CHRYSLER VOYAGER 1996 Service Manual

VOYAGER 1996

CHRYSLER

CHRYSLER

https://www.carmanualsonline.info/img/25/56867/w960_56867-0.png

CHRYSLER VOYAGER 1996 Service Manual

Page 1572 of 1938

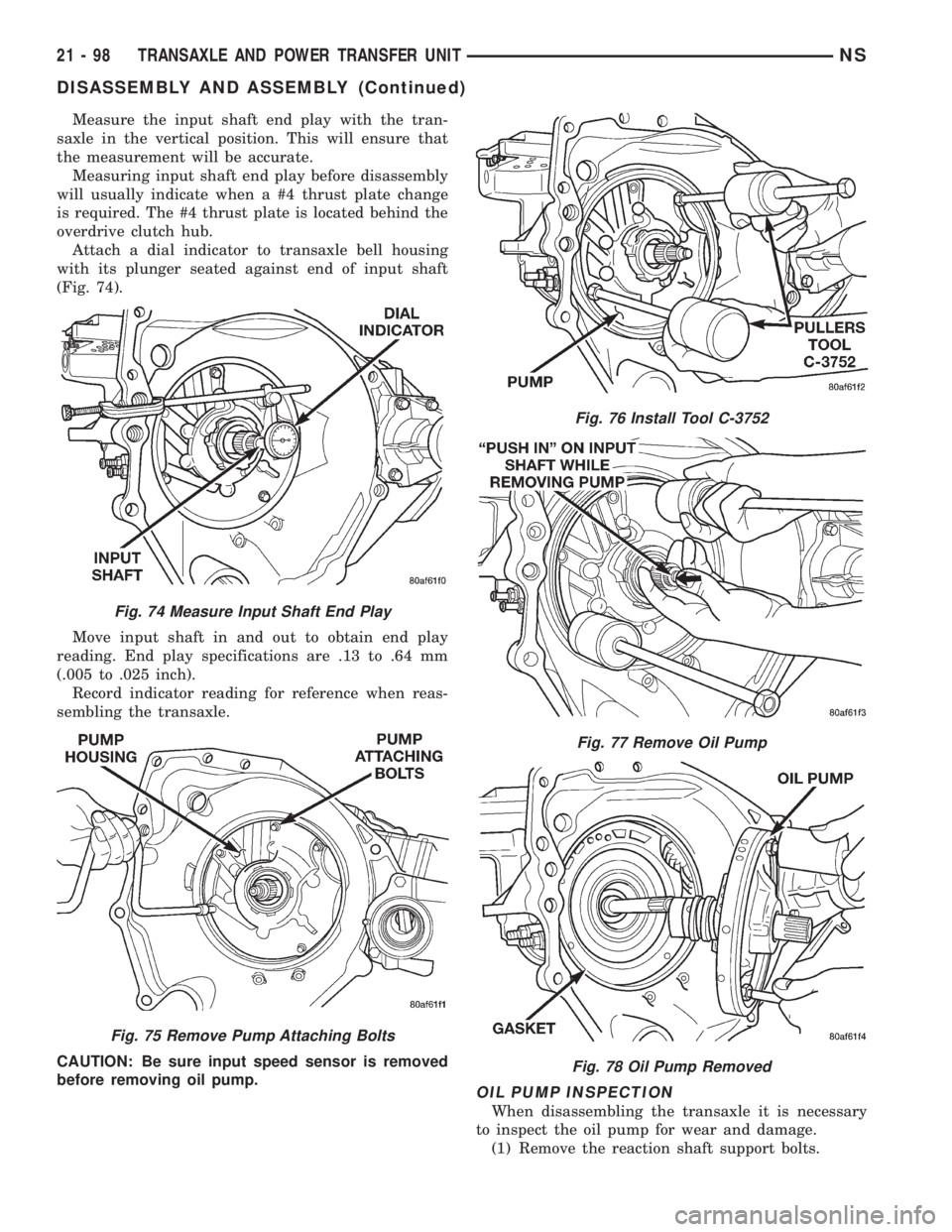

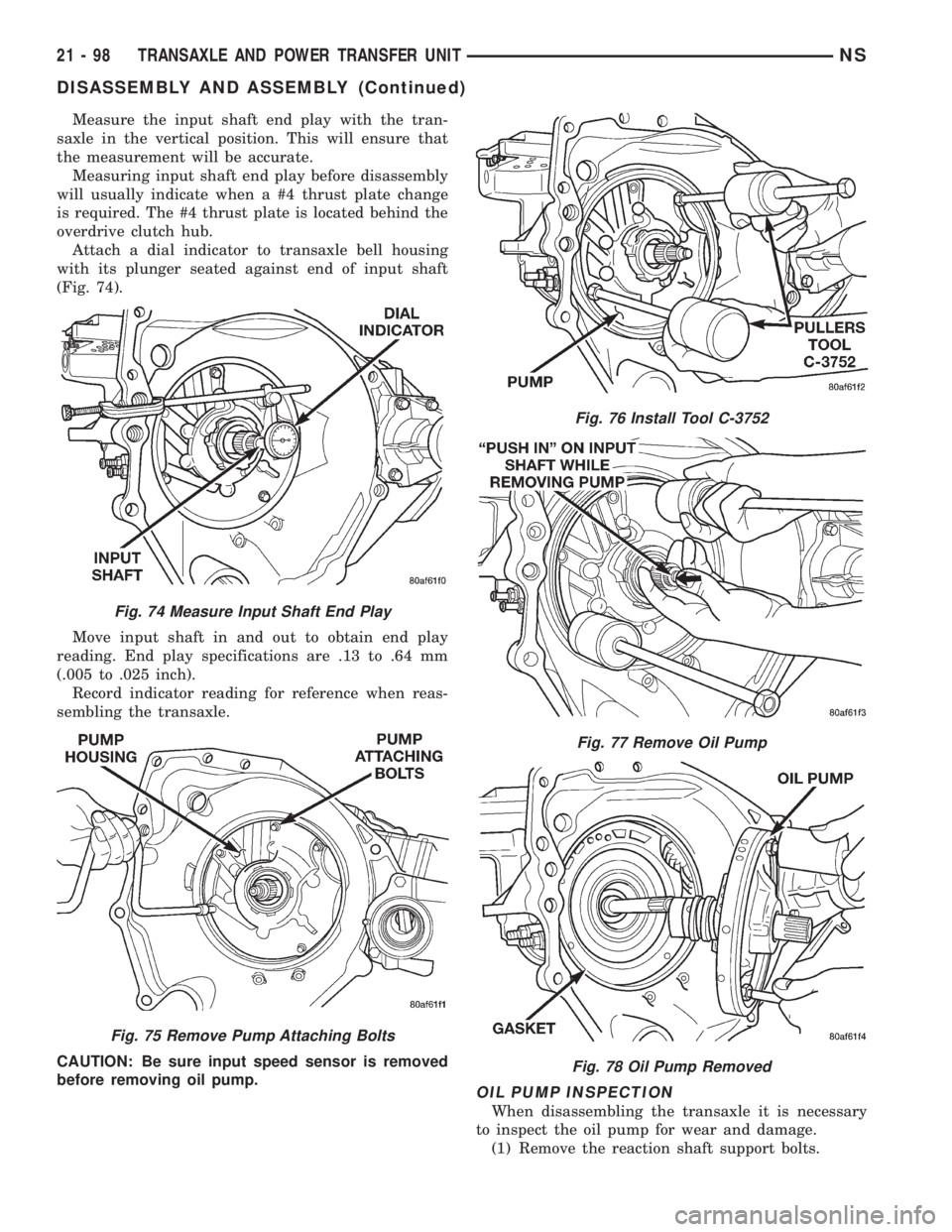

Measure the input shaft end play with the tran-

saxle in the vertical position. This will ensure that

the measurement will be accurate.

Measuring input shaft end play before disassembly

will usually indicate when a #4 thrust plate change

is required. The #4 thrust plate is located behind the

overdrive clutch hub.

Attach a dial indicator to transaxle bell housing

with its plunger seated against end of input shaft

(Fig. 74).

Move input shaft in and out to obtain end play

reading. End play specifications are .13 to .64 mm

(.005 to .025 inch).

Record indicator reading for reference when reas-

sembling the transaxle.

CAUTION: Be sure input speed sensor is removed

before removing oil pump.

OIL PUMP INSPECTION

When disassembling the transaxle it is necessary

to inspect the oil pump for wear and damage.

(1) Remove the reaction shaft support bolts.

Fig. 74 Measure Input Shaft End Play

Fig. 75 Remove Pump Attaching Bolts

Fig. 76 Install Tool C-3752

Fig. 77 Remove Oil Pump

Fig. 78 Oil Pump Removed

21 - 98 TRANSAXLE AND POWER TRANSFER UNITNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1573 of 1938

