DATSUN B110 1969 Service Manual PDF

Manufacturer: DATSUN, Model Year: 1969, Model line: B110, Model: DATSUN B110 1969Pages: 136, PDF Size: 5.64 MB

Page 61 of 136

GooliDI

Sptem

mechamsm

IS

adopted

to

prevent

the

water

leakage

and

nOIse

completely

Note

The

water

pump

must

not

be

disassembled

since

the

bearings

are

shrmkage

fitted

to

their

bores

If

any

part

of

water

pump

is

found

defective

replace

pump

assembly

Removal

Dram

coolmg

water

completely

Take

the

fan

belt

ofT

the

pulley

Remove

fan

and

pulley

Remove

the

water

pump

Installation

InstallatIOn

IS

the

reverse

of

removal

THERMOSTAT

A

pellet

type

thermostat

IS

used

m

the

water

outlet

passage

to

control

the

flow

of

coolant

provldmg

fast

engme

warm

up

and

regulatmg

coolant

temperature

A

wax

pellet

m

the

ther

mo

tat

expands

when

heated

and

contracts

when

cooled

The

pellet

IS

connected

through

a

piston

to

a

valve

and

when

the

pellet

IS

heated

pressure

IS

exerted

agamst

a

rubber

dIaphragm

and

the

valve

opens

As

the

pellet

IS

cooled

the

contractIOn

allows

the

sprmg

to

close

the

valve

Removal

Dram

coohng

water

Remove

radiator

hose

Remove

water

outlet

elbow

Then

take

out

the

thermostat

Inspection

To

test

the

thermostat

for

proper

operatmg

temperature

submerg

he

umt

m

a

contamer

of

water

Heat

the

water

and

observe

the

tem

perature

Measure

temperature

when

the

thermostat

valve

Just

starts

rlsmg

If

thermostat

does

not

operate

at

the

above

specIfied

temperatures

It

must

be

replaced

Installation

When

mstalhng

the

thermostat

apply

adheSIve

Three

Bond

to

both

SIdes

of

the

packmg

for

preventIOn

of

water

leakage

In

stall

the

thermostat

