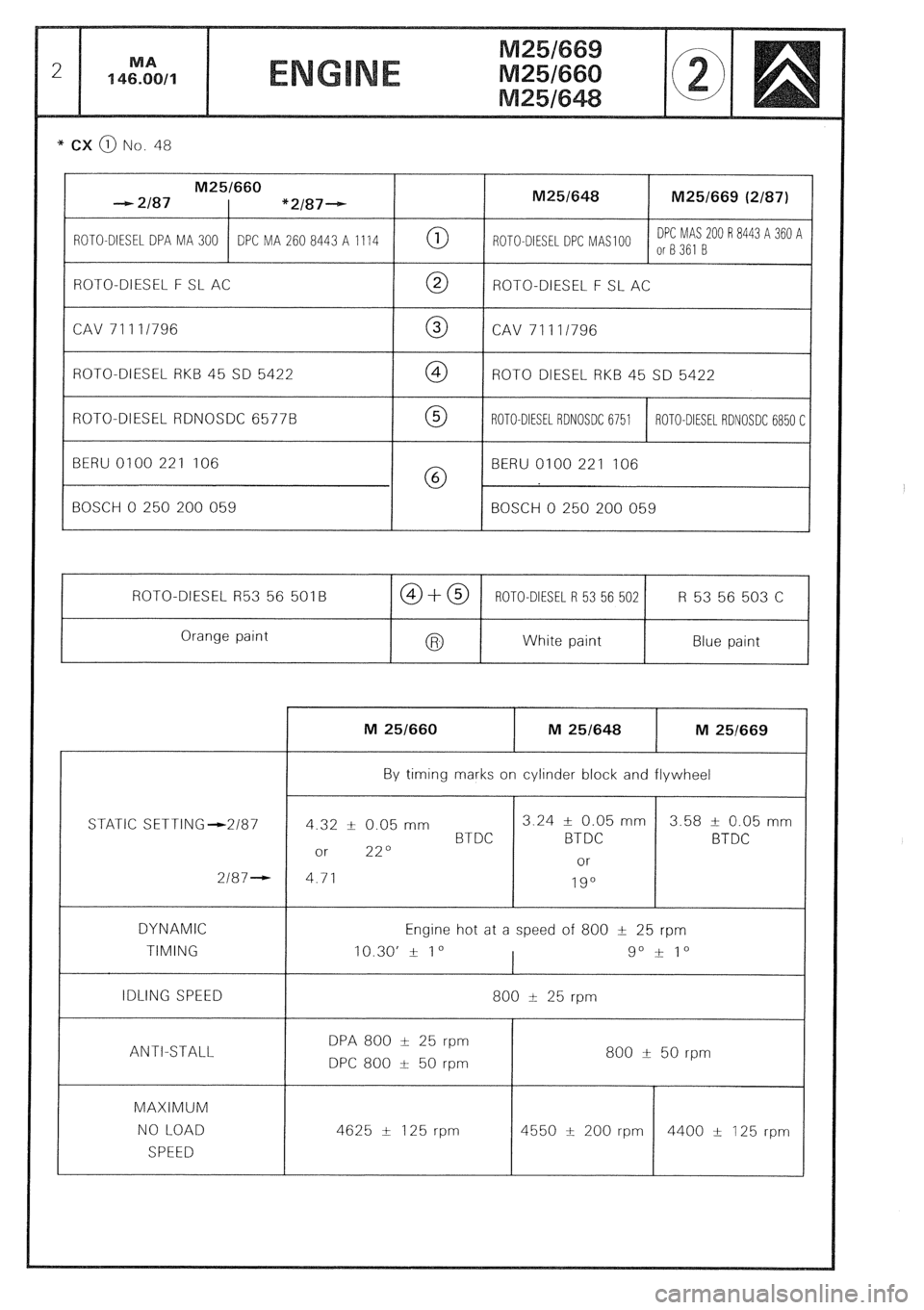

* CX @ No. 48

M25/660

- 2187 “2/87-- M25/648 M25/669 (2/87)

