torque CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1358 of 1938

REMOVAL AND INSTALLATION

THROTTLE BODY

REMOVAL

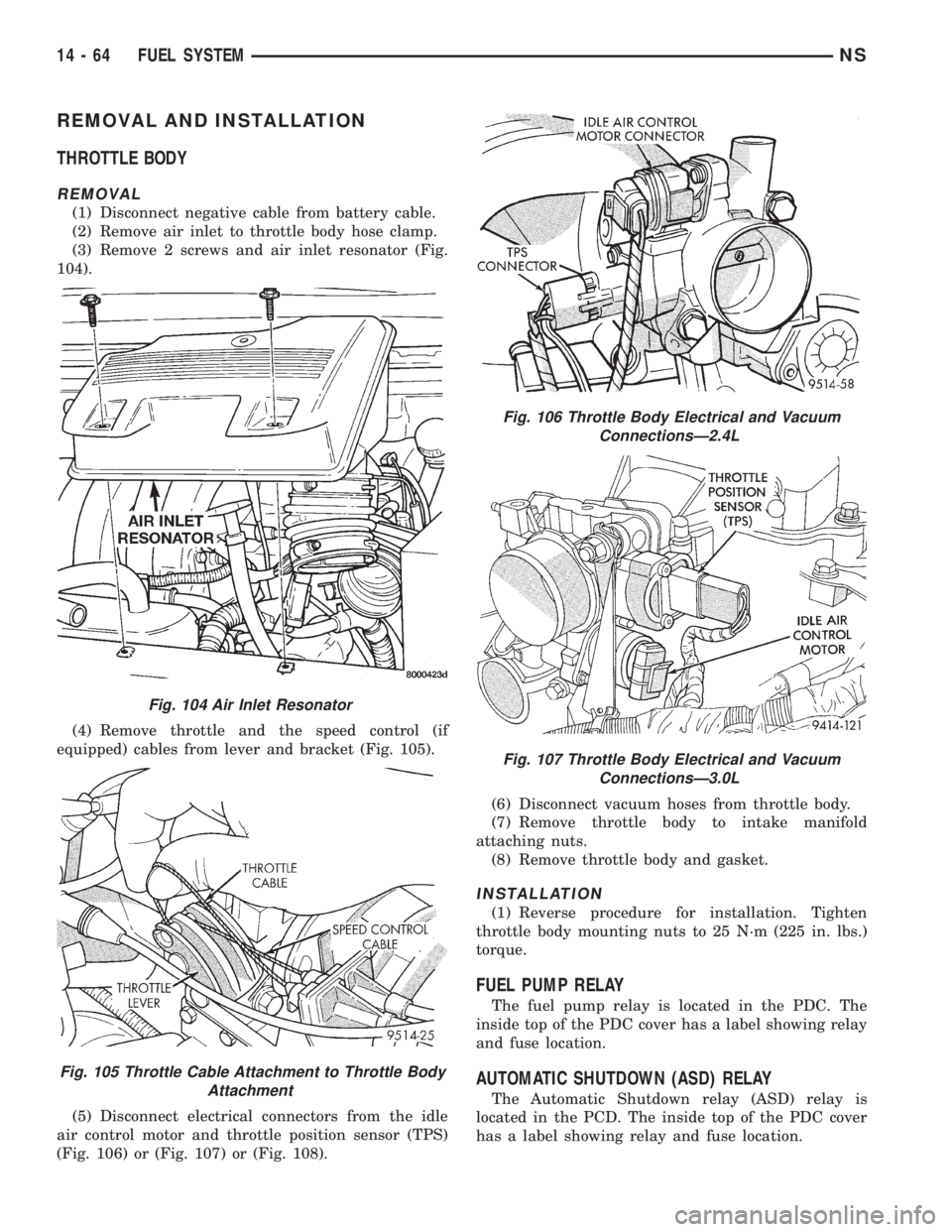

(1) Disconnect negative cable from battery cable.

(2) Remove air inlet to throttle body hose clamp.

(3) Remove 2 screws and air inlet resonator (Fig.

104).

(4) Remove throttle and the speed control (if

equipped) cables from lever and bracket (Fig. 105).

(5) Disconnect electrical connectors from the idle

air control motor and throttle position sensor (TPS)

(Fig. 106) or (Fig. 107) or (Fig. 108).(6) Disconnect vacuum hoses from throttle body.

(7) Remove throttle body to intake manifold

attaching nuts.

(8) Remove throttle body and gasket.

INSTALLATION

(1) Reverse procedure for installation. Tighten

throttle body mounting nuts to 25 N´m (225 in. lbs.)

torque.

FUEL PUMP RELAY

The fuel pump relay is located in the PDC. The

inside top of the PDC cover has a label showing relay

and fuse location.

AUTOMATIC SHUTDOWN (ASD) RELAY

The Automatic Shutdown relay (ASD) relay is

located in the PCD. The inside top of the PDC cover

has a label showing relay and fuse location.

