engine DATSUN 210 1979 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 196 of 548

2

Engine

rotates

but

does

not

run

smoothly

This

may

be

caused

by

the

ignition

Condition

Location

Engine

misses

Distributor

Ignition

coil

High

tension

cable

Spark

plugs

IC

ignition

unit

Engine

causes

knocking

very

often

Distributor

Spark

plugs

Engine

does

not

deliver

enough

power

Distributor

Spark

plugs

Engine

Electrical

System

system

or

other

engine

conditions

not

related

to

ignition

system

Therefore

first

complete

inspection

of

ignition

system

should

be

carried

out

Probable

cause

Foreign

matter

onpicl

up

coil

Improper

air

gap

Leak

of

electricity

at

cap

and

rotor

head

Breakage

of

pick

up

coil

lead

wire

Worn

or

shaky

breaker

plate

Worn

or

shaky

distributor

driVing

shaft

Layer

short

circuit

or

inferior

quality

coil

Deterioration

of

insulation

with

cense

quenlleak

of

electricity

Fouled

Leak

of

electricity

at

upper

porcelain

insulator

Spark

plug

gap

too

narrow

Faulty

IC

ignition

unit

Breakage

of

circuit

Detached

connection

Improper

ignition

timing

too

advanced

Coming

off

or

breakage

of

governor

spring

Worn

pin

or

hole

of

governor

Burnt

too

much

Improper

ignition

timing

too

retarded

Improper

functioning

governor

Foreign

particles

stuck

in

air

gap

Fouled

EE

38

Corrective

action

Clean

Correct

Repair

or

replace

Replace

Replace

assembly

Replace

aSsembly

Replace

with

good

one

Replace

Clean

Repair

or

replace

Correct

or

replace

Replace

Replace

Repair

Correct

Correct

or

replace

Replace

Replace

Correct

Replace

assembly

Clean

Clean

Page 197 of 548

DATSUN

210

Model

8310

Series

SECTIONER

ENGINE

REMOVAL

INSTAllATION

CONTENTS

ENGINE

REMOVAL

AND

INSTALLATION

REMOVAL

INSTALLATION

ER

2

ER

3

ER

5

ENGINE

MOUNTING

INSULATOR

SERVICE

DATA

AND

SPECIFICATIONS

TIGHTENING

TORQUE

ER

5

ER

6

ER

6

Page 198 of 548

Engine

Re

lloval

In

tallation

ENGINE

REMOVAL

AND

INSTAllATION

I

Jp

40

1

Front

engine

mounting

ms

ulato

R

H

2

Front

c118ine

mounting

bracket

R

H

3

Front

engine

mounting

bracket

L

K

4

Front

engine

mounting

insulator

L

H

5

Rear

engine

mounting

mem

ber

6

Re4

f

engine

mounting

insulator

Tightening

torque

kg

