

SPECIFICATIONS (Continued)

Page 1428 of 1938

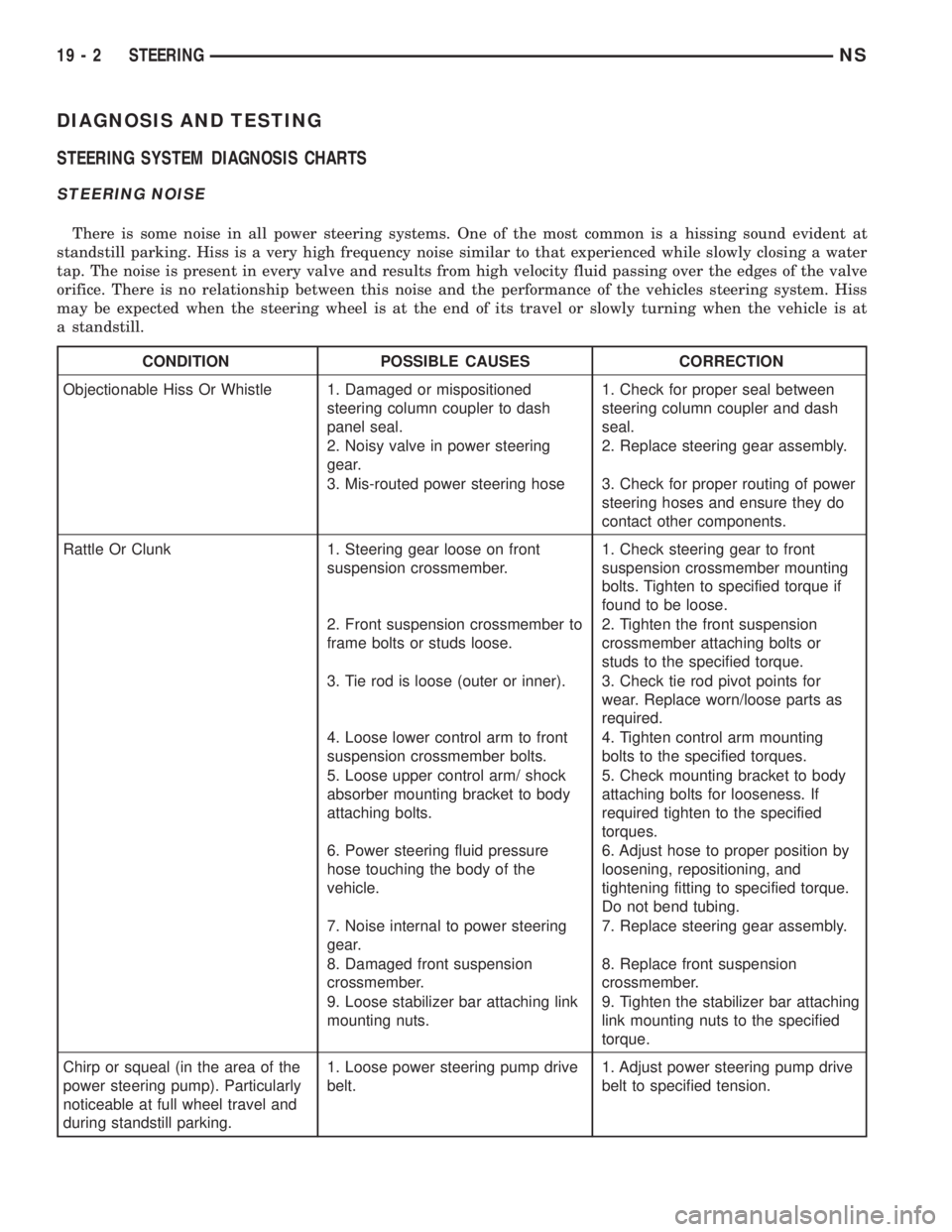

DIAGNOSIS AND TESTING

STEERING SYSTEM DIAGNOSIS CHARTS

STEERING NOISE

There is some noise in all power steering systems. One of the most common is a hissing sound evident at

standstill parking. Hiss is a very high frequency noise similar to that experienced while slowly closing a water

tap. The noise is present in every valve and results from high velocity fluid passing over the edges of the valve

orifice. There is no relationship between this noise and the performance of the vehicles steering system. Hiss

may be expected when the steering wheel is at the end of its travel or slowly turning when the vehicle is at

a standstill.

