torque CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1439 of 1938

(18) Remove the 3 previously loosened bolts

attaching the front bracket to the power steering

pump and separate the power steering pump from

the front bracket prior to removing the pump from

the vehicle.

(19) The power steering pump is removed from the

vehicle by pulling it out through the exhaust tunnel

area in the floor pan of the vehicle.

INSTALL

(1) Install power steering pump back in vehicle

using the reverse order of its removal through the

exhaust tunnel are of the vehicle.

(2) Install the power steering pump on its cast

mounting bracket and loosely install nut to hold

pump in place (Fig. 9).

(3) Install the front bracket on the power steering

pump and loosely install the 3 mounting bolts (Fig.

10). Then install the nut and bolt attaching the front

bracket to the cast bracket (Fig. 10).

(4) Tighten the 3 power steering pump mounting

bolts (Fig. 10) to a torque of 54 N´m (40 ft. lbs.).

NOTE: Before installing power steering fluid pres-

sure hose on power steering pump, inspect the

O-ring on the pressure hose for damage and

replace if necessary.

(5) Install the power steering fluid pressure line

onto the output fitting of the power steering pump

(Fig. 8). Tighten the pressure line to pump fitting

tube nut to a torque of 31 N´m (275 in. lbs.).

(6) Install the power steering fluid, low pressure

return hose on the power steering pump low pressure

fitting (Fig. 8).Be sure hose clamps are properly

reinstalled.

(7) Install the power steering fluid supply hose

from the power steering fluid reservoir, on the power

steering pump fluid fitting (Fig. 7).Be sure hose is

clear of accessory drive belts all hose clamps

are properly reinstalled.

(8) Install the power steering pump drive belt on

pulley. See Cooling, Group 7 for detailed installation

procedure.

(9) Install the accessory drive splash shield (Fig.

6).

(10) Install the power steering fluid return hose on

the steel tube at the front suspension cradle (Fig. 5).

(11) Install a screw type hose clamp on the power

steering hose to steel tube connection.Be sure hose

clamps are properly reinstalled.Tighten the screw

clamp to a torque of 2 N´m (18 in. lbs.).

CAUTION: The protective heat shield sleeves must

cover the entire rubber hose and hose to tube con-

nection portion of both the power steering fluid

pressure and return hoses (Fig. 5). This is requiredto prevent the overheating of the power steering

hoses.

(12) When used, properly position the protective

heat sleeves on the power steering hoses (Fig. 5).

Then, tie strap the heat sleeves to the power steering

hoses to keep them in their proper position.

(13) Install the exhaust pipe on the exhaust man-

ifold. Install all exhaust system hangers/isolators on

the exhaust system brackets.

(14) Connect the oxygen sensor wiring harness to

the vehicle wiring harness. Install wiring harness

grommet in the floor pan of the vehicle.

(15) Lower vehicle.

(16) Adjust the power steering pump drive belt.

See Cooling, Group 7 for detailed adjustment proce-

dure.

(17) Tighten the top nut and bottom bolt on the

power steering pump front mounting bracket (Fig. 3)

to a torque of 54 N´m (40 ft. lbs.).

CAUTION: Do not use automatic transmission fluid

in power steering system. Only use MoparT, Power

Steering Fluid, or equivalent.

(18) Fill the remote power steering pump fluid res-

ervoir to correct fluid level.

(19) Install cap on power steering fluid reservoir.

(20) Connect the negative battery cable on the

negative battery post.

(21) Start engine and turn steering wheel several

times from stop to stop to bleed air from fluid in sys-

tem. Stop engine, check fluid level, and inspect sys-

tem for leaks. See Checking Fluid Level.

3.0 LITER POWER STEERING PUMP

REMOVE

WARNING: POWER STEERING OIL, ENGINE COM-

PONENTS AND THE EXHAUST SYSTEM MAY BE

EXTREMELY HOT IF ENGINE HAS BEEN RUNNING.

DO NOT START ENGINE WITH ANY LOOSE OR DIS-

CONNECTED HOSES. DO NOT ALLOW HOSES TO

TOUCH HOT EXHAUST MANIFOLD OR CATALYST.

(1) Remove the (-) negative battery cable from the

battery and isolate cable.

(2) Remove cap from power steering fluid reser-

voir.

(3) Using a siphon pump, remove as much power

steering fluid as possible from the power steering

fluid reservoir.

NSSTEERING 19 - 13

REMOVAL AND INSTALLATION (Continued)

Page 1441 of 1938

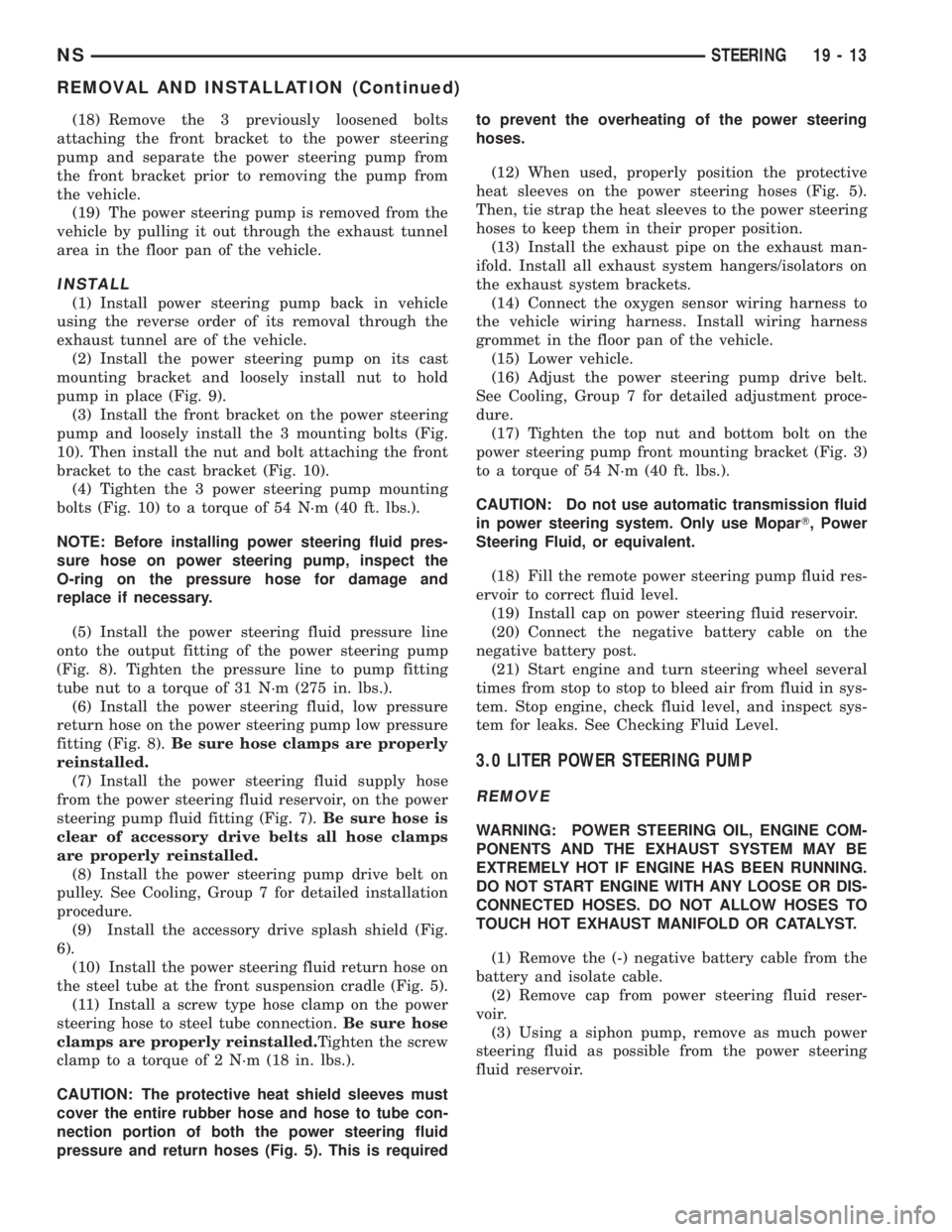

(13) Remove the power steering fluid return hose

(Fig. 15) from the power steering pump.