m

ft

lb

i

J

3

2

to

4

3

23

to

31

@

1

6

to

2

1

12

10

15

@

1

6

to

2

1

12

to

15

@

0

91a

1

2

6

510

8

1

@

0

9101

2

6

5

to

8

1

3

2

to

4

3

23

to

31

E

R479

Fig

ER

1

Engine

Mounting

ER

2

Page 199 of 548

REMOVAL

It

is

much

easier

to

remove

engine

and

transmission

as

a

single

unit

than

to

remove

alone

After

removal

engine

can

be

separated

from

the

transmission

assembly

WARNING

a

Place

wheel

chocks

in

fronl

of

front

wheels

and

in

rear

of

rear

wheels

b

Be

sure

to

hoist

engine

in

a

safe

manner

c

You

should

not

remove

engine

until

exhaust

system

has

com

pletely

cooled

off

Otherwise

you

may

burn

your

self

and

or

fire

may

break

out

in

fuel

line

Note

Fender

coven

should

be

used

to

protect

car

body

1

Disconnect

battery

ground

cable

from

battery

terminal

and

fusible

link

at

wire

connector

2

Remove

hood

as

follows

CAUTION

Have

an

assistant

help

you

so

as

to

prevent

damage

to

body

I

Mark

hood

hinge

locations

on

hood

to

facilitate

reinstallation

2

Support

hood

by

ltand

and

re

move

bolts

securing

it

to

hood

hinge

being

careful

not

to

let

hood

slip

when

bolts

are

removed

See

Fig

ER

2

3

Remove

hood

from

hood

hinge

f

Il

I

BF133A

Fig

ER

2

Removing

Hood

Remove

under

cover

Drain

radiator

coolant

and

engine

3

4

oil

5

Disconnect

upper

and

lower

hoses

from

radiator

and

disconnect

oil

cooler

hoses

automatic

transmission

only

6

Remove

four

bolts

securing

radia

Engine

Removal

Installation

tor

to

body

and

detach

radiator

after

removing

radiator

shroud

7

Remove

air

cleaner

assembly

from

carburetor

as

follows

1

Remove

fresh

air

duct

from

air

cleaner

2

Remove

hot

air

duct

from

air

cleaner

3

Loosen

air

cleaner

band

bolt

4

Disconnect

air

cleaner

to

air

pump

hose

at

air

cleaner

5

Disconnect

air

cleaner

ta

rocker

cover

hose

at

rocker

cover

6

Disconnect

air

cleaner

to

A

B

valve

hose

at

air

cleaner

7

Disconnect

air

cleaner

to

related

vacuum

hoses

at

air

cleaner

8

Disconnect

accelerator

control

wire

from

carburetor

9

Disconnect

the

following

cables

wires

and

hoses

Wire

to

auto

choke

heater

Wire

to

throttle

opener

cut

solenoid

or

