torque DATSUN 210 1979 Workshop Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 202 of 548

Engine

Removal

Installation

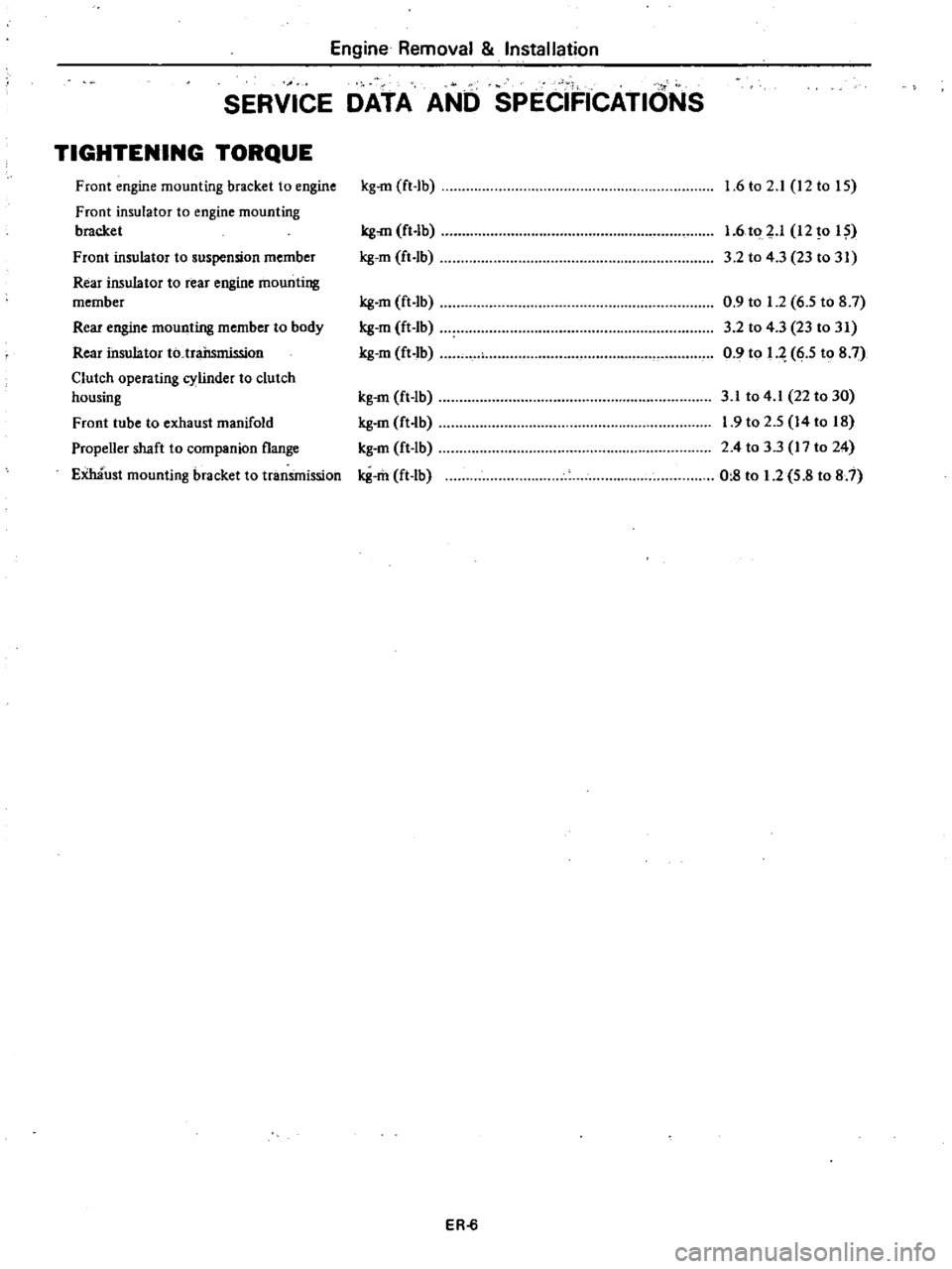

SERVICE

DATA

AND

SPECIFICATIONS

TIGHTENING

TORQUE

Front

engine

mounting

bracket

to

engine

Front

insulator

to

engine

mounting

bracket

Front

insulator

to

suspension

member

Rear

insulator

to

rear

engine

mounting

member

Rear

engine

mounting

member

to

body

Rear

insulator

to

trailsmission

Clutch

operating

cylinder

to

clutch

housing

Front

tube

to

exhaust

manifold

Propeller

shaft

to

companion

flange

Emaust

mounting

bracket

to

tranSmission

kg

rn

ft

lb

kg

rn

ft

Ib

gem

ft

Ib

g

m

ft

lb

g

m

ft

Ib

g

m

ft

Ib

kg

m

ft

Ib

g

m

ft

lb

kg

m

ft

lb

g

m

ft

Ib

ER

6

1

6

to

2

1

12

to

IS

1

6

to

p

12

0

I

3

2

to

4

3

23

to

31

0

9

to

1

2

6

5

to

8

7

3

2

to

4

3

23

to

31

0

9

to

q

6

5

to

8

7

3

1

to

4

1

22

to

30

1

9

to

2

5

14

to

18

2

4

to

3

3

17

to

24

0

8

to

1

2

5

8

to

8

7

Page 203 of 548

DATSUN

210

Model

8310

Series

SECTIONCL

CLUTCH

CONTENTS

ADJUSTMENT

CLUTCH

PEDAL

HEIGHT

CLUTCH

PEDAL

FREE

TRAVEL

BLEEDING

CLUTCH

SYSTEM

CLUTCH

CONTROL

CLUTCH

PEDAL

CLUTCH

MASTER

CYLINDER

OPERATING

CYLINDER

CLUTCH

LINE

CLUTCH

UNIT

CLUTCH

DISC

AND

COVER

CL

2

CL

2

CL

2

CL

2

CL

3

CL

3

CL

4

CL

5

CL

6

CL

7

CL

7

RELEASE

BEARING

PILOT

BUSHING

SERVICE

DATA

AND

SPECIFICATIONS

GENERAL

SPECIFICATIONS

INSPEctiON

AND

ADJUSTMENT

TIGHTENING

TORQUE

TROUBLE

DIAGNOSES

AND

I

ECTIONS

SPECIAL

SERVICE

TOOLS

CL

8

CL

9

CL

10

CL

10

CL10

CL

11

CL

12

CL

14

Page 204 of 548

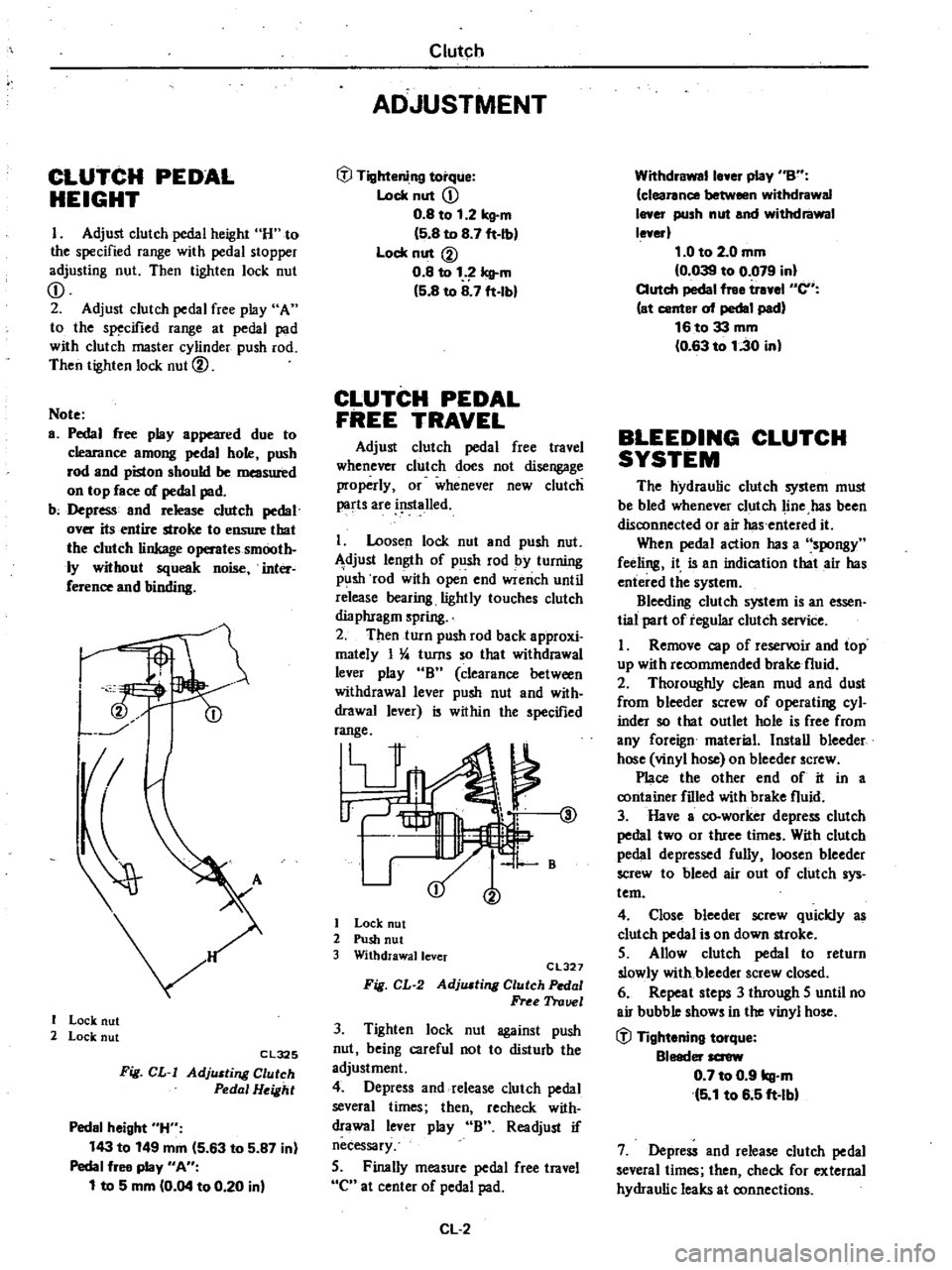

CLUTCH

PEDAL

HEIGHT

I

Adjust

clutch

pedal

height

H

to

the

specified

range

with

pedal

stopper

adjusting

nut

Then

tighten

lock

nut

CD

2

Adjust

clutch

pedal

free

play

A

to

the

specified

range

at

pedal

pad

with

clutch

master

cylinder

push

rod

Then

tighten

lock

nut

@

Note

a

Pedal

free

play

appeared

due

to

clearance

among

pedal

hole

push

rod

and

piston

should

be

measured

on

top

face

of

pedal

pad

b

Depress

and

release

clutch

pedal

over

its

entire

stroke

to

ensure

that

the

clutch

linkage

operates

smooth

ly

without

squeak

noise

inter

ference

and

binding

I

I

Lock

nut

2

Lock

nut

Cl325

Fig

CL

I

AdjlUting

Clutch

Pedal

Height

Pedal

height

H

143

to

149

mm

5

63

to

5

87

in

