torque DATSUN 210 1979 Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 86 of 548

DATSUN

210

Model

8310

Series

SECTIONEF

ENGINE

FUEL

CONTENTS

AUTOMATIC

TEMPERATURE

CONTROL

A

T

C

AIR

CLEANER

DESCRIPTION

OPERATION

REMOVAL

AND

INSTAllATION

INSPECTION

IDLE

COMPENSATOR

DESCRIPTION

INSPECTION

FUEL

FILTER

DESCRIPTION

FUEL

PUMP

OPERATING

TEST

REMOVAL

AND

INSTAllATION

DISASSEMBLY

EF

2

EF

2

EF

2

EF

3

EF

4

EF

5

EF

5

EF

5

EF

6

EF

6

EF

6

EF

6

EF

7

EF

7

INSPECTION

ASSEMBLY

CARBURETOR

DESCRIPTION

STRUCTURE

AND

OPERATION

INSPECTION

AND

ADJUSTMENT

MAJOR

SERVICE

OPERATION

TROUBLE

DIAGNOSES

AND

CORRECTIONS

SERVICE

DATA

AND

SPECIFICATIONS

GENERAL

SPECIFICATIONS

INSPECTION

AND

ADJUSTMENT

TIGHTENING

TORQUE

EF

7

EF

7

EF

B

EF

B

EF

B

EF

14

EF

23

EF

30

EF

32

EF

32

EF

32

EF

34

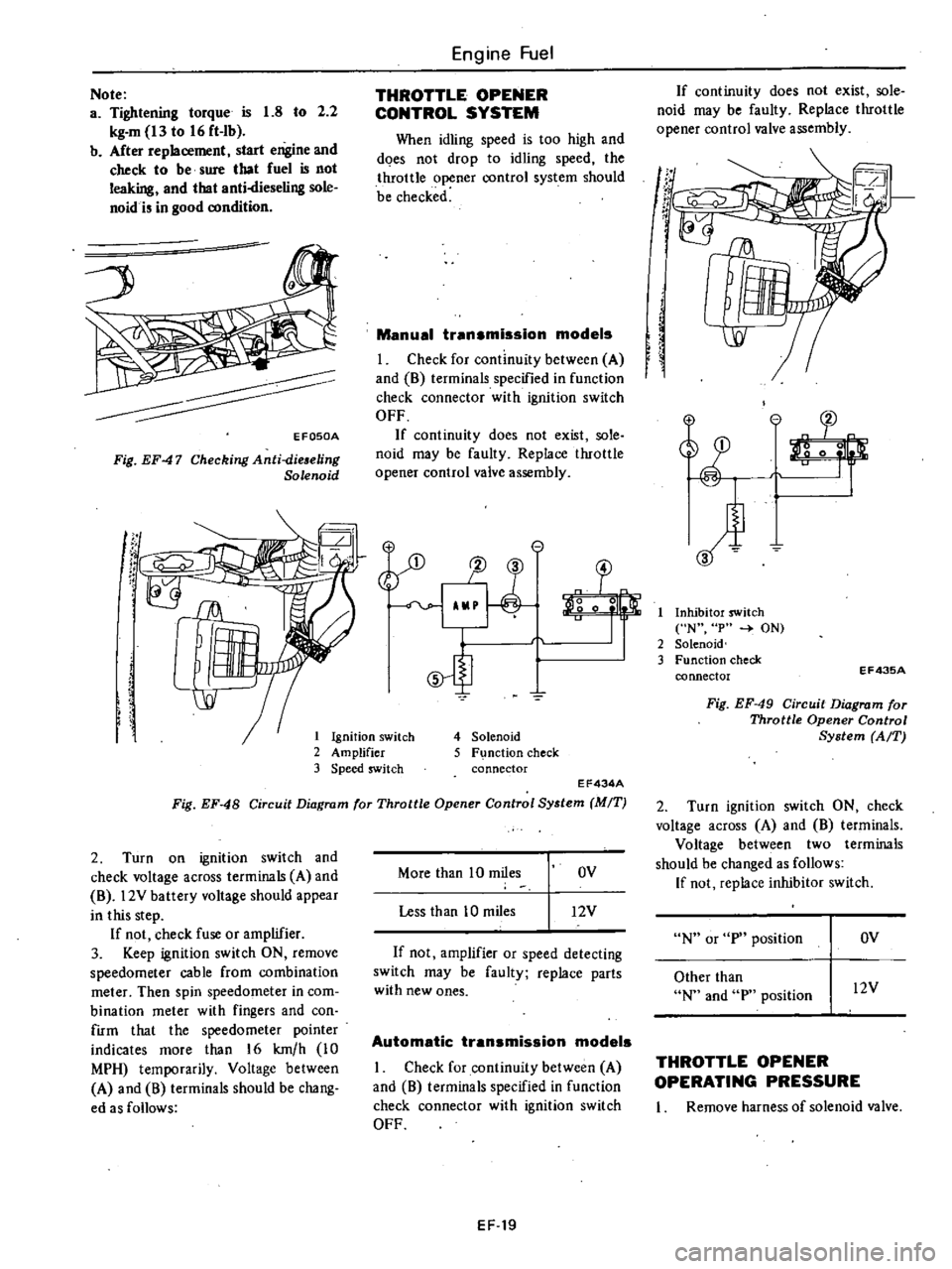

Page 104 of 548

1

Ignition

switch

2

Amplifier

3

Speed

switch

Note

a

Tightening

torque

is

1

8

to

2

2

kg

m

13

to

16

ft

Ib

b

After

replacement

start

engine

and

check

to

be

sure

that

fuel

is

not

leaking

and

that

anti

dieseling

sole

noid

i

in

good

condition

EFOSOA

Fig

EF47

Checking

Anti

dieaeling

Solenoid

l

SJ

Engine

Fuel

THROTTLE

OPENER

CONTROL

SYSTEM

When

idling

speed

is

too

high

and

does

not

drop

to

idling

speed

the

throttle

opener

control

system

should

be

checked

Manual

transmission

models

I

Check

for

continuity

between

A

and

8

terminals

specified

in

function

check

connector

with

ignition

switch

OFF

If

continuity

does

not

exist

sole

noid

may

be

faulty

Replace

throttle

opener

control

valve

assembly

e

1J

3

o

0

5

4

Solenoid

5

F

nction

check

connector

EF434A

Fig

EF

48

Circuit

Diagram

for

Throttle

Opener

Control

System

MIT

2

Turn

on

ignition

switch

and

check

voltage

across

terminals

A

and

8

l2V

battery

voltage

should

appear

in

this

step

If

not

check

fuse

or

amplifier

3

Keep

ignition

switch

ON

remove

speedometer

cable

from

combination

meter

Then

spin

speedometer

in

com

bination

meter

with

fingers

and

con

firm

that

the

speedometer

pointer

indicates

more

than

16

km

h

10

MPH

temporarily

