check oil DATSUN 210 1979 Owner's Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 92 of 548

5

The

pressure

gauge

indicates

static

fuel

pressure

in

the

line

The

gauge

reading

should

be

within

the

specified

value

Fuel

pump

pressure

0

21

to

0

27

kg

em2

3

0

to

3

8

pli

I

Note

If

the

fuel

in

the

carburetor

float

chamber

has

run

out

and

engine

has

stopped

remove

clip

and

pour

fuel

into

carburetor

Fasten

clip

securely

and

repeat

static

pres

sure

test

If

pressure

is

not

within

the

specifi

ed

limit

remove

pump

as

an

assembly

CAPACITY

TEST

The

capacity

test

is

conducted

only

when

static

pressure

is

within

the

specification

To

conduct

this

test

proceed

as

follows

1

Disconnect

pressure

gauge

from

T

connector

and

in

its

vacant

place

install

a

suitable

container

as

a

fuel

sump

2

Start

engine

and

run

at

1

000

pm

3

Pump

should

deliver

the

specified

amouni

of

fuel

If

little

or

no

fuel

flows

from

open

end

of

pipe

it

is

an

indication

that

fuel

line

is

clogged

or

pump

is

mal

functioning

Fuel

pump

capacity

450

cc

27

46

eu

inl

min

at

1

000

rpm

REMOVAL

AND

INSTALLATION

Note

When

disconnecting

fuel

lines

use

a

container

to

receive

fuel

remaining

in

fuel

hoses

I

Disconnect

inlet

and

outlet

fuel

hoses

from

fuel

pump

2

Remove

fuel

pump

3

To

install

reverse

the

order

of

removal

Engine

Fuel

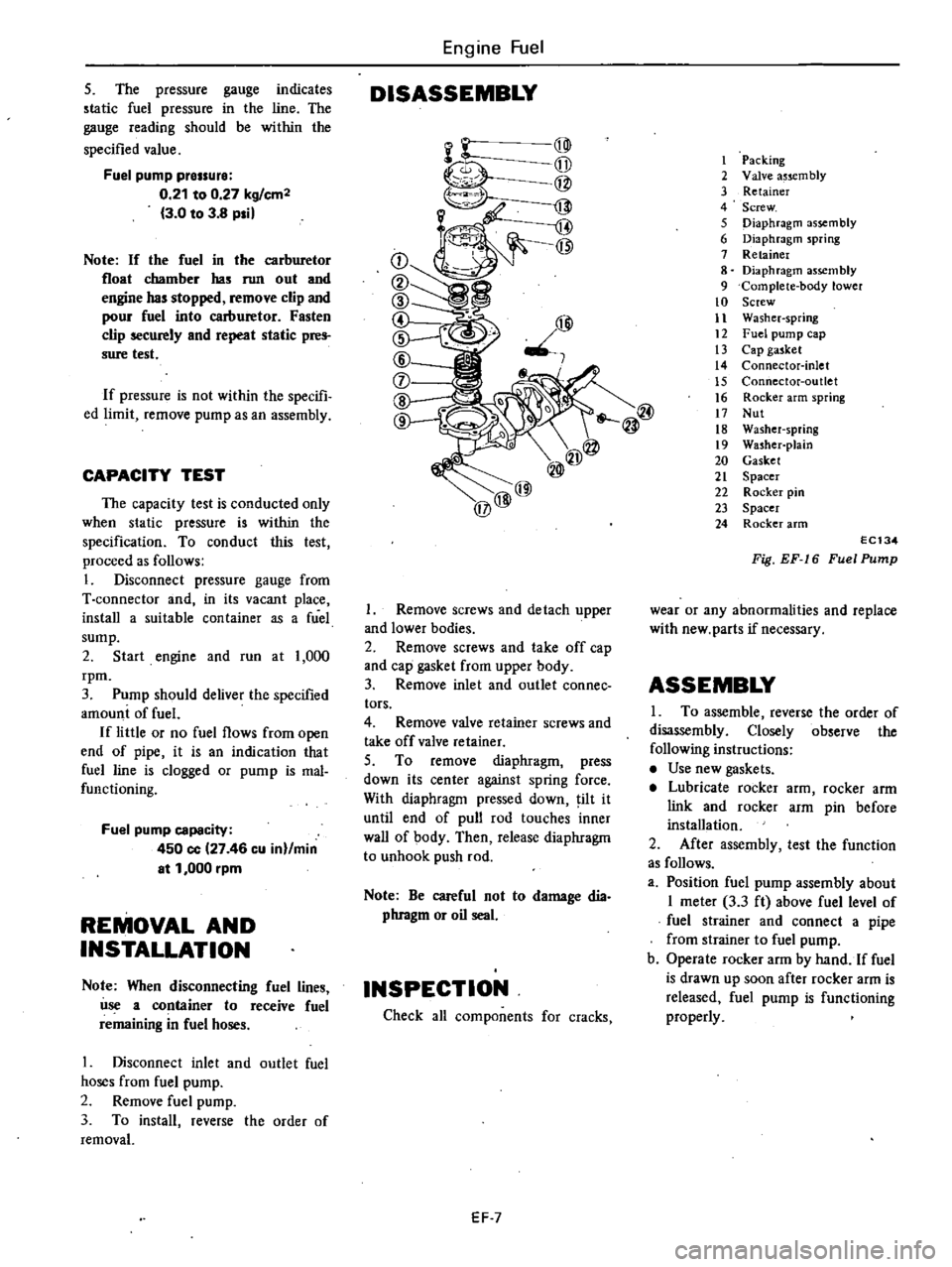

DISASSEMBLY

@@

@@

@

@@

1

Remove

screws

and

detach

upper

and

lower

bodies

2

Remove

screws

and

take

off

cap

and

cap

gasket

from

upper

body

3

Remove

inlet

and

outlet

connee

tors

4

Remove

valve

retainer

screws

and

take

off

valve

retainer

S

To

remove

diaphragm

press

down

its

center

against

spring

force

With

diaphragm

pressed

down

ilt

it

until

end

of

pull

rod

touches

inner

wall

of

body

Then

release

diaphragm

to

unhook

push

rod

Note

Be

careful

not

to

damage

dia

phragm

or

oil

seal

INSPECTION

Check

all

components

for

cracks

EF

7

I

Packing

2

Valve

a5scm

bly

3

Retainer

4

Screw

5

Diaphragm

assembly

6

Diaphragm

spring

7

Retainer

8

Diaphragm

assembly

9

Complete

body

lower

10

Screw

11

Washer

spring

12

Fuel

pump

cap

13

Cap

gasket

14

Connector

inlet

15

Connector

outlet

16

Rocker

arm

spring

17

Nut

18

Washer

spring

19

Washer

pJain

20

Gasket

21

Spacer

22

Rocker

pin

23

Spacer

24

Rocker

arm

EC134

Fig

EF

16

Fuel

Pump

wear

or

any

abnormalities

and

replace

with

new

parts

if

necessary

ASSEMBLY

I

To

assemble

reverse

the

order

of

disassembly

Closely

observe

the

following

instructions

Use

new

gaskets

Lubricate

rocker

arm

rocker

arm

link

and

rocker

arm

pin

before

installation

2

After

assembly

test

the

function

as

follows

a

Position

fuel

pump

assembly

about

I

meter

3

3

ft

above

fuel

level

of

fuel

strainer

and

connect

a

pipe

from

strainer

to

fuel

pump

b

Operate

rocker

arm

by

hand

If

fuel

is

drawn

up

soon

after

rocker

arm

is

released

fuel

pump

is

functioning

properly

Page 125 of 548

Emission

Control

System

CRANKCASE

EMISSION

CONTROL

SYSTEM

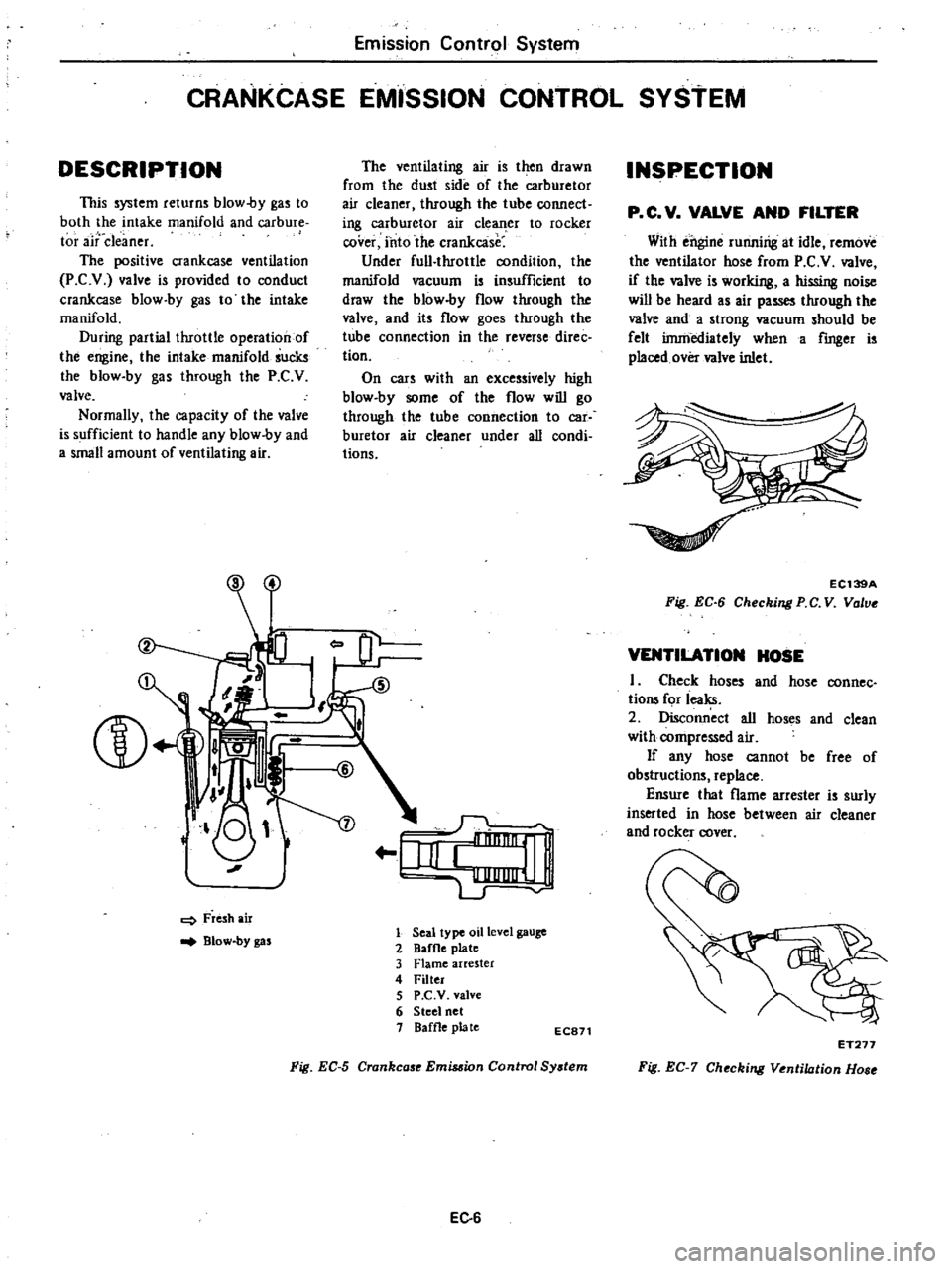

DESCRIPTION

This

system