throttle

switch

Wire

to

fuel

cut

solenoid

Wire

to

vacuum

switching

valve

High

tension

cable

between

igni

tion

coil

and

distributor

Battery

cable

to

starter

motor

Wire

to

distributor

Wire

to

thermal

transmitter

Wire

to

alternator

Engine

ground

cable

oil

pressure

switch

and

engine

harness

No

2

See

Fig

ER

3

o

1

Ground

cable

2

Engine

harness

No

2

3

Oil

pressure

switch

Fig

ER

3

EA368

Disconnecting

Cable

and

Wire

Fuel

hose

at

fuel

pump

and

fuel

return

hose

at

connection

Air

pump

air

cleaner

hose

Carbon

canister

hoses

Heater

inlet

and

outlet

hoses

if

so

equipped

ER

3

Vacuum

hose

of

brake

booster

at

intake

manifold

Air

conditioner

equipped

model

10

Remove

compressor

belt

To

remove

loosen

idler

pulley

nut

and

adjusting

bolt

1

Remove

air

pump

2

Remove

compressor

retaining

bolts

and

move

compressor

toward

fender

to

facilitate

removal

of

engine

Nole

Never

discharge

gas

from

com

pressor

while

work

is

being

per

formed

II

Compressor

EA478

Fig

ER

4

Location

of

Air

Compressor

3

Disconnect

vacuum

hose

of

air

conditioner

from

connector

of

intake

manifold

4

Remove

F

i

C

D

actuator

from

bracket

II

Remove

clutch

operating

cylin

der

from

clutch

housing

manual

trans

mission

only

dJ

Tightening

torque

Clutch

operating

cylinder

E

A3

to

clutch

housing

3

1

to

4

1

kg

22

to

30

ft

lbl

Fig

ER

5

Removing

Clutch

Operating

Cylinder

Page 200 of 548

12

Disconnect

speedometer

cable

from

rear

extension

housing

13

Remove

transmission

control

linkage

I

For

cars

equipped

with

manual

transmission

remove

gear

shift

control

lever

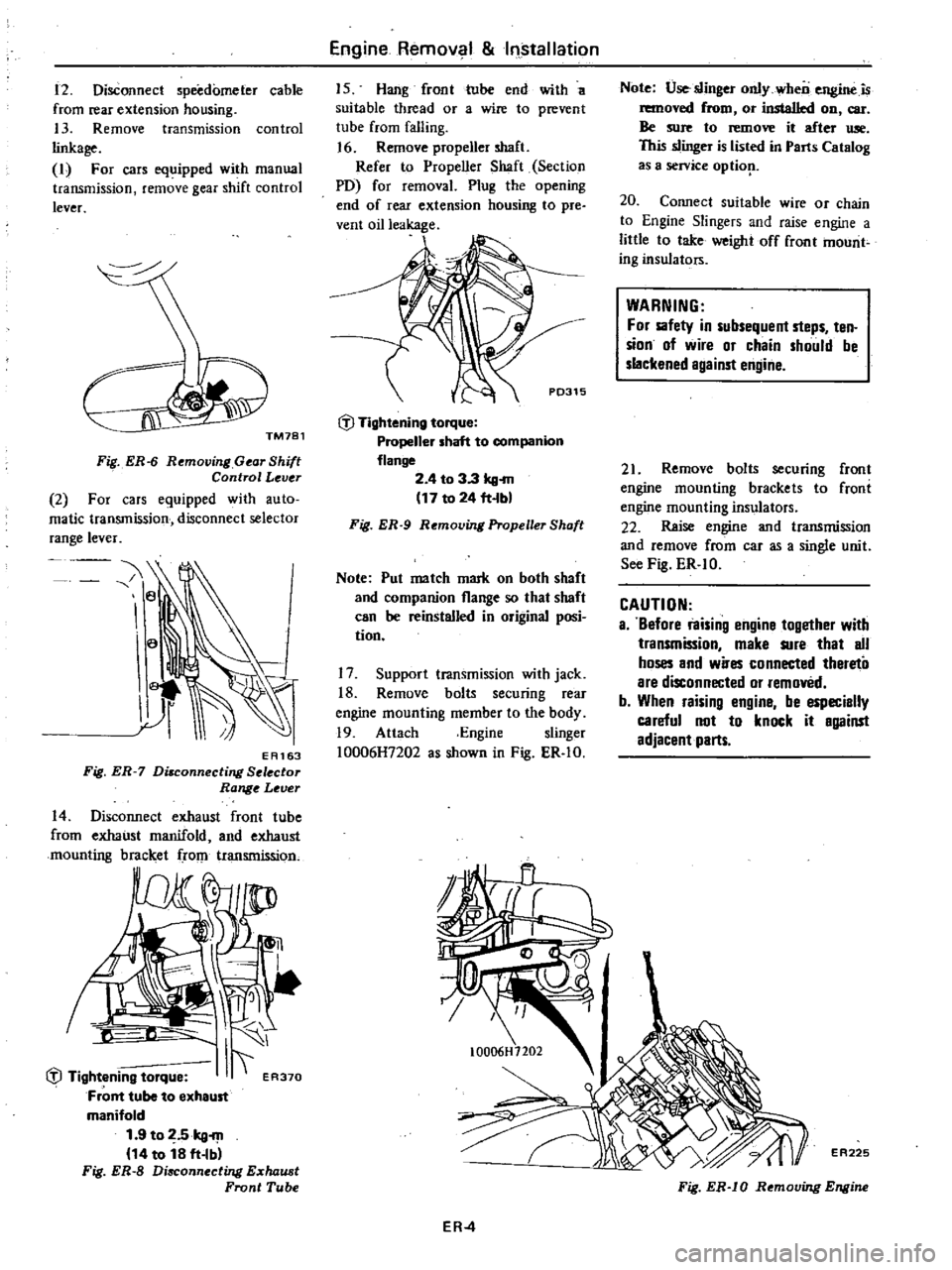

Fig

ER

6

Removing

Gear

Shift

Control

Lever

2

For

cars

equipped

with

auto

matic

transmission

disconnect

selector

range

lever

e

a

EA163

Fig

ER

7

Di8connecting

Selector

Range

Lever

14

Disconnect

exhaust

front

tube

from

exhaust

manifold

and

exhaust

mounting

bracket

rom

transmission

I

liJ

Tightening

torque

I

ER370

Front

tube

to

exheust

manifold

1

9

to

2

5kg

m

14

to

18

ft

Ibl

Fig

ER

S

Disconnecting

E

chaust

Front

Tube

Engine

Remov

1

Installation

15

Hang

front

tube

end

with

a

suitable

thread

or

a

wire

to

prevent

tube