Fig. 104 Air Inlet Resonator

Fig. 105 Throttle Cable Attachment to Throttle Body

Attachment

Fig. 106 Throttle Body Electrical and Vacuum

ConnectionsÐ2.4L

Fig. 107 Throttle Body Electrical and Vacuum

ConnectionsÐ3.0L

14 - 64 FUEL SYSTEMNS

Page 1359 of 1938

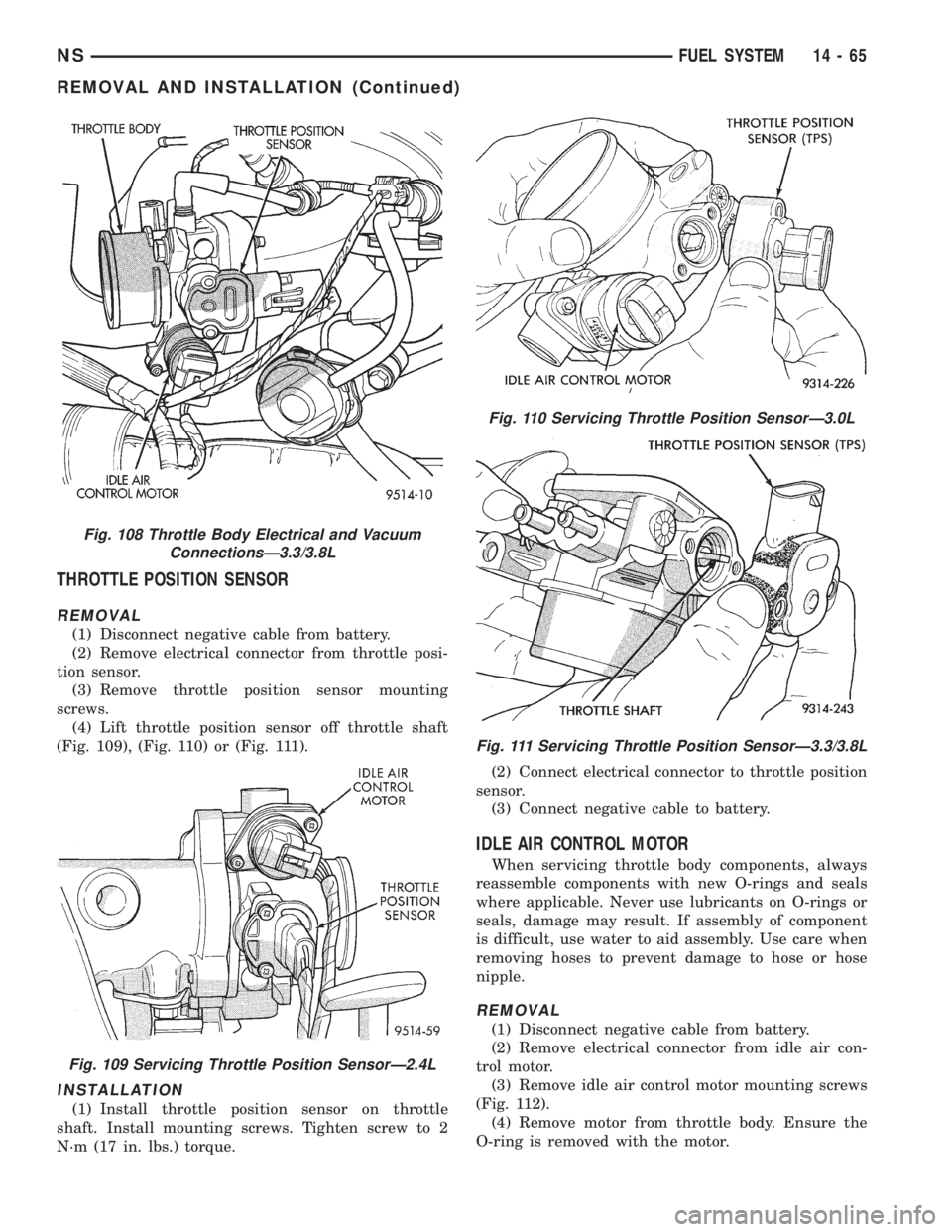

THROTTLE POSITION SENSOR

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove electrical connector from throttle posi-

tion sensor.

(3) Remove throttle position sensor mounting

screws.

(4) Lift throttle position sensor off throttle shaft

(Fig. 109), (Fig. 110) or (Fig. 111).

INSTALLATION

(1) Install throttle position sensor on throttle

shaft. Install mounting screws. Tighten screw to 2

N´m (17 in. lbs.) torque.(2) Connect electrical connector to throttle position

sensor.

(3) Connect negative cable to battery.

IDLE AIR CONTROL MOTOR

When servicing throttle body components, always

reassemble components with new O-rings and seals

where applicable. Never use lubricants on O-rings or

seals, damage may result. If assembly of component

is difficult, use water to aid assembly. Use care when

removing hoses to prevent damage to hose or hose

nipple.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove electrical connector from idle air con-

trol motor.

(3) Remove idle air control motor mounting screws

(Fig. 112).

(4) Remove motor from throttle body. Ensure the

O-ring is removed with the motor.

Fig. 108 Throttle Body Electrical and Vacuum

ConnectionsÐ3.3/3.8L

Fig. 109 Servicing Throttle Position SensorÐ2.4L

Fig. 110 Servicing Throttle Position SensorÐ3.0L

Fig. 111 Servicing Throttle Position SensorÐ3.3/3.8L

NSFUEL SYSTEM 14 - 65

REMOVAL AND INSTALLATION (Continued)

Page 1360 of 1938

INSTALLATION

(1) The new idle air control motor has a new

O-ring installed on it. If pintle measures more than 1

inch (25 mm) it must be retracted. Use the DRB Idle

Air Control Motor Open/Close Test to retract the

pintle (battery must be connected.)

(2) Carefully place idle air control motor into

throttle body.

(3) Install mounting screws. Tighten screws to 2

N´m (17 in. lbs.) torque.

(4) Connect electrical connector to idle air control

motor.

(5) Connect negative cable to battery.

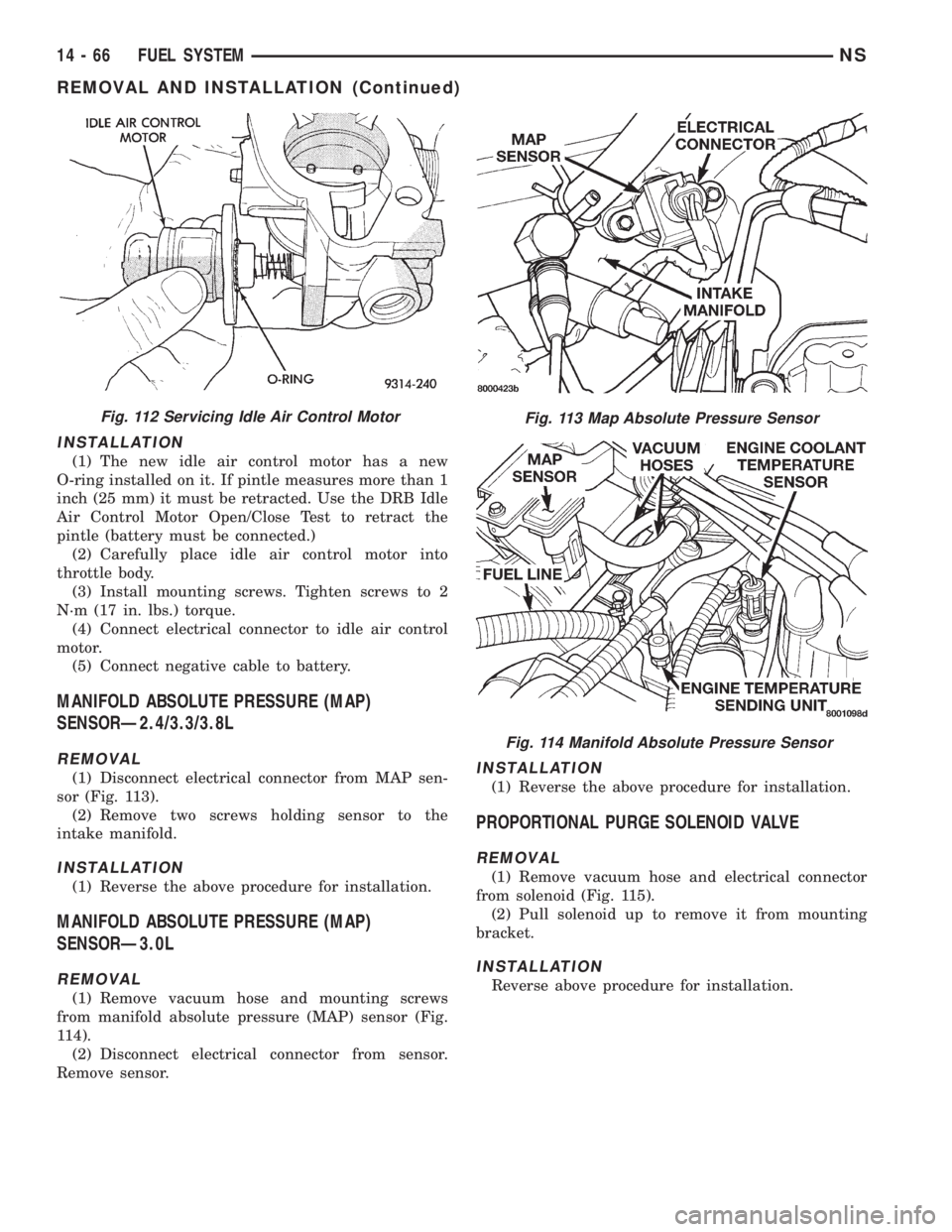

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSORÐ2.4/3.3/3.8L

REMOVAL

(1) Disconnect electrical connector from MAP sen-

sor (Fig. 113).

