DATSUN 510 1968 Service Repair Manual

Manufacturer: DATSUN, Model Year: 1968, Model line: 510, Model: DATSUN 510 1968Pages: 252, PDF Size: 12.2 MB

Page 121 of 252

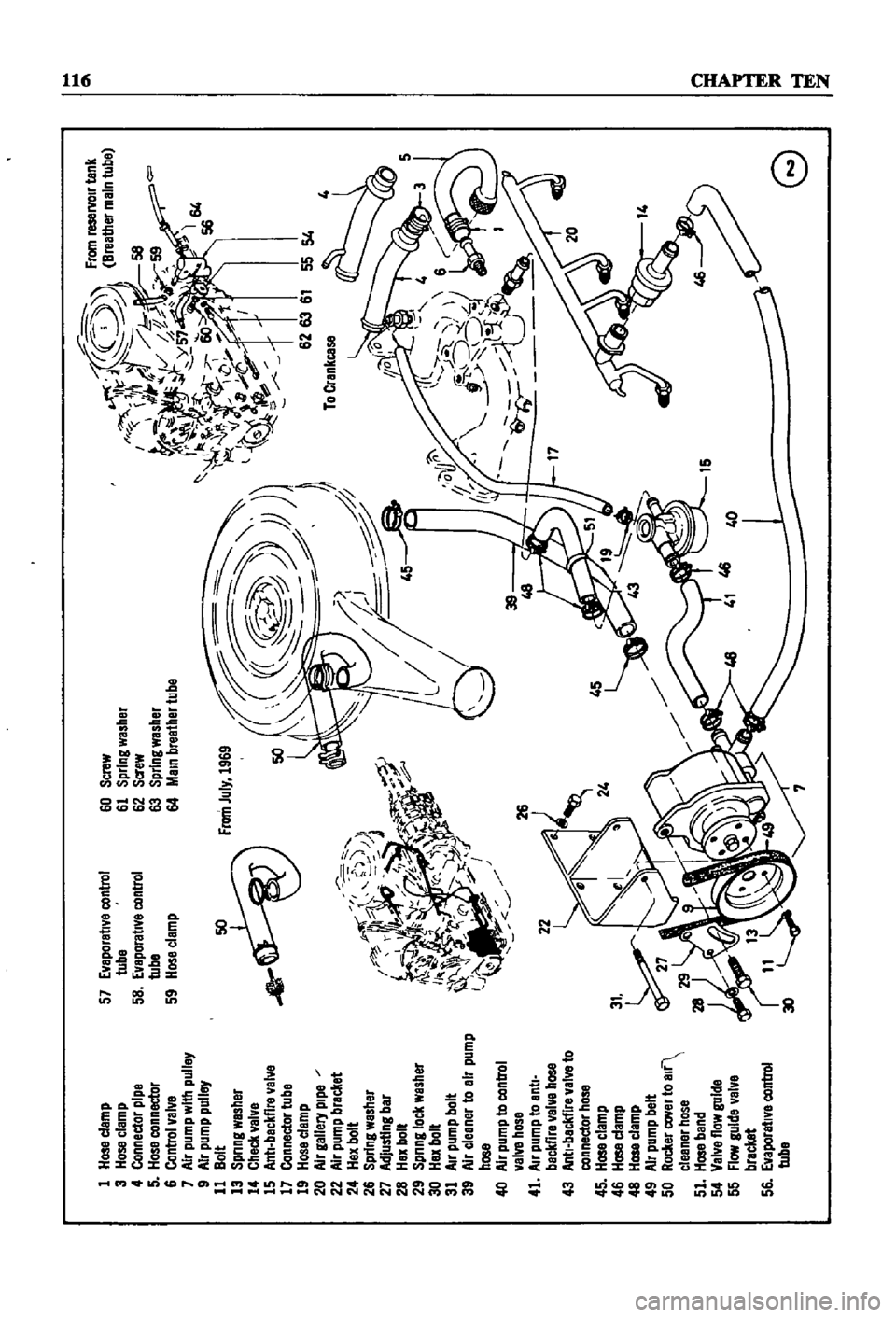

1

Hose

clemp

3

Hose

clamp

4

Connector

pipe

5

Hose

connector

6

Control

valve

7

Air

pump

with

pulley

9

Air

pump

pulley

11

Bolt

13

Spnng

washer

14

Check

valve

15

Antl

beckllre

elve

17

Connector

tube

19

Hose

c1emp

20

Air

gellery

pipe

22

Air

pum

p

bracket

24

Hex

bolt

26

Spring

washer

27

Adjusting

bar

28

Hex

bolt

29

Spnng

lock

washer

30

Hex

bolt

31

Air

pump

bolt

39

Air

c1eener

to

air

pump

hose

40

Air

pump

to

control

alve

hose

41

Air

pump

to

anti

beckllre

velve

hose

43

Antl

backllre

valve

to

connector

hose

45

Hose

clemp

46

Hose

clemp

48

Hose

c1emp

49

Air

pump

belt

50

Rocker

cover

to

alf

clBllner

hosa

51

Hose

band

54

Velve

1I0w

guide

55

Flow

gulda

valve

brackBt

56

Eveporatlve

control

tube

57

Evaporative

control

tube

58

Eveporatlve

control

tube

59

Hose

clamp

60

Screw

61

Spring

washer

62

Screw

63

Spring

washer

64

Main

breather

tube

50

15

