DATSUN B110 1969 Service Manual PDF

Manufacturer: DATSUN, Model Year: 1969, Model line: B110, Model: DATSUN B110 1969Pages: 136, PDF Size: 5.64 MB

Page 71 of 136

Brakes

Remove

the

lock

plate

located

Immediately

III

front

of

the

turn

buckle

remove

the

clip

III

the

passenger

compartment

SIde

and

discon

nect

the

front

cable

I

Spong

balancer

G

Wheel

cyhnder

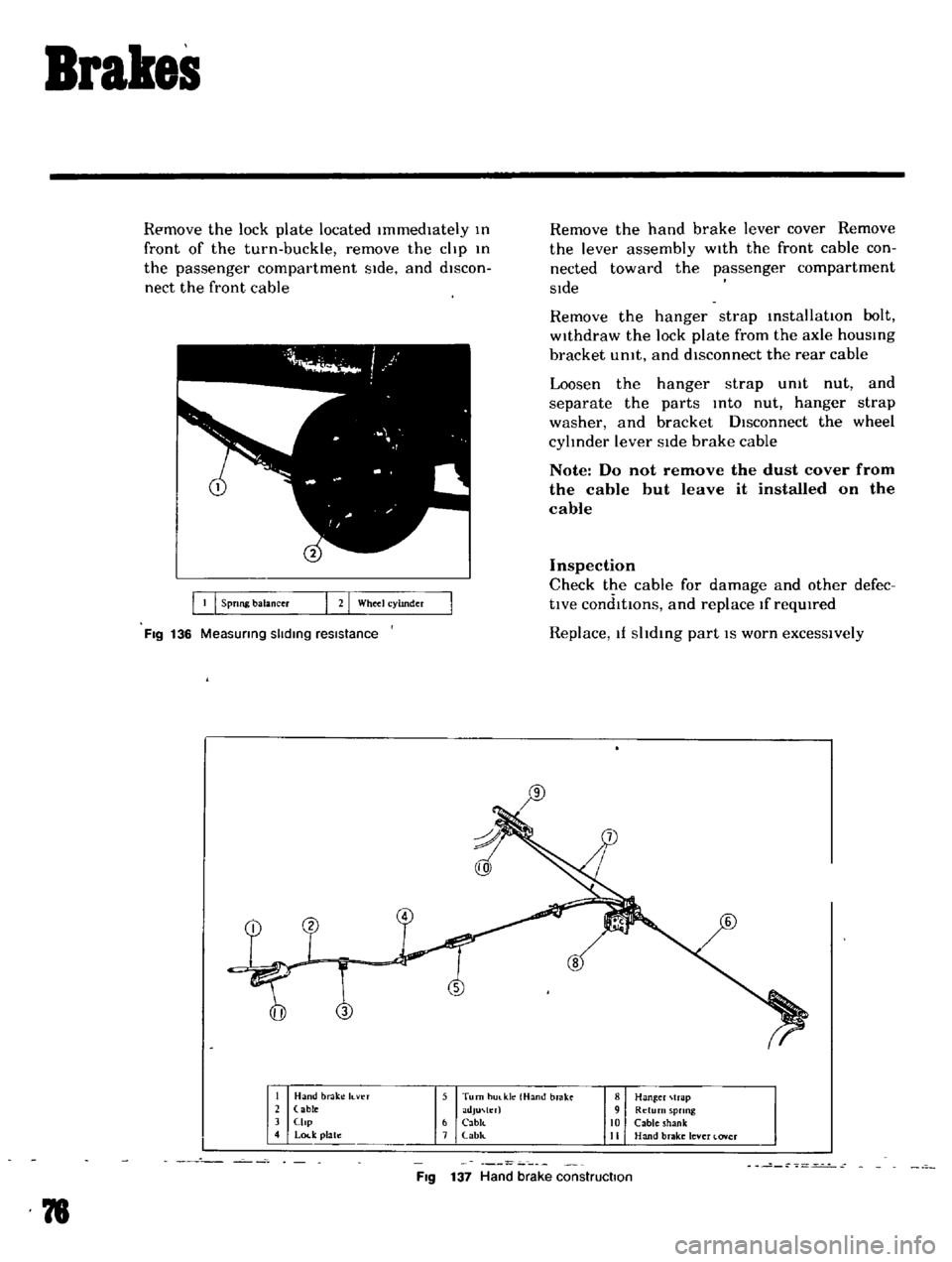

FIg

136

Measunng

slidIng

resistance

Remove

the

hand

brake

lever

cover

Remove

the

lever

assembly

wIth

the

front

cable

con

nected

toward

the

passenger

compartment

SIde

Remove

the

hanger

strap

installatIOn

bolt

withdraw

the

lock

plate

from

the

axle

hOUSIng

bracket

umt

and

disconnect

the

rear

cable

Loosen

the

hanger

strap

umt

nut

and

separate

the

parts

Into

nut

hanger

strap

washer

and

bracket

DIsconnect

the

wheel

cylinder

lever

SIde

brake

cable

Note

Do

not

remove

the

dust

cover

from

the

cable

but

leave

it

installed

on

the

cable

Inspection

Check

the

cable

for

damage

and

other

defec

tlve

condlttons

and

replace

If

reqUIred

Replace

If

shdIng

part

IS

worn

excessively

1

Hand

brake

It

ver

2

able

J

Clip

4

Lock

plate

5

Turn

hUlkle

Hand

brake

adJU

h

r

6

CabJc

7

abk

8

Han

er

trap

9

Return

sprmg

10

Cable

shank

II

Hand

brake

lever

lover