Voltage

between

A

and

8

terminals

should

be

chang

ed

as

follows

More

than

10

miles

OV

Less

than

10

miles

12V

If

not

amplifier

or

speed

detecting

switch

may

be

faulty

replace

parts

with

new

ones

Automatic

transmission

models

I

Check

for

continuity

between

A

and

8

terminals

specified

in

function

check

connector

with

ignition

switch

OFF

EF

19

If

continuity

does

not

exist

sole

noid

may

be

faulty

Replace

throttle

opener

control

valve

assembly

If

t

r

If

I

Inhibitor

switch

N

p

ON

2

Solenoid

3

Function

check

connector

EF43SA

Fig

EF

49

Circuit

Diagram

for

Throttle

Opener

Control

System

AfT

2

Turn

ignition

switch

ON

check

voltage

across

A

and

8

terminals

Voltage

between

two

terminals

should

be

changed

as

follows

If

not

replace

inhibitor

switch

N

or

p

position

OV

Other

than

N

and

p

position

l2V

THROTTLE

OPENER

OPERATING

PRESSURE

I

Remove

harness

of

solenoid

valve

Page 119 of 548

TIGHTENING

TORQUE

Anti

dieseling

solenoid

valve

kg

m

ft

Ib

Engine

Fuel

1

8

to

2

2

13

to

16

EF

34

Page 120 of 548

DATSUN

210

Model

8310

Series

SECTIONEC

EMISSION

CONTROL

SYSTEM

CONTENTS

GENERAL

DESCRIPTION

CRANKCASE

EMISSION

CONTROL

SYSTEM

DESCRIPTION

INSPECTION

EXHAUST

EMISSION

CONTROL

SYSTEM

DESCRIPTION

EARLY

FUEL

EVAPORATIVE

E

F

E

SYSTEM

AIR

INJECTION

SYSTEM

A

IS

AIR

INDUCTION

SYSTEM

A

I

S

EXHAUST

GAS

RECIRCULATION

E

G

R

1

CONTROL

SYSTEM

EC

2

EC

6

EC

6

EC

6

EC

7

EC

7

EC

8

EC

9

EC

18

EC

21

SPARK

T

MING

CONTROL

SYSTEM

CATALYTIC

CONVERTER

EVAPORATIVE

EMISSION

CONTROL

SYSTEM

DESCRIPTION

OPERATION

REMOVAL

AND

INSTALLATION

INSPECTION

SERVICE

DATA

AND

SPECIFICATIONS

INSPECTION

AND

ADJUSTMENT

TIGHTENING

TORQUE

SPECIAL

SERVICE

TOOLS

EC

26

EC

33

E

C

35

EC

35

EC

36

EC

36

EC

36

EC

38

EC

38

EC

38

EC

39

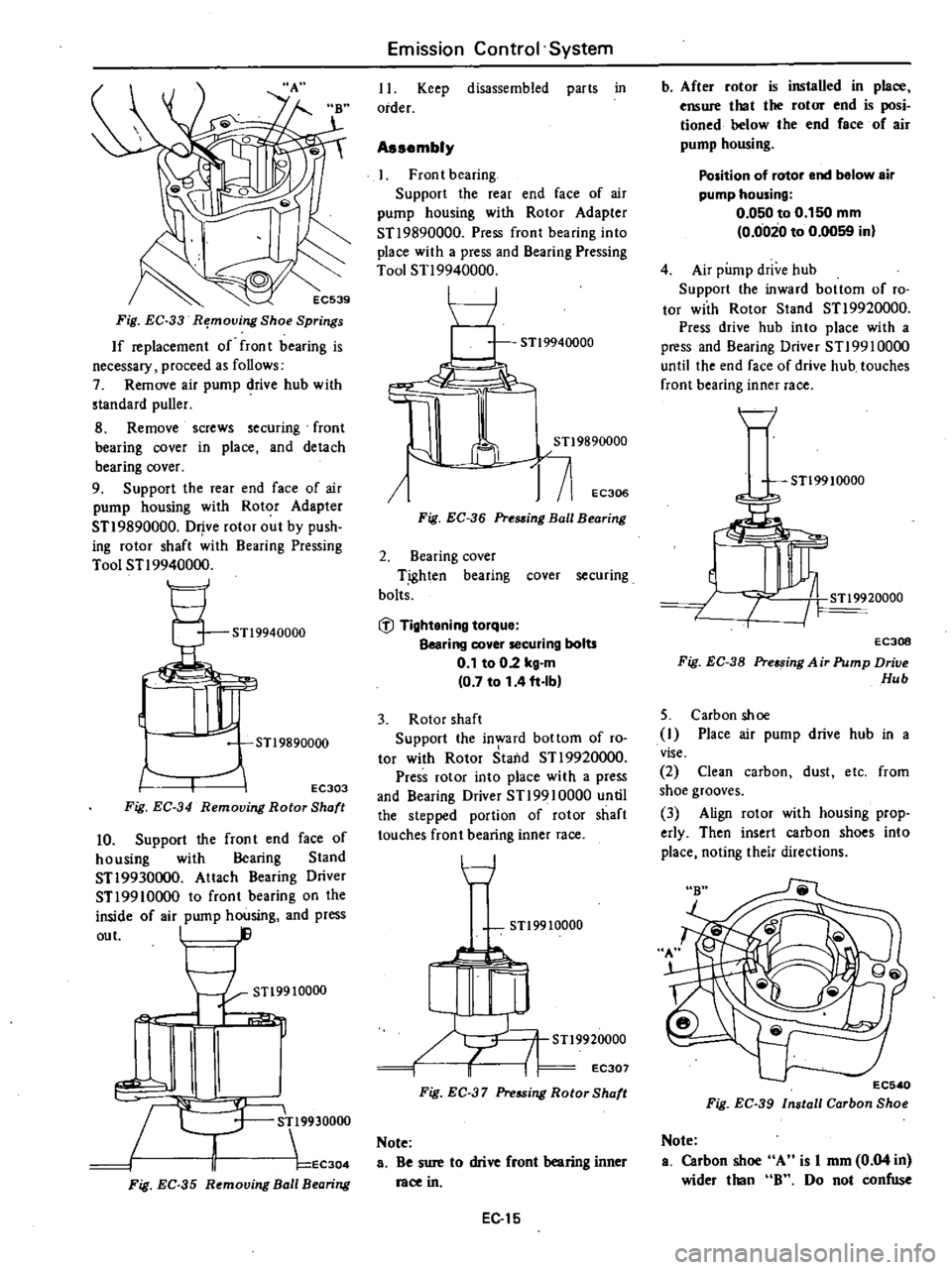

Page 134 of 548

Fig

EC

33

R

moving

Shoe

Springs

If

replacement

of

fron

t

bearing

is

necessary

proceed

as

follows

7

Remove

air

pump

drive

hub

with

standard

puller

8

Remove

screws

securing

front

bearing

cover

in

place

and

detach

bearing

cover

9

Support

the

rear