returns

blow

by

gas

to

both

the

intake

manifold

and

carbure

tor

aitdeaner

The

positive

crankcase

ventilation

P

C

v

valve

is

provided

to

conduct

crankcase

blow

by

gas

to

the

intake

manifold

During

partial

throttle

operation

of

the

engine

the

intake

manifold

sucks

the

blow

by

gas

through

the

P

C

V

valve

Normally

the

capacity

of

the

valve

is

sufficient

to

handle

any

blow

by

and

a

small

amount

of

ventilating

air

L

J

J

o

I

Fresh

air

Blow

by

gas

The

ventilating

air

is

then

drawn

from

the

dust

side

of

the

carburetor

air

cleaner

through

the

tube

connect

ing

carburetor

air

cle

er

to

rocker

cover

into

the

crankcase

Under

full

throttle

condition

the

manifold

vacuum

is

insufficient

to

draw

the

blow

by

flow

through

the

valve

and

its

flow

goes

through

the

tube

connection

in

the

reverse

direc

tion

On

cars

with

an

excessively

high

blow

by

some

of

the

flow

will

go

through

the

tube

connection

to

car

buretor

air

cleaner

under

all

condi

tions

r

IiI

e

1

LJ

1

Seal

type

oil

level

gauge

2

DafOe

plate

3

Flame

arrester

4

Filter

5

P

C

V

valve

6

Steel

net

1

Baffle

plate

EC871

Fig

EC

5

Crankcase

Emis

ion

Control

Sy

tem

EC

6

INSPECTION

p

C

V

VALVE

AND

FILTER

With

ei

gine

runnirig

at

idle

remove

the

ventilator

hose

from

P

C

V

valve

if

the

valve

is

working

a

hissing

noise

wiD

be

heard

as

air

passes

through

the

valve

and

a

strong

vacuum

should

be

felt

irnniediately

when

a

fmger

is

placed

over

valve

inlet

EC139A

Fig

EC

6

Checking

PC

V

Vo

ve

VENTILATION

HOSE

I

Check

hoses

and

hose

connec

tions

for

ieaks

2

oisconn

ct

all

hoses

and

clean

with

compressed

air

If

any

hose

cannot

be

free

of

obstructions

replace

Ensure

that

flame

arrester

is

surly

inserted

in

hose

between

air

cleaner

and

rocker

rover

ET277

Fig

EC

7

Checking

Ventilation

Hose

Page 128 of 548

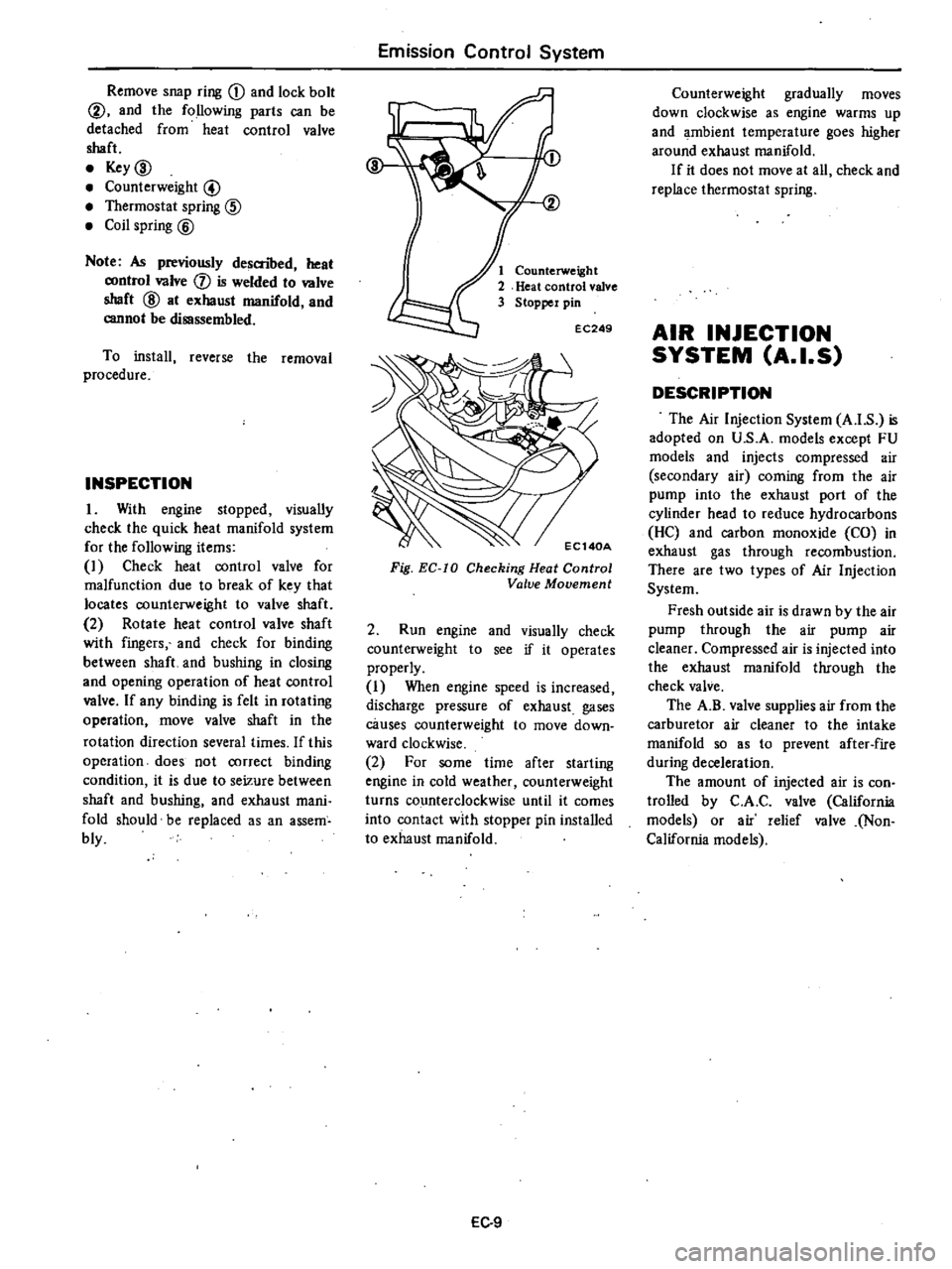

Remove

snap

ring

CD

and

lock

bolt

@

and

the

following

parts

can

be

detached

from

heat

control

valve

shaft

Key

ID

Counterweight

@

Thermostat

spring

@

Coil

spring

@

Note

As

previously

descnbed

heat

control

valve

j

is

welded

to

valve

shaft

@

at

exhaust

manifold

and

cannot

be

disassembled

To

install

reverse

the

removal

procedure

INSPECTION

1

With

engine

stopped

visually

check

the

quick

heat

manifold

system

for

the

following

items

I

Check

heat

control

valve

for

malfunction

due

to

break

of

key

that

locates

counterweight

to

valve

shaft

2

Rotate

heat

control

valve

shaft

with

fingers

and

check

for

binding

between

shaft

and

bushing

in

closing

and

opening

operation

of

heat

control

valve

If

any

binding

is

felt

in

rotating

operation

move

valve

shaft

in

the

rotation

direction

several

times

If

this

operation

does

not

correct

binding

condition

it

is

due

to

seizure

between

shaft

and

bushing

and

exhaust

mani

fold

should

be

replaced

as

an

assem

bly

Emission

Control

System

Counterweight

Heat

control

valve

Stopper

pin

EC249

Fig

EC

IO

Checking

Heat

Control

Valve

Movement

2

Run

engine

and

visually

check

counterweight

to

see

