service DATSUN 210 1979 Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 317 of 548

Propeller

Shaft

Differential

Carrier

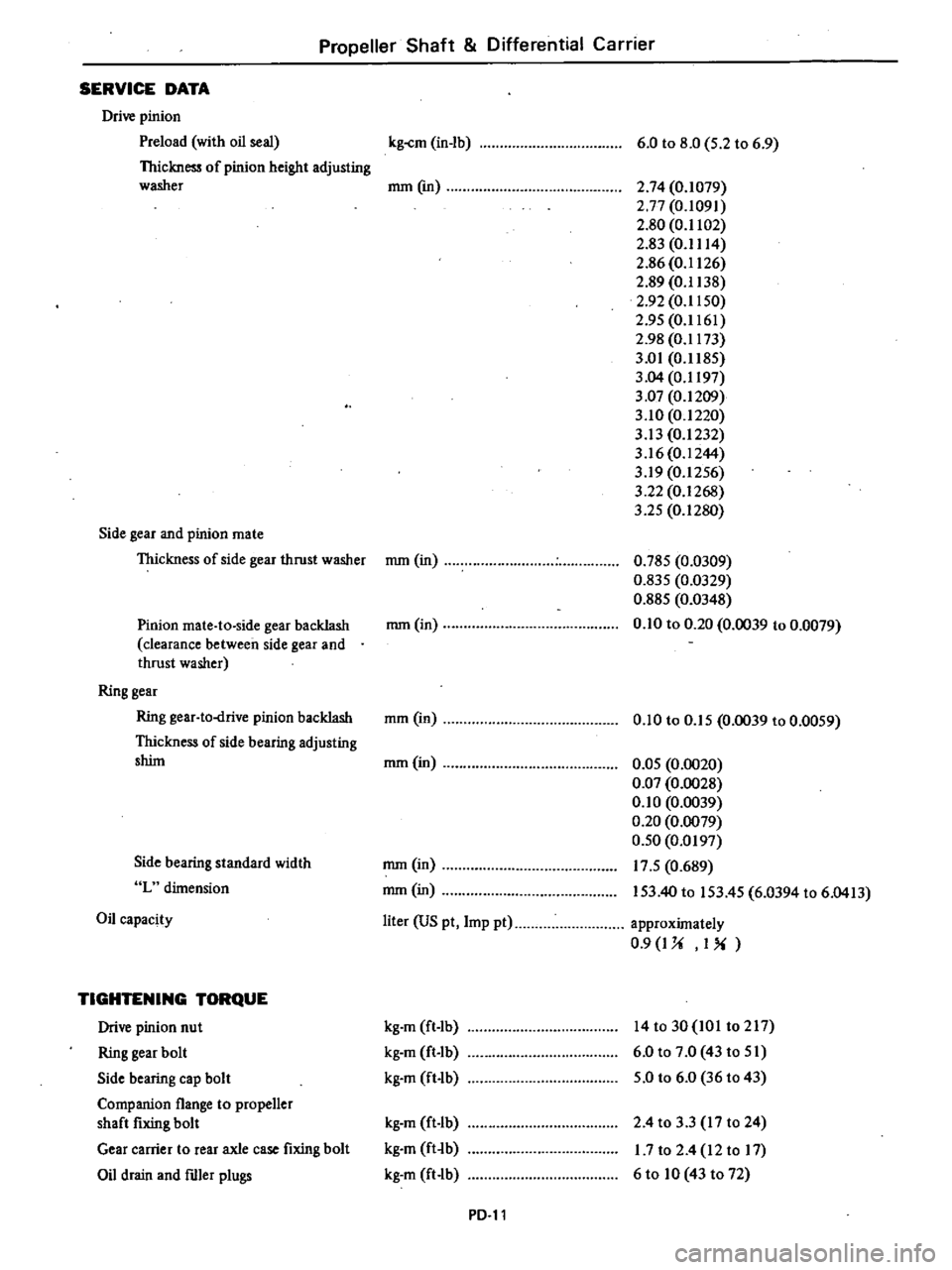

SERVICE

DATA

Drive

pinion

Preload

with

oil

seal

Thickness

of

pinion

height

adjusting

washer

Side

gear

and

pinion

mate

Thickness

of

side

gear

thrust

washer

Pinion

mate

to

side

gear

backlash

clearance

between

side

gear

and

thrust

washer

Ring

gear

Ring

gear

to

drive

pinion

backlash

Thickness

of

side

bearing

adjusting

shint

Side

bearing

standard

width

L

dimension

Oil

capacity

TIGHTENING

TORQUE

Drive

pinion

nut

Ring

gear

bolt

Side

bearing

cap

bolt

Companion

flange

to

propener

shaft

fixing

bolt

Gear

carrier

to

rear

axle

case

fixing

bolt

Oil

drain

and

ftller

plugs

kg

cm

in

lb

6

0

to

8

0

5

2

to

6

9

mm

em

2

74

0

1079

2

77

0

1091

2

80

0

1102

2

g3

0

1114

2

86

0

1126

2

89

0

1138

2

92

0

1150

2

95

0

1161

2

98

0

1173

3

01

0

1185

3

04

0

1197

3

07

0

1209

3

10

0

1220

3

13

0

1232

3

16

0

1244

3

19

0

1256

3

22

0

1268

3

25

0

1280

mm

in

0

785

0

0309

0

835

0

0329

0

885

0

0348

0

10

to

0

20

0

0039

to

0

0079

mmOn

mm

in

0

10

to

0

15

0

0039

to

0

0059

mm

in

0

05

0

0020

0

Q7

0

0028

0

10

0

0039

0

20

0

0079

0

50

0

0197

17

5

0

689

153

40

to

153

45

6

0394

to

6

0413

mm

in

mm

in

liter

US

pt

Imp

pt

approximately

0

9

I

U

I

kg

m

ft

Ib

kg

m

ft

Ib

kg

m

ft

lb

14to30

IOI

t0217

6

0

to

7

0

43

to

51

5

0

to

6

0

36

to

43

kg

m

ft

Ib

kg

m

ft

b

kg

m

ft

lb

2

4

to

3

3

17

to

24

1

7

