Citroen GRAND C4 PICASSO RHD 2016 2.G Owner's Manual

Manufacturer: CITROEN, Model Year: 2016, Model line: GRAND C4 PICASSO RHD, Model: Citroen GRAND C4 PICASSO RHD 2016 2.GPages: 523, PDF Size: 13.63 MB

Page 291 of 523

289

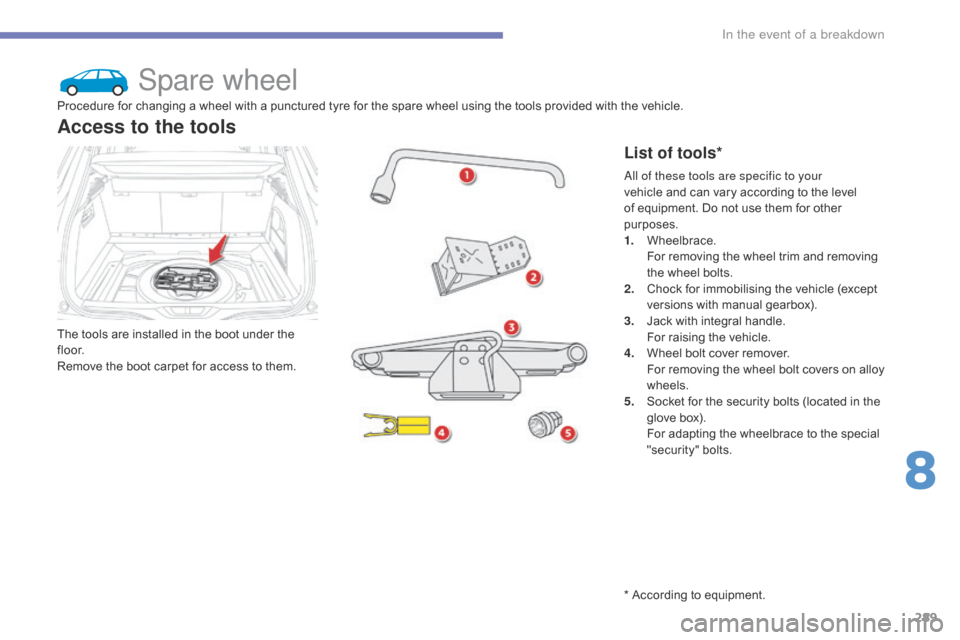

Spare wheel

The tools are installed in the boot under the fl o o r.

Remove

the boot carpet for access to them.

Access to the tools

List of tools*

Procedure for changing a wheel with a punctured tyre for the spare wheel using the tools provided with the vehicle.

A ll of these tools are specific to your

vehicle

and can vary according to the level

o

f equipment. Do not use them for other

p

urposes.

1.

W

heelbrace.

F

or removing the wheel trim and removing

t

he wheel bolts.

2.

C

hock for immobilising the vehicle (except

v

ersions with manual gearbox).

3.

J

ack with integral handle.

F

or raising the vehicle.

4.

W

heel bolt cover remover.

F

or removing the wheel bolt covers on alloy

w

heels.

5.

S

ocket for the security bolts (located in the

g

love box).

F

or adapting the wheelbrace to the special

"s

ecurity"

b

olts.

*

According to equipment.