(2) Remove two screws holding sensor to the

intake manifold.

INSTALLATION

(1) Reverse the above procedure for installation.

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSORÐ3.0L

REMOVAL

(1) Remove vacuum hose and mounting screws

from manifold absolute pressure (MAP) sensor (Fig.

114).

(2) Disconnect electrical connector from sensor.

Remove sensor.

INSTALLATION

(1) Reverse the above procedure for installation.

PROPORTIONAL PURGE SOLENOID VALVE

REMOVAL

(1) Remove vacuum hose and electrical connector

from solenoid (Fig. 115).

(2) Pull solenoid up to remove it from mounting

bracket.

INSTALLATION

Reverse above procedure for installation.

Fig. 112 Servicing Idle Air Control MotorFig. 113 Map Absolute Pressure Sensor

Fig. 114 Manifold Absolute Pressure Sensor

14 - 66 FUEL SYSTEMNS

REMOVAL AND INSTALLATION (Continued)

Page 1363 of 1938

(4) When the sensor is removed, the exhaust man-

ifold threads must be cleaned with an 18 mm X 1.5 +

6E tap. If using original sensor, coat the threads with

Loctite 771-64 anti-seize compound or equivalent.

INSTALLATION

(1) Reverse removal procedure to install a new

sensor.

New sensors are packaged with compound on the

threads and no additional compound is required. The

sensor must be tightened to 27 N´m (20 ft. lbs.)

torque.

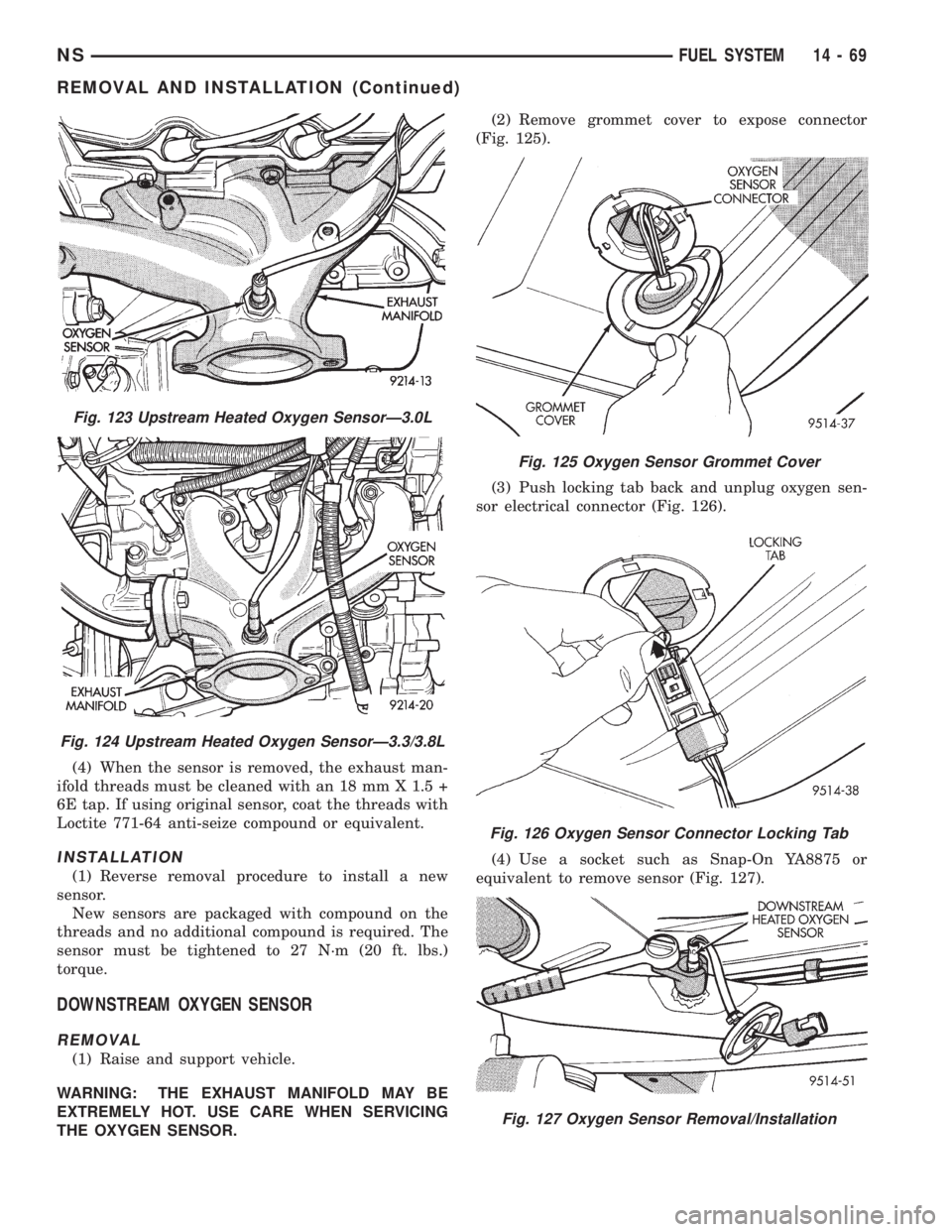

DOWNSTREAM OXYGEN SENSOR

REMOVAL

(1) Raise and support vehicle.

WARNING: THE EXHAUST MANIFOLD MAY BE

EXTREMELY HOT. USE CARE WHEN SERVICING

THE OXYGEN SENSOR.(2) Remove grommet cover to expose connector

(Fig. 125).

(3) Push locking tab back and unplug oxygen sen-

sor electrical connector (Fig. 126).

(4) Use a socket such as Snap-On YA8875 or

equivalent to remove sensor (Fig. 127).

Fig. 123 Upstream Heated Oxygen SensorÐ3.0L

Fig. 124 Upstream Heated Oxygen SensorÐ3.3/3.8L

Fig. 125 Oxygen Sensor Grommet Cover

Fig. 126 Oxygen Sensor Connector Locking Tab

Fig. 127 Oxygen Sensor Removal/Installation

NSFUEL SYSTEM 14 - 69

REMOVAL AND INSTALLATION (Continued)

Page 1364 of 1938

(5) When the sensor is removed, the exhaust man-

ifold threads must be cleaned with an 18 mm X 1.5 +

6E tap. If using original sensor, coat the threads with

Loctite 771-64 anti-seize compound or equivalent.

INSTALLATION

(1) Reverse removal procedure to install a new

sensor.

New sensors are packaged with compound on the

threads and no additional compound is required. The

sensor must be tightened to 27 N´m (20 ft. lbs.)

torque.

KNOCK SENSOR

For removal/installation procedures refer to Group

8D- Ignition System, Service Procedures.