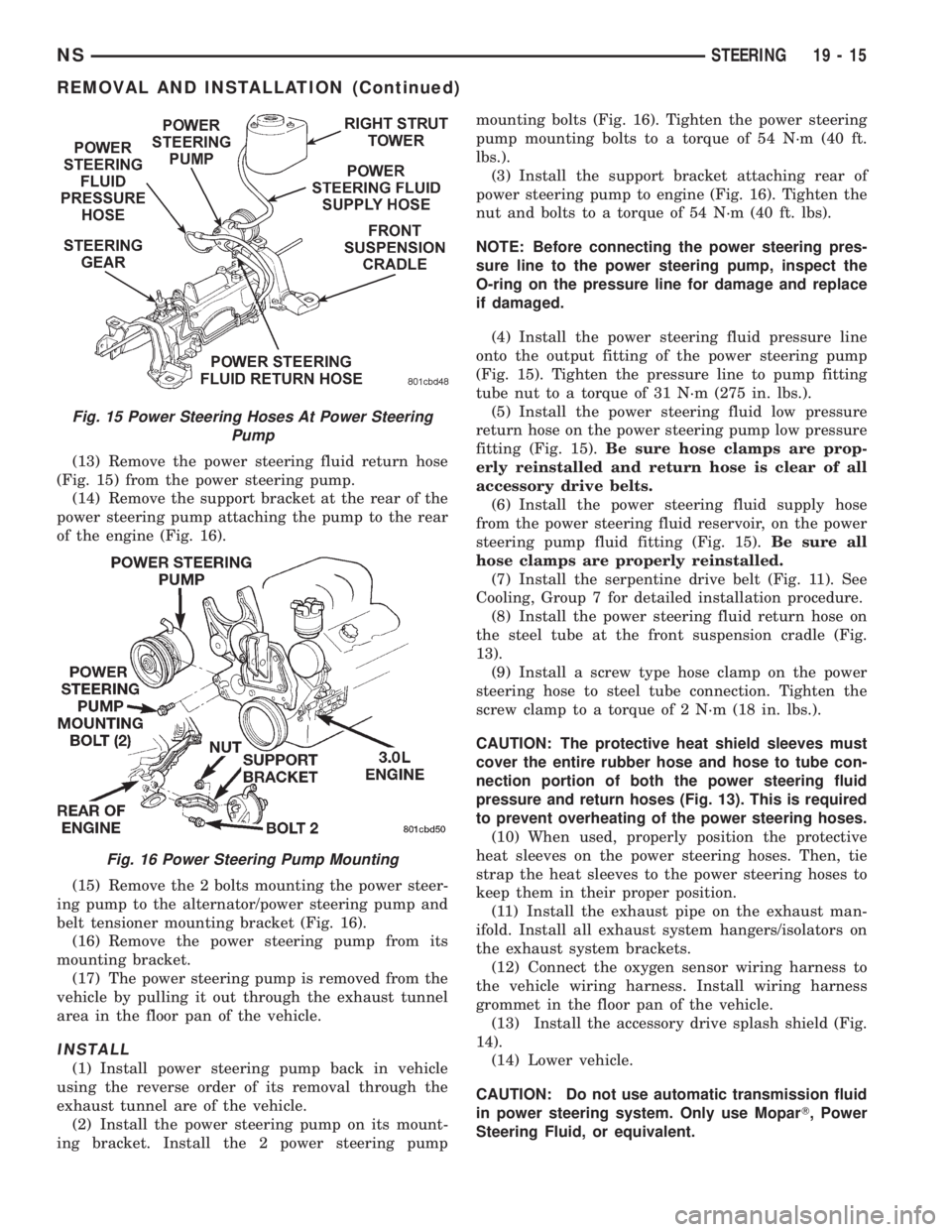

(14) Remove the support bracket at the rear of the

power steering pump attaching the pump to the rear

of the engine (Fig. 16).

(15) Remove the 2 bolts mounting the power steer-

ing pump to the alternator/power steering pump and

belt tensioner mounting bracket (Fig. 16).

(16) Remove the power steering pump from its

mounting bracket.

(17) The power steering pump is removed from the

vehicle by pulling it out through the exhaust tunnel

area in the floor pan of the vehicle.

INSTALL

(1) Install power steering pump back in vehicle

using the reverse order of its removal through the

exhaust tunnel are of the vehicle.

(2) Install the power steering pump on its mount-

ing bracket. Install the 2 power steering pumpmounting bolts (Fig. 16). Tighten the power steering

pump mounting bolts to a torque of 54 N´m (40 ft.

lbs.).

(3) Install the support bracket attaching rear of

power steering pump to engine (Fig. 16). Tighten the

nut and bolts to a torque of 54 N´m (40 ft. lbs).

NOTE: Before connecting the power steering pres-

sure line to the power steering pump, inspect the

O-ring on the pressure line for damage and replace

if damaged.

(4) Install the power steering fluid pressure line

onto the output fitting of the power steering pump

(Fig. 15). Tighten the pressure line to pump fitting

tube nut to a torque of 31 N´m (275 in. lbs.).

(5) Install the power steering fluid low pressure

return hose on the power steering pump low pressure

fitting (Fig. 15).Be sure hose clamps are prop-

erly reinstalled and return hose is clear of all

accessory drive belts.

(6) Install the power steering fluid supply hose

from the power steering fluid reservoir, on the power

steering pump fluid fitting (Fig. 15).Be sure all

hose clamps are properly reinstalled.

(7) Install the serpentine drive belt (Fig. 11). See

Cooling, Group 7 for detailed installation procedure.

(8) Install the power steering fluid return hose on

the steel tube at the front suspension cradle (Fig.

13).

(9) Install a screw type hose clamp on the power

steering hose to steel tube connection. Tighten the

screw clamp to a torque of 2 N´m (18 in. lbs.).

CAUTION: The protective heat shield sleeves must

cover the entire rubber hose and hose to tube con-

nection portion of both the power steering fluid

pressure and return hoses (Fig. 13). This is required

to prevent overheating of the power steering hoses.

(10) When used, properly position the protective

heat sleeves on the power steering hoses. Then, tie

strap the heat sleeves to the power steering hoses to

keep them in their proper position.

(11) Install the exhaust pipe on the exhaust man-

ifold. Install all exhaust system hangers/isolators on

the exhaust system brackets.

(12) Connect the oxygen sensor wiring harness to

the vehicle wiring harness. Install wiring harness

grommet in the floor pan of the vehicle.

(13) Install the accessory drive splash shield (Fig.

14).

(14) Lower vehicle.

CAUTION: Do not use automatic transmission fluid

in power steering system. Only use MoparT, Power

Steering Fluid, or equivalent.

Fig. 15 Power Steering Hoses At Power Steering

Pump

Fig. 16 Power Steering Pump Mounting

NSSTEERING 19 - 15

REMOVAL AND INSTALLATION (Continued)

