DATSUN 210 1979 Service Manual

Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 331 of 548

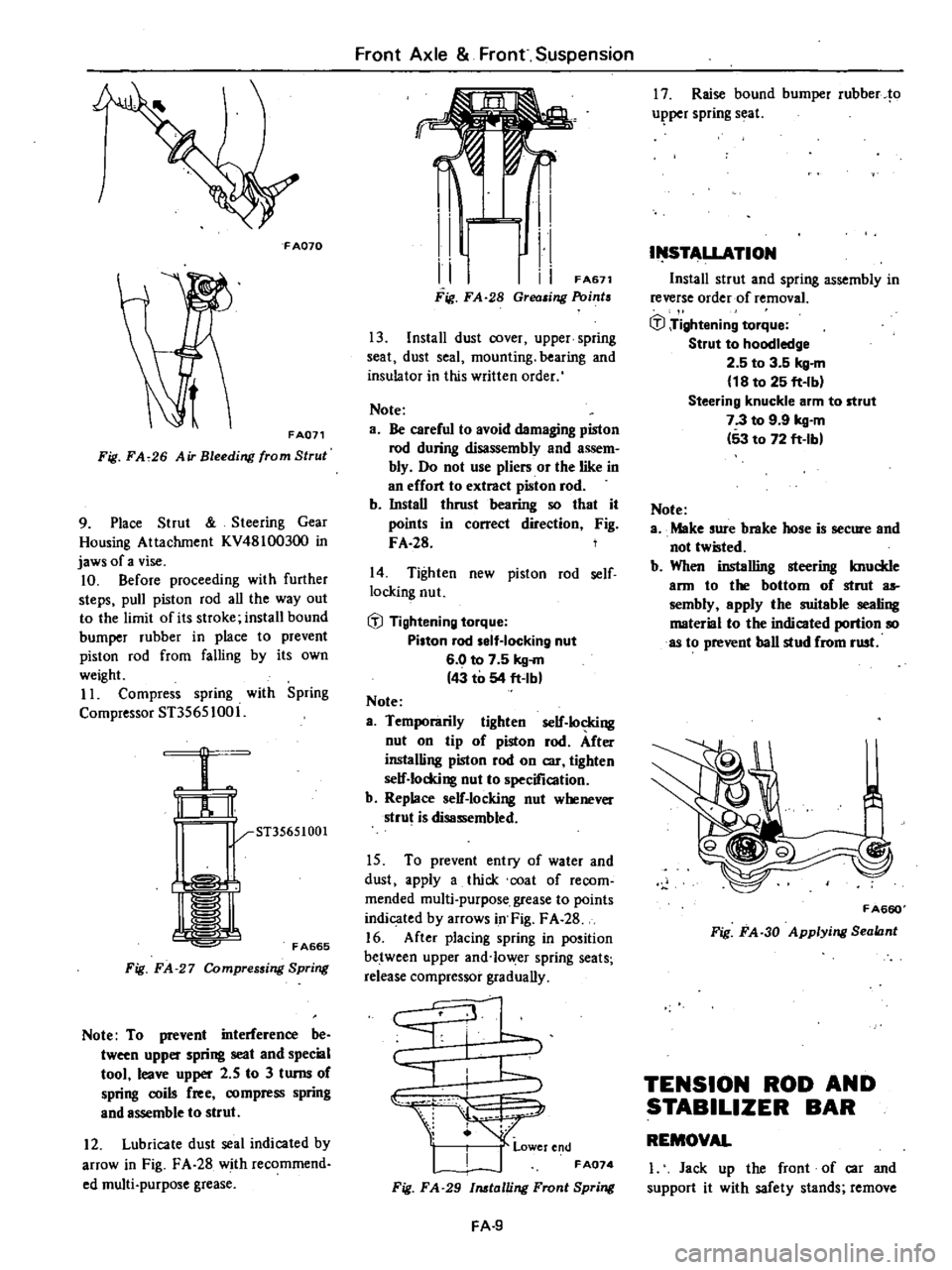

FA070

FA071

Fig

FA

26

Air

Bleeding

from

Strul

9

Place

Strut

Steering

Gear

Housing

Attachment

KV48100300

in

jaws

of

a

vise

10

Before

proceeding

with

further

steps

pull

piston

rod

all

the

way

out

to

the

limit

of

its

stroke

install

bound

bumper

rubber

in

place

to

prevent

piston

rod

from

falling

by

its

own

weight

11

Compress

spring

with

Spring

Compressor

ST35651001

ST35651001

r

l

I

FA665

Fig

FA

27

Compressing

Spring

Note

To

prevent

interference

be

tween

upper

spring

seat

and

special

tool

leave

upper

2

5

to

3

turns

of

spring

coils

free

compress

spring

and

assemble

to

strut

12

Lubricate

dust

seal

indicated

by

arrow

in

Fig

FA

28

with

recommend

ed

multi

purpose

grease

Front

Axle

Front

Suspension

I

1

i

I

FA671

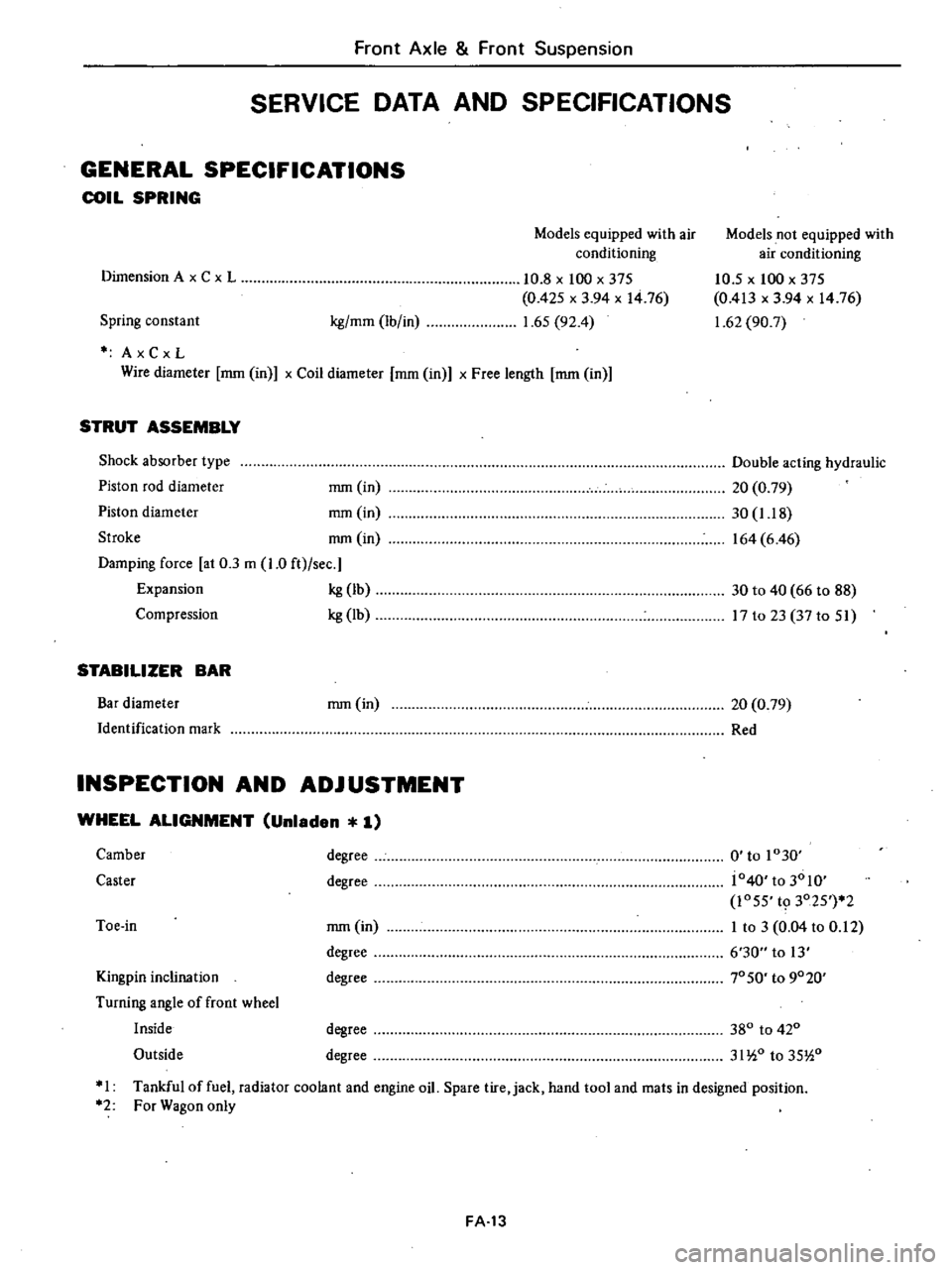

Fig

FA

28

Grea

ing

Point

13

Install

dust

cover

upper

spring

seat

dust

seal

mounting

bearing

and

insulator

in

this

written

order

Note

a

Be

careful

to

avoid

damaging

piston

rod

during

disassembly

and

assem

bly

Do

not

use

pliers

or

the

like

in

an

effort

to

extract

piston

rod

b

InstaU

thrust

bearing

so

that

it

points

in

correct

direction

Fig

FA

28

14

Tighten

new

piston

rod

self

locking

nut

fil

Tightening

torque

Pi

ton

rod

elf

Iocking

nut

6

0

to

7

5

kg

m

43

to

54

ft

lbl

Note

a

Temporarily

tighten

self

locking

nut

on

tip

of

piston

rod

After

installing

piston

rod

on

car

tighten

self

locking

nut

to

specification

b

Replace

self

locking

nut

whenever

strut

is

disassembled

15

To

prevent

entry

of

water

and

dust

apply

a

thick

coat

of

recom

mended

multi

purpose

grease

to

points

indicated

by

arrows

in

Fig

F

A

28

16

After

placing

spring

in

position

between

upper

and

lo

er

spring

seats

release

compressor

graduaUy

I

J

k

1

jt

r

end

FA074

Fig

FA

29

talling

Front

Spring

FA

9

17

Raise

bound

bumper

rubber

10

u

per

spring

seal

I

STALLATION

Install

strut

and

spring

assembly

in

reverse

order

of

removaL

fil

Tightening

torque

Strut

to

hoodledge

2

5

to

3

5

kg

m

18

to

25

ft

Ib

Steering

knuckle

arm

