torque CHRYSLER VOYAGER 1996 Manual Online

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 252 of 1938

SPECIFICATIONS

COOLING SYSTEM CAPACITY

TORQUE CHART

SPECIAL TOOLS

COOLING

2.0L Gasoline *10.6 liters (11 qts.)

2.5L VM Diesel *10.0 liters (10.6 qts.)

*Includes Heater and Coolant recovery/pressure Tank.

COMPONENT 2.0L

GASOLINE2.5L VM

Thermostat

Cover Bolts105 in-lbs 10.8 N´m (96 in.

lbs.)

Water Pump

Mounting Bolts12 N´m (105 in.

lbs.)22.6 N´m (204

in. lbs.)

Water Pump

Pulley BoltsN/A 27.5 N´m (240

in. lbs.)

Upper Radiator

Mounting

Bracket Bolts12 N´m (105 in.

lbs.)12 N´m (105 in.

lbs.)

Turbocharger

Oil Supply LineN/A 24.5 N´m (215

in. lbs.)

Turbocharger

Oil Return LineN/A 10.8 N´m (96 in.

lbs.)

Water Pump

Housing NutsN/A 9.5 N´m (84 in.

lbs.)

Water Manifold

BoltsN/A 11.2 N´m (96 in.

lbs.)

Coolant Bottle

Bolts2.0 N´m (18 in.

lbs.)10.8 N´m (96 in.

lbs.)

Belt Tension Gauge C-4162

7 - 12 COOLING SYSTEMNS/GS

Page 253 of 1938

BATTERY

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

SAFETY PRECAUTIONS AND WARNINGS..... 1

DESCRIPTION AND OPERATION

BATTERY IGNITION OFF DRAW (IOD)........ 1

CHARGING TIME REQUIRED............... 2

DIAGNOSIS AND TESTING

BATTERY BUILT-IN TEST INDICATOR........ 2

BATTERY IGNITION OFF DRAW (IOD)........ 3

BATTERY LOAD TEST..................... 4

BATTERY OPEN CIRCUIT VOLTAGE TEST..... 6SERVICE PROCEDURES

BATTERY CHARGING..................... 6

CHARGING COMPLETELY DISCHARGED

BATTERY............................. 7

VISUAL INSPECTION..................... 7

REMOVAL AND INSTALLATION

BATTERY TRAY.......................... 9

BATTERY............................... 8

SPECIFICATIONS

BATTERY SPECIFICATIONS............... 10

TORQUE.............................. 10

GENERAL INFORMATION

INTRODUCTION

The battery stores, stabilizes, and delivers electri-

cal current to operate various electrical systems in

the vehicle. The determination of whether a battery

is good or bad is made by its ability to accept a

charge. It also must supply high-amperage current

for a long enough period to be able to start the vehi-

cle. The capability of the battery to store electrical

current comes from a chemical reaction. This reac-

tion takes place between the sulfuric acid solution

(electrolyte) and the lead +/- plates in each cell of the

battery. As the battery discharges, the plates react

with the acid from the electrolyte. When the charging

system charges the battery, the water is converted to

sulfuric acid in the battery. The concentration of acid

in the electrolyte is measured as specific gravity

using a hydrometer. The original equipment (OE)

battery is equipped with a hydrometer (test indica-

tor) built into the battery cover. The specific gravity

indicates the battery's state-of-charge. The OE bat-

tery is sealed and water cannot be added.

The battery is vented to release gases that are cre-

ated when the battery is being charged and dis-

charged. The battery top, posts, and terminals should

be cleaned when other under hood maintenance is

performed.

When the electrolyte level is below the top of the

plates, Clear in the test Indicator, the battery must

be replaced. The battery must be completely charged,

and the battery top, posts, and cable clamps must be

cleaned before diagnostic procedures are performed.

SAFETY PRECAUTIONS AND WARNINGS

WARNING: DO NOT ALLOW JUMPER CABLE

CLAMPS TO TOUCH EACH OTHER WHEN CON-

NECTED TO A BOOSTER SOURCE. DO NOT USE

OPEN FLAME NEAR BATTERY. REMOVE METALLIC

JEWELRY WORN ON HANDS OR WRISTS TO AVOID

INJURY BY ACCIDENTAL ARCING OF BATTERY

CURRENT.

WHEN USING A HIGH OUTPUT BOOSTING DEVICE,

DO NOT ALLOW THE DISABLED VEHICLE'S BAT-

TERY TO EXCEED 16 VOLTS. PERSONAL INJURY

OR DAMAGE TO ELECTRICAL SYSTEM CAN

RESULT.

TO PROTECT THE HANDS FROM BATTERY ACID, A

SUITABLE PAIR OF HEAVY DUTY RUBBER

GLOVES, NOT THE HOUSEHOLD TYPE, SHOULD

BE WORN WHEN REMOVING OR SERVICING A

BATTERY. SAFETY GLASSES ALSO SHOULD BE

WORN.

