shaft CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1539 of 1938

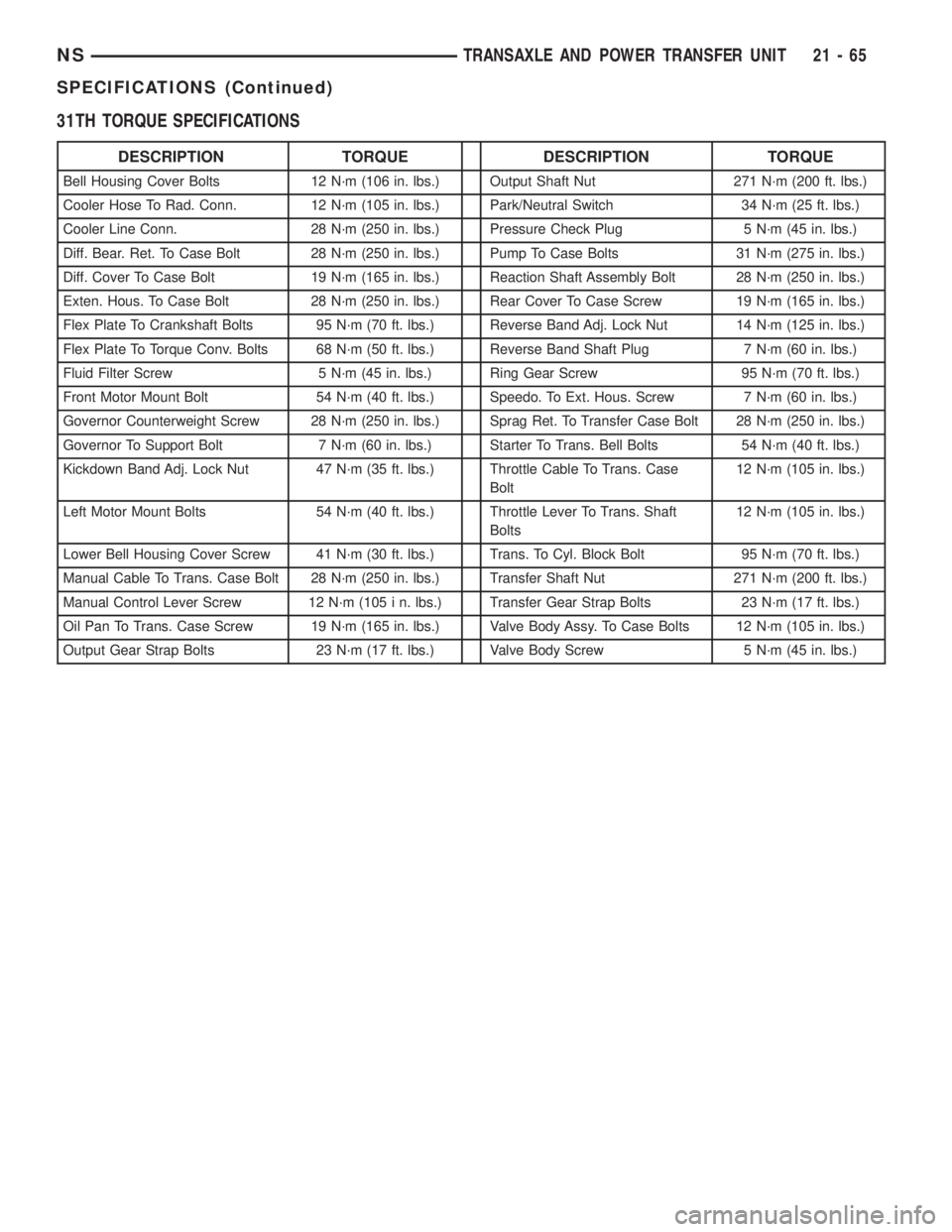

31TH TORQUE SPECIFICATIONS

DESCRIPTION TORQUE DESCRIPTION TORQUE

Bell Housing Cover Bolts 12 N´m (106 in. lbs.) Output Shaft Nut 271 N´m (200 ft. lbs.)

Cooler Hose To Rad. Conn. 12 N´m (105 in. lbs.) Park/Neutral Switch 34 N´m (25 ft. lbs.)

Cooler Line Conn. 28 N´m (250 in. lbs.) Pressure Check Plug 5 N´m (45 in. lbs.)

Diff. Bear. Ret. To Case Bolt 28 N´m (250 in. lbs.) Pump To Case Bolts 31 N´m (275 in. lbs.)

Diff. Cover To Case Bolt 19 N´m (165 in. lbs.) Reaction Shaft Assembly Bolt 28 N´m (250 in. lbs.)

Exten. Hous. To Case Bolt 28 N´m (250 in. lbs.) Rear Cover To Case Screw 19 N´m (165 in. lbs.)

Flex Plate To Crankshaft Bolts 95 N´m (70 ft. lbs.) Reverse Band Adj. Lock Nut 14 N´m (125 in. lbs.)

Flex Plate To Torque Conv. Bolts 68 N´m (50 ft. lbs.) Reverse Band Shaft Plug 7 N´m (60 in. lbs.)

Fluid Filter Screw 5 N´m (45 in. lbs.) Ring Gear Screw 95 N´m (70 ft. lbs.)

Front Motor Mount Bolt 54 N´m (40 ft. lbs.) Speedo. To Ext. Hous. Screw 7 N´m (60 in. lbs.)

Governor Counterweight Screw 28 N´m (250 in. lbs.) Sprag Ret. To Transfer Case Bolt 28 N´m (250 in. lbs.)

Governor To Support Bolt 7 N´m (60 in. lbs.) Starter To Trans. Bell Bolts 54 N´m (40 ft. lbs.)

Kickdown Band Adj. Lock Nut 47 N´m (35 ft. lbs.) Throttle Cable To Trans. Case

Bolt12 N´m (105 in. lbs.)

Left Motor Mount Bolts 54 N´m (40 ft. lbs.) Throttle Lever To Trans. Shaft

Bolts12 N´m (105 in. lbs.)