Page 1443 of 1938

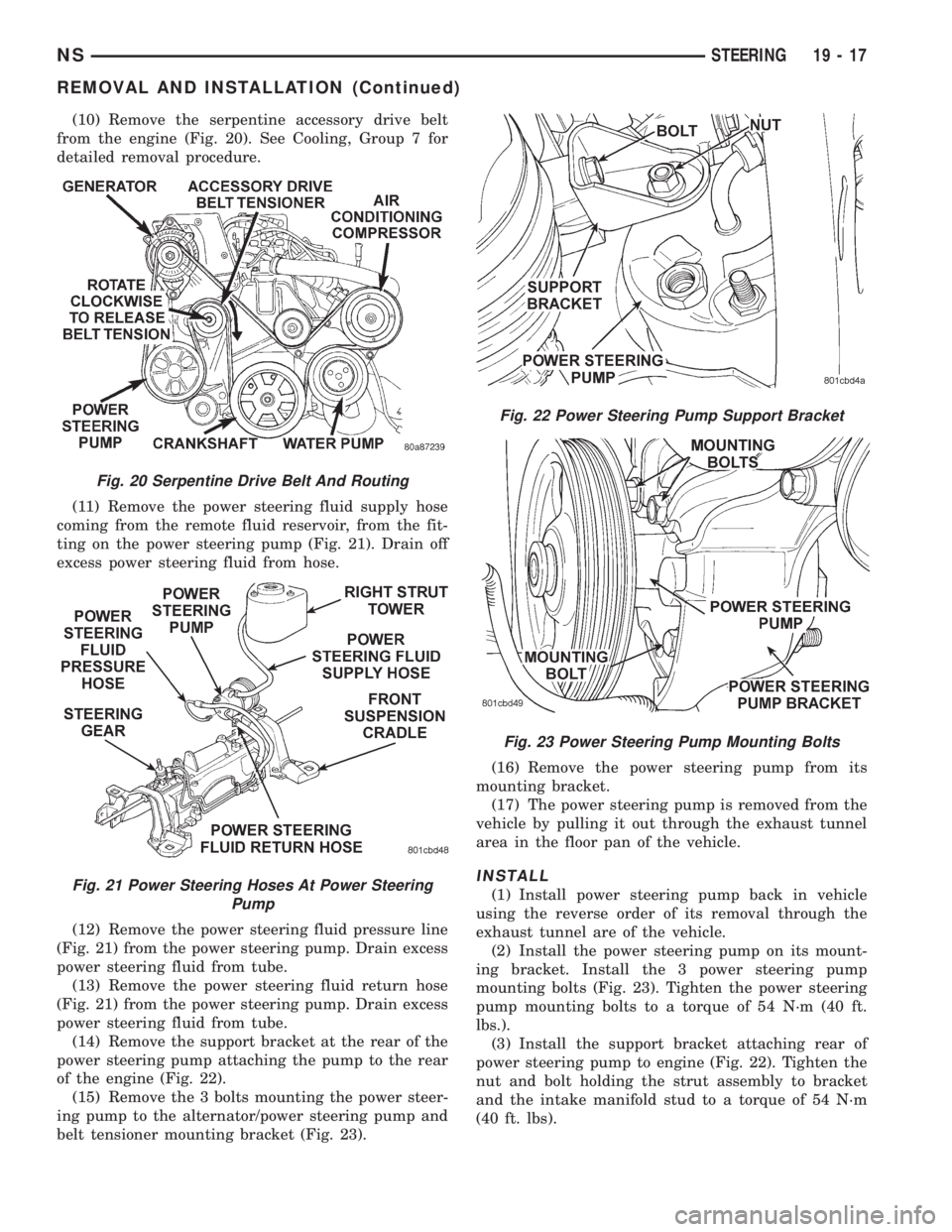

(10) Remove the serpentine accessory drive belt

from the engine (Fig. 20). See Cooling, Group 7 for

detailed removal procedure.

(11) Remove the power steering fluid supply hose

coming from the remote fluid reservoir, from the fit-

ting on the power steering pump (Fig. 21). Drain off

excess power steering fluid from hose.

(12) Remove the power steering fluid pressure line

(Fig. 21) from the power steering pump. Drain excess

power steering fluid from tube.

(13) Remove the power steering fluid return hose

(Fig. 21) from the power steering pump. Drain excess

power steering fluid from tube.

(14) Remove the support bracket at the rear of the

power steering pump attaching the pump to the rear

of the engine (Fig. 22).

(15) Remove the 3 bolts mounting the power steer-

ing pump to the alternator/power steering pump and

belt tensioner mounting bracket (Fig. 23).(16) Remove the power steering pump from its

mounting bracket.

(17) The power steering pump is removed from the

vehicle by pulling it out through the exhaust tunnel

area in the floor pan of the vehicle.

INSTALL

(1) Install power steering pump back in vehicle

using the reverse order of its removal through the

exhaust tunnel are of the vehicle.

(2) Install the power steering pump on its mount-

ing bracket. Install the 3 power steering pump

mounting bolts (Fig. 23). Tighten the power steering

pump mounting bolts to a torque of 54 N´m (40 ft.

lbs.).

(3) Install the support bracket attaching rear of

power steering pump to engine (Fig. 22). Tighten the

nut and bolt holding the strut assembly to bracket

and the intake manifold stud to a torque of 54 N´m

(40 ft. lbs).

Fig. 20 Serpentine Drive Belt And Routing

Fig. 21 Power Steering Hoses At Power Steering

Pump

Fig. 22 Power Steering Pump Support Bracket

Fig. 23 Power Steering Pump Mounting Bolts

NSSTEERING 19 - 17

REMOVAL AND INSTALLATION (Continued)

Page 1444 of 1938

NOTE: Before installing power steering pressure

hose on power steering pump, inspect the O-ring

on the power steering pressure hose for damage

and replace if required.

(4) Install the power steering fluid pressure line

onto the output fitting of the power steering pump

(Fig. 21). Tighten the pressure line to pump fitting

tube nut to a torque of 31 N´m (275 in. lbs.).

(5) Install the power steering fluid, low pressure

return hose on the power steering pump low pressure

fitting (Fig. 21).Be sure hose clamps are prop-

erly reinstalled.

(6) Install the power steering fluid supply hose

from the power steering fluid reservoir, on the power

steering pump fluid fitting (Fig. 21).Be sure hose is

clear of accessory drive belts and all hose

clamps are properly reinstalled.

(7) Install the serpentine drive belt (Fig. 20). See

Cooling, Group 7 for detailed installation procedure.

(8) Install the power steering fluid return hose on

the steel tube at the front suspension cradle (Fig.

18).

(9) Install a screw type hose clamp on the power

steering hose to steel tube connection.Be sure hose

clamps are properly reinstalled.Tighten the screw

clamp to a torque of 2 N´m (18 in. lbs.).

CAUTION: The protective heat shield sleeves must

cover the entire rubber hose and hose to tube con-

nection portion of both the power steering fluid

pressure and return hoses (Fig. 18). This is required

to keep the power steering hoses from becoming

overheated.

(10) When used, properly position the protective

heat sleeves on the power steering hoses (Fig. 18).

Then, tie strap the heat sleeves to the power steering

hoses to keep them in their proper position.

(11) Install the exhaust pipe on the exhaust man-

ifold. Install all exhaust system hangers/isolators on

the exhaust system brackets.

(12) Connect the oxygen sensor wiring harness to

the vehicle wiring harness. Install wiring harness

grommet in the floor pan of the vehicle.

(13) Install the accessory drive splash shield (Fig.

19).

(14) Lower vehicle.

CAUTION: Do not use automatic transmission fluid

in power steering system. Only use MoparT, Power

Steering Fluid, or equivalent.

(15) Fill the remote power steering pump fluid res-

ervoir to correct fluid level.

(16) Install cap on power steering fluid reservoir.(17) Connect the negative battery cable on the

negative battery post.

(18) Start engine and turn steering wheel several

times from stop to stop to bleed air from fluid in sys-

tem. Stop engine, check fluid level, and inspect sys-

tem for leaks. See Checking Fluid Level.