end

face

of

air

pump

housing

with

Rotor

Adapter

STI

9890000

Drive

rotor

out

by

push

ing

rotor

shaft

with

Bearing

Pressing

Tool

STI

9940000

STl9940000

JJr

STl9890000

EC303

Fig

EC

34

Removing

Rotor

Shaft

10

Support

the

fron

t

end

face

of

housing

with

Bearing

Stand

STI9930000

Attach

Bearing

Driver

STI

9910000

to

front

bearing

on

the

inside

of

air

pump

housing

and

press

out

I

STl9910000

1

c

R

9930000

II

EC304

Fig

EC

35

R

mouing

Ball

B

aring

Emission

Control

System

II

Keep

disassembled

parts

in

order

Assembly

Front

bearing

Support

the

rear

end

face

of

air

pump

housing

with

Rotor

Adapter

STI

9890000

Press

front

bearing

into

place

with

a

press

and

Bearing

Pressing

Tool

STI

9940000

I

I

J

j

71

EC306

Fig

EC

36

Pre88ing

Ball

Bearing

2

Bearing

cover

T

ighten

bearing

cover

securing

bolts

@

Tightening

torque

Bearing

cover

securing

bolts

0

1

to

02

kg

m

0

7

to

1

4

ft

Ib

3

Rotor

shaft

Support

the

in

ard

bottom

of

ro

tor

with

Rotor

Staild

STI

9920000

Press

rotor

into

place

with

a

press

and

Bearing

Driver

STI9910000

until

the

stepped

portion

of

rotor

shaft

touches

front

bearing

inner

race

t

7

STl9910000

STl9920000

i

I

EC307

Fig

EC

37

Pressing

Rotor

Shaft

Note

a

Be

sure

to

drive

front

bearing

inner

race

in

EC

15

b

After

rotor

is

installed

in

place

ensure

that

the

rotor

end

is

posi

tioned

helow

the

end

face

of

air

pump

housing

Position

of

rotor

end

below

air

pump

housing

0

050

to

0

150

mm

0

0020

to

0

0059

in

4

Air

pump

drive

hub

Support

the

inward

bottom

of

ro

tor

with

Rotor

Stand

STI

9920000

Press

drive

hub

into

place

with

a

press

and

Bearing

Driver

STI99l0000

until

the

end

face

of

drive

hub

touches

front

bearing

inner

race

H

STl99

10000

EC30B

Fig

EC

38

Pre

sing

A

ir

Pump

Drive

Hub

5

Carbon

shoe

I

Place

air

pump

drive

hub

in

a

vise

2

Clean

carbon

dust

etc

from

shoe

grooves

3

Align

rotor

with

housing

prop

erly

Then

insert

carbon

shoes

into

place

noting

their

directions

EC5

0

Fig

EC

39

Install

Carbon

Sho

Note

a

Carbon

sh

A

is

I

mm

0

04