Lower Bell Housing Cover Screw 41 N´m (30 ft. lbs.) Trans. To Cyl. Block Bolt 95 N´m (70 ft. lbs.)

Manual Cable To Trans. Case Bolt 28 N´m (250 in. lbs.) Transfer Shaft Nut 271 N´m (200 ft. lbs.)

Manual Control Lever Screw 12 N´m (105 i n. lbs.) Transfer Gear Strap Bolts 23 N´m (17 ft. lbs.)

Oil Pan To Trans. Case Screw 19 N´m (165 in. lbs.) Valve Body Assy. To Case Bolts 12 N´m (105 in. lbs.)

Output Gear Strap Bolts 23 N´m (17 ft. lbs.) Valve Body Screw 5 N´m (45 in. lbs.)

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 65

SPECIFICATIONS (Continued)

Page 1544 of 1938

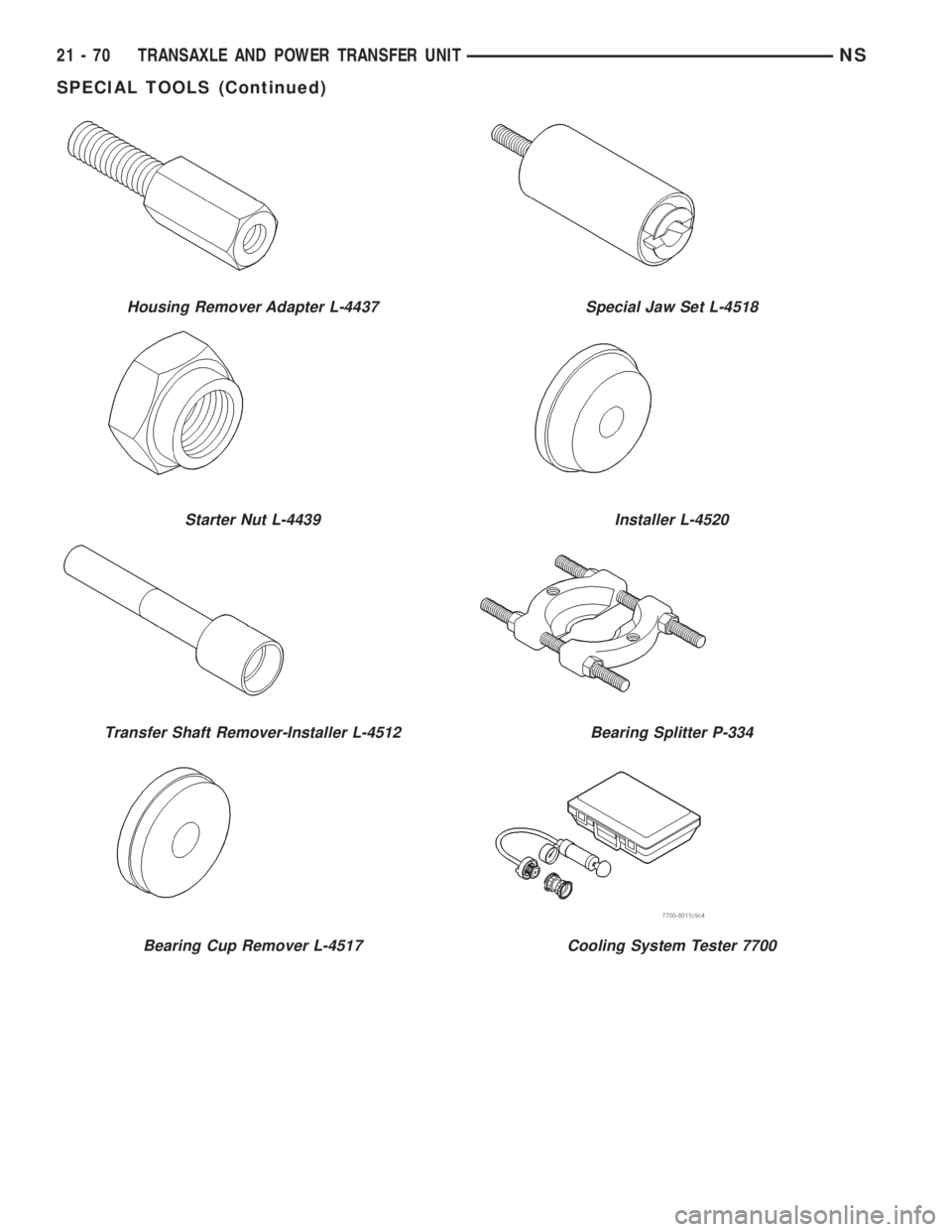

Housing Remover Adapter L-4437

Starter Nut L-4439

Transfer Shaft Remover-Installer L-4512

Bearing Cup Remover L-4517

Special Jaw Set L-4518

Installer L-4520

Bearing Splitter P-334

Cooling System Tester 7700

21 - 70 TRANSAXLE AND POWER TRANSFER UNITNS

SPECIAL TOOLS (Continued)

