fuse CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 2419 of 2585

(3) Connect the HVAC wire harness connector to

the blend door actuator.

(4) Install the silencer under the driver side end of

the instrument panel (Refer to 23 - BODY/INSTRU-

MENT PANEL/INSTRUMENT PANEL SILENCER -

INSTALLATION).

(5) Reconnect the battery negative cable.

(6) Perform the heater-A/C control calibration pro-

cedure (Refer to 24 - HEATING & AIR CONDITION-

ING/CONTROLS - FRONT/A/C-HEATER CONTROL

- STANDARD PROCEDURE - HEATER-A/C CON-

TROL CALIBRATION).

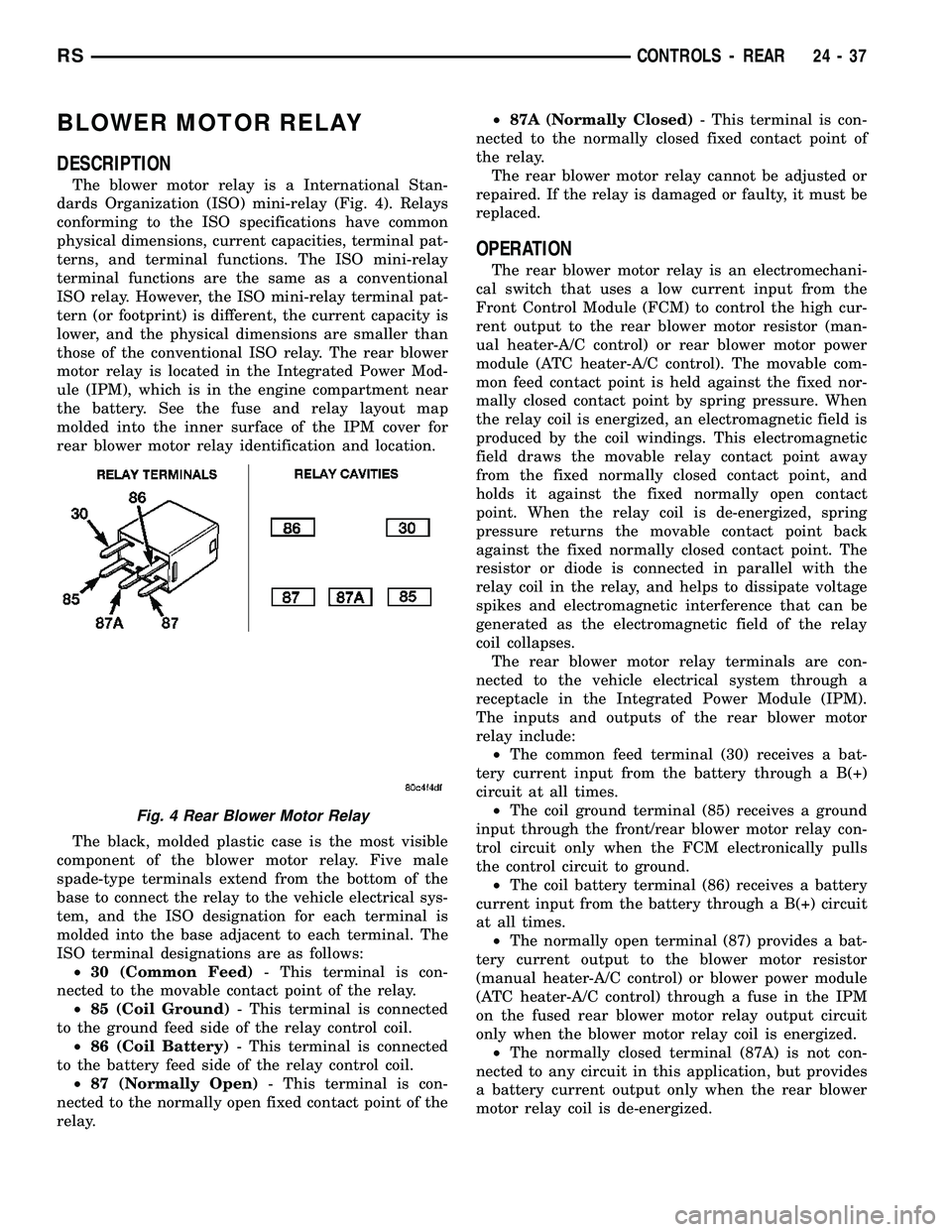

BLOWER MOTOR RELAY

DESCRIPTION

The blower motor relay is a International Stan-

dards Organization (ISO) mini-relay (Fig. 12). Relays

conforming to the ISO specifications have common

physical dimensions, current capacities, terminal pat-

terns, and terminal functions. The ISO mini-relay

terminal functions are the same as a conventional

ISO relay. However, the ISO mini-relay terminal pat-

tern (or footprint) is different, the current capacity is

lower, and the physical dimensions are smaller than

those of the conventional ISO relay. The blower

motor relay is located in the Integrated Power Mod-

ule (IPM), which is in the engine compartment near

the battery. See the fuse and relay layout map

molded into the inner surface of the IPM cover for

blower motor relay identification and location.The black, molded plastic case is the most visible

component of the blower motor relay. Five male

spade-type terminals extend from the bottom of the

base to connect the relay to the vehicle electrical sys-

tem, and the ISO designation for each terminal is

molded into the base adjacent to each terminal. The

ISO terminal designations are as follows:

²30 (Common Feed)- This terminal is con-

nected to the movable contact point of the relay.

²85 (Coil Ground)- This terminal is connected

to the ground feed side of the relay control coil.

²86 (Coil Battery)- This terminal is connected

to the battery feed side of the relay control coil.

²87 (Normally Open)- This terminal is con-

nected to the normally open fixed contact point of the

relay.

²87A (Normally Closed)- This terminal is con-

nected to the normally closed fixed contact point of

the relay.

The blower motor relay cannot be adjusted or

repaired. If the relay is damaged or faulty, it must be

replaced.

OPERATION

The blower motor relay is an electromechanical

switch that uses a low current input from the Front

Control Module (FCM) to control the high current

output to the blower motor resistor (manual heater-

A/C control) or blower power module (ATC control).

The movable common feed contact point is held

against the fixed normally closed contact point by

spring pressure. When the relay coil is energized, an

electromagnetic field is produced by the coil wind-

ings. This electromagnetic field draws the movable

relay contact point away from the fixed normally

closed contact point, and holds it against the fixed

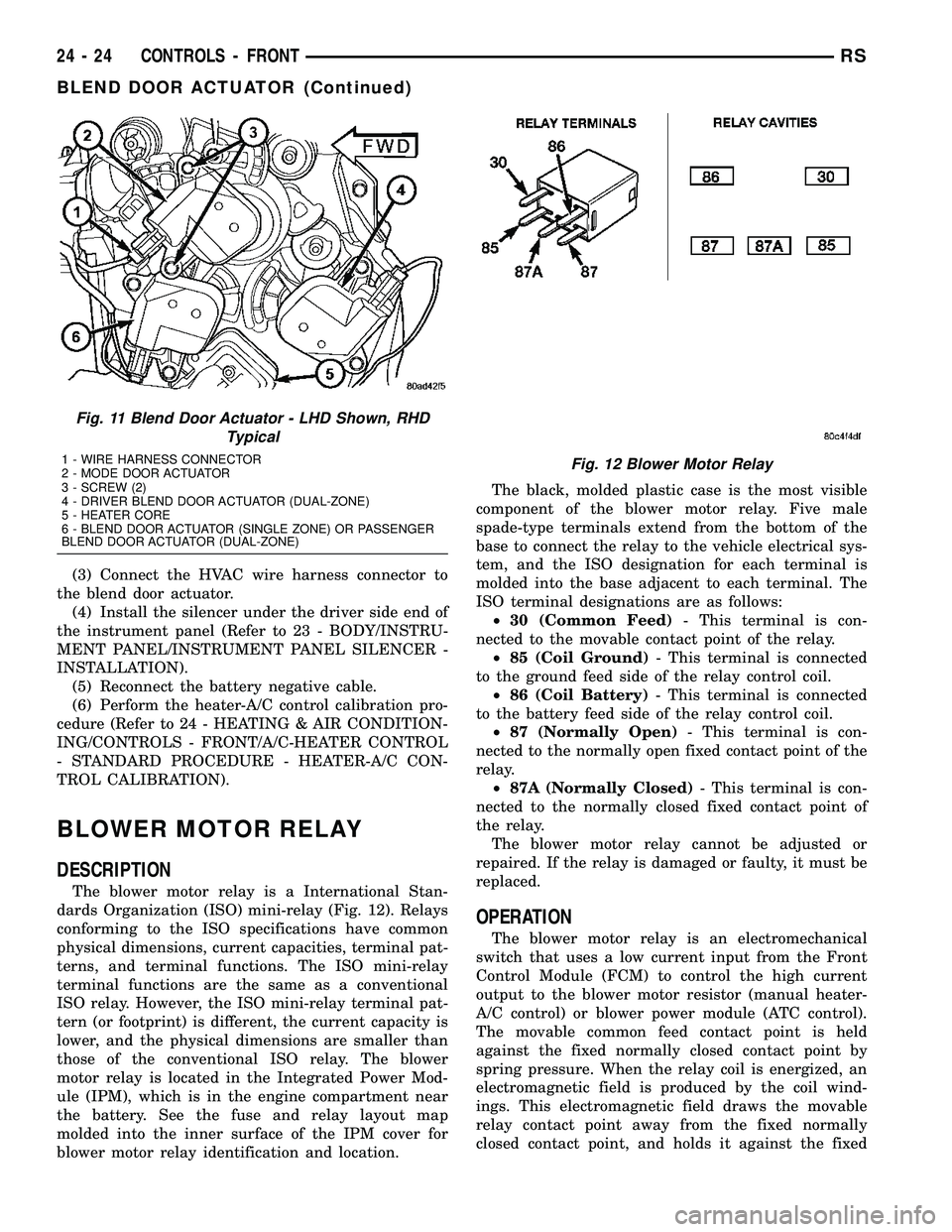

Fig. 11 Blend Door Actuator - LHD Shown, RHD

Typical

1 - WIRE HARNESS CONNECTOR

2 - MODE DOOR ACTUATOR

3 - SCREW (2)