i

Page 122 of 252

EMISSION

CONTROL

SYSTEM

117

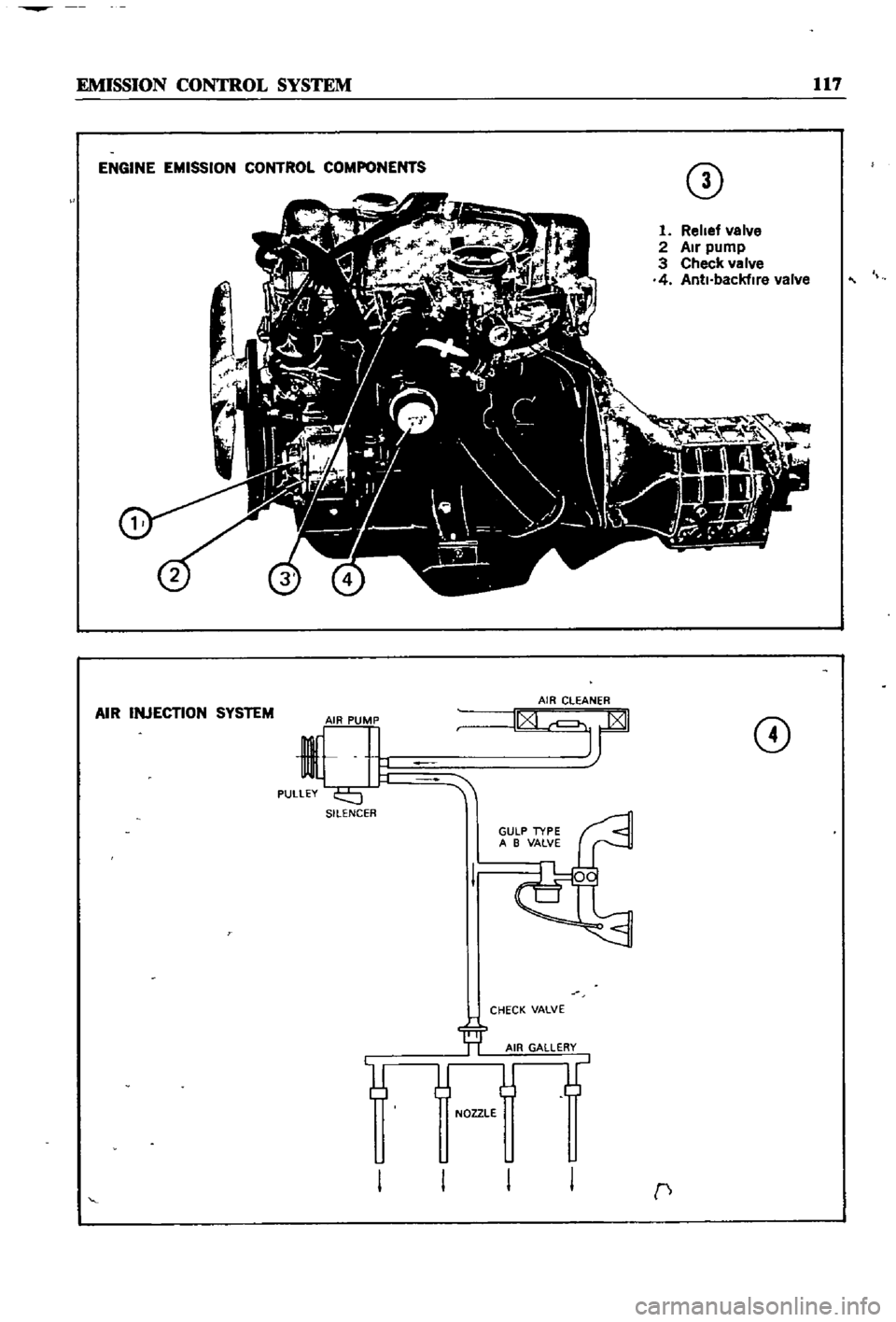

ENGINE

EMISSION

CONTROL

COMPONENTS

CD

1

Relief

valve

2

Air

pump

3

Check

valve

4

Anti

backfire

valve

AIR

INJECTION

SYSTEM

CD

SILENCER

CHECK

VALVE

NOZZLE

c

Page 123 of 252

0

COO

lL

0

W

GOtl

WITH

M

tlUA

TRt

tlSMISSIOtl

IGNlilON

E

TiE

1

B

v

r

NElli

AI

GEA

SWI1

CH

Cl

lliCH

PEDAl

1

ANSt

ISSION

CA

BllREiO

G

1

0

OIS1

IBll1

O

IGNlilON

COIl

OllAI

POINi

0lSiRI6lliOR

AO

l

ANCED

B

EA

E

REiA

OEO

r

R

SWI1

CH

AI

ACCEI

E

AiOR

PEDAl

S

Nl1C

DETEcTIOG

IDE

ll

E

T

lRO

rrLE

OS

O

1

C

cTI

O

CLOSE

RO

rrLEI

OS

O

l

t

Page 124 of 252

EMISSION

CONTROL

S

IS

TEM

SEDAN

AND

SlATION

YfAGON

Yfl

tH

AUTOMATIC

TRANSMISSION

TO

DISTRIBUTOR

IGNITION

COIL

IGNITION

SWITCH

tnE

RETARDED

BREAKER

POINT

1

SPEED

SWITCH

THROTTLE

SWITCH

SWITCH

DETECTING

WIDE

OPEN

THROTTLE

POSITION

SWITCH

DETECTING

CLOSE

THROTTLE

POS

iION

Q

Z

S

e

l

Page 125 of 252

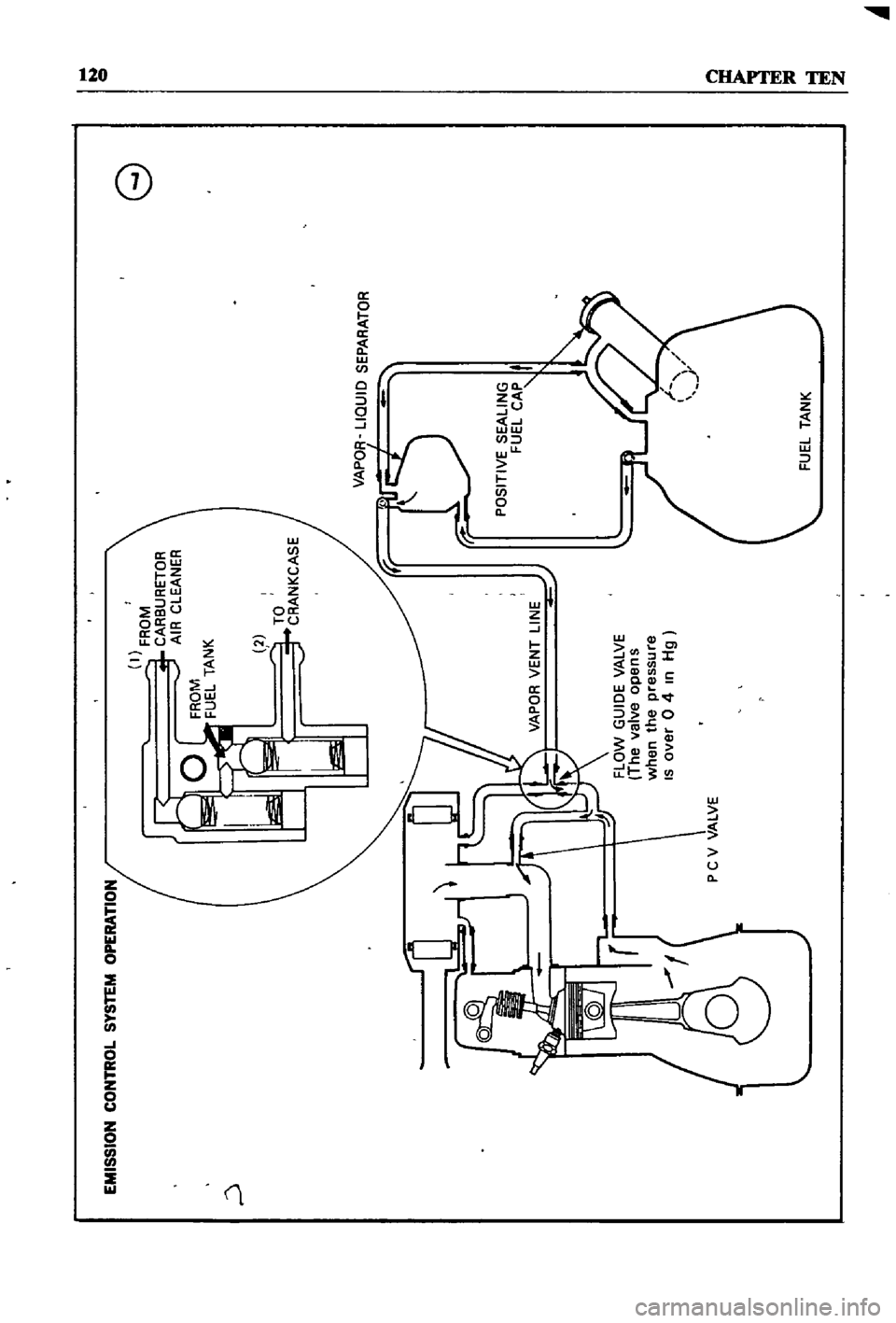

8

EtAISS

ON

CON1tt

o

SYStEtA

OrEft

A1ION

l

fflOM

C

fI

3UflEiOfl

11

1

CLE

NI

R

fROM

fUEL

i

N