AIR CLEANER ELEMENT

REMOVAL

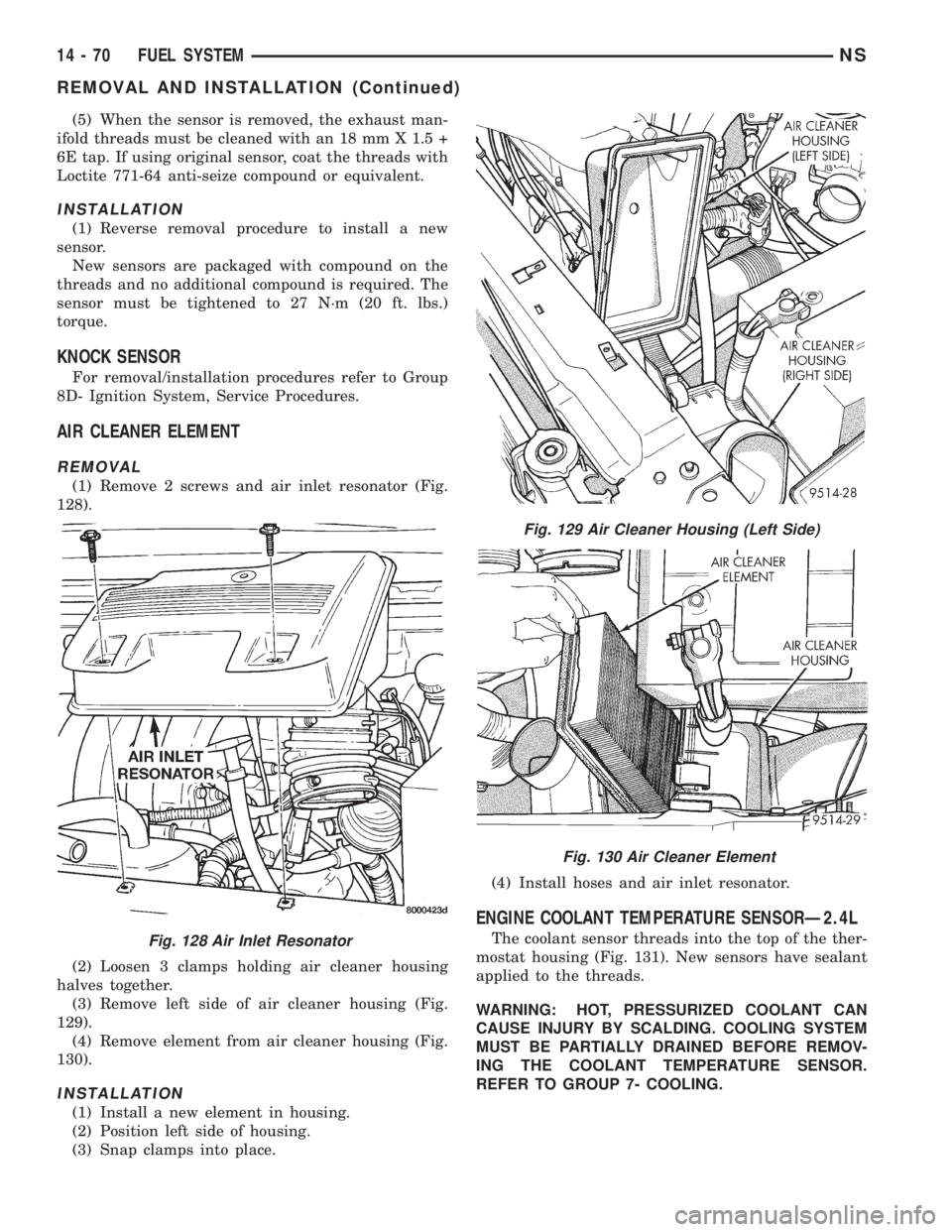

(1) Remove 2 screws and air inlet resonator (Fig.

128).

(2) Loosen 3 clamps holding air cleaner housing

halves together.

(3) Remove left side of air cleaner housing (Fig.

129).

(4) Remove element from air cleaner housing (Fig.

130).

INSTALLATION

(1) Install a new element in housing.

(2) Position left side of housing.

(3) Snap clamps into place.(4) Install hoses and air inlet resonator.

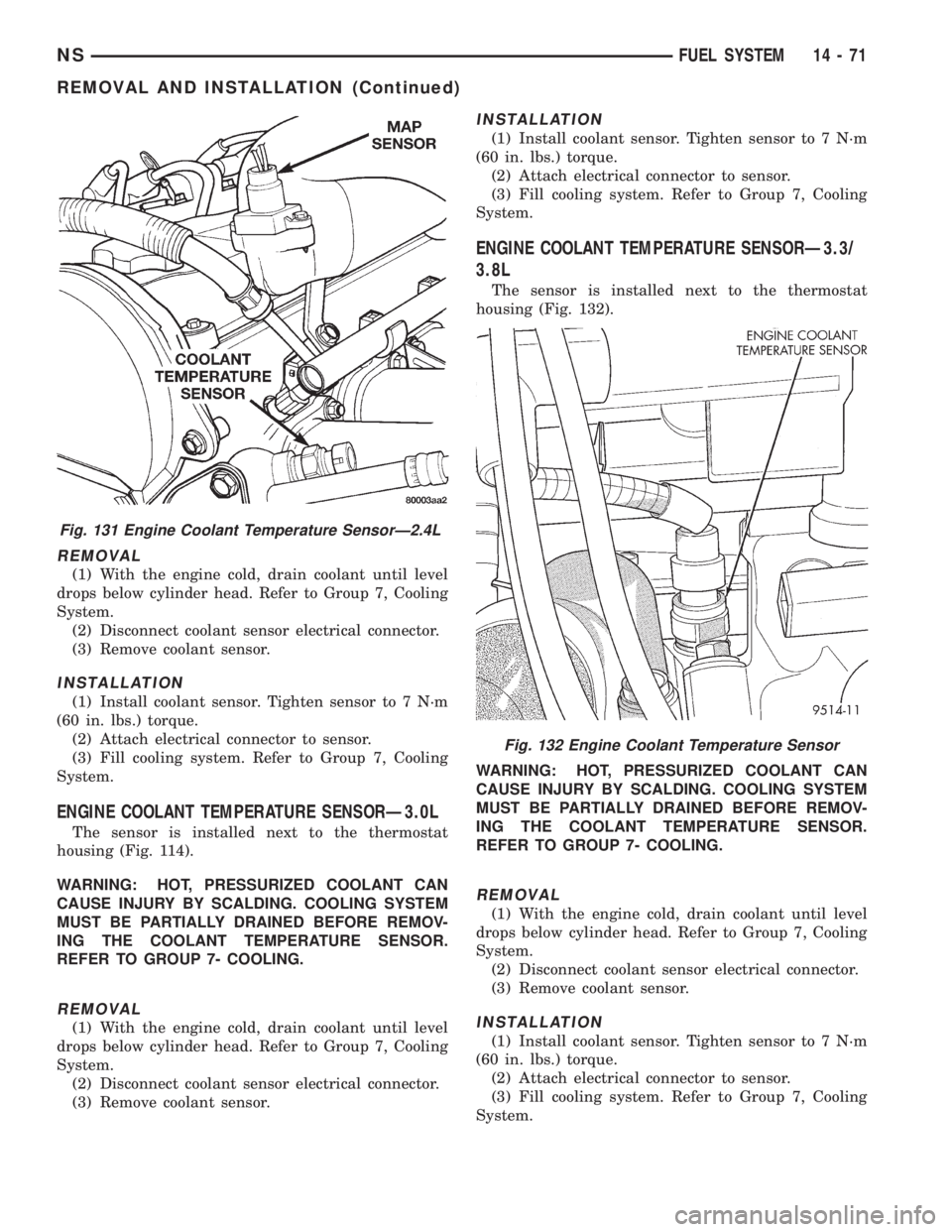

ENGINE COOLANT TEMPERATURE SENSORÐ2.4L

The coolant sensor threads into the top of the ther-

mostat housing (Fig. 131). New sensors have sealant

applied to the threads.