8

In the event of a breakdown

Page 292 of 523

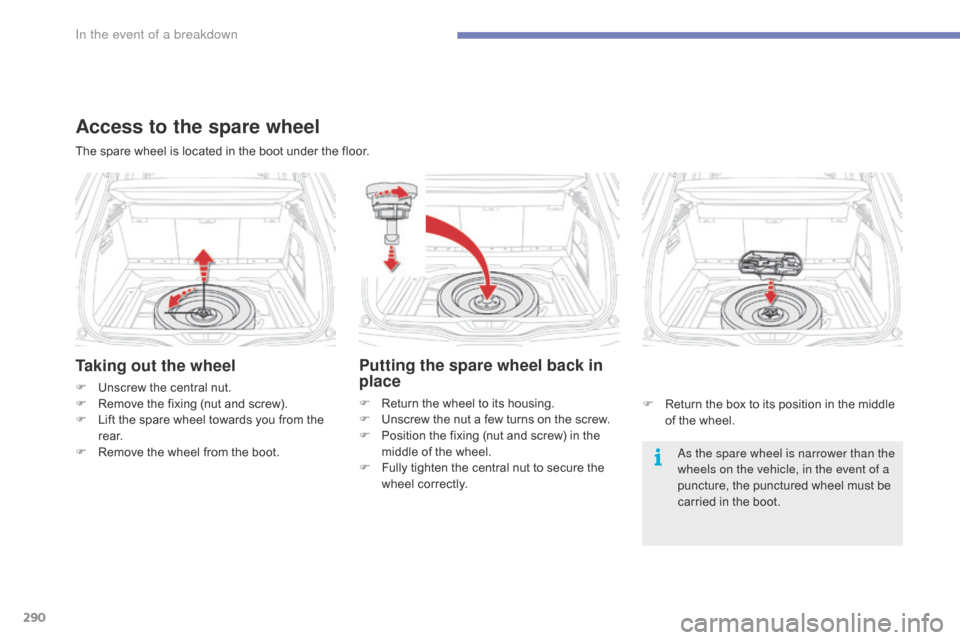

290

Taking out the wheel

F Unscrew the central nut.

F R emove the fixing (nut and screw).

F

L

ift the spare wheel towards you from the

r

e a r.

F

R

emove the wheel from the boot. As the spare wheel is narrower than the

wheels on the vehicle, in the event of a

puncture,

the punctured wheel must be

c

arried in the boot.

The

spare wheel is located in the boot under the floor.

Access to the spare wheel

Putting the spare wheel back in

place

F Return

the wheel to its housing.

F U nscrew the nut a few turns on the screw.

F

P

osition the fixing (nut and screw) in the

m

iddle of the wheel.

F

F

ully tighten the central nut to secure the

w

heel correctly. F

R eturn the box to its position in the middle

o

f the wheel.

In the event of a breakdown

Page 293 of 523

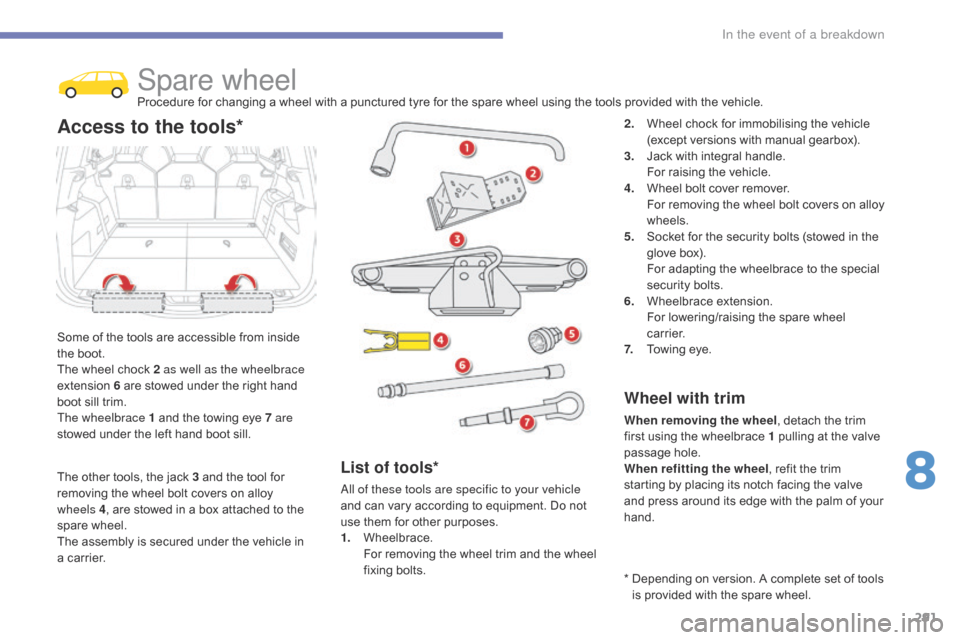

291

Spare wheelProcedure for changing a wheel with a punctured tyre for the spare wheel using the tools provided with the vehicle.

S

ome

of

the

tools are accessible from inside

t

he

boot.

The

wheel

chock 2 as well as the wheelbrace

extension

6

are stowed under the right hand

b

oot

sill

trim.