m

reverse

sequence

of

removal

USA

Canadd

Olher

coun

t

nes

Valve

opemng

temperature

177

to

r8710

16710

F

183

193

173

Valve

lIft

O

oF

031

203

031

212

031

194

WI

fL

g

0

I

l

1

L

JI

I

I

I

I

a

J

i

o

wa

r

outlet

EI

Thermostat

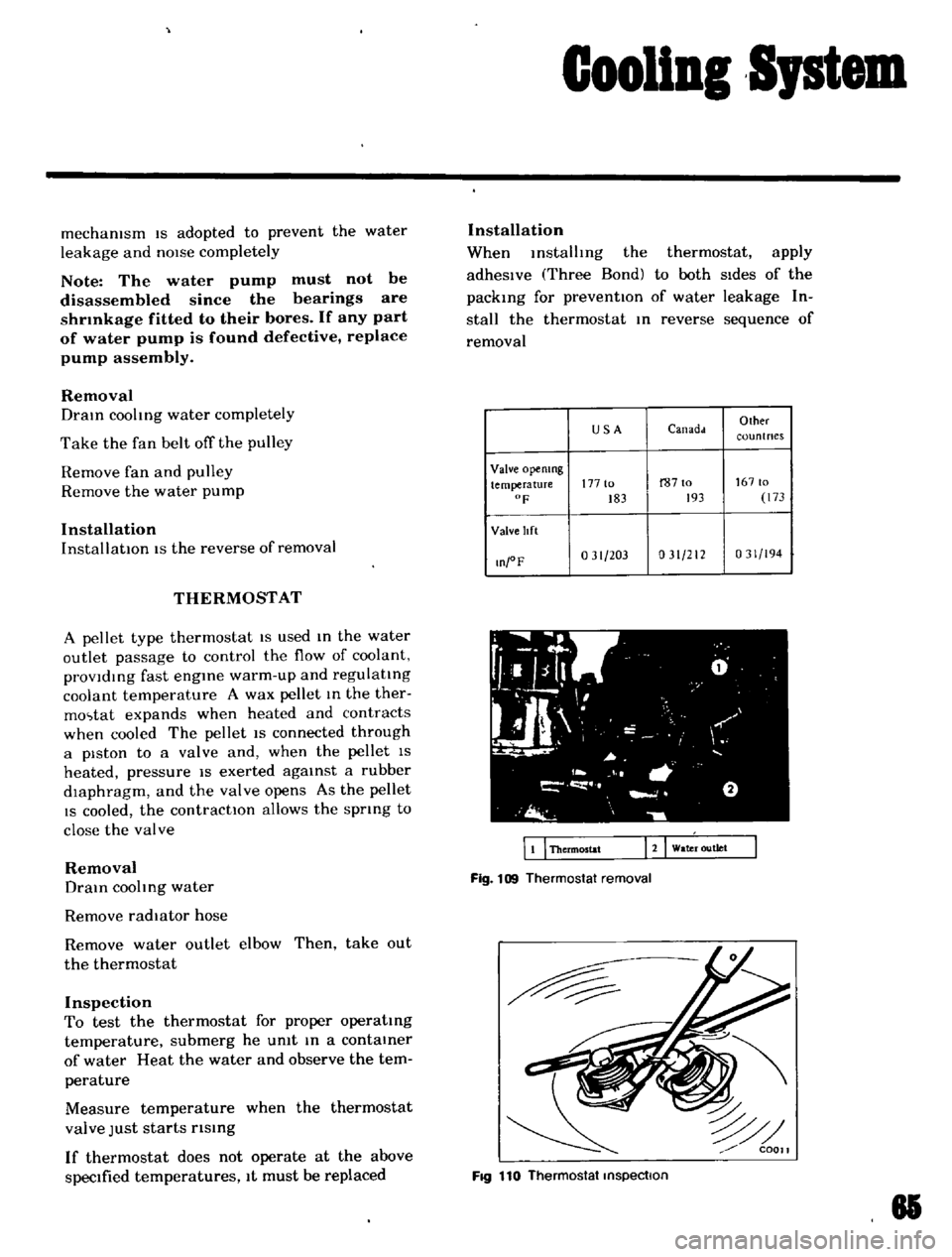

Fig

109

Thermostat

removal

FIQ

110

Thermostat

inspection

81

Page 62 of 136

Gooliol

SJstem

RADIATOR

The

radiator

IS

of

a

down

flow

type

w1th

an

ex

panslOn

tank

located

on

the

top

of

tube

sec

tlOn

Pressure

IS

applted

to

the

system

and

the

I

eltef

valve

Incorporated

In

the

radiator

filler

cap

controls

the

pressure

at

approximately

13

Ib

sq

In

Removal

DraIn

cooltng

water

DIsconnect

radiator

upper

hose

lower

hose

and

hose

to

the

reservOir

tank

Detach

the

radiator

assembly

by

removmg

SIX

fiXIng

bolts

Inspection

Check

for

water

leakage

and

cracks

USIng

a

cap

tester

If

such

defects

are

detected

repair

88

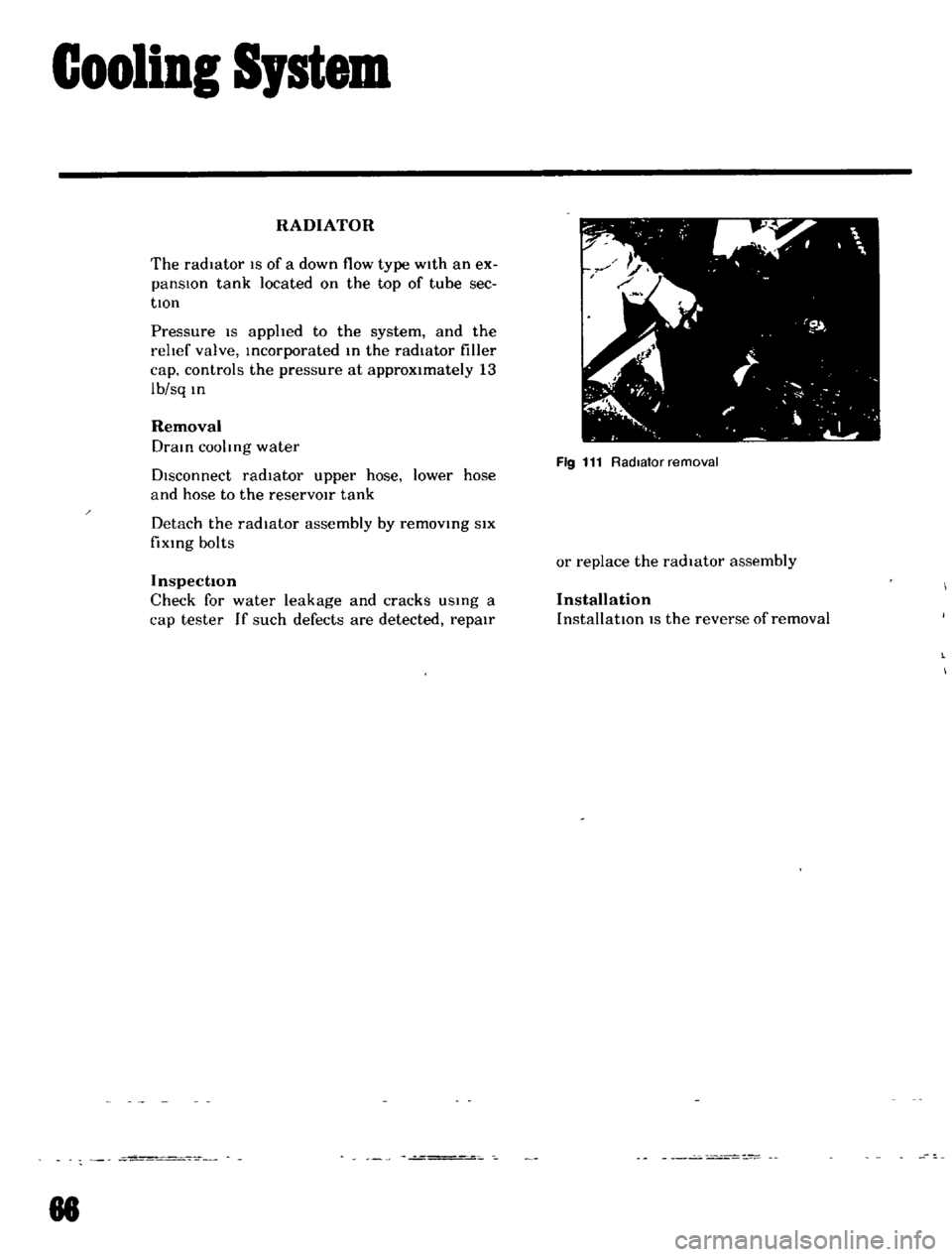

Fig

111

Radiator

removal

or

replace

the

radIator

assembly

Installation

InstallatIOn

IS

the

reverse

of

removal

Page 63 of 136

Brakes

Jl

r7

I

J

I

lip

b

Ih

ih

p

lIJ

11

yhndu

blolk

2

Spnn

7

Air

hlu

k

r

12

PI

lon

3

LVI

pm

H

Rl

t

llmll

nn

13

lh

L

prm

hlm

8001

I

YOkl

pnn

5

lIJ

n

ll

prill

111

1

lon

Ii

15

Yoh

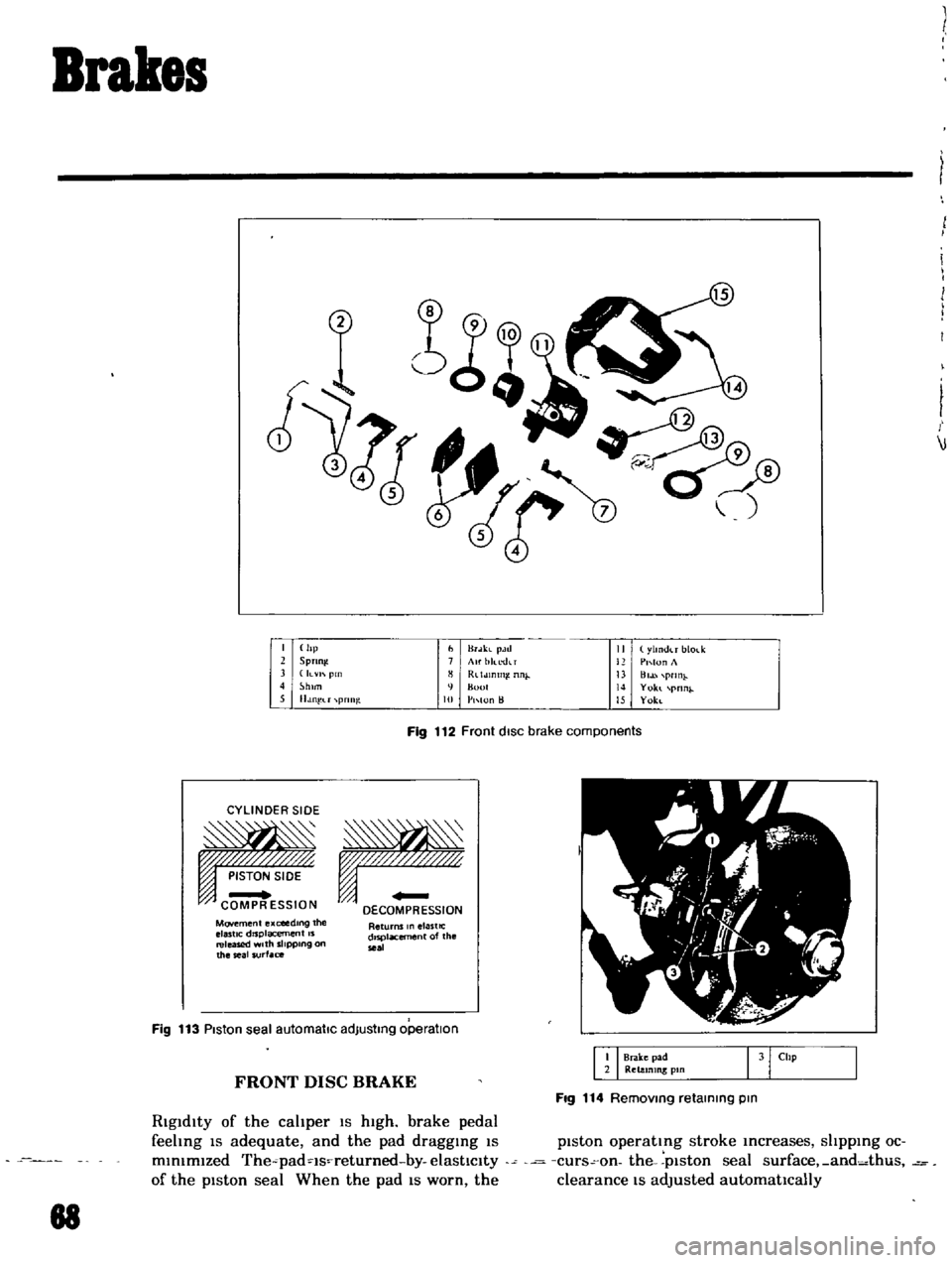

Fig

112

Front

diSC

brake

components

Movement

exceeding

the

elastic

dISplacement

IS

released

with

slipping

on

the

seal

surf

a

Returns

elastIC

displacement

of

the

seal

CYLINDER

SIDE

DECOMPRESSION

Fig

113

PIston

seal

automatic

adjusting

operation

FRONT

DISC

BRAKE

I

Brake

pad

2

Retalnl

pin

I

Clip

FIg

114

RemOVing