4 - DRIVER BLEND DOOR ACTUATOR (DUAL-ZONE)

5 - HEATER CORE

6 - BLEND DOOR ACTUATOR (SINGLE ZONE) OR PASSENGER

BLEND DOOR ACTUATOR (DUAL-ZONE)Fig. 12 Blower Motor Relay

24 - 24 CONTROLS - FRONTRS

BLEND DOOR ACTUATOR (Continued)

Page 2420 of 2585

normally open contact point. When the relay coil is

de-energized, spring pressure returns the movable

contact point back against the fixed normally closed

contact point. The resistor or diode is connected in

parallel with the relay coil in the relay, and helps to

dissipate voltage spikes and electromagnetic interfer-

ence that can be generated as the electromagnetic

field of the relay coil collapses.

The blower motor relay terminals are connected to

the vehicle electrical system through a receptacle in

the Integrated Power Module (IPM). The inputs and

outputs of the blower motor relay include:

²The common feed terminal (30) receives a bat-

tery current input from the battery through a B(+)

circuit at all times.

²The coil ground terminal (85) receives a ground

input through the front/rear blower motor relay con-

trol circuit only when the FCM electronically pulls

the control circuit to ground.

²The coil battery terminal (86) receives a battery

current input from the battery through a B(+) circuit

at all times.

²The normally open terminal (87) provides a bat-

tery current output to the blower motor resistor

(manual heater-A/C control) or blower power module

(automatic heater-A/C control) through a fuse in the

IPM on the fused front blower motor relay output cir-

cuit only when the blower motor relay coil is ener-

gized.

²The normally closed terminal (87A) is not con-

nected to any circuit in this application, but provides

a battery current output only when the blower motor

relay coil is de-energized.

Refer to the appropriate wiring information for

diagnosis and testing of the micro-relay and for com-

plete HVAC wiring diagrams.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Unlatch and remove the cover from the Inte-

grated Power Module (IPM) (Fig. 13).

(3) See the fuse and relay layout map molded into

the inner surface of the IPM cover for front blower

motor relay identification and location.(4) Remove the front blower motor relay from the

IPM by pulling the relay straight up.

INSTALLATION

(1) Refer to the fuse and relay layout map on the

inner surface of the integrated power module (IPM)

cover for front blower motor relay identification and

location.

(2) Position the front blower motor relay to the

proper receptacle in the IPM.

(3) Align the front blower motor relay terminals

with the terminal cavities in the IPM receptacle.

(4) Push down firmly on the front blower motor

relay until the terminals are fully seated in the ter-

minal cavities in the IPM receptacle.

(5) Install the cover onto the IPM.

(6) Reconnect the negative battery cable.

Fig. 13 Integrated Power Module - Typical

1 - BATTERY THERMAL GUARD

2 - INTEGRATED POWER MODULE

3 - FRONT CONTROL MODULE

RSCONTROLS - FRONT24-25

BLOWER MOTOR RELAY (Continued)

Page 2432 of 2585

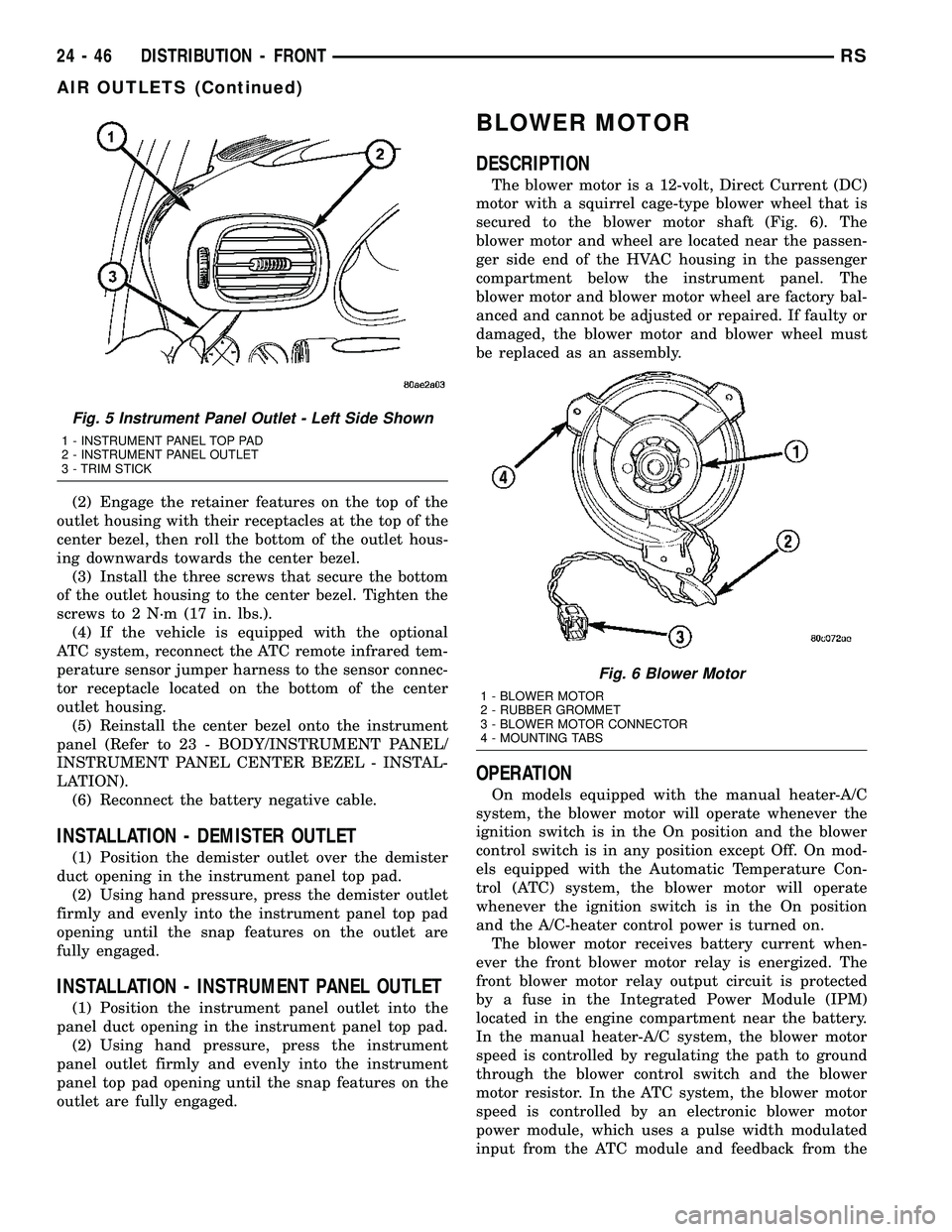

BLOWER MOTOR RELAY

DESCRIPTION

The blower motor relay is a International Stan-

dards Organization (ISO) mini-relay (Fig. 4). Relays

conforming to the ISO specifications have common

physical dimensions, current capacities, terminal pat-

terns, and terminal functions. The ISO mini-relay

terminal functions are the same as a conventional

ISO relay. However, the ISO mini-relay terminal pat-

tern (or footprint) is different, the current capacity is

lower, and the physical dimensions are smaller than

those of the conventional ISO relay. The rear blower

motor relay is located in the Integrated Power Mod-

ule (IPM), which is in the engine compartment near

the battery. See the fuse and relay layout map

molded into the inner surface of the IPM cover for

rear blower motor relay identification and location.

The black, molded plastic case is the most visible

component of the blower motor relay. Five male

spade-type terminals extend from the bottom of the

base to connect the relay to the vehicle electrical sys-

tem, and the ISO designation for each terminal is

molded into the base adjacent to each terminal. The

ISO terminal designations are as follows:

²30 (Common Feed)- This terminal is con-

nected to the movable contact point of the relay.

²85 (Coil Ground)- This terminal is connected

to the ground feed side of the relay control coil.

²86 (Coil Battery)- This terminal is connected

to the battery feed side of the relay control coil.

²87 (Normally Open)- This terminal is con-

nected to the normally open fixed contact point of the

relay.²87A (Normally Closed)- This terminal is con-

nected to the normally closed fixed contact point of

the relay.

The rear blower motor relay cannot be adjusted or

repaired. If the relay is damaged or faulty, it must be

replaced.