to

2

4

12

to

17

6

to

10

43

to

72

PD

ll

Page 319 of 548

Propeller

Shaft

Differential

Carrier

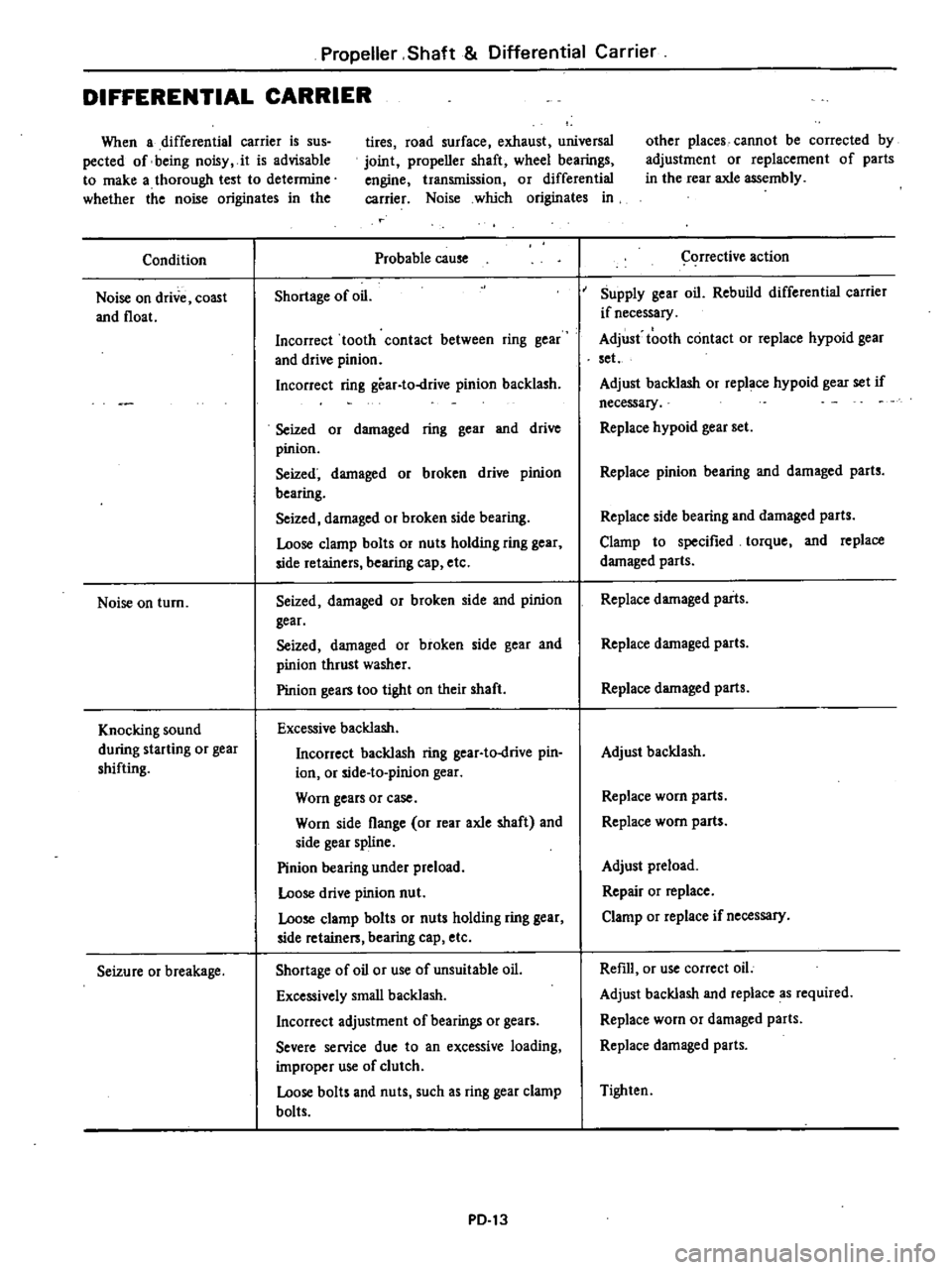

DIFFERENTIAL

CARRIER

When

a

differential

carrier

is

sus

pected

of

being

noisy

it

is

advisable

to

make

a

thorough

test

to

determine

whether

the

noise

originates

in

the

tires

road

surface

exhaust

universal

joint

propeller

shaft

wheel

bearings

engine

transmission

or

differential

carrier

Noise

which

originates

in

Condition

Noise

on

drive

coast

and

float

Noise

on

turn

Knocking

sound

during

starting

or

gear

shifting

Seizure

or

breakage

Probable

cause

Shortage

of

oil

Incorrect

tooth

contact

between

ring

gear

and

drive

pinion

Incorrect

ring

gear

to

drive

pinion

backlash

Seized

or

damaged

ring

gear

and

drive

pinion

Seized

damaged

or

broken

drive

pinion

bearing

Seized

damaged

or

broken

side

bearing

Loose

clamp

bolts

or

nuts

holding

ring

gear

side

retainers

bearing

cap

etc

Seized

damaged

or

broken

side

and

pinion

gear

Seized

damaged

or

broken

side

gear

and

pinion

thrust

washer

Pinion

gears

too

tight

on

their

shaft

Excessive

backlash

Incorrect

backlash

ring

gear

to

drive

pin

ion

or

side

ta

pinion

gear

Worn

gears

or

case

Worn

side

flange

or

rear

axle

shaft

and

side

gear

spline

Pinion

bearing

under

preload

Loose

drive

pinion

nut

Loose

clamp

bolts

or

nuts

holding

ring

gear

side

retainers

bearing

cap

etc

Shortage

of

oil

or

use

of

unsuitable

oil

Excessively

small

backlash

Incorrect

adjustment

of

bearings

or

gears

Severe

service

due

to

an

excessive

loading

improper