CONDITION POSSIBLE CAUSES CORRECTION

Objectionable Hiss Or Whistle 1. Damaged or mispositioned

steering column coupler to dash

panel seal.1. Check for proper seal between

steering column coupler and dash

seal.

2. Noisy valve in power steering

gear.2. Replace steering gear assembly.

3. Mis-routed power steering hose 3. Check for proper routing of power

steering hoses and ensure they do

contact other components.

Rattle Or Clunk 1. Steering gear loose on front

suspension crossmember.1. Check steering gear to front

suspension crossmember mounting

bolts. Tighten to specified torque if

found to be loose.

2. Front suspension crossmember to

frame bolts or studs loose.2. Tighten the front suspension

crossmember attaching bolts or

studs to the specified torque.

3. Tie rod is loose (outer or inner). 3. Check tie rod pivot points for

wear. Replace worn/loose parts as

required.

4. Loose lower control arm to front

suspension crossmember bolts.4. Tighten control arm mounting

bolts to the specified torques.

5. Loose upper control arm/ shock

absorber mounting bracket to body

attaching bolts.5. Check mounting bracket to body

attaching bolts for looseness. If

required tighten to the specified

torques.

6. Power steering fluid pressure

hose touching the body of the

vehicle.6. Adjust hose to proper position by

loosening, repositioning, and

tightening fitting to specified torque.

Do not bend tubing.

7. Noise internal to power steering

gear.7. Replace steering gear assembly.

8. Damaged front suspension

crossmember.8. Replace front suspension

crossmember.

9. Loose stabilizer bar attaching link

mounting nuts.9. Tighten the stabilizer bar attaching

link mounting nuts to the specified

torque.

Chirp or squeal (in the area of the

power steering pump). Particularly

noticeable at full wheel travel and

during standstill parking.1. Loose power steering pump drive

belt.1. Adjust power steering pump drive

belt to specified tension.