in

wider

than

B

Do

not

confuse

Page 135 of 548

them

b

If

carbon

shoes

are

exposed

beyond

the

rotor

end

face

remove

carbon

shoes

and

clean

shoe

grooves

Reas

semble

carbon

shoes

6

Vane

1

Pack

vane

bearing

with

high

melting

poinf

grease

MIL

G

3S45

A

Es

o

ANDOK260

or

equivalent

and

insert

dummy

shaft

into

the

vane

bearing

STl9900000

EC563

Fig

EC

40

Va

Assembly

2

Install

vane

in

place

on

rotor

uMng

Dummy

Shaft

STl9900000

as

a

guide

Note

The

woes

may

require

6

to

16

km

4

to

10

miles

wear

in

running

time

In

the

event

a

slight

squeaking

still

remains

drive

the

car

about

64

to

80

km

h

40

to

SO

MPH

In

most

cases

6

to

16

km

4

to

10

miles

will

be

sufficient

for

wear

in

7

Shoe

spring

Place

shoe

springs

in

deeper

groave

of

shoe

11

I

11

1

EC123

Fig

EC

4I

Ins

tolling

Shoe

Spring

Note

When

installing

a

shoe

spring

make

sure

that

the

outward

bend

ing

side

faces

in

shoe

and

that

both

ends

of

sJlri

face

in

the

wall

of

Emission

Control

System

shoe

groove

6e

Sure

to

push

spring

in

SO

that

spring

end

face

is

flush

with

rotor

8

Rotor

ring

Install

rotor

ring

by

correctly

align

ing

the

rear

end

face

of

rotor

with

the

on

mark

in

rotor

ring

and

tighten

screws

with

Hexagon

Wrench

ST

98

10000

l

l

Tightening

torque

Rotor

ring

screw

0

5

to

0

7

kg

m

13

6

to

5

1

ft

lb

Fig

EC

42

Installing

Rotor

Ring

9

Removal

of

dummy

shaft

CarefuDy

withdraw

dummy

shaft

from

vane

10

Vane

shaft

Pack

rear

bearing

with

high

melting

pain

t

grease

MIL

G

3S45

A

Esso

ANDOK

260

or

equivalent

Apply

thin

coating

of

grease

to

vane

shaft

and

rotor

ring

and

insert

vanf

shafi

into

its

bearing

Note

a

Do

not

apply

an

undue

stress

to

vane

shaft

when

inserting

b

If

two

vanes

are

dislocated

when

inserting

vane

shaft

correctly

align

Yanes

by

inserting

dummy

shaft

Then

draw

out

dummy

shaft

and

insert

vane

shaft

c

When

wear

occurs

on

vane

shaft

or

when

replacement

of

rear

bearing

is

necessary

replace

rear

rover

assem

bly

J

I

End

cover

Position

end

cover

in

place

Snugly

tighten

the

bolt