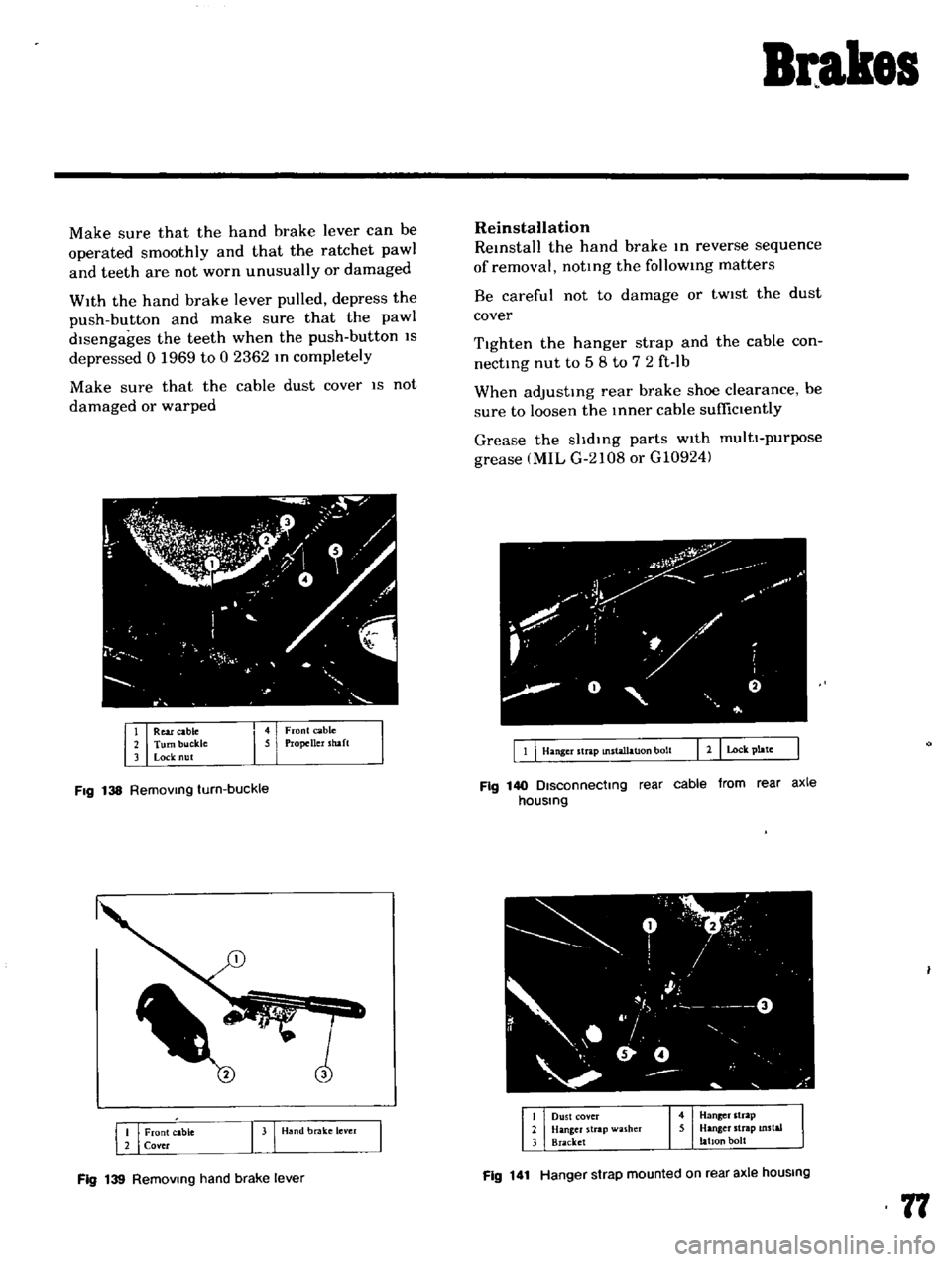

FIg

137

Hand

brake

construction

78

Page 72 of 136

Brakes

Make

sure

that

the

hand

brake

lever

can

be

operated

smoothly

and

that

the

ratchet

pawl

and

teeth

are

not

worn

unusually

or

damaged

With

the

hand

brake

lever

pulled

depress

the

push

button

and

make

sure

that

the

pawl

disengages

the

teeth

when

the

push

button

IS

depressed

0

1969

to

0

2362

In

completely

Make

sure

that

the

cable

dust

cover

1S

not

damaged

or

warped

FIg

138

Removing

turn

buckle

I

Front

cabl

2

Cover

CI

H

nd

brok

1

Ye

Fig

139

Removing

hand

brake

lever

Reinstallation

Remstall

the

hand

brake

m

reverse

sequence

of

removal

notmg

the

folloWIng

matters

Be

careful

not

to

damage

or

tW1St

the

dust

cover

TIghten

the

hanger

strap

and

the

cable

con

nectmg

nut

to

5

8

to

7

2

ft

lb

When

adJustmg

rear

brake

shoe

clearance

be

sure

to

loosen

the

mner

cable

sufficIently

Grease

the

shdmg

parts

w1th

multI

purpose

grease

MIL

G

2108

or

G10924l

o

Lock

plate

Fig

140

Disconnecting

rear

cable

from

rear

axle

housing

i

O

j

0

I

J

i

Ii

0

j

0

0

V

I

Dust

cover

Hanger

strap

washer

Bracket

I

Fig

141

Hanger

strap

mounted

on

rear

axle

hOUSing

77

Page 73 of 136

Brakes

ADJUSTMENT

Front

Disc

Brake

Ordinarily

adJu

