window CHRYSLER VOYAGER 2001 Manual PDF

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 2540 of 4284

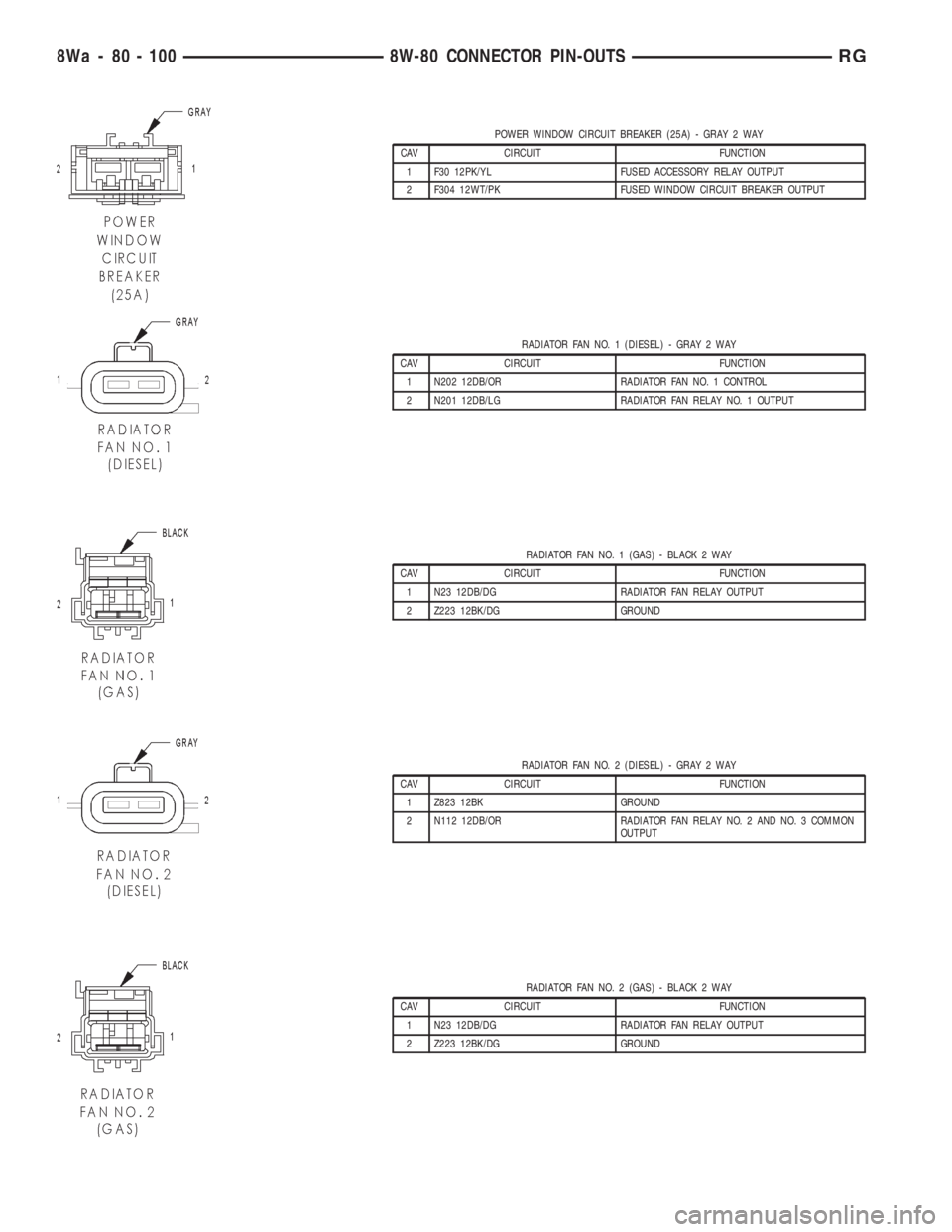

POWER WINDOW CIRCUIT BREAKER (25A) - GRAY 2 WAY

CAV CIRCUIT FUNCTION

1 F30 12PK/YL FUSED ACCESSORY RELAY OUTPUT

2 F304 12WT/PK FUSED WINDOW CIRCUIT BREAKER OUTPUT

RADIATOR FAN NO. 1 (DIESEL) - GRAY 2 WAY

CAV CIRCUIT FUNCTION

1 N202 12DB/OR RADIATOR FAN NO. 1 CONTROL

2 N201 12DB/LG RADIATOR FAN RELAY NO. 1 OUTPUT

RADIATOR FAN NO. 1 (GAS) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 N23 12DB/DG RADIATOR FAN RELAY OUTPUT

2 Z223 12BK/DG GROUND

RADIATOR FAN NO. 2 (DIESEL) - GRAY 2 WAY

CAV CIRCUIT FUNCTION

1 Z823 12BK GROUND

2 N112 12DB/OR RADIATOR FAN RELAY NO. 2 AND NO. 3 COMMON

OUTPUT

RADIATOR FAN NO. 2 (GAS) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 N23 12DB/DG RADIATOR FAN RELAY OUTPUT

2 Z223 12BK/DG GROUND

8Wa - 80 - 100 8W-80 CONNECTOR PIN-OUTSRG

Page 2551 of 4284

RIGHT MID READING LAMP (PREMIUM/LUXURY) - GRAY 3 WAY

CAV CIRCUIT FUNCTION

1 M22 20YL/OR COURTESY LAMPS DRIVER

2 Z327 20BK/OR GROUND

3 M27 20YL/LB READING LAMPS DRIVER

