ECO mode DATSUN 210 1979 User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 105 of 548

EF053A

Fig

EF

50

Removing

JWrneu

of

Solenoid

valve

2

Connect

rubber

hose

between

vacuum

gauge

and

intake

manifold

Note

A

quick

response

type

boost

gauge

such

as

Bourdon

s

type

is

recommended

a

mercury

type

manometer

should

not

be

used

3

Warm

up

engine

until

it

reaches

operating

temperature

Then

confirm

that

engine

idling

speed

is

specified

valve

Engine

idling

speed

Manual

transmission

700

rpm

Engine

Fuel

Automatic

transmission

in

0

position

650rpm

Note

On

automatic

transmission

models

never

race

engine

when

gearshift

lever

is

in

0

position

4

Run

engine

under

no

load

In

crease

engine

speed

to

3

000

to

3

500

rpm

then

quickly

close

throttle

valve

S

At

the

time

manifold

vacuum

pressure

increases

abruptly

to

600

rnmHg

23

6

inHg

or

above

and

then

gradually

decreases

to

the

level

set

at

idling

a

Maximum

negative

pressure

b

Operating

pressure

c

Idling

pressure

Nega

ive

pressure

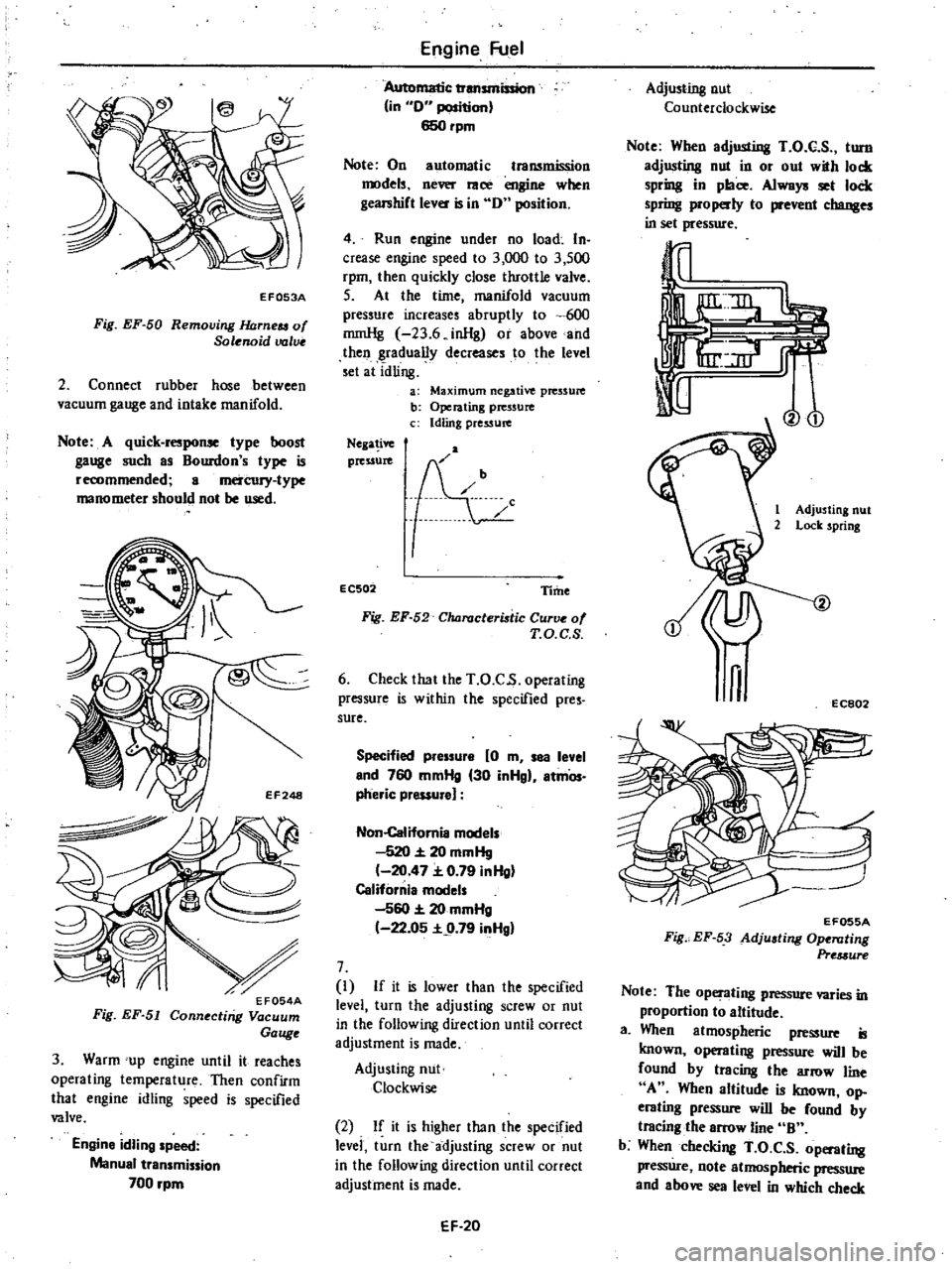

EC502

Time

Fig

EF

52

Characteristic

Curve

of

T

O

C

S

6

Check

that

the

T

O

C

s

operating

pressure

is

within

the

specified

pres

sure

Specified

pressure

0

m

sea

level

end

760

mmHg

30

inHgl

atmOs

pheric

pressure

Non

Califomia

models

520

20

mmHg

20

47

0

79

inHg

California

models

560

20

mmHg

22

05

9

79

inHgl

7

I

If

it

is

lower

than

the

specified

level

turn

the

adjusting

screw

or

nut

in

the

following

direction

until

correct

adjustment

is

made

Adjusting

nut

Clockwise

2

If

it

is

higher

than

the

specified

levei

turn

the

adjusting

screw

or

nut

in

the

following

direction

until

correct

adjustment

is

made

EF

20

Adjusting

nut

Counterclockwise

Note

When

adjusting

T

O

C

S

turn

adjusting

nut

in

or

out

with

lock

spring

in

place

Always

set

lock

spring

properly

to

prevent

changes

in

set

pressure

Vo

1

Adjusting

nut

2

Lock

spring

n

EC802

EF055A

Fig

EF

53

Adjusting

Ope

llting

Pre

3ure

Note

The

operating

pressure

varies

in

proportion

to

altitude

a

When

atmospheric

pressure

is

known

operating

pressure

will

be

found

by

tracing

the

arrow

line

A

When

altitude

is

known

op

erating

pressure

will

be

found

by

tracing

the

arrow

line

B

b

When

checking

T

O

C

S