use

of

clutch

Loose

bolts

and

nuts

such

as

ring

gear

clamp

bolts

PD

13

other

places

cannot

be

corrected

by

adjustment

or

replacement

of

parts

in

the

rear

axle

assembly

orrective

action

Supply

gear

oil

Rebuild

differential

carrier

if

necessary

Adjust

tooth

contact

or

replace

hypoid

gear

set

Adjust

backlash

or

replace

hypoid

gear

set

if

necessary

Replace

hypoid

gear

set

Replace

pinion

bearing

and

damaged

parts

Replace

side

bearing

and

damaged

parts

Clamp

to

specified

torque

and

replace

damaged

parts

Replace

damaged

parts

Replace

damaged

parts

Replace

damaged

parts

Adjust

backlash

Replace

worn

parts

Replace

worn

parts

Adjust

preload

Repair

or

replace

Clamp

or

replace

if

necessary

Refill

or

use

correct

oil

Adjust

backlash

and

replace

as

required

Replace

worn

or

damaged

parts

Replace

damaged

parts

Tighten

Page 321 of 548

Propeller

Shaft

Differential

Carrier

SPECIAL

SERVICE

TOOLS

Tool

number

tool

name

IKent

Moore

No

I

Reference

page

or

Fig

No

Unit

application

Drive

pinion

flange

wrench

J

25774

Fig

PD

6

Page

PD

7

ST31530000

ST0632001i0

Differential

carrier

attachment

ST3003S000

Drive

pinion

rear

inner

race

puller

set

Puller

Base

CD

ST30031000

00

ST30032000

ST33051001

Differential

sIde

bearing

puller

oiij

9

J

25601

Fig

PD4

Page

PD

9

J

25733

CD

J

25733

1

00

J

25733

2

Fig

PD

7

Fig

PD

9

Tool

number

tool

name

ST33052000

Adapter

@

KV38101800

Solid

punch

ST3250SOO0

CD

ST32501000

00

ST32502000

Side

bearing

adjust

weight

Weight

block

Master

gauge

Er

ST33220000

Differential

side

bearing

drift