tment

IS

not

requIred

because

clearance

between

pad

and

rotor

IS

adjusted

automattcally

by

elasttclty

of

the

pIston

seal

I

iJ

1

el

i

C

1

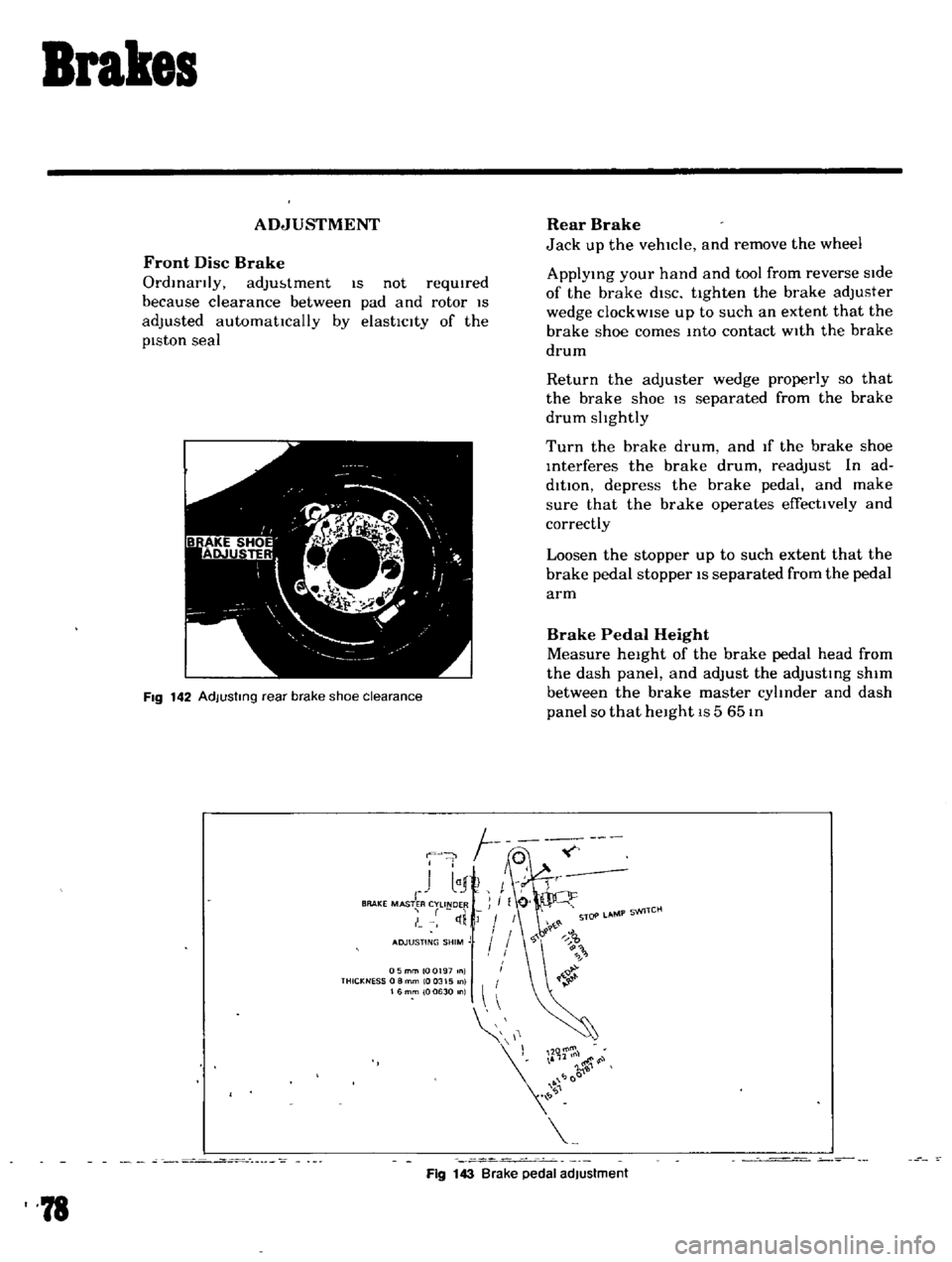

FIg

142

AdJustmg

rear

brake

shoe

clearance

F

J

I

1

I

r

BRAKE

MASTER

CYLINDER

I

tI

Rear

Brake

Jack

up

the

vehicle

and

remove

the

wheel

ApplYing

your

hand

and

tool

from

reverse

side

of

the

brake

diSC

ttghten

the

brake

adjuster

wedge

clockWise

up

to

such

an

extent

that

the

brake

shoe

comes

Into

contact

With

the

brake

drum

Return

the

adjuster

wedge

properly

so

that

the

brake

shoe

IS

separated

from

the

brake

drum

slIghtly

Turn

the

brake

drum

and

If

the

brake

shoe

Interferes

the

brake

drum

readjust

In

ad

dition

depress

the

brake

pedal

and

make

sure

that

the

brake

operates

effecttvely

and

correctly

Loosen

the

stopper

up

to

such

extent

that

the

brake

pedal

stopper

IS

separated

from

the

pedal

arm

Brake

Pedal

Height

Measure

height

of

the

brake

pedal

head

from

the

dash

panel

and

adjust

the

adjusting

shim

between

the

brake

master

cylInder

and

dash

panel

so

that

height

IS

5

65

In

05mmlOQ197

nl

THICKNESS

0

8

mm

10

0315

0

16mm

100630

n

11

r

l00

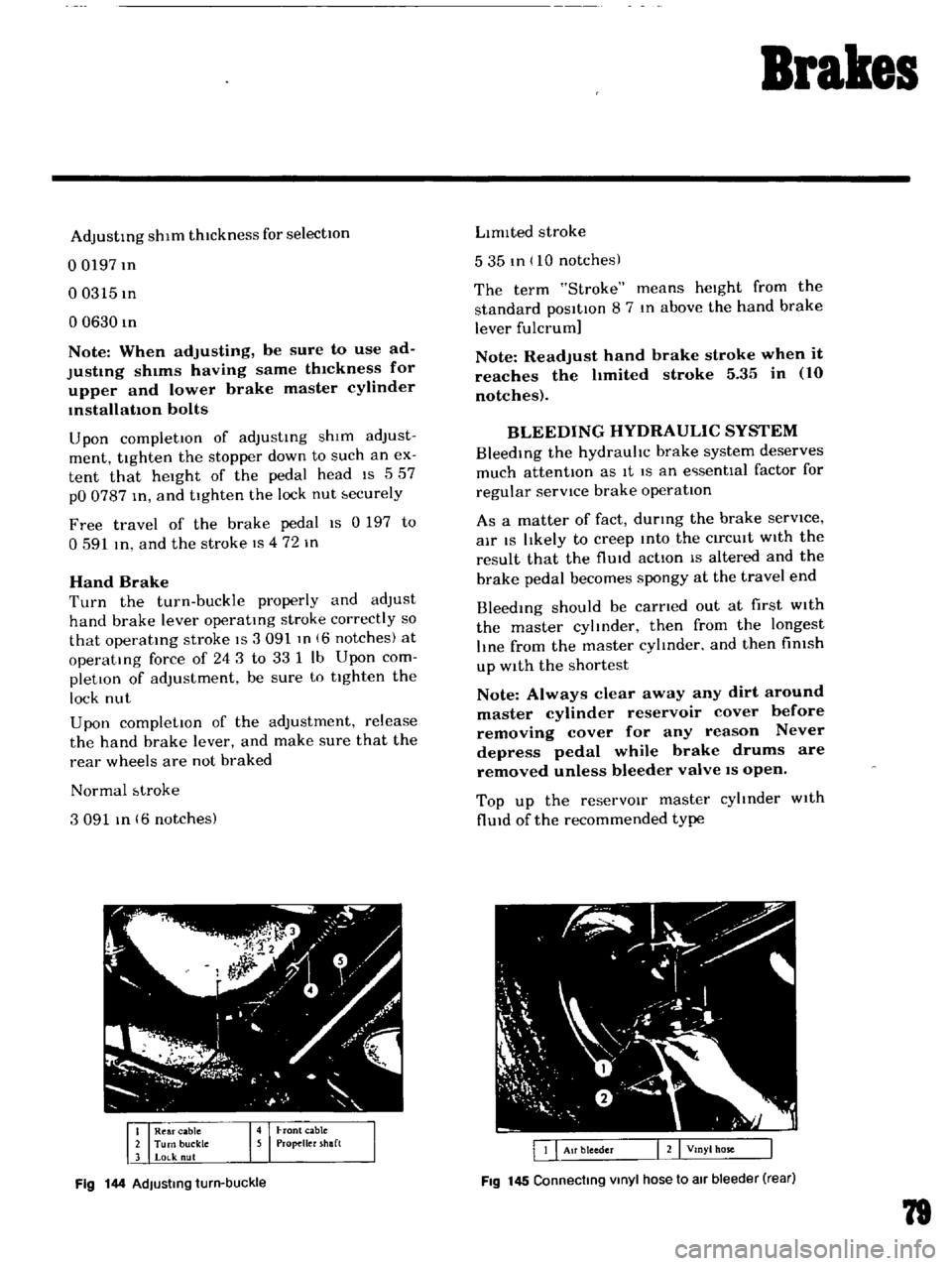

Fig

143

Brake

pedal

adjustment

78

Page 74 of 136