POWER STEERING FLUID RESERVOIR TO PUMP

SUPPLY HOSE

REMOVE

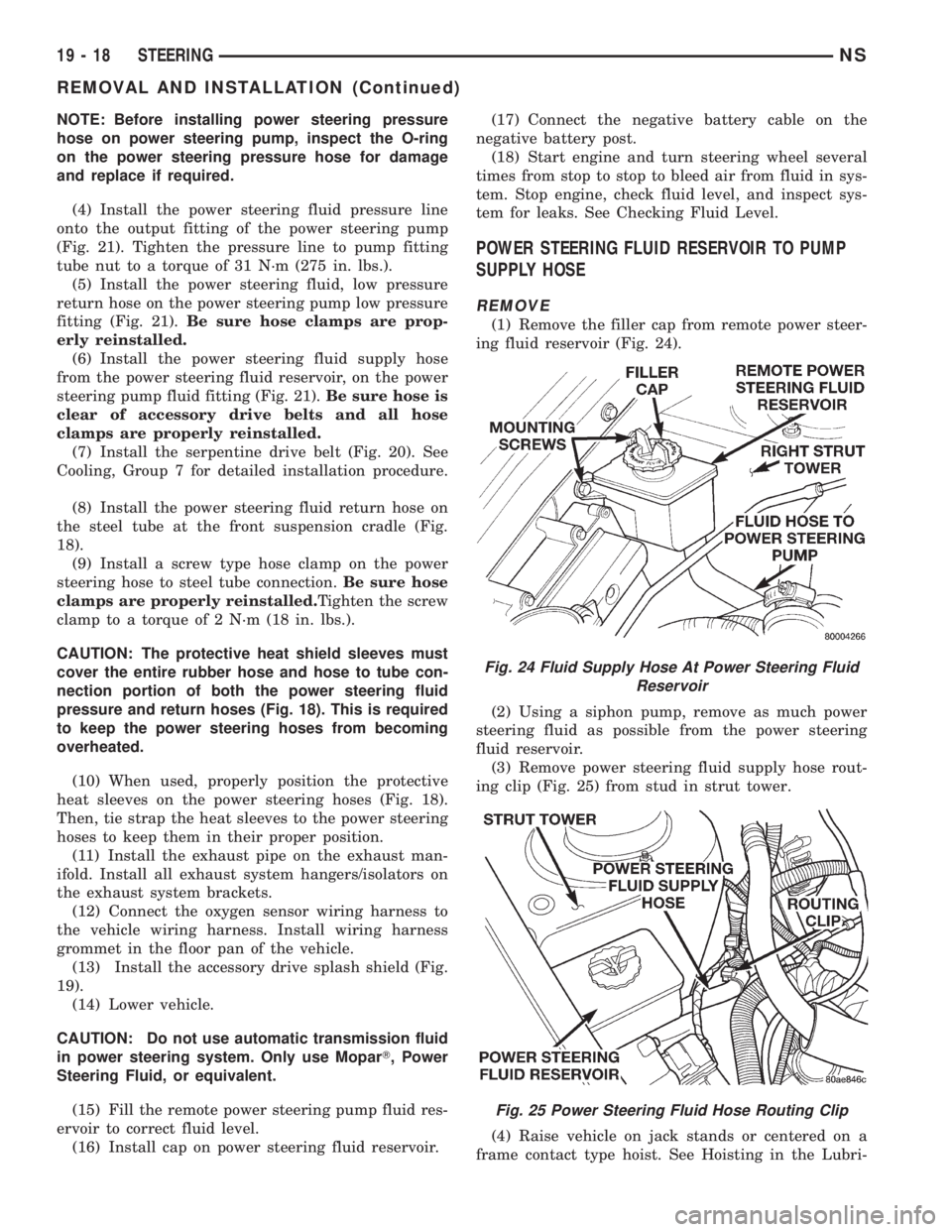

(1) Remove the filler cap from remote power steer-

ing fluid reservoir (Fig. 24).

(2) Using a siphon pump, remove as much power

steering fluid as possible from the power steering

fluid reservoir.

(3) Remove power steering fluid supply hose rout-

ing clip (Fig. 25) from stud in strut tower.

(4) Raise vehicle on jack stands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

Fig. 24 Fluid Supply Hose At Power Steering Fluid

Reservoir

Fig. 25 Power Steering Fluid Hose Routing Clip

19 - 18 STEERINGNS

REMOVAL AND INSTALLATION (Continued)

Page 1446 of 1938

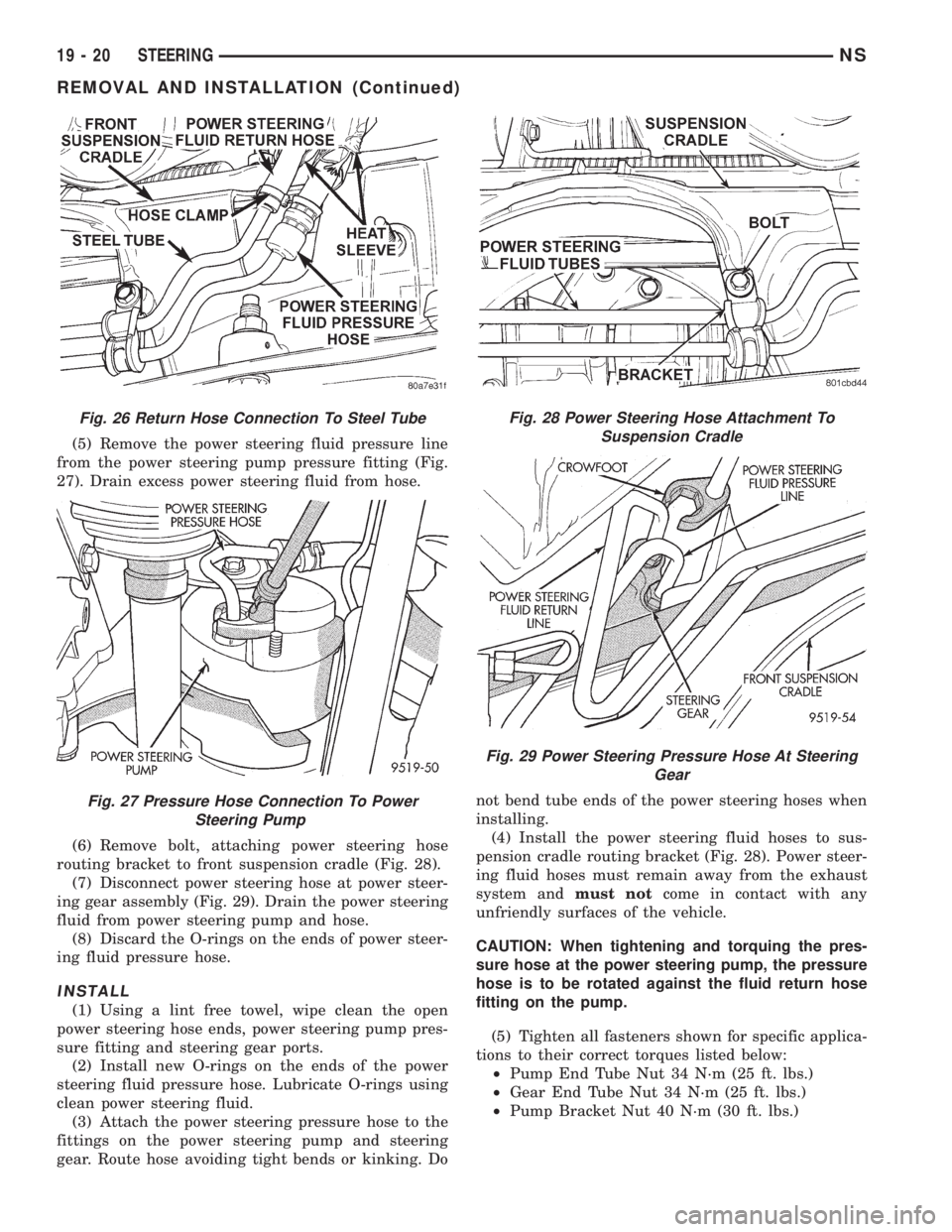

(5) Remove the power steering fluid pressure line

from the power steering pump pressure fitting (Fig.

27). Drain excess power steering fluid from hose.

(6) Remove bolt, attaching power steering hose

routing bracket to front suspension cradle (Fig. 28).

(7) Disconnect power steering hose at power steer-

ing gear assembly (Fig. 29). Drain the power steering

fluid from power steering pump and hose.

(8) Discard the O-rings on the ends of power steer-

ing fluid pressure hose.

INSTALL

(1) Using a lint free towel, wipe clean the open

power steering hose ends, power steering pump pres-

sure fitting and steering gear ports.

(2) Install new O-rings on the ends of the power

steering fluid pressure hose. Lubricate O-rings using

clean power steering fluid.

(3) Attach the power steering pressure hose to the

fittings on the power steering pump and steering

gear. Route hose avoiding tight bends or kinking. Donot bend tube ends of the power steering hoses when

installing.

(4) Install the power steering fluid hoses to sus-

pension cradle routing bracket (Fig. 28). Power steer-

ing fluid hoses must remain away from the exhaust

system andmust notcome in contact with any

unfriendly surfaces of the vehicle.

CAUTION: When tightening and torquing the pres-

sure hose at the power steering pump, the pressure

hose is to be rotated against the fluid return hose

fitting on the pump.

(5) Tighten all fasteners shown for specific applica-

tions to their correct torques listed below:

²Pump End Tube Nut 34 N´m (25 ft. lbs.)

²Gear End Tube Nut 34 N´m (25 ft. lbs.)

²Pump Bracket Nut 40 N´m (30 ft. lbs.)