to

strut

7

3

to

9

9

kg

m

53

to

72

ft

lb

Note

a

Make

sure

brake

hose

is

secure

and

not

tw

ted

b

When

installing

steering

knuckle

ann

to

the

bottom

of

strut

as

sembly

epply

the

suitable

sealing

material

to

the

indicated

portion

so

as

to

prevent

ball

stud

from

rust

FA660

Fig

FA

30

Applying

Sealant

TENSION

ROD

AND

STABILIZER

BAR

REMOVAL

I

Jack

up

the

front

of

car

and

support

it

with

safety

stands

remove

Page 332 of 548

wheels

2

Remove

splaahboard

if

necessary

3

Back

off

nut

securing

tension

rod

to

bracket

and

remove

bolts

which

secure

tension

rod

to

lower

arm

Tension

rod

can

then

be

taken

out

4

Remove

nuts

securing

stabilizer

bar

to

connecting

rod

Note

Two

wrenches

are

n

1

in

this

B

5

Remove

bolts

and

nuts

securing

stabilizer

bar

bracket

in

position

Stabilizer

bar

can

then

be

iaken

o

t

CV

3

@

I

Lower

ann

5

Tension

rod

2

Stabilizer

bar

bracket

connecting

rod

6

Tension

rod

3

Stabilizer

bar

4

Stabilizer

bar

bracket

FA129

Fig

FA

31

Removing

Tension

Rod

and

Stabilizer

Bar

INSPECTION

I

Check

tension

rod

and

stabilizer

bar

for

evidence

of

deformation

or

cracks

if

necessary

replace

2

Check

rubber

parts

such

as

ten

sion

rod

and

stabilizer

bar

bushings

to

be

sure

they

are

not

deteriorated

or

cracked

if

1ecessary

replace

INSTAllATION

Install

tension

rod

and

stabilizer

bar

in

tJ

1e

reverse

order

of

removal

noting

the

following

I

Be

sure

stabilizer

bar

is

not

closer

to

either

side

but

is

located

at

the

middle

If

stabilizer

bar

is

new

use

the

following

procedure

to

center

the

stabilizer

bar

Position

arm

with

white

paipt

mark

toward

left

side

of

car

Front

Axle

Front

Suspension

Set

slabillz

rliar

mount

bushingS

So

that

outer

side

of

stabilizer

bar

bushing

is

brought

into

inner

side

of

marking

e

o

I

19

e

1

Marking

2

Bushing

3

Marking

4

While

painting

5

Marking

0

A

F

A667

Fig

FA

32

Centering

8lDbilize

Bar

2

Chec

to

be

sure

that

tension

rod

bushing

is

propelly

centered

in

its

seat

3

Be

sure

that

tension

rod

bracket

bolt

is

correctly

torqued

Note

a

Noting

direction

of

tension

rod

bushing

properly

center

bushing

in

tension

rod

bushing

washer

Fig