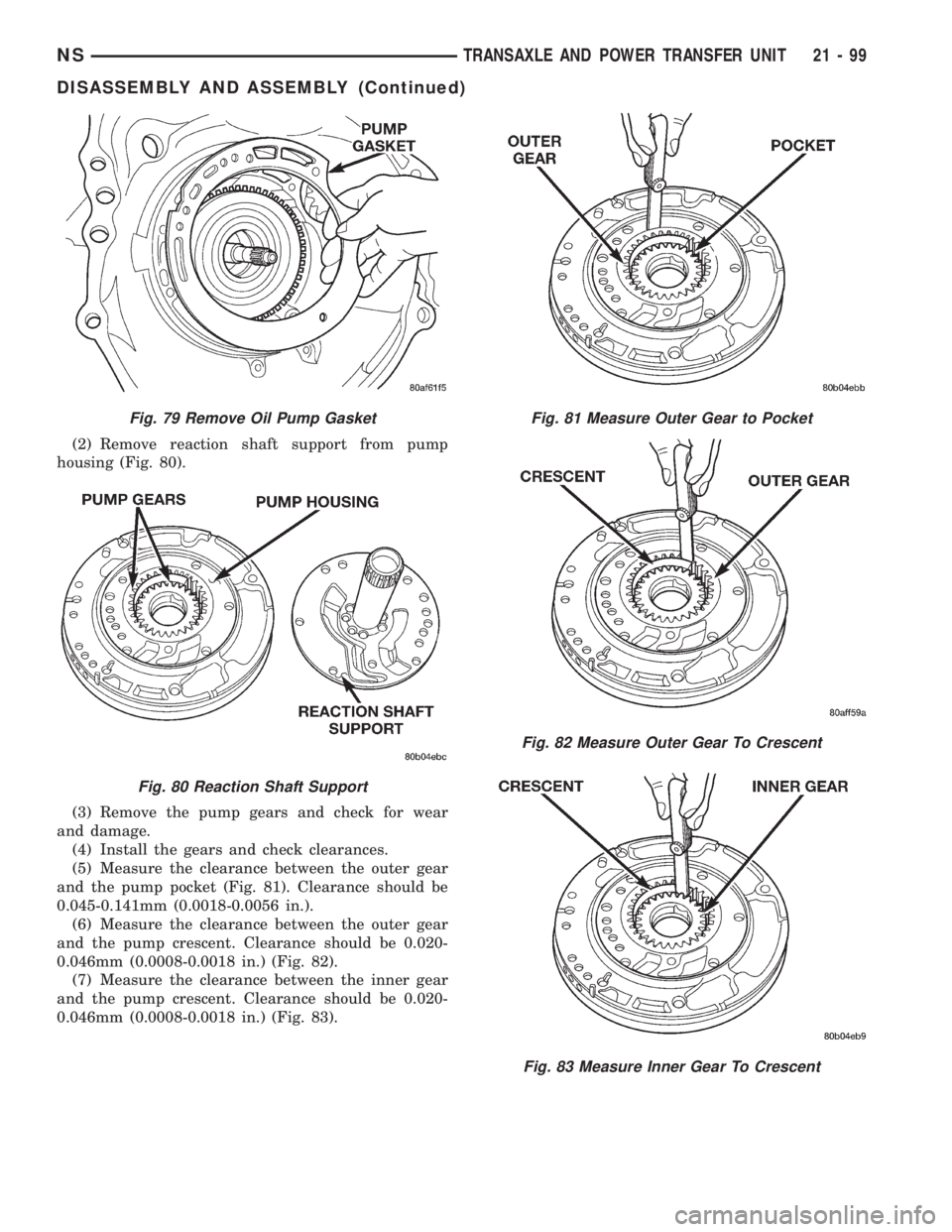

(2) Remove reaction shaft support from pump

housing (Fig. 80).

(3) Remove the pump gears and check for wear

and damage.

(4) Install the gears and check clearances.

(5) Measure the clearance between the outer gear

and the pump pocket (Fig. 81). Clearance should be

0.045-0.141mm (0.0018-0.0056 in.).

(6) Measure the clearance between the outer gear

and the pump crescent. Clearance should be 0.020-

0.046mm (0.0008-0.0018 in.) (Fig. 82).

(7) Measure the clearance between the inner gear

and the pump crescent. Clearance should be 0.020-

0.046mm (0.0008-0.0018 in.) (Fig. 83).

Fig. 79 Remove Oil Pump Gasket

Fig. 80 Reaction Shaft Support

Fig. 81 Measure Outer Gear to Pocket

Fig. 82 Measure Outer Gear To Crescent

Fig. 83 Measure Inner Gear To Crescent

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 99

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1577 of 1938

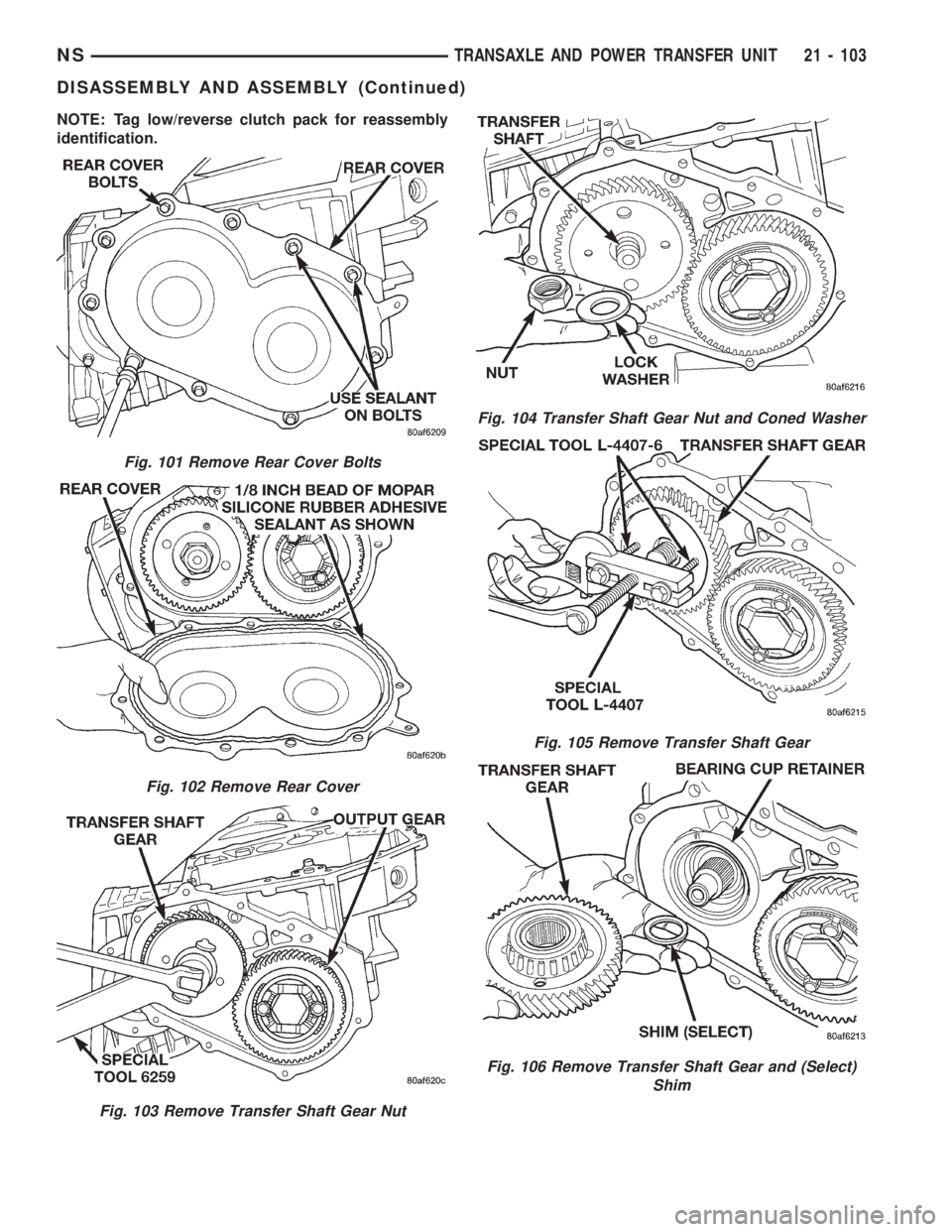

NOTE: Tag low/reverse clutch pack for reassembly

identification.