lC

fLOW

GUIOE

L

E

1M

Jahre

opens

Vlhen

the

pressure

IS

o

Jer

0

4

In

t

g

fUEL

i

N

lC

s

Page 126 of 252

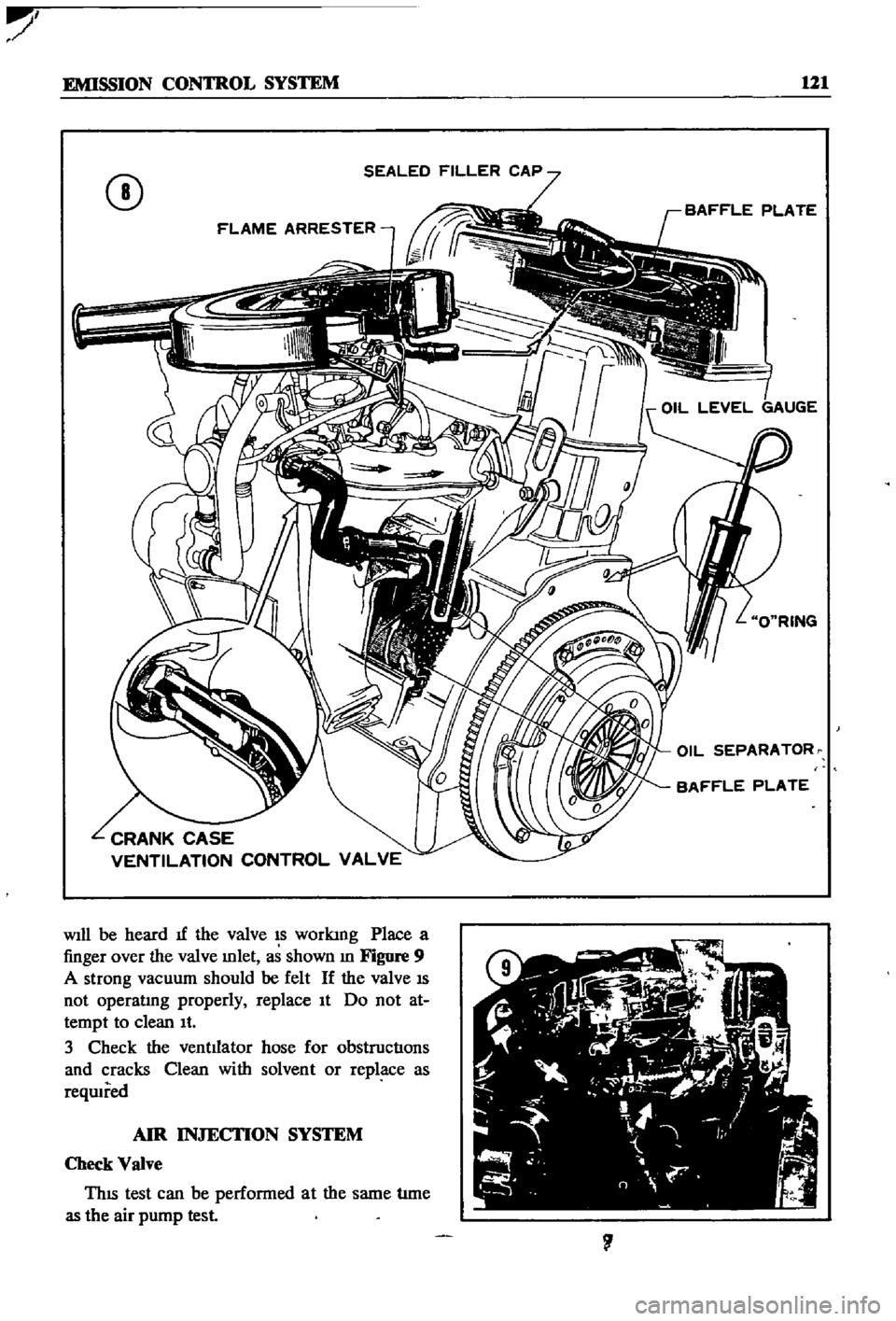

EMISSION

CONTROL

SYSTEM

121

CD

FLAME

ARRESTER

CRANK

CASE

VENTILATION

CONTROL

VALVE

WIll

be

heard

1f

the

valve

IS

workIng

Place

a

finger

over

the

valve

mlet

as

shown

In

Figure

9

A

strong

vacuum

should

be

felt

If

the

valve

IS

not

operatmg

properly

replace

It

Do

not

at

tempt

to

clean

It

3

Check

the

ventilator

hose

for

obstructIons

and

cracks

Clean

with

solvent

or

replace

as

reqwred

AIR

INJECTION

SYSTEM

Check

Valve

ThIS

test

can

be

performed

at

the

same

tIme

as

the

air

pump

test

OIL

SEPARATOR

1

Page 127 of 252

122

CHAPTER

TEN

1

Start

the

engIne

and

bnng

It

up

to

normal

operatIng

temperature

2

Inspect

all

hoses

and

connectIons

for

leaks

and

detenoratIon

Shut

off

the

engme

Replace

any

defectIve

hoses

3

Remove

the

hose

attached

to

the

check

valve

4

VIsually

Inspect

the

posItIon

of

the

valve

plate

InsIde

the

valve

body

See

Figure

10

It

should

be

lIghtly

posItIoned

agaInst

the

valve