close

to

the

dowel

Then

tighten

end

cover

bolts

EC

t6

l

l

Tighteningtnrque

End

cover

bolts

0

7

to

0

9

kg

m

5

1

to

6

5

ft

bl

EC302

Fig

EC

43

lnstolling

End

Cover

12

Pulley

Tighten

pulley

securing

bolts

Tightening

torque

Pulley

securing

bolts

0

75

to

0

90

kg

m

5

4

to

6

5

ft

Ib

INSPECTION

The

following

procedures

are

re

commended

for

checking

and

or

as

certaining

that

the

various

components

of

the

exhaust

emission

control

system

are

opera

ting

properly

The

engine

and

all

components

mu

t

be

at

normal

operating

tempera

tures

when

the

tests

are

performed

Prior

to

performing

any

extensive

diag

nosis

of

the

exhaust

control

ystem

h

must

be

determined

that

the

engine

as

a

unit

is

functioning

properly

Air

injection

s

stem

hoses

Check

air

system

hoses

for

loose

connections

cracks

or

deterioration

Retighten

01

replace

if

necessary

Air

pump

I

Operate

engine

until

it

reaches

normal

operating

temperature

2

Inspect

all

hose

hose

connec

tions

and

air

gaDery

for

leaks

and

correct

if

necessary

before

checking

air

injection

pump

Page 143 of 548

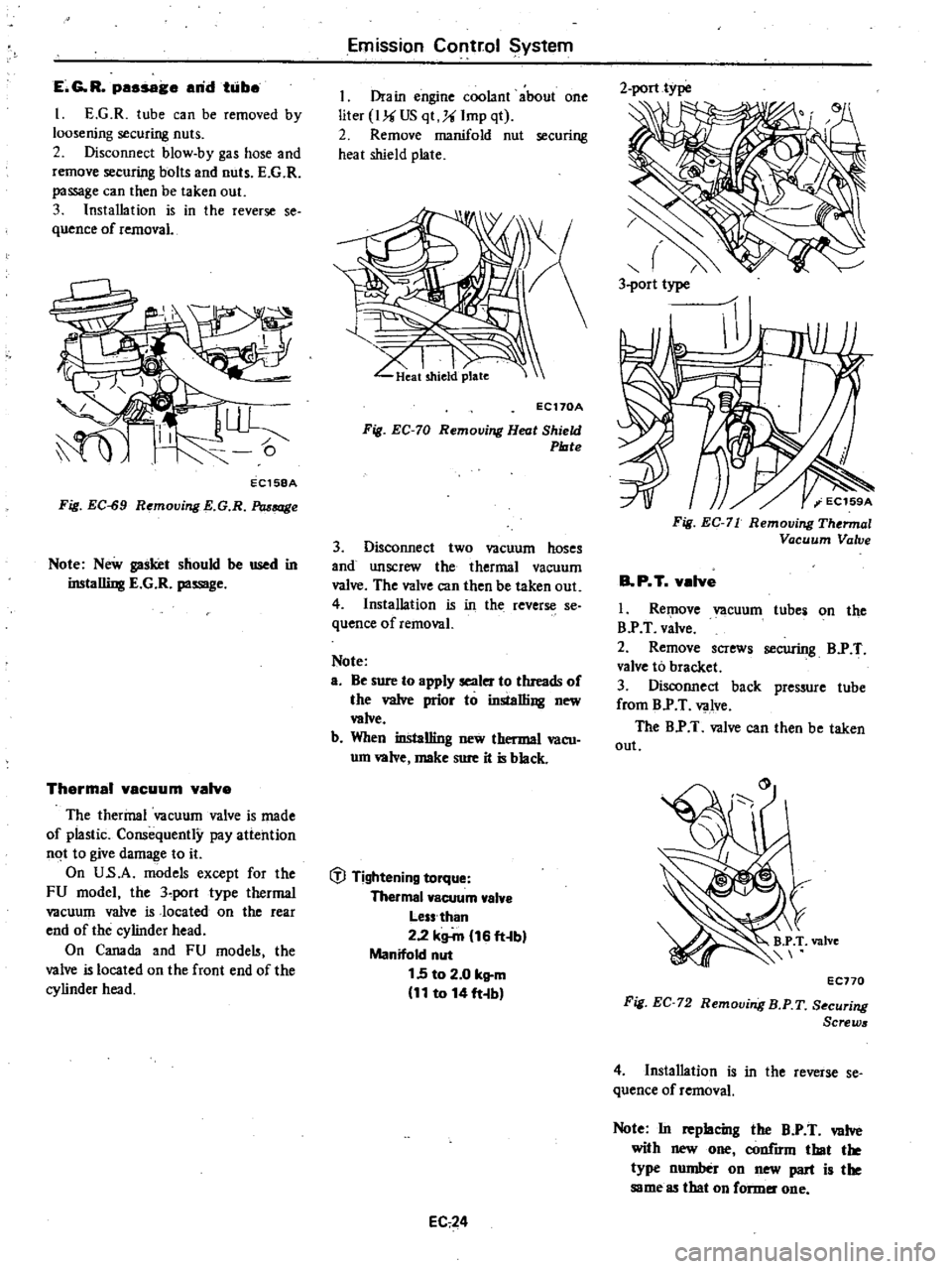

E

G

R

passage

arid

taibe

I

E

G

R

tube

can

be

removed

by

loosening

securing

nuts

2

Disconnect

blow

by

gas

hose

and

remove

securing

bolts

and

nuts

E

G

R

passage

can

then

be

taken

out

3

Installation

is

in

the

reverse

se

quence

of

removal

EC158A

Fig

EC

S9

Removing

E

G

R

Passage

Note

New

gasket

should

be

used

in

installing

E

G

R

passage

Thermal

vacuum

valve

The

thermal

vacuum

valve

is

made

of

plastic

Consequently

pay

attention

not

to

give

damage

to

it

On

U

s

A

models

except

for

the

FU

model

the

3

port

type

thermal

vacuum

valve

is

located

on

the

rear

end

of

the

cylinder

head

On

Canada

and

FU

mode

the

valve

is

located

on

the

front

end

of

the

cylinder

head

Emission

Corltr

ol

System

I

Drain

engine

coolant

about

one

liter

I

US

qt

Imp

qt

2

Remove

manifold

nut

securing

heat

shield

plate

I

I

LIkat

shield

plate

EC170A

Fig

EC

70

Removing

Heat

Shield

Plate

3

Disconnect

two

vacuum

hoses