DESCRIPTION AND OPERATION

BATTERY IGNITION OFF DRAW (IOD)

A completely normal vehicle will have a small

amount of current drain on the battery with the key

out of the ignition. It can range from 5 to 25 milli-

amperes after all the modules time out. If a vehicle

will not be operated for approximately a 20 days, the

IOD fuse should be pulled to eliminate the vehicle

electrical drain on the battery. The IOD fuse is

NSBATTERY 8A - 1

Page 262 of 1938

SPECIFICATIONS

BATTERY SPECIFICATIONS

CRANKING RATING

The current battery can deliver for 30 seconds and

maintain a terminal voltage of 7.2 volts or greater at

specified temperature.

RESERVE CAPACITY RATING

The length of time a battery can deliver 25 amps

and maintain a minimum terminal voltage of 10.5

volts at 27ÉC (80ÉF).

TORQUE

DESCRIPTION TORQUE

Battery Hold Down Bolt Clamp

Bolt....................14N´m(125 in. lbs.)

Fig. 19 Speed Control Servo Removal

Load Test

(Amps)Cold Cranking

Rating @ 0ÉFReserve

Capacity

250 Amp 500 Amp 110 Minutes

300 Amp 600 Amp 120 Minutes

340 Amp 685 Amp 125 Minutes

8A - 10 BATTERYNS

REMOVAL AND INSTALLATION (Continued)

Page 263 of 1938

BATTERY

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION........................ 1