seat

away

from

the

aIr

dlstnbutor

manifold

5

Insert

a

probe

Into

the

valve

connectIon

on

the

check

valve

Depress

the

valve

plate

It

should

return

freely

agaInst

the

valve

seat

when

released

6

Leave

the

hose

dISconnected

and

start

the

engme

7

Slowly

Increase

engine

speed

to

1

500

rpm

Watch

for

exhaust

gas

leakage

at

the

check

valve

There

should

not

be

any

The

valve

may

flutter

or

VIbrate

at

Idle

speeds

ThIS

IS

normal

Replace

the

valve

u

defecuve

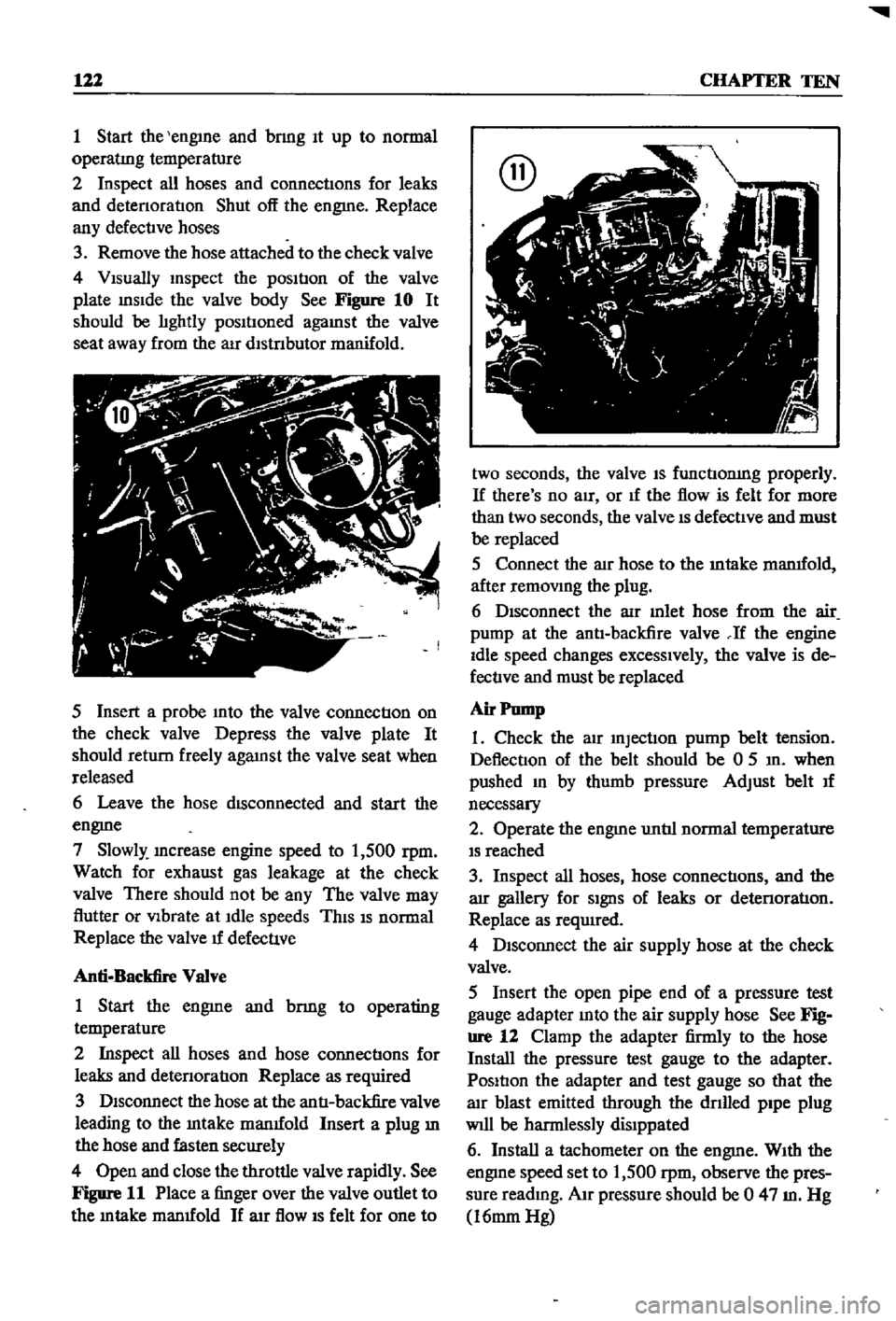

Anti

Backfire

Valve

1

Start

the

engme

and

bnng

to

operating

temperature

2

Inspect

all

hoses

and

hose

connectIons

for

leaks

and

detenoratIon

Replace

as

required

3

DIsconnect

the

hose

at

the

antI

backfire

valve

leading

to

the

Intake

manuold

Insert

a

plug

ill

the

hose

and

fasten

securely

4

Open

and

close

the

throttle

valve

rapidly

See

Figure

11

Place

a

finger

over

the

valve

outlet

to

the

m

take

manuold

If

arr

flow

IS

felt

for

one

to

two

seconds

the

valve

IS

functIonIng

properly

If

there

s

no

aIr

or

If

the

flow

is

felt

for

more

than

two