Page 1551 of 1938

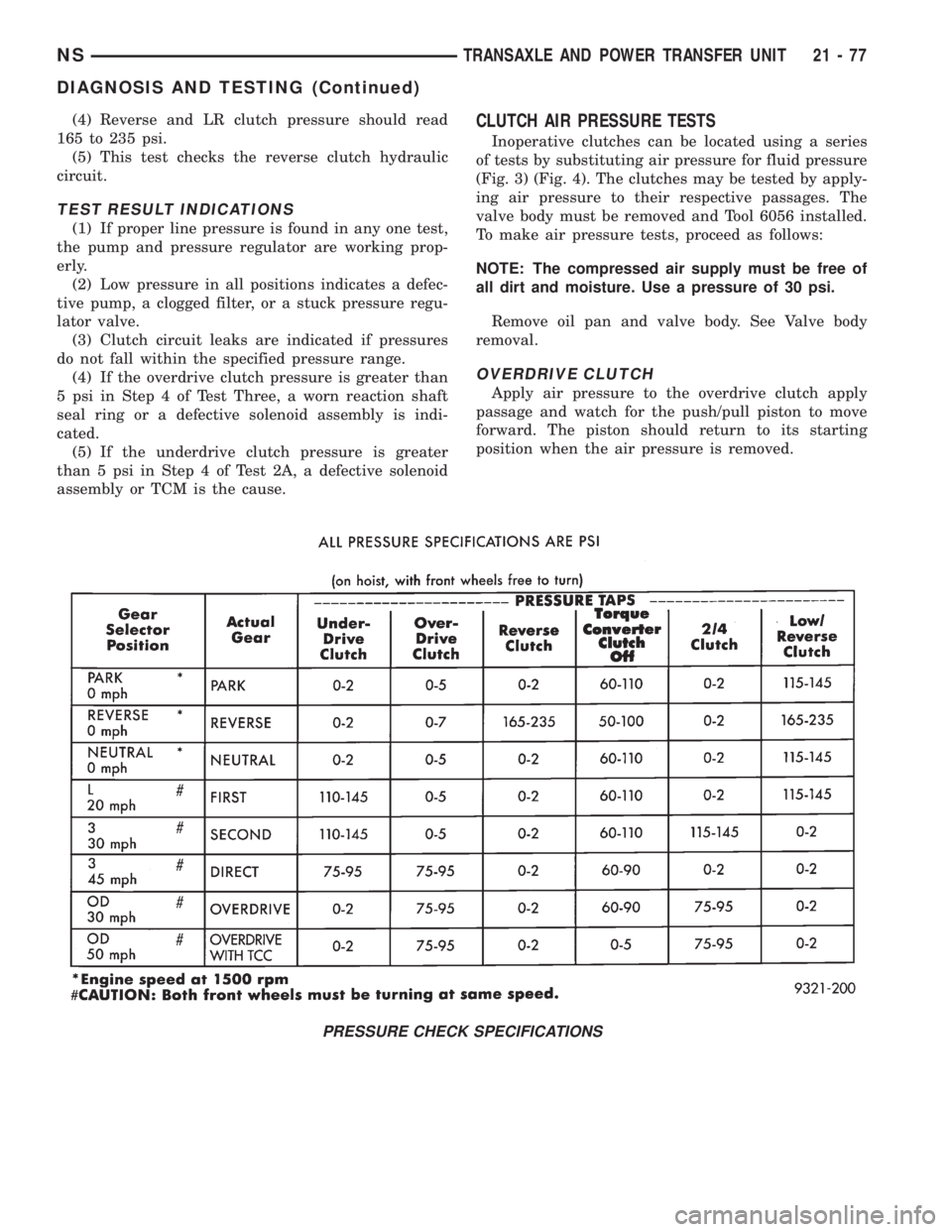

(4) Reverse and LR clutch pressure should read

165 to 235 psi.

(5) This test checks the reverse clutch hydraulic

circuit.

TEST RESULT INDICATIONS

(1) If proper line pressure is found in any one test,

the pump and pressure regulator are working prop-

erly.

(2) Low pressure in all positions indicates a defec-

tive pump, a clogged filter, or a stuck pressure regu-

lator valve.

(3) Clutch circuit leaks are indicated if pressures

do not fall within the specified pressure range.

(4) If the overdrive clutch pressure is greater than

5 psi in Step 4 of Test Three, a worn reaction shaft

seal ring or a defective solenoid assembly is indi-

cated.

(5) If the underdrive clutch pressure is greater

than 5 psi in Step 4 of Test 2A, a defective solenoid

assembly or TCM is the cause.

CLUTCH AIR PRESSURE TESTS

Inoperative clutches can be located using a series

of tests by substituting air pressure for fluid pressure

(Fig. 3) (Fig. 4). The clutches may be tested by apply-

ing air pressure to their respective passages. The

valve body must be removed and Tool 6056 installed.

To make air pressure tests, proceed as follows:

NOTE: The compressed air supply must be free of

all dirt and moisture. Use a pressure of 30 psi.

Remove oil pan and valve body. See Valve body

removal.

OVERDRIVE CLUTCH

Apply air pressure to the overdrive clutch apply

passage and watch for the push/pull piston to move

forward. The piston should return to its starting

position when the air pressure is removed.

PRESSURE CHECK SPECIFICATIONS

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 77

DIAGNOSIS AND TESTING (Continued)

Page 1552 of 1938

REVERSE CLUTCH

Apply air pressure to the reverse clutch apply pas-

sage and watch for the push/pull piston to move rear-

ward. The piston should return to its starting

position when the air pressure is removed.

2/4 CLUTCH

Apply air pressure to the feed hole located on the

2/4 clutch retainer. Look in the area where the 2/4

piston contacts the first separator plate and watch

carefully for the 2/4 piston to move rearward. The

piston should return to its original position after the

air pressure is removed.

LOW/REVERSE CLUTCH

Apply air pressure to the low/reverse clutch feed

hole (rear of case, between 2 bolt holes). Then, look

in the area where the low/reverse piston contacts thefirst separator plate. Watch carefully for the piston to

move forward. The piston should return to its origi-

nal position after the air pressure is removed.

UNDERDRIVE CLUTCH

Because this clutch piston cannot be seen, its oper-

ation is checked by function. Air pressure is applied

to the low/reverse and the 2/4 clutches. This locks the

output shaft. Use a piece of rubber hose wrapped

around the input shaft and a pair of clamp-on pliers

to turn the input shaft. Next apply air pressure to

the underdrive clutch. The input shaft should not

rotate with hand torque. Release the air pressure

and confirm that the input shaft will rotate.

FLUID LEAKAGE-TORQUE CONVERTER HOUSING

AREA

(1) Check for source of leakage.

(2) Fluid leakage at or around the torque converter

area may originate from an engine oil leak. The area

should be examined closely. Factory fill fluid is red

and, therefore, can be distinguished from engine oil.

(3) Prior to removing the transaxle, perform the

following checks:

(4) When leakage is determined to originate from

the transaxle, check fluid level prior to removal of

the transaxle and torque converter.