Fig. 26 Return Hose Connection To Steel Tube

Fig. 27 Pressure Hose Connection To Power

Steering Pump

Fig. 28 Power Steering Hose Attachment To

Suspension Cradle

Fig. 29 Power Steering Pressure Hose At Steering

Gear

19 - 20 STEERINGNS

REMOVAL AND INSTALLATION (Continued)

Page 1447 of 1938

(6) Install the power steering fluid return hose on

the steel tube at the front suspension cradle (Fig.

26).

(7) Install a screw type hose clamp on the power

steering hose to steel tube connection. Tighten the

screw clamp to a torque of 2 N´m (18 in. lbs.).

CAUTION: The protective heat sleeves must cover

the entire rubber hose and hose to tube connection

portion of both the power steering fluid pressure

and return hoses (Fig. 26).

(8) When used, properly position the protective

heat sleeves on the power steering hoses. Then, tie

strap the heat sleeves to the power steering hoses to

keep them in their proper position.

(9) After hoses are installed and power steering

system is filled with fluid and cap is installed on res-

ervoir. Start the engine and check for leaks. (See

Pump Installation).

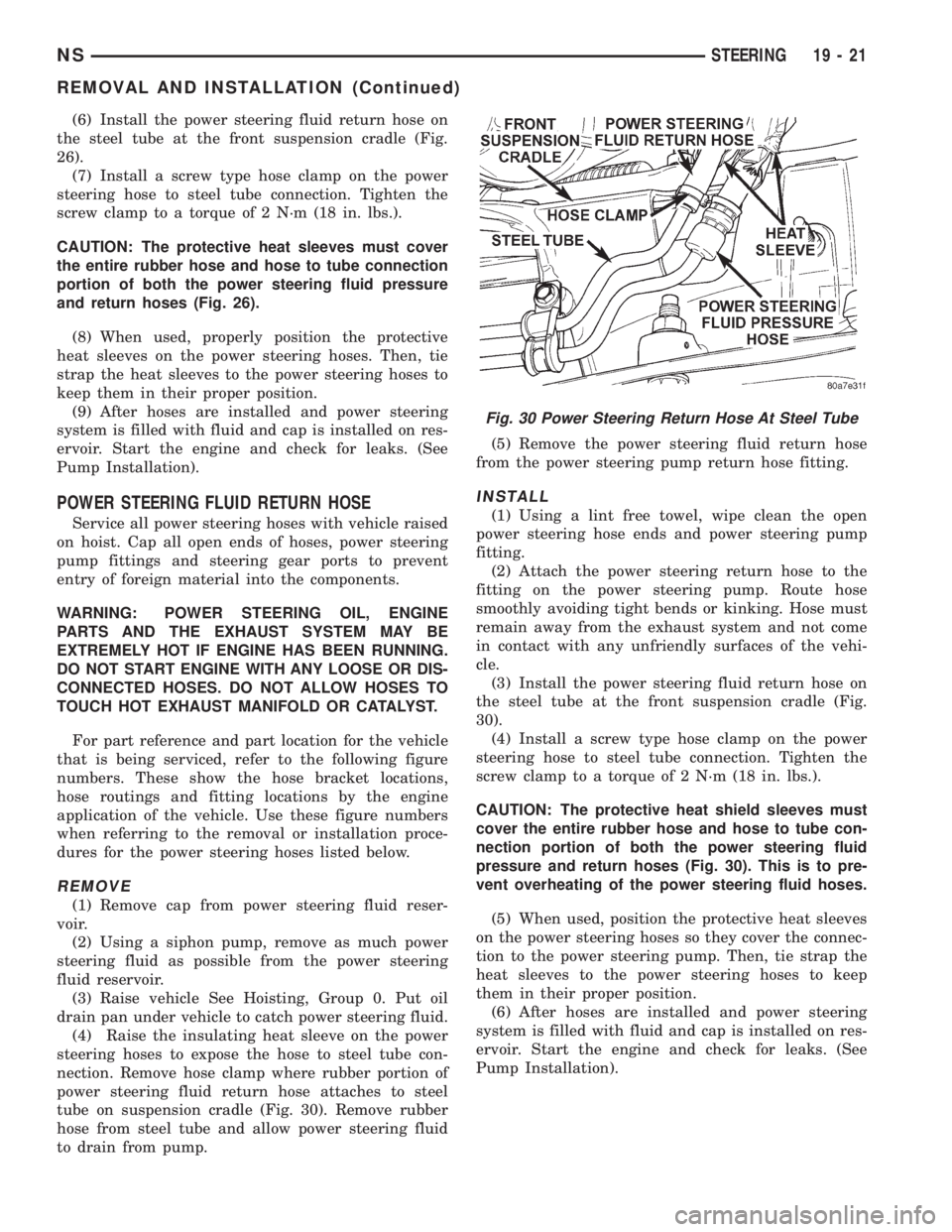

POWER STEERING FLUID RETURN HOSE

Service all power steering hoses with vehicle raised

on hoist. Cap all open ends of hoses, power steering

pump fittings and steering gear ports to prevent

entry of foreign material into the components.

WARNING: POWER STEERING OIL, ENGINE

PARTS AND THE EXHAUST SYSTEM MAY BE

EXTREMELY HOT IF ENGINE HAS BEEN RUNNING.

DO NOT START ENGINE WITH ANY LOOSE OR DIS-

CONNECTED HOSES. DO NOT ALLOW HOSES TO

TOUCH HOT EXHAUST MANIFOLD OR CATALYST.

For part reference and part location for the vehicle

that is being serviced, refer to the following figure

numbers. These show the hose bracket locations,

hose routings and fitting locations by the engine

application of the vehicle. Use these figure numbers

when referring to the removal or installation proce-

dures for the power steering hoses listed below.

REMOVE

(1) Remove cap from power steering fluid reser-

voir.

(2) Using a siphon pump, remove as much power

steering fluid as possible from the power steering

fluid reservoir.

(3) Raise vehicle See Hoisting, Group 0. Put oil

drain pan under vehicle to catch power steering fluid.

(4) Raise the insulating heat sleeve on the power

steering hoses to expose the hose to steel tube con-

nection. Remove hose clamp where rubber portion of

power steering fluid return hose attaches to steel

tube on suspension cradle (Fig. 30). Remove rubber

hose from steel tube and allow power steering fluid

to drain from pump.(5) Remove the power steering fluid return hose

from the power steering pump return hose fitting.

INSTALL

(1) Using a lint free towel, wipe clean the open

power steering hose ends and power steering pump

fitting.

(2) Attach the power steering return hose to the

fitting on the power steering pump. Route hose

smoothly avoiding tight bends or kinking. Hose must

remain away from the exhaust system and not come

in contact with any unfriendly surfaces of the vehi-

cle.

(3) Install the power steering fluid return hose on

the steel tube at the front suspension cradle (Fig.

30).

(4) Install a screw type hose clamp on the power

steering hose to steel tube connection. Tighten the

screw clamp to a torque of 2 N´m (18 in. lbs.).

CAUTION: The protective heat shield sleeves must

cover the entire rubber hose and hose to tube con-

nection portion of both the power steering fluid

pressure and return hoses (Fig. 30). This is to pre-

vent overheating of the power steering fluid hoses.

(5) When used, position the protective heat sleeves

on the power steering hoses so they cover the connec-

tion to the power steering pump. Then, tie strap the

heat sleeves to the power steering hoses to keep

them in their proper position.

(6) After hoses are installed and power steering

system is filled with fluid and cap is installed on res-

ervoir. Start the engine and check for leaks. (See

Pump Installation).