seconds

the

valve

IS

defectIve

and

must

be

replaced

5

Connect

the

alr

hose

to

the

mtake

manuold

after

remOVIng

the

plug

6

DIsconnect

the

aIr

mlet

hose

from

the

air

pump

at

the

antI

backfire

valve

If

the

engine

Idle

speed

changes

excessIvely

the

valve

is

de

fectIve

and

must

be

replaced

Air

Pump

1

Check

the

atr

InjectIon

pump

belt

tension

DeflectIon

of

the

belt

should

be

0

5

In

when

pushed

In

by

thumb

pressure

Adjust

belt

u

necessary

2

Operate

the

engme

untIl

normal

temperature

IS

reached

3

Inspect

all

hoses

hose

connectIons

and

the

arr

gallery

for

SIgnS

of

leaks

or

detenoratIon

Replace

as

required

4

DIsconnect

the

air

supply

hose

at

the

check

valve

5

Insert

the

open

pipe

end

of

a

pressure

test

gauge

adapter

Into

the

air

supply

hose

See

Fig

ure

12

Clamp

the

adapter

firmly

to

the

hose

Install

the

pressure

test

gauge

to

the

adapter

PosItIon

the

adapter

and

test

gauge

so

that

the

alr

blast

emitted

through

the

dnlled

pipe

plug

Will

be

harmlessly

dislppated

6

Install

a

tachometer

on

the

engme

WIth

the

engIne

speed