Pedal

free

play

An

1

to

5

mm

0

04

to

0

20

in

Clutch

ADJUSTMENT

tfl

Tightening

torque

Lock

nut

CD

0

8

to

1

2

kg

m

5

8

to

8

7

ft

Ib

Lock

nut

@

0

8

to

1

Icll

m

5

8

to

8

7

ft

lbl

CLUTCH

PEDAL

FREE

TRAVEL

Adjust

clutch

pedal

free

travel

whenever

clutch

does

not

disengage

properly

or

whenever

new

clutch

parts

are

i

lslalled

I

Loosen

lock

nut

and

push

nut

djust

length

of

push

rod

by

turning

p

lsh

rod

with

open

end

wrench

until

release

bearing

lightly

touches

clutch

dia

phragm

spring

2

Then

turn

push

rod

back

approxi

mately

I

4

turns

so

that

withdrawal

lever

play

B

clearance

between

withdrawal

lever

push

nut

and

with

drawal

lever

is

within

the

specified

range

V

@

1

B

I

Lock

nut

2

Push

nut

3

Withdrawallcver

CL327

Fig

CL

2

AdjlUting

Clutch

Pedal

Free

Trauel

3

Tighten

lock

nut

against

push

nut

being

careful

not

to

disturb

the

adjustment

4

Depress

and

release

clutch

pedal

several

times

then

recheck

with

drawal

lever

play

B

Readjust

if

necessary

5

Finally

measure

pedal

free

travel

C

at

center

of

pedal

pad

CL

2

Withdrawalle

er

play

nBn

clearance

between

withdrawal

I

er

push

nut

and

withdrawal

le

erl

1

0

to

2

0

mm

0

039

to

0

079

in

Clutch

pedal

free

tr

el

en

at

center

of

pedal

pad

16to33

mm

0

63

to

1

30

in

BLEEDING

CLUTCH

SYSTEM

The

hydraulic

clutch

system

must

be

bled

whenever

clutch

line

has

been

disconnected

or

air

has

entered

it

When

pedal

action

has

a

spongy

feeling

it

is

an

indication

that

air

has

entered

the

system

Bleeding

clutch

system

is

an

essen

tial

part

of

regular

clutch

service

I

Remove

cap

of

reservoir

and

top

up

with

recommended

brake

fluid

2

Thoroughly

clean

mud

and

dust

from

bleeder

screw

of

operating

cyl

inder

so

that

outlet

hole

is

free

from

any

foreign

material

Install

bleeder

hose

vinyl

hose

on

bleeder

screw

Place

the

other

end

of

it

in

a

container

filled

with

brake

fluid

3

Have

a

co

worker

depress

clutch

pedal

two

or

three

times

With

clutch

pedal

depressed

fully

loosen

bleeder

screw

to

bleed

air

out

of

clutch

sys

tem

4

Close

bleeder

screw

quickly

as

clutch

pedal

is

on

down

stroke

5

Allow

clutch

pedal

to

return

slowly

with

bleeder

screw

closed

6

Repeat

steps

3

through

5

until

no

air

bubble

shows

in

the

vinyl

hose

tfl

Tightening