from

falling

J

6

Remove

propeller

shaft

Refer

to

Propeller

Shaft

Section

PO

for

removal

Plug

the

opening

end

of

rear

extension

housing

to

pre

vent

oil

leakage

P0315

liJ

Tightening

torque

Propeller

shaft

to

companion

flange

2

4

to

3

3

kg

m

17

to

24

ft

bl

Fig

ER

9

Removing

Propeller

Shaft

Note

Pul

me

tch

mark

on

both

shaft

and

companion

flange

so

that

shoft

can

be

reinstalled

in

original

posi

tion

17

Support

transmission

with

jack

18

Remove

bolts

securing

rear

engine

mounting

member

to

the

body

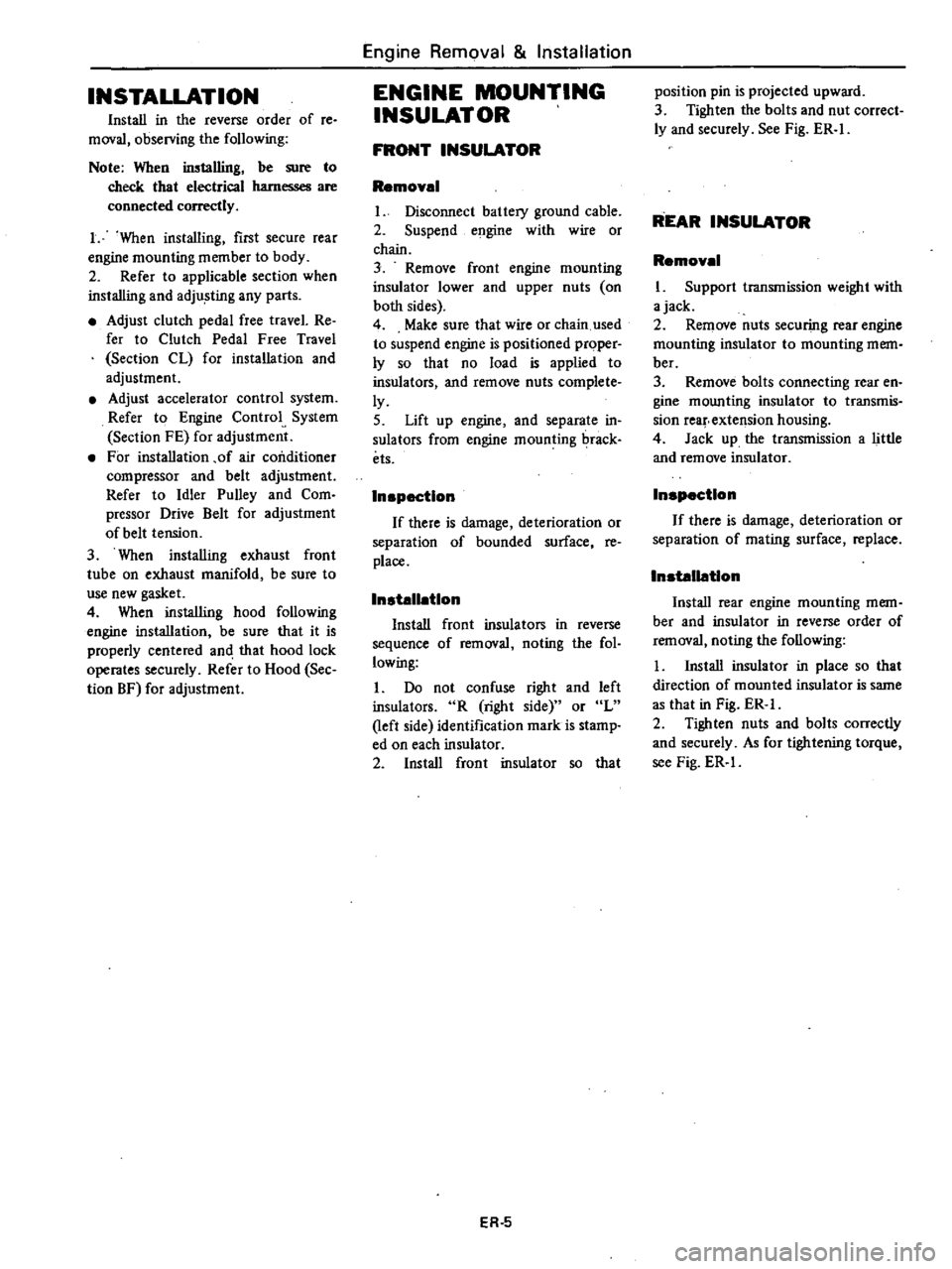

19

Attach

Engine

slinger

10006H7202

as

shown

in

Fig

ER

IO

Note

Use

slinger

only

wheo

engine

is

removed

from

or

installed

on

car

Be

sure

to

remove

it

efter

Ulle

This

slinger

is

listed

in

Parts

Cet

log

as

a

service

optiop

20

Connect

suitable

wire

or

chain

to

Engine

Slingers

and

raise

engine

a

little

to

take

weight

off

front

mount

ing

insulators

WARNING

For

sofety

in

subsequent

steps

ten

sion

of

wire

or

chain

should

be

slackened

against

engine

21

Remove

bolts

securing

front

engine

mounting

brackets

to

froni

engine

mounting

insulators

22

Reise

engine

and

transmission

and

remove

from

car

as

a

single

unit

See

Fig

ER

IO

CAUTION

a

Before

raising

engine

10gether

with

transmission

make

sure

that

all

hoses

and

wires

connected

thereto

are

disconnected

or

removed

b

When

raising

engine

be

especially

careful

not

to

knock

it

against

adjacent

parts

ER

4

EA225

Fig

ER

IO

Removing

Engine

Page 201 of 548

INSTALLATION

Install

in

the

reverse

order

of

re

moval

observing

the

following

Note

When

inslal1ing

be

sure

to

check

thaI

electrical

harnesses

are

connected

ly

1

When

installing

first

secure

rear

engine

mounting

member

to

body

2

Refer

to

applicable

section

when

installing

and

adjusting

any

parts

Adjust

clutch

pedal

free

travel

Re

fer

to

Clutch

Pedal

Free

Travel

Section

CL

for

installation

and

adjustment

Adjust

accelerator

control

system

Refer

to

Engine

Control

System

Section

FE

for

adjustment

For

installation

of

air

conditioner

compressor

and

belt

adjustment

Refer

to

Idler

Pulley

and

Com

pressor

Drive

Belt

for

adjustment

of