(5) High oil level can result in oil leakage out the

vent in the manual shaft. If the fluid level is high,

adjust to proper level.

(6) After performing this operation, inspect for

leakage. If a leak persists, perform the following

operation on the vehicle. This will determine if the

torque converter or transaxle is leaking.

TORQUE CONVERTER LEAKAGE

Possible sources of torque converter leakage are:

²Torque converter weld leaks at the outside

(peripheral) weld.

²Torque converter hub weld.

NOTE: Hub weld is inside and not visible. Do not

attempt to repair. Replace torque converter.

SHIFT POSITION INDICATOR

The transmission range sensor (on the valve body)

sends a signal to the TCM on the position of the

transaxle manual valve lever. The TCM receives the

switch signal and processes the data. The TCM sends

the Shift Lever Position (SLP) information to the

BCM via the CCD bus. The BCM then outlines with

a box the appropriate shifter position indicator in the

instrument cluster.

Fig. 3 Air Pressure Test Plate

Fig. 4 Testing Reverse Clutch

21 - 78 TRANSAXLE AND POWER TRANSFER UNITNS

DIAGNOSIS AND TESTING (Continued)

Page 1560 of 1938

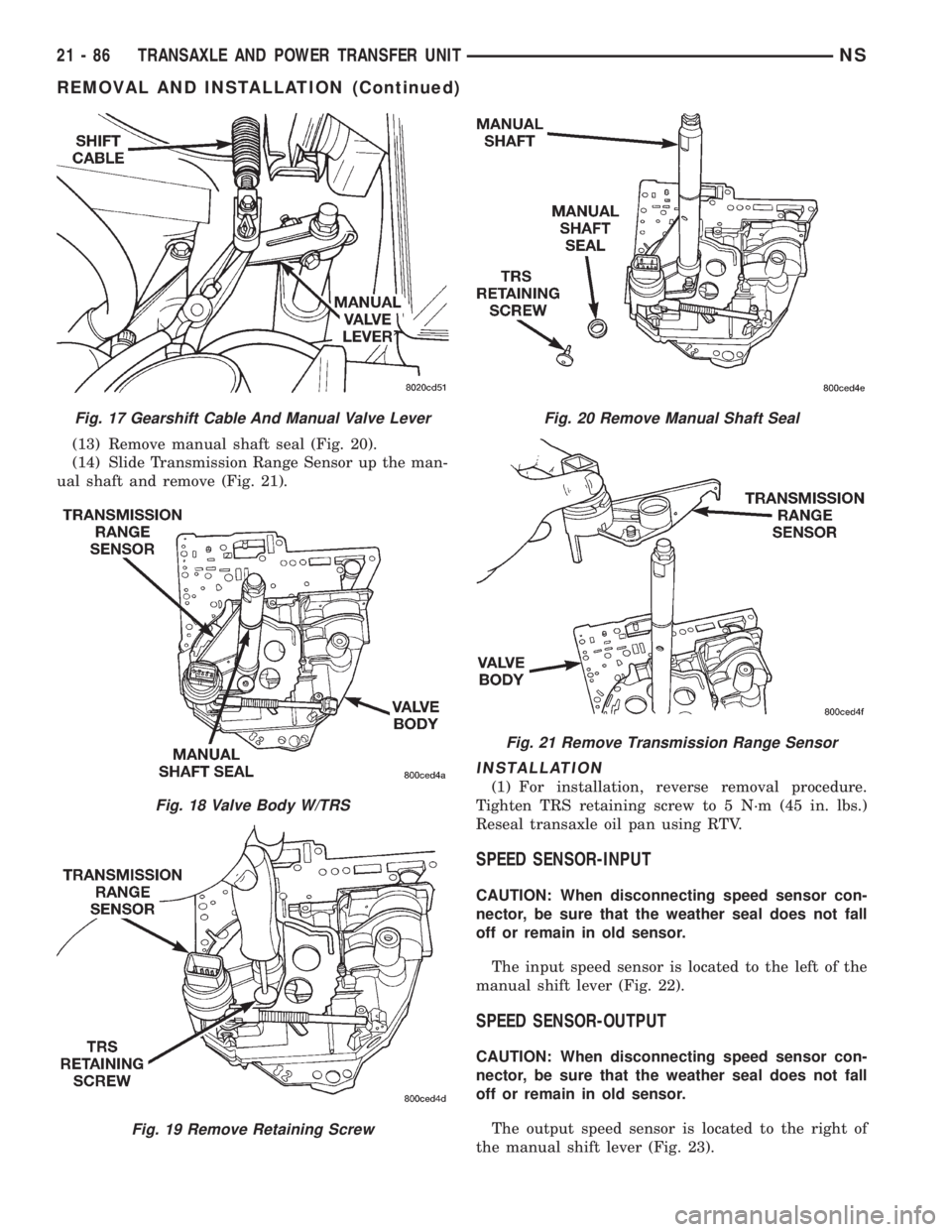

(13) Remove manual shaft seal (Fig. 20).

(14) Slide Transmission Range Sensor up the man-

ual shaft and remove (Fig. 21).

INSTALLATION

(1) For installation, reverse removal procedure.

Tighten TRS retaining screw to 5 N´m (45 in. lbs.)

Reseal transaxle oil pan using RTV.

SPEED SENSOR-INPUT

CAUTION: When disconnecting speed sensor con-

nector, be sure that the weather seal does not fall

off or remain in old sensor.

The input speed sensor is located to the left of the

manual shift lever (Fig. 22).

SPEED SENSOR-OUTPUT

CAUTION: When disconnecting speed sensor con-

nector, be sure that the weather seal does not fall

off or remain in old sensor.

The output speed sensor is located to the right of

the manual shift lever (Fig. 23).