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING. COOLING SYSTEM

MUST BE PARTIALLY DRAINED BEFORE REMOV-

ING THE COOLANT TEMPERATURE SENSOR.

REFER TO GROUP 7- COOLING.Fig. 128 Air Inlet Resonator

Fig. 129 Air Cleaner Housing (Left Side)

Fig. 130 Air Cleaner Element

14 - 70 FUEL SYSTEMNS

REMOVAL AND INSTALLATION (Continued)

Page 1365 of 1938

REMOVAL

(1) With the engine cold, drain coolant until level

drops below cylinder head. Refer to Group 7, Cooling

System.

(2) Disconnect coolant sensor electrical connector.

(3) Remove coolant sensor.

INSTALLATION

(1) Install coolant sensor. Tighten sensor to 7 N´m

(60 in. lbs.) torque.

(2) Attach electrical connector to sensor.

(3) Fill cooling system. Refer to Group 7, Cooling

System.

ENGINE COOLANT TEMPERATURE SENSORÐ3.0L

The sensor is installed next to the thermostat

housing (Fig. 114).

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING. COOLING SYSTEM

MUST BE PARTIALLY DRAINED BEFORE REMOV-

ING THE COOLANT TEMPERATURE SENSOR.

REFER TO GROUP 7- COOLING.

REMOVAL

(1) With the engine cold, drain coolant until level

drops below cylinder head. Refer to Group 7, Cooling

System.

(2) Disconnect coolant sensor electrical connector.

(3) Remove coolant sensor.

INSTALLATION

(1) Install coolant sensor. Tighten sensor to 7 N´m

(60 in. lbs.) torque.

(2) Attach electrical connector to sensor.

(3) Fill cooling system. Refer to Group 7, Cooling

System.

ENGINE COOLANT TEMPERATURE SENSORÐ3.3/

3.8L

The sensor is installed next to the thermostat

housing (Fig. 132).

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING. COOLING SYSTEM

MUST BE PARTIALLY DRAINED BEFORE REMOV-

ING THE COOLANT TEMPERATURE SENSOR.

REFER TO GROUP 7- COOLING.

REMOVAL

(1) With the engine cold, drain coolant until level

drops below cylinder head. Refer to Group 7, Cooling

System.

(2) Disconnect coolant sensor electrical connector.

(3) Remove coolant sensor.

INSTALLATION

(1) Install coolant sensor. Tighten sensor to 7 N´m

(60 in. lbs.) torque.

(2) Attach electrical connector to sensor.

(3) Fill cooling system. Refer to Group 7, Cooling

System.

Fig. 131 Engine Coolant Temperature SensorÐ2.4L

Fig. 132 Engine Coolant Temperature Sensor

NSFUEL SYSTEM 14 - 71

REMOVAL AND INSTALLATION (Continued)

Page 1366 of 1938

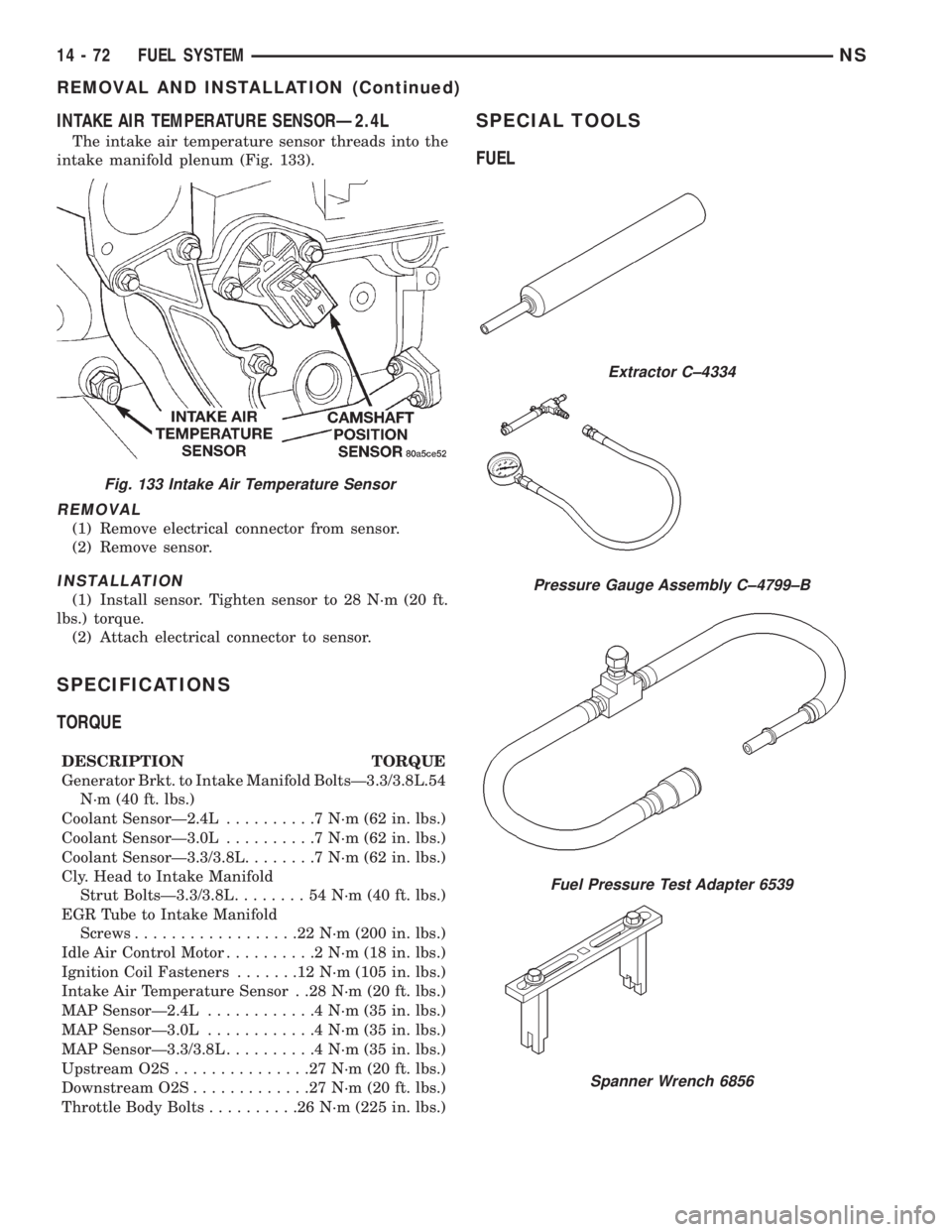

INTAKE AIR TEMPERATURE SENSORÐ2.4L

The intake air temperature sensor threads into the

intake manifold plenum (Fig. 133).

REMOVAL

(1) Remove electrical connector from sensor.

(2) Remove sensor.

INSTALLATION

(1) Install sensor. Tighten sensor to 28 N´m (20 ft.

lbs.) torque.

(2) Attach electrical connector to sensor.