belt

tension

3

When

installing

exhaust

front

tube

on

exhaust

manifold

be

sure

to

use

new

gasket

4

When

installing

hood

following

engine

installation

be

sure

that

it

is

properly

centered

and

that

hood

lock

operates

securely

Refer

to

Hood

See

tion

BF

for

adjustment

Engine

Removal

Installation

ENGINE

MOUNTING

INSULATOR

FRONT

INSULATOR

Removal

Disconnect

battery

ground

cable

2

Suspend

engine

with

wire

or

chain

3

Remove

front

engine

mounting

insulator

lower

and

upper

nuts

on

both

sides

4

Make

sure

that

wire

or

chain

used

to

suspend

engine

is

positioned

prqper

ly

so

that

no

load

is

applied

to

insulators

and

remove

nuts

complete

ly

5

Lift

up

engine

and

separate

in

sulators

from

engine

mounting

rack

ets

Inspection

If

there

is

damage

deterioration

or

separation

of

bounded

surface

re

place

Installation

Install

front

insulators

in

reverse

sequence

of

removal

noting

the

fol

lowing

1

Do

not

confuse

right

and

left

insulators

R

right

side

or

L

left

side

identification

mark

is

stamp

ed

on

each

insulator

2

Install

front

insulator

so

that

ER

5

position

pin

is

projected

upward

3

Tighten

the

bolts

and

nut

correct

ly

and

securely

See

Fig

ER

I

REAR

INSULATOR

Removal

l

Support

transmission

weight

with

ajack

2

Remove

nuts

securing

rear

engine

mounting

insulator

to

mounting

mem

ber

3

Remove

bolts

connecting

rear

en

gine

mounting

insulator

to

transmis

sion

reaf

extension

housing

4

Jack

up

the

transmission

a

little

and

remove

insulator

Inspection

If

there

is

damage

deterioration

or

separation

of

mating

surface

replace

Installation

Install

rear

engine

mounting

mem

ber

and

insulator

in

reverse

order

of

removal

noting

the

following

I

Install

insulator

in

place

so

that

direction

of

mounted

insulator

is

same

as

that

in

Fig

ER

2

Tighten

nuts

and

bolts

correctly

and

securely

As

for

tightening

torque

see

Fig

ER

l

Page 202 of 548

Engine

Removal

Installation

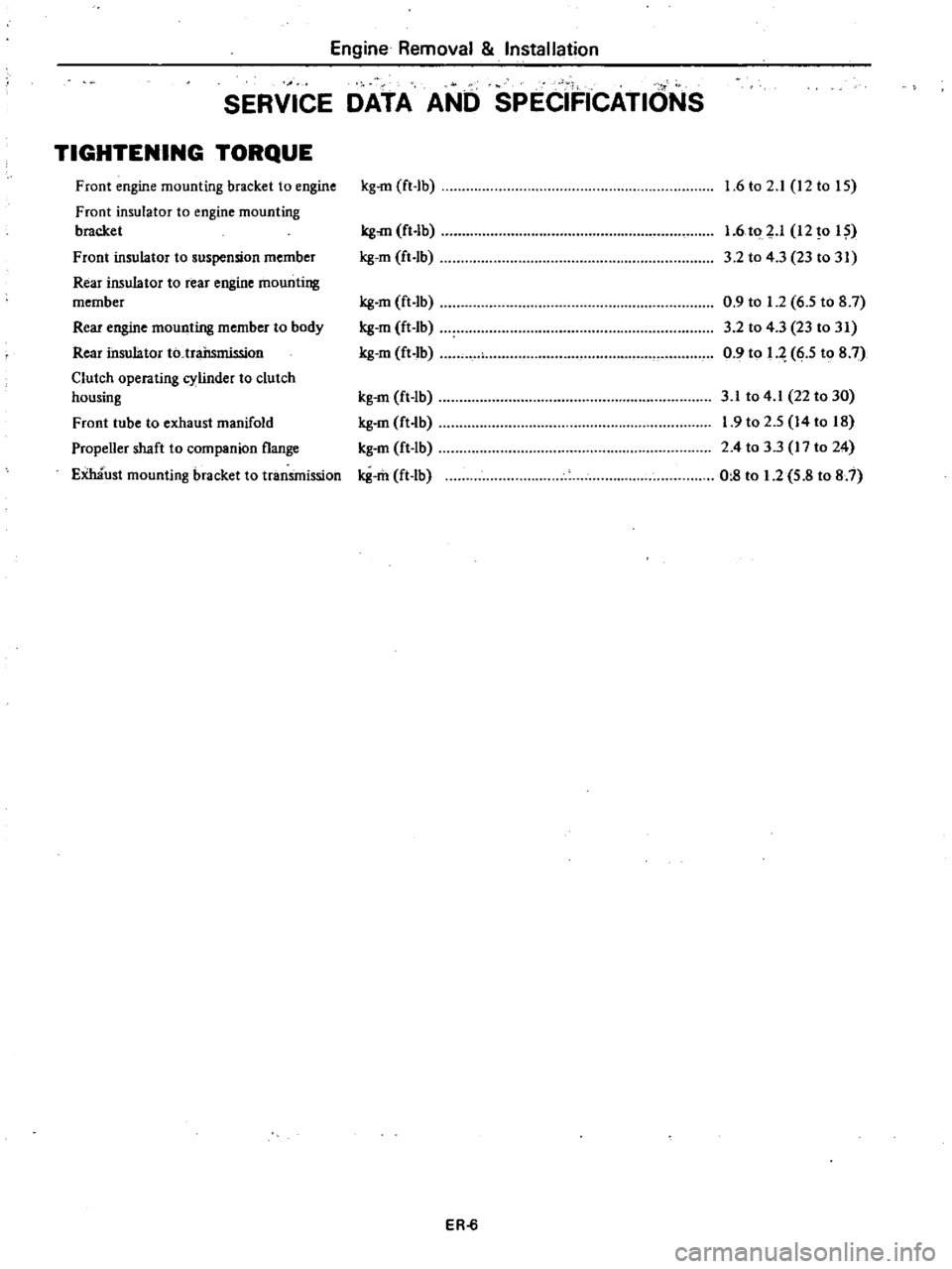

SERVICE

DATA

AND

SPECIFICATIONS

TIGHTENING

TORQUE

Front

engine

mounting

bracket

to

engine

Front

insulator

to

engine

mounting

bracket

Front

insulator

to

suspension

member

Rear

insulator