if

it

operates

properly

I

When

engine

speed

is

increased

discharge

pressure

of

exhaust

gases

causes

counterweight

to

move

down

ward

clockwise

2

For

some

time

after

starting

engine

in

cold

weather

counterweight

turns

counterclockwise

until

it

comes

into

contact

with

stopper

pin

installed

to

exhaust

manifold

EC

9

Counterweight

gradually

moves

down

clockwise

as

engine

warms

up

and

ambient

temperature

goes

higher

around

exhaust

manifold

If

it

does

not

move

at

all

check

and

replace

thermostat

spring

AIR

INJECTION

SYSTEM

A

I

S

DESCRIPTION

The

Air

Injection

System

A

I

S

is

adopted

on

U

S

A

models

except

FU

models

and

injects

compressed

air

secondary

air

coming

from

the

air

pump

into

the

exhaust

port

of

the

cylinder

head

to

reduce

hydrocarbons

He

and

carbon

monoxide

CO

in

exhaust

gas

through

recombustion

There

are

two

types

of

Air

Injection

System

Fresh

outside

air

is

drawn

by

the

air

pump

through

the

air

pump

air

cleaner

Compressed

air

is

injected

into

the

exhaust

manifold

through

the

check

valve

The

A

B

valve

supplies

air

from

the

carburetor

air

cleaner

to

the

intake

manifold

so

as

to

prevent

after

fire

during

deceleration

The

amount

of

injected

air

is

con

trolled

by

C

A

C

valve

California

models

or

air

relief

valve

Non

California

models

Page 144 of 548

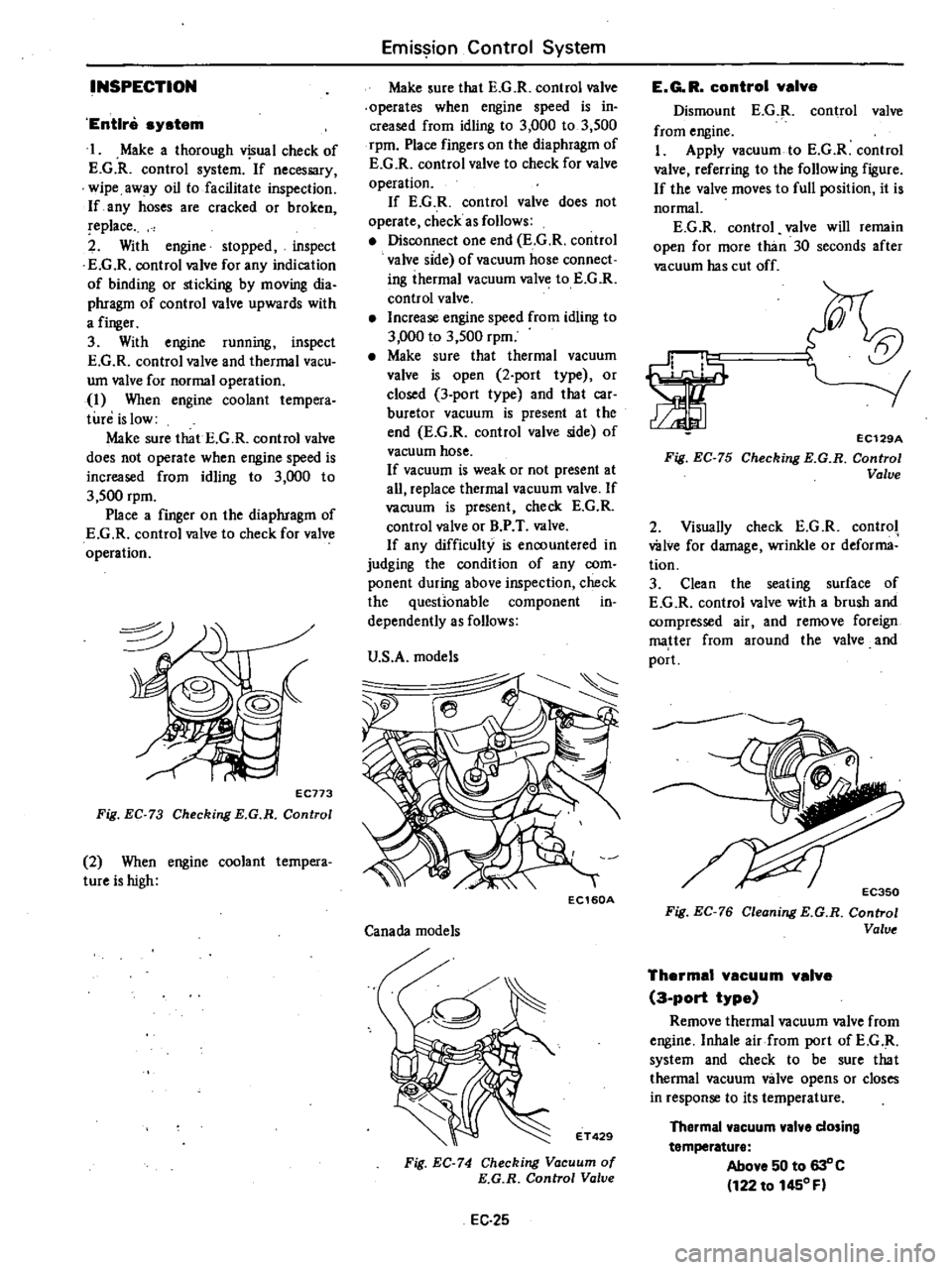

INSPECTION

Entire

system

I

Make

a

thorough

vjsual

check

of

E

G

R

control

system

If

necessary

wipe

away

oil

to

facilitate

inspection

If

any

hoses

are

cracked

or

broken

replace

2

With

engine

stopped

inspect

E

G

R

control

valve

for

any

indication

of

binding

or

sticking

by

moving

dia

phragm

of

control

valve

upwards

with

a

finger

3

With

engine

running

inspect

E

G

R

control

valve

and

thermal

vacu

um

valve

for

normal

operation

1

When

engine

coolant

tempera

tun

is

low

Make

sure

that

E

G

R

control

valve

does

not

operate

when

engine

speed

is

increased

from

idling

to

3

000

to

3

500

rpm

Place

a

finger

on

the

diaphragm

of

E

G

R

control

valve

to

check

for

valve

operation

EC773

Fig

EC

73

Checking

E

G

R

Control

2

When

engine

coolant

tempera

tureishigh

Emission

Control

System

Make

sure

that

E

G

R

control

valve

operates

when

engine

speed

is

in

creased

from

idling

to

3

000

to

3

500

rpm

Place

fingers

on

the

diaphragm

of

E

G

R

control

valve

to

check

for

valve

operation

If

E

G

R

control

valve

does

not

operate

check

as

follows

Disconnect

one

end

E

G

R

control

valve

side

of

vacuum

hose

connect

ing

ihermal

vacuum

valve

to

E

G

R

control

valve

Increase

engine

speed

from

idling

to

3

000

to

3

500

rpm

Make

sure

that

thermal

vacuum

valve

is

open

2

port

type

or

closed

3

port

type

and

that

car

buretor

vacuum

is

present

at

the

end

E

G

R

control

valve

side

of

vacuum

hose

If

vacuum

is

weak

or

not

present

at

all

replace

thermal

vacuum

valve

If

vacuum

is

present

check

E

G

R

control

valve

or

B

P

T

valve

If

any

difficulty

is

encountered

in

judging

the

condition

of

any

com

ponent

during

above

inspection