SPECIFICATIONS

TORQUE

DESCRIPTION TORQUE

Generator Brkt. to Intake Manifold BoltsÐ3.3/3.8L.54

N´m (40 ft. lbs.)

Coolant SensorÐ2.4L..........7N´m(62in.lbs.)

Coolant SensorÐ3.0L..........7N´m(62in.lbs.)

Coolant SensorÐ3.3/3.8L........7N´m(62in.lbs.)

Cly. Head to Intake Manifold

Strut BoltsÐ3.3/3.8L........54N´m(40ft.lbs.)

EGR Tube to Intake Manifold

Screws..................22N´m(200 in. lbs.)

Idle Air Control Motor..........2N´m(18in.lbs.)

Ignition Coil Fasteners.......12N´m(105 in. lbs.)

Intake Air Temperature Sensor . .28 N´m (20 ft. lbs.)

MAP SensorÐ2.4L............4N´m(35in.lbs.)

MAP SensorÐ3.0L............4N´m(35in.lbs.)

MAP SensorÐ3.3/3.8L..........4N´m(35in.lbs.)

Upstream O2S...............27N´m(20ft.lbs.)

Downstream O2S.............27N´m(20ft.lbs.)

Throttle Body Bolts..........26N´m(225 in. lbs.)

SPECIAL TOOLS

FUEL

Fig. 133 Intake Air Temperature Sensor

Extractor C±4334

Pressure Gauge Assembly C±4799±B

Fuel Pressure Test Adapter 6539

Spanner Wrench 6856

14 - 72 FUEL SYSTEMNS

REMOVAL AND INSTALLATION (Continued)

Page 1375 of 1938

leaks are not present. The component should be

replaced immediately if there is any evidence of deg-

radation that could result in failure.

Never attempt to repair a plastic fuel line/tube or a

quick±connect fitting. Replace complete line/tube as

necessary.

Avoid contact of any fuel tubes/hoses with other

vehicle components that could cause abrasions or

scuffing. Be sure that the fuel lines/tubes are prop-

erly routed to prevent pinching and to avoid heat

sources.

The lines/tubes/hoses are of a special construction.

If it is necessary to replace these lines/tubes/hoses,

use only original equipment type.

The hose clamps used to secure the rubber hoses

are of a special rolled edge construction. This con-

struction is used to prevent the edge of the clamp

from cutting into the hose. Only these rolled edge

type clamps may be used in this system. All other

types of clamps may cut into the hoses and cause

fuel leaks.

Where a rubber hose is joined to a metal tube

(staked), do not attempt to repair. Replace entire

line/tube assembly.

Use new original equipment type hose clamps.

Tighten hose clamps to 2 N´m (20 in. lbs.) torque.

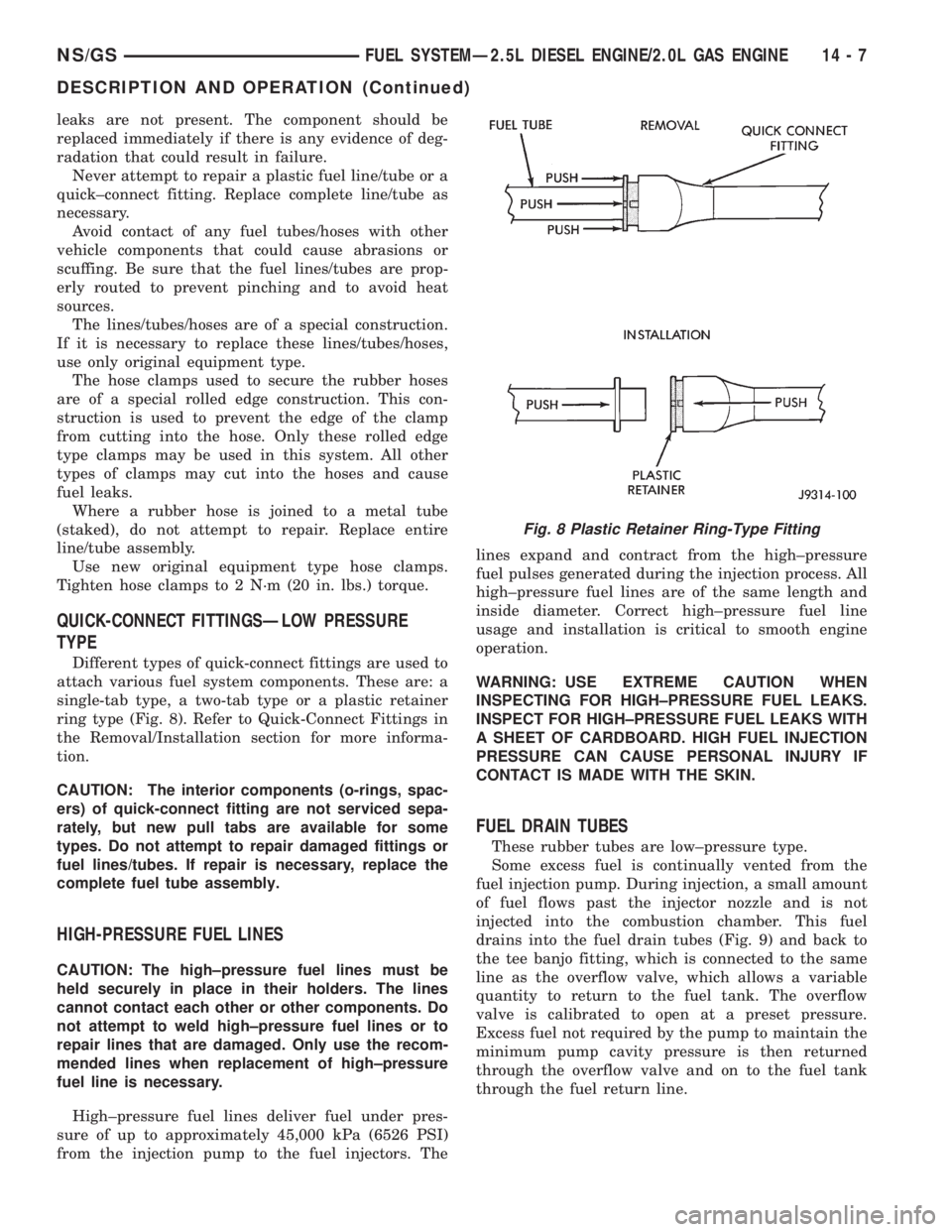

QUICK-CONNECT FITTINGSÐLOW PRESSURE

TYPE

Different types of quick-connect fittings are used to

attach various fuel system components. These are: a

single-tab type, a two-tab type or a plastic retainer

ring type (Fig. 8). Refer to Quick-Connect Fittings in

the Removal/Installation section for more informa-

tion.

CAUTION: The interior components (o-rings, spac-

ers) of quick-connect fitting are not serviced sepa-

rately, but new pull tabs are available for some

types. Do not attempt to repair damaged fittings or

fuel lines/tubes. If repair is necessary, replace the

complete fuel tube assembly.

HIGH-PRESSURE FUEL LINES

CAUTION: The high±pressure fuel lines must be

held securely in place in their holders. The lines

cannot contact each other or other components. Do

not attempt to weld high±pressure fuel lines or to

repair lines that are damaged. Only use the recom-

mended lines when replacement of high±pressure

fuel line is necessary.