19 - 2 STEERINGNS

Page 1430 of 1938

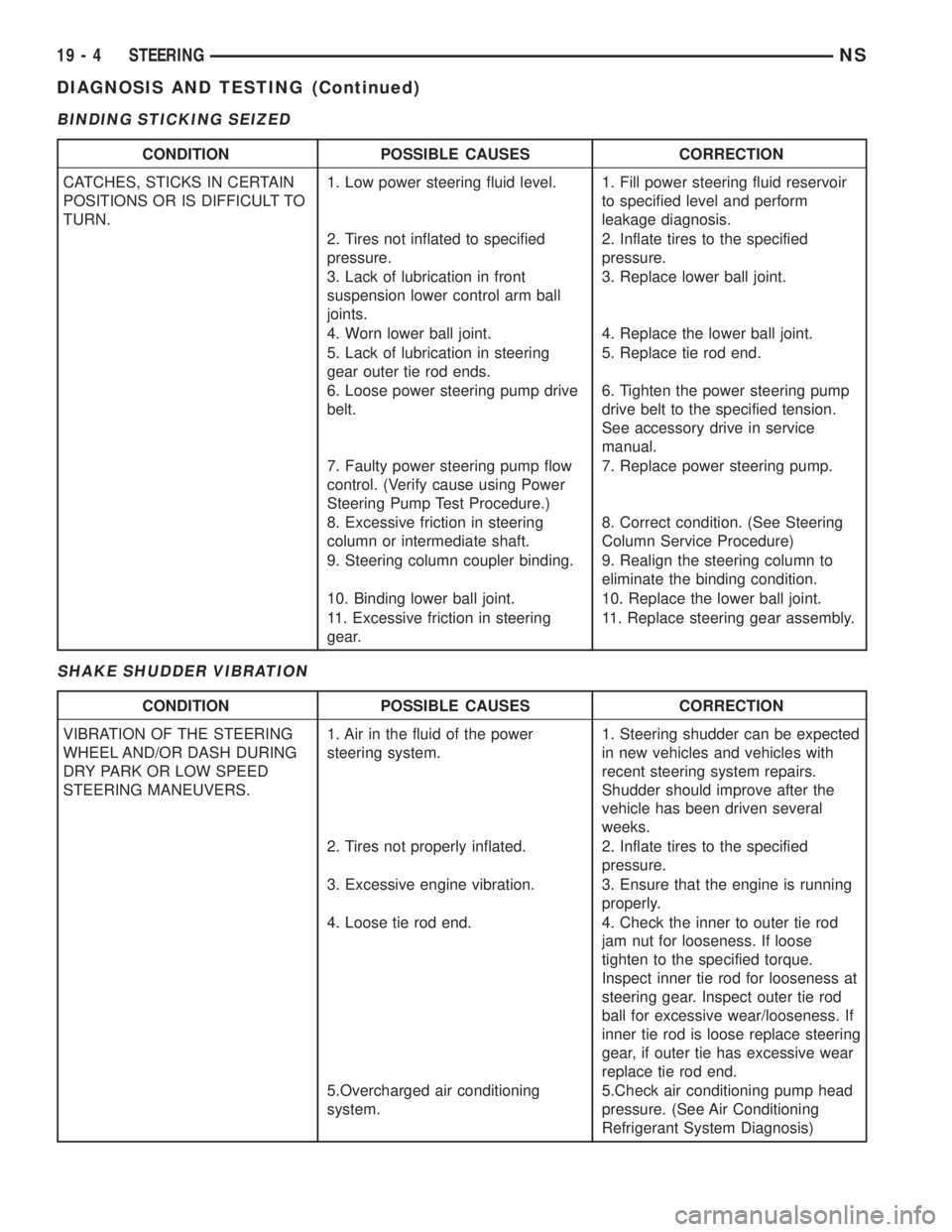

BINDING STICKING SEIZED

SHAKE SHUDDER VIBRATION

CONDITION POSSIBLE CAUSES CORRECTION

CATCHES, STICKS IN CERTAIN

POSITIONS OR IS DIFFICULT TO

TURN.1. Low power steering fluid level. 1. Fill power steering fluid reservoir

to specified level and perform

leakage diagnosis.

2. Tires not inflated to specified

pressure.2. Inflate tires to the specified

pressure.

3. Lack of lubrication in front

suspension lower control arm ball

joints.3. Replace lower ball joint.

4. Worn lower ball joint. 4. Replace the lower ball joint.

5. Lack of lubrication in steering

gear outer tie rod ends.5. Replace tie rod end.

6. Loose power steering pump drive

belt.6. Tighten the power steering pump

drive belt to the specified tension.

See accessory drive in service

manual.

7. Faulty power steering pump flow

control. (Verify cause using Power

Steering Pump Test Procedure.)7. Replace power steering pump.

8. Excessive friction in steering

column or intermediate shaft.8. Correct condition. (See Steering

Column Service Procedure)

9. Steering column coupler binding. 9. Realign the steering column to

eliminate the binding condition.

10. Binding lower ball joint. 10. Replace the lower ball joint.

11. Excessive friction in steering

gear.11. Replace steering gear assembly.