Brakes

Adjusting

shIm

thickness

for

selectIOn

o

0197

In

00315

In

o

0630

In

Note

When

adjusting

be

sure

to

use

ad

Jusbng

sh1ms

having

same

th1ckness

for

upper

and

lower

brake

master

cylinder

IOstallahon

bolts

Upon

completIOn

of

adjusting

shIm

adjust

ment

tighten

the

stopper

down

to

such

an

ex

tent

that

heIght

of

the

pedal

head

IS

5

57

pO

0787

In

and

tighten

the

lock

nut

becurely

Free

travel

of

the

brake

pedal

IS

0

197

to

0591

tn

and

the

stroke

IS

4

72

In

Hand

Brake

Turn

the

turn

buckle

properly

and

adjust

hand

brake

lever

operatmg

stroke

correctly

so

that

operatmg

stroke

IS

3

091

m

16

notches

at

operatIng

force

of

243

to

331

Ib

Upon

com

pletIOn

of

adjustment

be

sure

to

tIghten

the

lock

nut

Upon

completIOn

of

the

adjustment

release

the

hand

brake

lever

and

make

sure

that

the

rear

wheels

are

not

braked

Normal

btroke

3091

In

6

notches

Fig

144

AdJusting

turn

buckle

LImIted

stroke

535

tn

10

notches

The

term

Stroke

means

heIght

from

the

standard

posItIon

8

7

In

above

the

hand

brake

lever

fulcrum

Note

Readjust

hand

brake

stroke

when

it

reaches

the

hmited

stroke

5

35

in

10

notches

BLEEDING

HYDRAULIC

SYSTEM

BleedIng

the

hydrauhc

brake

system

deserves

much

attentIOn

as

It

IS

an

e