ST30611000

Drive

pinion

outer

race

drift

bar

i

IM

I

UI

r

l

JM

M

Md

Kent

Moore

No

Reference

or

Fig

No

Unit

application

J

25797

1

Fig

PD

9

Page

PD

g

FiJi

PD

IO

J

25407

3

CD

J

25407

3

00

J

25407

1

Fig

PD

12

J

25804

D1

Fig

PD

13

Page

PD

g

J

25742

1

Page

PD

6

PD

15

Applicable

to

all

B310

series

models

Page 323 of 548

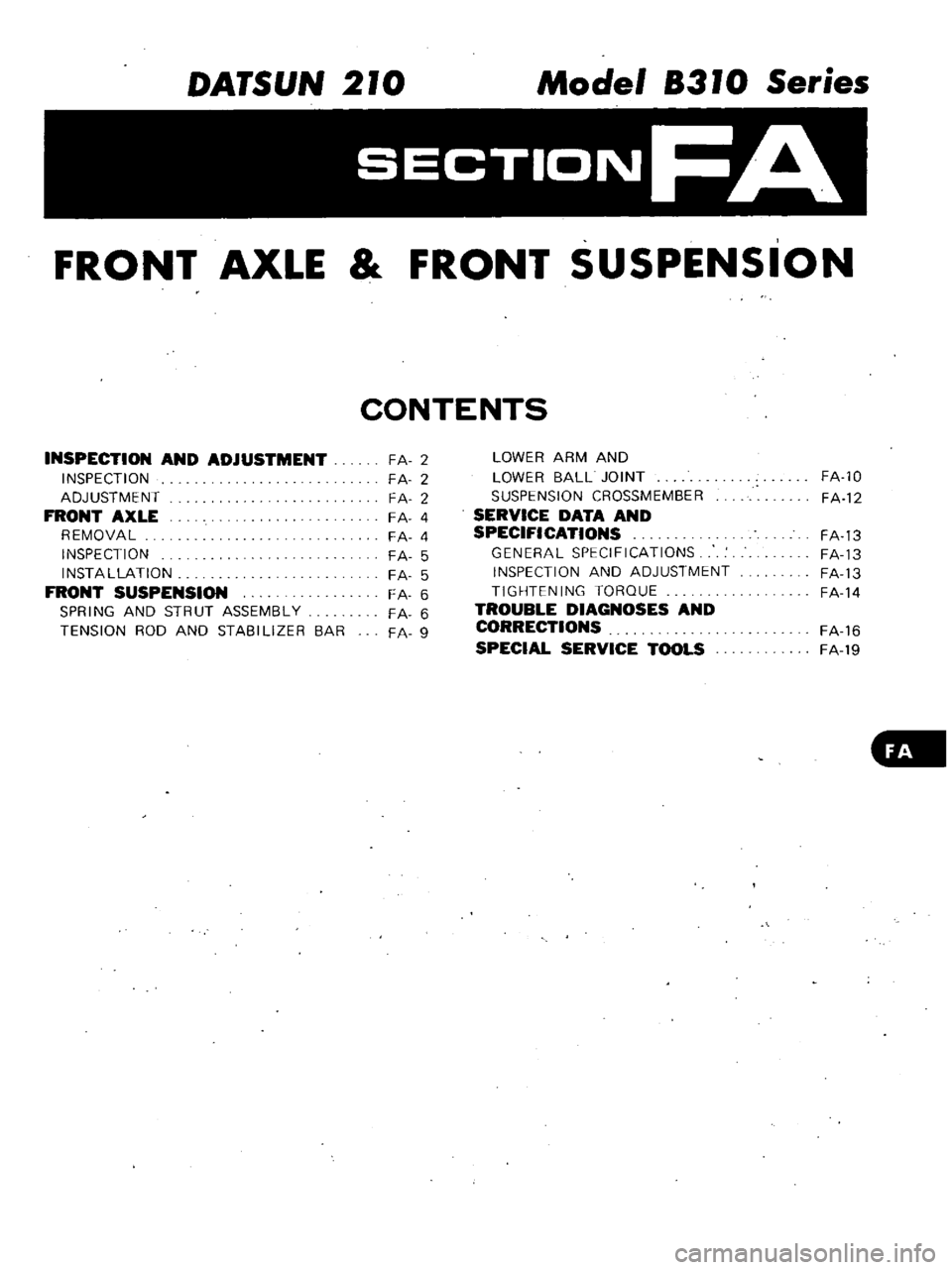

DATSUN

210

Model

8310

Series

SECTIONFA

FRONT

AXLE

FRONT

SUSPENSION

CONTENTS

INSPECTION

AND

ADJUSTMENT

INSPECTION

ADJUSTMENT

FRONT

AXLE

REMOVAL

INSPECTION

INSTAllATION

FRONT

SUSPENSION

SPRING

AND

STRUT

ASSEMBLY

TENSION

ROD

AND

STABILIZER

BAR

FA

2

FA

2

FA

2

FA

4

FA

4

FA

5

FA

5

FA

6

FA

6

FA

9

lOWER

ARM

AND

lOWER

BAll

JOINT

SUSPENSION

CRDSSMEMBER

SERVICE

DATA

AND

SPECIFICATIONS

GENERAL

SPECIFICATIONS

INSPECTION

AND

ADJUSTMENT

TIGHTENING

TORQUE

TROUBLE

DIAGNOSES

AND

CORRECTIONS

SPECIAL

SERVICE

TOOLS

FA

lO

FA

12

FA

13

FA

13

FA

13

FA

14

FA

16

FA

19

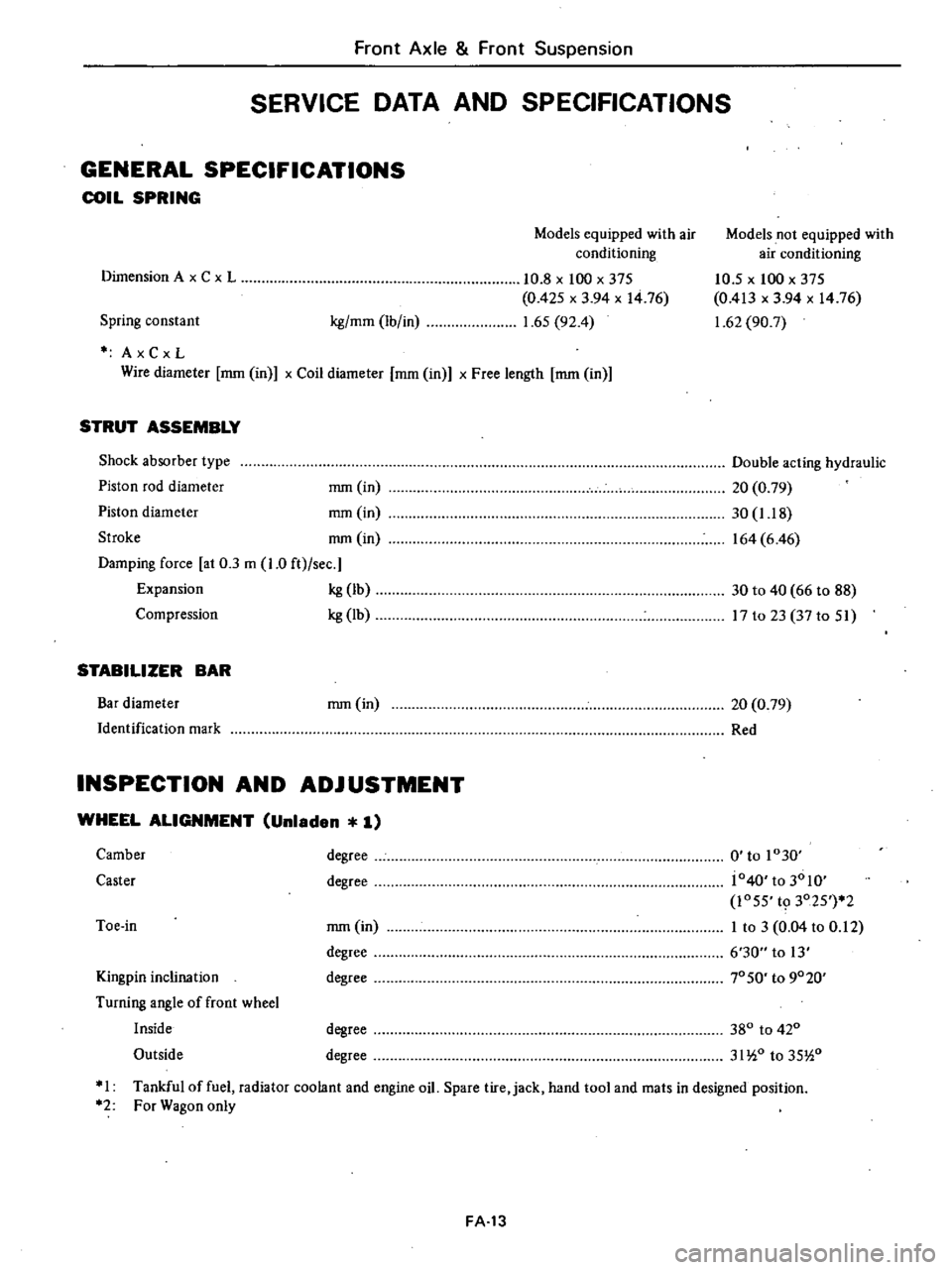

Page 335 of 548

Front

Axle

Front

Suspension

SERVICE

DATA

AND

SPECIFICATIONS

GENERAL

SPECIFICATIONS

COIL

SPRING

Models

equipped

with

air

conditioning

Models

not

equipped

with

air

conditioning

10

5

x

100

x

375

0

413

x

3

94

x

1476

1

62

90

7

Spring

constant

kg

mm

Ib

in

10

8

x

100

x

375

0

425

x

3

94

x

1476

1

65

92

4

Dimension

A

x

C

x

L

AxCxL

Wire

diameter

mm

in

x

Coil

diameter

mm

in

x

Free

length

mm

in

STRUT

ASSEMBLY

Shock

absorber

type

Piston

rod

diameter

mm

in

Piston

diameter

mm

in

Stroke

nun

in

Damping

force

at

0

3

m