operating

pressure

note

atmospheric

pressure

and

above

sea

level

in

which

check

Page 109 of 548

En9ineFuel

DISASSEMBLY

AND

ASSEMBLY

Except

FU

model

A

JS

@fB

@

Choke

chamber

@

Center

body

@

Throttle

chamber

1

Servo

diaphragm

of

throttle

opener

2

Dash

pot

3

Automatic

choke

cover

4

Automatic

choke

I

ody

and

diaphragm

chamber

S

Accelerating

pump

lever

6

Auxiliary

valve

7

Venturi

stopper

screw

8

Primary

and

secondary

maU

venturi

9

Secondary

slow

jet

I

I

l

c

I

liO

JCJ

@

c

1

@

11

i

I

rJ

@

10

Power

valve

11

Secondary

main

air

bleed

12

Primary

main

air

bleed

13

Injector

weight

14

Primary

slow

air

bleed

15

Accelerating

pump

16

Plug

17

Primary

slow

jet

18

Needle

valve

19

Float

20

Anti

c1ieseling

solenoid

valve

21

Primary

main

jet

22

Secondary

main

jet

23

Idle

limiter

cap

24

Idle

adjust

screw

25

Spring

26

Throttle

adjust

screw

27

Spring

28

Primary

and

secondary

throttle

valves

29

Fast

idle

adjust

screw

30

Accelerating

pump

rod

31

Throttle

retum

spring

32

Stroke

limiter

Note

Do

nOt

remove

the

puts

marked

with

an

uterisk

EF420A

Fig

EF

60

c

rburetor

EF

24

Page 110 of 548

FU

model

Engine

Fuel

If

@

Choke

chamber

@

Ceo

ter

body

@

Throttle

chamber

1

Dash

pot

2

An

tomatic

choke

cover

3

Automatic

choke

body

and

diaphragm

chamber

4

Throttle

valve

switch

assembly

5

Throttle

valve

switch

adjust

screw

6

Fast

idle

adjust

screw

7

Secondary

slow

jet

EF567A

8

Secondary

small

venturi

9

Primary

small

venturi

10

Power

valve

11

Secondary

main

air

bleed

12

Plug

13

Primary

main

air

bleed

14

Plug

15

Injector

weight

16

Primary

slow

air

bleed

17

Accelerating

pump

18

Needle

valve

19

Plug

20

Primary

slow

jet

21

Float

22

Anti

dieseling

solenoid

valve

23

Secondary

main

jet

24

Primary

main

jet

25

Idle

limiter

cap

26

Idle

adjust

screw

27

Throttle

adjust

screw

28

Vaeuum

screw

29

Primary

and

secondary

throttle

valves

Note

Do

not

remove

the

parts

muked

with

an

utemk

Fig

EF

61

Carburetor

EF

25

Page 112 of 548

Engine

Fuel

Choke

chamber

parts

FU

model

Except

FU

model

R

5

7

@

l

i

1

I

ft

Y

mJ

r

ft

1

@

@

1

EF421A

Tl@@

EF568A

EF

27

1

Secondary

slow

jet

2

Plug

3

Power

valve

bleed

d

mam

au

4

Seeon

ary

bleed

P

imary

maID

aIr

5

r

ight

6

Injector