retaining

pm

Rigidity

of

the

cahper

IS

high

brake

pedal

feehng

IS

adequate

and

the

pad

draggIng

IS

piston

operating

stroke

Increases

shpplng

oc

mlmmlzed

The

padqs

returned

by

elastIcity

curs

on

the

plston

seal

surface

and

thus

of

the

piston

seal

When

the

pad

IS

worn

the

clearance

IS

adjusted

automatIcally

88

Page 64 of 136

r

Brakes

Moreover

In

order

to

prevent

brake

squeahng

a

shIm

IS

Inserted

behind

the

pad

BRAKE

PAD

Replacement

Jack

up

front

UnIt

of

the

vehicle

and

remove

the

front

wheel

Remove

clip

from

the

retaining

pin

and

sup

porting

the

brake

pad

remove

the

retaining

pin

and

COil

spring

Unhook

the

hanger

spring

and

Withdraw

the

brake

pad

and

shim

With

a

pair

of

phers

Note

When

the

brake

pad

IS

removed

do

not

depress

the

brake

pedal

or

otherWise

the

piston

will

come

out

Inspection

Clearance

between

the

brake

pad

and

rotor

IS

adjusted

automatically

Check

the

brake

pad

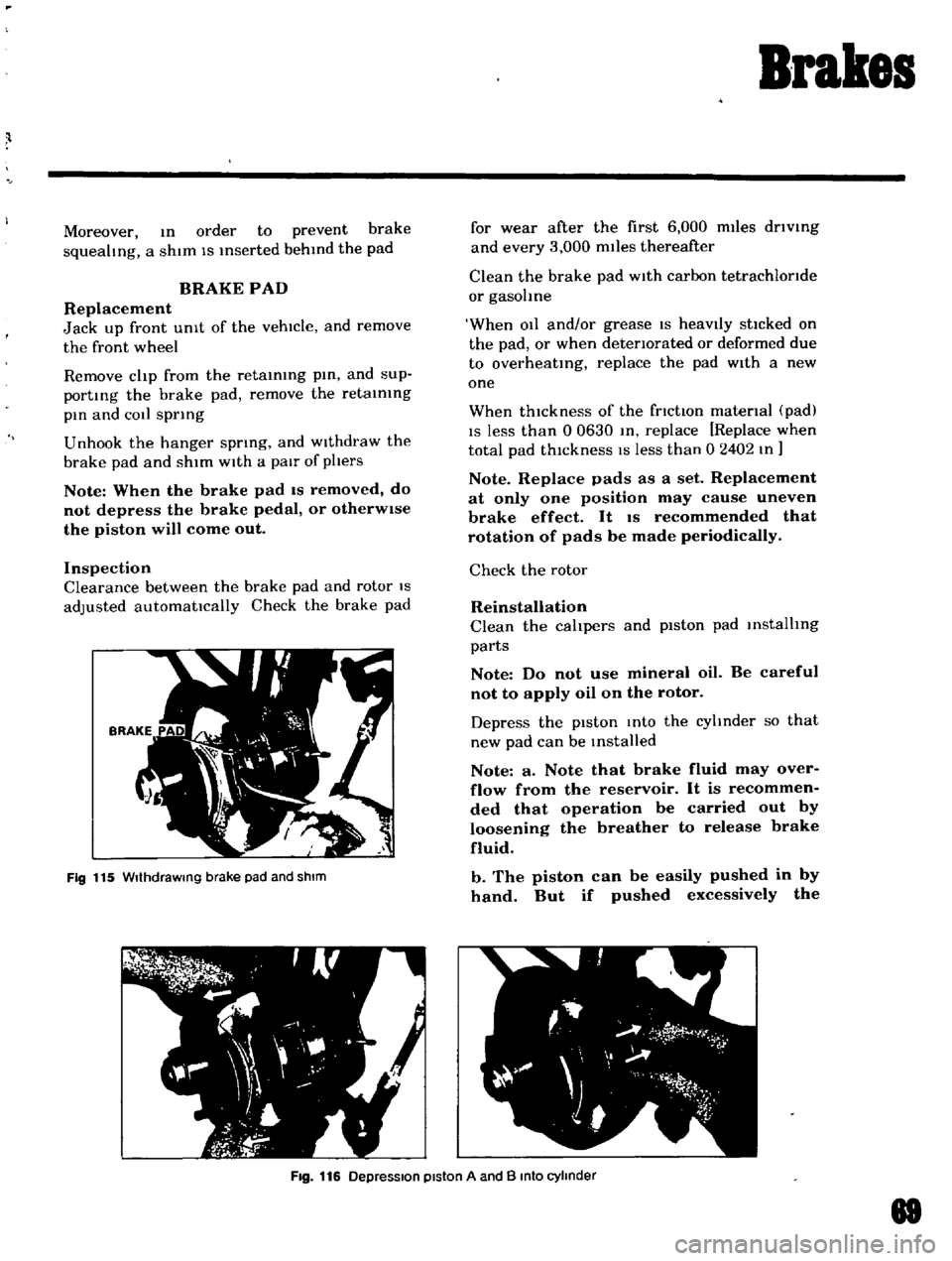

Fig

115

WIthdraWing

brake

pad

and

shIm

for

wear

after

the

first

6

000

miles

driVing

and

every

3

000

miles

thereafter

Clean

the

brake

pad

With

carbon

tetrachloride

or

gasohne

When

011

and

or

grease

IS

heavIly

stlcked

on

the

pad

or

when

deteriorated

or

deformed

due

to

overheating

replace

the

pad

With

a

new

one

When

thickness

of

the

friction

material

pad

IS

less

than

0

0630

In

replace

Replace

when

total

pad

thIckness

IS

less

than

0

2402

In

Note

Replace

pads

as

a

set

Replacement

at

only

one

position

may

cause

uneven

brake

effect

It

IS

recommended

that

rotation

of

pads

be

made

periodically

Check

the

rotor

Reinstallation

Clean

the

calipers