The wheelbrace 1

and the towing eye 7 are

stowed

under

the left hand boot sill.

Access to the tools*2. Wheel chock for immobilising the vehicle (

except versions with manual gearbox).

3.

J

ack with integral handle.

F

or raising the vehicle.

4.

W

heel bolt cover remover.

F

or removing the wheel bolt covers on alloy

w

heels.

5.

S

ocket for the security bolts (stowed in the

g

love box).

F

or adapting the wheelbrace to the special

s

ecurity bolts.

6.

W

heelbrace

e

xtension.

F

or lowering/raising the spare wheel

c

a r r i e r.

7.

T

owing eye.

Wheel with trim

When removing the wheel , detach the trim f

irst using the wheelbrace 1 pulling at the valve

p

assage hole.

When refitting the wheel ,

refit the trim

s

tarting by placing its notch facing the valve

a

nd press around its edge with the palm of your

han

d.

List of tools*

All of these tools are specific to your vehicle

and can vary according to equipment. Do not

u

se them for other purposes.

1.

W

heelbrace.

F

or removing the wheel trim and the wheel

f

ixing

bol

ts. *

D

epending on version. A complete set of tools

i

s provided with the spare wheel.

The

other

tools,

the

jack

3

and

the

tool

for

r

emoving

the

wheel

bolt

covers

on

alloy

w

heels

4 ,

are

stowed

in

a

box

attached

to

the

spar

e

w

heel.

The

assembly

is

secured

under

the

vehicle

in

a

carrier.

8

In the event of a breakdown

Page 294 of 523

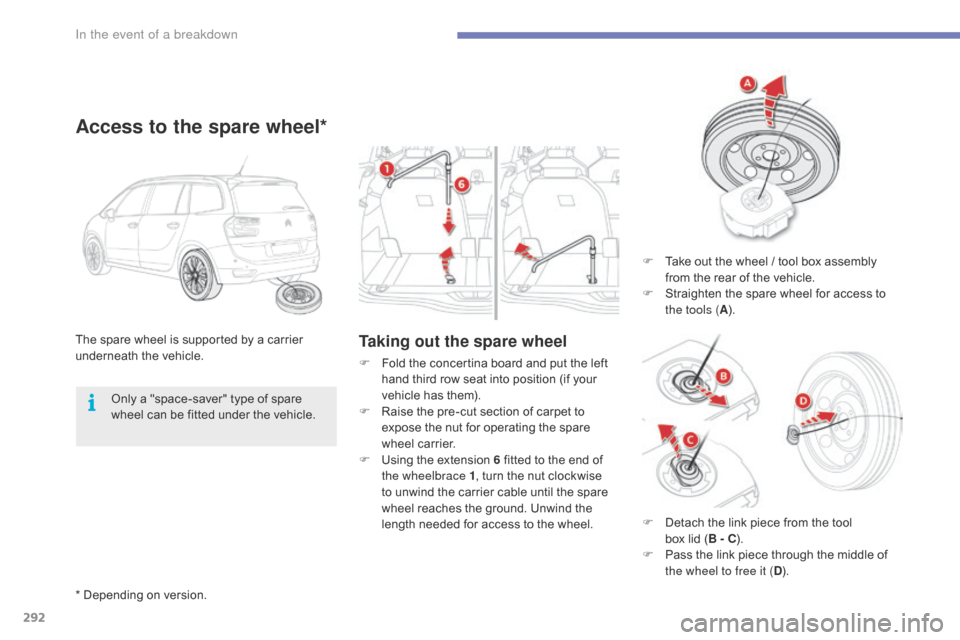

292

Taking out the spare wheelThe spare wheel is supported by a carrier underneath t he v ehicle.

Access to the spare wheel*

F Take out the wheel / tool box assembly f

rom the rear of the vehicle.

F

S

traighten the spare wheel for access to

t

he tools ( A).

F

F

old

the

concertina

board

and

put

the

left

h

and

third

row

seat

into

position

(if

your

v

ehicle

has

them).

F

R

aise

the

pre-cut

section

of

carpet

to

e

xpose

the

nut

for

operating

the

spare

w

heel

carrier.