Fig. 30 Power Steering Return Hose At Steel Tube

NSSTEERING 19 - 21

REMOVAL AND INSTALLATION (Continued)

Page 1450 of 1938

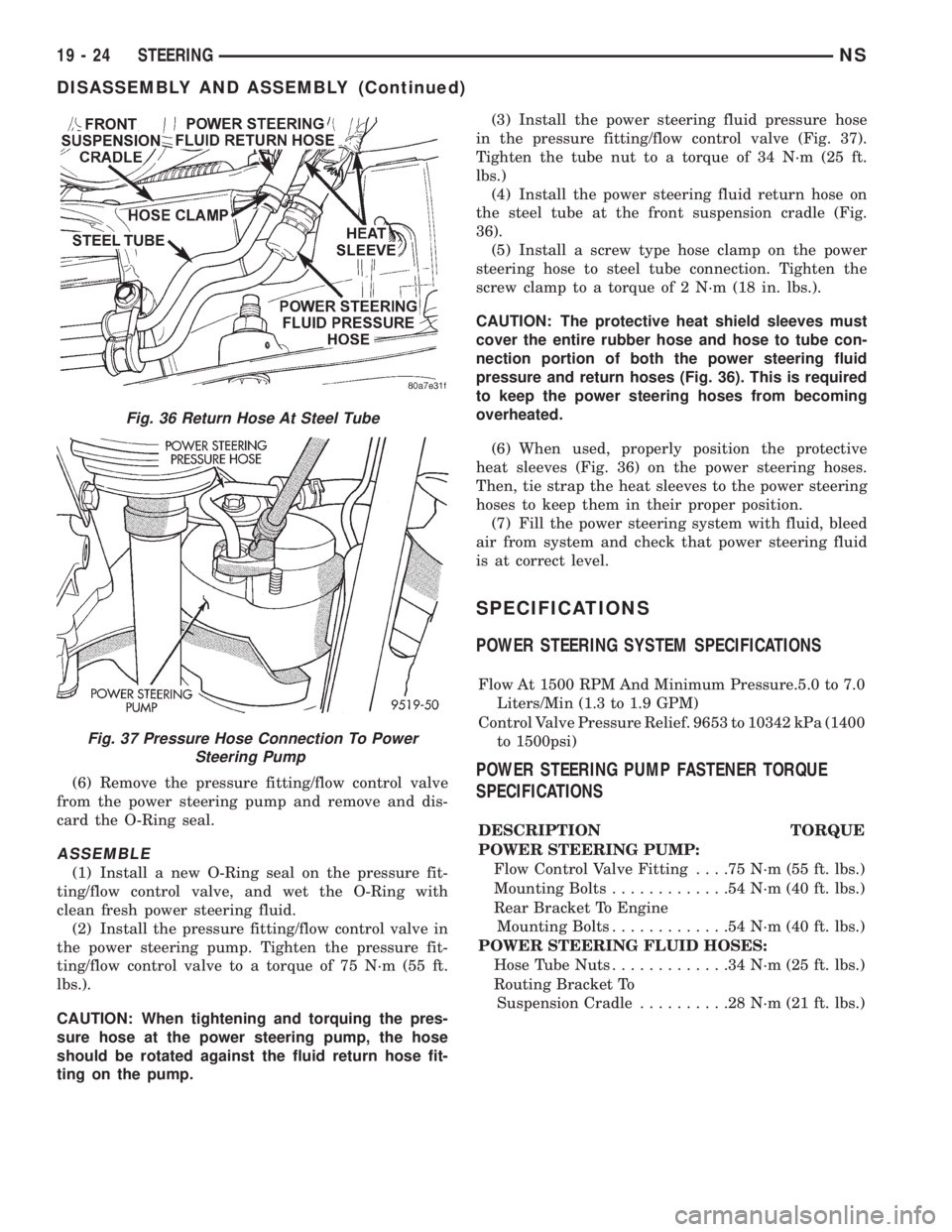

(6) Remove the pressure fitting/flow control valve

from the power steering pump and remove and dis-

card the O-Ring seal.

ASSEMBLE

(1) Install a new O-Ring seal on the pressure fit-

ting/flow control valve, and wet the O-Ring with

clean fresh power steering fluid.

(2) Install the pressure fitting/flow control valve in

the power steering pump. Tighten the pressure fit-

ting/flow control valve to a torque of 75 N´m (55 ft.

lbs.).

CAUTION: When tightening and torquing the pres-

sure hose at the power steering pump, the hose

should be rotated against the fluid return hose fit-

ting on the pump.(3) Install the power steering fluid pressure hose

in the pressure fitting/flow control valve (Fig. 37).

Tighten the tube nut to a torque of 34 N´m (25 ft.

lbs.)

(4) Install the power steering fluid return hose on

the steel tube at the front suspension cradle (Fig.

36).

(5) Install a screw type hose clamp on the power

steering hose to steel tube connection. Tighten the

screw clamp to a torque of 2 N´m (18 in. lbs.).

CAUTION: The protective heat shield sleeves must

cover the entire rubber hose and hose to tube con-

nection portion of both the power steering fluid

pressure and return hoses (Fig. 36). This is required

to keep the power steering hoses from becoming

overheated.

(6) When used, properly position the protective

heat sleeves (Fig. 36) on the power steering hoses.

Then, tie strap the heat sleeves to the power steering

hoses to keep them in their proper position.

(7) Fill the power steering system with fluid, bleed

air from system and check that power steering fluid

is at correct level.

SPECIFICATIONS

POWER STEERING SYSTEM SPECIFICATIONS

Flow At 1500 RPM And Minimum Pressure.5.0 to 7.0

Liters/Min (1.3 to 1.9 GPM)

Control Valve Pressure Relief. 9653 to 10342 kPa (1400

to 1500psi)

POWER STEERING PUMP FASTENER TORQUE

SPECIFICATIONS

DESCRIPTION TORQUE

POWER STEERING PUMP:

Flow Control Valve Fitting. . . .75 N´m (55 ft. lbs.)

Mounting Bolts.............54N´m(40ft.lbs.)

Rear Bracket To Engine

Mounting Bolts.............54N´m(40ft.lbs.)

POWER STEERING FLUID HOSES:

Hose Tube Nuts.............34N´m(25ft.lbs.)

Routing Bracket To

Suspension Cradle..........28N´m(21ft.lbs.)

Fig. 36 Return Hose At Steel Tube

Fig. 37 Pressure Hose Connection To Power

Steering Pump

19 - 24 STEERINGNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1452 of 1938