RIGHT PARK LAMP (BUILT-UP-EXPORT) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 Z344 16BR GROUND

2 L78 16BK FUSED PARK LAMP RELAY OUTPUT (RIGHT)

RIGHT POWER MIRROR - BLACK 12 WAY

CAV CIRCUIT FUNCTION

1 P174 20TN/LB (BUILT-UP-EXPORT) RIGHT FOLDING MIRROR UNFOLD DRIVER

2- -

3- -

4 P68 20TN/YL (MEMORY) RIGHT MIRROR HORIZONTAL POSITION SIGNAL

5 P66 20TN/LG (MEMORY) RIGHT MIRROR SENSOR GROUND

6 P67 20TN/OR (MEMORY) RIGHT MIRROR VERTICAL POSITION SIGNAL

7 P160 20TN/LG (BUILT-UP-EXPORT/

LHD)PASSENGER FOLDING MIRROR RELAY OUTPUT

7 P159 20TN/DG (BUILT-UP-EXPORT/

RHD)DRIVER FOLDING MIRROR FOLD DRIVER

8 Z216 20BK/DB GROUND

9 C16 20DB/GY FUSED REAR WINDOW DEFOGGER RELAY OUTPUT

10 P70 20TN/LB RIGHT MIRROR COMMON DRIVER (RIGHT/DOWN)

11 P72 20TN/GY RIGHT MIRROR VERTICAL DRIVER

12 P74 20TN/DB RIGHT MIRROR HORIZONTAL DRIVER

RIGHT REAR LAMP ASSEMBLY - BLACK 6 WAY

CAV CIRCUIT FUNCTION

1 Z362 18BK/BR (BUILT-UP-EXPORT) GROUND

1 L62 18WT/BR (EXCEPT BUILT-UP-EX-

PORT)RIGHT REAR TURN SIGNAL DRIVER

2 L62 18WT/BR (BUILT-UP-EXPORT) RIGHT REAR TURN SIGNAL DRIVER

3 L78 18WT/OR (EXCEPT BUILT-UP-EX-

PORT)FUSED PARK LAMP RELAY OUTPUT (RIGHT)