SAFETY PRECAUTIONS AND WARNINGS.... 1

DESCRIPTION AND OPERATION

BATTERY IGNITION OFF DRAW (IOD)....... 2

CHARGING TIME REQUIRED.............. 2

DIAGNOSIS AND TESTING

BATTERY DISCHARGING................. 3

BATTERY IGNITION OFF DRAW............ 3

BATTERY LOAD TEST................... 5

BATTERY OPEN CIRCUIT VOLTAGE TEST.... 6SERVICE PROCEDURES

BATTERY CHARGING.................... 6

CHARGING COMPLETELY DISCHARGED

BATTERY............................ 7

VISUAL INSPECTION.................... 7

REMOVAL AND INSTALLATION

BATTERY............................. 8

BATTERY TRAY........................ 9

SPECIFICATIONS

BATTERY SPECIFICATIONS............... 9

TORQUE............................. 10

GENERAL INFORMATION

INTRODUCTION

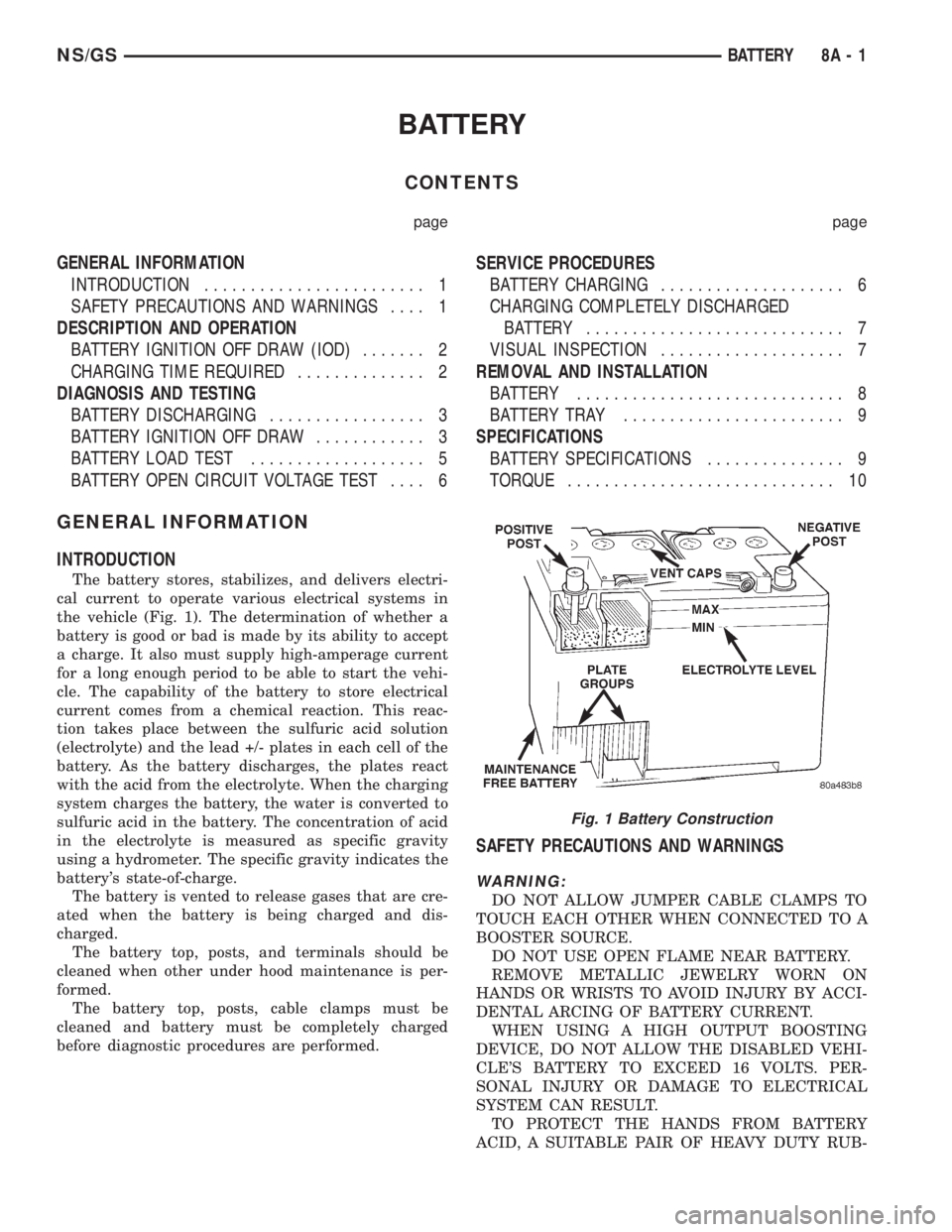

The battery stores, stabilizes, and delivers electri-

cal current to operate various electrical systems in

the vehicle (Fig. 1). The determination of whether a

battery is good or bad is made by its ability to accept

a charge. It also must supply high-amperage current

for a long enough period to be able to start the vehi-

cle. The capability of the battery to store electrical

current comes from a chemical reaction. This reac-

tion takes place between the sulfuric acid solution

(electrolyte) and the lead +/- plates in each cell of the

battery. As the battery discharges, the plates react

with the acid from the electrolyte. When the charging

system charges the battery, the water is converted to

sulfuric acid in the battery. The concentration of acid

in the electrolyte is measured as specific gravity

using a hydrometer. The specific gravity indicates the

battery's state-of-charge.

The battery is vented to release gases that are cre-

ated when the battery is being charged and dis-

charged.

The battery top, posts, and terminals should be

cleaned when other under hood maintenance is per-

formed.

The battery top, posts, cable clamps must be

cleaned and battery must be completely charged

before diagnostic procedures are performed.

SAFETY PRECAUTIONS AND WARNINGS

WARNING:

DO NOT ALLOW JUMPER CABLE CLAMPS TO

TOUCH EACH OTHER WHEN CONNECTED TO A

BOOSTER SOURCE.

DO NOT USE OPEN FLAME NEAR BATTERY.

REMOVE METALLIC JEWELRY WORN ON

HANDS OR WRISTS TO AVOID INJURY BY ACCI-

DENTAL ARCING OF BATTERY CURRENT.

WHEN USING A HIGH OUTPUT BOOSTING

DEVICE, DO NOT ALLOW THE DISABLED VEHI-

CLE'S BATTERY TO EXCEED 16 VOLTS. PER-

SONAL INJURY OR DAMAGE TO ELECTRICAL

SYSTEM CAN RESULT.

TO PROTECT THE HANDS FROM BATTERY

ACID, A SUITABLE PAIR OF HEAVY DUTY RUB-

Fig. 1 Battery Construction

NS/GSBATTERY 8A - 1

Page 272 of 1938

TORQUE

DESCRIPTION TORQUE

Battery Hold Down Bolt Clamp

Bolt...................14N´m(125 in. lbs.)

Fig. 20 Speed Control Servo Removal

Reserve Cold Cranking Reserve

(Amps) Rating @ -17.8C (0.0F) Capacity

DIN/BCI

200 Amp 500 Amp 110

Minutes

250 Amp 600 Amp 120

Minutes

315 Amp 685 Amp 125

Minutes

8A - 10 BATTERYNS/GS

SPECIFICATIONS (Continued)