we

7

Plug

t

8

Primary

slow

Je

d

valve

9

Anti

dieseling

solenOl

t

O

P

imary

malO

Je

1

r

main

Jet

11

Secondary

iliary

valve

12

Aux

screw

13

Venturi

stopper

duv

small

nd

seeon

J

14

Prima

a

ventuns

tl

not

J

eIIlove

the

p

Note

Do

tIt

an

asterISk

markedwt

CENTER

BODY

PARTS

slow

jet

1

Secondary

aU

yen

turi

2

Secondary

sm

Yen

turi

3

Primary

small

4

Power

valve

n

air

bleed

5

Secondary

m3J

6

Plug

on

air

bleed

7

Primary

mm

8

Plug

9

nJ

eetor

weight

pump

10

Accelerating

11

Plug

et

12

Primary

l

w

J

lenoid

valve

13

An

ti

dieseling

50

mamJet

14

Secondary

t

IS

Primary

mamJc

ill

y

valve

16

Aux

ar

the

parts

Do

not

remOVe

t

Note

th

an

utens

marked

WI

EF

63

Center

Body

FIg

Page 113 of 548

Engine

Fuel

Throttle

chamber

parts

Except

FU

model

1

1

4

@

EF087A

1

Throttle

return

spring

2

lluottlc

opencr

adjusuctew

3

Accelerating

pump

rod

4

Fa

t

idle

adjust

5CICW

5

Primary

and

secondary

throttle

valve

6

Sprin8

1

Idle

adjust

screw

8

Idle

limiter

cap

9

Spring

10

Throttle

adjust

rew

oG

I

l

I

r

Y

Note

Do

not

remove

the

puts

ked

with

an

uterisk

FU

model

on

TIlROTfLE

CHAMBER

PARTS

1

Throttle

valve

switch

adjust

screw

2

Fast

idle

adjust

screw

3

limiter

cap

4

Idle

adjust

screw

S

Throttle

adjust

screw

6

Vacuum

screw

7

Primary

and

secondary

throttle

valves

Note

Do

not

remove

the

putl

marked

with

an

uterist

EF864

Fig

EF

64

Throttle

Chamber

EF

28

Page 117 of 548

Engine

Fuel

SERVICE

DATA

AND

SPECIFICATIONS

GENERAL

SPECIFICATIONS

CARBURETOR

California

models

Non

caJ

ifornia

model

Manual

tranlDlWion

Automatic

transmission

Manual

transmission

FU

model

utomatic

transmission

Type

DCH306

6t

DCH306

63

DCH306

60E

DCH306

67

DCH306

68

3

DCH306

69

1

DCH306

60

2

DCH306

12

4

Primary

Secondary

Primary

Secondary

Primuy

Secondary

Primary

Secondary

Primary

Secondary

Outer

diameter

26

1

02

30

1

18

26

1

02

30

1

18

26

1

02

30

1

18

26

1

02

30

1

18

26

1

02

30

1

18

mm

in

Venturi

diameter

23

0

9t

27

1

06

23

0

91

27

1

06

23

0

91

27

1

06

22

0

87

27

1

06

23

0

91

27

1

06

mm

in

Main

jet

107

145

107

1145

106

145

1107

145

105

1145

104

2

t04

4

Main

air

bleed

95

180

95

180

1110

80

65

1M

195

80

Slow

jet

1145

150

145

150

145

150

146