senttal

factor

for

regular

servICe

brake

operatIon

As

a

matter

of

fact

durmg

the

brake

serVice

air

IS

lIkely

to

creep

Into

the

CirCUIt

WIth

the

result

that

the

flUId

actIon

IS

altered

and

the

brake

pedal

becomes

spongy

at

the

travel

end

Bleedmg

should

be

carned

out

at

first

WIth

the

master

cylmder

then

from

the

longest

lIne

from

the

master

cylmder

and

then

fimsh

up

With

the

shortest

Note

Always

clear

away

any

dirt

around

master

cylinder

reservoir

cover

before

removing

cover

for

any

reason

Never

depress

pedal

while

brake

drums

are

removed

unless

bleeder

valve

IS

open

Top

up

the

reservOIr

master

cyltnder

With

flUId

of

the

recommended

type

Fig

145

Connecting

Vinyl

hose

to

air

bleeder

rear

79

Page 75 of 136

Brakes

Thoroughly

Wipe

the

bleeder

screw

and

from

any

mud

or

dust

present

so

that

the

outlet

hole

IS

free

from

foreign

matter

Attach

a

VInyl

hose

to

the

wheel

cyhnder

bleeder

screw

Dip

the

end

of

the

VInyl

hose

In

a

Jar

contaInIng

some

brake

flUId

Depress

the

brake

pedal

two

to

three

times

and

keep

the

pedal

fully

depressed

With

the

brake

pedal

fully

depressed

loosen

the

bleeder

screw

exhaust

air

and

rettghten

the

bleeder

screw

qUIckly

Return

the

brake

pedal

slowly

Repeat

the

operatIons