and

piston

pad

installing

parts

Note

Do

not

use

mineral

oil

Be

careful

not

to

apply

oil

on

the

rotor

Depress

the

pIston

Into

the

cyhnder

so

that

new

pad

can

be

Installed

Note

a

Note

that

brake

fluid

may

over

flow

from

the

reservoir

It

is

recommen

ded

that

operation

be

carried

out

by

loosening

the

breather

to

release

brake

fluid

b

The

piston

can

be

easily

pushed

in

by

hand

But

if

pushed

excessively

the

Fig

116

DepreSSion

piston

A

and

B

Into

cylinder

88

Page 65 of 136

Brakes

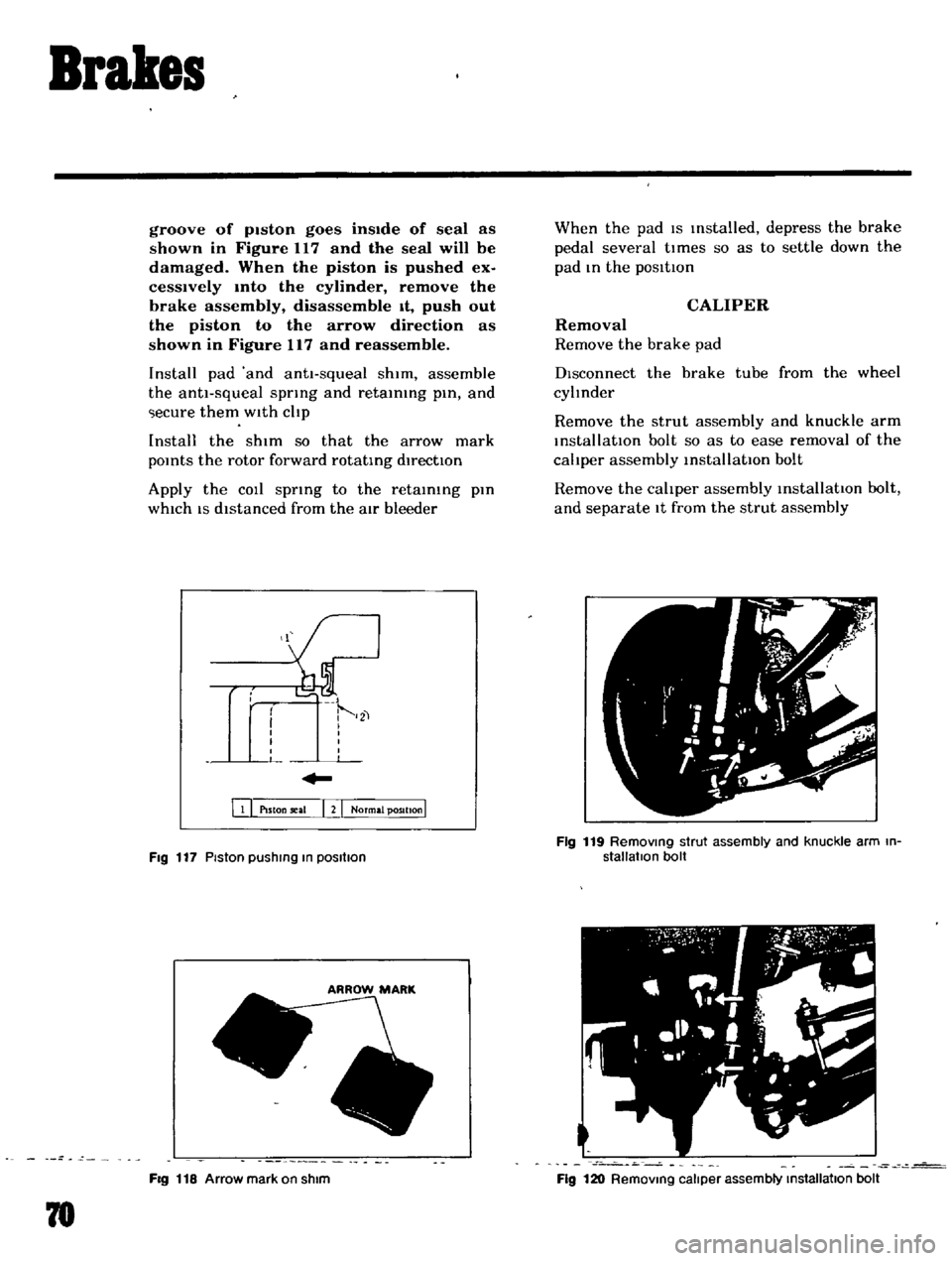

groove

of

pIston

goes

insIde

of

seal

as

shown

in

Figure

117

and

the

seal

will

be

damaged

When

the

piston

is

pushed

ex

cesslvely

mto

the

cylinder

remove

the

brake

assembly

disassemble

It

push

out

the

piston

to

the

arrow

direction

as

shown

in

Figure

117

and

reassemble

Install

pad

and

antt

squeal

shim

assemble

the

anti

squeal

spring

and

retaining

pin

and

ecure

them

with

cltp

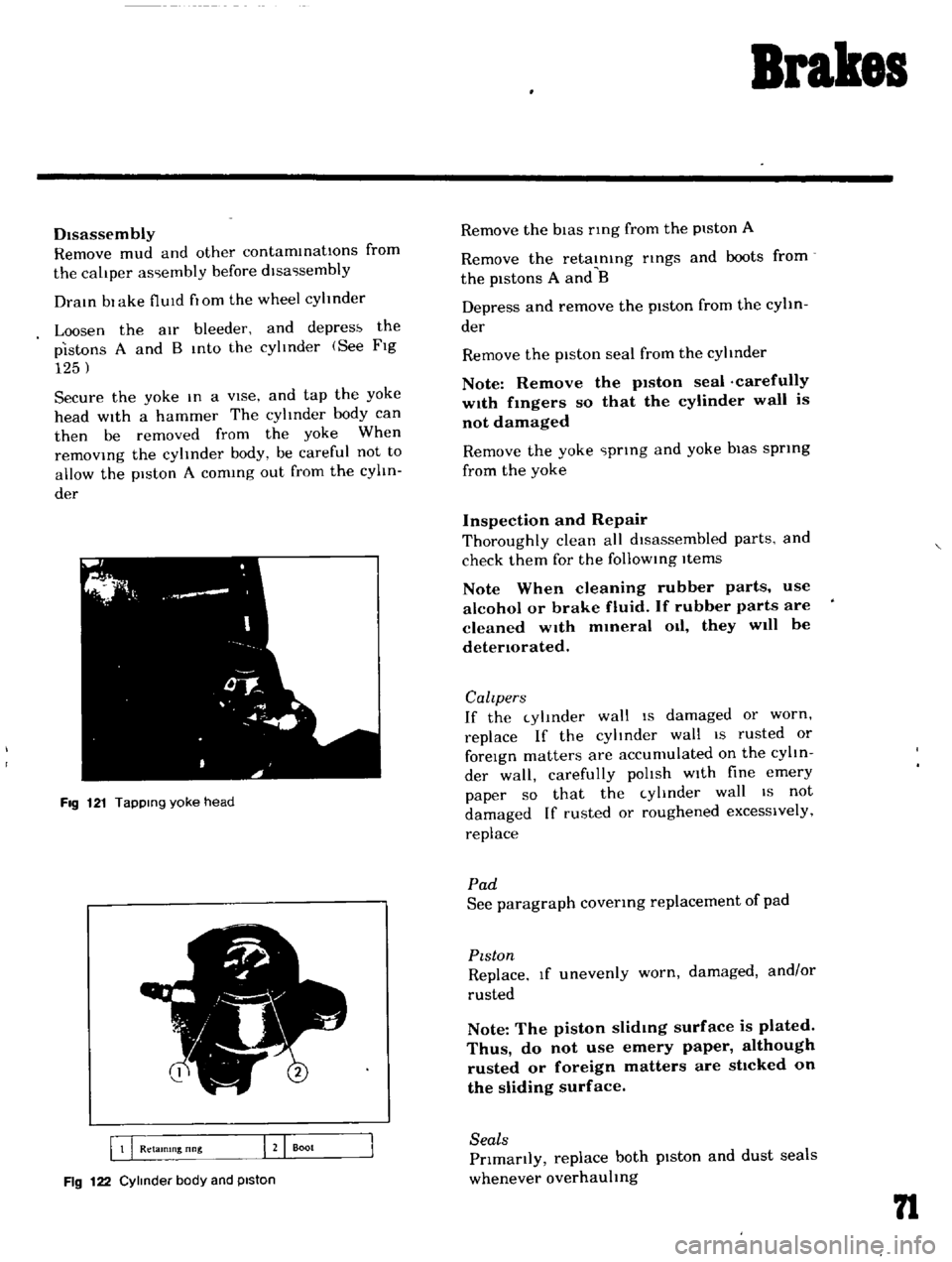

Install

the

shim

so

that

the

arrow

mark

pOints

the

rotor

forward

rotating

directIOn

Apply

the

COIl

spring

to

the

retaining

pin

which

IS

distanced

from

the

atr

bleeder

111

PlSton

seal

I

2

I

Normal

position

I

Fig

117

Piston

pushIng

In

posllIon

FIg

118

Arrow

mark

on

shim

78

When

the

pad

IS

Installed

depress

the

brake

pedal

several

tl

mes

so

as

to

settle

down

the

pad

In

the

posltton

CALIPER

Removal

Remove

the

brake

pad

DIsconnect

the

brake

tube

from

the

wheel

cyltnder

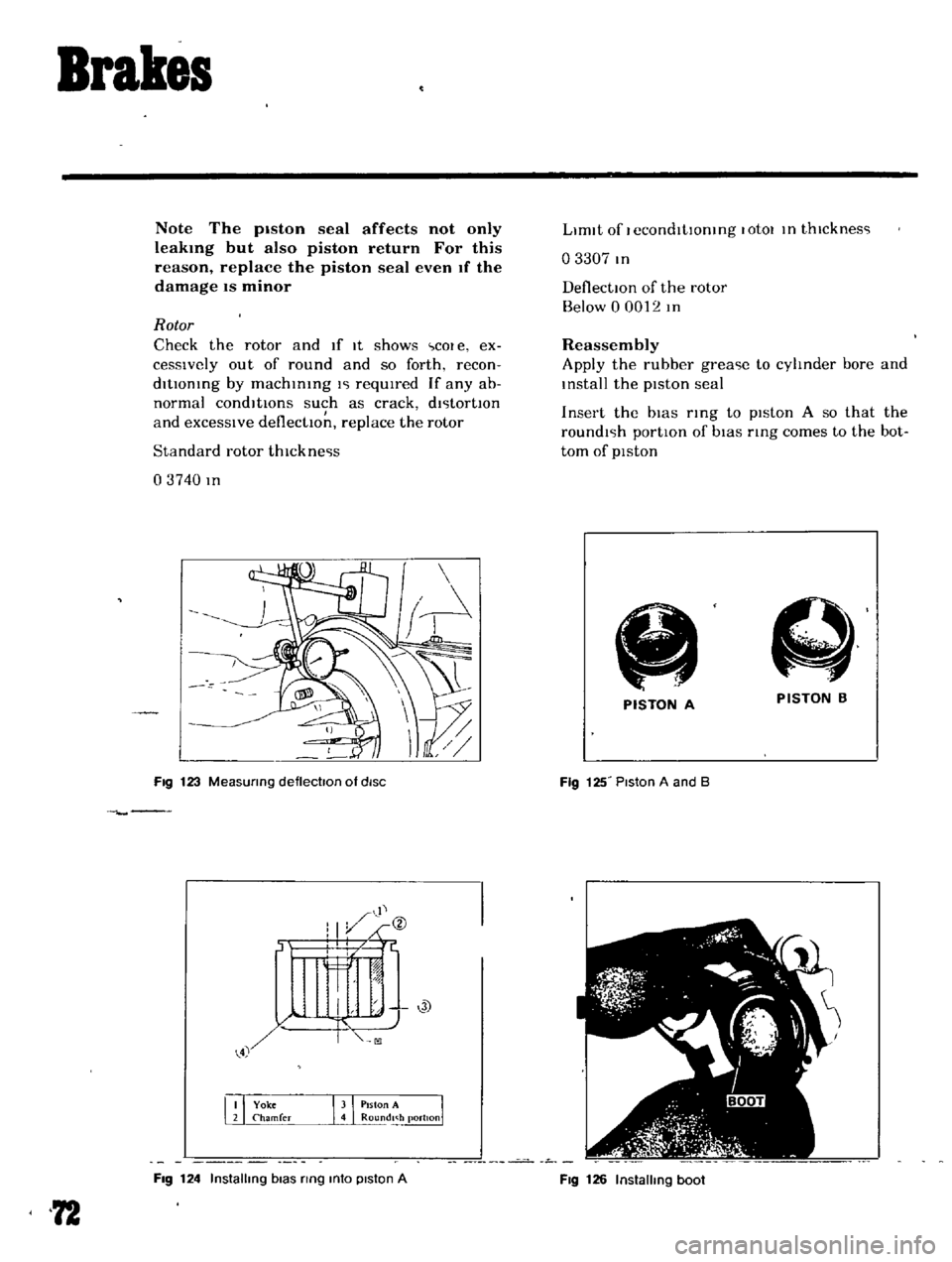

Remove

the

strut

assembly

and

knuckle

arm

installatIOn

bolt

so

as

to

ease

removal

of

the

cahper

assembly

installatIOn

bolt