check

the

questionable

component

in

dependently

as

follows

U

S

A

models

Ie

EC160A

Canada

models

ET429

Fig

EC

74

Checking

Vacuum

of

E

G

R

Control

Valve

EC

25

E

G

R

control

valve

Dismount

E

G

R

control

valve

from

engine

I

Apply

vacuum

to

E

G

R

control

valve

referring

to

the

following

figure

If

the

valve

moves

to

full

position

it

is

normal

E

G

R

control

valve

will

remain

open

for

more

than

30

seconds

after

vacuum

has

cut

off

5t

orr

rl

1

1

Fig

EC

75

EC129A

Checking

E

G

R

Control

Valve

2

Visually

check

E

G

R

control

wive

for

damage

wrinkle

or

deforma

tion

3

Clean

the

seating

surface

of

E

G

R

control

valve

with

a

brush

and

compressed

air

and

remove

foreign

matter

from

around

the

valve

and

port

Fig

EC

76

Cleoning

E

G

R

Control

Valve

Thermal

vacuum

valve

3

port

type

Remove

thermal

vacuum

valve

from

engine

Inhale

air

from

port

ofE

G

R

system

and

check

to

be

sure

that

thermal

vacuum

valve

opens

or

closes

in

response

to

its

temperature

Thermal

vacuum

valve

dosing

temperature

Above

50

to

630

C

122

to

1450

F

Page 152 of 548

e

In

o

L

1

Ignition

switch

2

Vacuum

switching

v3

lve

3

Top

detecting

switch

4

Function

check

connector

EC330A

i

Fig

EC

99

Checking

Top

Detecting

l

Switch

Vacuum

dela

valve

Remove

vacUum

delay

valve

2

Blow

air

from

th

port

of

the

distributor

side

The

vacuum

delay

valve

is

in

go

ij

condition

if

the

air

flows

through

the

valve

3

Try

again

from

the

opposit

side

of

the

valve

Th

valve

is

in

goo

condition

if

th

a

flow

resistance

is

greater

than

the

step

2

abov

Distributor

side

Carburetor

side

Distribu

tor

side

Carburetor

side

EC346

Fig

EC

100

Checking

Vocuum

Dewy

Valve

Emission

Control

Syst

m

4

If

the

condition

of

spark

delay

valve

is

questionable

dip

port

into

a

cup

filled

with

water

Blow

air

from

brown

face

side

Small

air

bubbles

should

appear

CAUTION

Be

c

areful

to

avoid

entry

of

oil

or

dirt

into

valve

7

E

C279

Fig

EC

101

Checking

Vacuum

D

lDy

Valve

CATALYTIC

CONVERTER

California

dels

DESCRIPTION

1

The

catalytic

converter

accelerates

the

chemical

reaction

of

hydrocarbons

CD

0

He

and

carbon

monoxide

O

in

the

exhaust

gas

and

changes

them

into

non

harmful

carbon

dioxide

C02

and

water

H20

This

chemical

reac

tiOD

process

requires

the

proper

a

mount

of

air

which

is

supplied

by

the

air

pump

Refer

to

the

item

AJ

S

This

air

is

called

secondary

air

The

Catalytic

converter

is

mounted

0

the

models

destinbd

for

California

OPERATION

Exhaust

gas

emitted

from

the

en

gine

contains

some

harmful

substances

due

to

incomplete

combustion

in

the

combustion

chamber

The

air

injection

stem

i

designed

to

reduce

the

con

tent

of

such

substances

in

the

exhaust

gas

In

this

system

the

secondary

air

is

led

from

the

ch

ck

valve

and

injected

in

o

the

exhaust

manifold

With

this

injection

of

the

secondary

air

hydro

carbons

He

and

carbon

monoxide

CO

in

the

exhaust

gas

are

gradually

oxidized

with

oxygen

02

in

the

secondary

air

and

converted

into

nOD

harmful

carbon

dioxide