1

0

ft

sec

Expansion

kg

Ib

Compression

kg

Ib

Double

acting

hydraulic

20

0

79

30

1

18

164

6

46

30

to

40

66

to

88

17

to

23

37

to

51

STABILIZER

BAR

Bar

diameter

Identification

mark

mm

in

20

0

79

Red

INSPECTION

AND

ADJUSTMENT

WHEEL

ALIGNMENT

Unladen

1

Kingpin

inclination

Turning

angle

of

front

wheel

Inside

Outside

mm

in

degree

degree

0

to

1030

j040

to

3010

1055

t9

3025

2

I

to

3

0

04

to

0

12

6

30

to

13

70

SO

to

9020

Camber

Caster

degree

degree

Toe

in

degree

degree

380

to

420

31

io

to

35

i0

I

Tankful

of

fuel

radiator

coolant

and

engine

oil

Spare

tire

jack

hand

tool

and

mats

in

designed

position

2

For

Wagon

only

FA

13

Page 341 of 548

Front

Axle

Front

Suspension

SPECIAL

SERVICE

TOOLS

Tool

number

tool

name

CD

S13532

I

000

@

S135322000

ID

ST35325000

Front

wheel

bearing

drift

Inner

Front

wheel

bearing

drift

Outer

Drift

bar

@

GJ

KV48

100300

Strut

and

steering

gear

housing

attachment

ST3565S001

CD

ST35651001

@

S135652000

I

Coil

spring

compressor

set

Coil

spring

compressor

Clamp

Kent

Moore

No

Reference

page

or

Fig

No

Page

F

A

5

J

25729

Fig

FA

18

Fig

F

A

20

PageFA

8

Page

FA

9

Fig

FA

IS

Fig

FA

19

Fig

F

A

27

Tool

number

tool

name

S135500001

G

land

packing

wrench

KV

40

I

0

1900

G

land

packing

guide

CI

HT72520000

ilalljoinl

remover

S136720000

Transverse

link

bushing

replacer

set

t9

11

FA

19

Kent

Moore

No

Reference

page

or

Fig

No

J

25825

Fig

F

A

20

Fig

FA

25

Fig

FA

24

Page

FA

IO

J

25847

Fig

FA

37

Fig

F

A

39

Page 342 of 548

DATSUN

210

Model

8310