torque

Bleeder

screw

0

7

to

0

9

kg

m

5

1

to

6

5

ft

lbl

7

Depress

and

release

clutch

pedal

several

times

then

check

for

external

hydraulic

leaks

at

connections

Page 205 of 548

Note

a

Brake

fluid

conlaining

air

is

white

and

has

visible

air

bubbles

b

Brake

fluid

containing

no

air

runs

out

of

bleeder

screw

in

a

1lO6d

stream

without

air

bubbles

c

Pay

close

attention

to

clutch

fluid

level

in

reservoir

during

bleeding

operation

Clutch

d

Pour

brake

fluid

into

reServoir

up

to

the

specified

level

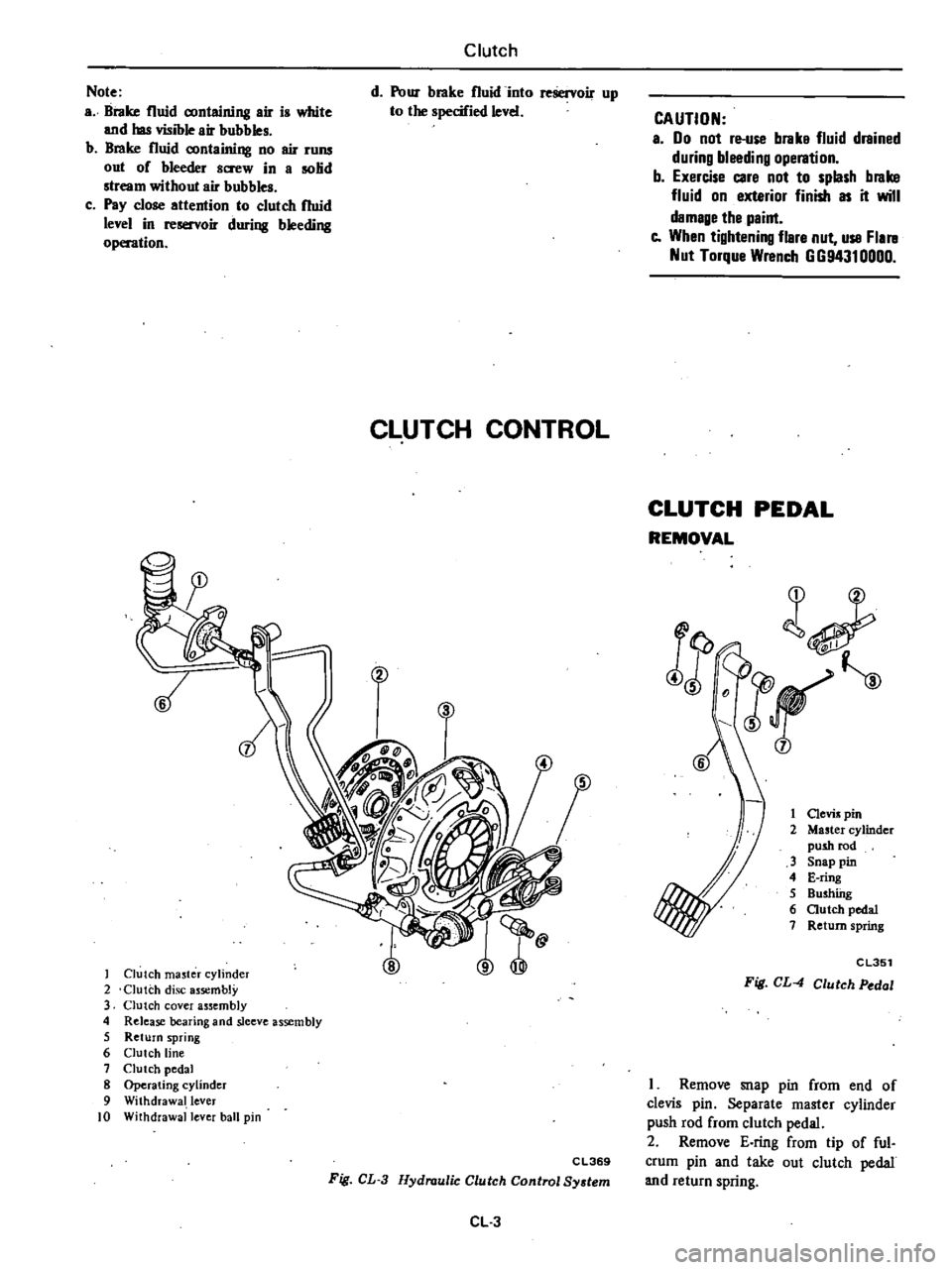

CLUTCH

CONTROL

Clutch

ma5ter

cylinder

2

Clutch

disc

assembly

3

Clutch

cover

assembly

4

Release

bearing

and

sleeve

assembly

5

Return

spring

6

Clutch

line

7

Clutch

pedal

8

Operating

cylinder

9

Withdrawal

lever

10

Withdrawal

lever

ball

pin

CAUTION

a

00

not

re

use

brake

fluid

drained

during

bleeding

operation

b

Exercise

care

not

to

splash

brake

fluid

on

exterior

finish

as

it

will

damage

the

paint

e

When

tightening

flare

nut

use

Flal

ll

Nut

Torque

Wrench

GG94310000

CLUTCH

PEDAL

REMOVAL

l

JF

j

1

Clevis

pin

2

Master

cylinder

push

rod

3

Snap

pin

4

E

ring

5

Bushfug

6

autch

pedal

7

Return

spring

j

CL351

Fig

CL

4

Clutch

Pedal

C

L369

Fig

CL

3

Hydraulic

Clutch

Control

System

CL

3

I

Remove

snap

pin

from

end

of

clevis

pin

Separate

master

cylinder

push

rod

from

clutch

pedal

2

Remove

E

ring

from

tip

of

ful

crum

pin

and

take

out

clutch

pedal

and

return

spring

Page 207 of 548

are

clean

and

free

from

foreign

matter

Cearance

between

cylinder

bore

and

piston

Leu

than

0

15

mm

0

0059

in

ASSEMBLY

Assemble

clutch

master

cylinder

in

the

reverse

order

of

disassembly

Ob

serve

the

following

I

Dip

piston

cup

in

brake

fluid

before

installing

Make

sure

that

it

is

correctly

faced

in

position

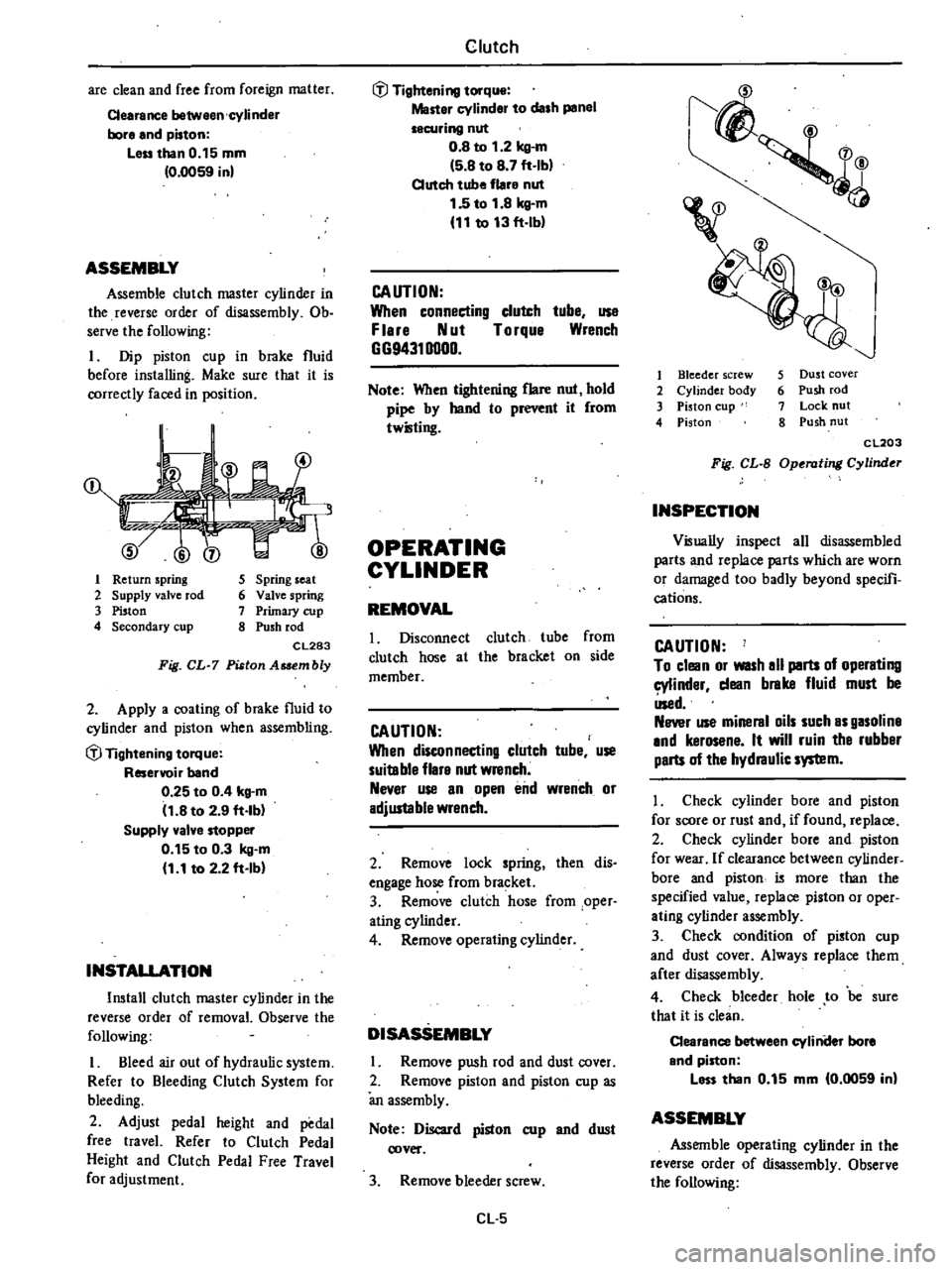

1

Return

spring

2

Supply

valve

rod

3

Piston

4

Secondary

cup

5

Spring

seat

6

Valve

spring

7

Primary

cup

8

Push

rod

CL283

Fig

CL

7

Piston

Asaembly

2

Apply

a

coating

of

brake

fluid

to

cylinder

and

piston

when

assembling

if

Tightening

torque

Reservoir

band

0

25

to

0

4

kg

m

11

8

to

2

9

ft

lb

Supply

valve

stopper

0

15

to

0

3

kg

m

1

1

to

2

2

ft

Ib

INSTALLATION

Install

clutch

master

cylinder

in

the

reverse

order

of

removal

Observe

the

following

I