C02

and

water

HP

The

catalytic

converter

further

cleans

engine

exhaust

gas

Through

catalytic

action

it

changes

residual

hydrocarbons

and

carbon

monoxide

contained

in

exhaust

gas

into

carbon

dioxide

and

water

before

exhaust

gas

is

discharged

to

the

atmosphere

0

Secondary

air

Carbon

monoxide

hydrocarbon

Carbon

dioxide

gas

Nater

EC

i

A

I

Front

tube

2

Catalytic

converter

3

Center

tube

4

Main

murner

EC

33

EC215

Fig

EC

I02

Function

of

Catalytic

Converter

Page 153 of 548

REMOVAL

AND

INSTALLATION

I

Jack

up

the

car

Note

Apply

parking

brake

and

place

wheel

chocks

2

Remove

screws

securing

lower

shelter

of

catalytic

converter

Loosen

flange

bolt

connecting

catalytic

converter

to

front

and

rear

exhaust

tube

Catalytic

converter

assembly

can

then

be

taken

out

3

Installation

i

in

the

reverse

se

quence

of

removal

CAUTION

a

Be

careful

not

to

damage

catalytic

co

when

handliilg

b

Never

wet

catalyzer

with

water

oil

etc

t

J

Tightening

torque

Catalyti

converter

bolts

2

6

to

3

4

kg

m

19

to

25

ft

lb

Emission

Control

System

EC075A

EC076A

Fig

EC

103

Removing

Catalytic

Converter

INSPECTION

PrelimInary

In

pectlon

Vi

ually

check

condition

of

all

component

parts

including

hose

tubes

and

wires

replace

if

necessary

Refer

to

Air

Injection

System

for

inspection

EC

34

Catalytic

converter

Whether

catalytic

converter

is

nor

mal

or

not

can

e

checked

by

ob

serving

variation

in

CO

percentage

The

checking

procedure

is

as

follows

Apply

parking

brake

Shift

gears

into

Neutral

for

manual

transmis

sion

and

N

or

P

for

automatic

transmission

position

I

Adjust

engine

idling

speed

and

CO

percentage

Refer

to

Adjusting

Carburetor

Idle

RPM

and

Mixture

Ratio

for

adjustment

2

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

and

make

sure

that

specified

CO

percent

age

obtained

3

Remove

cap

and

connect

air

hose

to

air

check

valve

If

idling

speed

increases

readjust

it

to

specified

speed

with

throttle

adjusting

screw

4

Warm

up

engine

for

about

four

minutes

at

2

000

pm

under

no

load

S

Measure

Ci

percentage

at

idling

speed

After

stepAhas

been

complet

ed

wait

for

one

minute

before

making

CO

percentage

measurement

6

If

CO

percentage

measured

in

step

5

is

less

than

0

3

the

catalytic

converter

is

normaL

7

If

CO

percentage

measured

in

step

5

is

over

0

3

recheck

AJ

S

and

1

replace

air

check

valVe

The

perform

inspection

steps

4

and

S

8

If

CO

percentage

is

still

over

0

3

in

step

7

catalyt

iC

converter

i

mal

functioning

Replace

catalytic

con

verter

Page 159 of 548

DATSUN

210

Model

8310

Series

SECTIONEE

ENGINE

ELECTRICAL

SYSTEM

CONTENTS

BATTERY

CHECKING

ELECTROLYTE

LEVEL

CHECKING

SPECIFIC

GRAVITY

CHARGING

INSTALLATION

STARTING

MOTOR

STARTING

CIRCUIT

CONSTRUCTION

REMOVAL

AND

INSTALLATION

DISASSEMBL

Y

CLEANING

AND

INSPECTION

ASSEMBL

Y

TEST

CHARGING

CIRCUIT

ALTERNATOR

DESCRIPTION

REMOVAL

DISASSEMBLY

INSPECTION

AND

REPAIR

ASSEMBLY

ALTERNATOR

TEST

REGULATOR

DESCRIPTION

INSPECTION

IGNITION

CIRCUIT

EE

2

EE

2

EE

2

EE

3

EE

3

EE

4

EE

4

EE

5

EE

6

EE

6

EE

6

EE

8