FA

33

Direclion

of

Tension

Rod

BUlhing

b

After

installation

make

sure

mini

mum

clearances

between

tension

rods

end

stabilizer

bar

are

equal

on

both

sides

c

Closely

observe

torq

ue

specification

when

tightening

tension

rod

bracket

retaining

bolts

d

First

tighten

tension

rod

on

bracket

side

to

specified

torque

setting

then

install

the

other

end

on

lower

arm

fJ

Tightening

tOlque

Tension

rod

bushing

installation

nut

4

5

to

5

11rg

33

to

37

ft

lbl

FA

10

Tension

rOd

to

Lower

ann

5

1

to

6

1

kg

m

137

to

44

ft

Ibl

Tension

rod

bracket

to

body

3

2

to

4

3

kg

m

23

to

31

ft

Ibl

Stabilizer

bar

bleck

t

1

6to2

11rg

112

to

15

ft

lbl

Stabilizel

bel

connecting

rod

1

6

to

2

1

kg

m

12

to

15

ft

lbl

LOWER

ARM

AND

LOWER

BALL

JOINT

The

lower

ann

is

connected

to

the

suspension

member

through

a

rubber

bwhing

end

to

the

strut

through

a

ball

joint

The

lower

ball

joint

is

assembled

at

the

factory

and

cannot

be

disassem

bled

REMOVAL

1

Block

rear

wheels

with

chocks

2

Jack

up

front

of

car

and

support

it

with

safety

stands

remove

wheel

3

Remove

splashboard

4

Separate

knuckle

arm

from

strut

5

Pry

colter

pin

off

and

separate

side

rod

fromknilckle

arm

using

Ball

Joint

Remover

HT72520000

FA661

Fig

FA

34

Remoliing8ideRod

Ball

Joint

6

Remove

tension

rod

and

stabilizer

bar

from

lower

ann

7

Remove

bolt

connecting

lower

ann

to

suspension

crossmember

Page 333 of 548

FA731

Fig

FA

35

Removing

Wwer

Arm

8

Remove

suspension

ball

joint

from

lower

arm

9

Place

knuckle

arm

in

a

vise

Re

move

suspension

ball

joint

from

knuckle

arm

using

a

press

@

I

r

662

Fig

FA

36

Remouing

Suspension

Ball

Joint

10

Withdraw

lower

arm

bushing

from

transverse

link

using

Front

Lower

Arm

Bushing

Replacer

Set

ST36720000

and

a

press

Mrl

o

o

o

0

F

A669

Fig

FA

37

Removing

Wwer

Am

BuNUng

INSPECTION

Lower

arm

I

Repair

or

replace

lower

arm

if

deformed

cracked

or

damaged

Front

Axle

Front

Suspension

2

Replace

bushing

if

excessively

worn

or

cracked

3

Make

sure

mating

surface

of

bush

ing

is

clean

and

free

from

oil

or

grease

apply

soapy

water

to

bushing

to

facili

tate

installation

Lower

bell

Joint

I