above

Air

WIll

no

longer

come

out

from

the

bleeder

screw

but

brake

flUId

comes

out

When

atr

stIll

eXists

In

brake

flUId

It

appears

whIte

due

to

aIr

bub

ble

Conduct

aIr

bleedIng

on

other

wheel

cyhnders

In

the

same

manner

Note

a

Check

the

reservoir

for

fluid

level

during

bleeding

operation

b

FlUid

withdrawn

in

the

operation

should

not

be

used

refilling

bleeding

again

for

c

When

the

master

cylinder

is

dIsassem

bled

or

replaced

conduct

air

bleeding

on

the

wheel

cylinder

which

is

located

most

near

the

master

cyhnder

d

Ordinarily

air

bleeding

is

performed

in

the

following

sequence

Rear

left

Rear

right

Front

left

Front

right

e

Do

not

return

the

brake

pedal

before

retightening

the

bleeder

screw

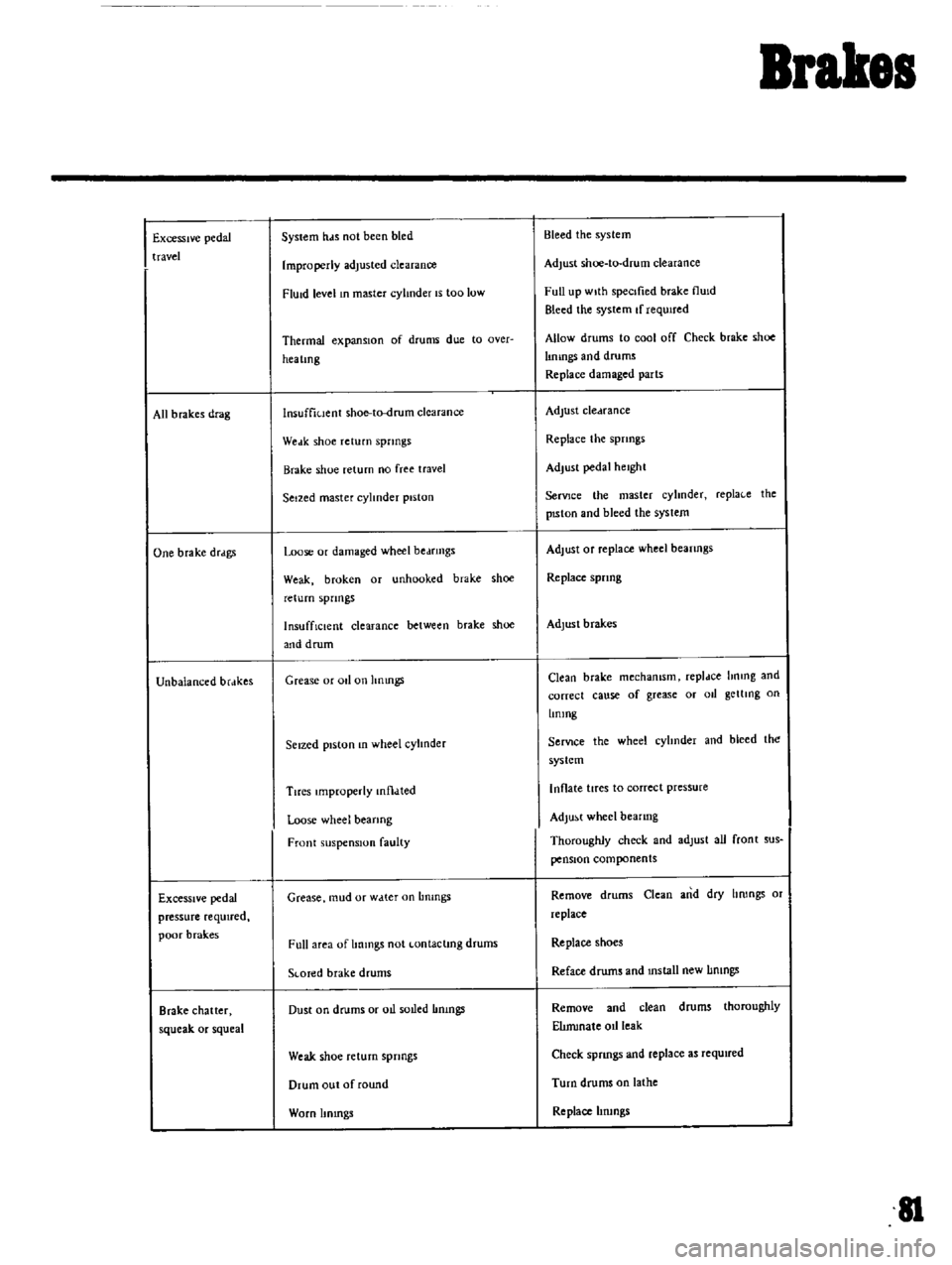

TROUBLE

SHOOTING

Condition

Probable

cause

Corretttve

dellon

Spongy

pedal

Au

In

brake

lines

Bleed

Ihoroughly

Swollen

hose

due

to

detenoratlOn

or

use

of

Replace

ho

e

md

bleed

the

system

poor

qualIty

brake

flUid

Use

of

a

brake

flu

d

wIth

a

bOilIng

pomt

Change

wIth

the

spectlied

brake

flUId

dnd

which

15

too

low

bleed

system

ReservOir

filler

cap

vent

hole

clogged

Tins

Clean

reserVOIr

filler

cap

and

bleed

the

promotes

a

Vdcuum

In

master

cylinder

that

system

suckS

In

air

through