EE

8

EE

10

EE

13

EE

13

EE

14

EE

14

EE

14

EE

16

EE

17

EE

1B

EE

18

EE

18

EE

20

DESCRIPTION

DISTRIBUTOR

CONSTRUCTION

CHECKING

AND

ADJUSTMENT

I

ISASSEMBL

Y

AND

ASSEMBLY

IC

IGNITION

UNIT

DESCRIPTION

REMOVAL

AND

INSTALLATION

CHECKING

IC

IGNITION

SYSTEM

IGNITION

COIL

SPARK

PLUG

INSPECTION

CLEANING

AND

REGAP

SERVICE

DATA

AND

SPECIFICATIONS

GENERAL

SPECIFICATIONS

INSPECTION

AND

ADJUSTMENT

TIGHTENING

TORQUE

TROUBLE

DIAGNOSES

AND

CORRECTIONS

I

BATTERY

II

STARTING

MOTOR

III

ALTERNATOR

Including

voltage

regulator

IV

IGNITION

CIRCUIT

EE

20

EE

22

EE

22

EE

23

EE

23

EE

24

EE

24

EE

25

EE

25

EE

28

EE

29

EE

29

EE

29

EE

30

EE

30

EE

31

EE

33

EE

34

EE

34

EE

35

EE

36

EE

37

Page 164 of 548

REMOVAL

AND

INSTALLATION

Disconnect

battery

ground

cable

Disconnect

harness

connector

and

battery

cable

at

magnetic

switch

2

Remove

bolts

securing

starting

motor

to

transmission

case

Pull

start

iog

motor

forward

and

remove

it

3

Inst

1I

starting

motor

in

reverse

order

of

removal

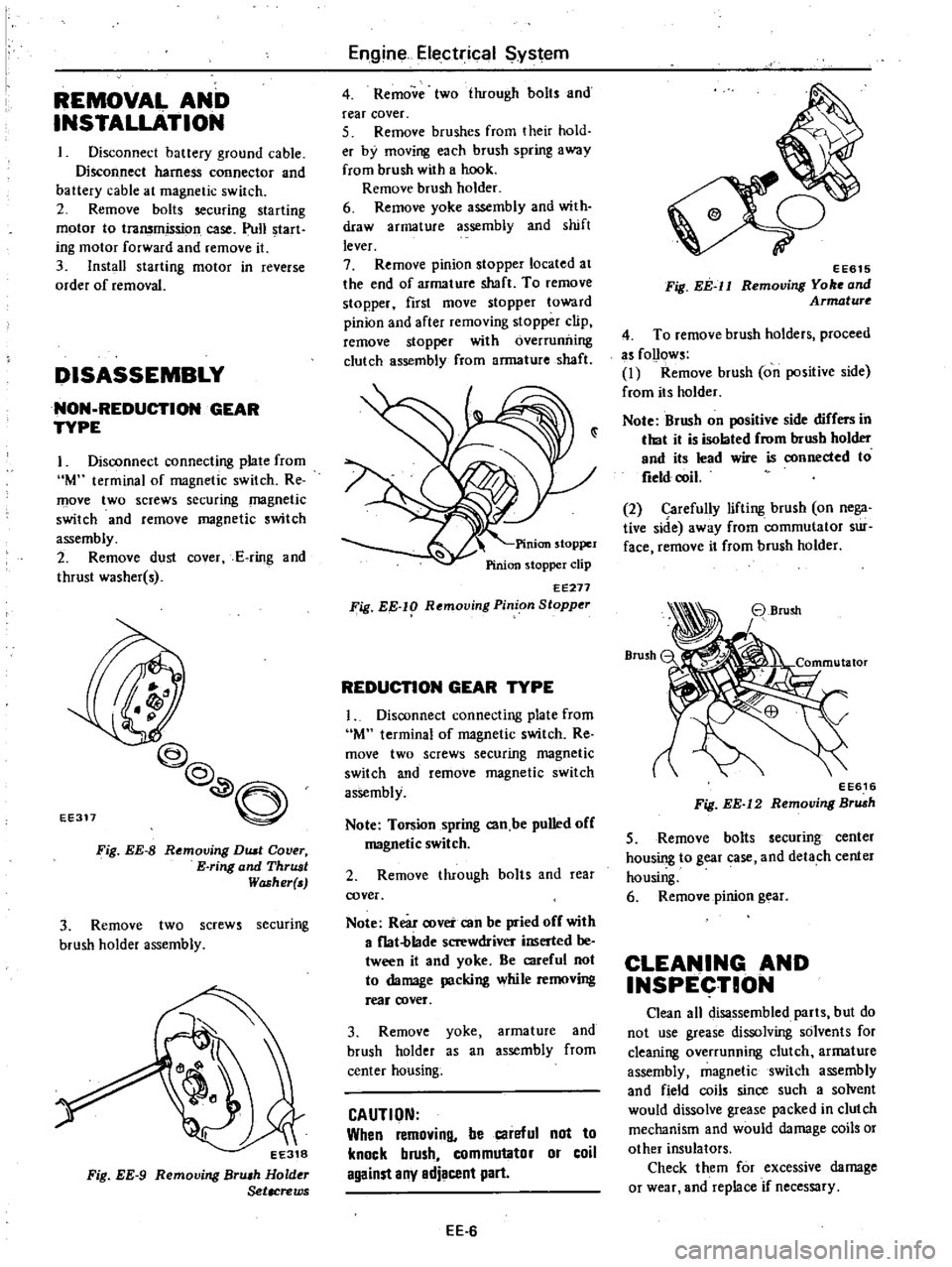

DISASSEMBLY

NON

REDUCTION

GEAR

TYPE

I

Disconnect

connecting

plate

from

M

terminal

of

magnetic

switch

Re

move

two

screws

securing

magnetic

switch

and

remove

magnetic

switch

assembly

2

Remove

dust

cover

E

ring

and

thrust

washer

s

EE311

@@

O

Fig

EE

8

Removing

DUll

Cover

E

ring

and

ThrUJJt

Washer

3

Remove

two

screws

securing

brush

holder

assembly

EE318

Fig

EE

9

Removing

Bru

h

Hold

Setacrews

Engine

Electrical

ystem

4

Remove

two

ihrough

bolts

and

rear

cover

5

Remove

brushes

from

their

hold

er

by

moving

each

brush

spring

away

from

brush

with

a

hook

Remove

brush

holder

6

Remove

yoke

assembly

and

with

draw

armature

assembly

and

shift

lever

7

Remove

pinion

stopper

located

at

the

end

of

armature

shaft

To

remove

stopper

first

move

stopper

toward

pinion

and

after

removing

stopper

clip

remove

stopper

with

overruniling

clutch

assembly

from

armature

shaft

EE271

Fig

EE

lg

Rf

moving

Pinion

Stopper

REDUCTION

GEAR

TYPE

1

Disconnect

connecting

plate

from

M

terminal

of

magnetic

switch

Re

move

two

screws

securing

magnetic

switch

and

remove

magnetic

switch

assembly

Note

Torsion

spring

can

be

pulled

off

magnetic

switch

2

Remove

through

baIts

and

rea

cover

Note

Rear

cover

can

be

pried

off

with

a

f1at

blade

screwdriver

inserted

be

tween

it

and

yoke

Be

careful

not

to

damage

packing

while

removing

reaf

cover

3

Remove

yoke

armature

and

brush

holder

as

an

assembly

from

center

housing

CAUTION

When

removing

be

careful

not

to

knock

brush

commutator

or

coil

against

any

adjacent

part

EE

6

o

7

EE615

Fig

EE

ll

Removing

Yo

and

Armature

4

To

remove

brush

holders

proceed

as

follows

I

Remove

brush

on

positive

side

from

its

holder

Note

Brush

on

positive

side

differs

in

that

it

is

isolated

from

brush

holder

and

its

lead

wire

is

connected

to

field

coil

2

Carefully

lifting

brush

on

nega

tive

side

away

from

commutator

sur

face

remove

it

from

brush

holder

EE616

Fig

EE

12

Removing

Br

h

5

Remove

bolts

securing

center

housing

to

gear

case

and