Series

SECTIONRA

REAR

AXLE

REAR

SUSPENSION

CONTENTS

LINK

TYPE

REAR

AXLE

REAR

AXLE

ASSEMBLY

REAR

AXLE

SHAFT

AND

WHEEL

BEARING

REAR

AXLE

CASE

REAR

SUSPENSION

SHOCK

ABSORBER

COIL

SPRING

LI

N

K

ASSEMBLY

RA

2

RA

3

RA

3

RA

4

RA

5

RA

5

RA

5

RA

6

RA

6

SERVICE

DATA

AND

SPECIFICATIONS

GENERAL

SPECIFICATIONS

INSPECTION

AND

ADJUSTMENT

SHOCK

ABSORBER

REAR

AXLE

TIGHTENING

TORQUE

TROUBLE

DIAGNOSES

AND

CORRECTIONS

SPECIAL

SERVICE

TOOLS

RA

8

RA

8

RA

8

RA

8

RA

8

RA

9

RA

lO

RA

ll

Page 347 of 548

I

AA552

Fig

RA

18

Shock

A

bllOrber

Upper

End

2

Remove

bolt

securing

shock

ab

sorber

lower

end

and

remove

shock

absorber

Note

When

removing

shock

ebsorber

lower

end

from

bracket

Iueeze

shock

absorber

end

lift

it

out

right

aJ

o

J

to

accommodate

emb

ss

ment

inside

bracket

c

RA486

Fig

RA

19

Shock

Absorber

Lower

End

Brocket

Inspection

I

Test

shock

absorber

and

compare

with

specification

given

in

Service

Data

and

Specifications

Replace

if

nece

ry

2

Check

for

cracks

Also

check

pis

ton

rod

for

straightness

3

Check

all

rubber

parts

for

wear

cracks

damage

or

deformation

Re

place

if

necessary

Installation

Install

shock

absorber

in

the

reverse

order

of

removal

Note

Tighten

shock

absorber

upper

end

nut

to

specification

until

it

is

fully

tightened

to

thread

end

of

pis

ton

rod

Then

securely

tighten

lock

nut

Rear

Axle

Rear

Suspension

@

Tightening

tonlU1l

Shock

absorber

upper

end

nut

1

5

to

2

0

kg

m

11

to

14

ft

b

Shock

absorber

lower

end

n1

t

7

0

to

8

0

k

l

m

51

to

58

ft

bl

CAUTION

I

Be