CONDITION POSSIBLE CAUSES CORRECTION

VIBRATION OF THE STEERING

WHEEL AND/OR DASH DURING

DRY PARK OR LOW SPEED

STEERING MANEUVERS.1. Air in the fluid of the power

steering system.1. Steering shudder can be expected

in new vehicles and vehicles with

recent steering system repairs.

Shudder should improve after the

vehicle has been driven several

weeks.

2. Tires not properly inflated. 2. Inflate tires to the specified

pressure.

3. Excessive engine vibration. 3. Ensure that the engine is running

properly.

4. Loose tie rod end. 4. Check the inner to outer tie rod

jam nut for looseness. If loose

tighten to the specified torque.

Inspect inner tie rod for looseness at

steering gear. Inspect outer tie rod

ball for excessive wear/looseness. If

inner tie rod is loose replace steering

gear, if outer tie has excessive wear

replace tie rod end.

5.Overcharged air conditioning

system.5.Check air conditioning pump head

pressure. (See Air Conditioning

Refrigerant System Diagnosis)

19 - 4 STEERINGNS

DIAGNOSIS AND TESTING (Continued)

Page 1432 of 1938

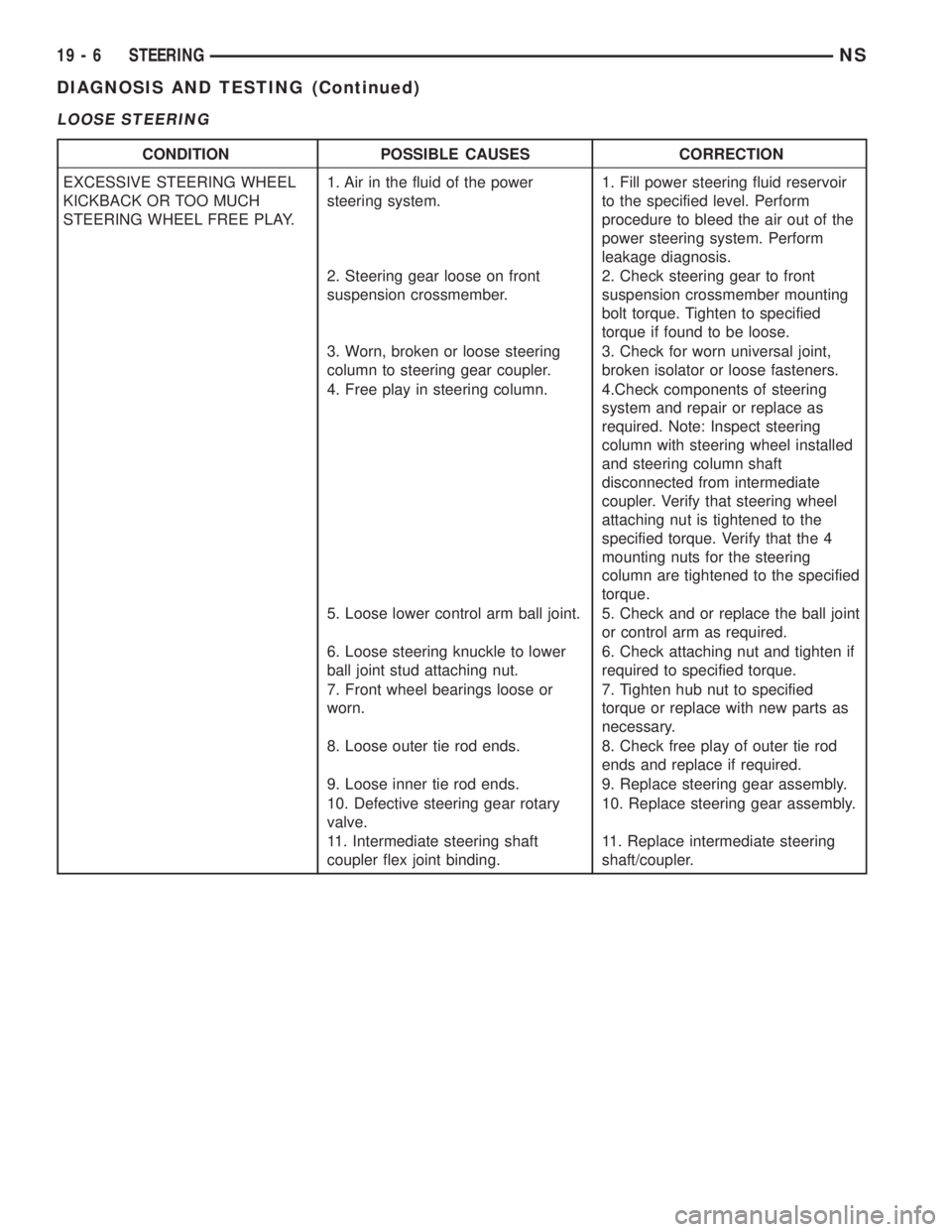

LOOSE STEERING

CONDITION POSSIBLE CAUSES CORRECTION

EXCESSIVE STEERING WHEEL

KICKBACK OR TOO MUCH

STEERING WHEEL FREE PLAY.1. Air in the fluid of the power

steering system.1. Fill power steering fluid reservoir

to the specified level. Perform

procedure to bleed the air out of the

power steering system. Perform

leakage diagnosis.

2. Steering gear loose on front

suspension crossmember.2. Check steering gear to front

suspension crossmember mounting

bolt torque. Tighten to specified

torque if found to be loose.

3. Worn, broken or loose steering

column to steering gear coupler.3. Check for worn universal joint,

broken isolator or loose fasteners.

4. Free play in steering column. 4.Check components of steering

system and repair or replace as

required. Note: Inspect steering

column with steering wheel installed

and steering column shaft

disconnected from intermediate

coupler. Verify that steering wheel