Fig. 101 Remove Rear Cover Bolts

Fig. 102 Remove Rear Cover

Fig. 103 Remove Transfer Shaft Gear Nut

Fig. 104 Transfer Shaft Gear Nut and Coned Washer

Fig. 105 Remove Transfer Shaft Gear

Fig. 106 Remove Transfer Shaft Gear and (Select)

Shim

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 103

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1578 of 1938

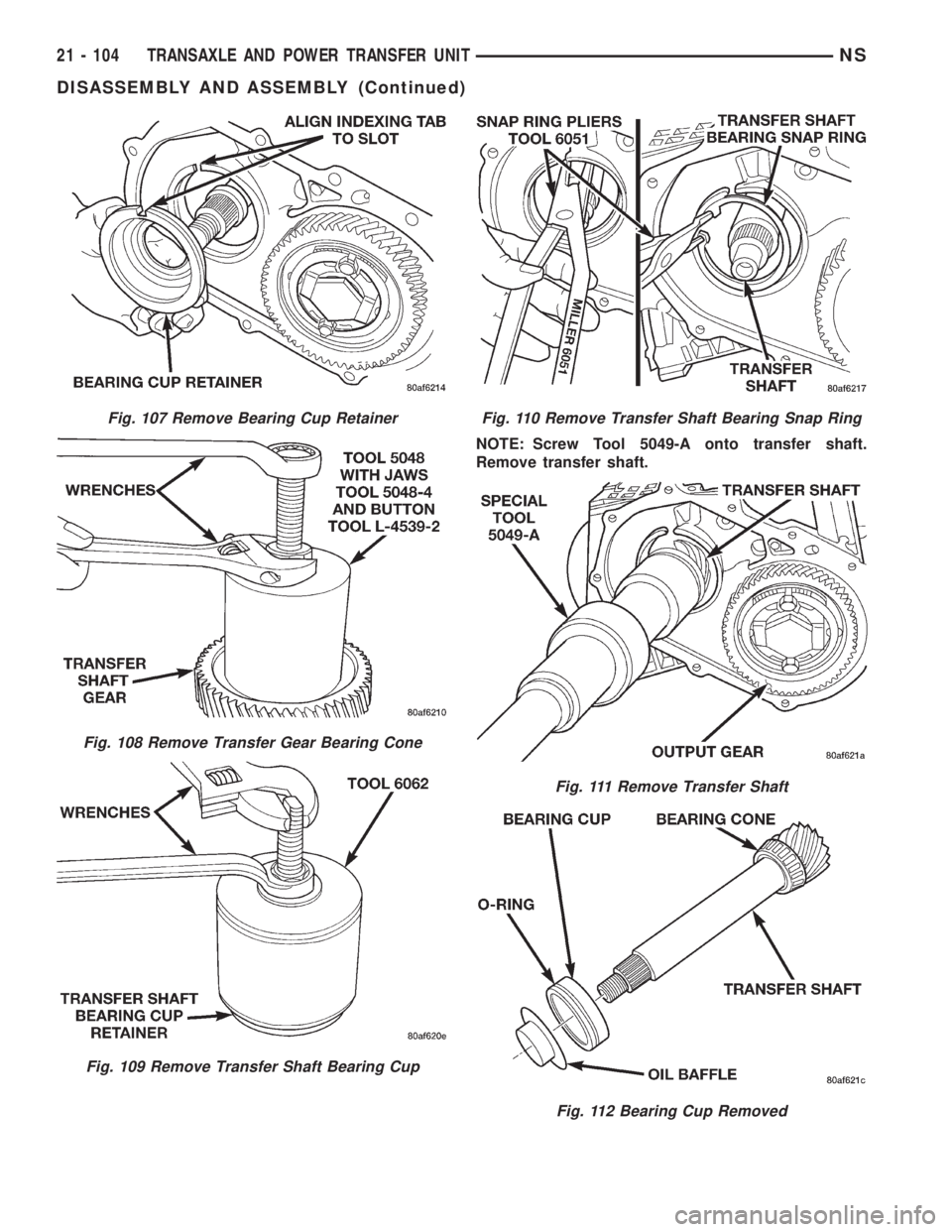

NOTE: Screw Tool 5049-A onto transfer shaft.

Remove transfer shaft.

Fig. 107 Remove Bearing Cup Retainer

Fig. 108 Remove Transfer Gear Bearing Cone

Fig. 109 Remove Transfer Shaft Bearing Cup

Fig. 110 Remove Transfer Shaft Bearing Snap Ring

Fig. 111 Remove Transfer Shaft

Fig. 112 Bearing Cup Removed

21 - 104 TRANSAXLE AND POWER TRANSFER UNITNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1579 of 1938