F

U

sing

the

extension

6

fitted

to

the

end

of

t

he wheelbrace 1 ,

turn

the

nut

clockwise

t

o

unwind

the

carrier

cable

until

the

spare

w

heel

reaches

the

ground.

Unwind

the

l

ength

needed

for

access

to

the

wheel.

Only

a

"space-saver"

type

of

spare

w

heel

can

be

fitted

under

the

vehicle.

*

Depending

on

version. F

D

etach the link piece from the tool

b

ox lid ( B - C).

F

P

ass the link piece through the middle of

t

he wheel to free it ( D).

In the event of a breakdown

Page 295 of 523

293

A punctured wheel from the vehicle cannot be fitted under the vehicle. It

m

ust

b

e

c

arried

i

n

t

he

b

oot.

U

se

a

c

over

t

o protect the boot.

F

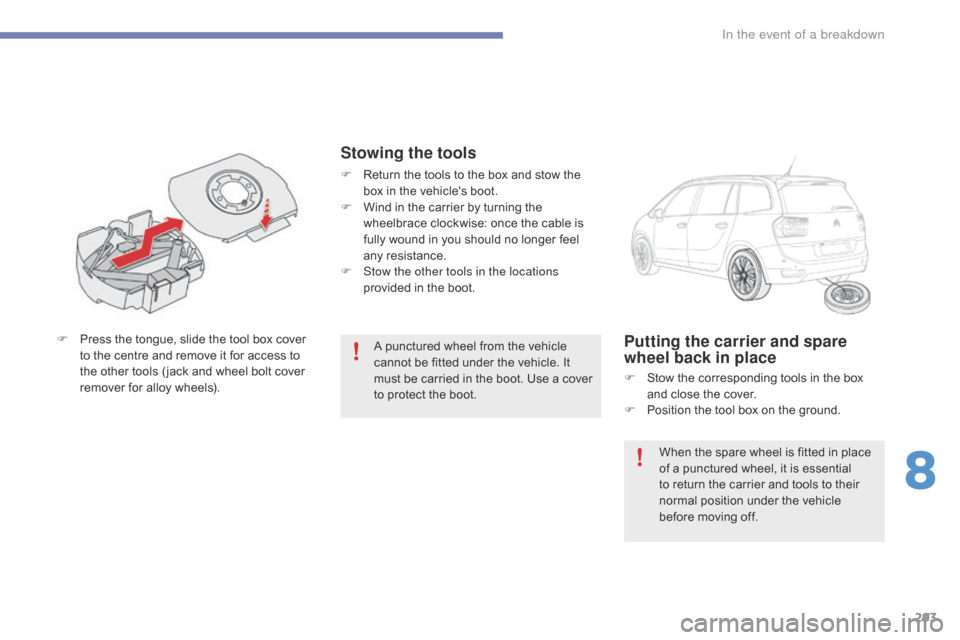

P

ress

the

tongue,

slide

the

tool

box

cover

t

o

the

centre

and

remove

it

for

access

to

t

he

other

tools

( jack

and

wheel

bolt

cover

r

emover

for

alloy

wheels).Putting the carrier and spare

wheel back in place

F Stow the corresponding tools in the box a

nd close the cover.

F

P

osition the tool box on the ground.

Stowing the tools

F Return the tools to the box and stow the b

ox in the vehicle's boot.

F

W

ind in the carrier by turning the

w

heelbrace clockwise: once the cable is

f

ully wound in you should no longer feel

an

y

r

esistance.

F

S

tow the other tools in the locations

provided

in the boot.

When

the spare wheel is fitted in place

o

f a punctured wheel, it is essential

t

o return the carrier and tools to their

n

ormal position under the vehicle

b

efore moving off.