and

unscrew

the

thermal

vacuum

valve

The

valve

can

then

be

taken

out

4

Installation

is

in

the

reverse

se

quence

of

removal

Note

a

Be

sure

to

apply

sealer

to

threads

of

the

valve

prior

to

installing

new

wive

b

When

installing

new

thermal

vacu

um

wive

make

sure

it

is

black

t

J

Tightening

torque

Thermal

vacuum

valve

Less

than

2

2

kg

m

16

ft

b

Manifold

nut

1

5

to

2

0

kg

m

11

to

14

ft

b

EC

24

2

port

type

3

port

type

Fig

EC

71

Removing

Thermal

Vacuum

Valve

B

P

T

valve

I

Remove

vacuum

tube

on

the

B

P

T

valve

2

Remove

screws

securing

B

P

T

valve

to

bracket

3

Disconnect

back

pressure

tube

from

B

P

T

valve

The

B

P

T

valve

can

then

be

taken

out

EC770

Fig

EC

72

Removing

B

P

T

S

curing

Screws

4

Installation

is

in

the

reverse

se

quence

of

removal

Note

In

replacing

the

B

P

T

valve

with

new

one

h

that

the

type

number

on

new

part

is

the

same

85

that

on

former

one

Page 149 of 548

gear

box

I

Disconnect

a

pair

of

lead

wires

2

Unscrew

the

switch

body

itself

The

switch

can

then

be

taken

out

3

Installation

is

in

the

reverse

se

quence

of

removal

dl

Tightening

torque

Top

cietectingswitch

2

0

to

3

0

kll

m

14

to

22

fHbl

@

EC892

Fig

EC

89

Remouing

Top

Detecting

Switch

Top

detecting

switch

For

AfT

models

The

top

detecting

switch

is

installed

on

the

side

face

of

the

gear

box

I

Disconnect

a

lead

wire

for

top

switch

2

Loosen

switch

itself

Switch

can

then

be

taken

out

Note

When

the

switch

is

remo

ed

automatic

transmission

fluid

flows

out

Prepare

some

rugs

to

prevent

the

fluid

rom

flowing

out

EC169A

Fig

EC

90

Remouing

Top

Detecting

Switch

An

models

3

Insta

tion

is

in

the

reverse

se

quence

of

removal

Emission

Control

System

dl

r

ingtorq

Top

detecting

switch

2

0

to

3

0

kll

m

14

to

22

ft

bl

Thermal

vacuum

valve

3

port

type

The

thermal

vacuum

valve

is

instal

led

on

the

rear

end

of

the

engine

cylinder

head

I

Drain

engine

coolant

about

one

liter

lUllS

qt

Ulmp

qt

2

Remove

manifold

nut

securing

heat

shi

eld

plate

r

l

EC170A

Fig

EC

91

Remouing