Bleed

air

out

of

hydraulic

system

Refer

to

Bleeding

Clutch

System

for

bleeding

2

Adjust

pedal

height

and

pedal

free

travel

Refer

to

Clutch

Pedal

Height

and

Clutch

Pedal

Free

Travel

for

adjustment

Clutch

if

Tightening

torque

Master

cylinder

to

dash

panel

securing

nut

0

8

to

1

2

kg

m

5

8

to

8

7

ft

Ib

Clutch

tube

flare

nut

1

5

to

1

8

kg

m

11

to

13

ft

lb

CAUTION

When

connecting

clutch

tube

use

F

lere

Nut

Torque

Wrench

GG94310000

Note

When

tightening

flare

nut

hold

pipe

by

hand

to

r

it

from

twilling

OPERATING

CYLINDER

REMOVAL

I

Disconnect

clutch

tube

from

clutch

hose

at

the

bracket

on

side

member

CAUTION

When

disconnecting

clutch

tube

use

suitable

flare

nut

wrench

Never

use

an

open

end

wrench

or

adjustable

wrench

2

Remove

lock

spring

then

dis

engage

hose

from

bracket

3

Remove

clutch

hose

from

oper

ating

cylinder

4

Remove

operating

cylinder

DISASSEMBLY

Remove

push

rod

and

dust

cover

2

Remove

piston

and

piston

cup

as

an

assembly

Note

Discard

piston

cup

and

dust

cover

3

Remove

bleeder

screw

Cl

5

1

4

v

I

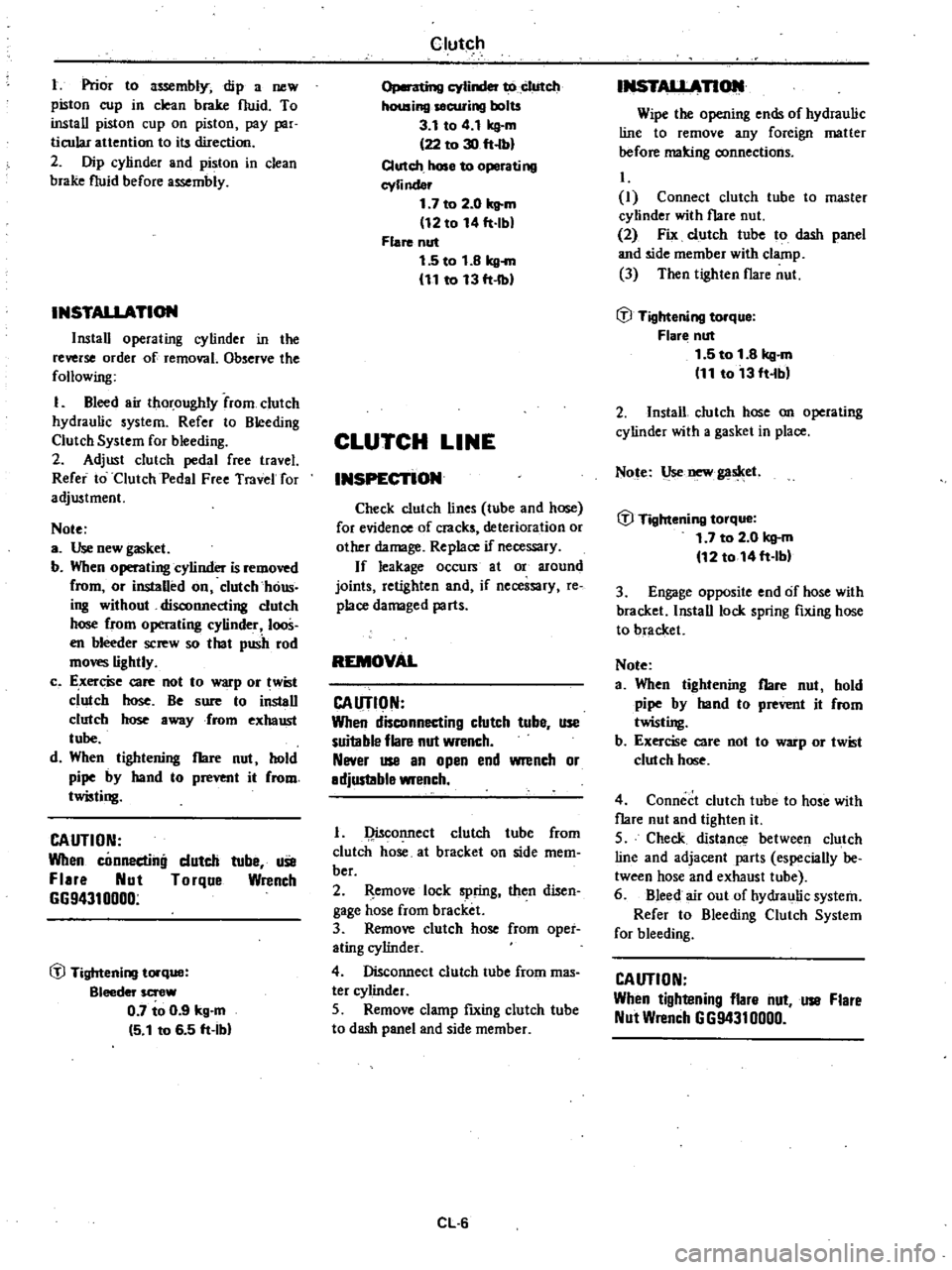

Bleeder

screw

2

Cylinder

body

3

Piston

cup

4

Piston

5

Dust

cover

6

Push

rod

7

Lock

nut

8

Push

nut

CL203

Fig

CL

B

Operating

Cylinder

INSPECTION

Visually

inspect

all

disassembled

parts

and

replace

parts

which

are

worn

or

damaged

too

badly

beyond

specifi

cations

CAUTION

To

clean

or

WISh

all

parts

of

operating

cylinder

dean

brake

fluid

must

be

Used

Never

use

mineral

oils

such

as

gasoline

and

kerosene

It

will

ruin

the

rubber

parts

of

the

hydraulic

system

I

Check

cylinder

bore

and

piston

for

score

or

rust

and

if

found

replace

2

Check

cylinder

bore

and

piston

for

wear

If

clearance

between

cylinder

bore

and

piston

i5

more

than

the

specified

value

replace

piston

or

oper

ating

cylinder

assembly

3

Check

condition

of

piston

cup

and

dust

cover

Always

replace

them

after

disassembly

4

Check

bleeder

hole

to

be

sure

that

it

is

clean

Clearance

between

cyliniler

bore

and

piston

less

than

0

15

mm

0

0059

in

ASSEMBLY

Assemble

operating

cylinder

in

the

reverse

order

of

disassembly

Observe

the

following

Page 208 of 548

t

Prior

to

lWembly

dip

a

new

piston

cup

in

clean

brake

fluid

To

install

piston

cup

on

piston

pay

par

ticular

auention

to

its

direction

2

Dip