Ball

joint

is

assembled

at

factory

and

cannot

be

disassembled

Check

ball

stud

turning

torque

with

nut

in

place

on

ball

stud

If

it

is

far

from

specifications

replace

liJ

Turning

torque

New

parts

40

to

100

kg

cm

35

to

87

in

Ibl

Used

parts

More

than

20

kg

cm

117

in

Ibl

lUJ

F

A333

Fig

FA

38

Lower

Ball

Joint

2

Check

condition

of

dust

cover

If

it

is

cracked

excessively

replace

ball

joint

3

Lubricate

ball

joint

with

recorn

mended

multi

purpose

grease

To

lubricate

remove

plug

and

in

stall

grease

nipple

Pump

grease

slowly

until

old

grease

is

completely

forced

out

After

greasing

reinstall

plug

Note

When

a

high

pressure

grease

gun

used

operate

it

carefully

so

that

grease

is

injected

slowly

and

new

grease

does

not

DOme

out

from

clamp

portion

INSTALLATION

Install

lower

arm

and

suspension

ball

joint

in

reverse

order

of

removal

FA

l

Lower

erm

buahln

I

Before

installing

bushing

rub

off

rust

or

paint

drops

from

insi

e

collar

on

lower

arm

with

emery

paper

2

Using

Replacer

Set

ST36720000

insert

bushing

with

a

press

until

end

face

of

bushing

is

aligned

with

collar

on

lower

arm

ST36720000

I

I

HA734

Fig

FA

39

Installiff

l

Wwer

Ami

Bu

hi1f

I

Lower

erm

end

atebIllzer

ber

To

install

lower

arm

and

stabilizer

bar

temporarily

tighten

securing

bolts

Then

tighten

bolts

to

specifications

at

curb

weight

with

tires

on

ground

liJ

Tightening

torque

Bell

joint

socket

to

lower

arm

5

1

to

6

1

kg

m

37

to

44

ft

Ibl

Bell

joint

socket

to

lowel

arm

with

tension

rod

5

1

to

6

1

kg

m

37

to

44

ft

Ibl

Bell

joint

to

knuck

le

arm

5

5

to

10

0

kg

m

140

to

72

ft

Ibl

Lower

IIrm

bolt

nut

3

9

to

5

0

kg

m

28

to

36

ft

Ibl

Side

lod

ball

joint

to

knuckle

arm

3

0

to

7

0

kg

m

122

to

51

ft

lbl

Steering

knuckle

erm

to

stlut

7

3

to

9

9

kg

m

53

to

72

ft

Ibl

Page 334 of 548

SUSPENSION

CROSSMEMBER

REMOVAL

Remove

lower

arm

referring

to

previous

part

of

this

section

2

With

an

overhead

hoist

and

lifting

cable

support

weighi

of

engine

to

remove

loads

from

mountings

3

Remove

engine

mounting

nuts

Separate

suspension

crossmember

from

engine

4

Remove

bolt

indicated

by

arrow

and