3 L50 18WT/TN (BUILT-UP-EXPORT) PRIMARY BRAKE SWITCH SIGNAL

4 L1 18WT/LG BACK-UP LAMP DRIVER

5 L38 20WT/YL (BUILT-UP-EXPORT) REAR FOG LAMP SWITCH OUTPUT

5 Z362 18BK/BR (EXCEPT BUILT-UP-

EXPORT)GROUND

6 L78 18WT/OR (BUILT-UP-EXPORT) FUSED PARK LAMP RELAY OUTPUT (RIGHT)

6 L50 18WT/TN (EXCEPT BUILT-UP-EX-

PORT)PRIMARY BRAKE SWITCH SIGNAL

RG8W-80 CONNECTOR PIN-OUTS8Wa - 80 - 111

Page 2552 of 4284

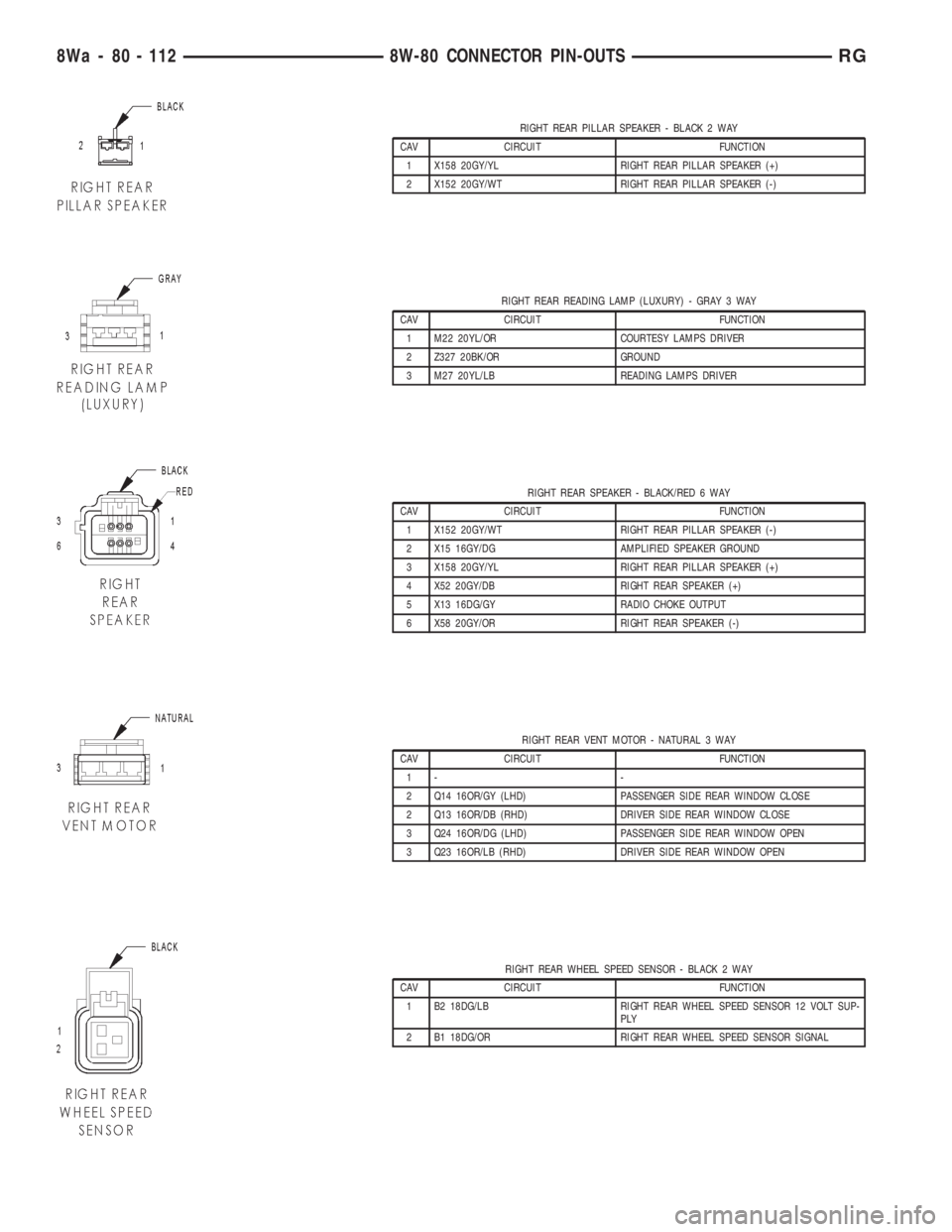

RIGHT REAR PILLAR SPEAKER - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 X158 20GY/YL RIGHT REAR PILLAR SPEAKER (+)

2 X152 20GY/WT RIGHT REAR PILLAR SPEAKER (-)

RIGHT REAR READING LAMP (LUXURY) - GRAY 3 WAY

CAV CIRCUIT FUNCTION

1 M22 20YL/OR COURTESY LAMPS DRIVER

2 Z327 20BK/OR GROUND

3 M27 20YL/LB READING LAMPS DRIVER

RIGHT REAR SPEAKER - BLACK/RED 6 WAY

CAV CIRCUIT FUNCTION

1 X152 20GY/WT RIGHT REAR PILLAR SPEAKER (-)

2 X15 16GY/DG AMPLIFIED SPEAKER GROUND

3 X158 20GY/YL RIGHT REAR PILLAR SPEAKER (+)

4 X52 20GY/DB RIGHT REAR SPEAKER (+)

5 X13 16DG/GY RADIO CHOKE OUTPUT

6 X58 20GY/OR RIGHT REAR SPEAKER (-)

RIGHT REAR VENT MOTOR - NATURAL 3 WAY

CAV CIRCUIT FUNCTION

1- -

2 Q14 16OR/GY (LHD) PASSENGER SIDE REAR WINDOW CLOSE

2 Q13 16OR/DB (RHD) DRIVER SIDE REAR WINDOW CLOSE

3 Q24 16OR/DG (LHD) PASSENGER SIDE REAR WINDOW OPEN

3 Q23 16OR/LB (RHD) DRIVER SIDE REAR WINDOW OPEN

RIGHT REAR WHEEL SPEED SENSOR - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 B2 18DG/LB RIGHT REAR WHEEL SPEED SENSOR 12 VOLT SUP-

PLY

2 B1 18DG/OR RIGHT REAR WHEEL SPEED SENSOR SIGNAL

8Wa - 80 - 112 8W-80 CONNECTOR PIN-OUTSRG

Page 2566 of 4284

Component/Ground Color Location Fig.