cylinder

and

piston

in

clean

brake

fluid

before

assembly

INSTALLATION

Install

operating

cylinder

in

the

reverse

order

of

removal

Observe

the

following

1

Bleed

air

thoroughly

from

clutch

hydraulic

system

Refer

to

Bleeding

Clutch

System

for

bleeding

2

Adjust

clutch

pedal

free

travel

Refer

to

Clutch

Pedal

Free

Travel

for

adjustment

Note

a

Use

new

gasket

b

When

operating

cylinder

is

removed

from

or

instaUed

on

clutch

haus

ing

without

disconnecting

clutch

hose

from

operating

cylinder

loos

en

bleeder

screw

so

that

push

rod

mo

lightly

c

E

xer

e

care

not

to

p

or

wist

clutch

hose

Be

sure

to

install

clutch

hose

away

from

exhaust

tube

d

When

tightening

flare

nut

hold

pipe

by

hand

to

prevent

it

from

twisting

CAUTION

When

connecting

dutch

tuhe

uSe

Flare

Nut

Torque

Wrench

G694310000

@

Tightening

torque

Bleeder

screw

0

7

to

0

9

kg

m

5

1

to

6

5

ft

Ihl

Clutch

o

cylinder

to

clutch

housing

securing

bolts

3

1

to

4

1

kg

m

22

to

30

ft

lbl

Clutch

hose

to

operating

cyli

nder

1

7

to

2

0

kg

m

12

to

14

ft

lbl

Flare

nut

1

5

to

1

8

kg

m

11

to

13

ft

Ibl

CLUTCH

LINE

INSPECTION

Check

clutch

lines

tube

and

hose

for

evidence

of

cracks

deterioration

or

other

damage

Replace

if

necessary

If

leakage

occurs

at

or

around

joints

retighten

and

if

necessary

re

place

damaged

parts

REMOVAL

CAUTION

When

disconnecting

clutch

tube

use

suitable

flare

nut

wrench

Never

use

an

open

end

wrench

or

adjustable

wrench

1

Qisconnect

clutch

tube

from

clutch

hose

at

bracket

on

side

mem

ber

2

emove

lock

spring

then

disen

gage

hose

from

bracket

3

Remove

clutch

hose

from

oper

ating

cylinder

4

Disconnect

clutch

tube

from

mas

ter

cylinder

5

Remove

clamp

fIxing

clutch

tube

to

dash

panel

and

side

member

CL

6

INSTALLAnOlll

Wipe

the

opening

ends

of

hydraulic

line

to

remove

any

foreign

matter

before

malting

connections

I

Connect

clutch

tuhe

to

master

cylinder

with

flare

nut

2

Fix

clutch

tube

to

dash

panel

and

side

member

with

clamp

3

Then

tighten

flare

nut

@

Tightening

torque

Flar

nut

1

5

to

1

8

kg

m

11

to

13

ft

Ibl

2

InstaU

clutch

hose

on

operating

cylinder

with

a

gasket

in

place

Note

Use

new

gaslcet

@

Tightening

torque

1

7

to

2

0

kg

m

12

to

14ft

lbl

3

Engage

opposite

end

of

hose

with

bracket

InstaU

lock

spring

fIxing