High±pressure fuel lines deliver fuel under pres-

sure of up to approximately 45,000 kPa (6526 PSI)

from the injection pump to the fuel injectors. Thelines expand and contract from the high±pressure

fuel pulses generated during the injection process. All

high±pressure fuel lines are of the same length and

inside diameter. Correct high±pressure fuel line

usage and installation is critical to smooth engine

operation.

WARNING: USE EXTREME CAUTION WHEN

INSPECTING FOR HIGH±PRESSURE FUEL LEAKS.

INSPECT FOR HIGH±PRESSURE FUEL LEAKS WITH

A SHEET OF CARDBOARD. HIGH FUEL INJECTION

PRESSURE CAN CAUSE PERSONAL INJURY IF

CONTACT IS MADE WITH THE SKIN.

FUEL DRAIN TUBES

These rubber tubes are low±pressure type.

Some excess fuel is continually vented from the

fuel injection pump. During injection, a small amount

of fuel flows past the injector nozzle and is not

injected into the combustion chamber. This fuel

drains into the fuel drain tubes (Fig. 9) and back to

the tee banjo fitting, which is connected to the same

line as the overflow valve, which allows a variable

quantity to return to the fuel tank. The overflow

valve is calibrated to open at a preset pressure.

Excess fuel not required by the pump to maintain the

minimum pump cavity pressure is then returned

through the overflow valve and on to the fuel tank

through the fuel return line.

Fig. 8 Plastic Retainer Ring-Type Fitting

NS/GSFUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE 14 - 7

DESCRIPTION AND OPERATION (Continued)

Page 1380 of 1938

FUEL HEATER RELAY TEST

The fuel heater relay is located in the Power Dis-

tribution Center (PDC). Refer to RelaysÐOperation/

Testing in Fuel Ingection System section of this

group for test procedures.

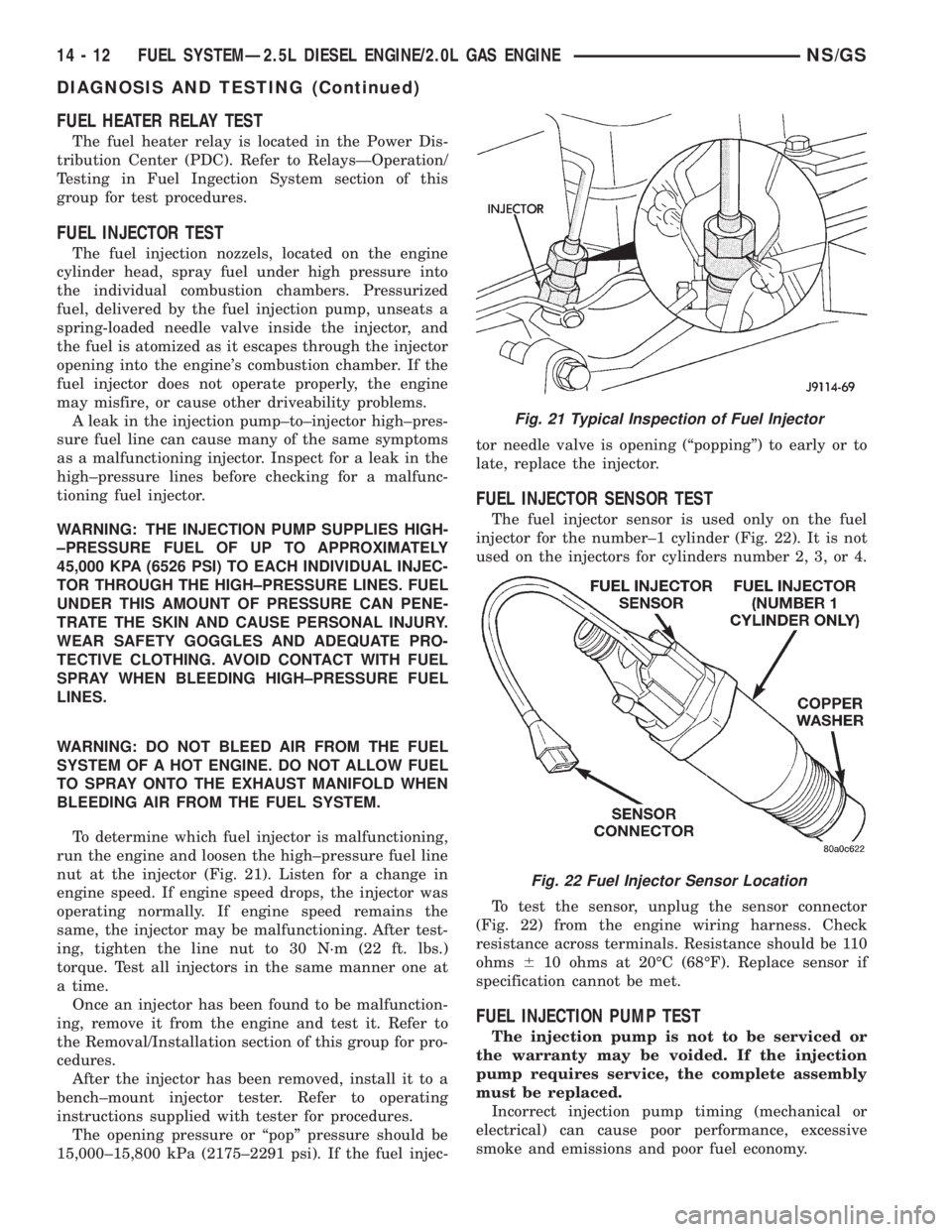

FUEL INJECTOR TEST

The fuel injection nozzels, located on the engine

cylinder head, spray fuel under high pressure into

the individual combustion chambers. Pressurized

fuel, delivered by the fuel injection pump, unseats a

spring-loaded needle valve inside the injector, and

the fuel is atomized as it escapes through the injector

opening into the engine's combustion chamber. If the

fuel injector does not operate properly, the engine

may misfire, or cause other driveability problems.

A leak in the injection pump±to±injector high±pres-

sure fuel line can cause many of the same symptoms

as a malfunctioning injector. Inspect for a leak in the

high±pressure lines before checking for a malfunc-

tioning fuel injector.

WARNING: THE INJECTION PUMP SUPPLIES HIGH-

±PRESSURE FUEL OF UP TO APPROXIMATELY

45,000 KPA (6526 PSI) TO EACH INDIVIDUAL INJEC-

TOR THROUGH THE HIGH±PRESSURE LINES. FUEL

UNDER THIS AMOUNT OF PRESSURE CAN PENE-

TRATE THE SKIN AND CAUSE PERSONAL INJURY.

WEAR SAFETY GOGGLES AND ADEQUATE PRO-

TECTIVE CLOTHING. AVOID CONTACT WITH FUEL

SPRAY WHEN BLEEDING HIGH±PRESSURE FUEL

LINES.

WARNING: DO NOT BLEED AIR FROM THE FUEL

SYSTEM OF A HOT ENGINE. DO NOT ALLOW FUEL

TO SPRAY ONTO THE EXHAUST MANIFOLD WHEN

BLEEDING AIR FROM THE FUEL SYSTEM.

To determine which fuel injector is malfunctioning,

run the engine and loosen the high±pressure fuel line

nut at the injector (Fig. 21). Listen for a change in

engine speed. If engine speed drops, the injector was

operating normally. If engine speed remains the

same, the injector may be malfunctioning. After test-

ing, tighten the line nut to 30 N´m (22 ft. lbs.)

torque. Test all injectors in the same manner one at

a time.