Driver Heated Seat Module C3 GN At Seat N/S

Driver Power Seat Front Riser

MotorRD At Seat N/S

Driver Power Seat Horizontal

MotorBK At Seat N/S

Driver Power Seat Rear Riser

MotorRD At Seat N/S

Driver Power Seat Recliner Motor GN At Seat N/S

Driver Power Seat Switch GN At Switch N/S

Driver Power Window Motor RD At Motor N/S

Driver Power Window Switch GN At Switch N/S

Driver Power Window Switch

(RHD)NAT At Switch N/S

Driver Seatbelt Switch WT At Switch on Seat Harness N/S

Driver Seatbelt Tensioner On Seat Harness N/S

EGR Solenoid (Diesel) BK Above Transmission

Right Side of EngineN/S

EGR Solenoid GY Above Transmission

Right Side of Engine10, 11, 12,

14

Electric Wiper De-Icer-C1 WT Right Side Instrument Panel 16, 20, 23

Electric Wiper De-Icer-C2 WT Left Side Instrument Panel 16, 17 22

Engine Control Module C1

(Diesel)BK Right Side of Engine 12

Engine Control Module C2

(Diesel)BK Right Side of Engine 12

Engine Coolant Temperature

Sensor (Gas)BK On Cylinder Block N/S

Engine Coolant Temperature

Sensor (Diesel)BL On Cylinder Block 12

Engine Oil Pressure Sensor

(Diesel)BK Rear of Engine 13

Engine Oil Pressure Switch LTGN On Cylinder Block 10

Engine Oil Temperature Sensor

(Diesel)BK Rear of Engine 13

EVAP/Purge Solenoid BK Right Motor Mount 10, 14

Evaporator Temperature Sensor BK Right Side of HVAC N/S

Floor Console Lamp BK At Lamp N/S

Floor Console Power Outlet RD At Front Console N/S

Front Blower Module C1 (ATC) BK On HVAC N/S

Front Blower Module C2 (ATC) BK On HVAC N/S

Front Cigar Lighter RD/NAT Rear of Lighter 16, 19, 21

Front Reading Lamps/Switch BK At Switch N/S

Front Washer Pump Motor BK Right Fender Well 4

Fuel Heater (Diesel) BK Left Rear Engine Compartment N/S

Fuel Injector No.1 BK At Fuel Injector N/S

8Wa - 90 - 4 8W-90 CONNECTOR/GROUND LOCATIONS BUXRG

CONNECTOR/GROUND LOCATIONS BUX (Continued)

Page 2570 of 4284

Component/Ground Color Location Fig.