ROTO-DIESEL DPA MA 300 DPC MA 260 8443 A 1114 0 ROTO-DIESEL DPC MAS 100 DPC MAS 200 R 8443 A 360 A

or8361 B

ROTO-DIESEL F SL AC

0 ROTO-DIESEL F SL AC

CAV 71111796 0 CAV 71111796

ROTO-DIESEL RKB 45 SD 5422 @ ROT0 DIESEL RKB 45 SD 5422

ROTO-DIESEL RDNOSDC 6577B 0 ROTO-DIESEL RDNOSDC 6751 ROTO-DIESEL RDNOSDC 6850 C

BERU 0100 221 106

@ BERU 0100 221 106

BOSCH 0 250 200 059 BOSCH 0 250 200 059

ROTO-DIESEL R53 56 501B CO+@ ROTO-DIESEL R 53 56 502 R 53 56 503 C

Orange paint

White paint Blue paint

STATIC SETTING-2187

2187-

DYNAMIC

TIMING

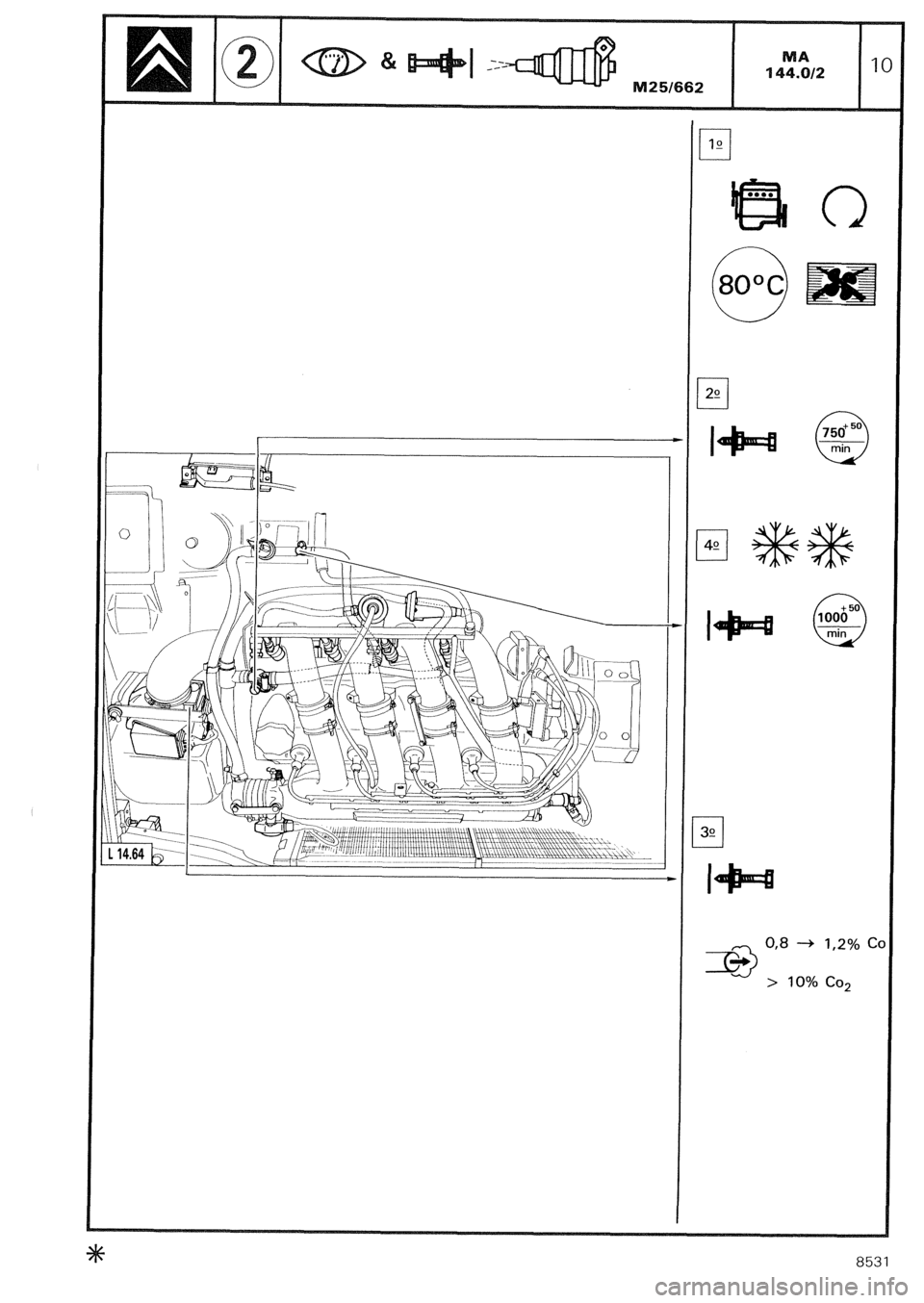

IDLING SPEED

ANTI-STALL

MAXIMUM

NO LOAD

SPEED M 251660 M 25/648 M 251669

By timing marks on cylinder block and flywheel

4 12 k 0.05 mm 3.24 f 0.05 mm 3.58 t- 0.05 mm

BTDC BTDC BTDC

or 22O

or

4.71

19”