hose

to

bracket

Note

a

When

tightening

flare

nut

hold

pipe

by

hand

to

prevent

it

from

twisting

b

Exercise

care

not

to

warp

or

twist

clu1ch

hose

4

Connect

clutch

tube

to

hose

with

flare

nut

and

tighten

it

5

Check

distance

between

clutch

line

and

adjacent

parts

especially

be

tween

hose

and

exhaust

tube

6

Bleed

air

out

of

hydraulic

system

Refer

to

Bleeding

Clutch

System

for

bleeding

CAUTION

When

tightening

flare

nut

use

Flare

Nut

Wrench

G

G9431

0000

Page 210 of 548

3

Check

disc

plate

for

runout

when

ever

the

old

disc

or

a

new

one

is

installed

4

If

runout

exceeds

the

specified

value

at

outer

circumference

of

fac

g

replace

or

repair

disc

Runout

limit

ltotal

indicator

reading

Less

than

0

5

mm

0

020

in

R

from

hub

center

85

mm

3

35

in

CAUTION

When

repairing

disc

plate

never

hold

it

forcibly

with

pUers

or

bend

it

exces

sively

otherwise

facing

will

be

dam

aged

CL112

Fig

CL

12

Repairing

DiM

Runout

5

Check

fit

of

disc

hub

on

transmis

sion

main

drive

gear

splines

for

smooth

sliding

If

splines

are

worn

clutch

disc

r

main

drive

gear

should

be

replaced

that

is

backlash

exceeds

the

specified

value

at

outer

edge

of

clutch

disc

Backlash

Less

than

0

4

mm

0

016

in

Clutch

cover

a

embly

I

Check

the

end

surface

of

dia

phragm

spring

for

wear

If

excessive

wear

is

found

replace

cluich

cover

assembly

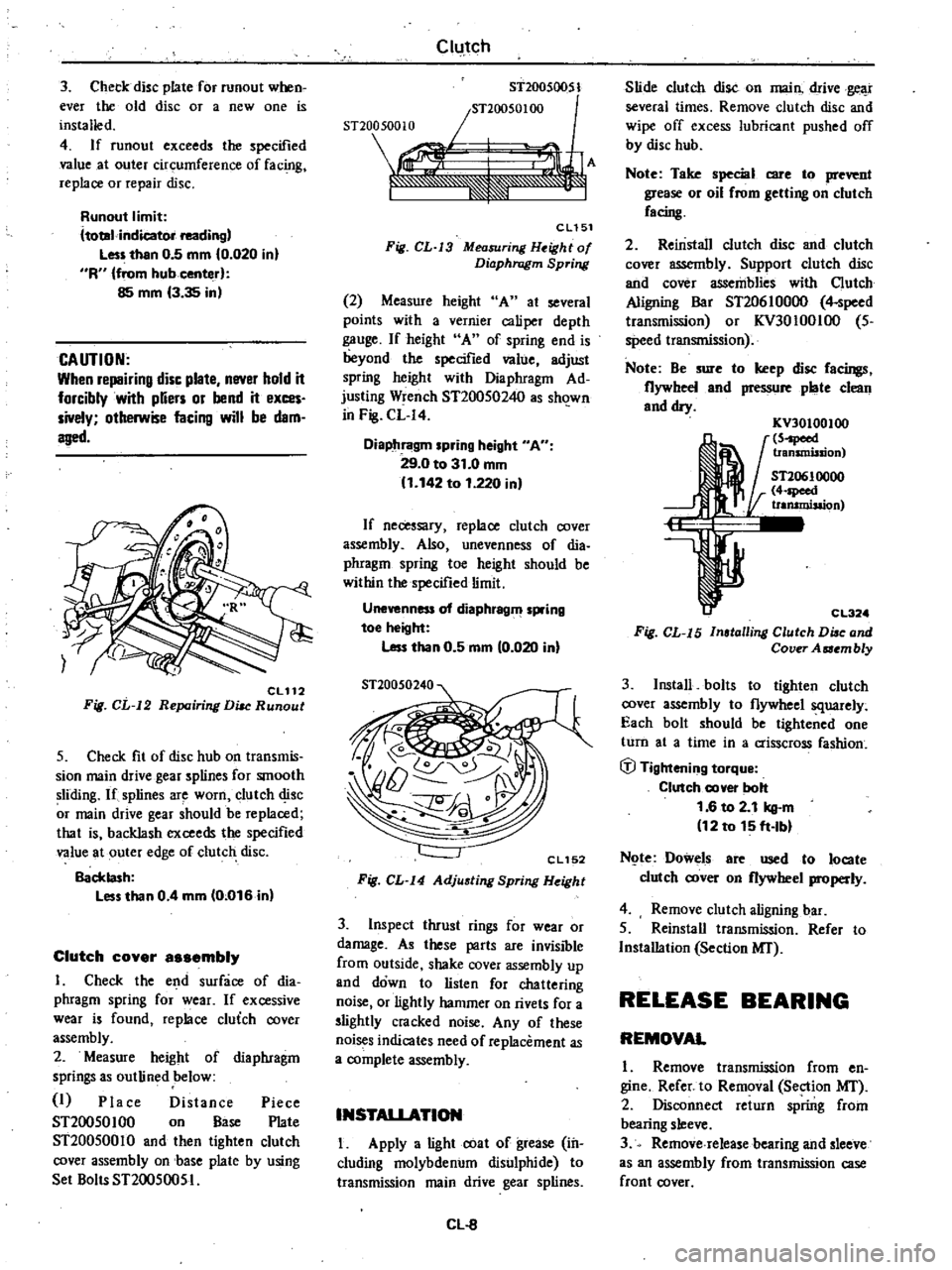

2

Measure

height

of

diaphragm

springs

as

outlined

below

I

Place

Distance

Piece

ST20050100

on

Base

Plate

ST20050010

and

then

tighten

clutch

cover

assembly

on

base

plate

by

using

Set

Bolts

ST20050051

Clutch

ST200S0051

snOO50100

snoo

500

10

re1

F

A

J

eLlSl

Fig

CL

J3

Measuring

H

ight

of

Diaphragm

Spring

2

Measure

height

A

at

several

points

with

a

vernier

caliper

depth

gauge

If

height

A

of

spring

end

is

beyond

the

specified

value

adjust

spring

height

with

Diaphragm

Ad

justing

Wrench

ST20050240

as

sh

1wn

in

Fig

CL

I4

Diaphragm

spring

height

A

29

0

to

31

0

mm

1

142

to

1

220

in

If

necessary

replace

clutch

cover

assembly

Also

unevenness

of

dia

phragm

spring

toe

height

should

be

within

the

specified

limit

Unevenness

of

diaphragm

spring

toe

height

Less

than

0

5

mm

0

020

in

CL152

Fig

CL

I4

Adjusting

Spring

Height

3

Inspect

thrust

rings

for

wear

or

damage

As