separate

suspension

crossmember

from

car

body

Front

Axle

Front

Suspension

n

FA732

Fig

FA

40

Removing

SUlpemion

Croumember

INSPECTION

Check

suspension

crossmember

for

evidence

of

deformation

or

cracking

if

necessary

replace

FA

12

INSTALLAnON

Install

suspension

crossmember

in

reverse

order

of

removal

noting

the

following

fj

Tightening

torque

Suspension

member

to

boiI

y

fIe

me

3

2

to

4

3

kltm

23

to

31

ft

lb

Engine

mounting

insulator

to

suspension

member

3

2

to

4

3

ka

m

23

to

31

ft

b

Page 335 of 548

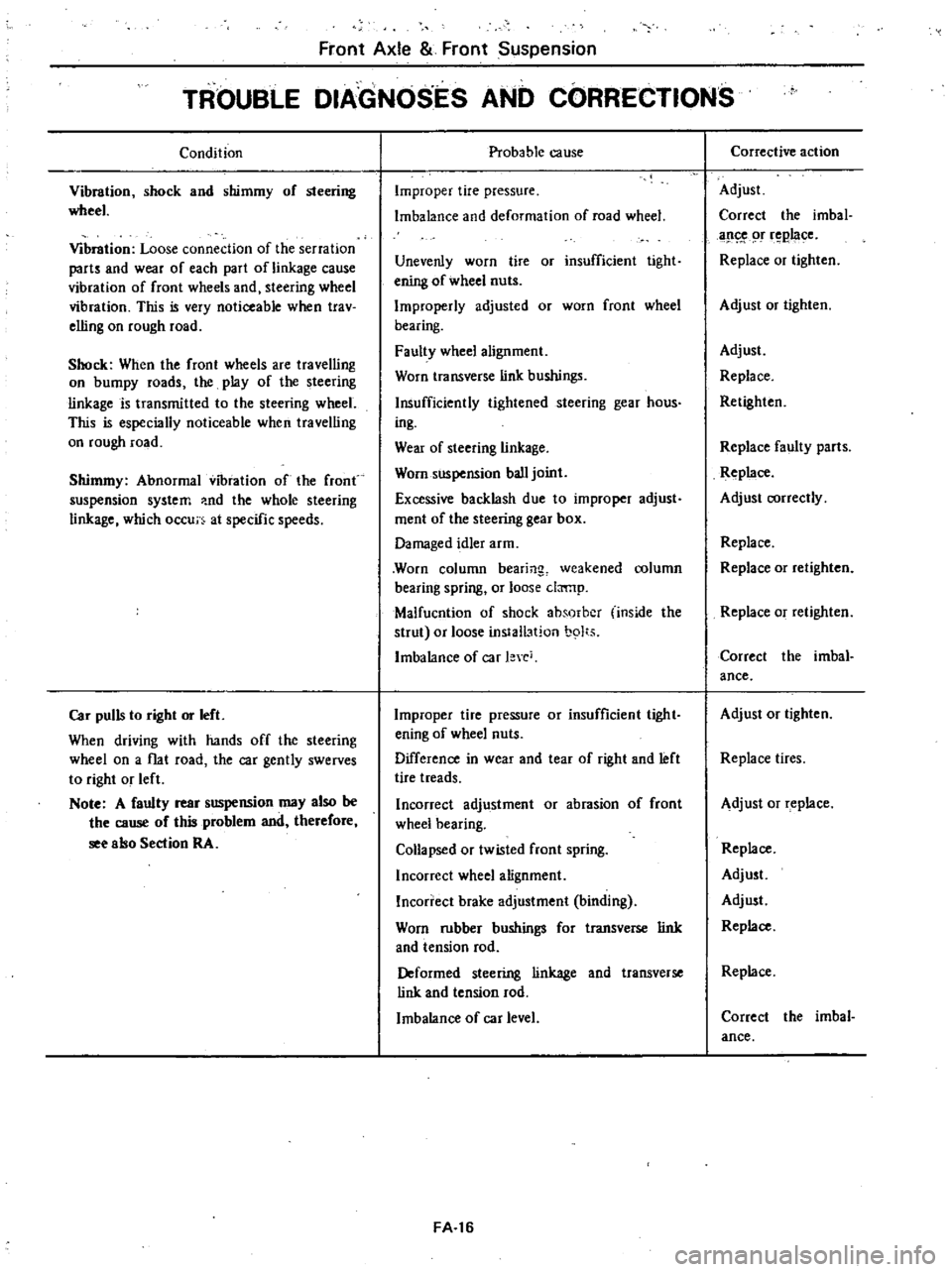

Front

Axle

Front

Suspension

SERVICE

DATA

AND

SPECIFICATIONS

GENERAL

SPECIFICATIONS

COIL

SPRING

Models

equipped

with

air

conditioning

Models

not

equipped

with

air

conditioning

10

5

x

100

x

375

0

413

x

3

94

x

1476

1

62

90

7

Spring

constant

kg

mm

Ib

in

10

8

x

100

x

375

0

425

x

3

94

x

1476

1

65

92

4

Dimension

A

x

C

x

L

AxCxL

Wire

diameter

mm

in

x

Coil

diameter

mm

in

x

Free

length

mm

in

STRUT

ASSEMBLY

Shock

absorber

type

Piston

rod

diameter

mm

in

Piston

diameter

mm

in

Stroke

nun

in

Damping

force

at

0

3

m

1

0

ft

sec

Expansion

kg

Ib

Compression

kg

Ib

Double

acting

hydraulic

20

0

79

30

1

18

164

6

46

30

to

40

66

to

88

17

to

23

37

to

51

STABILIZER

BAR

Bar

diameter

Identification

mark

mm

in

20

0

79

Red

INSPECTION

AND

ADJUSTMENT

WHEEL

ALIGNMENT

Unladen

1

Kingpin

inclination

Turning

angle

of

front

wheel

Inside

Outside

mm

in

degree

degree

0

to

1030

j040

to

3010

1055

t9

3025

2

I

to

3

0

04

to

0

12

6

30

to

13

70

SO

to

9020

Camber

Caster

degree

degree

Toe

in

degree

degree

380

to

420

31

io

to

35

i0

I

Tankful

of

fuel

radiator

coolant

and

engine

oil

Spare

tire

jack

hand

tool

and

mats

in

designed

position

2

For

Wagon

only

FA

13

Page 336 of 548

WHEEL

BEARING

Wheel

bearing

axial

play

Wheel

bearing

nut

tightening

torque

Return

angle

Rotation

starting

torque

With

new

grease

seal

With

used

grease

seal

At

wheel

hub

bolt

With

new

grease

seal

With

used

grease

seal

SUSPENSIONBA

JOINT

Turning

torque

New

parts

Used

parts

TIGHTENIN

TORQUE

LOWERBAl

L

JOINT

Ball

joint

socket

to

lower

arm

Ball

joint

to

knuckle

arm

Stud