attaching nut is tightened to the

specified torque. Verify that the 4

mounting nuts for the steering

column are tightened to the specified

torque.

5. Loose lower control arm ball joint. 5. Check and or replace the ball joint

or control arm as required.

6. Loose steering knuckle to lower

ball joint stud attaching nut.6. Check attaching nut and tighten if

required to specified torque.

7. Front wheel bearings loose or

worn.7. Tighten hub nut to specified

torque or replace with new parts as

necessary.

8. Loose outer tie rod ends. 8. Check free play of outer tie rod

ends and replace if required.

9. Loose inner tie rod ends. 9. Replace steering gear assembly.

10. Defective steering gear rotary

valve.10. Replace steering gear assembly.

11. Intermediate steering shaft

coupler flex joint binding.11. Replace intermediate steering

shaft/coupler.

19 - 6 STEERINGNS

DIAGNOSIS AND TESTING (Continued)

Page 1433 of 1938

VEHICLE LEADS TO THE SIDE

POWER STEERING FLUID LEAK

CONDITION POSSIBLE CAUSES CORRECTION

STEERING WHEEL DOES NOT

WANT RETURN TO CENTER

POSITION.1. Radial tire lead. 1.Rotate tires as recommended in

the Tire And Wheel Group of this

service manual.

2. Front suspension misaligned. 2. Align the front suspension as

required. Refer to the Wheel

Alignment Procedure in the

Suspension Group of this service

manual for the required wheel

alignment procedure.

3. Wheel braking. 3. Check for dragging brakes. Refer

to the procedures in the Brake

Group of this service manual.

4. Unbalanced steering gear valve.

(If this is the cause, the steering

efforts will be very light in direction

of lead and heavier in the opposite

direction.4. Replace steering gear.

STEERING WHEEL HAS FORE

AND AFT LOOSENESS.1. Steering wheel to steering column

shaft retaining nut not properly

tightened and torqued.1. Tighten the retaining nut to its

specified torque specification.

2. Steering column lower bearing

spring retainer slipped on steering

column shaft.2. Replace steering column.