Memory Seat Rear Vertical Motor RD Under Seat N/S

Memory Seat Rear Vertical

Position SensorBK Under Seat N/S

Memory Seat Recliner Motor GN Under Seat N/S

Memory Seat Recliner Position

SensorBK Under Seat N/S

Memory Seat Switch BK At Switch Driver Door N/S

Message Center WT Rear of Message Center 16, 17, 23

Mode Door Actuator BK Left Side of HVAC N/S

Multi Function Switch BK At Steering Column 16, 17, 18,

19, 26

Occupant Restraint Controller YL/RD Right Side of Instrument Panel 16, 20, 21

Output Speed Sensor GY Front of Transmission 15

Overhead Console BK Front of Console N/S

Oxygen Sensor 1/1 Upstream GY Rear of Engine 10, 11, 15

Oxygen Sensor 1/2 Downstream BK Rear of Engine 10, 11, 15

Park/Neutral Positon Switch BK Front of Transmission 11

Passenger Airbag YL Passenger Side of Instrument Panel 16, 19, 20,

25

Passenger Blend Door Actuator On HVAC N/S

Passenger Door Courtesy Lamp BK At Lamp 33

Passenger Door Lock Switch BK At Switch 33

Passenger Folding Mirror Relay BL Right Kick Panel N/S

Passenger Heated Seat Back GN At Seat N/S

Passenger Heated Seat Cushion BK At Seat N/S

Passenger Heated Seat Module

C1GY At Heated Seat N/S

Passenger Heated Seat Module

C2GY At Heated Seat Back N/S

Passenger Heated Seat Module

C3GN At Heated Seat N/S

Passenger Power Seat Front

Riser MotorRD Under Seat N/S

Passenger Power Seat Horizontal

MotorBK Under Seat N/S

Passenger Power Seat Rear

Riser MotorRD Under Seat N/S

Passenger Power Seat Recliner

MotorGN Under Seat N/S

Passenger Power Seat Switch GN At Switch N/S

Passenger Power Window Motor RD At Motor 33

Passenger Power Window Switch BK At Switch 33

Passenger Seatbelt Switch On Seat Harness N/S

Passenger Seatbelt Tensioner On Seat Harness N/S

Power Folding Mirror Switch BK Near Steering Column 26

8Wa - 90 - 8 8W-90 CONNECTOR/GROUND LOCATIONS BUXRG

CONNECTOR/GROUND LOCATIONS BUX (Continued)

Page 2571 of 4284

Component/Ground Color Location Fig.

Power Liftgate Module C1 BK Left Quarter 35, 36

Power Liftgate Module C2 BK Left Quarter 35, 36

Power Liftgate Motor BK Left Quarter 36

Power Mirror Switch BK Rear of Switch 25

Power Outlet NAT Instrument Panel N/S

Power Seat Circuit Breaker GY Under Seat N/S

Powertrain Control Module C1 GY/BK LT Fender Side Shield N/S

Powertrain Control Module C2 GY LT Fender Side Shield N/S

Power Window Circuit Breaker GY Left Side Kick Panel 31, 32

Radiator Fan No.1 BK Left Side At Motor 1

Radiator Fan No.1 (Diesel) GY Left Side At Motor 3

Radiator Fan No.2 BK Right Side At Motor 1

Radiator Fan No.2 (Diesel) GY Right Side At Motor N/S

Radiator Fan Relay BK Top of Left Front Frame Rail 1

Radiator Fan Relay No. 1

(Diesel)BL Left Front Engine Compartment 3

Radiator Fan Relay No. 2

(Diesel)BL Left Front Engine Compartment 3

Radiator Fan Relay No. 3

(Diesel)BL Left Front Engine Compartment 3

Radio C1 GY Rear of Radio 16, 19, 21

Radio C2 BK Rear of Radio 16, 19, 21

Radio C3 WT/RD Rear of Radio 16, 21

Radio C4 Rear of Radio 16

Radio Choke LTGY Rear of Radio 31, 32

Rear A/C-Heater Unit LT/GN Right Quarter Panel N/S

Rear Automatic Temperature

Control Switch (ATC)BK Rear of Switch 30

Rear Blower Front Control Switch BK Rear of Switch

Rear Blower Rear Control Switch

C1BK At Switch In Headliner

Rear Blower Rear Control Switch

C2BK At Switch In Headliner

Rear Power Outlet RD Left Quarter Panel 36

Rear Washer Pump Motor BK Right Fender Well 4

Rear Wiper Motor BK At Motor 38

Recirculation Door Actuator NAT Right Side of HVAC

Remote Keyless Entry Antenna

(JAPAN)BK Right Upper Instrument Panel 23

Remote Keyless Entry Module BK/RD Top Left of I.P. 16, 17, 23

Right B-Pillar Switch GY Right B Pillar 29

Right Cinch/Release Motor BK Rear of Sliding Door 34

Right Combination Relay BK Left Quarter Panel N/S

Right Cylinder Lock Switch BK Right Front Door 33

RG8W-90 CONNECTOR/GROUND LOCATIONS BUX8Wa-90-9

CONNECTOR/GROUND LOCATIONS BUX (Continued)