nut

STRUT

Steering

knuckle

arm

to

strut

Strut

to

hoodledge

Piston

rod

self

locking

nut

Gland

packing

DISC

BRAKE

Rotor

to

hub

SIDE

ROD

Side

rod

ball

jOIDt

to

knuckle

arm

LOWER

ARM

Lower

arm

bolt

nut

Side

rod

adjusting

nut

TENSION

ROD

Tension

rod

bushing

installation

nut

Tension

rod

to

lower

arm

Tension

rod

bracket

to

body

Frpn

Axle

Front

Suspension

mm

in

0

0

kg

m

ft

lb

degree

3

0

to

3

5

22

to

25

900

kg

cm

in

lbr

kg

em

in

Ib

Less

than

7

0

6

1

1

0

to

4

5

0

9

to

3

9

kg

lb

kg

lb

Less

than

1

2

2

6

0

1

7

to

0

79

0

37

to

1

74

kg

cm

in

Ib

kg

cm

in

Ib

40

to

100

35

to

87

More

than

20

17

kg

m

ft

Ib

5

1

to

6

1

37

to

44

5

5

to

10

0

40

to

72

7

3

to

9

9

53

to

72

2

5

to

3

5

18

to

25

6

0

to

7

5

43

to

54

8

0

to

11

0

58

to

80

3

9

to

5

3

28

to

38

3

0

to

7

0

22

to

51

3

9

to

5

0

2810

36

8

0

to

10

0

58

to

72

4

5

to

5

1

33

to

37

5

1

to

6

1

37

to

44

3

2

to

4

3

23

to

31

FA

14

Page 337 of 548

Front

Axle

Front

Suspension

STABILIZER

BAR

Stabilizer

bar

bracket

Stabilizer

bar

connecting

rod

1

6

to

2

1

12

to

15

1

6

to

2

1

12

to

15

SUSPENSION

CROSSMEMBER

Suspension

member

to

body

frame

Engine

mounting

insulator

to

suspension

member

3

2

to

4

3

23

to

31

3

2

to

4

3

23

to

31

FA

15

Page 338 of 548

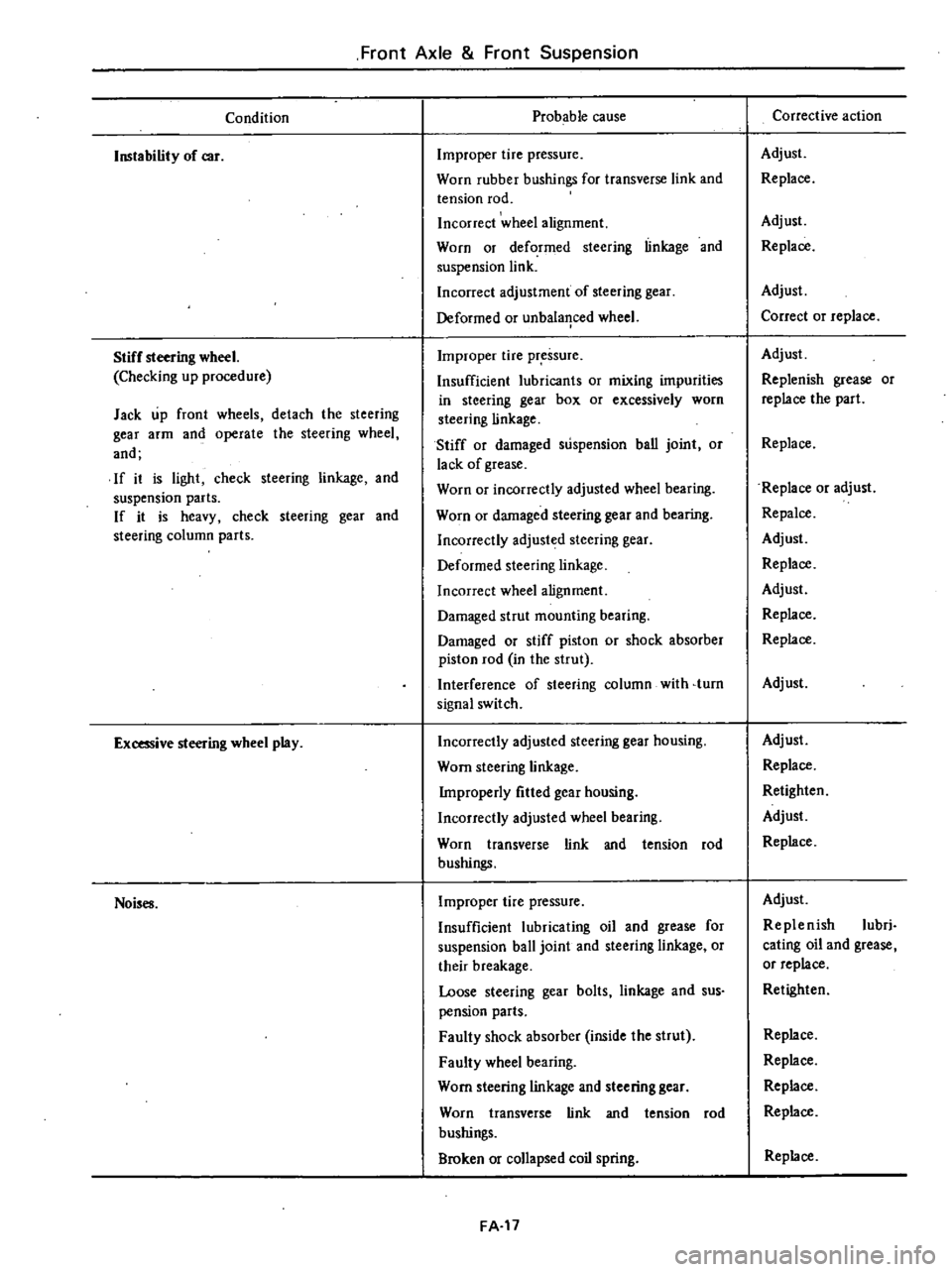

Front

Axle

Front

Suspension

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Vibration

shock

and

shimmy

of

steering

wheel

Vibration

Loose

connection

of

the

serration

parts

and

wear

of

each

part

of

linkage

cause

vibration

of

front

wheels

and

steering

wheel

vibration

This

is

very

noticeable

when

trav

elling

on

rough

road

Shock

When

the

front

wheels

are

travelling

on

bumpy

roads

the

play

of

the

steering

linkage

is

transmitted

to

the

steering

wheel

This

is

especially

noticeable

when

travelling

on

rough

road

Shimmy

Abnormal

vibration

of

the

front

suspension

system

nd

the

whole

steering

linkage

which

occu

at

specific

speeds

Car

pulls

to

right

or

left

When

driving

with

hands

off

the

steering

wheel

on

a

flat

road

the

car

gently

swerves

to

right

or

left

Note

A

faulty

rear