detach

center

housing

6

Remove

pinion

gear

CLEANING

AND

INSPECTION

Clean

all

disassembled

parts

but

do

not

use

grease

dissolving

solvents

for

cleaning

overrunning

clutch

armature

assembly

magnetic

switch

assembly

and

field

coils

since

such

a

solvent

would

dissolve

grease

packed

in

clutch

mechanism

and

would

damage

coils

or

other

insulators

Check

them

for

excessive

damage

or

wear

and

replace

if

necessary

Page 165 of 548

TERMINAL

Check

terminal

for

damage

and

wear

and

replace

magnetic

switch

assembly

if

necessary

FIELD

COIL

Check

field

coil

for

insulation

If

the

insulation

of

oil

is

damaged

or

worn

it

should

be

replaced

Testing

field

coil

for

continuity

Connect

the

probe

of

a

circuit

tester

or

an

ohmmeter

to

field

coil

two

positive

terminal

of

positive

brush

holder

If

tester

shows

no

continuity

field

circuit

or

coil

is

open

Replace

it

Fig

EE

13

Testing

Field

Coil

for

Continuity

Testing

field

coli

for

ground

Place

one

probe

of

circuit

tester

onto

yoke

and

the

other

of

to

field

coil

lead

positive

terminal

If

very

little

resistance

is

read

field

coil

is

grounded

Replace

it

I

EE017

Fig

EE

14

Testing

Field

Coil

for

Ground

Engine

Electrical

System

BRUSHES

AND

BRUSH

LEAD

WIRE

Check

the

surface

condition

of

brush

contact

and

wear

of

brush

If

a

loose

contact

is

found

it

should

be

replaced

If

brush

is

worn

so

that

its

length

is

less

than

specified

value

replace

Minimum

length

of

brush

Non

reduction

gear

type

12

mm

0

47

in

Reduction

gear

type

11

mm

0

43

in

Check

the

connection

of

lead

clip

and

lead

wire

Check

brush

holders

and

spring

clip

to

see

if

they

are

not

deformed

or

bent

and

will

properly

hold

brushes

against

the

commutator

If

brushes

or

brush

holders

are

dirty

they

should

be

cleaned

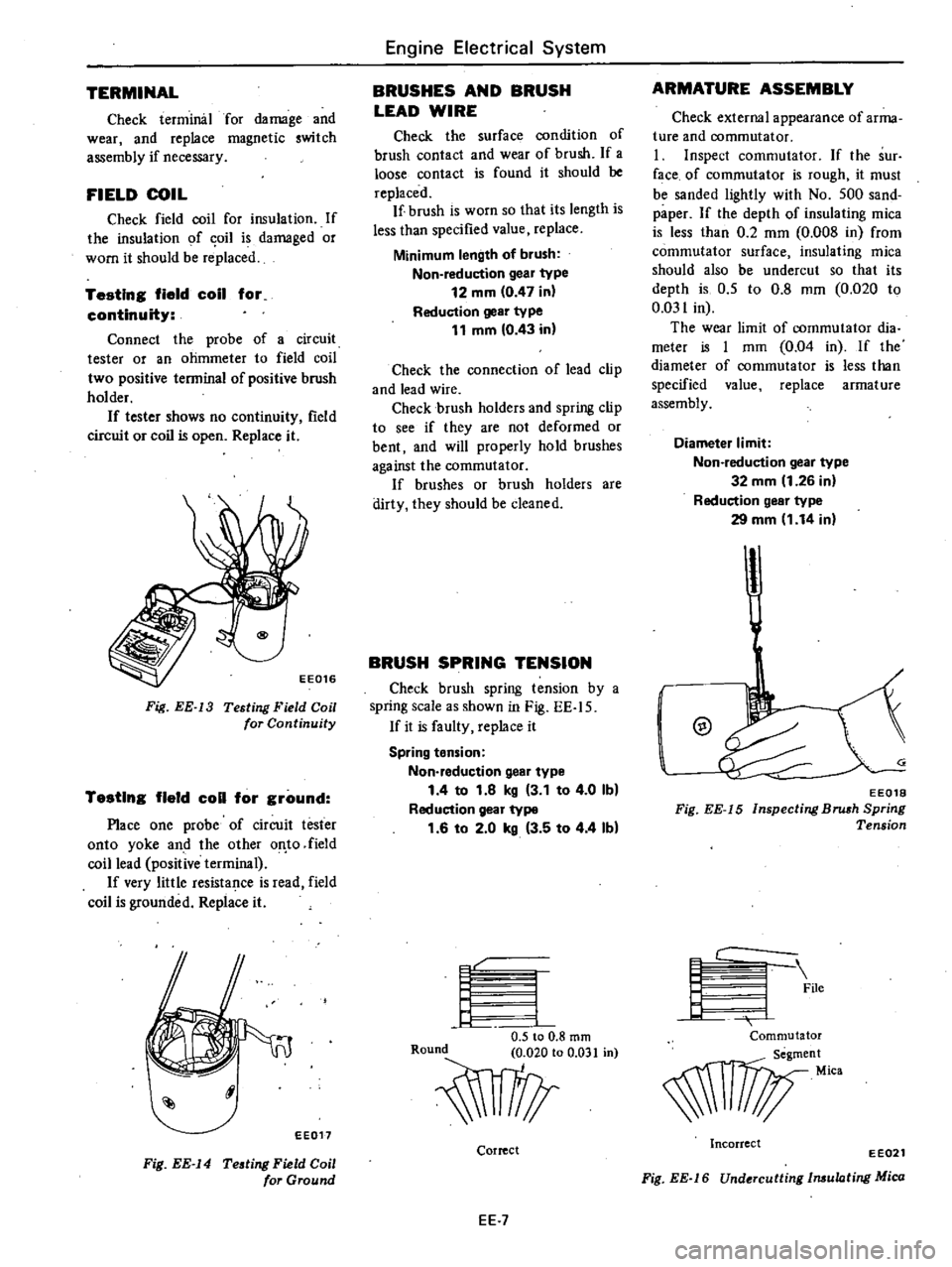

BRUSH

SPRING

TENSION

Check

brush

spring

tension

by

a

spring

scale

as

shown

in

Fig

EE

l

5

If

it

is

faulty

replace

it

Spring

tension

Non

reduction

geaf

type

1

4

to

1

8

kg

3

1

to

4

0

Ib

Reduction

gear

type

1

6

to

2

0

kg

3

5

to

4

4

Ib

I

r

4

1

0

5

to

0

8

rom

O

iO

Correct

EE

7

ARMATURE

ASSEMBLY

Check

external

appearance

of

arma

ture

and

oommutator

I

Inspect

commutator

If

the

sur

face

of

commutator

is

rough

it

must

be

sanded

lightly

with

No

500

sand

paper

If

the

depth

of

insulating

mica

is

less

than

0

2

mm

0

008

in

from

commutator

surface

insulating

mica

should

also

be

undercut

so

that

its

depth

is

0

5

to

0

8

mm

0

020

to

0

031

in

The

wear

limit

of

commutator

dia

meter

is

I

mm

0

04

in

If

the

diameter

of

commutator

is

less

than

specified

value

replace

armature

assembly

Diameter

limit

Non

reduction

gear

type

32

mm

1

26

in

Reduction

gear

type

29

mm

1

14

in

I

@

EE018

Fig

EE

15

Inspecting

Bnah

Spring

Tension

c

I

File

Commutator

nt

I

1

11

Mica

Incorrect

EE021

Fig

EE

16

Undercutting

Imulating

Mica

Page 166 of 548

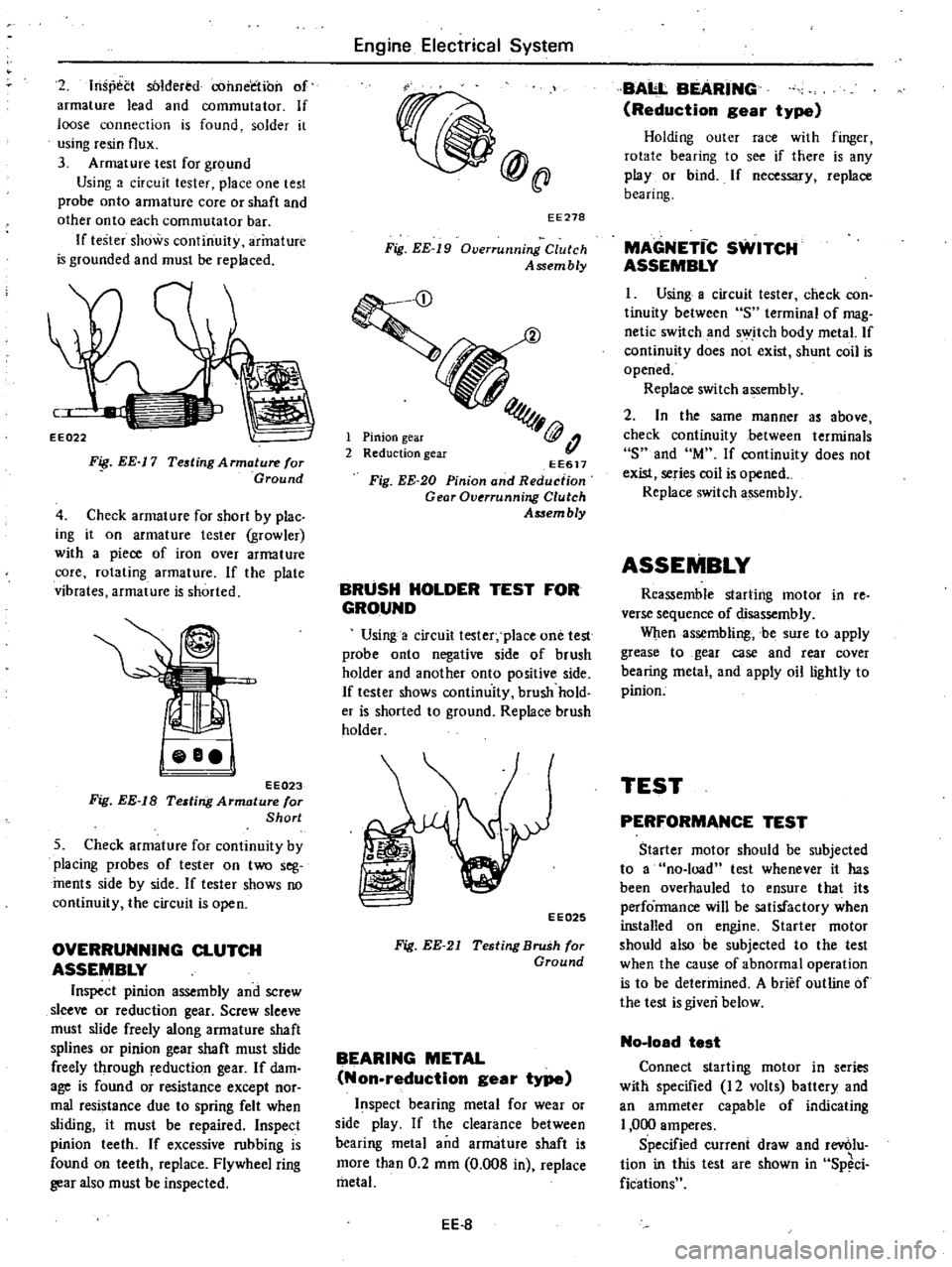

2

Inspect

silldered

conneetibn

of

armature

lead

and

commutator

If

loose

connection

is

found