set

to

1

500

rpm

observe

the

pres

sure

readmg

AIr

pressure

should

be

0

47

m

Hg

16mm

Hg

Page 128 of 252

EMISSION

CONTROL

SYSTEM

123

7

If

the

pressure

does

not

meet

reqwrements

dISconnect

the

aIr

supply

hose

to

the

antI

backfire

valve

Clamp

a

plug

mto

the

hose

and

repeat

the

pressure

test

8

If

the

air

mJection

pump

does

not

meet

the

pressure

specIfication

It

should

be

replaced

NOTE

Repair

of

the

air

injection

pump

is

possible

but

have

the

lob

done

by

your

dealer

9

Close

the

hole

of

the

test

gauge

by

finger

With

the

engme

runnmg

at

1

500

rpm

See

Figure

13

If

a

leakIng

sound

is

heard

or

leakIng

air

is

felt

at

the

relIef

valve

the

relIef

valve

IS

defectIve

RepaIr

or

replace

as

reqUIred

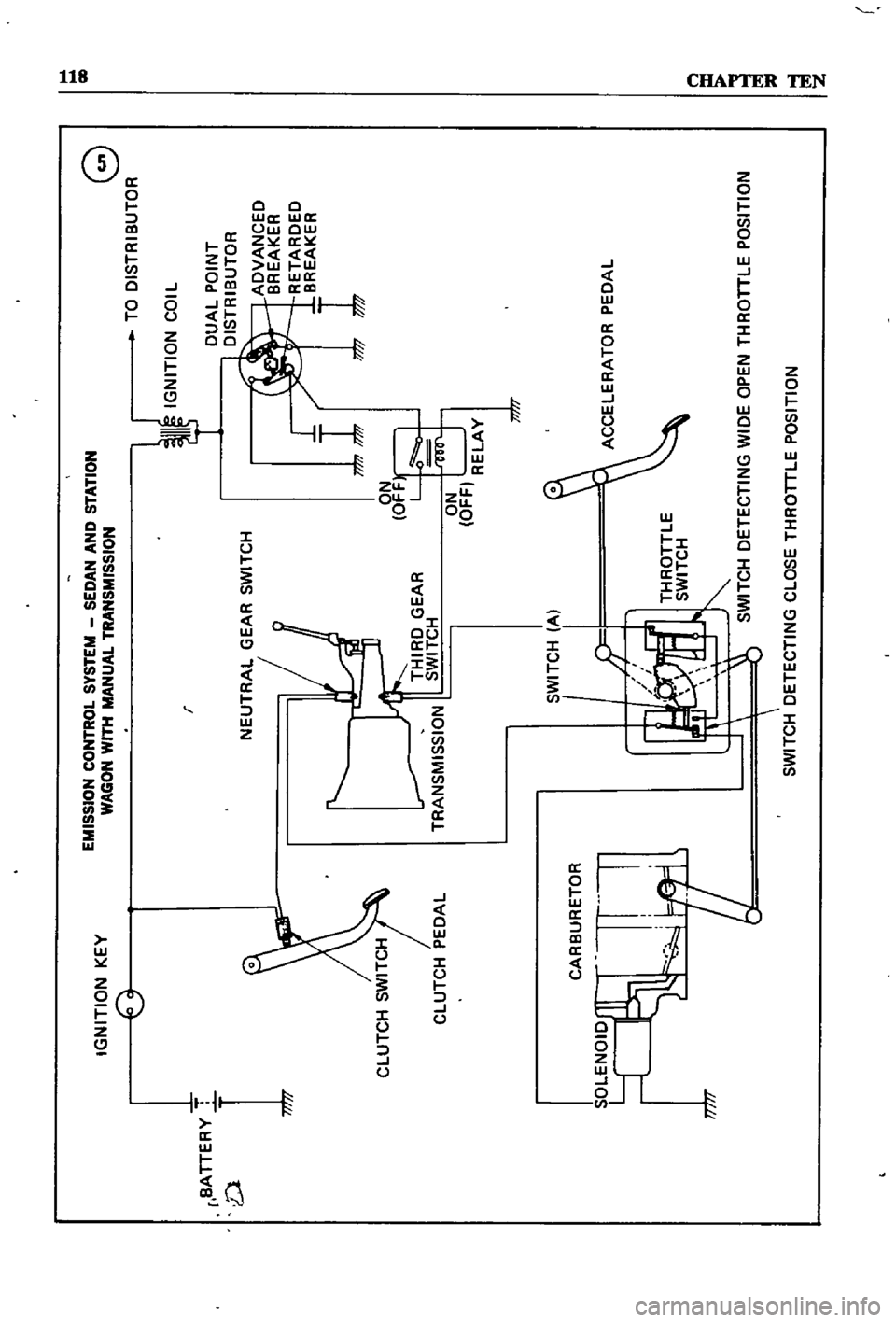

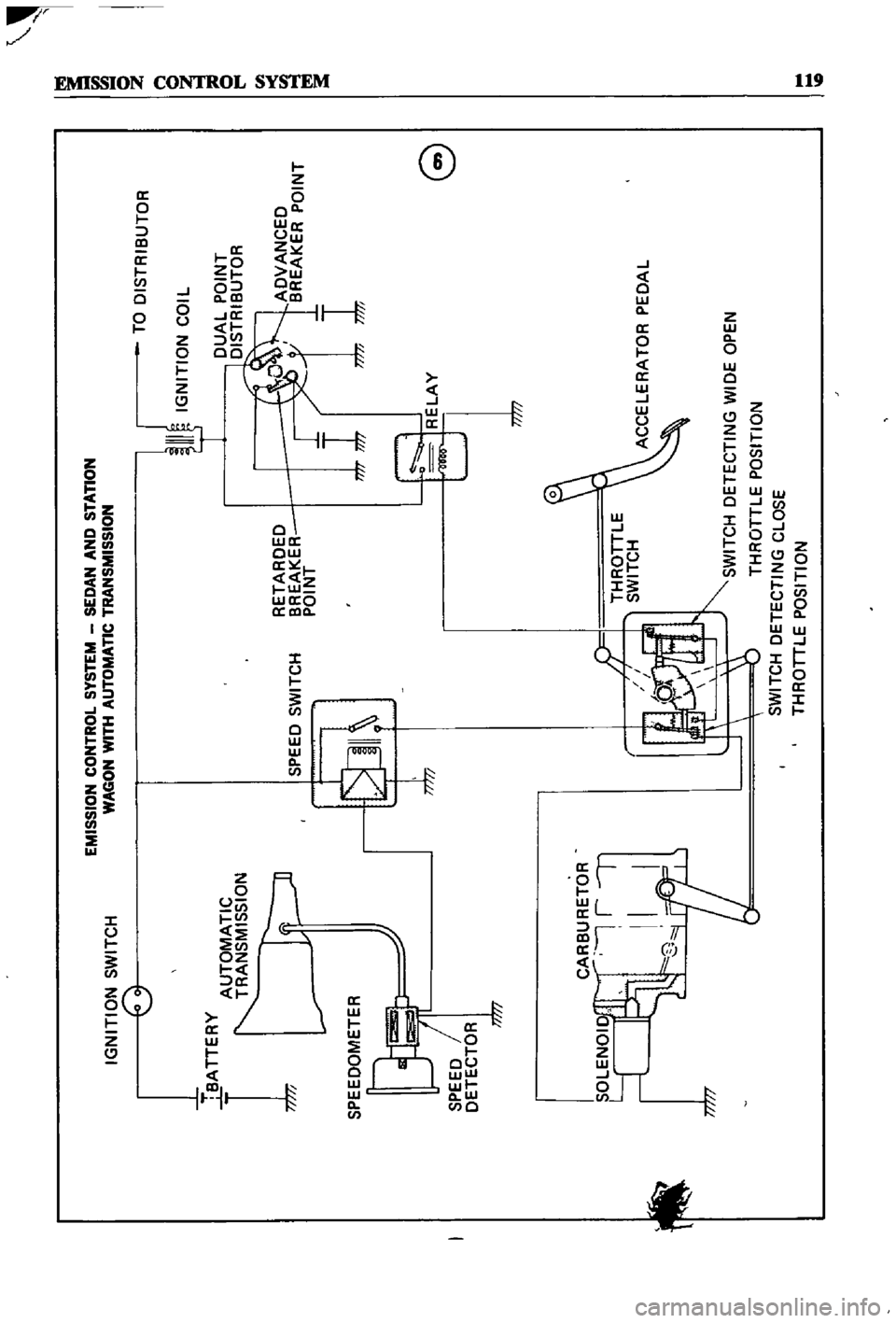

ENGINE

MODIFICATIONS

SYSTEM

Testlng

and

mamtenance

of

the

sWitches

relays

and

solenOIds

comprismg

the

engine

modIficatIons

reqwres

SpecIal

knowledge

and

test

eqUIpment

If

the

mechanic

suspects

that

troubles

eXist

In

these

parts

check

With

a

dealer

Mamtenance

of

the