to

rear

engine

mounting

member

Rear

engine

mounting

member

to

body

Rear

insulator

to

trailsmission

Clutch

operating

cylinder

to

clutch

housing

Front

tube

to

exhaust

manifold

Propeller

shaft

to

companion

flange

Emaust

mounting

bracket

to

tranSmission

kg

rn

ft

lb

kg

rn

ft

Ib

gem

ft

Ib

g

m

ft

lb

g

m

ft

Ib

g

m

ft

Ib

kg

m

ft

Ib

g

m

ft

lb

kg

m

ft

lb

g

m

ft

Ib

ER

6

1

6

to

2

1

12

to

IS

1

6

to

p

12

0

I

3

2

to

4

3

23

to

31

0

9

to

1

2

6

5

to

8

7

3

2

to

4

3

23

to

31

0

9

to

q

6

5

to

8

7

3

1

to

4

1

22

to

30

1

9

to

2

5

14

to

18

2

4

to

3

3

17

to

24

0

8

to

1

2

5

8

to

8

7

Page 209 of 548

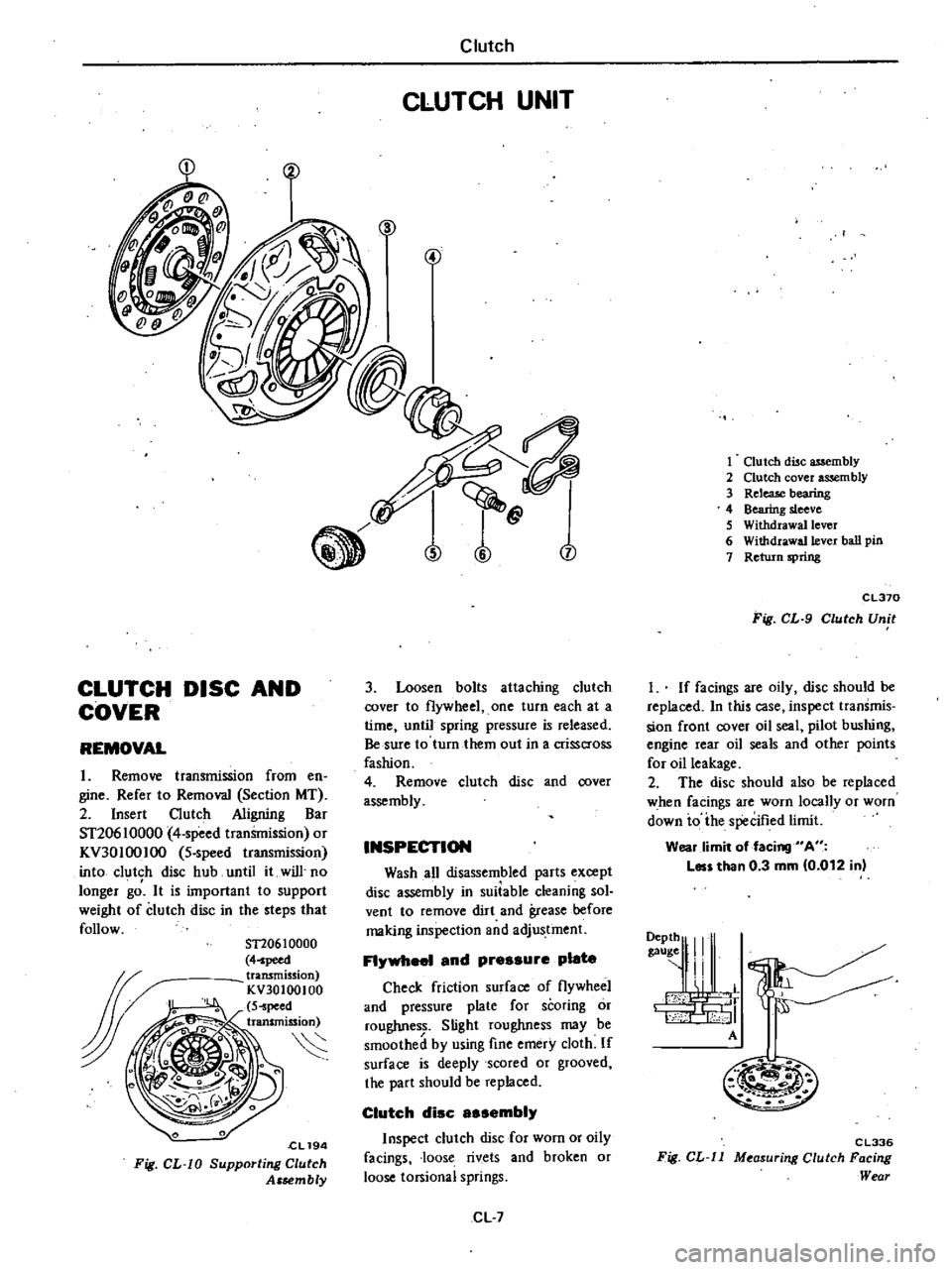

CLUTCH

DISC

AND

COVER

REMOVAL

1

Remove

transmission

from

en

gine

Refer

to

Removal

Section

MT

2

Insert

Clutch

Aligning

Bar

ST20610000

4

speed

tranSmission

or

KV30100IOO

5

speed

transmission

into

clutch

disc

hub

until

it

will

no

longer

gd

It

is

important

to

support

weight

of

clutch

disc

in

the

steps

that

follow

ST20610000

4

peed

transmission

KV30100100

S

peed

transmission

S

cL194

Fig

CL

W

Supporting

Clutch

Assembly

Clutch

CLUTCH

UNIT

n

j

3

Loosen

bolts

attaching

clutch

cover

to

flywheel

one

turn

each

at

a

time

until

spring

pressure

is

released

Be

sure

to

turn

them

out

in

a

crisscross

fashion

4

Remove

clutch

disc

and

cover

assembly

INSPECTION

Wash

all

disassembled

parts

except

disc

assembly

in

suiiable

cleaning

sol

vent

to

remove

dirt

and

grease

before

making

inspection

and

adjustment

FI

1

and

pressure

plate

Check

friction

surface

of

flywheel

and

pressure

plate

for

scoring

or

roughness

Slight

roughness

may

be

smoothed

by

using

fine

emery

cloth

If

surface

is

deeply

scored

or

grooved

the

part

should

be

replaced

Clutch

disc

sembi

Inspect

clutch

disc

for

worn

or

oily

facings

loose

rivets

and

broken

or

loose

torsional

springs

CL

7

1

Clutch

disc

assembly

2

Clutch

cover

assembly

3

ReleaJe

bearing

4

Bearing

sleeve

S

Withdrawal

lever

6

Withdrawa11ever

ball

pin

7

Return

spring

CL370

Fig

CL

9

Clutch

Unit

I

If

facings

are

oily

disc

should

be

replaced

In

this

case

inspect

transmis

sion