3. Loose steering column to

instrument panel mounting nuts.3. Verify that the 4 mounting nuts for

the steering column are tightened to

the specified torque.

4. Binding intermediate steering

shaft coupler.4. Disconnect intermediate steering

coupler and see if looseness no

longer exists. If yes replace

intermendiate steering coupler.

CONDITION POSSIBLE CAUSES CORRECTION

LOW FLUID LEVEL WITH: NO

VISIBLE SIGNS OF A LEAK ON

THE STEERING GEAR, POWER

STEERING PUMP, FLOOR OR

ANYWHERE ELSE.1. Overfilled power steering pump

fluid reservoir.1. Adjust the power steering fluid fill

to the correct level.

LOW FLUID LEVEL WITH:

VISIBLE LEAK ON STEERING

GEAR, POWER STEERING

PUMP, FLOOR OR ANYWHERE

ELSE.2. Power steering hose connections

at the power steering pump or

steering gear.2. Check for loose fittings and if

found, tighten the fitting to its

specified torque. If fittings are tight

examine the fittings for damaged or

missing O-ring seals and replace as

required.

3. Power steering pump or power

steering gear leaking.3. Identify the location of the leak

and repair or replace the component

as required. Refer to Power Steering

Pump and/or Power Steering Gear in

this group of the service manual for

required procedures.

NSSTEERING 19 - 7

DIAGNOSIS AND TESTING (Continued)