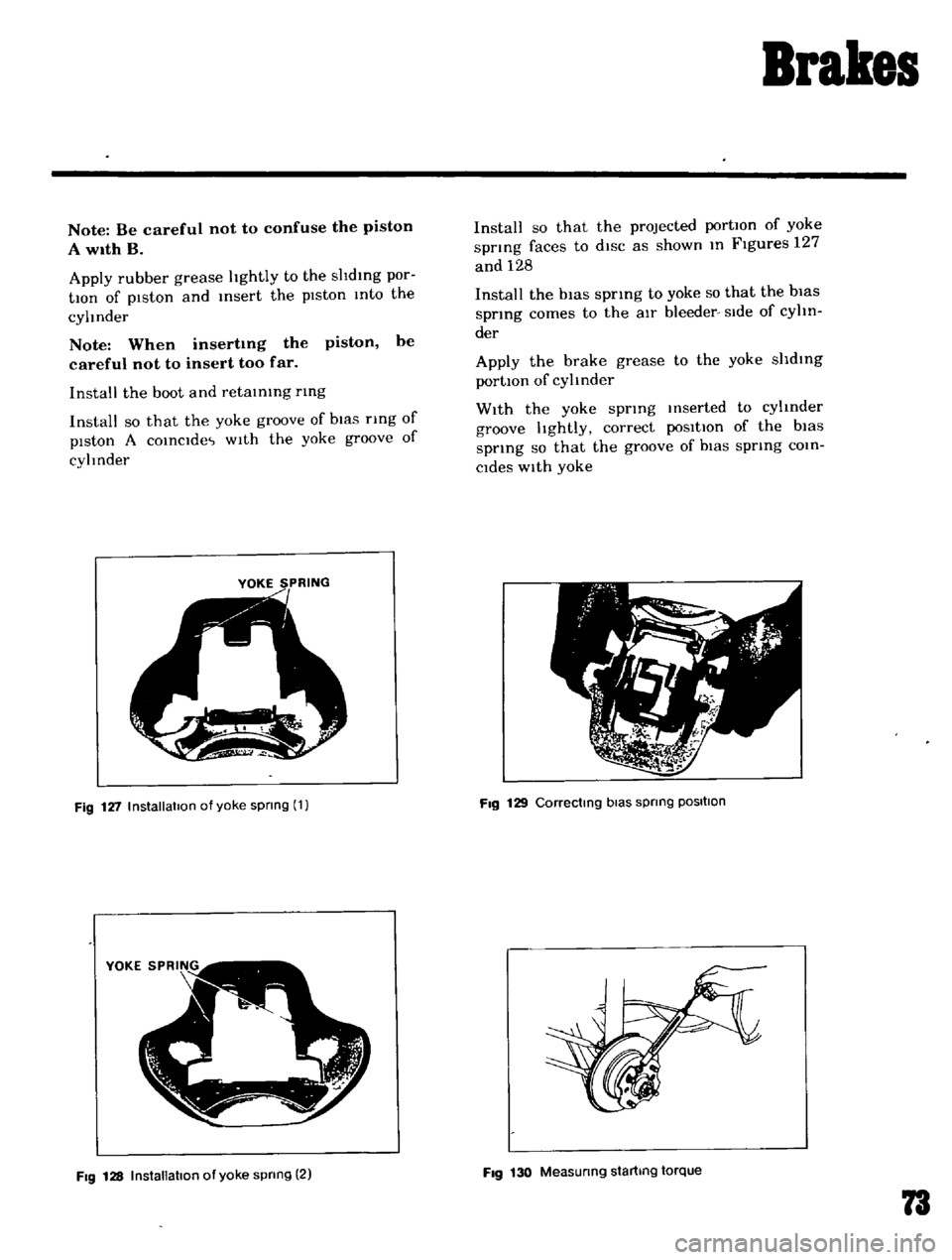

Remove

the

cahper

assembly

installatIOn

bolt

and

separate

It

from

the

strut

assembly

Fig

119

RemOVing

strut

assembly

and

knuckle

arm

in

stallatIon

bolt

Fig

120

RemOVing

caliper

assembly

Installallon

bolt

Page 66 of 136

Brakes

DIsassembly

Remove

mud

and

other

contamInations

from

the

caLiper

as

embly

before

dlsa

sembly

DraIn

bl

ake

fluId

flOm

the

wheel

cylinder

Loosen

the

aIr

bleeder

and

depres

the

pistons

A

and

B

Into

the

cylInder

See

FIg

125

Secure

the

yoke

In

a

vIse

and

tap

the

yoke

head

with

a

hammer

The

cylinder

body

can

then

be

removed

from

the

yoke

When

remOVIng

the

cylinder

body

be

careful

not

to

allow

the

piston

A

comIng

out

from

the

cylIn

der

FIg

121

TapPing

yoke

head

5

I

B

Q

Retamlng

nng

J

Boot

Fig

122

Cylinder

body

and

piston

Remove

the

bIas

nng

from

the

piston

A

Remove

the

retaInIng

nngs

and

boots

from

the

pistons

A

and

B

Depress

and

remove

the

piston

from

the

cylin

der

Remove

the

piston

seal

from

the

cylinder

Note

Remove

the

p1ston

seal

carefully

w1th

fmgers

so

that

the

cylinder

wall

is

not

damaged

Remove

the

yoke

prIng

and

yoke

bias

sprIng

from

the

yoke

Inspection

and

Repair

Thoroughly

clean

all

dIsassembled

parts

and

check

them

for

the

follOWIng

Items

Note

When

cleaning

rubber

parts

use

alcohol

or

brake

fluid

If

rubber

parts

are

cleaned

wIth

mmeral

Oil

they

will

be

detenorated

Calzpers

If

the

cylInder

wall

IS

damaged

or

worn

replace

If

the

cylinder

wall

IS

rusted

or

foreIgn

matters

are

accumulated

on

the

cylIn

der

wall

carefully

polIsh

wIth

fine

emery

paper

so

that

the

cylInder

wall

IS