dIstrIbutor

breaker

points

and

tImmg

of

engines

is

covered

m

Chapter

Four

EVAPORATIVE

EMISSION

y

CONTROL

SYSTEM

f

Detailed

informatIon

on

the

fuel

tank

and

connecting

fuel

lines

IS

given

In

Chapter

Seven

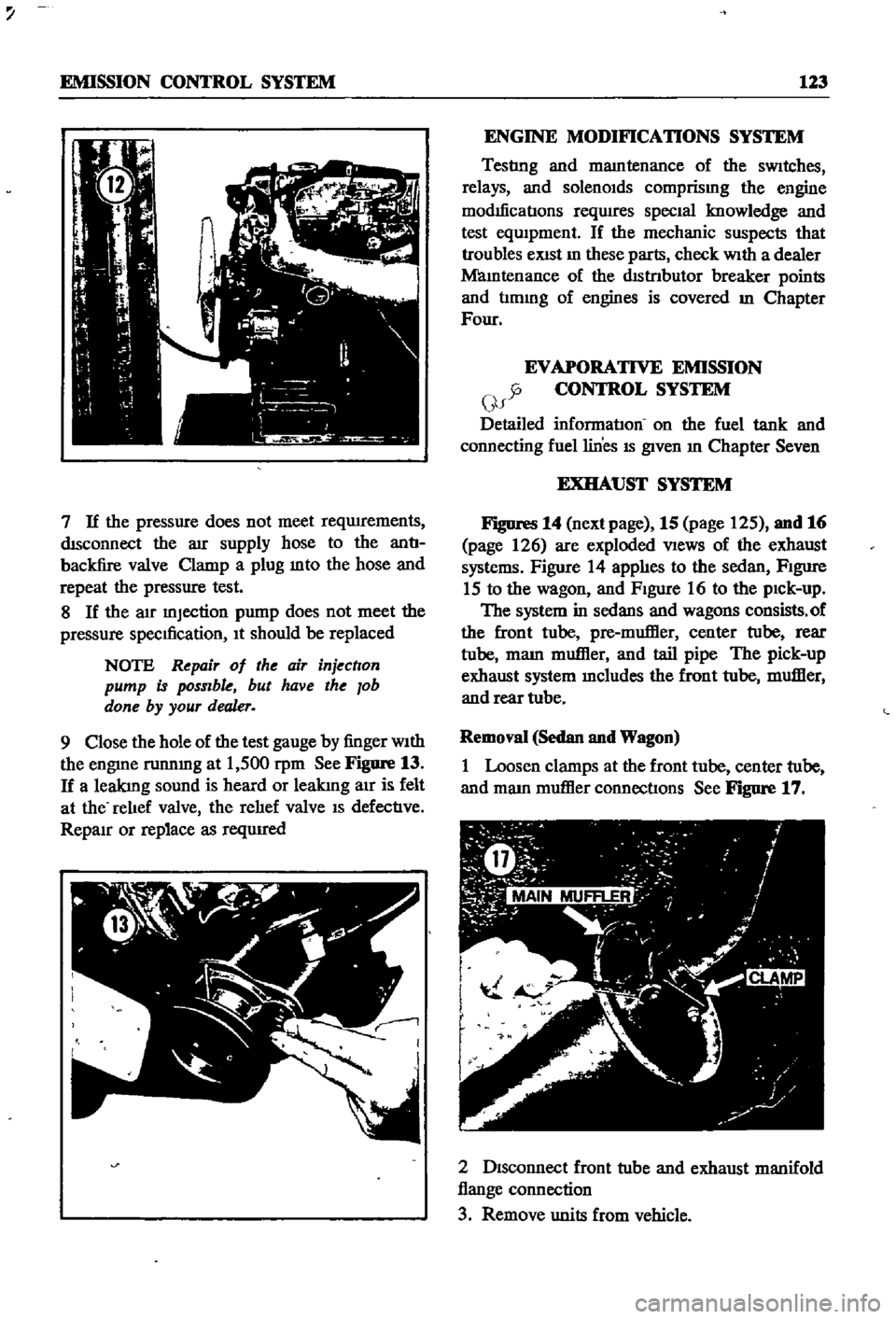

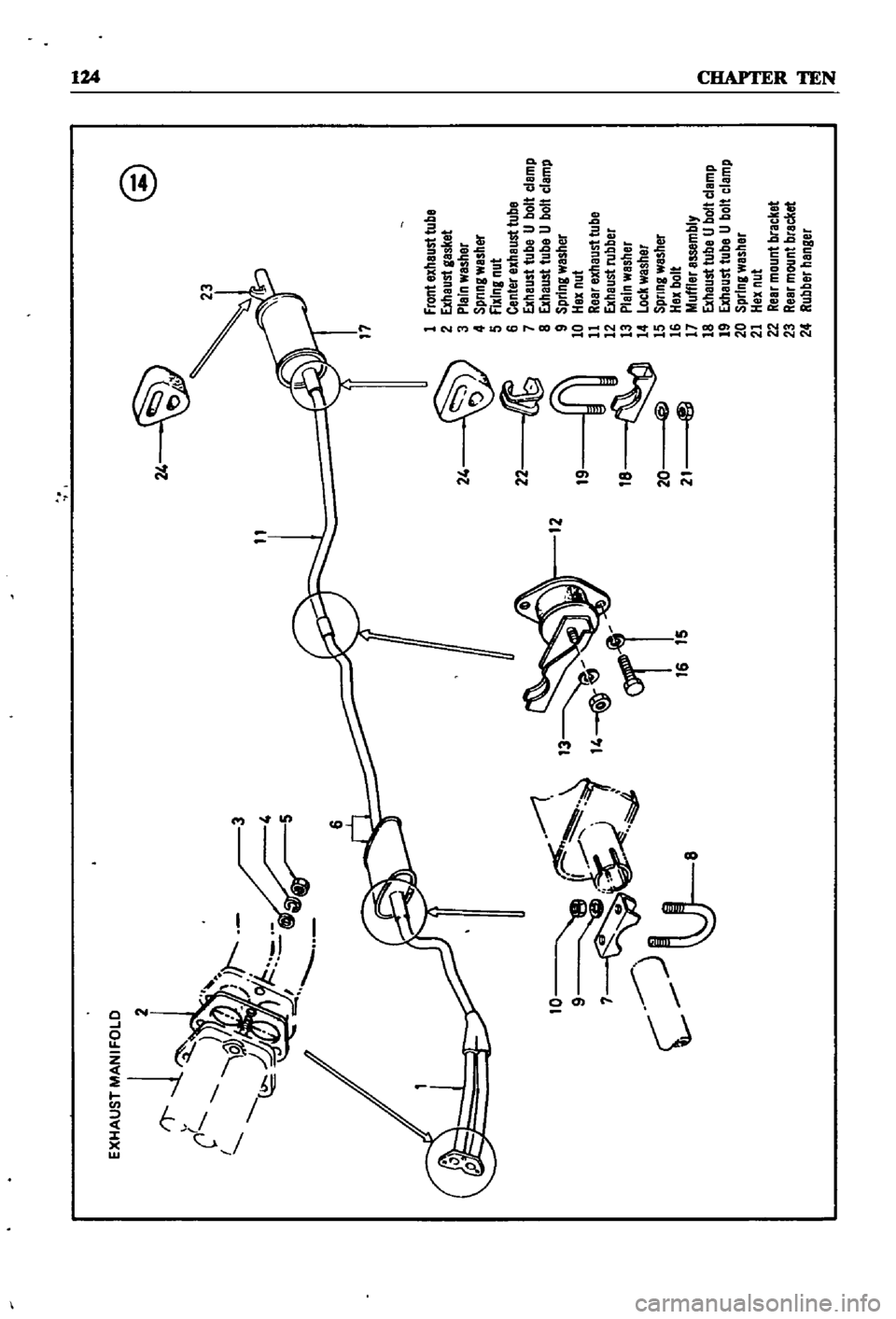

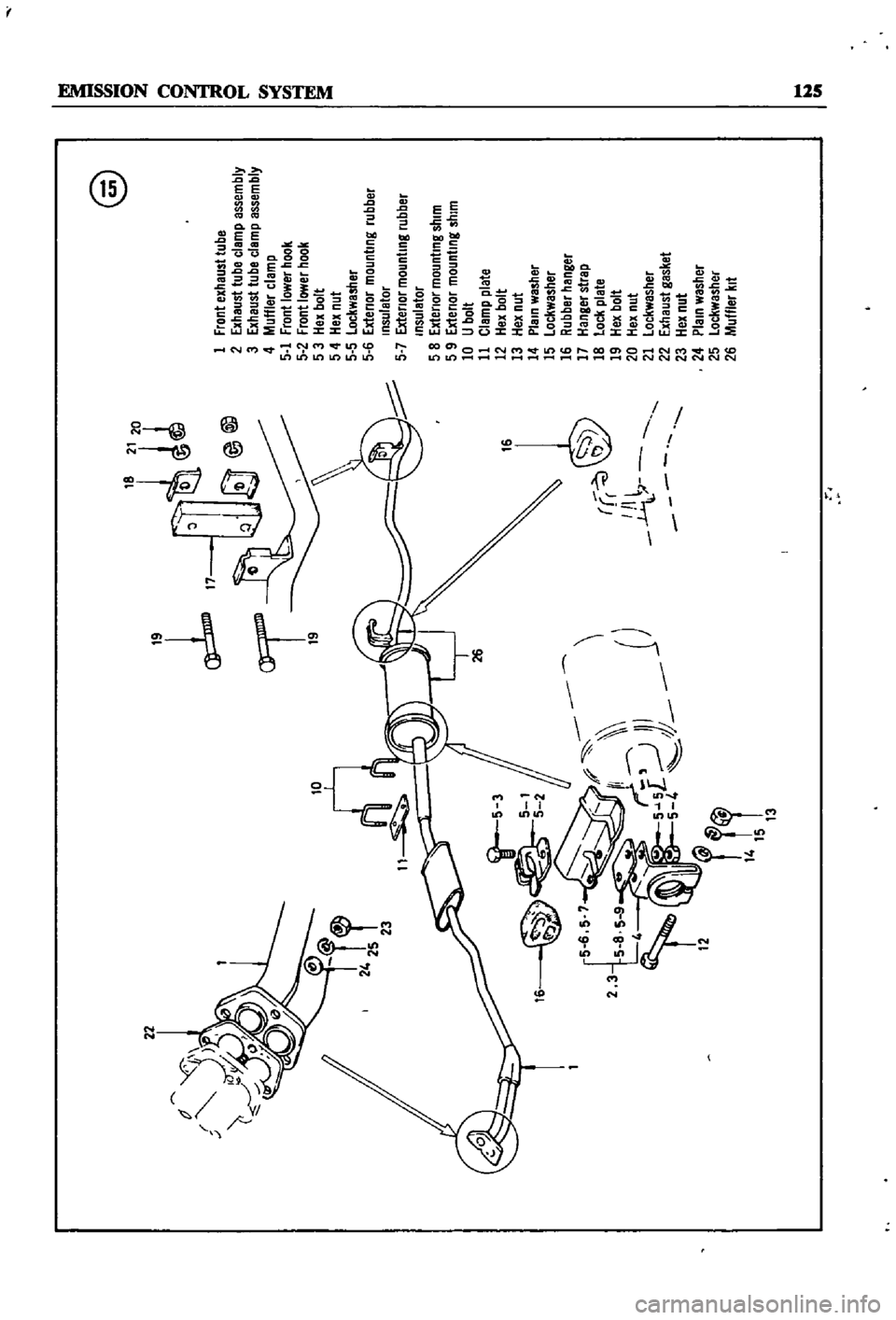

EXHAUST

SYSTEM

Figures

14

next

page

15

page

125

and

16

page

126

are

exploded

VIews

of

the

exhaust

systems

Figure

14

applIes

to

the

sedan

FIgure

15

to

the

wagon

and

FIgure

16

to

the

pIck

up

The

system

in

sedans

and

wagons

consists

of

the

front

tube

pre

muffier

center

tube

rear

tube

mam

muffier

and

tail

pipe

The

pick

up

exhaust

system

mcludes

the

front

tube

muffier

and

rear

tube

Removal

Sedan

and

Wagon

1

Loosen

clamps

at

the

front

tube

center

tube

and

mam

muffier

connectIons

See

Figure

17

2

DIsconnect

front

tube

and

exhaust

manifold

flange

connection

3

Remove

units

from

vehicle

Page 129 of 252

2

@

24

11

3

10

9

r

7

8

JI

4

J

c

U

12

24

22

19

18

@

20

ta

21

1

frontBxhaust

tube

2

Exheust

gasket

3

Plein

wesher