Once an injector has been found to be malfunction-

ing, remove it from the engine and test it. Refer to

the Removal/Installation section of this group for pro-

cedures.

After the injector has been removed, install it to a

bench±mount injector tester. Refer to operating

instructions supplied with tester for procedures.

The opening pressure or ªpopº pressure should be

15,000±15,800 kPa (2175±2291 psi). If the fuel injec-tor needle valve is opening (ªpoppingº) to early or to

late, replace the injector.

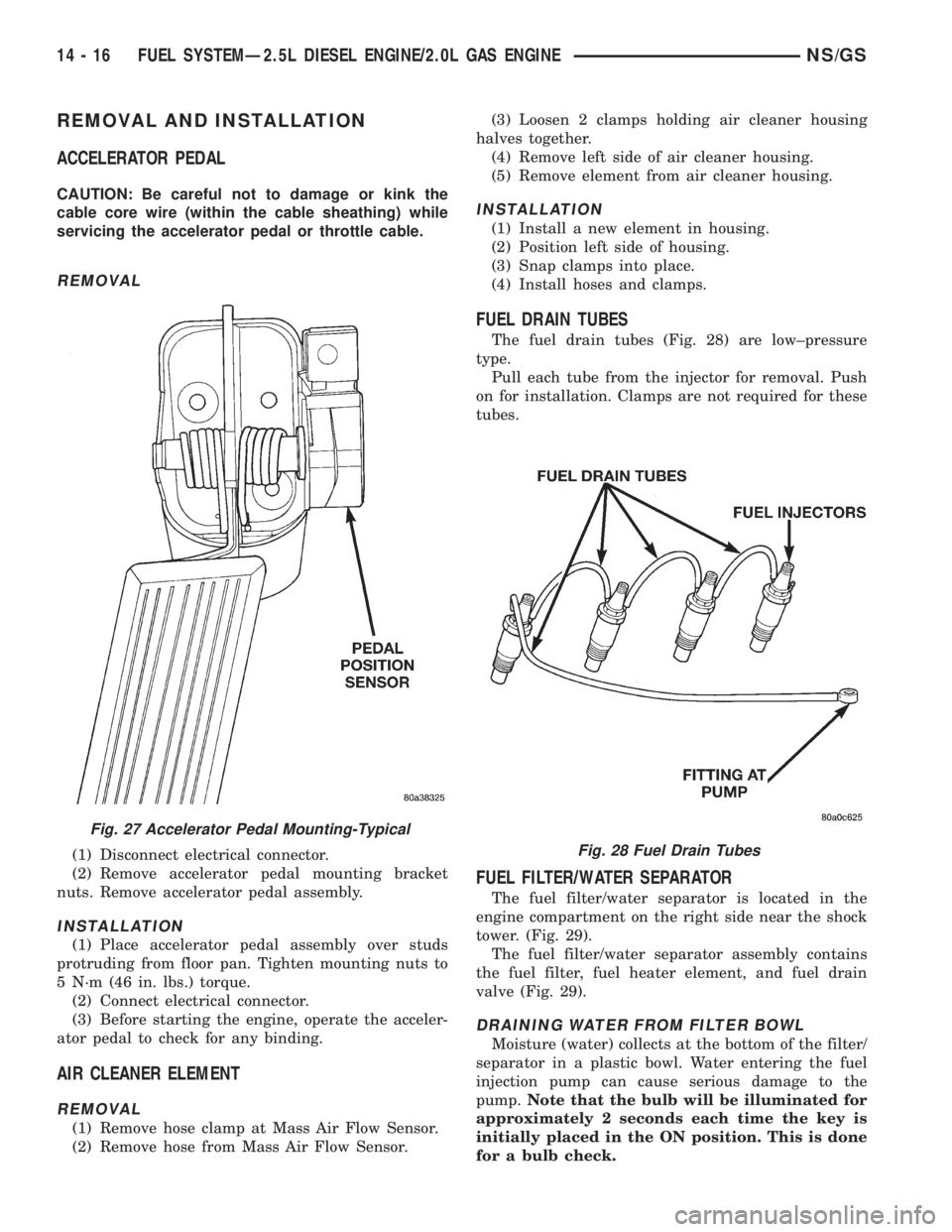

FUEL INJECTOR SENSOR TEST

The fuel injector sensor is used only on the fuel

injector for the number±1 cylinder (Fig. 22). It is not

used on the injectors for cylinders number 2, 3, or 4.

To test the sensor, unplug the sensor connector

(Fig. 22) from the engine wiring harness. Check

resistance across terminals. Resistance should be 110

ohms610 ohms at 20ÉC (68ÉF). Replace sensor if

specification cannot be met.

FUEL INJECTION PUMP TEST

The injection pump is not to be serviced or

the warranty may be voided. If the injection

pump requires service, the complete assembly

must be replaced.

Incorrect injection pump timing (mechanical or

electrical) can cause poor performance, excessive

smoke and emissions and poor fuel economy.

Fig. 21 Typical Inspection of Fuel Injector

Fig. 22 Fuel Injector Sensor Location

14 - 12 FUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINENS/GS

DIAGNOSIS AND TESTING (Continued)

Page 1384 of 1938

REMOVAL AND INSTALLATION

ACCELERATOR PEDAL

CAUTION: Be careful not to damage or kink the

cable core wire (within the cable sheathing) while

servicing the accelerator pedal or throttle cable.

REMOVAL

(1) Disconnect electrical connector.

(2) Remove accelerator pedal mounting bracket

nuts. Remove accelerator pedal assembly.

INSTALLATION

(1) Place accelerator pedal assembly over studs

protruding from floor pan. Tighten mounting nuts to

5 N´m (46 in. lbs.) torque.

(2) Connect electrical connector.

(3) Before starting the engine, operate the acceler-

ator pedal to check for any binding.

AIR CLEANER ELEMENT

REMOVAL

(1) Remove hose clamp at Mass Air Flow Sensor.

(2) Remove hose from Mass Air Flow Sensor.(3) Loosen 2 clamps holding air cleaner housing

halves together.

(4) Remove left side of air cleaner housing.

(5) Remove element from air cleaner housing.

INSTALLATION

(1) Install a new element in housing.

(2) Position left side of housing.

(3) Snap clamps into place.

(4) Install hoses and clamps.

FUEL DRAIN TUBES

The fuel drain tubes (Fig. 28) are low±pressure

type.

Pull each tube from the injector for removal. Push

on for installation. Clamps are not required for these

tubes.

FUEL FILTER/WATER SEPARATOR

The fuel filter/water separator is located in the

engine compartment on the right side near the shock

tower. (Fig. 29).

The fuel filter/water separator assembly contains

the fuel filter, fuel heater element, and fuel drain

valve (Fig. 29).

DRAINING WATER FROM FILTER BOWL

Moisture (water) collects at the bottom of the filter/

separator in a plastic bowl. Water entering the fuel

injection pump can cause serious damage to the

pump.Note that the bulb will be illuminated for

approximately 2 seconds each time the key is

initially placed in the ON position. This is done

for a bulb check.

Fig. 27 Accelerator Pedal Mounting-Typical

Fig. 28 Fuel Drain Tubes

14 - 16 FUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINENS/GS