not

damaged

If

rusted

or

roughened

excessively

replace

Pad

See

paragraph

covenng

replacement

of

pad

PIston

Replace

If

unevenly

worn

damaged

and

or

rusted

Note

The

piston

slidmg

surface

is

plated

Thus

do

not

use

emery

paper

although

rusted

or

foreign

matters

are

sttcked

on

the

sliding

surface

Seals

Prlmanly

replace

both

pIston

and

dust

seals

whenever

overhauling

n

Page 67 of 136

Brakes

Note

The

piston

seal

affects

not

only

Ieakmg

but

also

piston

return

For

this

reason

replace

the

piston

seal

even

If

the

damage

IS

minor

Rotor

Check

the

rotor

and

If

It

shows

cOl

e

ex

cesslvely

out

of

round

and

so

forth

recon

ditIOnIng

by

machInIng

l

l

requIred

If

any

ab

normal

condItIOns

such

as

crack

dl

ltortlOn

and

excessIve

deflectIOn

replace

the

rotor

Standard

rotor

thlckne

ls

03740

In

Fig

123

MeaSUring

deflectoon

of

diSC

Fig

124

Installing

bias

ring

mto

piston

A

72

LImIt

of

I

econdltlOntng

lotOl

In

thlcknes

l

o

3307

In

DeflectIOn

of

the

rotor

Below

0

0012

In

Reassembly

Apply

the

rubber

grea

le

to

cylinder

bore

and

Install

the

pIston

seal

Insert

the

bIas

rIng

to

pIston

A

so

that

the

roundl

lh

portIon

of

bIas

ring

comes

to

the

bot

tom

of

pIston

A

PISTON

B

PISTON

A

Fig

125

Piston

A

and

B

Fig

126

Installing

boot

Page 68 of 136

Brakes

Note

Be

careful

not

to

confuse

the

piston

A

with

B

Apply

rubber

grease

hghtly

to

the

shdlng

par

tlon

of

p1ston

and

Insert

the

piston

Into

the

cyhnder

Note

When

insertmg

the

piston

be

careful

not

to

insert

too

far

Install

the

boot

and

retaining

nng

Install

so

that

the

yoke

groove

of

bIas

nng

of

piston

A

COinCide

wIth

the