8

In the event of a breakdown

Page 296 of 523

294

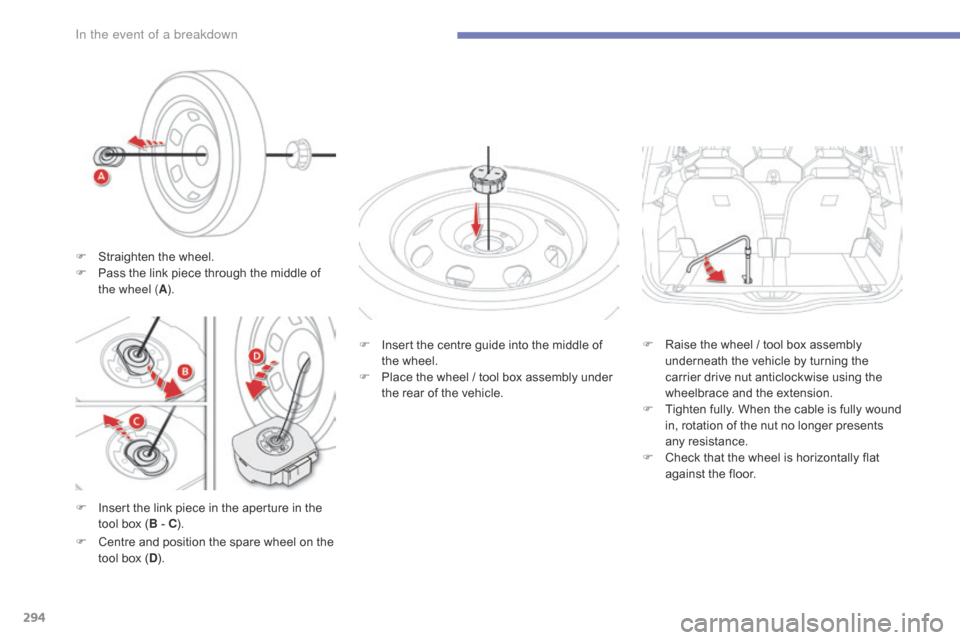

F Insert the link piece in the aperture in the t

ool box (B

- C). F

I

nsert the centre guide into the middle of

t

he wheel.

F

P

lace the wheel / tool box assembly under

t

he rear of the vehicle.

F

C

entre and position the spare wheel on the

t

ool box (D ). F

R

aise the wheel / tool box assembly

u

nderneath the vehicle by turning the

c

arrier drive nut anticlockwise using the

w

heelbrace and the extension.

F

T

ighten fully. When the cable is fully wound

i

n, rotation of the nut no longer presents

an

y

r

esistance.

F

C

heck that the wheel is horizontally flat

a

gainst the floor.

F

S

traighten the wheel.

F

P

ass the link piece through the middle of

t

he wheel (

A).

In the event of a breakdown

Page 297 of 523

295

Removing a wheel

Parking the vehicle

Immobilise the vehicle where it does not block traffic: the ground must be level,

s

table and not slippery.

Apply

the parking brake unless it has

b

een programmed to automatic mode,

s

witch off the ignition and engage first

g

ear* to block the wheels.

Check

that the braking warning lamp

a

nd the P warning lamp in the parking

b

rake control lever come on.

For

greater safety, place the chock 2

against

the wheel opposite to the one

b

eing

c

hanged.

The

occupants must get out of the

v

ehicle and wait where they are safe.

Never

go underneath a vehicle

s

upported by a jack; use an axle stand.

List of operations

F Remove the wheel bolt cover(s) using the t

ool 4 (depending on equipment).

F

F

it the security socket 5 on the

wheelbrace

1 to slacken the security bolt

(

if fitted).

F

S

lacken the other bolts (no more than a

1

/4 turn) using the wheelbrace 1

o

n l y.

* Position P

for

an

automatic

gearbox. Do

not use:

-

t

he jack for any purpose other than

l

ifting the vehicle,

-

a

ny other jack than the one

s

upplied by the manufacturer.F

P

lace the foot of the jack 3 on the ground

a

nd check that it is directly below the

f

ront A or rear B jacking point provided on

t

he underbody, whichever is closest to the w

heel to be changed.

Ensure that the jack is stable. If the

g

round is slippery or loose, the jack

m

ay slip or drop - Risk of injury!

Ensure

that the jack is positioned only

a

t one of the jacking points A or B

under

the vehicle, making sure that the

v

ehicle's contact sur face is centred on

t

he head of the jack. Other wise there is

a

risk of damage to the vehicle and/or of

t

he jack dropping - Risk of injury!