150

45

150

Powerjet

143

43

140

148

2

48

138

140

4

1

With

A15

engine

2

4

For

Canada

models

3

Common

to

models

with

A14

and

AlS

engines

except

Canada

INSPECTION

AND

ADJUSTMENT

A

T

C

AIR

CLEANER

Air

con

trol

valve

partially

opens

Air

control

valve

fully

opens

Oc

OF

Oc

F

38

to

54

100

to

129

Above

55

131

IDLE

COMPENSATOR

Idle

compensator

partially

opens

Bi

metal

No

I

Bi

metal

No

2

Idle

compensator

fully

opens

Bi

metal

No

I

Bi

metal

No

2

Oc

OF

60

to

70

140

to

158

70

to

80

158

to

176

Oc

OF

Above

70

158

Above

80

176

FUEL

PUMP

Fuel

pressure

Fuel

pump

capacity

kgfcm2

psi

cc

cu

in

min

at

rpm

0

27

3

8

450

27

46

1

000

EF

32

Page 118 of 548

a

California

models

Non

california

modeli

Except

Canada

Canada

III

C

A4

A15

A14

AI5

A

4

a

M

T

AfT

AfT

M

T

A

T

M

T

FU

A

r

MfT

AfT

11

1

4

DCH306

61

DCH306

63

DCH306

69

DCH306

60E

DCH306

68

DCH306

67

DCH306

68

DCH306

60

DCH306

12

0

a

Fuel

level

adjustment

Fuel

level

from

top

of

19

0

75

19

0

75

19

0

75

19

0

75

19

0

75

19

0

75

19

0

75

19

0

75

19

0

75

carburetor

body

mm

in

H

Gap

between

vlave

stem

and

float

scat

mm

in

t5

0

59

IS

0

59

IS

0

59

IS

0

59

IS

0

59

IS

0

59

IS

0

59

IS

0

59

IS

0

59

H

1

3

to

1

7

1

3

to

1

7

1

3

to

1

7

1

3

to

1

7

1

3

to

1

7

1

3to17

1

3

to

1

7

1

3

to

1

7

1

3

to

1

7

h

0

051

to

0

051

to

0

051

to

0

051

to

0

051

to

0

051

to

0

051

ro

0

051

to

0

051

to

0

067

0

067

0

067

0

067

0

067

0

067

0

067

0

067

0

067

Bi

metal

setting

Center

of

Center

of

Center

of

Center

of

Center

of

Center

of

Center

of

Center

of

Center

of

Bi

metal

setting

index

mark

index

mark

index

mark

index

mark

index

mark

index

mark

index

mark

index

mark

index

mark

Bi

metal

resistance

3

7

ro

8

9

3

7

to

8

9

3

7

to

8

9

3

7

to

8

9

3

7

to

8

9

3

7

to

8

9

3

7

to

8

9

3

7

to

8

9

3

7

to

8

9

at

210C

700F

n

m

Fast

idle

adjustment

Fast

idle

0

73

to

0

84

1

00

to

1

14

1

00

to

1

14

0

73

to

0

84

1

00

to

1

14

0

73

to

0

84

1

00

to

1

14

0

73

to

0

84

m

earn

2nd

step

1

00

to

1

14

CO

T1

0

0287

to

0

0394

to

0

0394

to

0

0287

to

0

0394

to

0

0287

to

0

0394

to

0

0287

to

0

0394

to

S

W

Gap