Fig. 17 Gearshift Cable And Manual Valve Lever

Fig. 18 Valve Body W/TRS

Fig. 19 Remove Retaining Screw

Fig. 20 Remove Manual Shaft Seal

Fig. 21 Remove Transmission Range Sensor

21 - 86 TRANSAXLE AND POWER TRANSFER UNITNS

REMOVAL AND INSTALLATION (Continued)

Page 1563 of 1938

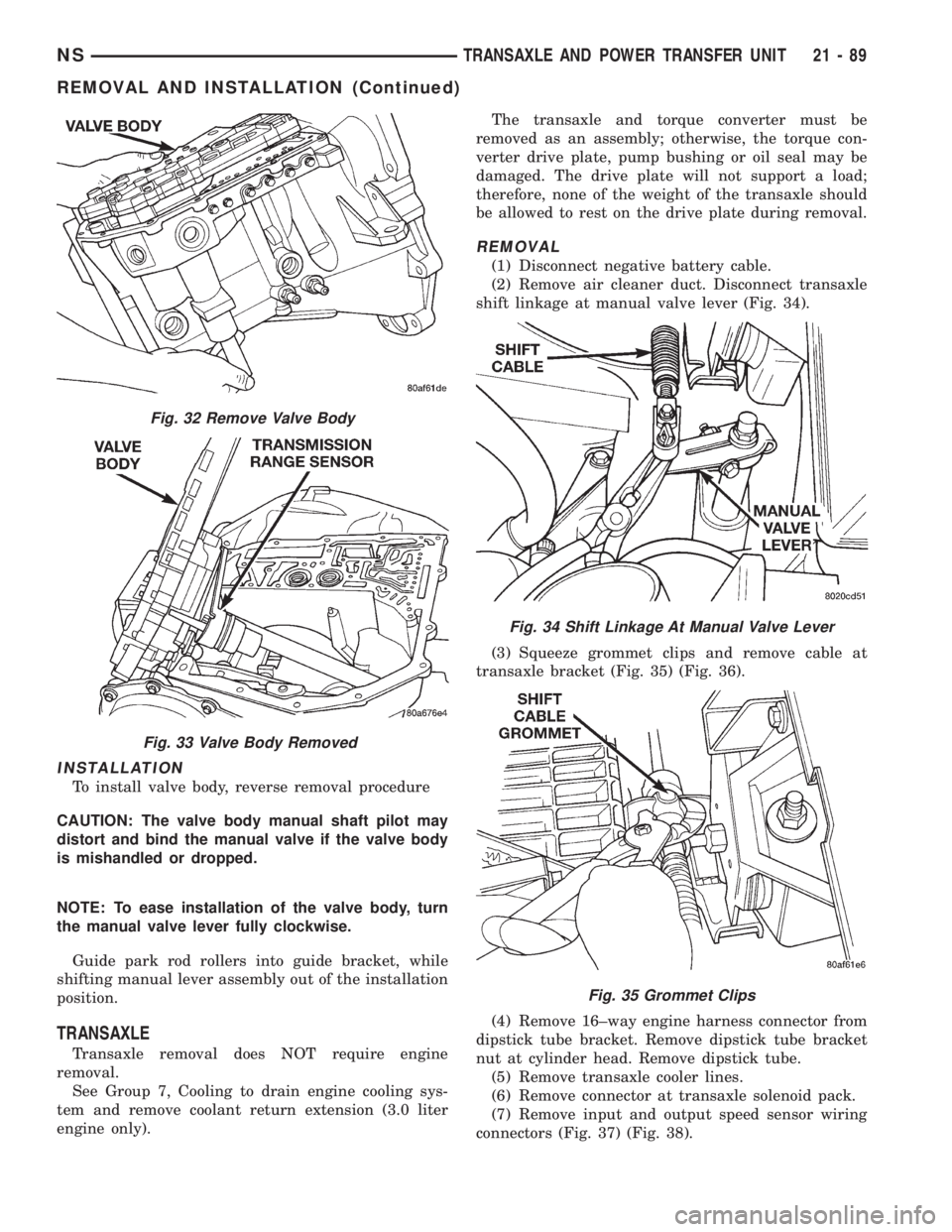

INSTALLATION

To install valve body, reverse removal procedure

CAUTION: The valve body manual shaft pilot may

distort and bind the manual valve if the valve body

is mishandled or dropped.

NOTE: To ease installation of the valve body, turn

the manual valve lever fully clockwise.

Guide park rod rollers into guide bracket, while

shifting manual lever assembly out of the installation

position.

TRANSAXLE

Transaxle removal does NOT require engine

removal.

See Group 7, Cooling to drain engine cooling sys-

tem and remove coolant return extension (3.0 liter

engine only).The transaxle and torque converter must be

removed as an assembly; otherwise, the torque con-

verter drive plate, pump bushing or oil seal may be

damaged. The drive plate will not support a load;

therefore, none of the weight of the transaxle should

be allowed to rest on the drive plate during removal.

REMOVAL

(1) Disconnect negative battery cable.

(2) Remove air cleaner duct. Disconnect transaxle

shift linkage at manual valve lever (Fig. 34).

(3) Squeeze grommet clips and remove cable at

transaxle bracket (Fig. 35) (Fig. 36).