yoke

groove

of

cyhnder

YOKE

SPRING

Fig

127

Installation

of

yoke

spnng

1

Fig

128

InstallatIOn

of

yoke

spnng

2

Install

so

that

the

projected

portIOn

of

yoke

spnng

faces

to

diSC

as

shown

In

Figures

127

and

128

Install

the

bias

spring

to

yoke

so

that

the

bias

spring

comes

to

the

aIr

bleeder

Side

of

cyhn

der

Apply

the

brake

grease

to

the

yoke

shdlng

portIOn

of

cylinder

With

the

yoke

spring

Inserted

to

cylinder

groove

hghtly

correct

poSitIOn

of

the

bias

spnng

so

that

the

groove

of

biaS

spring

COin

Cides

With

yoke

Fig

129

Correctmg

bias

spnng

POSItion

Fig

130

Measunng

startmg

torque

73

Page 69 of 136

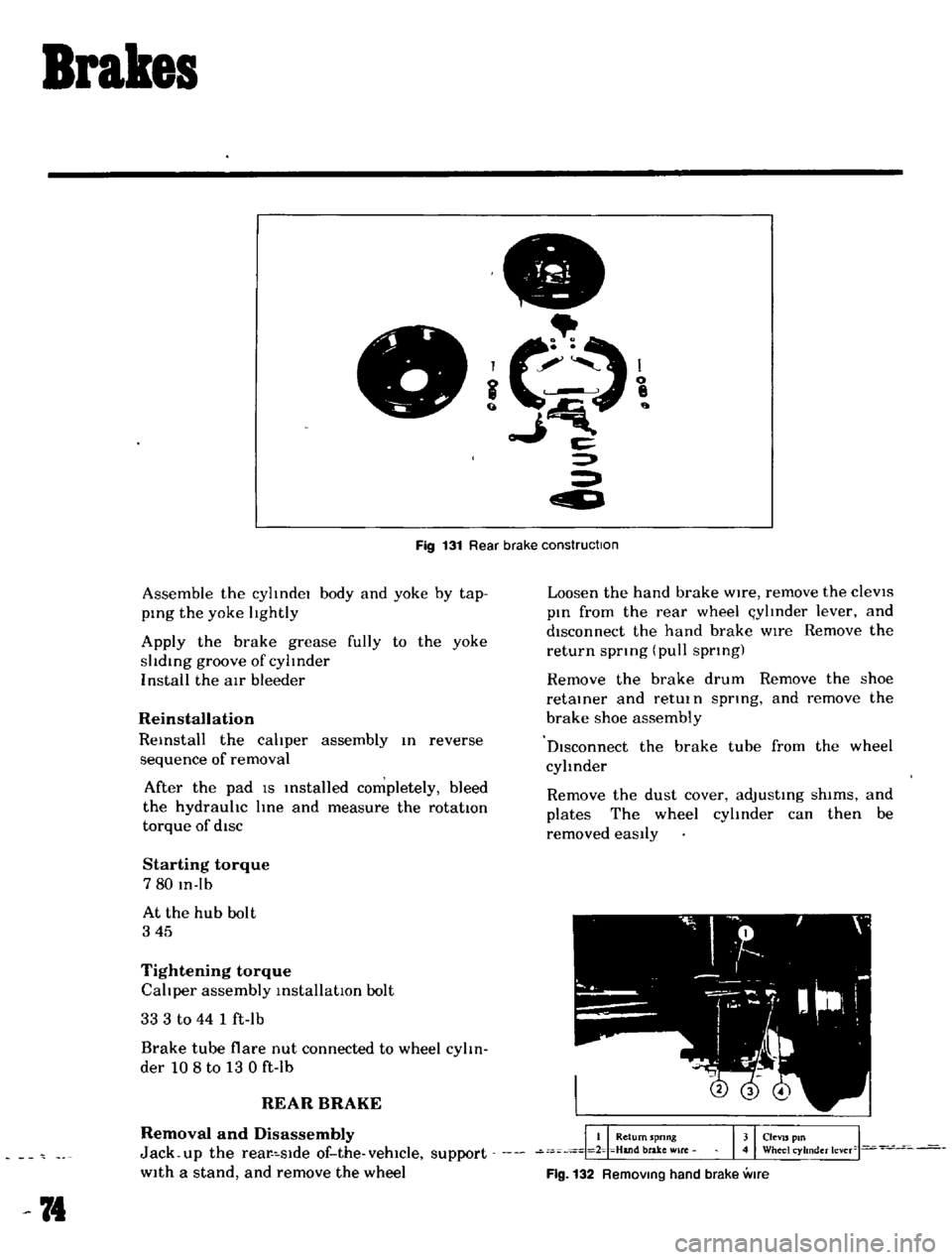

Brakes

c

Fig

131

Rear

brake

construction

Assemble

the

cylIndel

body

and

yoke

by

tap

ping

the

yoke

lIghtly

Apply

the

brake

grease

fully

to

the

yoke

slIding

groove

of

cylInder

I

nstall

the

air

bleeder

Reinstallation

Reinstall

the

calIper

assembly

In

reverse

sequence

of

removal

After

the

pad

IS

Installed

completely

bleed

the

hydraulIc

line

and

measure

the

rotatton

torque

of

diSC

Starting

torque

780

In

Ib

At

the

hub

bolt

345

Tightening

torque

CalIper

assembly

installatIOn

bolt

33

3

to

44

1

ft

lb

Brake

tube

flare

nut

connected

to

wheel

cylIn

der

108

to

13

0

ft

lb

REAR

BRAKE

Removal

and

Disassembly

Jack

up

the

rear

slde

of

the

vehicle

support

With

a

stand

and

remove

the

wheel

74

Loosen

the

hand

brake

Wire

remove

the

cleVIS

pin

from

the

rear

wheel

l

ylInder

lever

and

disconnect

the

hand

brake

wIre

Remove

the

return

spnng

pull

spnng

Remove

the

brake

drum

Remove

the

shoe

retainer

and

retUl

n

spnng

and

remove

the