between

throttle

valve

and

0

0331

0

0449

0

0449

0

0331

0

0449

0

0331

0

0449

0

0331

0

0449

Cl

carburetor

body

mm

in

Fast

idle

speed

at

2nd

earn

step

1

900

to

2

700

2

400

to

3

200

2

400

to

3

200

1

900

to

2

700

2

400

to

3

200

1

900

to

2

700

2

400

to

3

200

1

900

to

2

700

2

400

to

3

200

Cl

rpm

Vacuum

break

adjustment

1

80

to

1

98

1

80

to

1

98

1

80

to

1

98

1

80

to

1

98

1

80

to

1

98

1

98

to

2

16

1

80

to

1

98

1

80

to

1

98

1

80

to

1

98

Gap

between

choke

valve

0

0709

to

0

0709

to

0

0709

to

0

0709

to

0

0709

to

0

0780

to

0

0709

to

0

0709

to

0

0709

to

and

carburetor

body

mm

in

0

0780

0

0780

0

0780

0

0780

0

0780

0

0850

0

0780

0

0780

0

0780

Choke

unloader

adjustment

Gap

between

choke

valve

and

2

36

0

0929

2

36

0

0929

2

36

0

0929

2

36

0

0929

2

36

0

0929

2

17

0

0854

2

36

0

0929

2

36

0

0929

2

36

0

0929

carburetor

body

mmOn

Interlock

opening

of

primary

and

5

83

0

2295

5

83

0

2295

5

83

0

2295

5

83

0

2295

5

83

0

2295

5

83

0

2295

5

83

0

2295

5

83

0

2295

5

83

0

2295

secondary

throttle

valves

mm

On

Dash

pot

adjustment

1

900

to

2

100

1

900

to

2

100

1

900

to

2

100

2

300

to

2

500

1

900

to

2

100

1

900

to

2

100

1

900

to

2

100

2

300

to

2

500

1

900

to

2

100

without

loading

rpm

Throttle

opener

operating

pressure

560

20

560

20

560

20

520

20

520

20

520

20

5

0

20

520

20

0

m

sea

level

and

760

mmHg

22

05

22

05

22

05

20

47

20

47

20

47

20

47

20

47

29

9

inHg

atmospheric

pressure

0

79

0

79

0

79

0

79

0

79

0

79

0

79

0

79

mmHg

inHg

Page 128 of 548

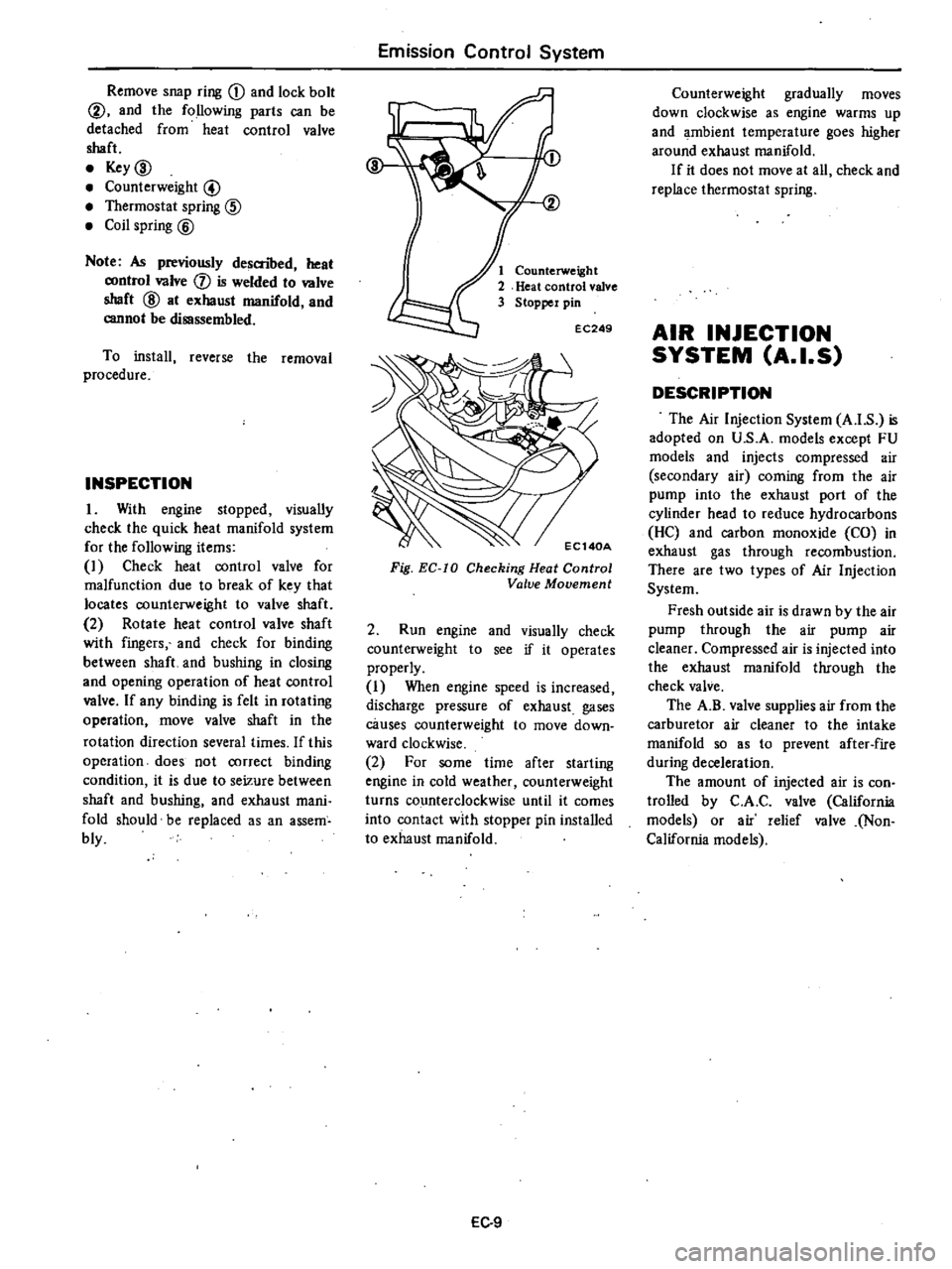

Remove

snap

ring

CD

and

lock

bolt

@

and

the

following

parts

can

be

detached

from

heat

control

valve

shaft

Key

ID

Counterweight

@

Thermostat

spring

@

Coil

spring

@

Note

As

previously

descnbed

heat

control

valve

j

is

welded

to

valve

shaft

@

at

exhaust

manifold

and

cannot

be

disassembled

To

install

reverse

the

removal

procedure

INSPECTION

1

With

engine

stopped

visually

check

the

quick

heat

manifold

system

for

the

following

items

I

Check

heat

control

valve

for

malfunction

due

to

break

of

key

that

locates

counterweight

to

valve

shaft

2

Rotate

heat

control

valve

shaft