these

parts

are

invisible

from

outside

shake

cover

assembly

up

and

down

to

listen

for

chattering

noise

or

lightly

hammer

on

rivets

for

a

slightly

cracked

noise

Any

of

these

noi

s

indicates

need

of

replacement

as

a

complete

assembly

INSTALlATION

I

Apply

a

light

coat

of

grease

in

cluding

molybdenum

disulphide

to

transmission

main

drive

gear

splines

Cl

8

Slide

clutch

disc

on

main

drive

gear

several

times

Remove

clutch

disc

and

wipe

off

excess

lubricant

pushed

off

by

disc

hub

Note

Take

special

care

to

prevent

grease

or

oil

rrom

getting

on

clutch

racing

2

Reinstall

clutch

disc

and

clutch

cover

assembly

Support

clutch

disc

and

cover

assemblies

with

Clutch

Aligning

Bar

ST20610000

4

speed

transmission

or

KV30100IOO

5

speed

transmission

Note

Be

sure

to

keep

disc

racings

flywheel

and

pressure

plate

clean

and

dry

KV30100100

5

peed

transmission

ST20610000

4

speed

trammisaion

CL32

Fig

CL

I5

Installing

Clutch

Diac

and

Cover

Aaembly

3

Install

bolts

to

tighten

clutch

cover

assembly

to

flywheel

squarely

Each

bolt

should

be

tightened

one

turn

at

a

time

in

a

crisscross

fashion

ifJ

Tightening

torque

Clutch

cover

bolt

1

6

to

2

1

kg

m

12

to

15

ft

Ibl

N

te

Dowels

are

used

to

locate

clutch

cover

on

flywheel

properly

4

Remove

clutch

aligning

bar

5

Reinstall

transmission

Refer

to

Installation

Section

MI

RELEASE

BEARING

REMOVAL

1

Remove

transmission

from

en

gine

Refer

to

Removal

Section

MI

2

Disconnect

return

spring

from

bearing

sleeve

3

Remove

release

bearing

and

sleeve

as

an

assembly

from

transmission

case

front

cover

Page 213 of 548

Clutch

Clutch

cover

Diaphragm

spring

height

mm

in

Unevenness

of

diaphragm

spnng

toe

height

mm

in

29

0

to

31

0

1

142

to

1

220

Less

than

O

5

0

020

TIGHTENING

TORQUE

Pedal

stopper

lock

nut

Master

cylinder

push

rod

lock

nut

Operating

cylinder

push

rod

lock

nut

Operating

cylinder

bleeder

screw

Master

cylinder

to

dash

panel

securing

nut

kg

m

ft

lb

Clutch

tube

flare

nut

kg

m

ft

Ib

kg

m

ft

b

kg

m

ft

Ib

kg

m

ft

b

kg

m

ft

b

0

8

to

1

2

5

8

to

8

7

0

8

to

1

2

5

8

to

8

7

0

8

to

1

2

5

8

to

8

7

0

7

to

0

9

5

1

to

6

5

0

8

to

1

2

5

8

to

8

7

1

5

to

1

8

11

to

13

Operating

cylinder

to

clutch

housing

securing

bolt

Qutch

hose

to

operating

cylinder

Qutch

cover