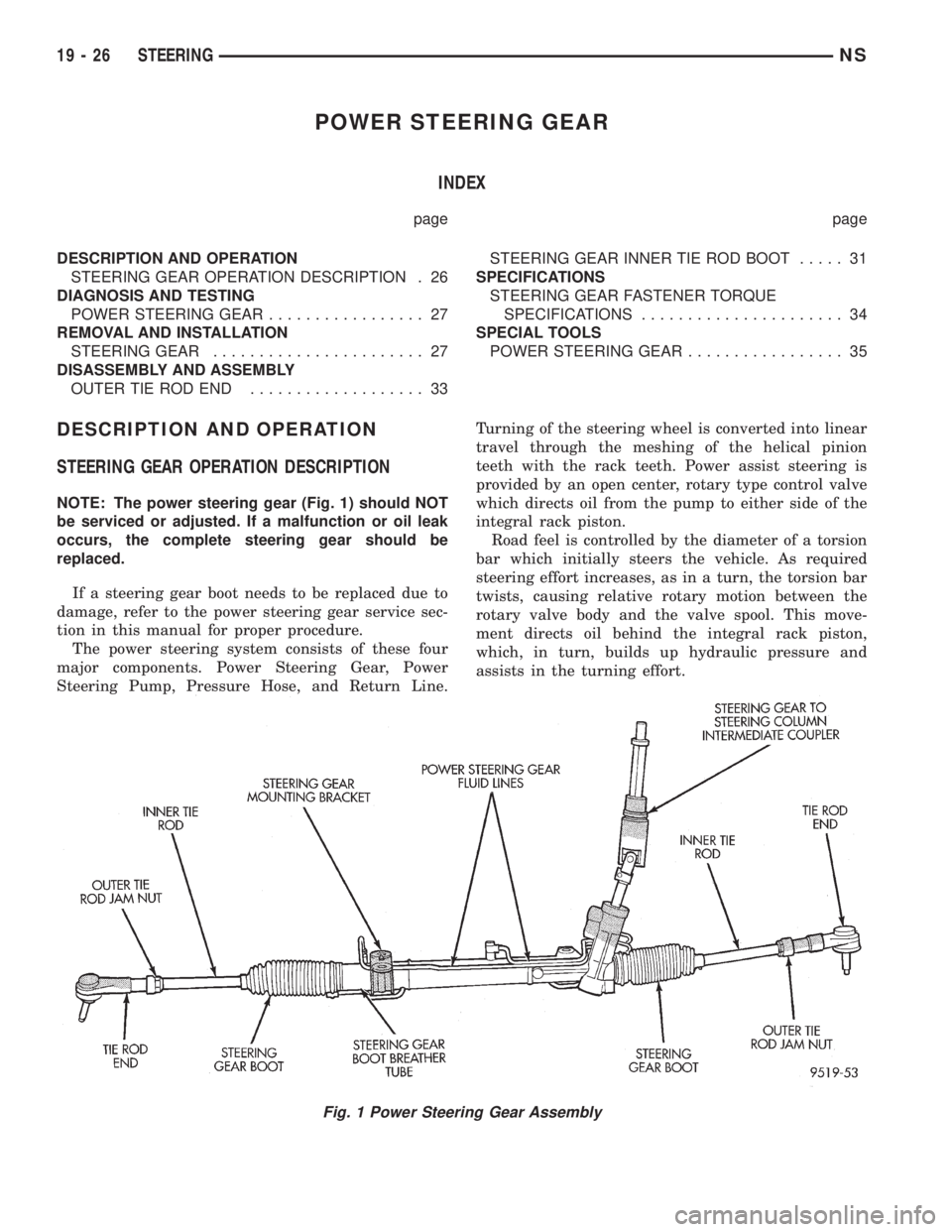

POWER STEERING GEAR

INDEX

page page

DESCRIPTION AND OPERATION

STEERING GEAR OPERATION DESCRIPTION . 26

DIAGNOSIS AND TESTING

POWER STEERING GEAR................. 27

REMOVAL AND INSTALLATION

STEERING GEAR....................... 27

DISASSEMBLY AND ASSEMBLY

OUTER TIE ROD END................... 33STEERING GEAR INNER TIE ROD BOOT..... 31

SPECIFICATIONS

STEERING GEAR FASTENER TORQUE

SPECIFICATIONS...................... 34

SPECIAL TOOLS

POWER STEERING GEAR................. 35

DESCRIPTION AND OPERATION

STEERING GEAR OPERATION DESCRIPTION

NOTE: The power steering gear (Fig. 1) should NOT

be serviced or adjusted. If a malfunction or oil leak

occurs, the complete steering gear should be

replaced.

If a steering gear boot needs to be replaced due to

damage, refer to the power steering gear service sec-

tion in this manual for proper procedure.

The power steering system consists of these four

major components. Power Steering Gear, Power

Steering Pump, Pressure Hose, and Return Line.Turning of the steering wheel is converted into linear

travel through the meshing of the helical pinion

teeth with the rack teeth. Power assist steering is

provided by an open center, rotary type control valve

which directs oil from the pump to either side of the

integral rack piston.

Road feel is controlled by the diameter of a torsion

bar which initially steers the vehicle. As required

steering effort increases, as in a turn, the torsion bar

twists, causing relative rotary motion between the

rotary valve body and the valve spool. This move-

ment directs oil behind the integral rack piston,

which, in turn, builds up hydraulic pressure and

assists in the turning effort.

Fig. 1 Power Steering Gear Assembly

19 - 26 STEERINGNS

Page 1456 of 1938

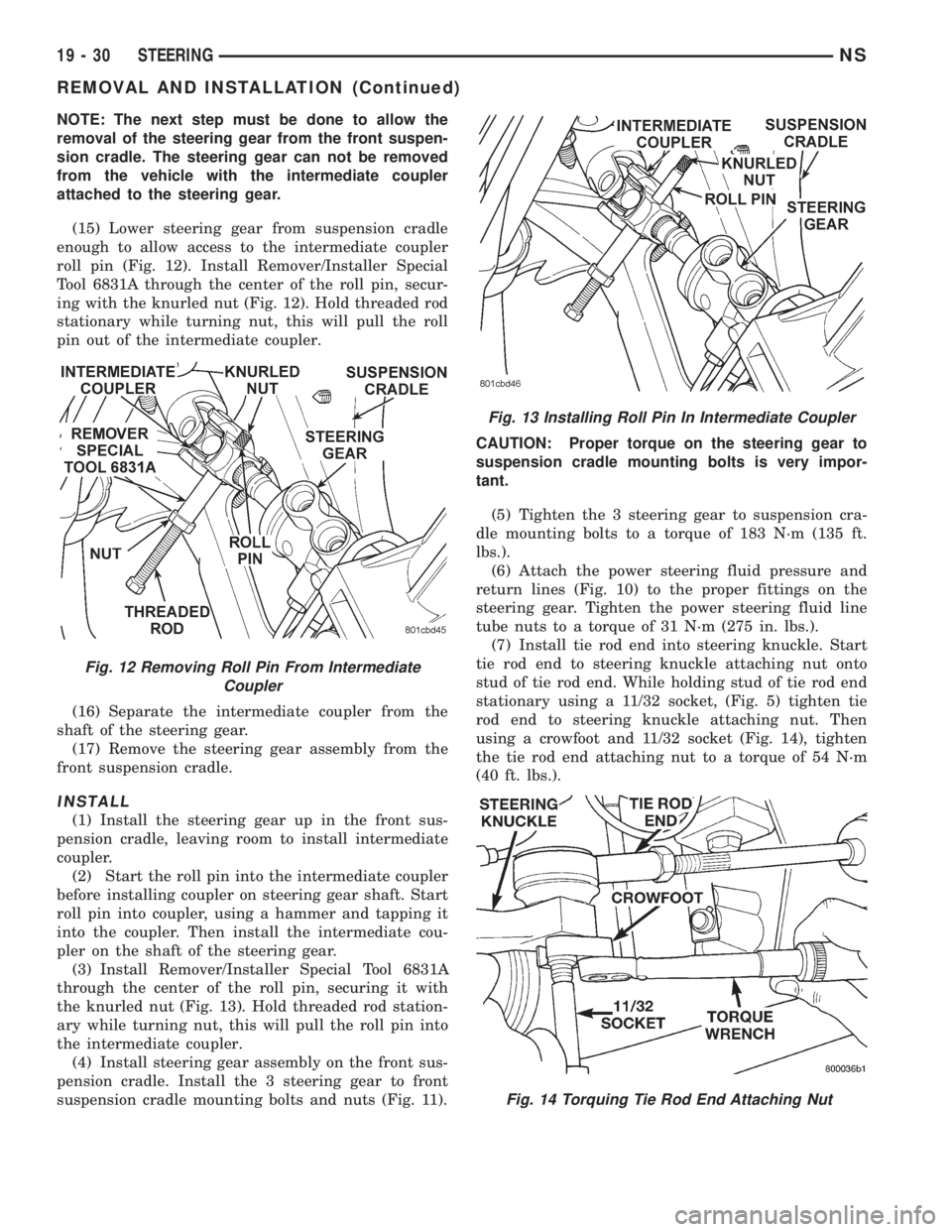

NOTE: The next step must be done to allow the

removal of the steering gear from the front suspen-

sion cradle. The steering gear can not be removed

from the vehicle with the intermediate coupler

attached to the steering gear.

(15) Lower steering gear from suspension cradle

enough to allow access to the intermediate coupler

roll pin (Fig. 12). Install Remover/Installer Special

Tool 6831A through the center of the roll pin, secur-

ing with the knurled nut (Fig. 12). Hold threaded rod

stationary while turning nut, this will pull the roll

pin out of the intermediate coupler.

(16) Separate the intermediate coupler from the

shaft of the steering gear.

(17) Remove the steering gear assembly from the

front suspension cradle.

INSTALL

(1) Install the steering gear up in the front sus-

pension cradle, leaving room to install intermediate

coupler.

(2) Start the roll pin into the intermediate coupler

before installing coupler on steering gear shaft. Start

roll pin into coupler, using a hammer and tapping it

into the coupler. Then install the intermediate cou-

pler on the shaft of the steering gear.

(3) Install Remover/Installer Special Tool 6831A

through the center of the roll pin, securing it with

the knurled nut (Fig. 13). Hold threaded rod station-

ary while turning nut, this will pull the roll pin into

the intermediate coupler.

(4) Install steering gear assembly on the front sus-

pension cradle. Install the 3 steering gear to front

suspension cradle mounting bolts and nuts (Fig. 11).CAUTION: Proper torque on the steering gear to

suspension cradle mounting bolts is very impor-

tant.

(5) Tighten the 3 steering gear to suspension cra-

dle mounting bolts to a torque of 183 N´m (135 ft.

lbs.).