OPERATION

The rear blower motor relay is an electromechani-

cal switch that uses a low current input from the

Front Control Module (FCM) to control the high cur-

rent output to the rear blower motor resistor (man-

ual heater-A/C control) or rear blower motor power

module (ATC heater-A/C control). The movable com-

mon feed contact point is held against the fixed nor-

mally closed contact point by spring pressure. When

the relay coil is energized, an electromagnetic field is

produced by the coil windings. This electromagnetic

field draws the movable relay contact point away

from the fixed normally closed contact point, and

holds it against the fixed normally open contact

point. When the relay coil is de-energized, spring

pressure returns the movable contact point back

against the fixed normally closed contact point. The

resistor or diode is connected in parallel with the

relay coil in the relay, and helps to dissipate voltage

spikes and electromagnetic interference that can be

generated as the electromagnetic field of the relay

coil collapses.

The rear blower motor relay terminals are con-

nected to the vehicle electrical system through a

receptacle in the Integrated Power Module (IPM).

The inputs and outputs of the rear blower motor

relay include:

²The common feed terminal (30) receives a bat-

tery current input from the battery through a B(+)

circuit at all times.

²The coil ground terminal (85) receives a ground

input through the front/rear blower motor relay con-

trol circuit only when the FCM electronically pulls

the control circuit to ground.

²The coil battery terminal (86) receives a battery

current input from the battery through a B(+) circuit

at all times.

²The normally open terminal (87) provides a bat-

tery current output to the blower motor resistor

(manual heater-A/C control) or blower power module

(ATC heater-A/C control) through a fuse in the IPM

on the fused rear blower motor relay output circuit

only when the blower motor relay coil is energized.

²The normally closed terminal (87A) is not con-

nected to any circuit in this application, but provides

a battery current output only when the rear blower

motor relay coil is de-energized.

Fig. 4 Rear Blower Motor Relay

RSCONTROLS - REAR24-37

Page 2433 of 2585

Refer to the appropriate wiring information for

diagnosis and testing of the micro-relay and for com-

plete HVAC wiring diagrams.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Unlatch and remove the cover from the Inte-

grated Power Module (IPM) (Fig. 5).

(3) See the fuse and relay layout map molded into

the inner surface of the IPM cover for rear blower

motor relay identification and location.

(4) Remove the rear blower motor relay from the

IPM.

INSTALLATION

(1) See the fuse and relay layout map molded into

the inner surface of the Integrated Power Module

(IPM) cover for rear blower motor relay identification

and location.

(2) Position the rear blower motor relay to the

proper receptacle in the IPM.

(3) Align the rear blower motor relay terminals

with the terminal cavities in the IPM relay recepta-

cle.

(4) Push down firmly on the rear blower motor

relay until the terminals are fully seated in the ter-

minal cavities in the IPM receptacle.

(5) Install the cover onto the IPM.

(6) Reconnect the battery negative cable.

BLOWER MOTOR RESISTOR

DESCRIPTION

A rear blower motor resistor is used on this model

when it is equipped with the manual heater-A/C sys-

tem. Models equipped with the optional Automatic

Temperature Control (ATC) system use a rear blower

motor power module, instead of the blower motor

resistor block (Refer to 24 - HEATING & AIR CON-

DITIONING/CONTROLS/POWER MODULE -

DESCRIPTION). The rear blower motor resistor

block is mounted to the rear HVAC housing, directly

above the expansion valve. The resistor block con-

sists of a molded plastic mounting plate with an inte-

gral connector receptacle. Concealed behind the

mounting plate is an electrical circuit board with two

resistors and a thermal fuse. The rear blower motor

resistor block is accessed for service by removing the

right quarter and D-pillar trim panels.

OPERATION

The rear blower motor resistor block is connected

to the vehicle electrical system through a dedicated

take out and connector of the rear HVAC wire har-

ness. The blower motor resistor has an electrical cir-

cuit board with two resistors, each of which will

reduce the current flow through the blower motor to

change the blower motor speed. The blower motor

switch in the manual heater-A/C system directs the

ground path for the rear blower motor through the

correct resistor to obtain the selected speed.

With the blower motor switch in the lowest speed

position, the ground path for the motor is applied

through both resistors. Each higher speed selected

with the blower motor switch applies the blower

motor ground path through fewer of the resistors,

increasing the blower motor speed. When the blower

motor switch is in the highest speed position, the

blower motor resistors are bypassed and the blower

motor receives a direct path to ground through the

blower motor switch.

The rear blower motor resistor block cannot be

adjusted or repaired and, if faulty or damaged, it

must be replaced.

DIAGNOSIS AND TESTING - REAR BLOWER

MOTOR RESISTOR BLOCK

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, further details on wire

harness routing and retention, as well as pin-out and

location views for the various wire harness connec-

tors, splices and grounds.

Fig. 5 Integrated Power Module - Typical

1 - BATTERY THERMAL GUARD

2 - INTEGRATED POWER MODULE

3 - FRONT CONTROL MODULE

24 - 38 CONTROLS - REARRS

BLOWER MOTOR RELAY (Continued)

Page 2441 of 2585

(2) Engage the retainer features on the top of the

outlet housing with their receptacles at the top of the

center bezel, then roll the bottom of the outlet hous-

ing downwards towards the center bezel.

(3) Install the three screws that secure the bottom

of the outlet housing to the center bezel. Tighten the

screws to 2 N´m (17 in. lbs.).

(4) If the vehicle is equipped with the optional

ATC system, reconnect the ATC remote infrared tem-

perature sensor jumper harness to the sensor connec-

tor receptacle located on the bottom of the center

outlet housing.

(5) Reinstall the center bezel onto the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL - INSTAL-

LATION).

(6) Reconnect the battery negative cable.

INSTALLATION - DEMISTER OUTLET

(1) Position the demister outlet over the demister

duct opening in the instrument panel top pad.

(2) Using hand pressure, press the demister outlet

firmly and evenly into the instrument panel top pad

opening until the snap features on the outlet are

fully engaged.

INSTALLATION - INSTRUMENT PANEL OUTLET

(1) Position the instrument panel outlet into the

panel duct opening in the instrument panel top pad.

(2) Using hand pressure, press the instrument

panel outlet firmly and evenly into the instrument

panel top pad opening until the snap features on the

outlet are fully engaged.

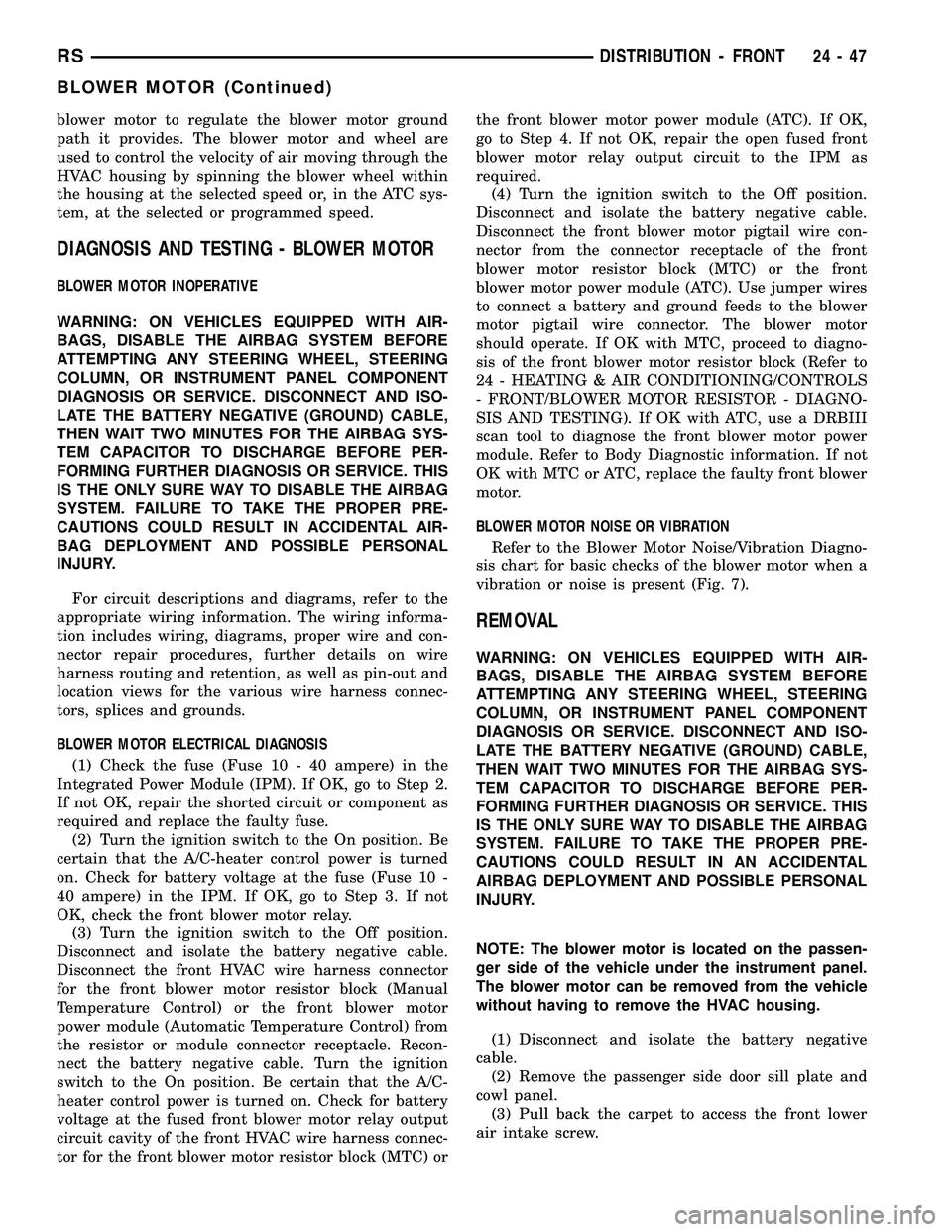

BLOWER MOTOR

DESCRIPTION

The blower motor is a 12-volt, Direct Current (DC)

motor with a squirrel cage-type blower wheel that is

secured to the blower motor shaft (Fig. 6). The

blower motor and wheel are located near the passen-

ger side end of the HVAC housing in the passenger

compartment below the instrument panel. The

blower motor and blower motor wheel are factory bal-

anced and cannot be adjusted or repaired. If faulty or

damaged, the blower motor and blower wheel must

be replaced as an assembly.