suspension

may

also

be

the

cause

of

this

problem

and

therefore

see

ebo

Section

RA

Proba

b

Ie

ca

use

Improper

tire

pressure

Imbalance

and

deformation

of

road

wheel

Unevenly

worn

tire

or

insufficient

tight

ening

of

wheel

nuts

Improperly

adjusted

or

worn

front

wheel

bearing

Faulty

wheel

alignment

Worn

transverse

link

bushings

Insufficiently

tightened

steering

gear

hous

ing

Wear

of

steering

linkage

Worn

suspension

ball

joint

Excessive

backlash

due

to

improper

adjust

ment

of

the

steering

gear

box

Damaged

idler

arm

Worn

column

bearing

weakened

column

bearing

spring

or

loose

drmp

Malfucntion

of

shock

absorber

inside

the

strut

or

loose

install3t

on

b9

t5

Imbalance

of

car

l

e

Improper

tire

pressure

or

insufficient

tight

ening

of

wheel

nuts

Difference

in

wear

and

tear

of

right

and

left

tire

treads

Incorrect

adjustment

or

abrasion

of

front

wheel

bearing

Collapsed

or

twisted

front

spring

Incorrect

wheel

alignment

Incorrect

brake

adjustment

binding

Worn

rubber

bushings

for

transverse

link

and

tension

rod

Deformed

steering

linkage

and

transverse

link

and

tension

rod

Imbalance

of

car

level

FA

16

Corrective

action

Adjust

Correct

the

imbal

ap

9f

r

B4I

e

Replace

or

tighten

Adjust

or

tighten

Adjust

Replace

Retighten

Replace

faulty

parts

Replace

Adjust

correctly

Replace

Replace

or

retighten

Replace

or

retighten

Correct

the

imbal

ance

Adjust

or

tighten

Replace

tires

Adjust

or

replace

Replace

Adjust

Adjust

Replace

Replace

Correct

the

imbal

ance

Page 339 of 548

Front

Axle

Front

Suspension

Condition

Instability

of

car

Stiff

steering

wheel

Checking

up

procedure

Jack

up

front

wheels

detach

the

steering

gear

arm

and

operate

the

steering

wheel

and

If

it

is

light

check

steering

linkage

and

suspension

parts

If

it

is

heavy

check

steering

gear

and

steering

column

parts

Excessive

steering

wheel

play

Noises

Probable

cause

Improper

tire

pressure

Worn

rubber

bushings

for

transverse

link

and

tension

rod

Incorrect

wheel

alignment

Worn

or

deformed

steering

linkage

and

suspension

link

Incorrect

adjustment

of

steering

gear

Deformed

or

unbala

1ced

wheel

Improper

tire

pressure

Insufficient

lubricants

or

mixing

impurities