Page 273 of 1938

STARTER

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DESCRIPTION AND OPERATION

SUPPLY CIRCUIT AND CONTROL CIRCUIT.... 1

DIAGNOSIS AND TESTING

CONTROL CIRCUIT TEST.................. 1

FEED CIRCUIT RESISTANCE TEST........... 3

FEED CIRCUIT TEST...................... 4REMOVAL AND INSTALLATION

STARTERÐ2.4L ENGINE.................. 5

STARTERÐ3.0L ENGINE.................. 6

STARTERÐ3.3/3.8L ENGINE............... 6

SPECIFICATIONS

STARTER .............................. 7

TORQUE............................... 7

GENERAL INFORMATION

INTRODUCTION

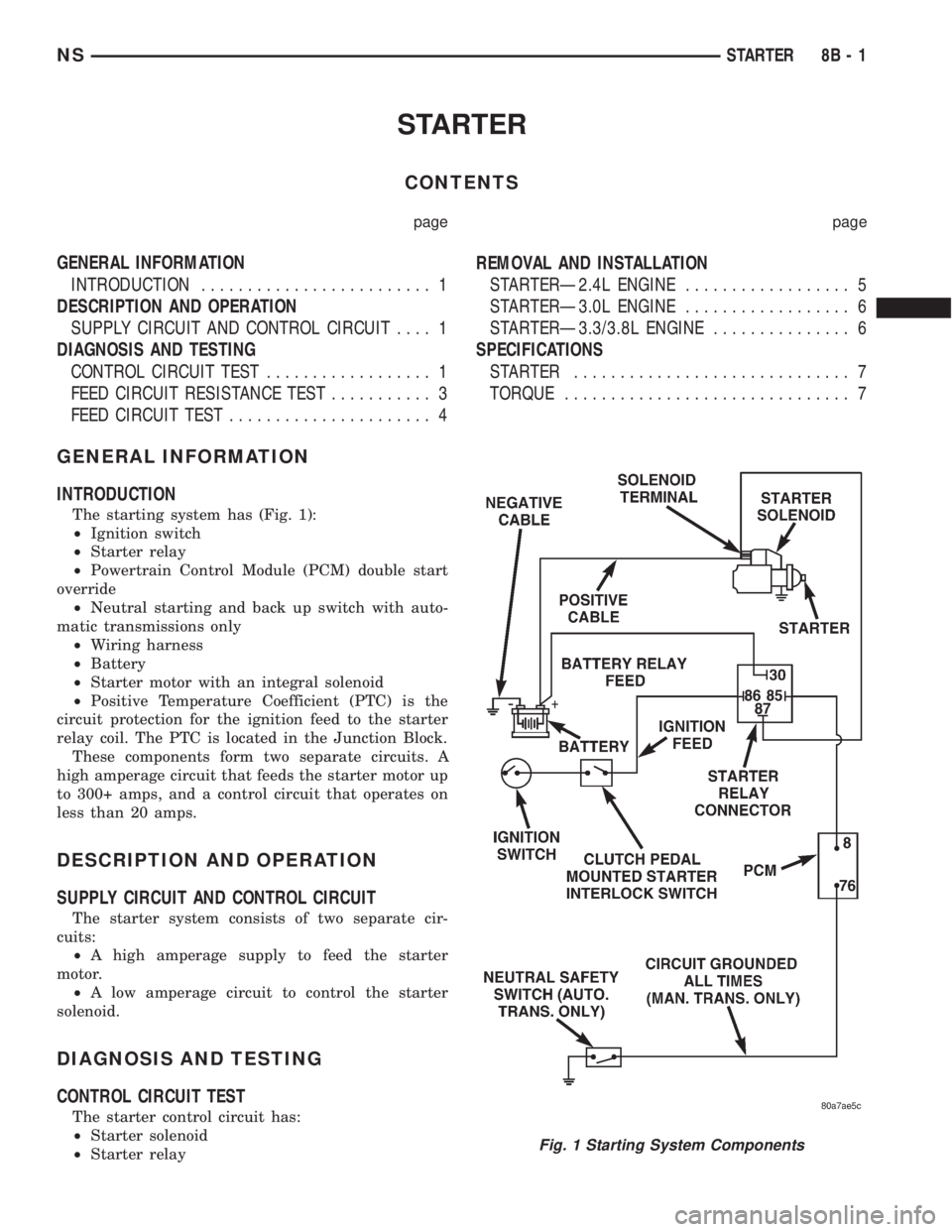

The starting system has (Fig. 1):

²Ignition switch

²Starter relay

²Powertrain Control Module (PCM) double start

override

²Neutral starting and back up switch with auto-

matic transmissions only

²Wiring harness

²Battery

²Starter motor with an integral solenoid

²Positive Temperature Coefficient (PTC) is the

circuit protection for the ignition feed to the starter

relay coil. The PTC is located in the Junction Block.

These components form two separate circuits. A

high amperage circuit that feeds the starter motor up

to 300+ amps, and a control circuit that operates on

less than 20 amps.

DESCRIPTION AND OPERATION

SUPPLY CIRCUIT AND CONTROL CIRCUIT

The starter system consists of two separate cir-

cuits:

²A high amperage supply to feed the starter

motor.

²A low amperage circuit to control the starter

solenoid.