OPERATION

On models equipped with the manual heater-A/C

system, the blower motor will operate whenever the

ignition switch is in the On position and the blower

control switch is in any position except Off. On mod-

els equipped with the Automatic Temperature Con-

trol (ATC) system, the blower motor will operate

whenever the ignition switch is in the On position

and the A/C-heater control power is turned on.

The blower motor receives battery current when-

ever the front blower motor relay is energized. The

front blower motor relay output circuit is protected

by a fuse in the Integrated Power Module (IPM)

located in the engine compartment near the battery.

In the manual heater-A/C system, the blower motor

speed is controlled by regulating the path to ground

through the blower control switch and the blower

motor resistor. In the ATC system, the blower motor

speed is controlled by an electronic blower motor

power module, which uses a pulse width modulated

input from the ATC module and feedback from the

Fig. 5 Instrument Panel Outlet - Left Side Shown

1 - INSTRUMENT PANEL TOP PAD

2 - INSTRUMENT PANEL OUTLET

3 - TRIM STICK

Fig. 6 Blower Motor

1 - BLOWER MOTOR

2 - RUBBER GROMMET

3 - BLOWER MOTOR CONNECTOR

4 - MOUNTING TABS

24 - 46 DISTRIBUTION - FRONTRS

AIR OUTLETS (Continued)

Page 2442 of 2585

blower motor to regulate the blower motor ground

path it provides. The blower motor and wheel are

used to control the velocity of air moving through the

HVAC housing by spinning the blower wheel within

the housing at the selected speed or, in the ATC sys-

tem, at the selected or programmed speed.

DIAGNOSIS AND TESTING - BLOWER MOTOR

BLOWER MOTOR INOPERATIVE

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring, diagrams, proper wire and con-

nector repair procedures, further details on wire

harness routing and retention, as well as pin-out and

location views for the various wire harness connec-

tors, splices and grounds.

BLOWER MOTOR ELECTRICAL DIAGNOSIS

(1) Check the fuse (Fuse 10 - 40 ampere) in the

Integrated Power Module (IPM). If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the On position. Be

certain that the A/C-heater control power is turned

on. Check for battery voltage at the fuse (Fuse 10 -

40 ampere) in the IPM. If OK, go to Step 3. If not

OK, check the front blower motor relay.

(3) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the front HVAC wire harness connector

for the front blower motor resistor block (Manual

Temperature Control) or the front blower motor

power module (Automatic Temperature Control) from

the resistor or module connector receptacle. Recon-

nect the battery negative cable. Turn the ignition

switch to the On position. Be certain that the A/C-

heater control power is turned on. Check for battery

voltage at the fused front blower motor relay output

circuit cavity of the front HVAC wire harness connec-

tor for the front blower motor resistor block (MTC) orthe front blower motor power module (ATC). If OK,

go to Step 4. If not OK, repair the open fused front

blower motor relay output circuit to the IPM as

required.

(4) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the front blower motor pigtail wire con-

nector from the connector receptacle of the front

blower motor resistor block (MTC) or the front

blower motor power module (ATC). Use jumper wires

to connect a battery and ground feeds to the blower

motor pigtail wire connector. The blower motor

should operate. If OK with MTC, proceed to diagno-

sis of the front blower motor resistor block (Refer to

24 - HEATING & AIR CONDITIONING/CONTROLS

- FRONT/BLOWER MOTOR RESISTOR - DIAGNO-

SIS AND TESTING). If OK with ATC, use a DRBIII

scan tool to diagnose the front blower motor power

module. Refer to Body Diagnostic information. If not

OK with MTC or ATC, replace the faulty front blower

motor.

BLOWER MOTOR NOISE OR VIBRATION

Refer to the Blower Motor Noise/Vibration Diagno-

sis chart for basic checks of the blower motor when a

vibration or noise is present (Fig. 7).

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

NOTE: The blower motor is located on the passen-

ger side of the vehicle under the instrument panel.

The blower motor can be removed from the vehicle

without having to remove the HVAC housing.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the passenger side door sill plate and

cowl panel.

(3) Pull back the carpet to access the front lower

air intake screw.

RSDISTRIBUTION - FRONT24-47

BLOWER MOTOR (Continued)

Page 2452 of 2585

DISTRIBUTION DUCT

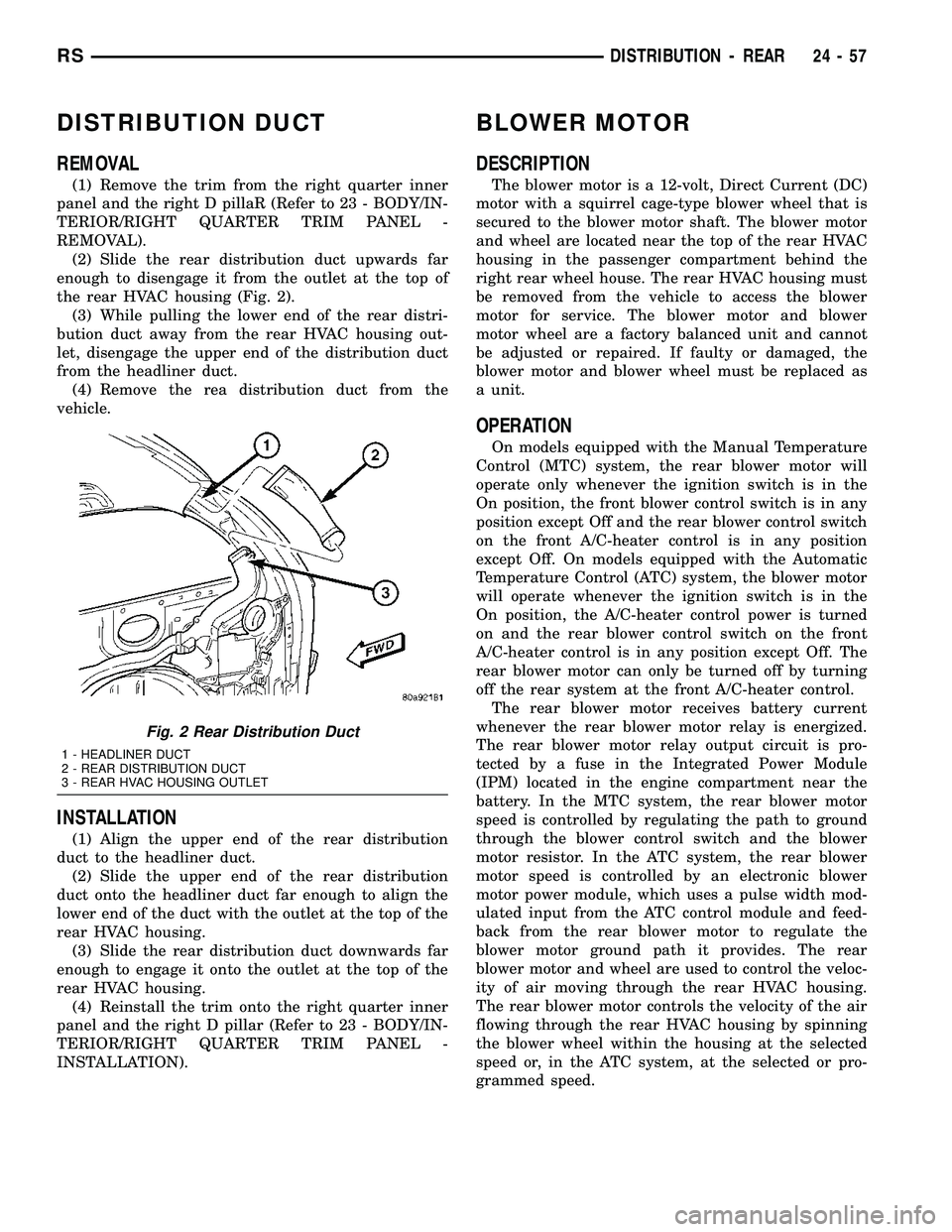

REMOVAL

(1) Remove the trim from the right quarter inner

panel and the right D pillaR (Refer to 23 - BODY/IN-

TERIOR/RIGHT QUARTER TRIM PANEL -

REMOVAL).

(2) Slide the rear distribution duct upwards far

enough to disengage it from the outlet at the top of

the rear HVAC housing (Fig. 2).

(3) While pulling the lower end of the rear distri-

bution duct away from the rear HVAC housing out-

let, disengage the upper end of the distribution duct

from the headliner duct.

(4) Remove the rea distribution duct from the

vehicle.