careful

not

to

damage

or

bend

piston

rod

during

operation

b

Do

not

open

or

heat

gas

filled

type

shock

absorbers

COIL

SPRING

Removal

Block

front

wheels

with

chocks

2

Raise

rear

of

car

high

enough

to

permit

working

underneath

and

place

stands

solidly

under

body

member

on

both

sides

3

Support

under

center

of

dif

ferential

carrier

with

a

garage

jack

4

Remove

rear

wheels

5

Remove

bolts

securing

shock

absorber

lower

ends

on

each

side

C

J

1

v

I

JJJ

RA485

Fig

RA

20

RemoviTIII

Bolt

Securing

Shock

Abwrber

Lower

End

6

Lower

jack

slowly

and

remove

coil

springs

on

each

side

after

they

are

fully

extended

RA546

Fig

RA

21

Removing

Coil

Spring

RA

6

Inspection

1

Check

coil

spring

for

yield

defor

mation

or

cracks

2

Test

spring

and

compare

with

specifications

given

in

Service

Data

and

Specifications

3

Check

all

rubber

parts

for

wear

cracks

damage

or

deformation

Re

place

if

necessary

InsteDatlon

Install

coil

spring

in

the

reverse

order

ofremoval

CAUTION

Correctly

fit

open

end

on

spring

seat

CD

Tightening

torque

Shock

absorber

lowel

end

nut

7

010

8

0

kg

51

to

58

ft

b

LINK

ASSEMBLY

Removal

It

is

possible

to

remove

one

link

assembly

alone

When

removing

more

than

two

link

assemblies

remove

axle

assembly

first

Refer

to

Rear

Axle

Assembly

for

removal

Remove

upper

link

or

lower

link

alone

by

removing

bolt

on

each

end

Fig

RA

22

Removing

Upper

Link

RA553

Fig

RA

23

Remouing

Lower

Link

Page 349 of 548

ear

Axl

Re

r

Suspen

sion

SERVICE

DATA

AND

SPECIFICATIONS

GENERAL

SPECIFICATIONS

Model