Hoot

Shield

Pwte

3

Disconnect

3

vacuum

hoses

and

unscrew

valve

itself

Valve

can

then

be

taken

out

4

Install

thermal

vacuum

valve

in

the

reverse

sequence

of

removal

At

this

time

the

valve

should

be

tighten

ed

to

a

tilt

angle

of

300

Note

Be

sure

to

apply

oealer

to

threads

o

the

valve

prior

to

instal

ling

new

valve

t

J

T1g11taning

torqUe

Thermal

cuum

waive

Less

than

2

2

kll

m

16

ft

bl

Manifold

nut

1

5

to

2

0kg

m

11

to

14

ft

bl

From

distributor

From

B

P

T

valve

From

air

cleaner

ECl71A

Fig

EC

92

mtalling

Thermal

Vacuum

Value

3

port

type

Vacl

ul11

delay

valVe

The

vacuum

delay

Valve

is

installed

on

the

midway

o

the

vacuum

tube

between

the

carburetor

and

distributor

vacuum

advance

mechanism

In

installing

the

valve

make

sure

that

the

brown

face

sid

is

connected

to

the

carburetor

side

Carburetor

sid

C

r

i

J

EG

30

Distributor

side

One

way

umbreDa

valve

Sintered

metal

disc

EC277

Fig

EC

93

In

tolling

Vacuum

Deloy

Value

Page 153 of 548

REMOVAL

AND

INSTALLATION

I

Jack

up

the

car

Note

Apply

parking

brake

and

place

wheel

chocks

2

Remove

screws

securing

lower

shelter

of

catalytic

converter

Loosen

flange

bolt

connecting

catalytic

converter

to

front

and

rear

exhaust

tube

Catalytic

converter

assembly

can

then

be

taken

out

3

Installation

i

in

the

reverse

se

quence

of

removal

CAUTION

a

Be

careful

not

to

damage

catalytic

co

when

handliilg

b

Never

wet

catalyzer

with

water

oil

etc

t

J

Tightening

torque

Catalyti

converter

bolts

2

6

to

3

4

kg

m

19

to

25

ft

lb

Emission

Control

System

EC075A

EC076A

Fig

EC

103

Removing

Catalytic

Converter

INSPECTION

PrelimInary

In

pectlon

Vi

ually

check

condition

of

all

component

parts

including

hose

tubes

and

wires

replace

if

necessary

Refer

to

Air

Injection

System

for

inspection

EC

34

Catalytic

converter

Whether

catalytic

converter

is

nor

mal

or

not

can

e

checked

by

ob

serving

variation

in

CO

percentage

The

checking

procedure

is

as

follows

Apply

parking

brake

Shift

gears

into

Neutral

for

manual

transmis

sion

and

N

or

P

for

automatic