front

cover

oil

seal

pilot

bushing

engine

rear

oil

seals

and

other

points

for

oil

leakage

2

The

disc

should

also

be

replaced

when

facings

are

worn

locally

or

worn

down

io

ihe

specified

limit

Wear

limit

of

facing

A

Les

than

0

3

mm

0

012

in

9111

I

A

M

m

C

L336

Fig

CL

ll

M

asur

ng

Clutch

Facing

Wear

Page 214 of 548

Condition

Clutch

slips

Clutch

drags

Clutch

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Probable

cause

and

testing

Corrective

action

Slipping

of

clutch

may

be

noticeable

when

any

of

the

following

symptoms

is

encountered

during

operation

I

Car

will

not

respond

to

erigine

speed

during

acceleration

2

Insufficient

car

speed

3

Lack

of

power

during

uphill

driving

Some

of

the

above

conditions

may

also

be

attributable

to

engine

problem

First

determine

whether

engine

or

clutch

is

causing

the

problem

If

slipping

clutch

is

left

unheeded

wear

and

or

overheating

will

occur

on

clutch

facing

to

such

an

extent

that

it

is

no

longer

serviceable

TO

TEST

FOR

SLIPPING

CLurCH

proceed

as

follows

During

upgrade

havelling

run

engine

at

about

40

to

50

km

h

25

to

31

MPH

with

gear

shift

lever

in

3rd

speed

position

shift

into

highest

gear

and

t

the

same

time

rev

up

engine

If

clutch

is

slipping

car

willnot

readily

respond

to

depression

of

accelerator

pedal

Clutch

facing

warn

excessively

Oil

or

grease

on

clutch

facing

Warped

clutch

cover

or

pressure

plate

Replace

Replace

Repair

or

replace

Dragging

clu

tch

is

particularly

noticeable

when

shifting

gears

especially

into

low

gear

TO

TEST

FOR

DRAGGING

CLurCH

proceed

as

follows

I

Start

engine

Disengage

clutch

Shift

into

reverse

gear

and

then

into

Neutral

Gradually

increase

engine

speed

and

again

shift

into

reverse

gear

If

clutch

is

dragging

gear

grating

is

heard

when

shifting

gears

from

Neutral

into

Reverse

2

Stop

engine

and

shift

gears

Conduct

this

test

at

each

gear

position

3

In

step

2

gears

are

shifted

smoothly

except

1st

speed

position

at

idling

a

If

dragging

is

encountered

at

the

end

of

shifting

check

condition

of

synchro

mechanism

in

transmission

b

If

dragging

is

encountered

at

the

beginning

of