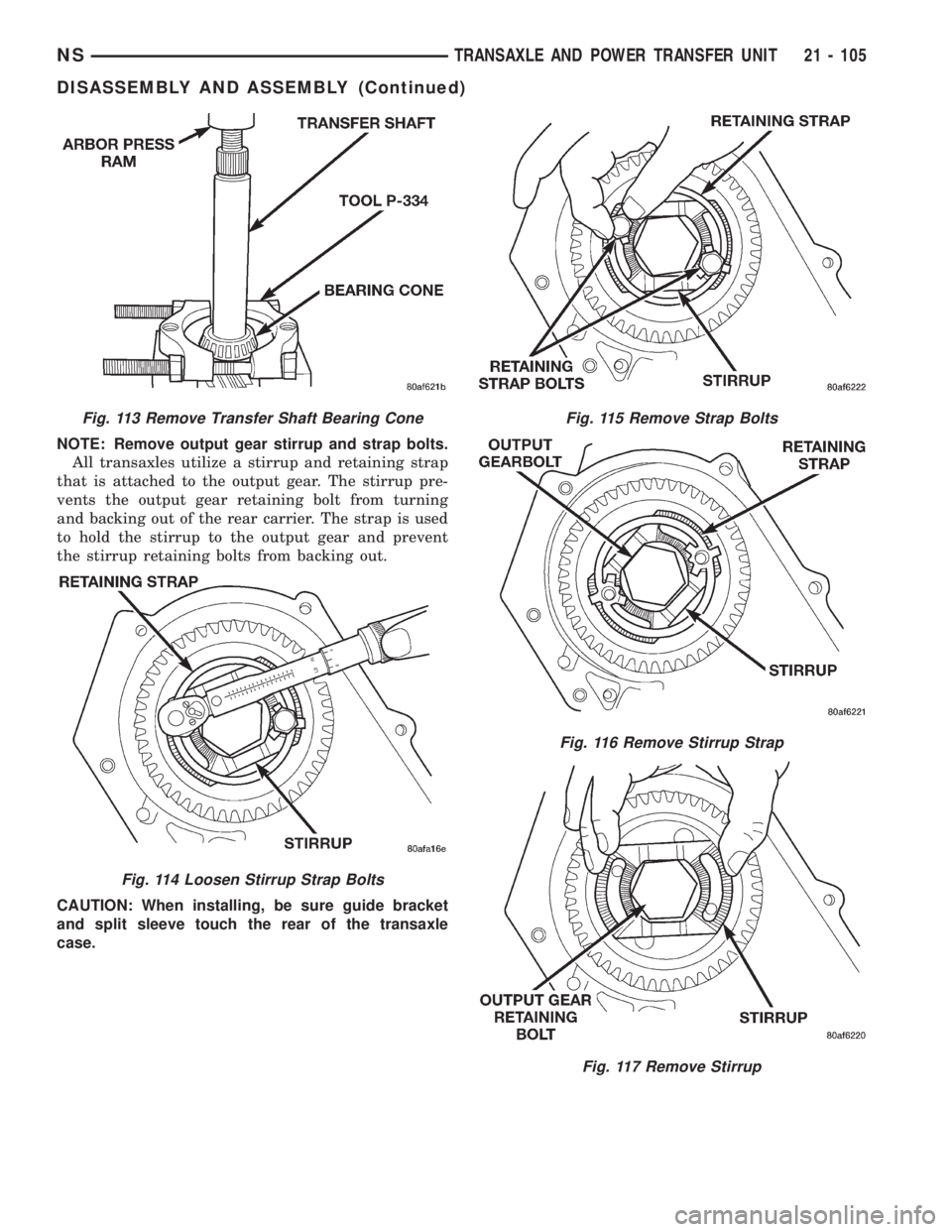

NOTE: Remove output gear stirrup and strap bolts.

All transaxles utilize a stirrup and retaining strap

that is attached to the output gear. The stirrup pre-

vents the output gear retaining bolt from turning

and backing out of the rear carrier. The strap is used

to hold the stirrup to the output gear and prevent

the stirrup retaining bolts from backing out.

CAUTION: When installing, be sure guide bracket

and split sleeve touch the rear of the transaxle

case.