with

fingers

and

check

for

binding

between

shaft

and

bushing

in

closing

and

opening

operation

of

heat

control

valve

If

any

binding

is

felt

in

rotating

operation

move

valve

shaft

in

the

rotation

direction

several

times

If

this

operation

does

not

correct

binding

condition

it

is

due

to

seizure

between

shaft

and

bushing

and

exhaust

mani

fold

should

be

replaced

as

an

assem

bly

Emission

Control

System

Counterweight

Heat

control

valve

Stopper

pin

EC249

Fig

EC

IO

Checking

Heat

Control

Valve

Movement

2

Run

engine

and

visually

check

counterweight

to

see

if

it

operates

properly

I

When

engine

speed

is

increased

discharge

pressure

of

exhaust

gases

causes

counterweight

to

move

down

ward

clockwise

2

For

some

time

after

starting

engine

in

cold

weather

counterweight

turns

counterclockwise

until

it

comes

into

contact

with

stopper

pin

installed

to

exhaust

manifold

EC

9

Counterweight

gradually

moves

down

clockwise

as

engine

warms

up

and

ambient

temperature

goes

higher

around

exhaust

manifold

If

it

does

not

move

at

all

check

and

replace

thermostat

spring

AIR

INJECTION

SYSTEM

A

I

S

DESCRIPTION

The

Air

Injection

System

A

I

S

is

adopted

on

U

S

A

models

except

FU

models

and

injects

compressed

air

secondary

air

coming

from

the

air

pump

into

the

exhaust

port

of

the

cylinder

head

to

reduce

hydrocarbons

He

and

carbon

monoxide

CO

in

exhaust

gas

through

recombustion

There

are

two

types

of

Air

Injection

System

Fresh

outside

air

is

drawn

by

the

air

pump

through

the

air

pump

air

cleaner

Compressed

air

is

injected

into

the

exhaust

manifold

through

the

check

valve

The

A

B

valve

supplies

air

from

the

carburetor

air

cleaner

to

the

intake

manifold

so

as

to

prevent

after

fire

during

deceleration

The

amount

of

injected

air

is

con

trolled

by

C

A

C

valve

California

models

or

air

relief

valve

Non

California

models

Page 130 of 548

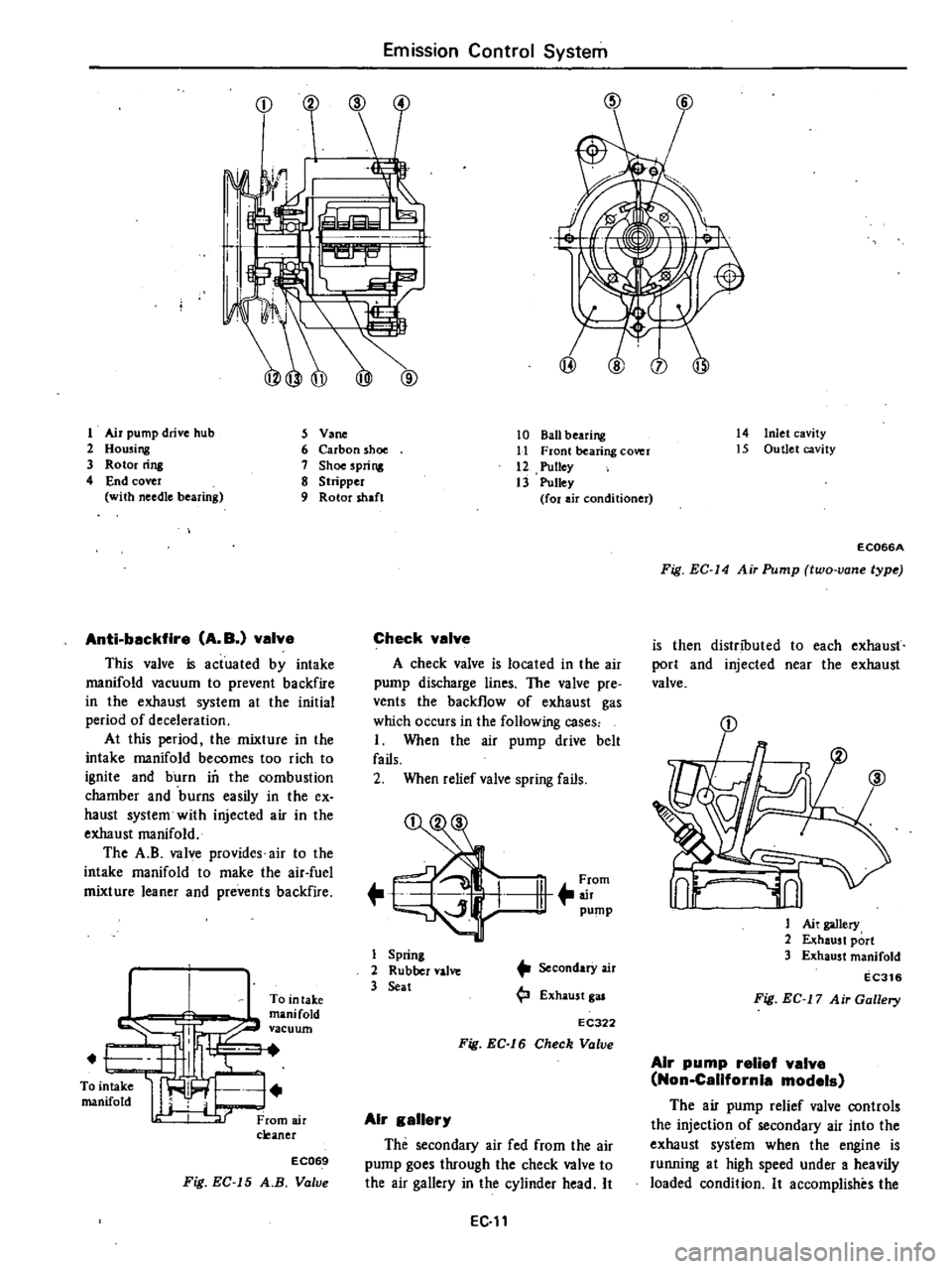

Emission

Control

System

r

@

@

CD

L

I

1

Air

pump

drive

hub

5

V

ne

2

Housing

6

Carbon

shoe

3

Rotor

rins

7

Shoe

spri

ng

4

End

cover

8

Stripper

with

needle

bearing

9

Rotor

shaft

Anti

backfire

A

B

valve

This

valve

is

actuated

by

intake

manifold

vacuum

to

prevent

backfire

in

the

exhaust

system

at

the

initial