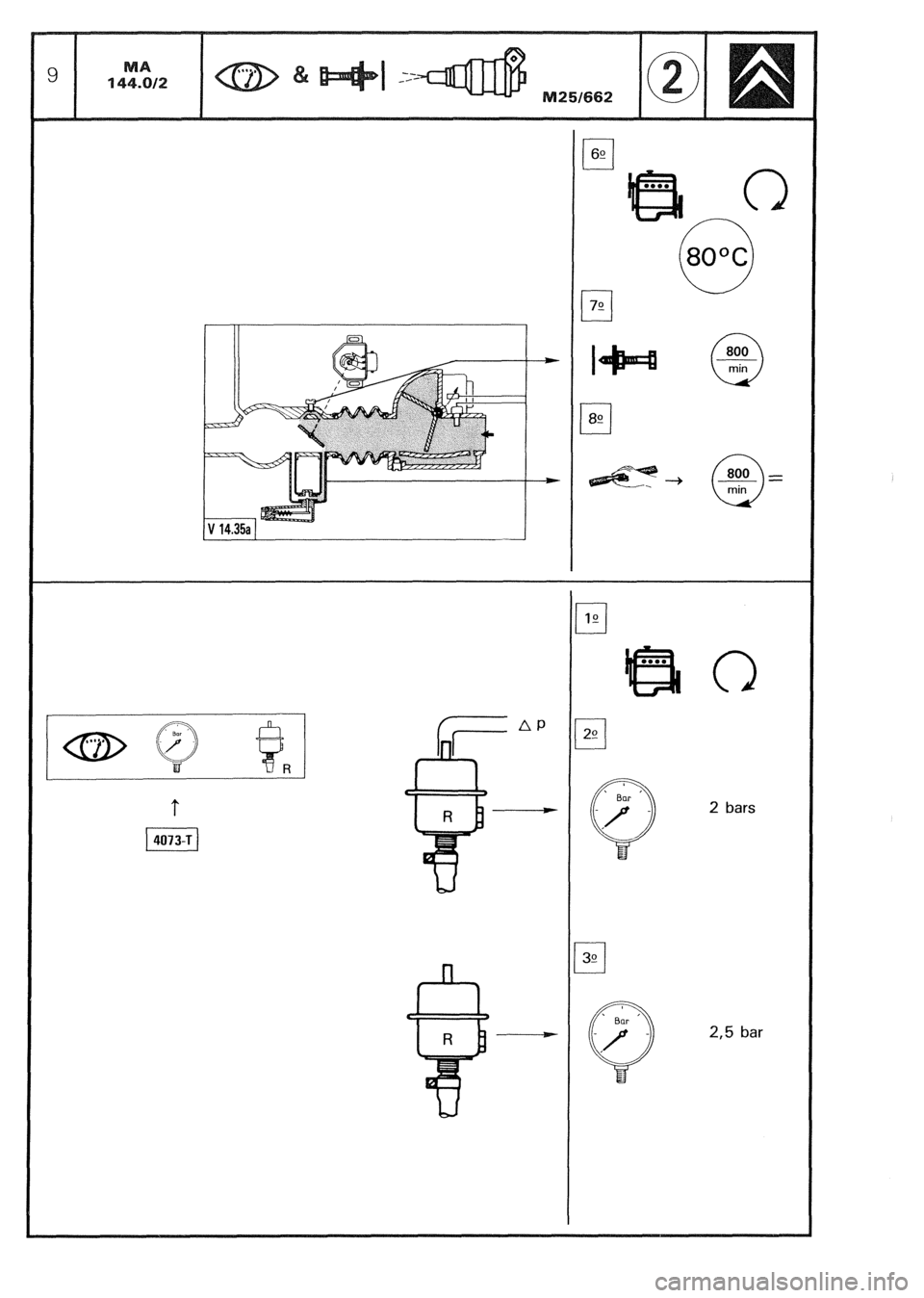

Engine hot at a speed of 800 t 25 rpm

10.30’ + 1 o

I go i 1”

800 I 25 rpm

DPA 800 t 25 rpm

DPC 800 t 50 rpm 800 & 50 rpm

4625 & 125 rpm

r

4400 + 125 rpm

RECOMMENDED TOOLS

2437-T.

3089-T.F.

3089-T.H.

4026-T-bis.

4059-T.

5008-T.C.

6027-T.

6030-T.

Dial-gauge.

Dial-gauge.

Feeler.

Injector test bench.

Right angled lever for dial-gauge.

Dial-gauge mounting fixing screw

Set of 3 tools.