transmission

position

I

Adjust

engine

idling

speed

and

CO

percentage

Refer

to

Adjusting

Carburetor

Idle

RPM

and

Mixture

Ratio

for

adjustment

2

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

and

make

sure

that

specified

CO

percent

age

obtained

3

Remove

cap

and

connect

air

hose

to

air

check

valve

If

idling

speed

increases

readjust

it

to

specified

speed

with

throttle

adjusting

screw

4

Warm

up

engine

for

about

four

minutes

at

2

000

pm

under

no

load

S

Measure

Ci

percentage

at

idling

speed

After

stepAhas

been

complet

ed

wait

for

one

minute

before

making

CO

percentage

measurement

6

If

CO

percentage

measured

in

step

5

is

less

than

0

3

the

catalytic

converter

is

normaL

7

If

CO

percentage

measured

in

step

5

is

over

0

3

recheck

AJ

S

and

1

replace

air

check

valVe

The

perform

inspection

steps

4

and

S

8

If

CO

percentage

is

still

over

0

3

in

step

7

catalyt

iC

converter

i

mal

functioning

Replace

catalytic

con

verter

Page 157 of 548

Emission

Control

System

SERVICE

DATA

AND

SPECIRCATIONS

INSPECTION

AND

ADJUSTMENT

AIR

PUMP

Air

pressure

With

engine

speed

at

2

600

pm

mrriHg

inHg

More

than

100

3

94

E

G

R

SYSTEM

Thermal

vacuum

valve

opening

temperature

U

S

A

models

except

FU

model

FU

and

Canada

models

Oc

OF

oC

F

SO

to

63

122

to

145

40

to

63

104

to

145

T

C

S

SYSTEM

Thermal

vacuum

valve

Except

Canada

and

FU

models

Closing

temperature

oC

F

Opening

temperature

OC

F

Above

SO

to

63

122

to

145

Below

5

to

18

41

to

64

5

to

18

and

SO

to

63

41

to

64

and

122

to

145

TIGHTENING

TORQUE

Air

pump

Bea

ring

cover

securing

bolt

Rotor

ring

screw

End

cover

bolt

Pulley

securing

bolt

Thermal

vacuum

valVe

BP

T

valve

mounting

sere

Top

detecting

switch

Catalytic

converter

bolt

kg

m

ft4b

kg

m

ft

lb

kg

m

ft

Ib

kg

m

ft

b

kg

m

ft

lb

kg

m

ft

Ib

kg

m

ft

Ib

kg

m

ft

lb

0

1

to

0

2

0

7

to

1

4

0

5

to

0

7

3

6

to

5

1

0

7

to

0

9

5

1

to

6

5

0

75

to

0

90

5

4

to

6

5

Less

than

2

2

16

0

38

to

0

51

2

7

to

3

7

2

0

to

3

0

14

to

22

2

6

to

3

4

19

to

25

EC

38