period

of

deceleration

At

this

period

the

mixture

in

the

intake

manifold

becomes

too

rich

to

ignite

and

burn

in

the

combustion

chamber

and

burns

easily

in

the

ex

haust

system

with

injected

air

in

the

exhaust

manifold

The

A

B

valve

provides

air

to

the

intake

manifold

to

make

the

air

fuel

mixture

leaner

and

prevents

backfire

To

in

take

manifold

vacuum

EC069

Fig

EC

15

A

B

Valve

10

Ball

bearing

11

Front

bearing

cOYer

12

Pulley

13

Pulley

for

air

conditioner

Check

valve

A

check

valve

is

located

in

the

air

pump

discharge

lines

The

valve

pre

vents

the

backflow

of

exhaust

gas

which

occurs

in

the

following

cases

I

When

the

air

pump

drive

belt

fails

2

When

relief

valve

spring

fails

1

11

rom

pump

1

Spring

2

Rubber

valve

3

Seat

SecondarY

air

4

J

Exhaust

gas

EC322

Fig

EC

16

Check

Valve

Air

gallery

The

secondary

air

fed

from

the

air

pump

goes

through

the

check

valve

to

the

air

gallery

in

the

cylinder

head

It

EC

lt

14

Inlet

cavity

15

Outlet

cavity

EC066A

Fig

EC

14

Air

Pump

two

vane

lype

is

then

distributed

to

each

exhaust

port

and

injected

near

the

exhaust

valve

0

iJl

Ai

gallery

2

Exhaust

port

3

Exhaust

manifold

EC316

Fig

EC

17

Air

Gallery

Air

pump

relief

valve

Non

California

models

The

air

pump

relief

valve

controls

the

injection

of

secondary

air

into

the

exhaust

system

when

the

engine

is

running

at

high

speed

under

a

heavily

loaded

condition

It

accomplishes

the

Page 131 of 548

following

functions

without

affecting

the

effectiveness

of

the

exhaust

emis

sion

control

system

Minimizes

exhaust

gas

tempera

ture

rise

2

Minimizes

horsepower

losses

reo

sulting

from

air

injection

into

the

exhaust

system

3

Protects

pump

from

excessive

back

pressure

To

carburetor

air

cleaner

Secondary

ir

Not

actuated

To

carburetor

air

cleaner

J

l

Secondary

sir

Actuated

EC294

Fig

EC

18

Air

Pump

Relief

Valve

c

A

C

valve

Californiamodels

The

C

A

C

valve

controls

the

quantity

of

secondary

air

fed

from

the

air

pump

according

to

the

load

condi

tion

and

it

discharges

the

secondary

air

into

the

atmosphere

to

prevent

overheating

of

the

catalytic

converter

This

valve

is

operated

by

intake

manifold

vacuum

and

air

pump

dis

charge

pressure

When

intake

manifold