I

Sedan

Hatchback

Wagon

Item

Type

Link

Coil

spring

Wire

diameter

mm

in

r

102

OA02

10

5

OA

13

Coil

diameter

nun

in

I

90

3

54

Free

length

nun

in

I

365

14

37

379

14

92

Effective

turns

I

8

75

Spring

constant

kg

mm

Ib

in

I

1

71

95

8

L91

I07

0

Identification

color

I

Yellow

Shock

absorber

Maximum

length

L

mm

in

I

540

2126

Stroke

nun

in

I

187

5

738

I

nDU

AA504

Shock

absorber

maximum

length

L

INSPECTION

AND

ADJUSTMENT

SHOCK

ABSORBER

Damping

force

at

0

3

m

LO

ft

s

Expansion

Compression

kg

lb

kg

lb

48

to

68

I

06

to

150

19

to

33

42

to

73

REAR

AXLE

End

play

Thickness

of

rear

axle

case

end

shim

mm

in

mm

in

0

10

to

0

45

0

0039

to

Om77

0

Q75

0

0030

0

150

0

0059

0

225

0

0089

0300

0

0118

RA

B

Page 352 of 548

Rear

Axle

Rear

Suspension

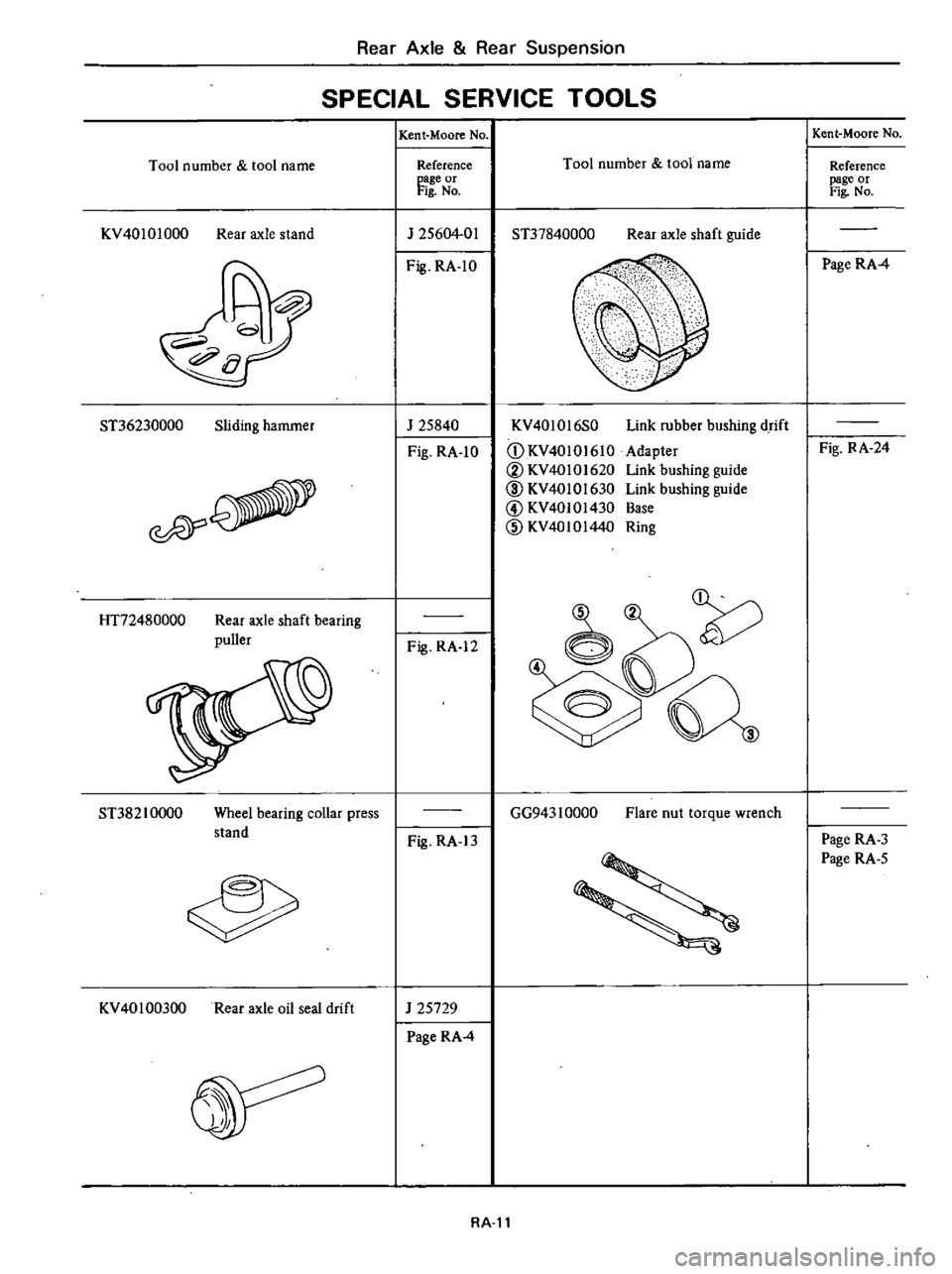

SPECIAL

SERVICE

TOOLS

Tool

number

tool

name

KV40101000

Rear

axle

stand

ST36230000

Sliding

hammer

esPY

HT72480000

Rear

axle

shaft

bearing

puller

ST38210000

Wheel

bearing

collar

press

stand

KV

401

00300

Rear

axle

oil

seal

drift

Kent

Moore

No

Reference

page

or

Fig

No

J

25604

01

Fig

RA

1O

J

25840

Fig

RA

1O

Fig

RA

12

Fig

RA

13

J

25729

Page

RA

4

Tool

number

tool

name

ST37840000

Rear

axle

shaft

guide

KV40l016S0

CD

KV40

10

I

610

V

KV40101620

ID

KV4010l630

@

KV40101430

CID

KV4010144

Link

rubber

bushing

drift

Adapter

Link

bushing

guide

Link

bushing

guide

Base

Ring

GG943

1

0000

Flare

nut

torque

wrench

RA

ll

Kent

Moore

No

Reference

page

or

Fig

No

Page

RA

4

Fig

RA

24

Page

RA

3

Page

RA

5