Page 2608 of 4284

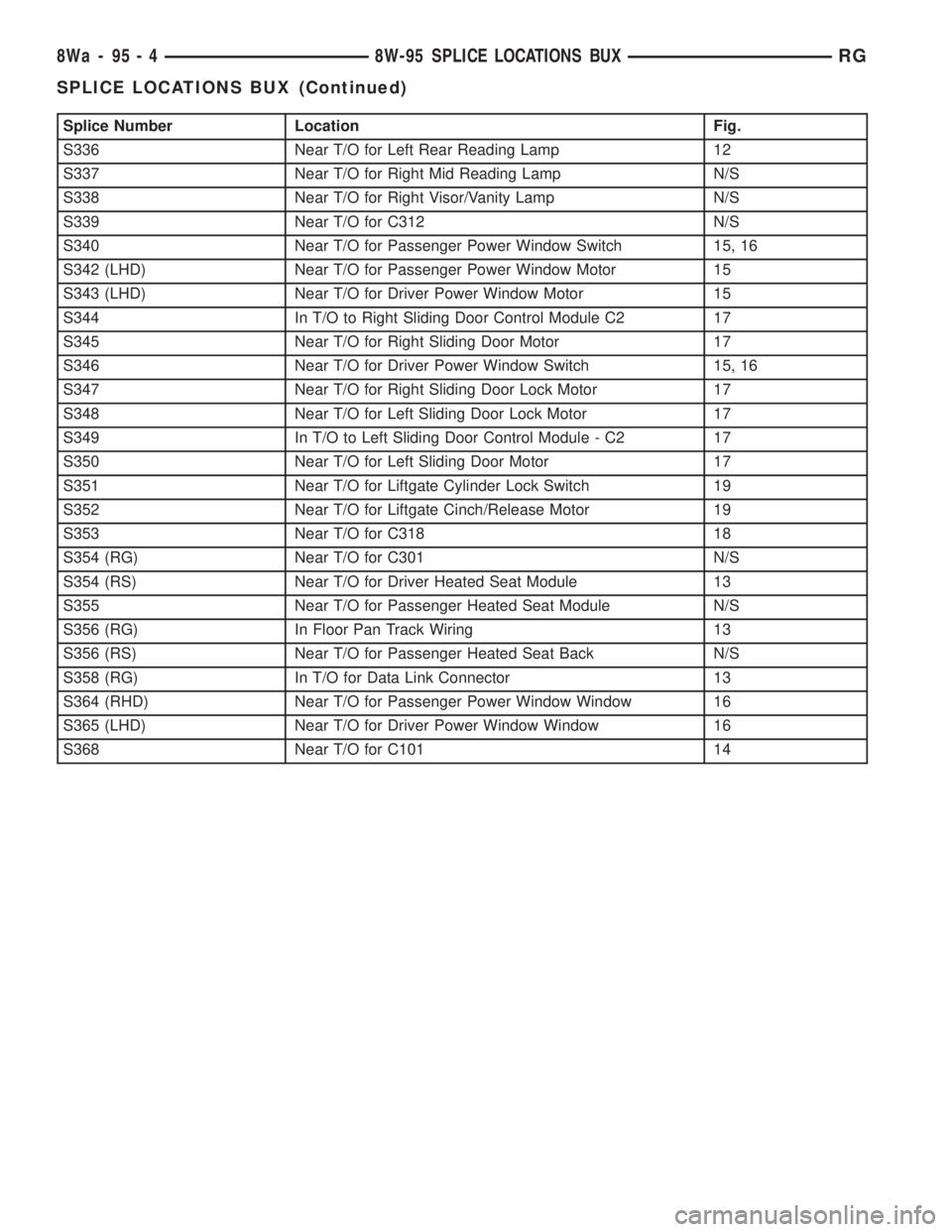

Splice Number Location Fig.

S336 Near T/O for Left Rear Reading Lamp 12

S337 Near T/O for Right Mid Reading Lamp N/S

S338 Near T/O for Right Visor/Vanity Lamp N/S

S339 Near T/O for C312 N/S

S340 Near T/O for Passenger Power Window Switch 15, 16

S342 (LHD) Near T/O for Passenger Power Window Motor 15

S343 (LHD) Near T/O for Driver Power Window Motor 15

S344 In T/O to Right Sliding Door Control Module C2 17

S345 Near T/O for Right Sliding Door Motor 17

S346 Near T/O for Driver Power Window Switch 15, 16

S347 Near T/O for Right Sliding Door Lock Motor 17

S348 Near T/O for Left Sliding Door Lock Motor 17

S349 In T/O to Left Sliding Door Control Module - C2 17

S350 Near T/O for Left Sliding Door Motor 17

S351 Near T/O for Liftgate Cylinder Lock Switch 19

S352 Near T/O for Liftgate Cinch/Release Motor 19

S353 Near T/O for C318 18

S354 (RG) Near T/O for C301 N/S

S354 (RS) Near T/O for Driver Heated Seat Module 13

S355 Near T/O for Passenger Heated Seat Module N/S

S356 (RG) In Floor Pan Track Wiring 13

S356 (RS) Near T/O for Passenger Heated Seat Back N/S

S358 (RG) In T/O for Data Link Connector 13

S364 (RHD) Near T/O for Passenger Power Window Window 16

S365 (LHD) Near T/O for Driver Power Window Window 16

S368 Near T/O for C101 14

8Wa - 95 - 4 8W-95 SPLICE LOCATIONS BUXRG

SPLICE LOCATIONS BUX (Continued)

Page 2885 of 4284

INLET FILTER

REMOVAL

(1) Remove fuel pump module. Refer to Fuel Pump

Module Removal in this section.