DIAGNOSIS AND TESTING

CONTROL CIRCUIT TEST

The starter control circuit has:

²Starter solenoid

²Starter relay

Fig. 1 Starting System Components

NSSTARTER 8B - 1

Page 279 of 1938

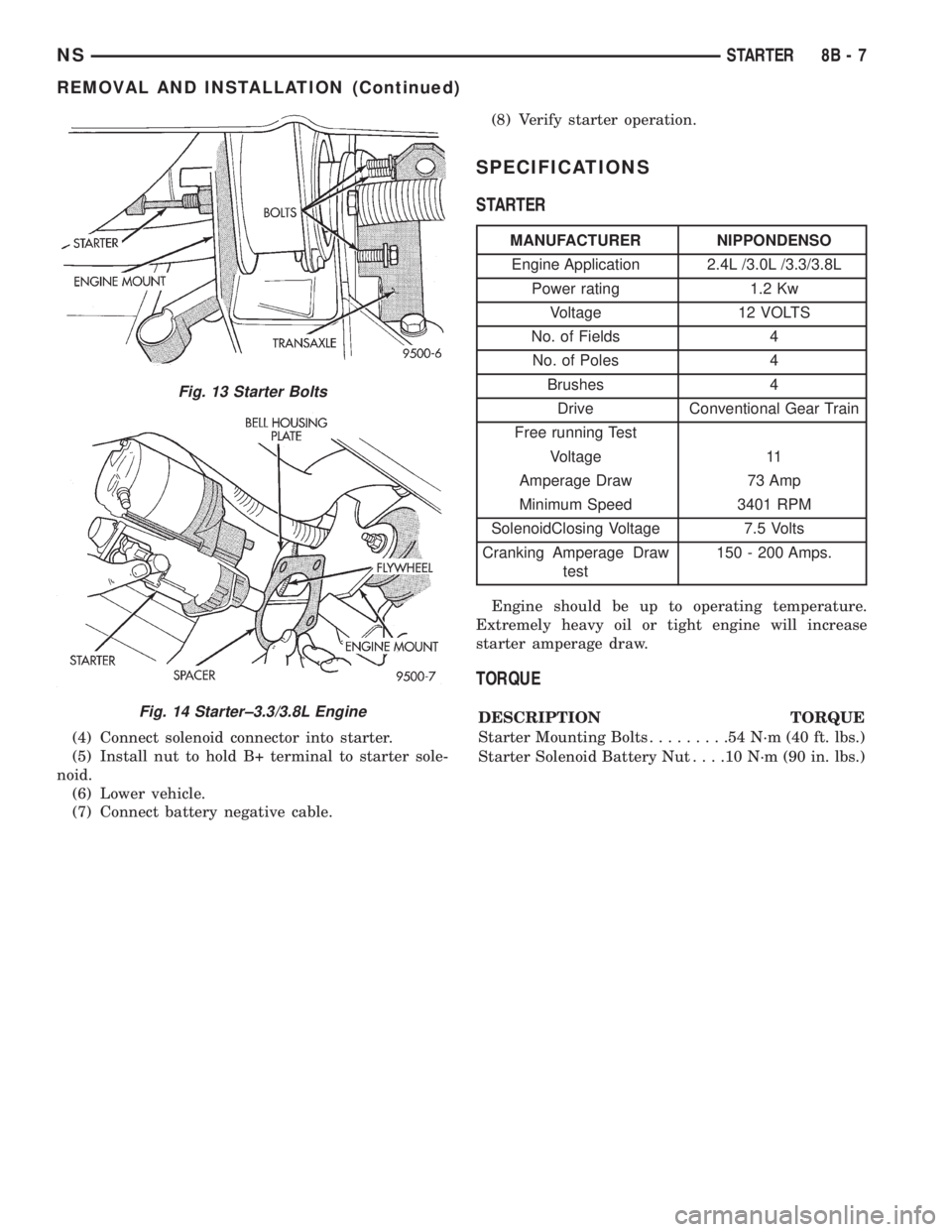

(4) Connect solenoid connector into starter.

(5) Install nut to hold B+ terminal to starter sole-

noid.

(6) Lower vehicle.

(7) Connect battery negative cable.(8) Verify starter operation.

SPECIFICATIONS

STARTER

Engine should be up to operating temperature.

Extremely heavy oil or tight engine will increase

starter amperage draw.

TORQUE

DESCRIPTION TORQUE

Starter Mounting Bolts.........54N´m(40ft.lbs.)

Starter Solenoid Battery Nut. . . .10 N´m (90 in. lbs.)

Fig. 13 Starter Bolts

Fig. 14 Starter±3.3/3.8L Engine

MANUFACTURER NIPPONDENSO

Engine Application 2.4L /3.0L /3.3/3.8L

Power rating 1.2 Kw

Voltage 12 VOLTS

No. of Fields 4

No. of Poles 4

Brushes 4

Drive Conventional Gear Train

Free running Test

Voltage 11

Amperage Draw 73 Amp

Minimum Speed 3401 RPM

SolenoidClosing Voltage 7.5 Volts

Cranking Amperage Draw

test150 - 200 Amps.