Dial-gauge mounting. CHECKING AND ADJUSTING

THE FUEL INJECTION SYSTEM

8531

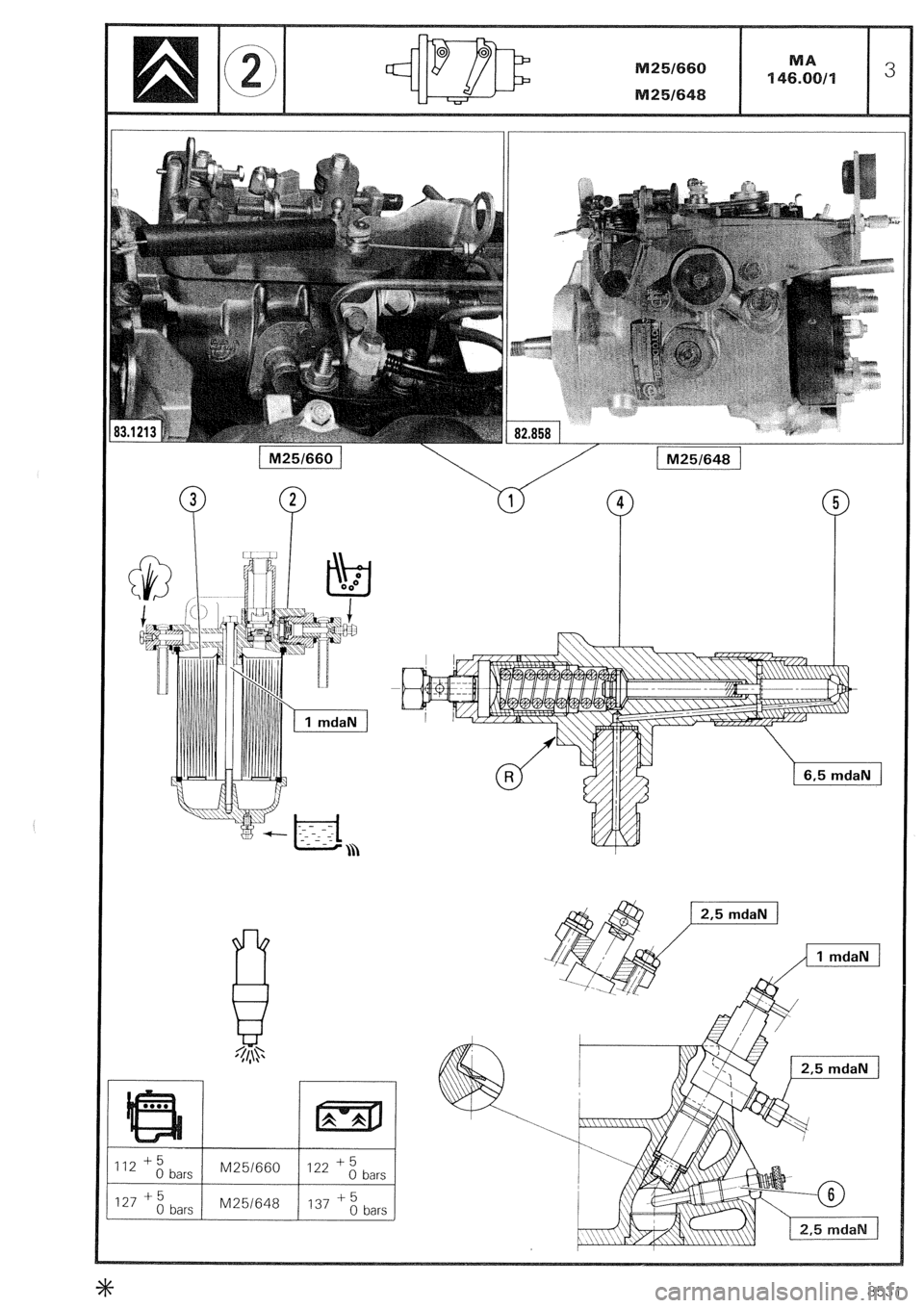

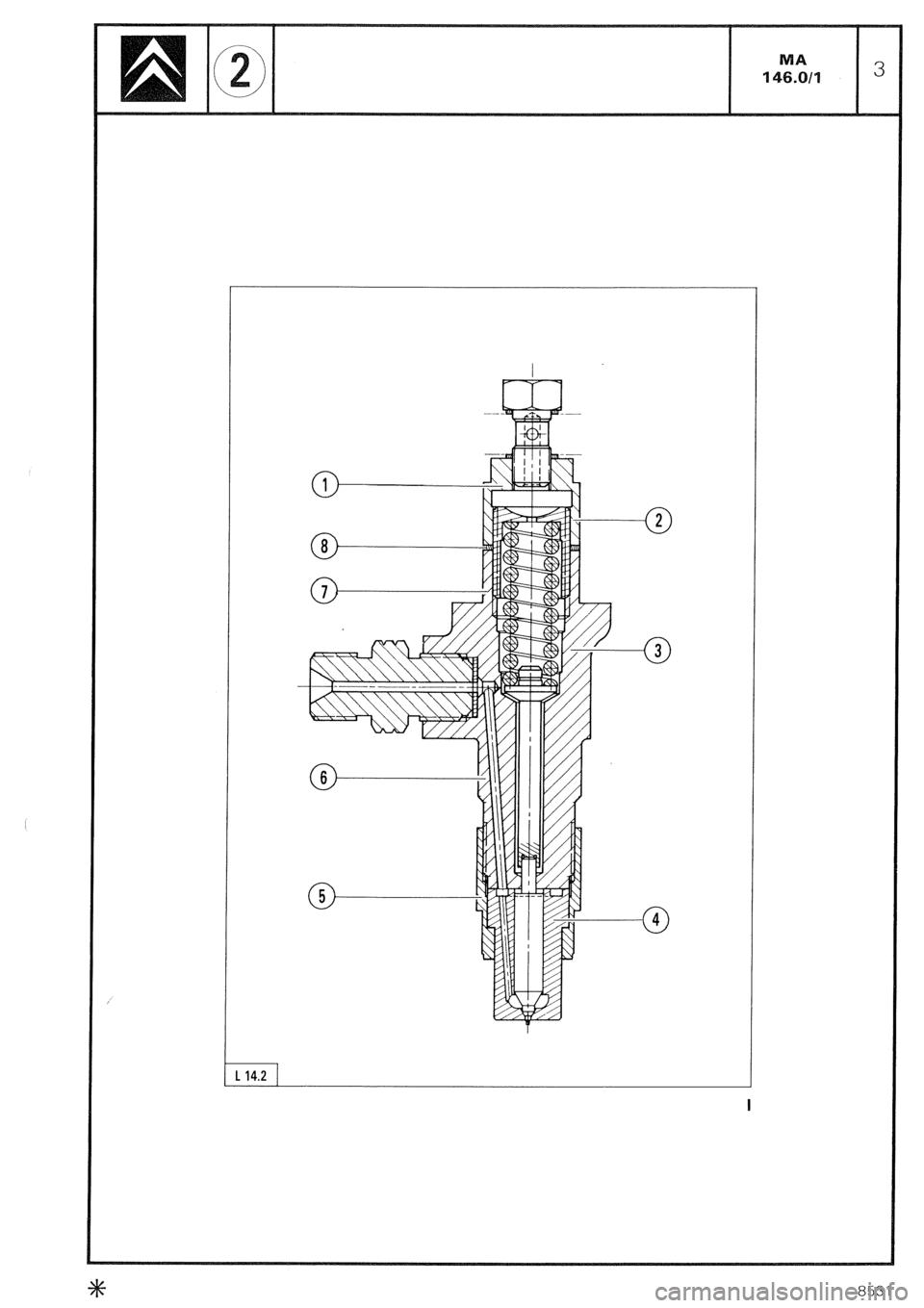

I. - ADJUSTING THE INJECTOR SETTING PRESSURE

Test fluid: Keep the equipment clean.

- Deodorized petroleum or Kerdanne or Dilutine. The parts should be lubricated before assembly.

- Viscosity: 1 to 2.5 centistoks at 2O’C.

- Density: 0.770 to 0.810 at 2O’C. - In the injector-carrier body (31, place:

- injector (4) and its nut (5),

Tighten to 6.5 mdaN

Precautions to be taken:

- push-rod (6),

- As the flash point of paraffin is low, it is essen-

- spring (7),

tial to ensure that all safety precautions are taken

before the test. - adjustment screw (2).