INSTALLATION

(1) Align the upper end of the rear distribution

duct to the headliner duct.

(2) Slide the upper end of the rear distribution

duct onto the headliner duct far enough to align the

lower end of the duct with the outlet at the top of the

rear HVAC housing.

(3) Slide the rear distribution duct downwards far

enough to engage it onto the outlet at the top of the

rear HVAC housing.

(4) Reinstall the trim onto the right quarter inner

panel and the right D pillar (Refer to 23 - BODY/IN-

TERIOR/RIGHT QUARTER TRIM PANEL -

INSTALLATION).

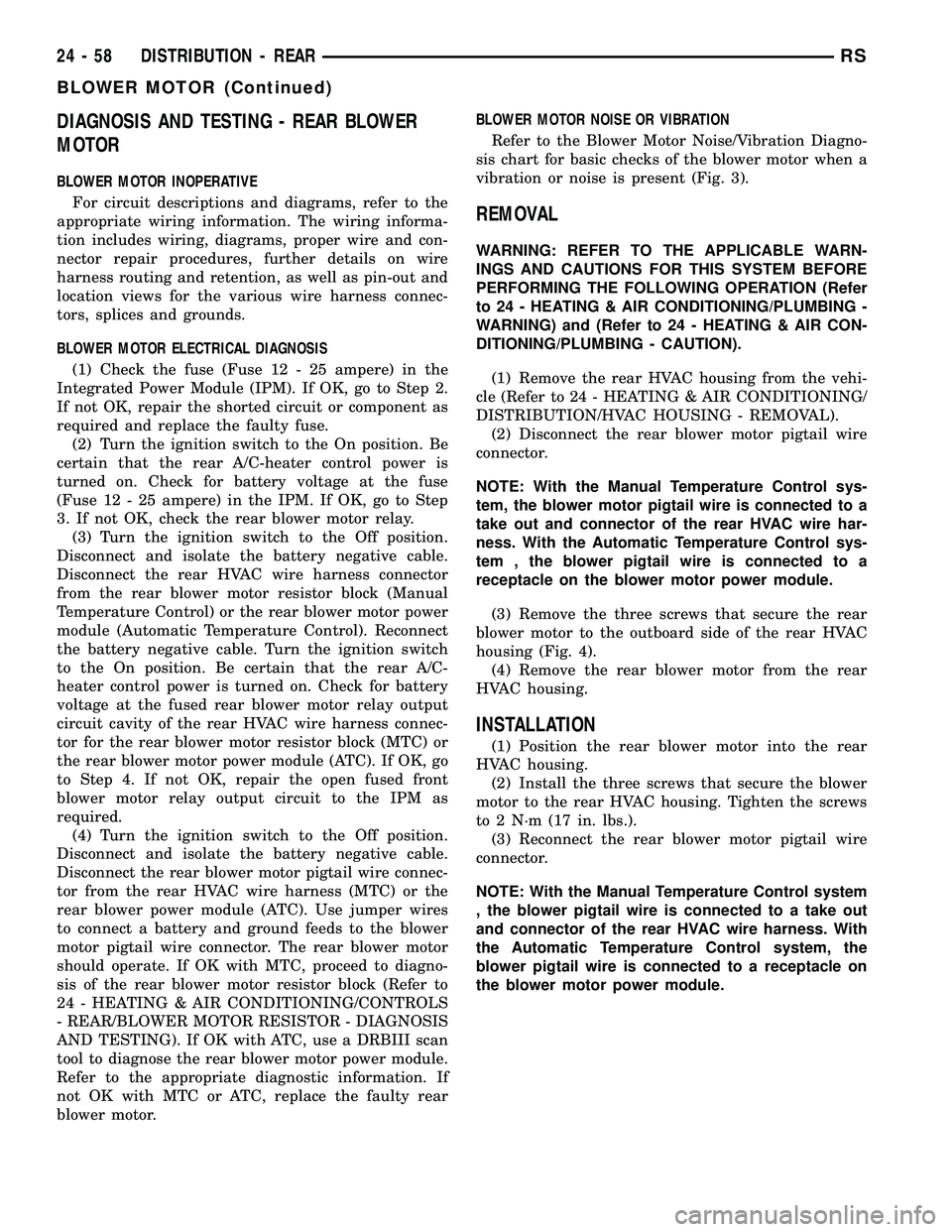

BLOWER MOTOR

DESCRIPTION

The blower motor is a 12-volt, Direct Current (DC)

motor with a squirrel cage-type blower wheel that is

secured to the blower motor shaft. The blower motor

and wheel are located near the top of the rear HVAC

housing in the passenger compartment behind the

right rear wheel house. The rear HVAC housing must

be removed from the vehicle to access the blower

motor for service. The blower motor and blower

motor wheel are a factory balanced unit and cannot

be adjusted or repaired. If faulty or damaged, the

blower motor and blower wheel must be replaced as

a unit.

OPERATION

On models equipped with the Manual Temperature

Control (MTC) system, the rear blower motor will

operate only whenever the ignition switch is in the

On position, the front blower control switch is in any

position except Off and the rear blower control switch

on the front A/C-heater control is in any position

except Off. On models equipped with the Automatic

Temperature Control (ATC) system, the blower motor

will operate whenever the ignition switch is in the

On position, the A/C-heater control power is turned

on and the rear blower control switch on the front

A/C-heater control is in any position except Off. The

rear blower motor can only be turned off by turning

off the rear system at the front A/C-heater control.

The rear blower motor receives battery current

whenever the rear blower motor relay is energized.

The rear blower motor relay output circuit is pro-

tected by a fuse in the Integrated Power Module

(IPM) located in the engine compartment near the

battery. In the MTC system, the rear blower motor

speed is controlled by regulating the path to ground

through the blower control switch and the blower

motor resistor. In the ATC system, the rear blower

motor speed is controlled by an electronic blower

motor power module, which uses a pulse width mod-

ulated input from the ATC control module and feed-

back from the rear blower motor to regulate the

blower motor ground path it provides. The rear

blower motor and wheel are used to control the veloc-

ity of air moving through the rear HVAC housing.

The rear blower motor controls the velocity of the air

flowing through the rear HVAC housing by spinning

the blower wheel within the housing at the selected

speed or, in the ATC system, at the selected or pro-

grammed speed.

Fig. 2 Rear Distribution Duct

1 - HEADLINER DUCT

2 - REAR DISTRIBUTION DUCT

3 - REAR HVAC HOUSING OUTLET

RSDISTRIBUTION - REAR24-57

Page 2453 of 2585

DIAGNOSIS AND TESTING - REAR BLOWER

MOTOR

BLOWER MOTOR INOPERATIVE

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring, diagrams, proper wire and con-

nector repair procedures, further details on wire

harness routing and retention, as well as pin-out and

location views for the various wire harness connec-

tors, splices and grounds.

BLOWER MOTOR ELECTRICAL DIAGNOSIS

(1) Check the fuse (Fuse 12 - 25 ampere) in the

Integrated Power Module (IPM). If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the On position. Be

certain that the rear A/C-heater control power is

turned on. Check for battery voltage at the fuse

(Fuse 12 - 25 ampere) in the IPM. If OK, go to Step

3. If not OK, check the rear blower motor relay.

(3) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the rear HVAC wire harness connector

from the rear blower motor resistor block (Manual

Temperature Control) or the rear blower motor power

module (Automatic Temperature Control). Reconnect

the battery negative cable. Turn the ignition switch

to the On position. Be certain that the rear A/C-

heater control power is turned on. Check for battery

voltage at the fused rear blower motor relay output

circuit cavity of the rear HVAC wire harness connec-

tor for the rear blower motor resistor block (MTC) or

the rear blower motor power module (ATC). If OK, go

to Step 4. If not OK, repair the open fused front

blower motor relay output circuit to the IPM as

required.

(4) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the rear blower motor pigtail wire connec-

tor from the rear HVAC wire harness (MTC) or the

rear blower power module (ATC). Use jumper wires

to connect a battery and ground feeds to the blower

motor pigtail wire connector. The rear blower motor

should operate. If OK with MTC, proceed to diagno-

sis of the rear blower motor resistor block (Refer to

24 - HEATING & AIR CONDITIONING/CONTROLS

- REAR/BLOWER MOTOR RESISTOR - DIAGNOSIS

AND TESTING). If OK with ATC, use a DRBIII scan

tool to diagnose the rear blower motor power module.

Refer to the appropriate diagnostic information. If

not OK with MTC or ATC, replace the faulty rear

blower motor.BLOWER MOTOR NOISE OR VIBRATION

Refer to the Blower Motor Noise/Vibration Diagno-

sis chart for basic checks of the blower motor when a

vibration or noise is present (Fig. 3).

REMOVAL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

(1) Remove the rear HVAC housing from the vehi-

cle (Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - REMOVAL).

(2) Disconnect the rear blower motor pigtail wire

connector.

NOTE: With the Manual Temperature Control sys-

tem, the blower motor pigtail wire is connected to a

take out and connector of the rear HVAC wire har-

ness. With the Automatic Temperature Control sys-

tem , the blower pigtail wire is connected to a

receptacle on the blower motor power module.

(3) Remove the three screws that secure the rear

blower motor to the outboard side of the rear HVAC

housing (Fig. 4).

(4) Remove the rear blower motor from the rear

HVAC housing.