Fig. 113 Remove Transfer Shaft Bearing Cone

Fig. 114 Loosen Stirrup Strap Bolts

Fig. 115 Remove Strap Bolts

Fig. 116 Remove Stirrup Strap

Fig. 117 Remove Stirrup

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 105

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1581 of 1938

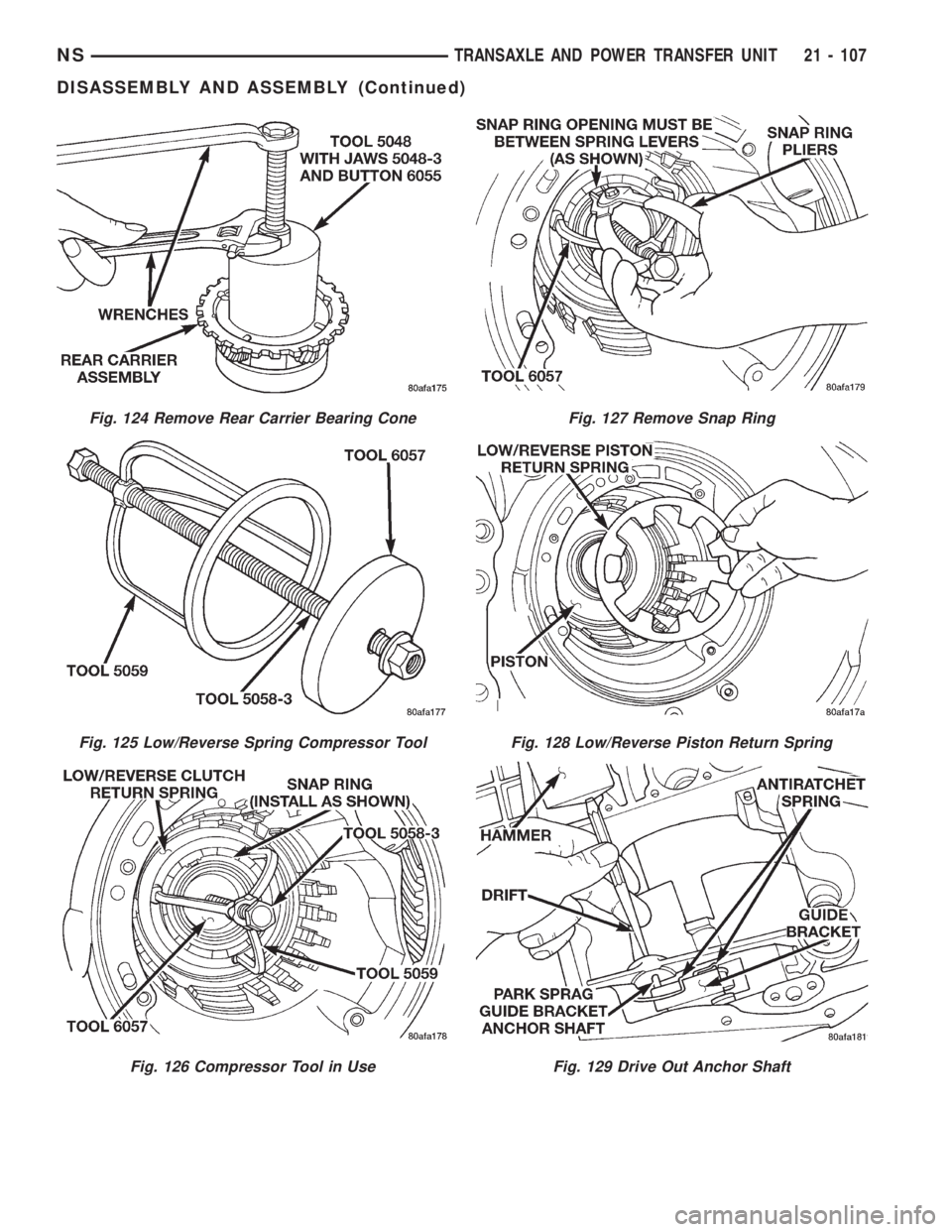

Fig. 124 Remove Rear Carrier Bearing Cone

Fig. 125 Low/Reverse Spring Compressor Tool

Fig. 126 Compressor Tool in Use

Fig. 127 Remove Snap Ring

Fig. 128 Low/Reverse Piston Return Spring

Fig. 129 Drive Out Anchor Shaft

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 107

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1582 of 1938

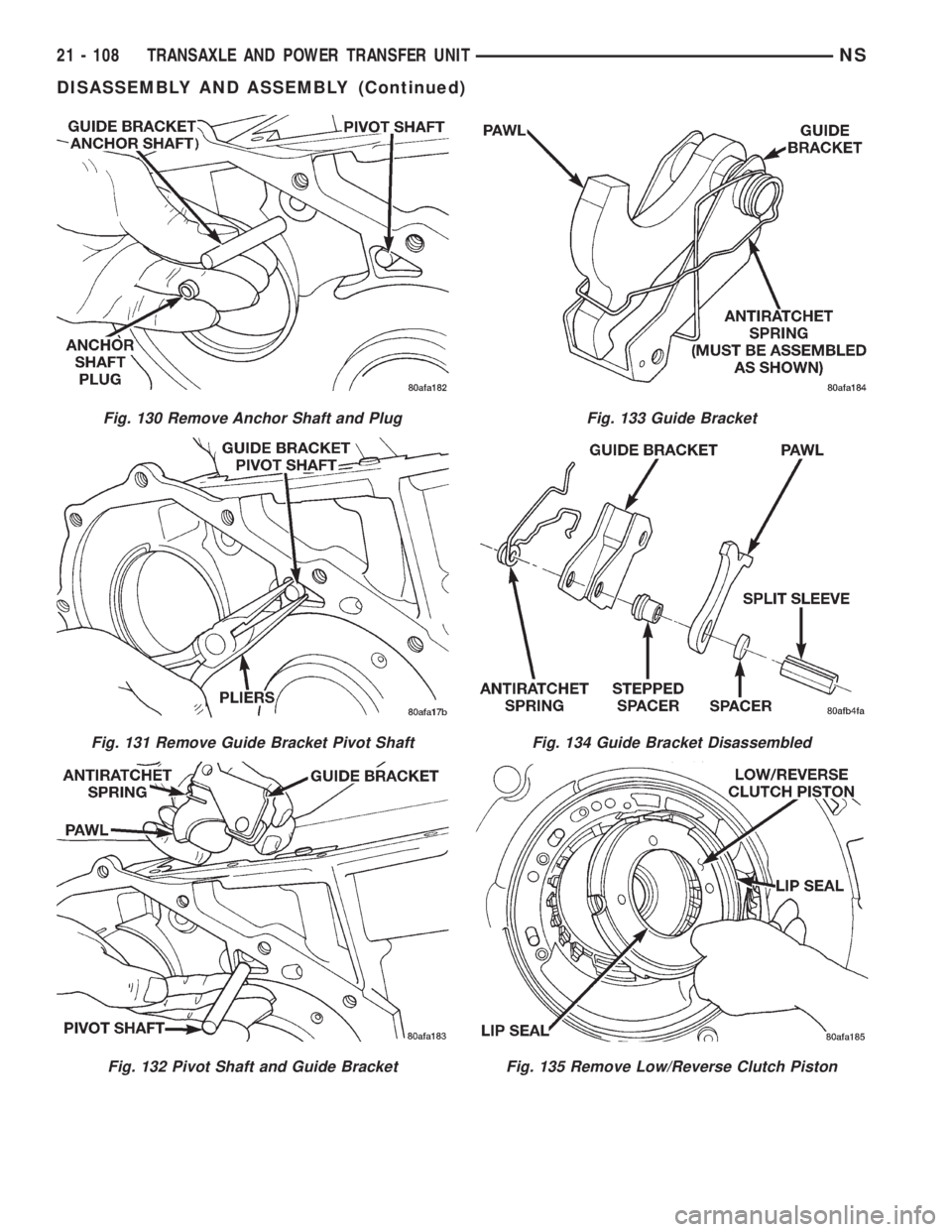

Fig. 130 Remove Anchor Shaft and Plug

Fig. 131 Remove Guide Bracket Pivot Shaft

Fig. 132 Pivot Shaft and Guide Bracket

Fig. 133 Guide Bracket

Fig. 134 Guide Bracket Disassembled

Fig. 135 Remove Low/Reverse Clutch Piston

21 - 108 TRANSAXLE AND POWER TRANSFER UNITNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1585 of 1938