(6) Attach the power steering fluid pressure and

return lines (Fig. 10) to the proper fittings on the

steering gear. Tighten the power steering fluid line

tube nuts to a torque of 31 N´m (275 in. lbs.).

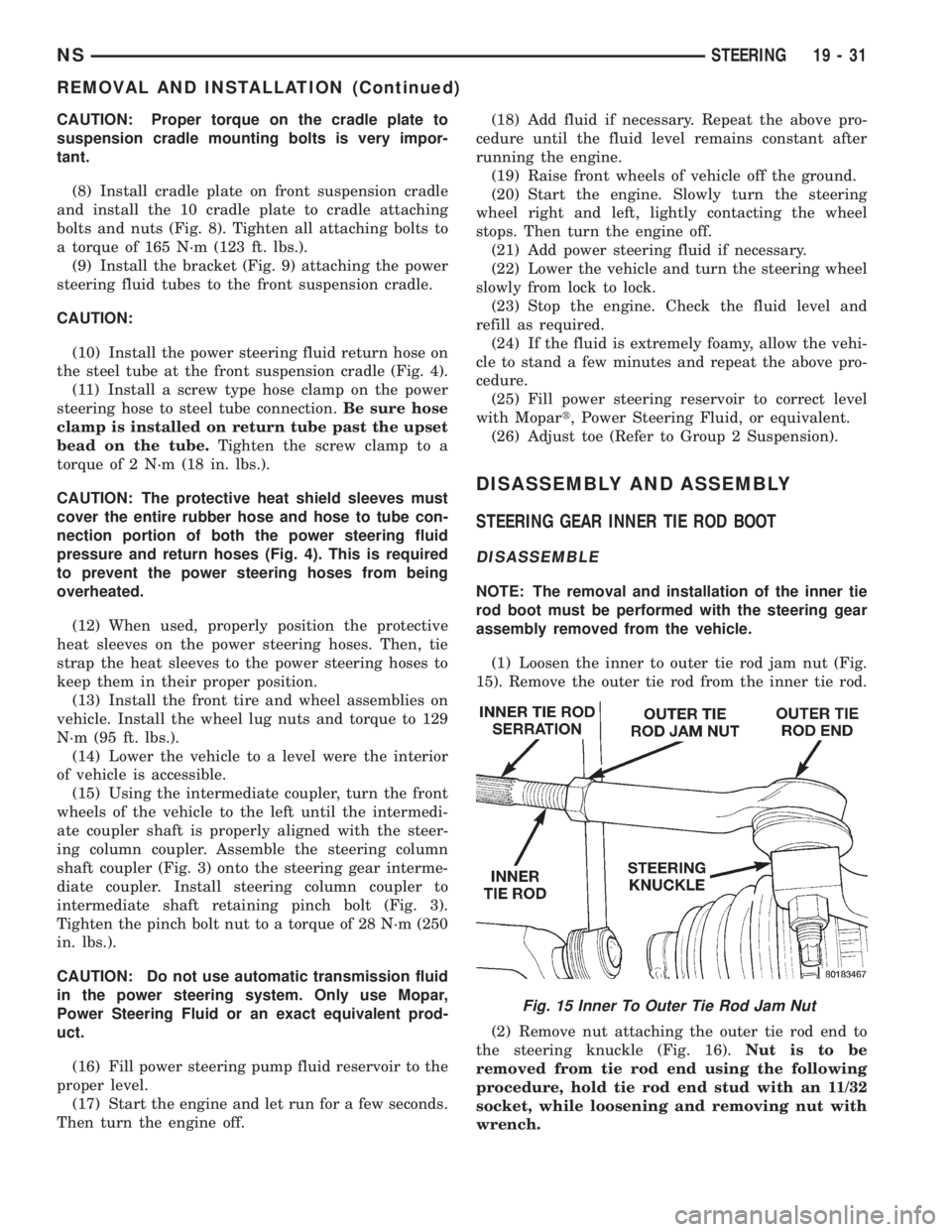

(7) Install tie rod end into steering knuckle. Start

tie rod end to steering knuckle attaching nut onto

stud of tie rod end. While holding stud of tie rod end

stationary using a 11/32 socket, (Fig. 5) tighten tie

rod end to steering knuckle attaching nut. Then

using a crowfoot and 11/32 socket (Fig. 14), tighten

the tie rod end attaching nut to a torque of 54 N´m

(40 ft. lbs.).

Fig. 12 Removing Roll Pin From Intermediate

Coupler

Fig. 13 Installing Roll Pin In Intermediate Coupler

Fig. 14 Torquing Tie Rod End Attaching Nut

19 - 30 STEERINGNS

REMOVAL AND INSTALLATION (Continued)

Page 1457 of 1938

CAUTION: Proper torque on the cradle plate to

suspension cradle mounting bolts is very impor-

tant.

(8) Install cradle plate on front suspension cradle

and install the 10 cradle plate to cradle attaching

bolts and nuts (Fig. 8). Tighten all attaching bolts to

a torque of 165 N´m (123 ft. lbs.).

(9) Install the bracket (Fig. 9) attaching the power

steering fluid tubes to the front suspension cradle.

CAUTION:

(10) Install the power steering fluid return hose on

the steel tube at the front suspension cradle (Fig. 4).

(11) Install a screw type hose clamp on the power

steering hose to steel tube connection.Be sure hose

clamp is installed on return tube past the upset

bead on the tube.Tighten the screw clamp to a

torque of 2 N´m (18 in. lbs.).

CAUTION: The protective heat shield sleeves must

cover the entire rubber hose and hose to tube con-

nection portion of both the power steering fluid

pressure and return hoses (Fig. 4). This is required

to prevent the power steering hoses from being

overheated.

(12) When used, properly position the protective

heat sleeves on the power steering hoses. Then, tie

strap the heat sleeves to the power steering hoses to

keep them in their proper position.

(13) Install the front tire and wheel assemblies on

vehicle. Install the wheel lug nuts and torque to 129

N´m (95 ft. lbs.).

(14) Lower the vehicle to a level were the interior

of vehicle is accessible.

(15) Using the intermediate coupler, turn the front

wheels of the vehicle to the left until the intermedi-

ate coupler shaft is properly aligned with the steer-

ing column coupler. Assemble the steering column

shaft coupler (Fig. 3) onto the steering gear interme-

diate coupler. Install steering column coupler to

intermediate shaft retaining pinch bolt (Fig. 3).

Tighten the pinch bolt nut to a torque of 28 N´m (250

in. lbs.).

CAUTION: Do not use automatic transmission fluid

in the power steering system. Only use Mopar,

Power Steering Fluid or an exact equivalent prod-

uct.

(16) Fill power steering pump fluid reservoir to the

proper level.

(17) Start the engine and let run for a few seconds.

Then turn the engine off.(18) Add fluid if necessary. Repeat the above pro-

cedure until the fluid level remains constant after

running the engine.

(19) Raise front wheels of vehicle off the ground.

(20) Start the engine. Slowly turn the steering

wheel right and left, lightly contacting the wheel

stops. Then turn the engine off.

(21) Add power steering fluid if necessary.

(22) Lower the vehicle and turn the steering wheel

slowly from lock to lock.

(23) Stop the engine. Check the fluid level and

refill as required.

(24) If the fluid is extremely foamy, allow the vehi-

cle to stand a few minutes and repeat the above pro-

cedure.

(25) Fill power steering reservoir to correct level

with Mopart, Power Steering Fluid, or equivalent.

(26) Adjust toe (Refer to Group 2 Suspension).

DISASSEMBLY AND ASSEMBLY

STEERING GEAR INNER TIE ROD BOOT

DISASSEMBLE

NOTE: The removal and installation of the inner tie

rod boot must be performed with the steering gear

assembly removed from the vehicle.

(1) Loosen the inner to outer tie rod jam nut (Fig.

15). Remove the outer tie rod from the inner tie rod.

(2) Remove nut attaching the outer tie rod end to

the steering knuckle (Fig. 16).Nut is to be

removed from tie rod end using the following

procedure, hold tie rod end stud with an 11/32

socket, while loosening and removing nut with

wrench.

Fig. 15 Inner To Outer Tie Rod Jam Nut

NSSTEERING 19 - 31

REMOVAL AND INSTALLATION (Continued)