bolt

kg

m

ft

lb

kg

m

ft

Ib

kg

m

ft

Ib

3

1

to

4

1

22

to

30

17

to

2

0

12

to

14

1

6

to

2

1

12

to

15

CL

11

Page 216 of 548

Clutch

SPECIAL

SERVICE

TOOLS

Tool

number

tool

name

ST206100ll0

Clutch

aligning

bar

KV30100100

Clutch

aligning

bar

STI0050100

Distance

piece

ST20050010

Base

plate

0

@

IKent

Moore

No

Reference

page

or

Fig

No

Unit

application

125673

Fig

CL

1O

Fig

CL

15

F4W60L

Fig

qIO

Fig

CL

15

FS5W60L

Fig

CL

13

Fig

CL

13

Tool

number

tool

name

ST2005005

I

Set

bolts

YVYYVYVV

ST20050240

Diaphragm

spring

adjusting

wrench

KVIOl02800

Pilot

bushing

puller

GG94310000

Flare

nut

torque

wrench

Applicable

to

all

B310

series

model

C114

Kent

Moore

No

Reference

page

or

FiR

No

Unit

application

Fig

CL

I3

Fig

CL

14

J25657

Fig

CL

21

Page

CL

3

Page

CL

5

Page

CUi

Page 217 of 548

DATSUN

210

Model

8310

Series

MANUAL

TRANSMISSION

CONTENTS

4

SPEED

TRANSMISSION

Model

F4W60L

REMOVAL

INSTALLATION

DISASSEMBL

Y

TRANSMISSION

CASE

DISASSEMBLY

DISASSEMBLY

OF

GEAR

ASSEMBLY

ADAPTER

PLATE

DISASSEMBLY

REAR

EXTENSION

DISASSEMBLY

INSPECTION

TRANSMISSION

CASE

AND

REAR

EXTENSION

BEARING

GEARS

AND

SHAFTS

BAULK

RING

SHIFTING

INSERT

01

L

SEAL

REAR

ENGINE

MOUNTING

INSULATOR

ASSEMBL

Y

FRONT

COVER

ASSEMBLY

TRANSMISSION

CASE

ASSEMBLY

REAR

EXTENSION

ASSEMBLY

ADAPTER

PLATE

ASSEMBLY

ASSEMBLY

OF

GEAR

ASSEMBLY

TRANSMISSION

ASSEMBLY

S

SPEED

TRANSMISSION

Model

fSSW60L

REMOVAL

INSTALLATION

MT

2

MT

3

MT

4

MT

5

MT

5

MT

5

MT

9

MT

9

MT

9

MT

9

MT

9

MT

9

MT10

MT10

MT10

MT10

MT10

MT10

MT10

MT10

MTll

MT

1

1

MT14

MT

16

MT17

MT18

DISASSEMBL

Y

TRANSMISSION

CASE

DISASSEMBLY

DISASSEMBLY

OF

GEAR

ASSEMBLY

ADAPTER

PLATE

DISASSEMBLY

REAR

EXTENSION

DISASSEMBLY

INSPECTION

TRANSMISSION

CASE

AND

REAR

EXTENSION

BEARING

GEARS

AND

SHAFTS

BAULK

RING

SHIFTING

INSERT

01

L

SEAL

REAR

ENGINE

MOUNTING

INSULATOR

ASSEMBLY

FRONT

COVER

ASSEMBLY

TRANSMISSION

CASE

ASSEMBLY

REAR

EXTENSION

ASSEMBLY

ADAPTER

PLATE

ASSEMBLY

ASSEMBLY

OF

GEAR

ASSEMBLY

TRANSMISSION

ASSEMBLY

SERVICE

DATA

AND

SPECIFICATIONS

GENERAL

SPECIFICATIONS

INSPECTION

AND

ADJUSTMENT

TIGHTENING

TORQUE

TROUBLE

DIAGNOSES

AND

CORRECTIONS

SPECIAL

SERVICE

TOOLS

MT19

MT19

MT19

MT

22

MT

22

MT

23

MT

23

MT

23

MT

23

MT

23

MT

24

MT

24

MT

24

MT

24

MT

24

MT

24

MT

24

MT

24

MT

25

MT

29

MT31

MT31

MT32

MT

33

MT

34

MT

35