in

steering

gear

box

or

excessively

worn

steering

linkage

Stiff

or

damaged

suspension

ban

joint

or

lack

of

grease

Worn

or

incorrectly

adjusted

wheel

bearing

Worn

or

damaged

steering

gear

and

bearing

Incorrectly

adjusted

steering

gear

Deformed

steering

linkage

Incorrect

wheel

alignment

Damaged

strut

mounting

bearing

Damaged

or

stiff

piston

or

shock

absorber

piston

rod

in

the

strut

Interference

of

steering

column

with

turn

signal

switch

Incorrectly

adjusted

steering

gear

housing

Worn

steering

linkage

Improperly

fitted

gear

housing

Incorrectly

adjusted

wheel

bearing

Worn

transverse

link

and

tension

rod

bushings

Improper

tire

pressure

Insufficient

lubricating

oil

and

grease

for

suspension

ball

joint

and

steering

linkage

or

their

breakage

Loose

steering

gear

bolts

linkage

and

sus

pension

parts

Faulty

shock

absorber

inside

the

strut

Faulty

wheel

bearing

Worn

steering

linkage

and

steering

gear

Worn

transverse

link

and

tension

rod

bushings

Broken

or

collapsed

coil

spring

FA

17

Corrective

action

Adjust

Replace

Adjust

Replace

Adjust

Correct

or

replace

Adjust

Replenish

grease

or

replace

the

part

Replace

Replace

or

adjust

Repalce

Adjust

Replace

Adjust

Replace

Replace

Adjust

Adjust

Replace

Retighten

Adjust

Replace

Adjust

Replenish

lubri

cating

oil

and

grease

or

replace

Retighten

Replace

Replace

Replace

Replace

Replace

Page 340 of 548

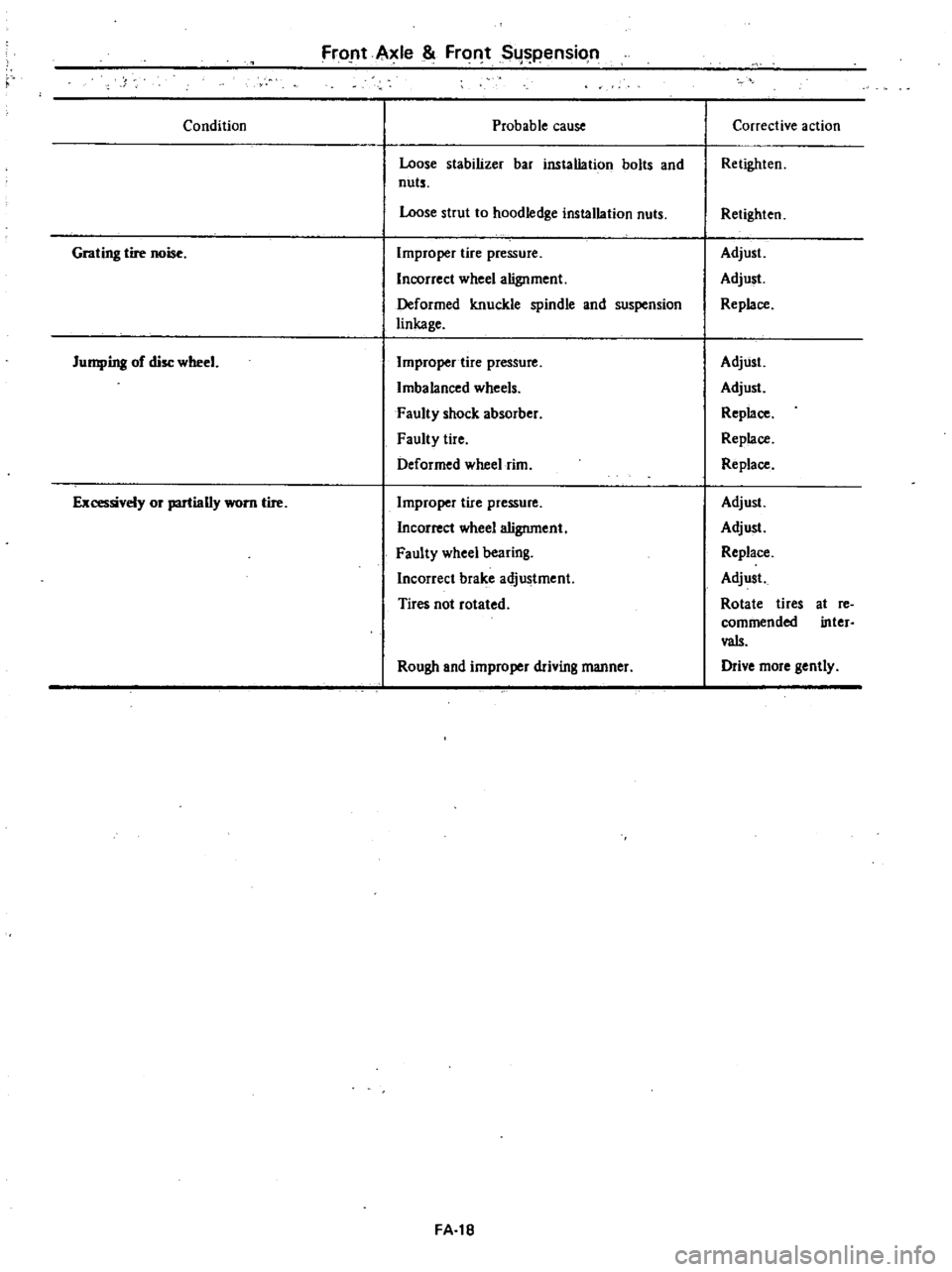

Front

Axle

Front

Suspension

Condition

Probable

cause

Loose

stabilizer

bar

installation

bolts

and

nuts

Loose

strut

to

hoodledge

installation

nuts

Grating

tire

noise

Improper

tire

pressure

Incorrect

wheel

alignment

Deformed

knuckle

spindle

and

suspension

linkage

Jumping

of

disc

wheel

Improper

tire

pressure

Imbalanced

wheels

Faulty

shock

absorber

Faulty

tire

Deformed

wheel

rim

Ex

t

J1

or

partially

worn

tire

Improper

tire

pressure

Incorrect

wheel

alignment

Faulty

wheel

bearing

Incorrect

brake

adjustment

Tires

not

rotated

Rough

and

improper

driving

manner

FA

18

Corrective

action

Retighten

Retighten

Adjust

Adjust

Replace

Adjust

Adjust

Replace

Replace

Replace

Adjust

Adjust

Replace

Adjust

Rotate

tires

commended

vaIs

Drive

more

gently

at

re

inter