shifting

proceed

to

step

4

below

4

Push

change

lever

toward

Reverse

ide

depress

pedal

to

check

for

free

travel

of

pedal

a

If

pedal

can

be

depressed

further

check

clutch

for

condition

b

If

pedal

cannot

be

depressed

further

proceed

to

step

5

below

5

Check

clutch

control

pedal

height

pedal

free

play

free

travel

withdrawal

lever

play

etc

If

any

abnormal

condition

does

not

exist

and

if

pedal

cannot

be

depressed

further

check

clutch

for

condition

Clutch

disc

runout

or

warped

Wear

or

rust

on

hub

splines

in

clutch

disc

Diaphragm

spring

toe

height

out

of

adjustment

or

toe

tip

worn

Worn

or

improperly

installed

parts

Replace

Clean

and

lubricate

with

grease

or

replace

Adjust

or

replace

Repair

or

replace

CL12

Page 215 of 548

Condition

Clutch

chatters

Noisy

clutch

Clutch

grabs

Clutch

Probable

cause

and

testing

Corr

ctive

action

Clutch

chattering

is

usually

noticeable

when

car

is

just

rolled

off

with

clutch

parlially

engaged

Weak

or

broken

clutch

disc

torsion

spring

Oil

or

grease

on

clutch

facing

Clutch

facing

out

of

proper

contact

or

clutch

disc

runout

Loose

rivets

Warped

pressure

plate

or

clutch

cover

surface

Unevenness

of

diaphragm

spring

toe

height

Loose

engine

mounting

or

deteriorated

rubber

A

noise

is

heard

after

clutch

is

disengaged

Damaged

release

bearing

A

noise

is

heard

when

clutch

is

disengaged

Insufficient

grease

on

the

sliding

surface

of

bearing

sleeve

Clutch

cover

and

bearing

are

not

in

stalled

correctly

Replace

Replace

Replace

Replace

Repair

or

replace

Adjust

or

replace

Retighten

or

replace

I

Replace

Apply

grease

Adjust

A

noise

is

heard

when

car

is

suddenly

rolled

off

with

clutch

partially

engaged

Damaged

pilot

bushing

I

Replace

When

grabbing

of

clutch

occurs

car

will

not

roll

off

smoothly

from

a

standing

start

or

clutch

will

be

engaged

before

clutch

pedal

is

fully

depressed

Oil

or

grease

on

clutch

facing

Clutch

facing

worn

or

loose

rivets

Wear

or

rust

on

splines

in

drive

shaft

and

clutch

disc

Warped

flywheel

or

pressure

plate

Loose

mountings

for

engine

or

power

train

units

CL13

Replace

Replace

Clean

or

replace

Repair

or

replace

Retighten