vacuum

is

small

or

in

the

high

load

range

the

No

2

valve

opens

when

it

is

great

or

in

the

low

load

range

the

No

I

valve

opens

If

air

pump

discharge

pressure

is

large

or

the

engine

is

running

at

a

high

speed

the

No

3

valve

opens

admitting

the

air

pump

discharge

pressure

to

the

No

2

dia

phragm

chamber

of

the

C

A

C

valve

mission

Control

System

and

opening

ihe

No

i

valve

At

this

point

the

No

2

valve

serves

as

a

relief

valve

F

111

air

pump

No

3

valve

EC787

Fig

EC

19

C

A

C

Valve

I

Engine

in

low

speed

and

light

load

When

the

engine

is

operating

under

these

conditions

intake

vacuum

is

high

The

No

2

valve

unitized

with

the

No

I

diaphragm

is

lifted

by

the

intake

manifold

vacuum

pushing

up

the

No

I

valve

These

valves

will

then

stop

at

a

position

where

a

balanced

condition

exists

between

air

pump

discharge

pressure

an

d

spring

tension

acting

on

the

No

I

and

No

2

valves

The

No

2

jiaphragm

however

does

not

move

due

to

low

engine

speed

low

air

pump

discharge

pressure

and

spring

tension

acting

on

the

No

3

valve

For

this

reason

these

valves

are

brought

to

a

balanced

condition

To

intake

manifold

t

i

l

3

Spring

4

ValveNo

3

5

Di

phragm

No

I

I

@

6

Spring

7

Valve

No

1

8

Valve

No

2

EC683

Fig

EC

20

Operation

of

C

A

C

Valve

1

2

Engine

in

low

speed

and

heavy

load

EC12

Wheo

the

engine

is

operating

under

these

cooditions

intake

manifold

vacuum

is

low

and

all

valves

are

balanced

t

To

intake

manUol

U

E

ii

ji

j

Ii

5

LL

jj

Ii

JI

l

Jij

ulJC

1t

To

atmosphere

EC685

Fig

EC

21

Operation

of

C

A

C

Valve

2

3

Engine

in

high

speed

and

middle

load

When

the

engine

is

operating

under

these

conditions

intake

manifold

vacuum

lies

midway

between

1

and

2

above

The

No

3

valve

moves

to

the

left

because

of

high

air

pump

discharge

pressure

To

intake

manifold

t

L

J

f

E

bt

I

5

tfi

11

I

LJr

To

tmg

J

j

1

EC

4

Fig

EC

22

Operation

of

C

A

C

Volve

3

REMOVAL

AND

INSTALLATION

Air

pump

air

cleaner

Loosen

nuts

securing

air

pump

air

cleaner

to

bracket

then

detach

air

cleaner

from

bracket

Air

cleaner

filter

and

air

cleaner

lower

body

are

built

into

a

unit

construction

Replace

air

cleaner

filter

and

lower

body

as

an

assembly