8

In the event of a breakdown

Page 298 of 523

296

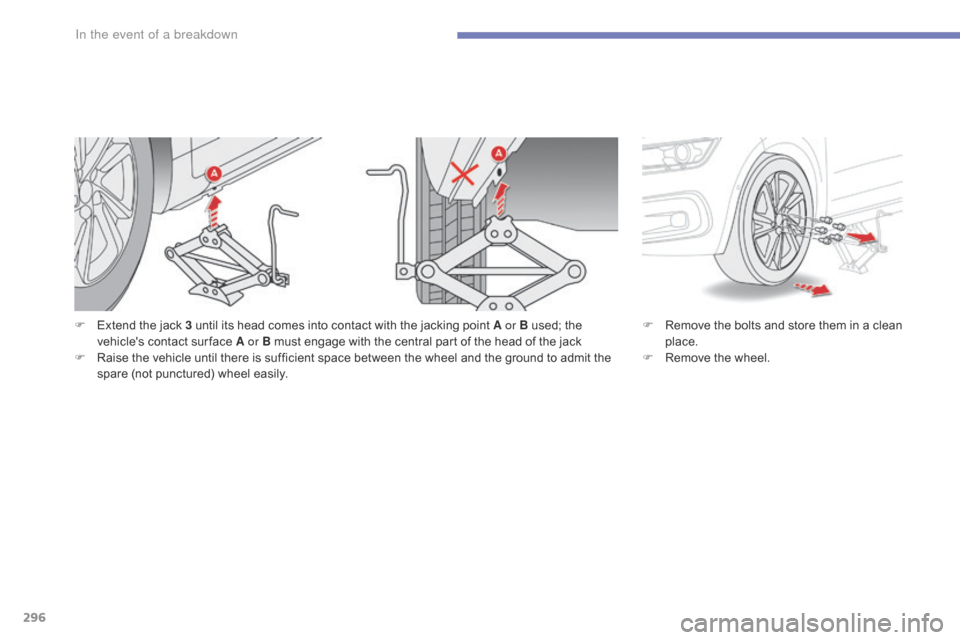

F Extend the jack 3 until its head comes into contact with the jacking point A or B used; the v

ehicle's contact sur face A or B must engage with the central part of the head of the jack

F

R

aise the vehicle until there is sufficient space between the wheel and the ground to admit the

s

pare (not punctured) wheel easily. F

R emove the bolts and store them in a clean p

lace.

F

R

emove the wheel.

In the event of a breakdown

Page 299 of 523

297

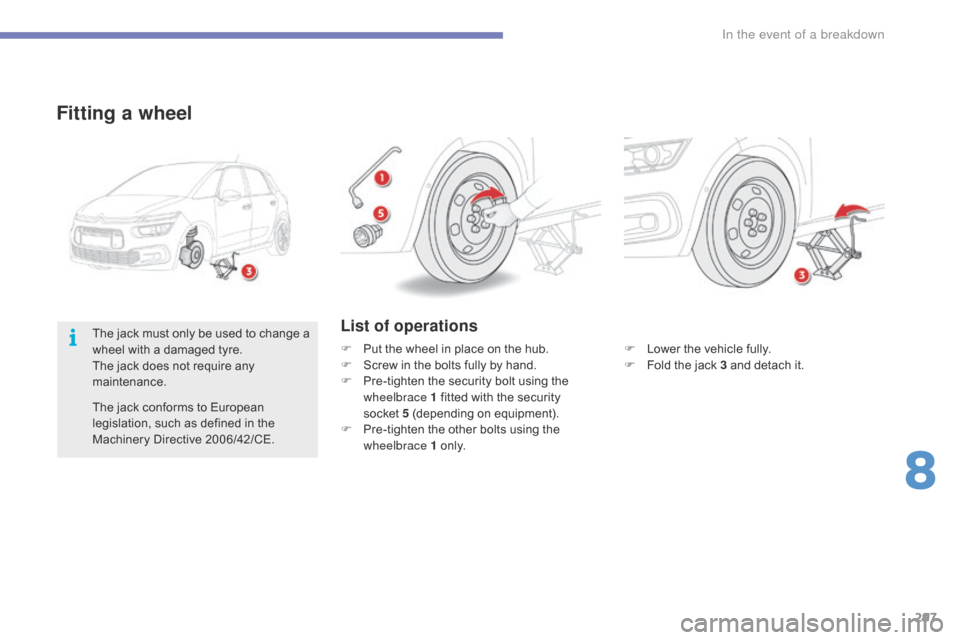

Fitting a wheel

F Lower the vehicle fully.