Page 1435 of 1938

POWER STEERING PUMP

INDEX

page page

DESCRIPTION AND OPERATION

POWER STEERING PUMP OPERATION....... 9

DIAGNOSIS AND TESTING

POWER STEERING PUMP FLOW RATE AND

PRESSURE TEST....................... 9

SERVICE PROCEDURES

POWER STEERING PUMP INITIAL

OPERATION.......................... 10

POWER STEERING SYSTEM FLUID LEVEL

CHECK.............................. 10

REMOVAL AND INSTALLATION

2.4 LITER POWER STEERING PUMP......... 11

3.0 LITER POWER STEERING PUMP........ 13

3.3/3.8 LITER POWER STEERING PUMP...... 16

POWER STEERING FLUID PRESSURE HOSE . . 19POWER STEERING FLUID RESERVOIR TO

PUMP SUPPLY HOSE................... 18

POWER STEERING FLUID RETURN HOSE.... 21

REMOTE POWER STEERING FLUID

RESERVOIR.......................... 22

DISASSEMBLY AND ASSEMBLY

POWER STEERING PUMP FLOW CONTROL

VALVE SEAL.......................... 23

POWER STEERING PUMP PULLEY.......... 23

SPECIFICATIONS

POWER STEERING PUMP FASTENER

TORQUE SPECIFICATIONS.............. 24

POWER STEERING SYSTEM

SPECIFICATIONS...................... 24

SPECIAL TOOLS

POWER STEERING PUMP................. 25

DESCRIPTION AND OPERATION

POWER STEERING PUMP OPERATION

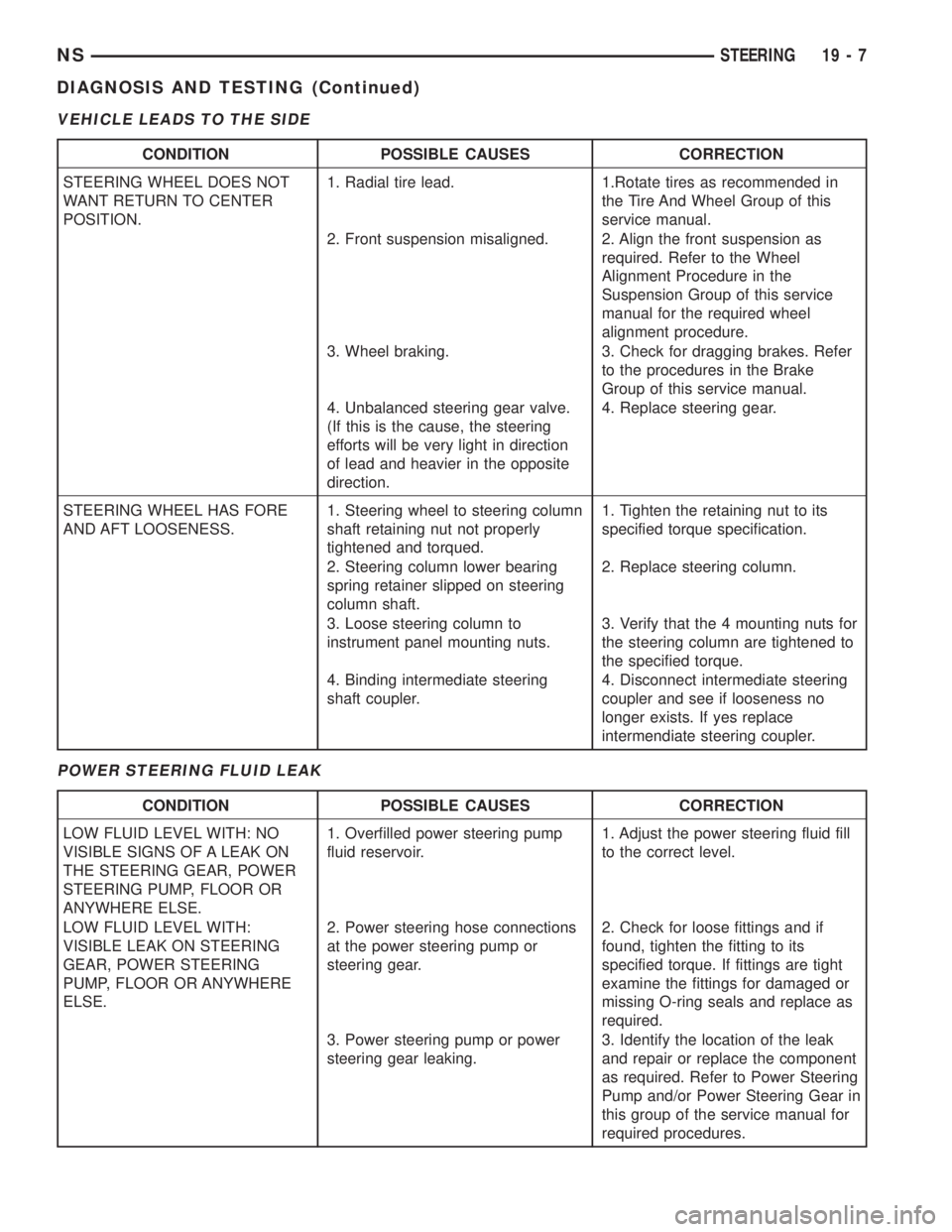

Hydraulic pressure for the operation of the power

steering gear is provided by a belt driven power

steering pump (Fig. 1). The power steering pump is a

constant flow rate and displacement vane type pump.

The power steering pump used on all applications is

the Vane-Submerged remote reservoir style power

steering pump.

The remote reservoir type pump (Fig. 1) has the

pump housing and internal components combined

with the fluid housing. But it has a remote reservoir

for the power steering fluid supply.