INSTALLATION

(1) Position the rear blower motor into the rear

HVAC housing.

(2) Install the three screws that secure the blower

motor to the rear HVAC housing. Tighten the screws

to 2 N´m (17 in. lbs.).

(3) Reconnect the rear blower motor pigtail wire

connector.

NOTE: With the Manual Temperature Control system

, the blower pigtail wire is connected to a take out

and connector of the rear HVAC wire harness. With

the Automatic Temperature Control system, the

blower pigtail wire is connected to a receptacle on

the blower motor power module.

24 - 58 DISTRIBUTION - REARRS

BLOWER MOTOR (Continued)

Page 2558 of 2585

FRONT DISC BRAKE SHOES

(CONTINENTAL TEVES BRAKES) -

INSTALLATION.......................5s-15

FRONT DISC BRAKE SHOES

(CONTINENTAL TEVES BRAKES) -

REMOVAL..........................5s-14

FRONT DISC BRAKE SHOES (DISC/DISC

BRAKES) - INSTALLATION...............5-16

FRONT DISC BRAKE SHOES (DISC/DISC

BRAKES) - REMOVAL..................5-14

FRONT DISC BRAKE SHOES (DISC/

DRUM BRAKES) - INSTALLATION.........5-17

FRONT DISC BRAKE SHOES (DISC/

DRUM BRAKES) - REMOVAL............5-15

FRONT DISC BRAKE SHOES (TRW

BRAKES) - INSTALLATION..............5s-16

FRONT DISC BRAKE SHOES (TRW

BRAKES) - REMOVAL.................5s-14

FRONT DOOR GLASS RUN

WEATHERSTRIP - INSTALLATION.......23-113

FRONT DOOR GLASS RUN

WEATHERSTRIP - REMOVAL...........23-113

FRONT DOOR INNER BELT MOLDING -

INSTALLATION......................23-115

FRONT DOOR INNER BELT MOLDING -

REMOVAL.........................23-115

FRONT DOOR OUTER BELT MOLDING -

INSTALLATION......................23-113

FRONT DOOR OUTER BELT MOLDING -

REMOVAL.........................23-113

FRONT DOOR WEATHERSTRIP -

INSTALLATION......................23-114

FRONT DOOR WEATHERSTRIP -

REMOVAL.........................23-114

FRONT FASCIA - INSTALLATION..........13-1

FRONT FASCIA - REMOVAL..............13-1

FRONT FENDER - INSTALLATION........23-52

FRONT FENDER - REMOVAL............23-52

FRONT FOG LAMP - DIAGNOSIS AND

TESTING............................8L-7

FRONT FOG LAMP - INSTALLATION.......8L-8

FRONT FOG LAMP - REMOVAL...........8L-8

FRONT FOG LAMP UNIT ALIGNMENT -

EXPORT - STANDARD PROCEDURE.......8L-9

FRONT FOG LAMP UNIT ALIGNMENT -

STANDARD PROCEDURE................8L-9

FRONT INBOARD - INSTALLATION, SEAT

BELT BUCKLE.......................8O-12

FRONT INBOARD - REMOVAL, SEAT

BELT BUCKLE.......................8O-12

FRONT MOUNT - INSTALLATION....9-131,9-49

FRONT MOUNT - REMOVAL........9-131,9-49

FRONT SEAT - INSTALLATION...........23-91

FRONT SEAT - REMOVAL..............23-91

FRONT SEAT BACK - INSTALLATION......23-92

FRONT SEAT BACK - REMOVAL.........23-92

FRONT SEAT CUSHION SIDE COVER -

INSTALLATION.......................23-94

FRONT SEAT CUSHION SIDE COVER -

REMOVAL..........................23-94

FRONT SEAT RISER - MANUAL TRACK -

INSTALLATION.......................23-95

FRONT SEAT RISER - MANUAL TRACK -

REMOVAL..........................23-94

FRONT SEAT TRACK - REAR COVER -

INSTALLATION.......................23-96

FRONT SEAT TRACK - REAR COVER -

REMOVAL..........................23-96

FRONT SEAT TRACK MANUAL

ADJUSTER - INSTALLATION............23-95

FRONT SEAT TRACK MANUAL

ADJUSTER - REMOVAL................23-95

FRONT SEAT TRACK POWER ADJUSTER

- INSTALLATION.....................23-95

FRONT SEAT TRACK POWER ADJUSTER

- REMOVAL.........................23-95

FRONT SEATBACK ASSIST STRAP -

INSTALLATION.......................23-92

FRONT SEATBACK ASSIST STRAP -

REMOVAL..........................23-92

FRONT SEATBACK COVER -

INSTALLATION.......................23-93

FRONT SEATBACK COVER - REMOVAL

....23-93

FRONT SEATBACK PANEL -

INSTALLATION

.......................23-93

FRONT SEATBACK PANEL - REMOVAL

....23-92

FRONT SUSPENSION - DESCRIPTION

......2-2

FRONT SUSPENSION - OPERATION

........2-2FRONT SUSPENSION FASTENER

TORQUE, SPECIFICATIONS...............2-3

FRONT SUSPENSION, SPECIAL TOOLS.....2-3

FRONT WASHER PUMP MOTOR -

INSTALLATION.......................8R-8

FRONT WASHER PUMP MOTOR -

REMOVAL...........................8R-8

FRONT WHEEL SPEED SENSOR -

INSTALLATION........................5-80

FRONT WHEEL SPEED SENSOR -

REMOVAL...........................5-79

FRONT WHEELHOUSE SPLASH SHIELD -

INSTALLATION.......................23-55

FRONT WHEELHOUSE SPLASH SHIELD -

REMOVAL..........................23-55

FRONT WIPER ARM ALIGNMENT -

STANDARD PROCEDURE...............8R-8

FRONT WIPER ARMS - INSTALLATION....8R-9

FRONT WIPER ARMS - REMOVAL........8R-9

FRONT WIPER MOTOR - INSTALLATION . . . 8R-9

FRONT WIPER MOTOR - REMOVAL.......8R-9

FRONT WIPER SYSTEM - DIAGNOSIS

AND TESTING........................8R-2

FRONT WIPER/WASHER SWITCH -

DIAGNOSIS AND TESTING..............8R-2

FRONT/QUAD SEAT CUSHION -

INSTALLATION.......................23-93

FRONT/QUAD SEAT CUSHION -

REMOVAL..........................23-93

FRONT-WHEEL-DRIVE - INSTALLATION....2-36

FRONT-WHEEL-DRIVE - REMOVAL........2-36

FUEL CORRECTION OR ADAPTIVE

MEMORIES, OPERATION...............14-20

FUEL DELIVERY - DESCRIPTION..........14-2

FUEL DELIVERY - OPERATION...........14-2

FUEL DELIVERY SYSTEM - DIAGNOSIS

AND TESTING........................14-2

FUEL DOSING PUMP - DESCRIPTION....24-115

FUEL DOSING PUMP - INSTALLATION . . . 24-116

FUEL DOSING PUMP - OPERATION.....24-115

FUEL DOSING PUMP - REMOVAL.......24-115

FUEL ENGINE OIL - DESCRIPTION,

FLEXIBLE.............................0-3

FUEL FILL DOOR - INSTALLATION.......23-52

FUEL FILL DOOR - REMOVAL...........23-52

FUEL FILL DOOR BLOCKER LATCH -

INSTALLATION.......................23-53

FUEL FILL DOOR BLOCKER LATCH -

REMOVAL..........................23-53

FUEL FILL DOOR BLOCKER LATCH

STRIKER - INSTALLATION..............23-53

FUEL FILL DOOR BLOCKER LATCH

STRIKER - REMOVAL.................23-53

FUEL FILL DOOR BLOCKER LOCKOUT

LINK - INSTALLATION.................23-54

FUEL FILL DOOR BLOCKER LOCKOUT

LINK - REMOVAL.....................23-53

FUEL FILLER CAP - DESCRIPTION.......25-12

FUEL FILLER CAP - OPERATION.........25-12

FUEL INJECTOR - DESCRIPTION.........14-26

FUEL INJECTOR - OPERATION..........14-26

FUEL LEVEL SENDING UNIT / SENSOR -

DESCRIPTION........................14-5

FUEL LEVEL SENDING UNIT / SENSOR -

INSTALLATION........................14-5

FUEL LEVEL SENDING UNIT / SENSOR -

OPERATION..........................14-5

FUEL LEVEL SENDING UNIT / SENSOR -

REMOVAL...........................14-5

FUEL LINE - INSTALLATION...........24-118

FUEL LINE - REMOVAL...............24-117

FUEL LINES/HOSES AND CLAMPS -

DESCRIPTION........................14-6

FUEL PRESSURE REGULATOR -

INSTALLATION........................14-7

FUEL PRESSURE REGULATOR -

OPERATION..........................14-7

FUEL PRESSURE REGULATOR -

REMOVAL...........................14-7

FUEL PUMP - DESCRIPTION.............14-8