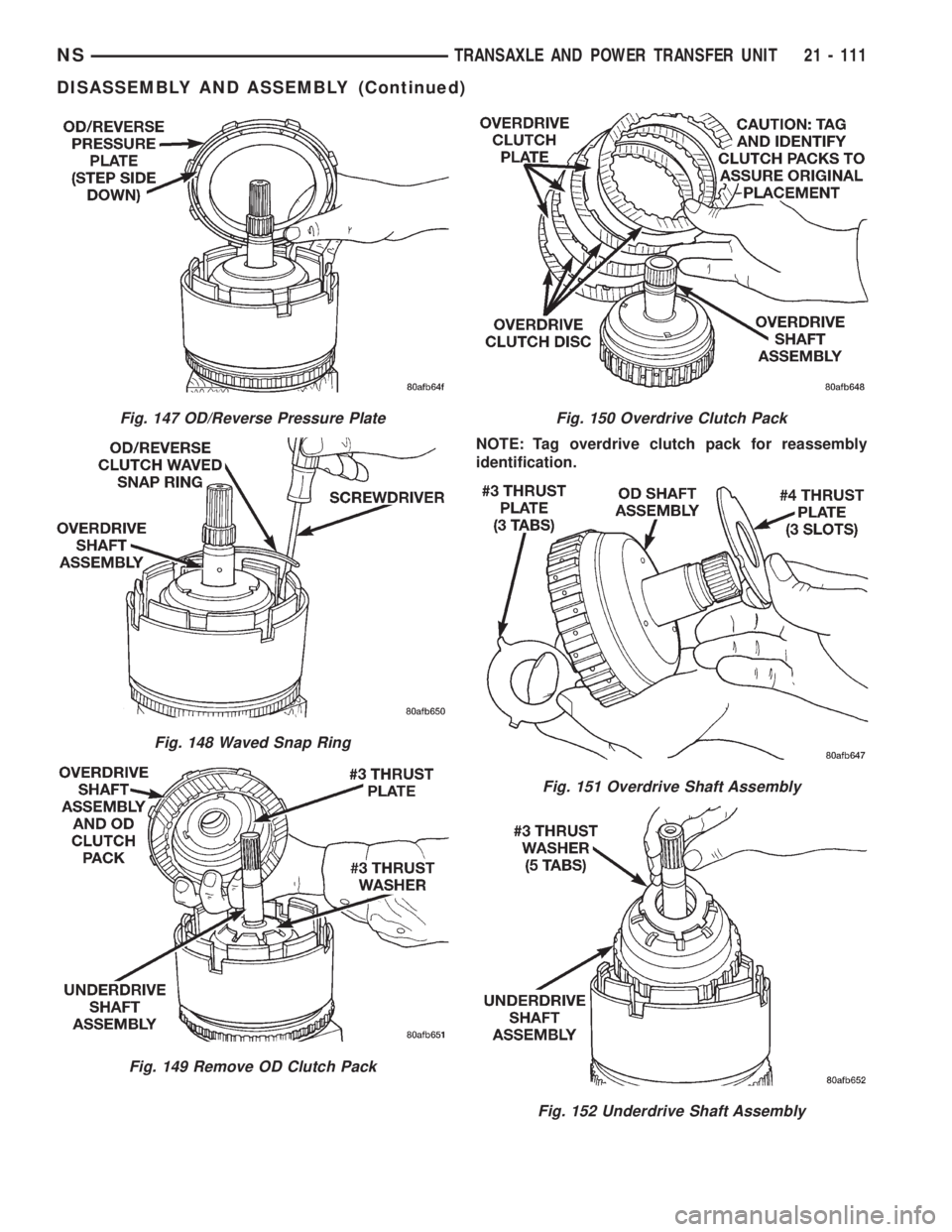

NOTE: Tag overdrive clutch pack for reassembly

identification.