(2) Using a thin straight blade screwdriver, pry

back the locking tabs on fuel pump reservoir and

remove the strainer (Fig. 22).

(3) Remove strainer O-ring from the fuel pump

reservoir body.

(4) Remove any contaminants in the fuel tank by

washing the inside of the fuel tank.

INSTALLATION

(1) Lubricate the strainer O-ring with clean engine

oil.

(2) Insert strainer O-ring into outlet of strainer so

that it sits evenly on the step inside the outlet.

(3) Push strainer onto the inlet of the fuel pump

reservoir body. Make sure the locking tabs on the

reservoir body lock over the locking tangs on the

strainer.

(4) Install fuel pump module. Refer to Fuel Pump

Module Installation in this section.

QUICK CONNECT FITTING

STANDARD PROCEDURES - QUICK-CONNECT

FITTINGS

REMOVAL

When disconnecting a quick-connect fitting, the

retainer will remain on the fuel tube nipple.WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE DISCONNECTING A QUICK-CONNECT FIT-

TINGS. REFER TO THE FUEL PRESSURE RELEASE

PROCEDURE.

(1) Perform Fuel Pressure Release Procedure.

Refer to the Fuel Pressure Release Procedure in this

section.

(2) Disconnect negative cable from battery or aux-

iliary jumper terminal.

(3) Squeeze retainer tabs together and pull fuel

tube/quick-connect fitting assembly off of fuel tube

nipple. The retainer will remain on fuel tube.

INSTALLATION

CAUTION: Never install a quick-connect fitting with-

out the retainer being either on the fuel tube or

already in the quick-connect fitting. In either case,

ensure the retainer locks securely into the quick-

connect fitting by firmly pulling on fuel tube and fit-

ting to ensure it is secured.

(1) Using a clean lint free cloth, clean the fuel tube

nipple and retainer.

(2) Prior to connecting the fitting to the fuel tube,

coat the fuel tube nipple with clean 30 weight engine

oil.

(3) Push the quick-connect fitting over the fuel

tube until theretainer seats and a click is heard.

(4) The plastic quick-connect fitting has windows

in the sides of the casing. When the fitting com-

pletely attaches to the fuel tube, the retainer locking

ears and the fuel tube shoulder are visible in the

windows. If they are not visible, the retainer was not

properly installed (Fig. 23).Do not rely upon the

audible click to confirm a secure connection.

Fig. 22 Inlet

1 - TABS

2 - INLET STRAINER

Fig. 23 Plastic Quick-Connect Fitting/Fuel Tube

Connection

1 - WINDOW

2-TAB(2)

3 - EAR

4 - SHOULDER (ON TUBE)

RSFUEL DELIVERY14-13

Page 3383 of 4284

When the conditions causing a water leak have

been determined, simulate the conditions as closely

as possible.

²If a leak occurs with the vehicle parked in a

steady light rain, flood the leak area with an open-

ended garden hose.

²If a leak occurs while driving at highway speeds

in a steady rain, test the leak area with a reasonable

velocity stream or fan spray of water. Direct the

spray in a direction comparable to actual conditions.

²If a leak occurs when the vehicle is parked on an

incline, hoist the end or side of the vehicle to simu-

late this condition. This method can be used when

the leak occurs when the vehicle accelerates, stops or

turns. If the leak occurs on acceleration, hoist the

front of the vehicle. If the leak occurs when braking,

hoist the back of the vehicle. If the leak occurs on left

turns, hoist the left side of the vehicle. If the leak

occurs on right turns, hoist the right side of the vehi-

cle. For hoisting recommendations refer to Group 0,

Lubrication and Maintenance, General Information

section.

WATER LEAK DETECTION

To detect a water leak point-of-entry, do a water

test and watch for water tracks or droplets forming

on the inside of the vehicle. If necessary, remove inte-

rior trim covers or panels to gain visual access to the

leak area. If the hose cannot be positioned without

being held, have someone help do the water test.

Some water leaks must be tested for a considerable

length of time to become apparent. When a leak

appears, find the highest point of the water track or

drop. The highest point usually will show the point of

entry. After leak point has been found, repair the

leak and water test to verify that the leak has

stopped.

Locating the entry point of water that is leaking

into a cavity between panels can be difficult. The

trapped water may splash or run from the cavity,

often at a distance from the entry point. Most water

leaks of this type become apparent after accelerating,

stopping, turning, or when on an incline.