rear

seal

Pedal

Yields

under

Detenorated

check

valve

Fit

a

new

check

valve

and

bleed

the

system

shght

pressure

ExterIlalleaks

Check

master

cyhnder

plpmg

and

wheel

cylInder

for

leaks

and

make

necessary

re

pairs

Master

cyhnder

leaks

through

pnmary

cap

Overhaul

master

cyhnder

80

Page 76 of 136

Brakes

Excessive

pedal

travel

All

b

rakes

drag

One

brake

drdgs

Unbalanced

brdkes

Excessive

pedal

pressure

required

poor

brak

es

Brake

chatter

squeak

or

squeal

System

hds

not

been

bled

Improperly

adjusted

clearance

FlUid

level

In

master

cylinder

IS

too

low

Thermal

expansIOn

of

drums

due

to

Qver

hea

lmg

lnsuffiuent

shoe

to

drum

clearance

Weak

shoe

return

springs

Brake

shoe

return

no

free

travel

Seized

master

cylinder

piston

Loose

or

damaged

wheel

bedfmgs

Weak

broken

or

unhooked

brake

shoe

return

spnngs

InsuffiCient

clearance

between

brake

shoe

and

drum

Grease

or

011

on

hnmgs

Seized

piston

In

wheel

cylInder

Tires

Improperly

mtl

lted

Loose

wheel

bearing

Front

suspension

faulty

Grease

mud

or

w

tter

on

Lmmgs

Full

area

of

Immgs

not

Lontaclmg

drums

SLOTed

brake

drums

Dust

on

drums

or

oIl

soLled

Immgs

Weak

shoe

return

springs

Drum

out

of

round

Worn

Itmngs

Bleed

the

system

Adjust

shoe

to

drum

clearance

Full

up

wIth