F F old the jack 3 and detach it.

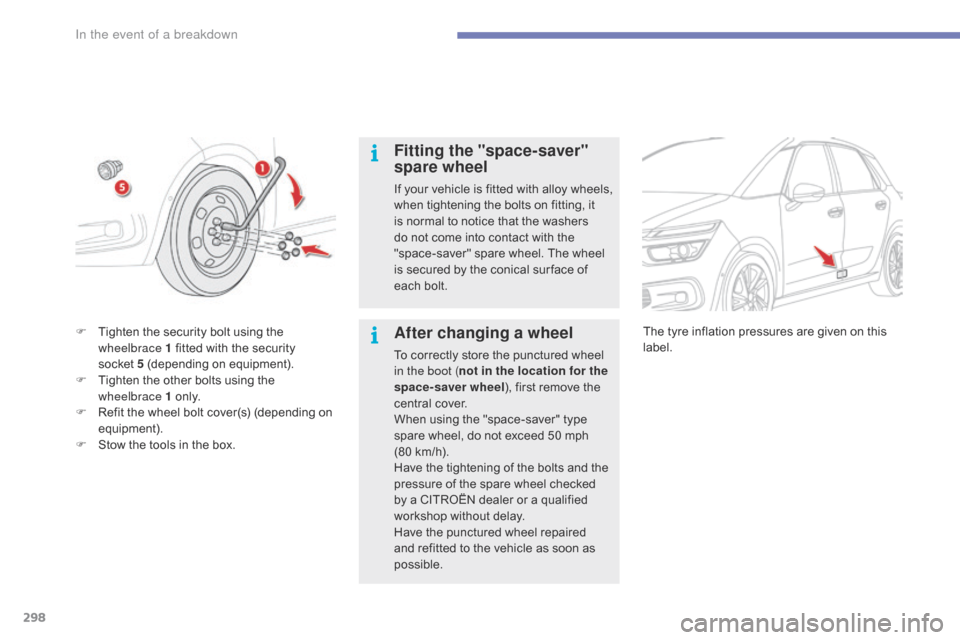

List of operations

F Put the wheel in place on the hub.

F S crew in the bolts fully by hand.

F

P

re-tighten the security bolt using the

w

heelbrace 1 fitted with the security

s

ocket 5

(depending on equipment).

F

P

re-tighten the other bolts using the

w

heelbrace 1

o

n l y.

The

jack

must

only

be

used

to

change

a

w

heel

with

a

damaged

tyre.

The

jack

does

not

require

any

m

aintenance.

The

jack

conforms

to

European

l

egislation,

such

as

defined

in

the

M

achinery

Directive

2006/42/CE.

8

In the event of a breakdown

Page 300 of 523

298

Fitting the "space-saver"

spare wheel

If your vehicle is fitted with alloy wheels, when tightening the bolts on fitting, it

i

s normal to notice that the washers

d

o not come into contact with the

"

space-saver" spare wheel. The wheel

i

s secured by the conical sur face of

e

ach bolt.

After changing a wheel

To correctly store the punctured wheel in the boot ( not in the location for the

space-saver wheel ),

first remove the

c

entral cover.

When

using the "space-saver" type

s

pare wheel, do not exceed 50 mph

(

80 km/h).

Have

the tightening of the bolts and the

p

ressure of the spare wheel checked

b

y a CITROËN dealer or a qualified

w

orkshop without delay.

Have

the punctured wheel repaired

a

nd refitted to the vehicle as soon as

p

ossible.

F

T

ighten

the

security

bolt

using

the

w

heelbrace 1

fitted

with

the

security

s

ocket 5

(depending

on

equipment).

F

T

ighten

the

other

bolts

using

the

w

heelbrace 1

o

n l y.

F

R

efit

the

wheel

bolt

cover(s)

(depending

on

e

quipment).

F

S

tow

the

tools

in

the

box. The

tyre inflation pressures are given on this lab

el.

In the event of a breakdown