FUEL PUMP - OPERATION..............14-8

FUEL PUMP MODULE - DESCRIPTION.....14-8

FUEL PUMP MODULE - INSTALLATION....14-9

FUEL PUMP MODULE - OPERATION

.......14-8

FUEL PUMP MODULE - REMOVAL

........14-8

FUEL PUMP RELAY - DESCRIPTION

......14-28

FUEL PUMP RELAY - OPERATION

........14-28

FUEL REQUIREMENTS - DESCRIPTION

......0-4FUEL REQUIREMENTS - DIESEL ENGINE

- DESCRIPTION........................0-6

FUEL, SPECIAL TOOLS............14-23,14-4

FUEL SYSTEM PRESSURE RELEASE

PROCEDURE - STANDARD

PROCEDURE.........................14-2

FUEL SYSTEM PRESSURE,

SPECIFICATIONS......................14-3

FUEL TANK - DESCRIPTION............14-10

FUEL TANK - INSTALLATION............14-12

FUEL TANK - OPERATION..............14-11

FUEL TANK - REMOVAL...............14-11

FUEL TANK - STANDARD PROCEDURE,

DRAINING...........................14-2

FUEL TANK FILLER TUBE -

INSTALLATION.......................14-13

FUEL TANK FILLER TUBE - REMOVAL....14-12

FULL OPEN SWITCH - DESCRIPTION....8N-12,

8N-31

FULL OPEN SWITCH - INSTALLATION....8N-13

FULL OPEN SWITCH - OPERATION . 8N-12,8N-31

FULL OPEN SWITCH - REMOVAL........8N-13

FUNCTIONS - DESCRIPTION, CIRCUIT . . 8W-01-6

FUSE - DESCRIPTION, IOD...........8W-97-3

FUSE - OPERATION, IOD.............8W-97-3

FUSES POWERING SEVERAL LOADS -

STANDARD PROCEDURE, TESTING

FOR A SHORT TO GROUND ON......8W-01-10

FWD - INSTALLATION..................2-45

FWD - INSTALLATION, REAR WHEEL

SPEED SENSOR.......................5-81

FWD - INSTALLATION, SPRING...........2-42

FWD - REMOVAL......................2-45

FWD - REMOVAL, REAR WHEEL SPEED

SENSOR............................5-81

FWD - REMOVAL, SPRING..............2-41

GALLERY PLUGS - STANDARD

PROCEDURE, ENGINE CORE AND OIL . 9-10,9-86

GAP AND FLUSH MEASUREMENTS -

SPECIFICATIONS....................23-124

GAP, SPECIFICATIONS - WHEEL SPEED

SENSOR AIR.........................5-79

GAS - INSTALLATION, MODULAR

CLUTCH ASSY - 2.4L..................6-11

GAS - REMOVAL, MODULAR CLUTCH

ASSY - 2.4L..........................6-11

GASKET - DIAGNOSIS AND TESTING,

CYLINDER HEAD.............9-24,9-99,9s-16

GASKET SURFACE PREPARATION -

STANDARD PROCEDURE, ENGINE....9-11,9-85

GASKETS AND SEALERS - STANDARD

PROCEDURE, FORM-IN-PLACE.......9-11,9-84

GASOLINE ENGINES - DIAGNOSIS AND

TESTING, SYSTEM CHARGE LEVEL

TEST..............................24-67

GEAR - DESCRIPTION.................19-26

GEAR - INSTALLATION, LHD............19-32

GEAR - INSTALLATION, RHD............19-33

GEAR & LINK ROD - DESCRIPTION, LIFT . 8N-16

GEAR & LINK ROD - INSTALLATION,

LIFT...............................8N-16

GEAR & LINK ROD - OPERATION, LIFT . . . 8N-16

GEAR & LINK ROD - REMOVAL, LIFT.....8N-16

GEAR - OPERATION...................19-27

GEAR - REMOVAL, LHD...............19-27

GEAR - REMOVAL, RHD...............19-31

GEAR END PLAY - ADJUSTMENT,

DIFFERENTIAL SIDE..................21-70

GEAR SHIFT CABLE - INSTALLATION....21-205

GEAR SHIFT CABLE - REMOVAL . 21-204,21s-105

GEAR SHIFT LEVER - INSTALLATION.....19-21

GEAR SHIFT LEVER - REMOVAL.........19-21

GEAR, SPECIAL TOOLS - POWER

STEERING..........................19-34

GEARSHIFT BOOT - INSTALLATION......21-73

GEARSHIFT BOOT - REMOVAL..........21-72

GEARSHIFT CABLE - CROSSOVER -

INSTALLATION.......................21-76

GEARSHIFT CABLE - CROSSOVER -

REMOVAL..........................21-73

GEARSHIFT CABLE - SELECTOR -

INSTALLATION

.......................21-84

GEARSHIFT CABLE - SELECTOR -

REMOVAL

..........................21-81

GEARSHIFT CABLE ADJUSTMENT,

ADJUSTMENTS

.....................21-206

GEARSHIFT KNOB - INSTALLATION

......21-87

GEARSHIFT KNOB - REMOVAL

..........21-87

RSINDEX15

Description Group-Page Description Group-Page Description Group-Page

Page 2559 of 2585

GEARSHIFT MECHANISM -

INSTALLATION.......................21-89

GEARSHIFT MECHANISM - REMOVAL....21-87

GEARTRAIN - DESCRIPTION,

PLANETARY.................21-232,21s-132

GEARTRAIN - OPERATION, PLANETARY . 21-232,

21s-132

GENERAL - WARNINGS.............8W-01-7

GENERAL DIAGNOSIS - DIAGNOSIS AND

TESTING, 41TE TRANSAXLE...........21-119

GENERAL DIAGNOSIS - DIAGNOSIS AND

TESTING, 4XTE TRANSAXLE...........21s-27

GENERATOR - DESCRIPTION...........8F-23

GENERATOR - OPERATION.............8F-23

GENERATOR DECOUPLER PULLEY -

DESCRIPTION..................8F-25,8F-27

GENERATOR DECOUPLER PULLEY -

DIAGNOSIS AND TESTING.........8F-25,8F-27

GENERATOR DECOUPLER PULLEY -

INSTALLATION..................8F-26,8F-28

GENERATOR DECOUPLER PULLEY -

OPERATION....................8F-25,8F-27

GENERATOR DECOUPLER PULLEY -

REMOVAL.....................8F-26,8F-28

GENERATOR, SPECIFICATIONS..........8F-22

GLASS - DESCRIPTION, HEATED.........8G-1

GLASS - INSTALLATION, DOOR.........23-17

GLASS - INSTALLATION, REAR DOOR . . . 23-111

GLASS - INSTALLATION, SIDE VIEW

MIRROR...........................23-59

GLASS - INSTALLATION, SLIDING DOOR . . . 23-110

GLASS - OPERATION, HEATED...........8G-2

GLASS - REMOVAL, DOOR.............23-17

GLASS - REMOVAL, REAR DOOR.......23-111

GLASS - REMOVAL, SIDE VIEW MIRROR . . 23-59

GLASS - REMOVAL, SLIDING DOOR.....23-110

GLASS INTEGRAL ANTENNA - EXPORT -

DESCRIPTION, QUARTER...............8A-9

GLASS INTEGRAL ANTENNA - EXPORT -

DIAGNOSIS AND TESTING, QUARTER.....8A-9

GLASS INTEGRAL ANTENNA - EXPORT -

OPERATION, QUARTER.................8A-9

GLASS PANEL - INSTALLATION........23-120

GLASS PANEL - REMOVAL............23-120

GLASS PANEL ADJUSTMENT,

ADJUSTMENTS - SUNROOF...........23-120

GLASS RUN WEATHERSTRIP -

INSTALLATION, FRONT DOOR..........23-113

GLASS RUN WEATHERSTRIP -

REMOVAL, FRONT DOOR.............23-113

GLOVE BOX - INSTALLATION...........23-64

GLOVE BOX - REMOVAL...............23-64

GLOVE BOX LAMP SWITCH -

INSTALLATION.......................8L-22

GLOVE BOX LAMP SWITCH - REMOVAL . . 8L-22

GLOVE BOX LATCH - INSTALLATION.....23-64

GLOVE BOX LATCH - REMOVAL.........23-64

GLOVE BOX LATCH STRIKER -

INSTALLATION.......................23-64

GLOVE BOX LATCH STRIKER - REMOVAL . 23-64

GRID LINE AND TERMINAL REPAIR -

STANDARD PROCEDURE...............8G-4

GRILLE - INSTALLATION, COWL

.........23-51

GRILLE - REMOVAL, COWL

............23-50

GRILLE OPENING REINFORCEMENT -

INSTALLATION

.......................23-54

GRILLE OPENING REINFORCEMENT -

REMOVAL

..........................23-54

GROCERY BAG RETAINER -

INSTALLATION, PLASTIC

..............23-105

GROCERY BAG RETAINER - REMOVAL,

PLASTIC

..........................23-104

GROMMET REPLACEMENT - STANDARD

PROCEDURE, PUSH-PIN

...............8N-28

GROUND - OPERATION, PCM

...........8E-15

GROUND - STANDARD PROCEDURE,

TESTING FOR A SHORT TO

..........8W-01-9

GROUND AND SPLICE INFORMATION -

DESCRIPTION, CONNECTOR

..........8W-01-7

GROUND ON FUSES POWERING

SEVERAL LOADS - STANDARD