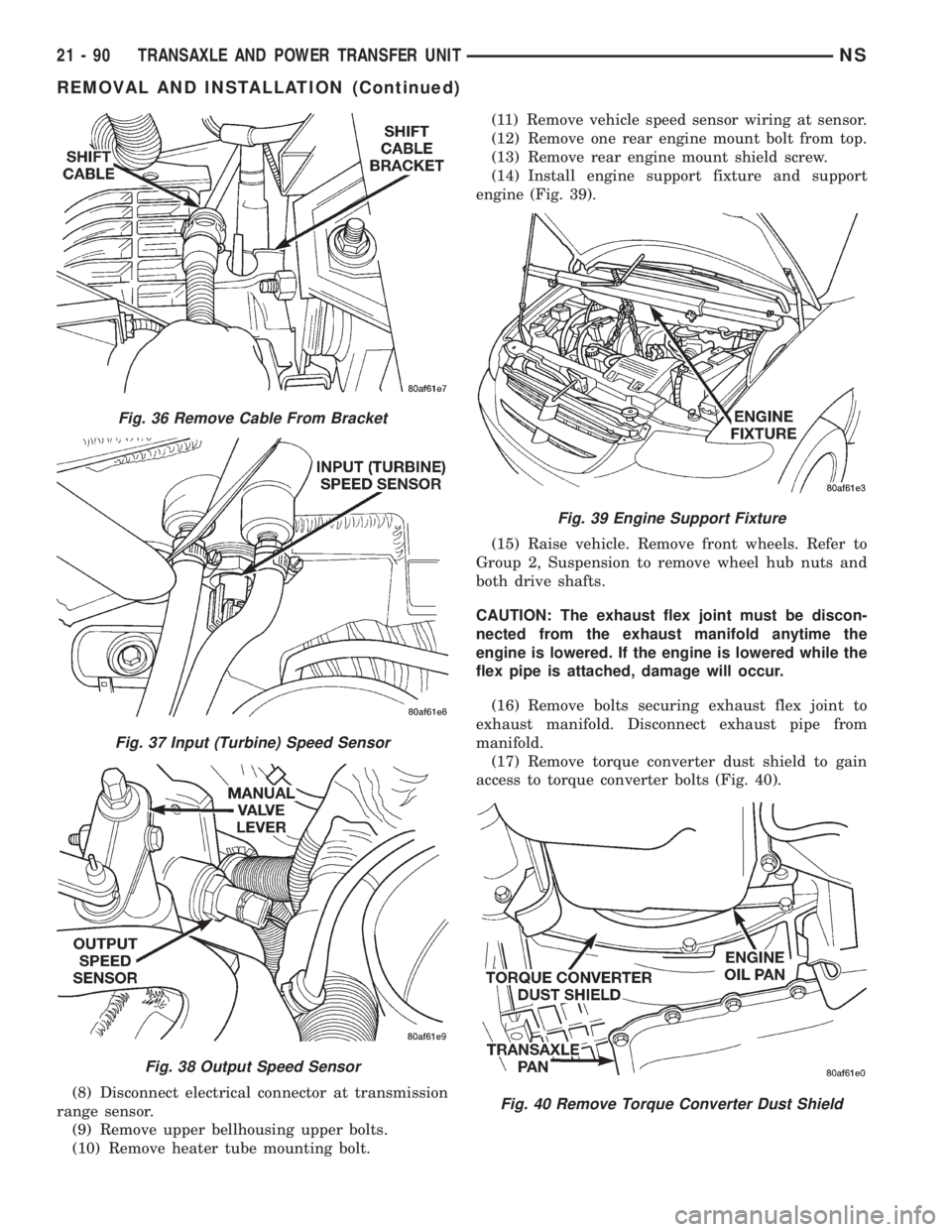

(4) Remove 16±way engine harness connector from

dipstick tube bracket. Remove dipstick tube bracket

nut at cylinder head. Remove dipstick tube.

(5) Remove transaxle cooler lines.

(6) Remove connector at transaxle solenoid pack.

(7) Remove input and output speed sensor wiring

connectors (Fig. 37) (Fig. 38).

Fig. 32 Remove Valve Body

Fig. 33 Valve Body Removed

Fig. 34 Shift Linkage At Manual Valve Lever

Fig. 35 Grommet Clips

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 89

REMOVAL AND INSTALLATION (Continued)

Page 1564 of 1938

(8) Disconnect electrical connector at transmission

range sensor.

(9) Remove upper bellhousing upper bolts.

(10) Remove heater tube mounting bolt.(11) Remove vehicle speed sensor wiring at sensor.

(12) Remove one rear engine mount bolt from top.

(13) Remove rear engine mount shield screw.

(14) Install engine support fixture and support

engine (Fig. 39).

(15) Raise vehicle. Remove front wheels. Refer to

Group 2, Suspension to remove wheel hub nuts and

both drive shafts.

CAUTION: The exhaust flex joint must be discon-

nected from the exhaust manifold anytime the

engine is lowered. If the engine is lowered while the

flex pipe is attached, damage will occur.

(16) Remove bolts securing exhaust flex joint to

exhaust manifold. Disconnect exhaust pipe from

manifold.

(17) Remove torque converter dust shield to gain

access to torque converter bolts (Fig. 40).

Fig. 36 Remove Cable From Bracket

Fig. 37 Input (Turbine) Speed Sensor

Fig. 38 Output Speed Sensor

Fig. 39 Engine Support Fixture

Fig. 40 Remove Torque Converter Dust Shield

21 - 90 TRANSAXLE AND POWER TRANSFER UNITNS

REMOVAL AND INSTALLATION (Continued)