solder

it

using

resin

flux

3

Armature

test

for

ground

Using

a

circuit

tester

place

one

test

probe

onto

armature

core

or

shaft

and

other

onto

each

commutator

bar

If

tester

shows

continuity

armature

is

grounded

and

must

be

replaced

L

L

I

EE022

F

EE

17

Teating

Armature

for

Ground

4

Check

armature

for

short

by

plac

ing

it

on

armature

tester

growler

with

a

piece

of

iron

over

arma

t

ure

core

rotating

armature

If

the

plate

vibrates

armature

is

shorted

jeBel

EE023

Fig

EE

18

Testing

Armature

or

Short

5

Check

armature

for

continuity

by

placing

probes

of

tester

on

two

seg

ments

side

by

side

If

tester

shows

no

continuity

the

circuit

is

open

OVERRUNNING

CLUTCH

ASSEMBLY

Inspect

pinion

assembly

and

screw

sleeve

or

reduction

gear

Screw

sleeve

must

slide

freely

along

armature

shaft

splines

or

pinion

gear

shaft

must

slide

freely

through

reduction

gear

If

dam

age

is

found

or

resistance

except

nor

mal

resistance

due

to

spring

felt

when

sliding

it

must

be

repaired

Inspect

pinion

teeth

If

excessive

rubbing

is

found

on

teeth

replace

Flywheel

ring

gear

also

must

be

inspected

Engine

Electrical

System

@

ll

EE278

Fig

EE

19

Overrunning

Clutch

Assembly

1

Pinion

gear

2

Reduction

gear

EE617

Fig

EE

20

Pinion

and

Reduction

Gear

Overrunni11C

Clutch

AS5em

bly

BRUSH

HOLDER

TEST

FOR

GROUND

Using

a

circuit

tester

place

one

test

probe

onto

negative

side

of

brush

holder

and

another

onto

positive

side

If

tester

shows

continuity

brush

hold

er

is

shorted

to

ground

Replace

brush

holder

EE025

Fig

EE

21

Testing

Brush

for

Ground

BEARING

METAL

Non

reduction

gear

type

spect

bearing

metal

for

wear

or

side

play

If

the

clearance

between

bearing

metal

and

armature

shaft

is

more

than

0

2

mm

0

008

in

replace

metal

EE

8

BAI

L

BEARING

Reduction

gear

type

Holding

outer

race

with

finger

rotate

bearing

to

see

if

there

is

any

play

or

bind

If

necessary

replace

bearing

MAGNETic

SWITCH

ASSEMBLY

I

Using

a

circuit

tester

check

con

tinuity

between

S

terminal

of

mag

netic

switch

and

switch

body

metal

If

continuity

does

not

exist

shunt

coil

is

opened

Replace

switch

assembly

2

In

the

same

manner

as

above

check

continuity

between

terminals

S

and

M

If

continuity

does

not

exist

series

coil

is

opened

Replace

switch

assembly

ASSEMBLY

Reassemble

starting

motor

in

re

verse

sequence

of

disassembly

When

assembling

be

sure

to

apply

grease

to

gear

case

and

rear

cover

bearing

metal

and

apply

oil

lightly

to

pinion

TEST

PERFORMANCE

TEST

Starter

motor

should

be

subjected

to

a

no

load

test

whenever

it

has

been

overhauled

to

ensure

that

its

perfo

rmance

will

be

satisfactory

when

installed

on

engine

Starter

motor

should

also

be

subjected

to

the

test

when

the

cause

of

abnormal

operation

is

to

be

determined

A

brief

outline

of

the

test

is

given

below

No

loadtest

Connect

starting

motor

in

series

willi

specified

12

volts

battery

and

an

ammeter

capable

of

indicating

1

000

amperes

Specified

current

draw

and

rev6lu

tion

in

this

test

are

shown

in

Sp

ci

Cications