4

Spnng

wesher

5

fixing

nut

6

Center

exhaust

tube

7

Exhaust

tube

U

bolt

clamp

8

Exhaust

tube

U

bolt

clamp

9

Spring

wesher

10

Hex

nut

11

Reer

exheusttube

12

Exhaust

rubber

13

Plain

washer

14

Lock

washer

15

Spnng

washer

16

Hex

bolt

17

Muffler

essembly

18

Exhaust

tube

U

bolt

clamp

19

Exhaust

tube

U

bolt

clamp

20

spring

wesher

21

Hex

nut

22

Rear

mount

bracket

23

Rear

mount

brecket

24

Rubber

henger

i

Page 130 of 252

22

rnL

T

II

19

2

16

rr

I

II

l

r

@

1

Front

exhaust

tube

2

Exhaust

tube

clamp

assembly

3

Exhaust

tube

clemp

assembly

4

Muffler

clamp

5

1

Front

lower

hook

5

2

Front

lower

hook

5

3

Hex

bolt

5

4

Hex

nut

5

5

Lockwasher

5

6

Extenor

mounting

rubber

Insulator

5

7

Extenor

mounting

rubber

Insulator

5

8

Extenor

mounting

shim

5

9

Extenor

mounting

shim

10

U

bolt

11

Clamp

plate

12

Hex

bolt

13

Hex

nut

14

Plain

washer

15

lockwasher

16

Rubber

hanger

17

Hanger

strap

18

lock

plate

19

Hex

bolt

20

Hex

nut

21

lockwasher

22

Exhaust

gasket

23

Hex

nut

24

Plain

washer

25

lockwasher

26

Muffler

kit

l

o

o

t

I

N

III