PROCEDURE, TESTING FOR A SHORT

TO

.............................8W-01-10

GUIDE - INSTALLATION, UNDER SEAT

STORAGE BIN

......................23-105

GUIDE - REMOVAL, UNDER SEAT

STORAGE BIN

......................23-105GUIDE PIN BUSHINGS (CONTINENTAL

TEVES BRAKES) - ASSEMBLY, CALIPER . . . 5s-24

GUIDE PIN BUSHINGS (CONTINENTAL

TEVES BRAKES) - DISASSEMBLY,

CALIPER...........................5s-23

GUIDE PIN BUSHINGS (DISC/DISC

BRAKES) - ASSEMBLY, CALIPER..........5-25

GUIDE PIN BUSHINGS (DISC/DISC

BRAKES) - DISASSEMBLY, CALIPER.......5-24

GUIDE PINS (DISC/DRUM BRAKES) -

INSTALLATION, DISC BRAKE CALIPER.....5-31

GUIDE PINS (DISC/DRUM BRAKES) -

REMOVAL, DISC BRAKE CALIPER.........5-31

GUIDE PINS (TRW BRAKES) -

INSTALLATION, DISC BRAKE CALIPER....5s-30

GUIDE PINS (TRW BRAKES) - REMOVAL,

DISC BRAKE CALIPER.................5s-30

HALF SHAFT - DIAGNOSIS AND TESTING . . . 3-1,

3-13

HALF SHAFT - FRONT - DESCRIPTION......3-1

HALF SHAFT - FRONT - INSTALLATION.....3-4

HALF SHAFT - FRONT - REMOVAL.........3-2

HALF SHAFT - FRONT - SPECIFICATIONS . . 3-15,

3-6

HALF SHAFT - REAR - DESCRIPTION......3-13

HALF SHAFT - REAR - INSTALLATION.....3-14

HALF SHAFT - REAR - REMOVAL.........3-13

HALF SHAFT INNER SEAL -

INSTALLATION.......................21-12

HALF SHAFT INNER SEAL - REMOVAL....21-12

HALF SHAFT SEAL - INSTALLATION,

OUTER..............................21-19

HALF SHAFT SEAL - REMOVAL, OUTER . . . 21-19

HANDLE - INSTALLATION, ASSIST.......23-74

HANDLE - INSTALLATION, EXTERIOR....23-22,

23-40

HANDLE - INSTALLATION, INSIDE LATCH . . 23-34

HANDLE - INSTALLATION, OUTSIDE......23-35

HANDLE - INSTALLATION, RECLINER.....23-90

HANDLE - REMOVAL, ASSIST...........23-74

HANDLE - REMOVAL, EXTERIOR . . . 23-21,23-40

HANDLE - REMOVAL, INSIDE LATCH.....23-34

HANDLE - REMOVAL, OUTSIDE.........23-35

HANDLE - REMOVAL, RECLINER........23-90

HANDLE ACTUATOR - INSTALLATION,

INSIDE.............................23-27

HANDLE ACTUATOR - REMOVAL, INSIDE . . 23-27

HANDLE CABLE - INSTALLATION, INSIDE . . 23-38

HANDLE CABLE - INSTALLATION,

OUTSIDE...........................23-37

HANDLE CABLE - REMOVAL, INSIDE.....23-37

HANDLE CABLE - REMOVAL, OUTSIDE....23-37

HANDLE SWITCH - DESCRIPTION,

EXTERIOR..........................8N-11

HANDLE SWITCH - INSTALLATION,

EXTERIOR..........................8N-12

HANDLE SWITCH - OPERATION,

EXTERIOR..........................8N-11

HANDLE SWITCH - REMOVAL, EXTERIOR . 8N-11

HANDLING AIRBAGS - STANDARD

PROCEDURE.........................8O-3

HANDLING TUBING AND FITTINGS -

STANDARD PROCEDURE...............24-70

HARNESS - DESCRIPTION, WIRING......8N-35

HARNESS - DIAGNOSIS AND TESTING,

WIRING..........................8W-01-7

HARNESS - INSTALLATION, WIRING.....8N-36

HARNESS - OPERATION, WIRING

........8N-35

HARNESS - REMOVAL, WIRING

.........8N-35

HCU (HYDRAULIC CONTROL UNIT) -

DESCRIPTION

........................5-89

HCU (HYDRAULIC CONTROL UNIT) -

OPERATION

..........................5-89

HEAD - CLEANING, CYLINDER

. 9-100,9-26,9s-17

HEAD - DESCRIPTION, CYLINDER

....9-24,9-99,

9s-16

HEAD - INSPECTION, CYLINDER

....9-101,9-26,

9s-17

HEAD - INSTALLATION, CYLINDER

. . 9-101,9-26,

9s-18

HEAD - REMOVAL, CYLINDER

. . 9-100,9-25,9s-17

HEAD COVER - CLEANING, CYLINDER

.....9-31

HEAD COVER - INSPECTION, CYLINDER

. . . 9-31

HEAD COVER - INSTALLATION,

CYLINDER

...........................9-31

HEAD COVER - LEFT - INSTALLATION,

CYLINDER

..........................9-103HEAD COVER - LEFT - REMOVAL,

CYLINDER..........................9-103

HEAD COVER - REMOVAL, CYLINDER.....9-31

HEAD COVER - RIGHT - INSTALLATION,

CYLINDER..........................9-103

HEAD COVER - RIGHT - REMOVAL,

CYLINDER..........................9-102

HEAD COVER-LEFT - INSTALLATION,

CYLINDER..........................9s-20

HEAD COVER-LEFT - REMOVAL,

CYLINDER..........................9s-20

HEAD COVER-RIGHT - INSTALLATION,

CYLINDER..........................9s-19

HEAD COVER-RIGHT - REMOVAL,

CYLINDER..........................9s-19

HEAD COVER(S) - DESCRIPTION,

CYLINDER.....................9-102,9s-19

HEAD GASKET - DIAGNOSIS AND

TESTING, CYLINDER..........9-24,9-99,9s-16

HEAD OFF - INSTALLATION, CYLINDER . . . 9-108,

9-33,9s-26

HEAD OFF - REMOVAL, CYLINDER . . 9-106,9-32,

9s-24

HEAD ON - INSTALLATION, CYLINDER . . . 9-108,

9-33,9s-26

HEAD ON - REMOVAL, CYLINDER . . . 9-106,9-32,

9s-24

HEADER TRIM - INSTALLATION, REAR....23-80

HEADER TRIM - REMOVAL, REAR.......23-80

HEADLAMP - DIAGNOSIS AND TESTING . . 8L-10

HEADLAMP - INSTALLATION............8L-12

HEADLAMP - REMOVAL.................8L-12

HEADLAMP SWITCH - DIAGNOSIS AND

TESTING...........................8L-12

HEADLAMP SWITCH - INSTALLATION....8L-13

HEADLAMP SWITCH - REMOVAL........8L-13

HEADLAMP UNIT - EXPORT -

INSTALLATION.......................8L-17

HEADLAMP UNIT - EXPORT - REMOVAL . . 8L-17

HEADLAMP UNIT ALIGNMENT - EXPORT

- STANDARD PROCEDURE.............8L-14

HEADLAMP UNIT ALIGNMENT -

STANDARD PROCEDURE...............8L-13

HEADLINER - INSTALLATION...........23-78

HEADLINER - REMOVAL...............23-78

HEADREST - INSTALLATION............23-89

HEADREST - REMOVAL................23-89

HEADREST SLEEVE - INSTALLATION.....23-90

HEADREST SLEEVE - REMOVAL.........23-90

HEAT DUCT - INSTALLATION, REAR

FLOOR.............................24-63

HEAT DUCT - REMOVAL, REAR FLOOR . . . 24-62

HEAT SHIELDS - DESCRIPTION..........11-6

HEAT SHIELDS - INSTALLATION..........11-7

HEAT SHIELDS - OPERATION............11-7

HEAT SHIELDS - REMOVAL.............11-7

HEAT STAKING - STANDARD

PROCEDURE........................23-10

HEATED GLASS - DESCRIPTION..........8G-1

HEATED GLASS - OPERATION...........8G-2

HEATED MIRRORS - DESCRIPTION.......8G-6

HEATED MIRRORS - OPERATION.........8G-6

HEATED SEAT ELEMENTS -

DESCRIPTION.......................8G-10

HEATED SEAT ELEMENTS - DIAGNOSIS

AND TESTING.......................8G-10

HEATED SEAT ELEMENTS -

INSTALLATION......................8G-11

HEATED SEAT ELEMENTS - OPERATION . . 8G-10

HEATED SEAT ELEMENTS - REMOVAL....8G-11

HEATED SEAT MODULE - DESCRIPTION....8E-8

HEATED SEAT MODULE - DIAGNOSIS

AND TESTING........................8E-9

HEATED SEAT MODULE - INSTALLATION . . 8E-10

HEATED SEAT MODULE - OPERATION.....8E-9

HEATED SEAT MODULE - REMOVAL.......8E-9

HEATED SEAT SENSOR - DESCRIPTION . . . 8G-12

HEATED SEAT SENSOR - DIAGNOSIS

AND TESTING.......................8G-12

HEATED SEAT SENSOR - OPERATION

....8G-12

HEATED SEAT SWITCH - DESCRIPTION,

DRIVER

.............................8G-8

HEATED SEAT SWITCH - DESCRIPTION,

PASSENGER

........................8G-12

HEATED SEAT SWITCH - DIAGNOSIS

AND TESTING, DRIVER

.................8G-9

HEATED SEAT SWITCH - DIAGNOSIS

AND TESTING, PASSENGER

............8G-13

16 INDEXRS

Description Group-Page Description Group-Page Description Group-Page