- Keep your hands away from the spray (use a - Adjust the pressure:

transparent protective screen).

The penetrating strength of these sprays is such

that they could create serious injuries and cause M 251660 M 251648 M 25/669

blood poisoning.

Pressure

112 t5 bars 127 t5 bars

setting

0 0

Checking the setting pressure: Injector RDNOSD RDNOSD RDNOSD

6577 B 6751 68-50 C

Actuate the pump lever slowly; record the pressure

value measured by the manometer on opening the Injector RKB45SD RKB45SD RKB45SD

Injector (calibration pressure). Write the value down. carrier 5422 5422 5422

The pressure setting is carried out using screw (2). Paint

Fig. I. mark orange white blue

Injector setting pressure adjustment screw (2)

is to be screwed in or out on the test bench

operated continually to keep the needle and its

If the pump lever is actuated with a brisk sharp action,

the injector should produce a very fine and homoge-

neous spray.

Checking the needle seat for leaks:

DISMANTLING Test should be carried out with the injector in a verti-

cal position.

To open an injector-carrier, place it in a vice equip- Wipe the end of the injector until dry.

ped with lead vice grips.

By actuating the pump lever, maintain a pressure

10 bars below the setting pressure.

The injector should not drip within 30 seconds,

Never tighten an injector-carrier alone in vice. Moistening should not be regarded as a reason for

rejection.