Fig. 147 OD/Reverse Pressure Plate

Fig. 148 Waved Snap Ring

Fig. 149 Remove OD Clutch Pack

Fig. 150 Overdrive Clutch Pack

Fig. 151 Overdrive Shaft Assembly

Fig. 152 Underdrive Shaft Assembly

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 111

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1588 of 1938

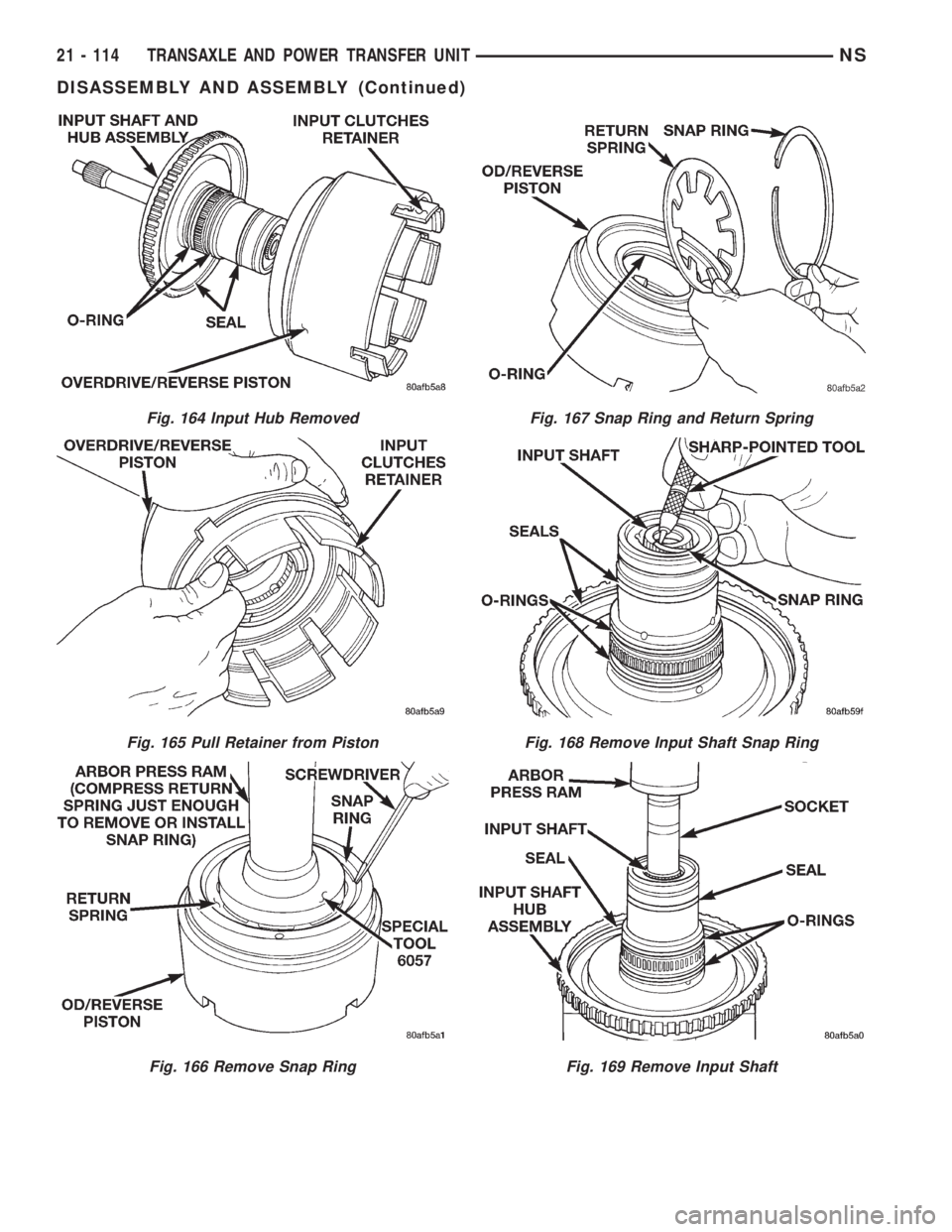

Fig. 164 Input Hub Removed

Fig. 165 Pull Retainer from Piston

Fig. 166 Remove Snap Ring

Fig. 167 Snap Ring and Return Spring

Fig. 168 Remove Input Shaft Snap Ring

Fig. 169 Remove Input Shaft

21 - 114 TRANSAXLE AND POWER TRANSFER UNITNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1589 of 1938

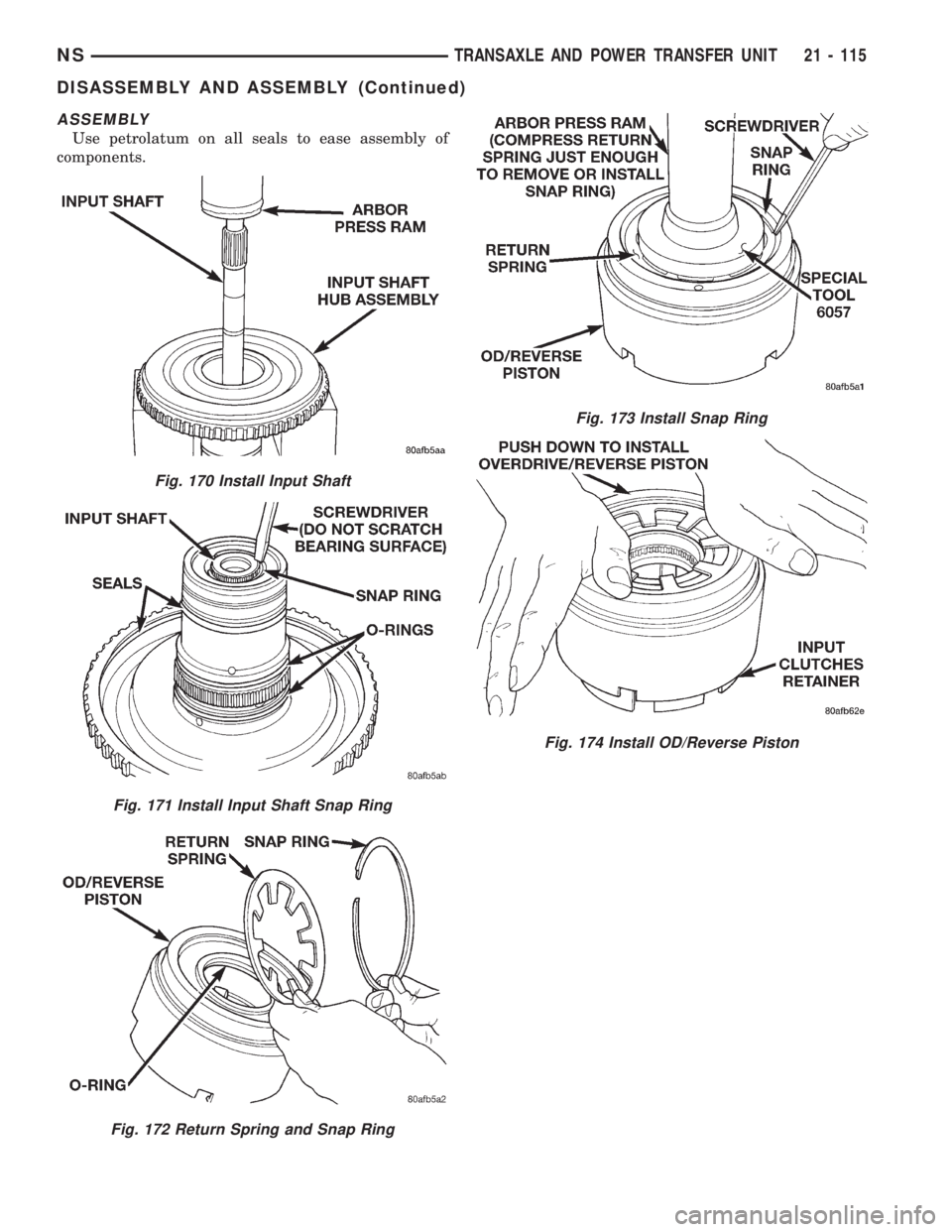

ASSEMBLY

Use petrolatum on all seals to ease assembly of

components.

Fig. 170 Install Input Shaft

Fig. 171 Install Input Shaft Snap Ring

Fig. 172 Return Spring and Snap Ring

Fig. 173 Install Snap Ring

Fig. 174 Install OD/Reverse Piston

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 115

DISASSEMBLY AND ASSEMBLY (Continued)