Page 1565 of 1938

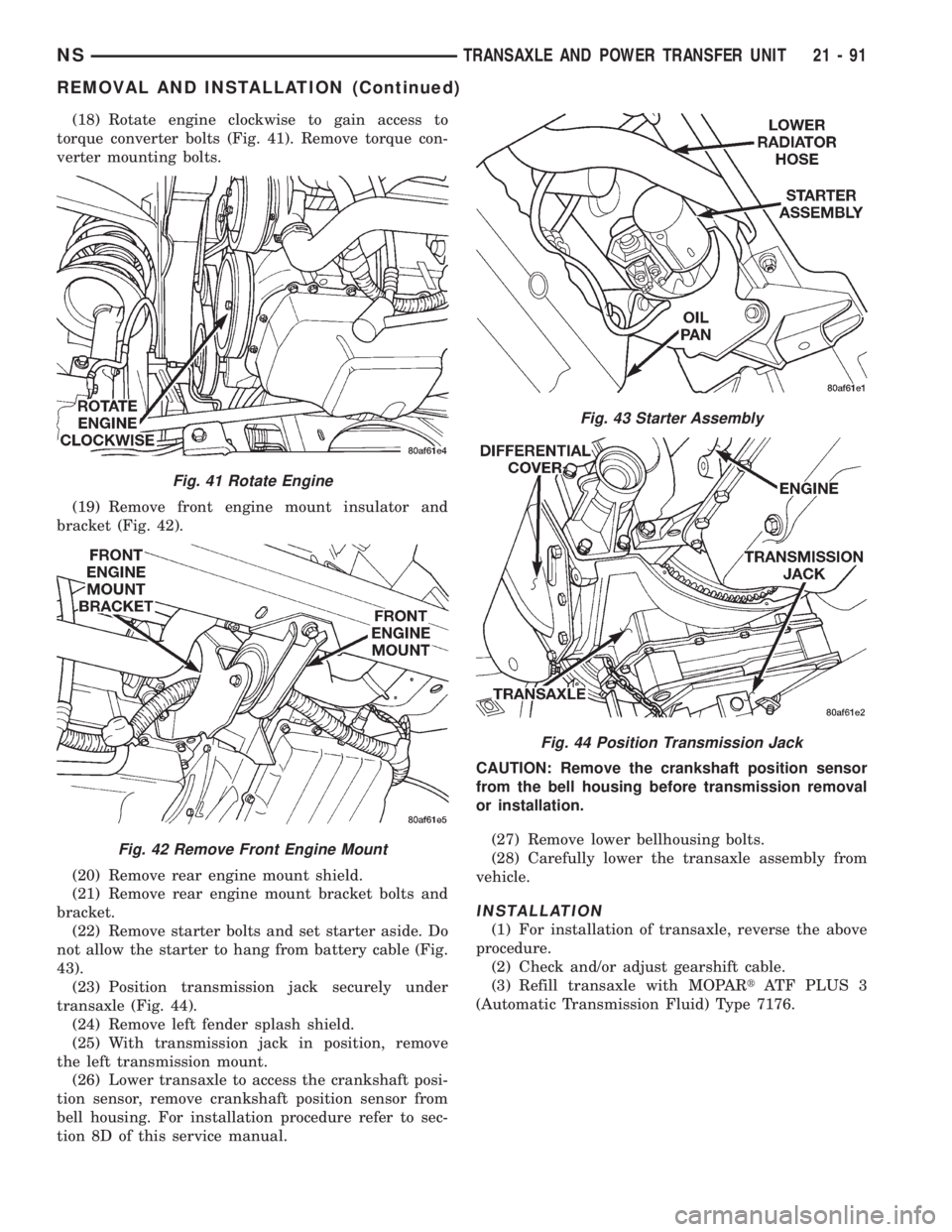

(18) Rotate engine clockwise to gain access to

torque converter bolts (Fig. 41). Remove torque con-

verter mounting bolts.

(19) Remove front engine mount insulator and

bracket (Fig. 42).

(20) Remove rear engine mount shield.

(21) Remove rear engine mount bracket bolts and

bracket.

(22) Remove starter bolts and set starter aside. Do

not allow the starter to hang from battery cable (Fig.

43).

(23) Position transmission jack securely under

transaxle (Fig. 44).

(24) Remove left fender splash shield.

(25) With transmission jack in position, remove

the left transmission mount.

(26) Lower transaxle to access the crankshaft posi-

tion sensor, remove crankshaft position sensor from

bell housing. For installation procedure refer to sec-

tion 8D of this service manual.CAUTION: Remove the crankshaft position sensor

from the bell housing before transmission removal

or installation.

(27) Remove lower bellhousing bolts.

(28) Carefully lower the transaxle assembly from

vehicle.

INSTALLATION

(1) For installation of transaxle, reverse the above

procedure.

(2) Check and/or adjust gearshift cable.

(3) Refill transaxle with MOPARtATF PLUS 3

(Automatic Transmission Fluid) Type 7176.

Fig. 41 Rotate Engine

Fig. 42 Remove Front Engine Mount

Fig. 43 Starter Assembly

Fig. 44 Position Transmission Jack

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 91

REMOVAL AND INSTALLATION (Continued)