NSSTARTER 8B - 7

REMOVAL AND INSTALLATION (Continued)

Page 281 of 1938

STARTING SYSTEM

CONTENTS

page

REMOVAL AND INSTALLATION

STARTER ............................. 1

REMOVAL AND INSTALLATION

STARTER

2.0L ENGINE

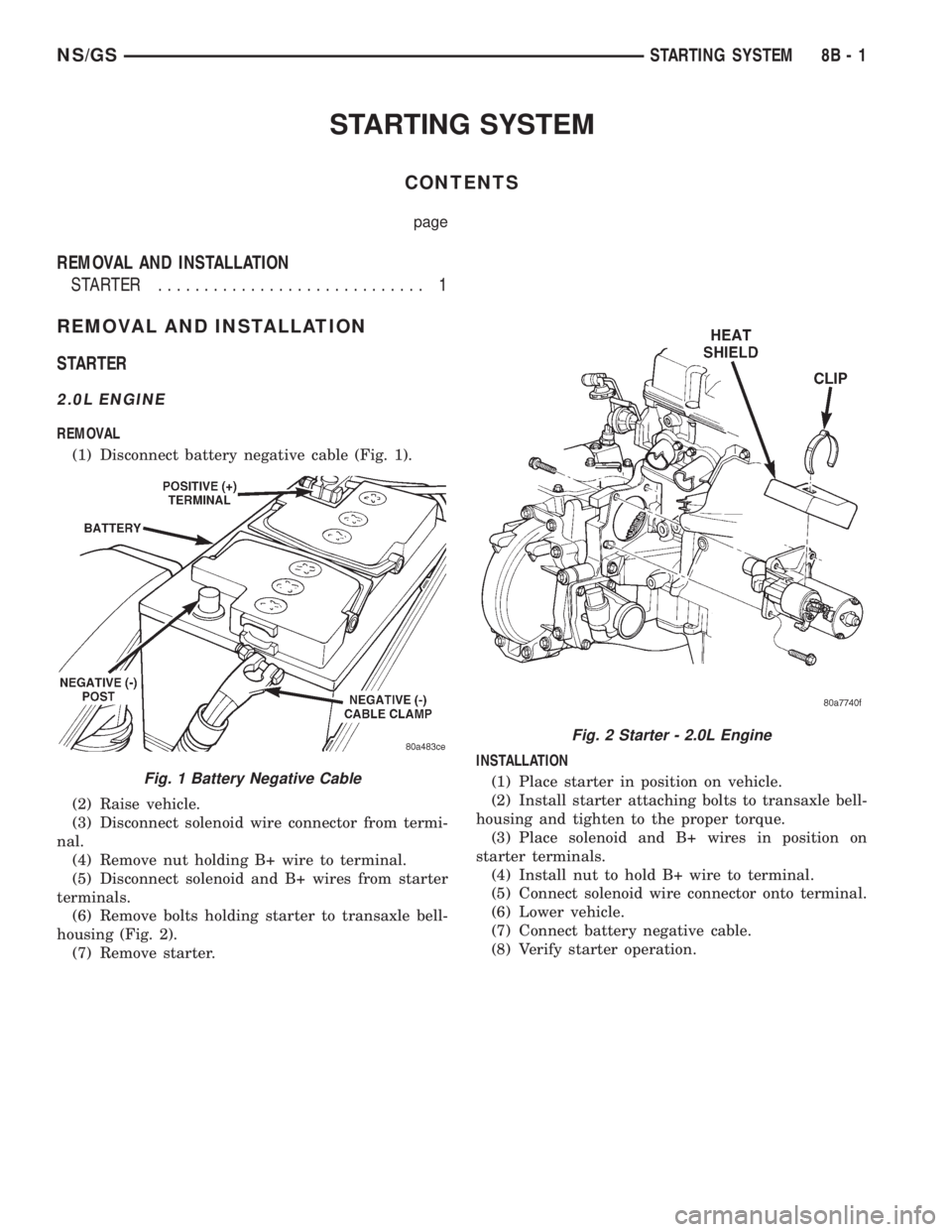

REMOVAL

(1) Disconnect battery negative cable (Fig. 1).

(2) Raise vehicle.

(3) Disconnect solenoid wire connector from termi-

nal.

(4) Remove nut holding B+ wire to terminal.

(5) Disconnect solenoid and B+ wires from starter

terminals.

(6) Remove bolts holding starter to transaxle bell-

housing (Fig. 2).

(7) Remove starter.INSTALLATION

(1) Place starter in position on vehicle.

(2) Install starter attaching bolts to transaxle bell-

housing and tighten to the proper torque.

(3) Place solenoid and B+ wires in position on

starter terminals.

(4) Install nut to hold B+ wire to terminal.

(5) Connect solenoid wire connector onto terminal.

(6) Lower vehicle.

(7) Connect battery negative cable.

(8) Verify starter operation.