brake

shoe

assembly

DIsconnect

the

brake

tube

from

the

wheel

cylinder

Remove

the

dust

cover

adjusting

shims

and

plates

The

wheel

cylInder

can

then

be

removed

eaSily

Flg

132

RemOVing

hand

brake

vme

Page 70 of 136

Brakes

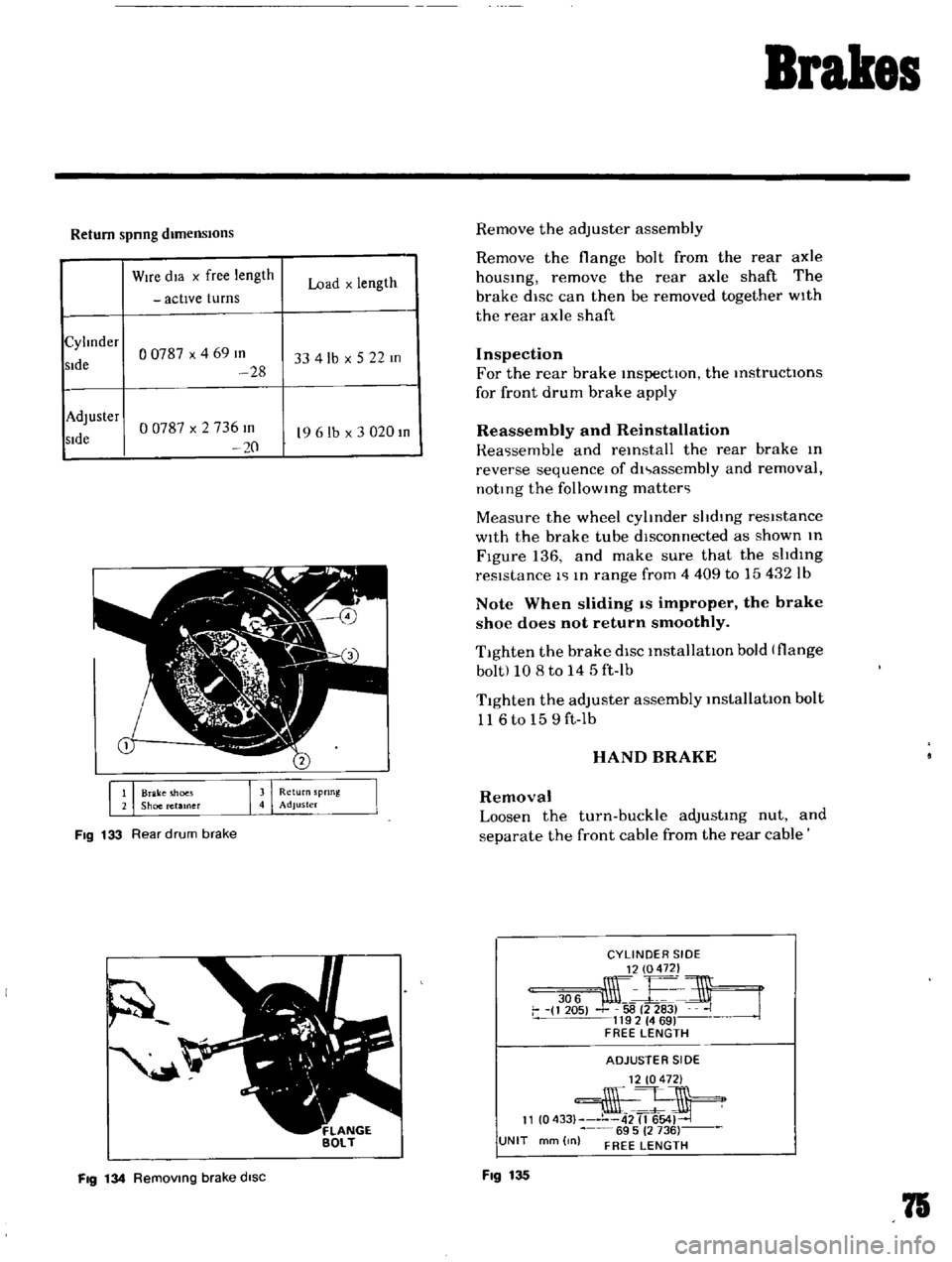

Return

spnng

dimensIOns

Wire

dla

x

free

length

Load

x

length

actIve

turns

Cylmder

o

0787

x

4

69

III

sIde

33

4lb

x

5

22

m

28

Adjuster

00787

x

2

736

m

sIde

19

6

lb

x

3

020

III

20

1

Brake

moes

2

Shoe

retamer

Fig

133

Rear

drum

brake

Fig

134

Removmg

brake

disc

Remove

the

adjuster

assembly

Remove

the

flange

bolt

from

the

rear

axle

housing

remove

the

rear

axle

shaft

The

brake

disc

can

then

be

removed

together

wIth

the

rear

axle

shaft

Inspection

For

the

rear

brake

inspectIOn

the

instructIOns

for

front

drum

brake

apply

Reassembly

and

Reinstallation

Rea

semble

and

reinstall

the

rear

brake

In

reverse

sequence

of

dl

assembly

and

removal

noting

the

follOWing

matter

Measure

the

wheel

cylinder

shdlng

resistance

With

the

brake

tube

dIsconnected

as

shown

In

Figure

136

and

make

sure

that

the

slIding

resIstance

1

In

range

from

4

409

to

15432

Ib

Note

When

sliding

IS

improper

the

brake

shoe

does

not

return

smoothly

Tighten

the

brake

diSC

installatIOn

bold

flange

bolt

10

8

to

14

5

ft

Ib

T1ghten

the

adjuster

assembly

installatIOn

bolt

116to

159ft

Ib

HAND

BRAKE

Removal

Loosen

the

turn

buckle

adjusting

nut

and

separate

the

front

cable

from

the

rear

cable

CYLINDER

SIDE

306

j

E

i

1

205

58

2

283

J

1192

469

FREE

LENGTH

ADJUSTE

R

51

DE

12

0472

2

11

0433

42

1654

69

5

2

736

UNIT

mm

0

FREE

LENGTH

Fig

135

75