Page 1566 of 1938

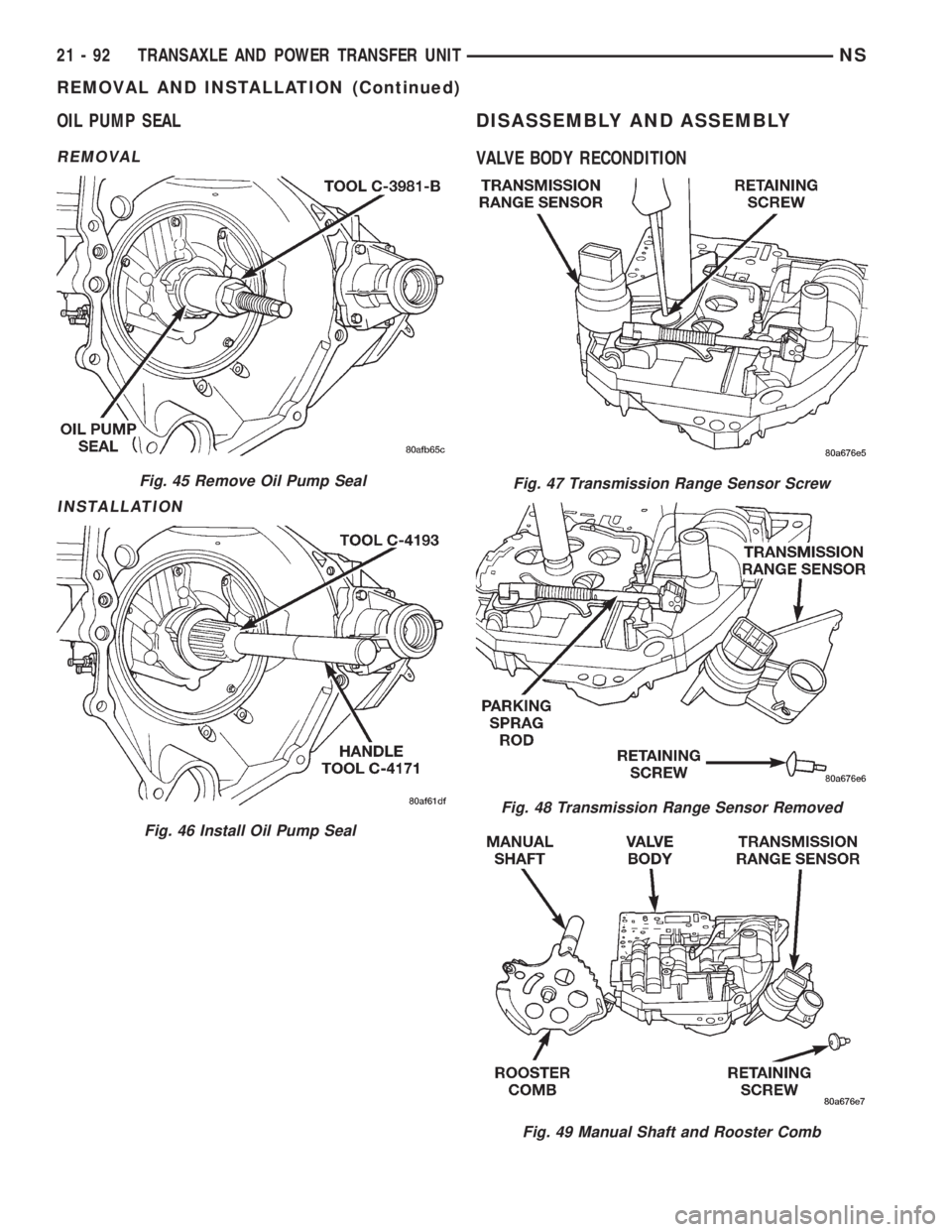

OIL PUMP SEAL

REMOVAL

INSTALLATION

DISASSEMBLY AND ASSEMBLY

VALVE BODY RECONDITION

Fig. 45 Remove Oil Pump Seal

Fig. 46 Install Oil Pump Seal

Fig. 47 Transmission Range Sensor Screw

Fig. 48 Transmission Range Sensor Removed

Fig. 49 Manual Shaft and Rooster Comb

21 - 92 TRANSAXLE AND POWER TRANSFER UNITNS

REMOVAL AND INSTALLATION (Continued)

Page 1567 of 1938

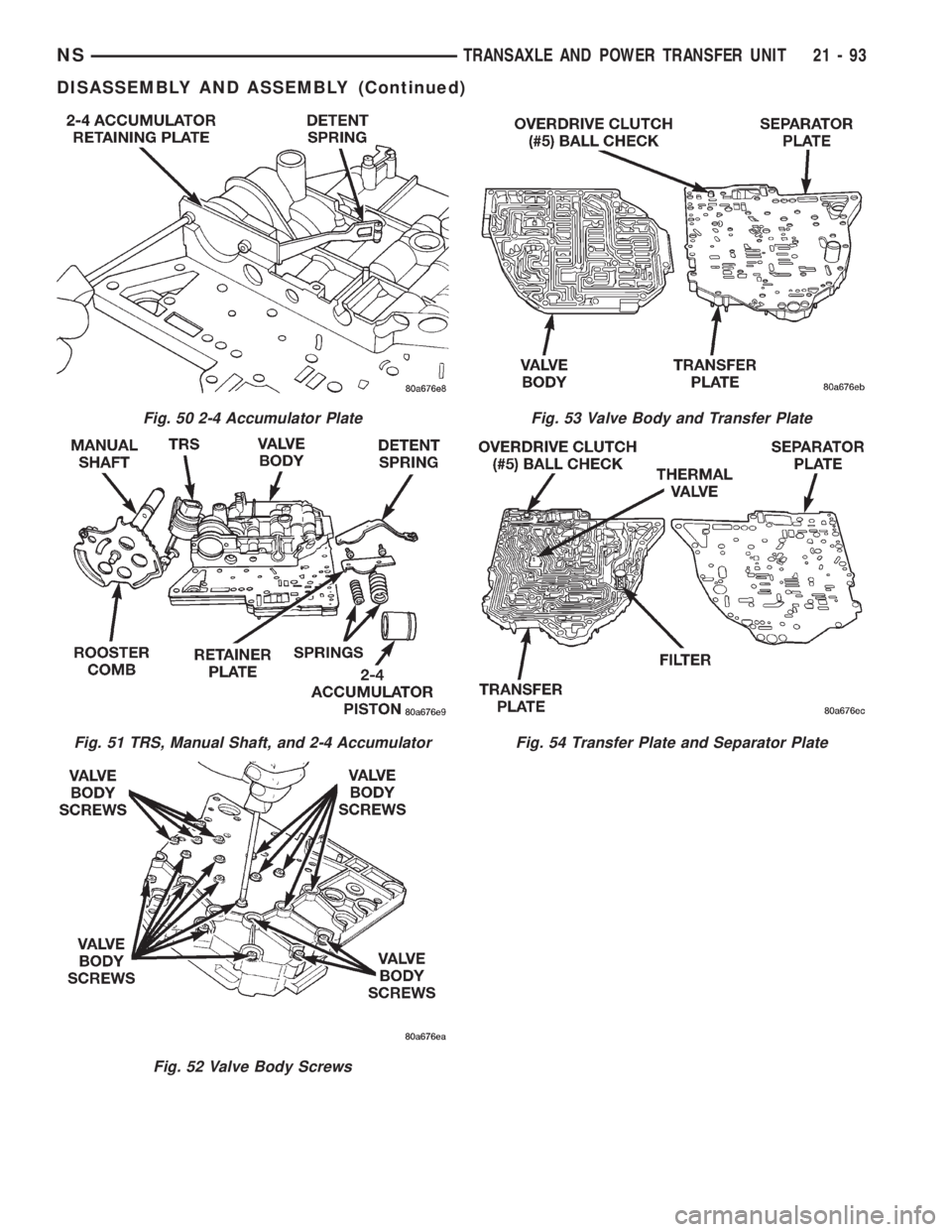

Fig. 50 2-4 Accumulator Plate

Fig. 51 TRS, Manual Shaft, and 2-4 Accumulator

Fig. 52 Valve Body Screws

Fig. 53 Valve Body and Transfer Plate

Fig. 54 Transfer Plate and Separator Plate

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 93

DISASSEMBLY AND ASSEMBLY (Continued)