DIAGNOSIS AND TESTING

POWER STEERING PUMP FLOW RATE AND

PRESSURE TEST

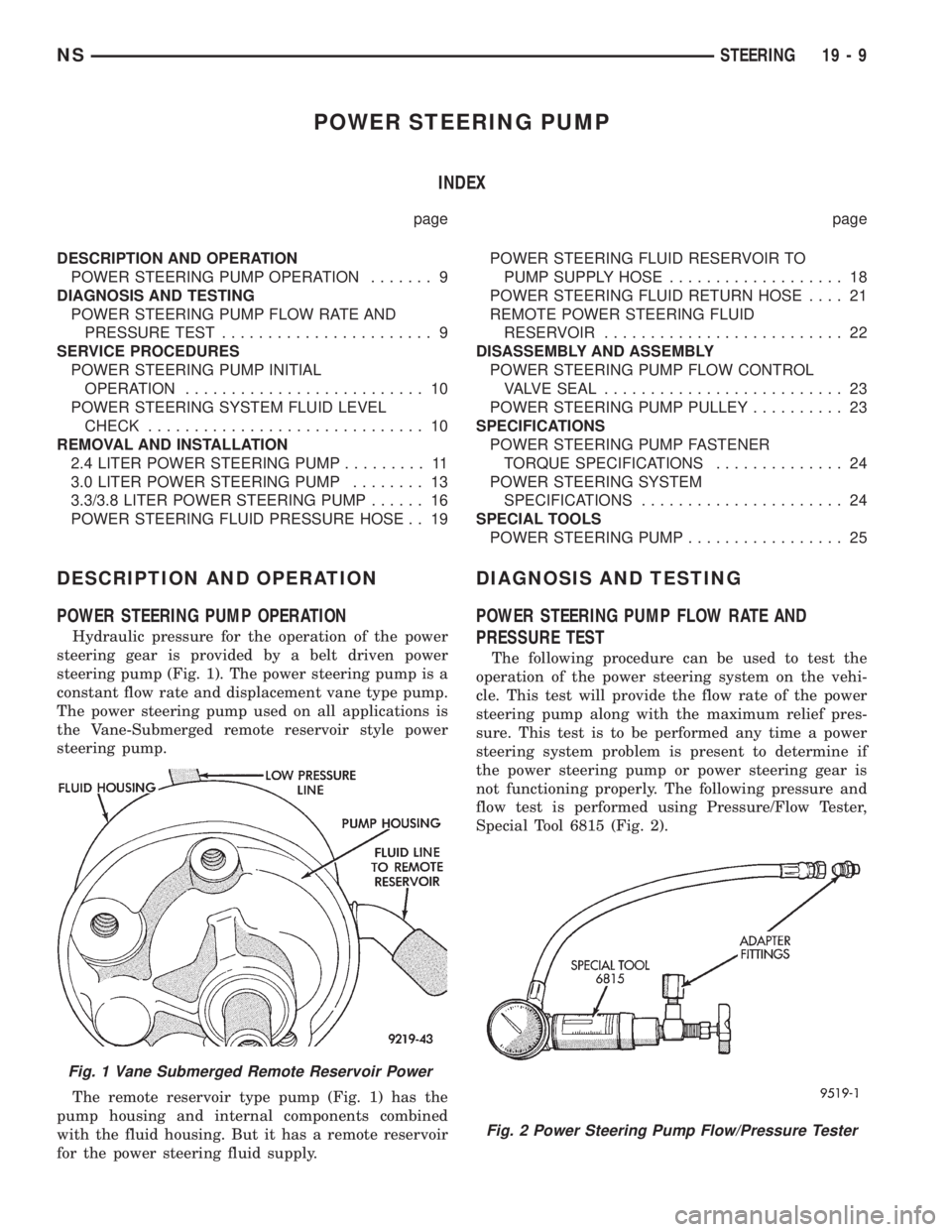

The following procedure can be used to test the

operation of the power steering system on the vehi-

cle. This test will provide the flow rate of the power

steering pump along with the maximum relief pres-

sure. This test is to be performed any time a power

steering system problem is present to determine if

the power steering pump or power steering gear is

not functioning properly. The following pressure and

flow test is performed using Pressure/Flow Tester,

Special Tool 6815 (Fig. 2).

Fig. 1 Vane Submerged Remote Reservoir Power

Fig. 2 Power Steering Pump Flow/Pressure Tester

NSSTEERING 19 - 9