MIRROR INSPECTION METHOD

When a leak point area is visually obstructed, use

a suitable mirror to gain visual access. A mirror can

also be used to deflect light to a limited-access area

to assist in locating a leak point.

BRIGHT LIGHT LEAK TEST METHOD

Some water leaks in the luggage compartment can

be detected without water testing. Position the vehi-

cle in a brightly lit area. From inside the darkened

luggage compartment inspect around seals and body

seams. If necessary, have a helper direct a drop lightover the suspected leak areas around the luggage

compartment. If light is visible through a normally

sealed location, water could enter through the open-

ing.

PRESSURIZED LEAK TEST METHOD

When a water leak into the passenger compart-

ment cannot be detected by water testing, pressurize

the passenger compartment and soap test exterior of

the vehicle. To pressurize the passenger compart-

ment, close all doors and windows, start engine, and

set heater control to high blower in HEAT position. If

engine can not be started, connect a charger to the

battery to ensure adequate voltage to the blower.

With interior pressurized, apply dish detergent solu-

tion to suspected leak area on the exterior of the

vehicle. Apply detergent solution with spray device or

soft bristle brush. If soap bubbles occur at a body

seam, joint, seal or gasket, the leak entry point could

be at that location.

DIAGNOSIS AND TESTING - WIND NOISE

Wind noise is the result of most air leaks. Air leaks

can be caused by poor sealing, improper body compo-

nent alignment, body seam porosity, or missing plugs

in the engine compartment or door hinge pillar areas.

All body sealing points should be airtight in normal

driving conditions. Moving sealing surfaces will not

always seal airtight under all conditions. At times,

side glass or door seals will allow wind noise to be

noticed in the passenger compartment during high

cross winds. Over compensating on door or glass

adjustments to stop wind noise that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After a repair pro-

cedure has been performed, test vehicle to verify

noise has stopped before returning vehicle to use.

Wind noise can also be caused by improperly fitted

exterior moldings or body ornamentation. Loose

moldings can flutter, creating a buzzing or chattering

noise. An open cavity or protruding edge can create a

whistling or howling noise. Inspect the exterior of the

vehicle to verify that these conditions do not exist.

VISUAL INSPECTION BEFORE TESTS

Verify that floor and body plugs are in place and

body components are aligned and sealed. If compo-

nent alignment or sealing is necessary, refer to the

appropriate section of this group for proper proce-

dures.

ROAD TESTING WIND NOISE

(1) Drive the vehicle to verify the general location

of the wind noise.

(2) Apply 50 mm (2 in.) masking tape in 150 mm

(6 in.) lengths along weatherstrips, weld seams or

RSBODY23-3

BODY (Continued)

Page 3390 of 4284

LUBRICANT USAGE

COMPONENT SERVICE INTERVAL LUBRICANT

Door Hinges - Hinge Pin and Pivot

Contact AreasAs Required Engine Oil

Hood Hingers - Pivot Points As Required Engine Oil

Lifgate Hinges As Required Engine Oil

Door Check Straps As Required Spray white lube (3)

Door Latches As Required Multi-Purpose Grease (Water

Resistant) (1)

Lifgate Latches As Required Spray white lube (3)

Lifgate Prop Pivots As Required Spray white lube (3)

Ash Receiver As Required Spray white lube (3)

Fuel Filler Door Remote Control

Latch MechanismAs Required Spray white lube (3)

Parking Brake Mechanism As Required Spray white lube (3)

Sliding Seat Tracks As Required Spray white lube (3)

All Other Hood Mechanisms As Required Multipurpose Grease (2)

Door Lock Cylinders As Required Lock Cylinder Lubricant (4)

Lifgate Lock Cylinder As Required Lock Cylinder Lubricant (4)

Sliding Door Upper Track As Required Multi-Purpose Grease NLGI Grade

2 EP (2)

Sliding Door Center Track Leading

EdgeAs Required Multi-Purpose Grease NLGI Grade

2 EP (2)

Sliding Door Lower Track Leading

EdgeAs Required Multi-Purpose Grease NLGI Grade

2 EP (2)

Window System Components

(Regulators, tracks, links, channel

areas Ð except glass run

weatherstrips and felt lubricator, if

equipped.)As Required Spray white lube (3)

1 MOPARž Wheel Bearing Grease (High Temperature)

2 MOPARž Multi-Mileage Lubricant or equivalent

3 MOPARž Spray white lube or equivalent

4 MOPARž Lock Cylinder Lubricant or equivalent

23 - 10 BODYRS

BODY (Continued)