Fig. 1 Battery Negative Cable

Fig. 2 Starter - 2.0L Engine

NS/GSSTARTING SYSTEM 8B - 1

Page 282 of 1938

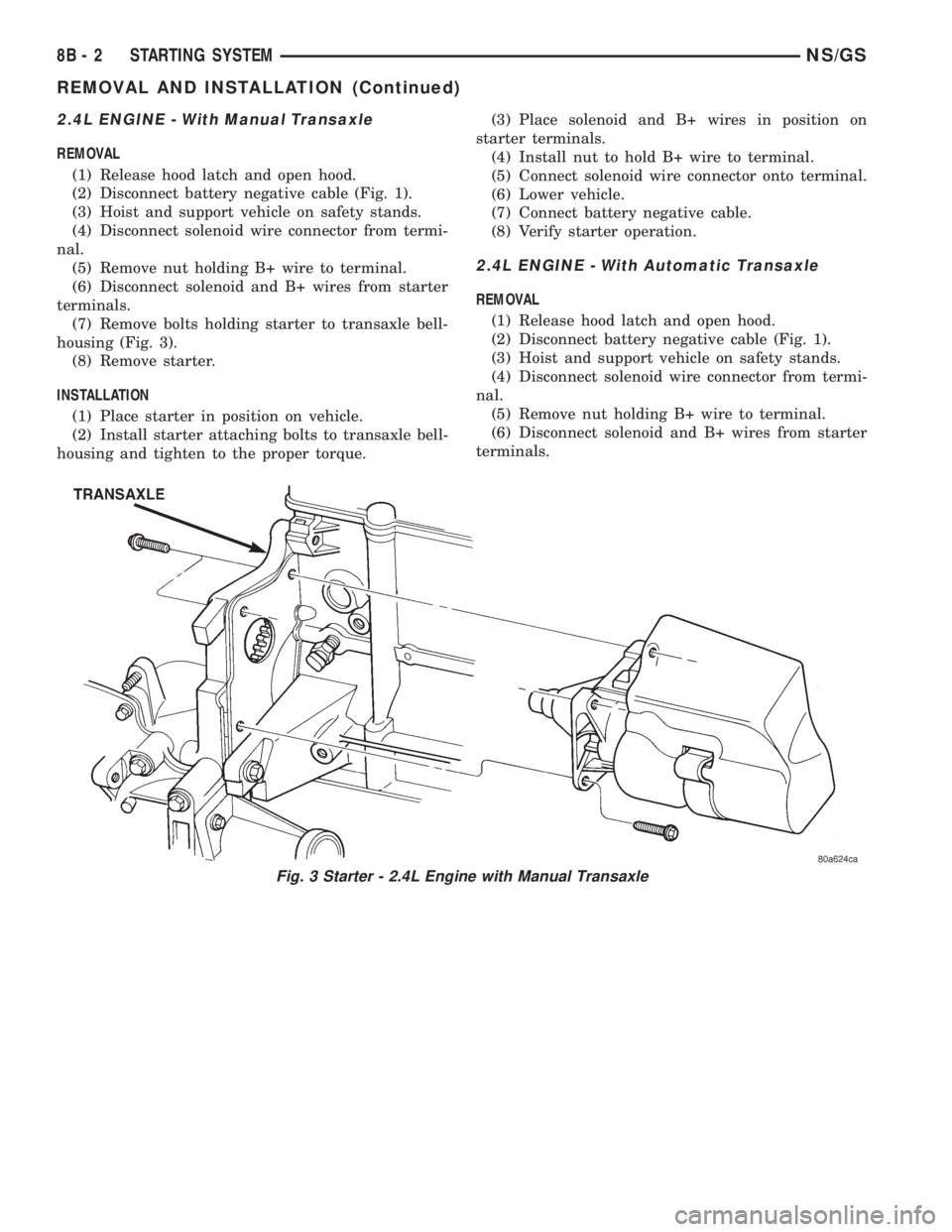

2.4L ENGINE - With Manual Transaxle

REMOVAL

(1) Release hood latch and open hood.

(2) Disconnect battery negative cable (Fig. 1).

(3) Hoist and support vehicle on safety stands.

(4) Disconnect solenoid wire connector from termi-

nal.

(5) Remove nut holding B+ wire to terminal.

(6) Disconnect solenoid and B+ wires from starter

terminals.

(7) Remove bolts holding starter to transaxle bell-

housing (Fig. 3).

(8) Remove starter.

INSTALLATION

(1) Place starter in position on vehicle.

(2) Install starter attaching bolts to transaxle bell-

housing and tighten to the proper torque.(3) Place solenoid and B+ wires in position on

starter terminals.

(4) Install nut to hold B+ wire to terminal.

(5) Connect solenoid wire connector onto terminal.

(6) Lower vehicle.

(7) Connect battery negative cable.

(8) Verify starter operation.

2.4L ENGINE - With Automatic Transaxle

REMOVAL

(1) Release hood latch and open hood.

(2) Disconnect battery negative cable (Fig. 1).

(3) Hoist and support vehicle on safety stands.

(4) Disconnect solenoid wire connector from termi-

nal.

(5) Remove nut holding B+ wire to terminal.

(6) Disconnect solenoid and B+ wires from starter

terminals.

Fig. 3 Starter - 2.4L Engine with Manual Transaxle

8B - 2 STARTING SYSTEMNS/GS

REMOVAL AND INSTALLATION (Continued)

Page 283 of 1938

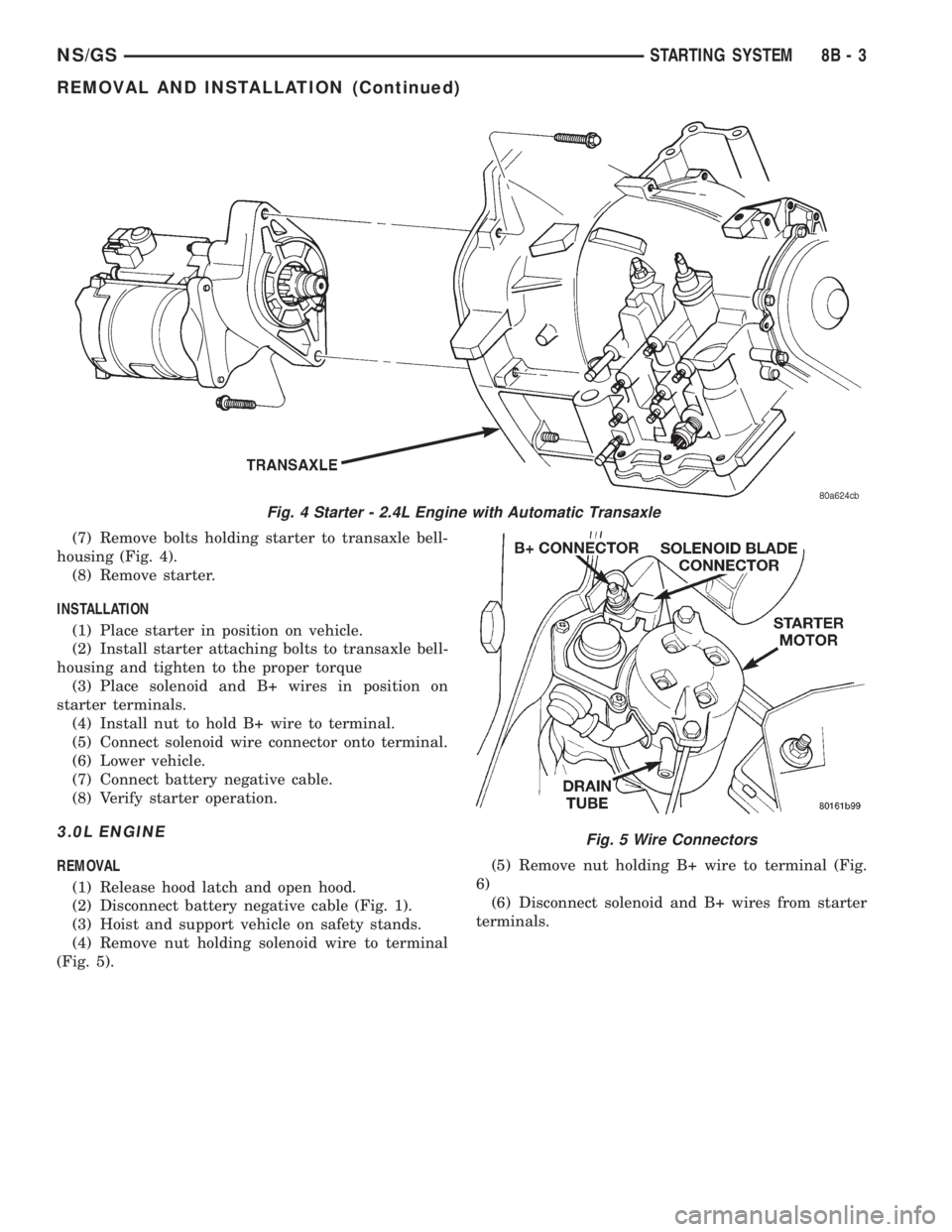

(7) Remove bolts holding starter to transaxle bell-

housing (Fig. 4).

(8) Remove starter.

INSTALLATION

(1) Place starter in position on vehicle.

(2) Install starter attaching bolts to transaxle bell-

housing and tighten to the proper torque

(3) Place solenoid and B+ wires in position on

starter terminals.

(4) Install nut to hold B+ wire to terminal.

(5) Connect solenoid wire connector onto terminal.

(6) Lower vehicle.

(7) Connect battery negative cable.

(8) Verify starter operation.

3.0L ENGINE

REMOVAL

(1) Release hood latch and open hood.

(2) Disconnect battery negative cable (Fig. 1).

(3) Hoist and support vehicle on safety stands.

(4) Remove nut holding solenoid wire to terminal

(Fig. 5).(5) Remove nut holding B+ wire to terminal (Fig.

6)

(6) Disconnect solenoid and B+ wires from starter

terminals.

Fig. 4 Starter - 2.4L Engine with Automatic Transaxle

Fig. 5 Wire Connectors

NS/GSSTARTING SYSTEM 8B - 3

REMOVAL AND INSTALLATION (Continued)