specIfied

brake

flUId

Bleed

the

system

If

requIred

Allow

drums

to

cool

off

Check

brake

shoe

lImngs

and

drums

Replace

damaged

parts

Adjust

cledrance

Replace

the

spnngs

Adjust

pedal

height

SerVJce

the

master

cyhnder

repla

e

the

pISton

and

bleed

the

syslem

Adjust

Of

replace

wheel

beanngs

Replace

spnng

Adjust

brakes

Clean

brake

mechamsm

repldce

hnmg

and

correct

cause

of

grease

or

011

getllng

on

Lmmg

SerVIce

the

wheel

cyhnder

and

bleed

the

system

Inflate

tires

to

correct

pressure

Adjust

wheel

bearing

Thoroughly

check

and

adlust

all

front

sus

pensIOn

components

Remove

drums

Clean

and

dry

hrongs

or

replace

Replace

shoes

Reface

drums

and

mstall

new

IImngs

Remove

and

clean

drums

thoroughly

ElImmale

oIl

leak

Check

spnngs

and

replace

as

required

Turn

drums

on

lathe

Replace

hrungs

II

Page 77 of 136

i

V

J

f1J

lr

f

t

Jtt

J

V

f

T

lfr

J

t

Yr

1

4

t

7

1

1

t

r

i

t

1

W

lQ

Page 78 of 136

pront

Suspension

Qj

@

@

I

Strut

mounting

Insulator

2

Strut

mounllng

bearing

3

Upper

pnng

o

r

at

4

Oumpu

rubblf

5

DU

tlOVU

6

P

ton

rod

7

F

ool

pring

8

Irut

embly

q

Hub

b

t

mbly

10

5pmdh

II

Ball

JOint

12

Trd

nwu

link

1

J

Tln

lon

rod

14

StJblluLr

15

SU

p

mIOn

mlmbt

r

Fig

146

Front

axle

and

suspension

assembly

I

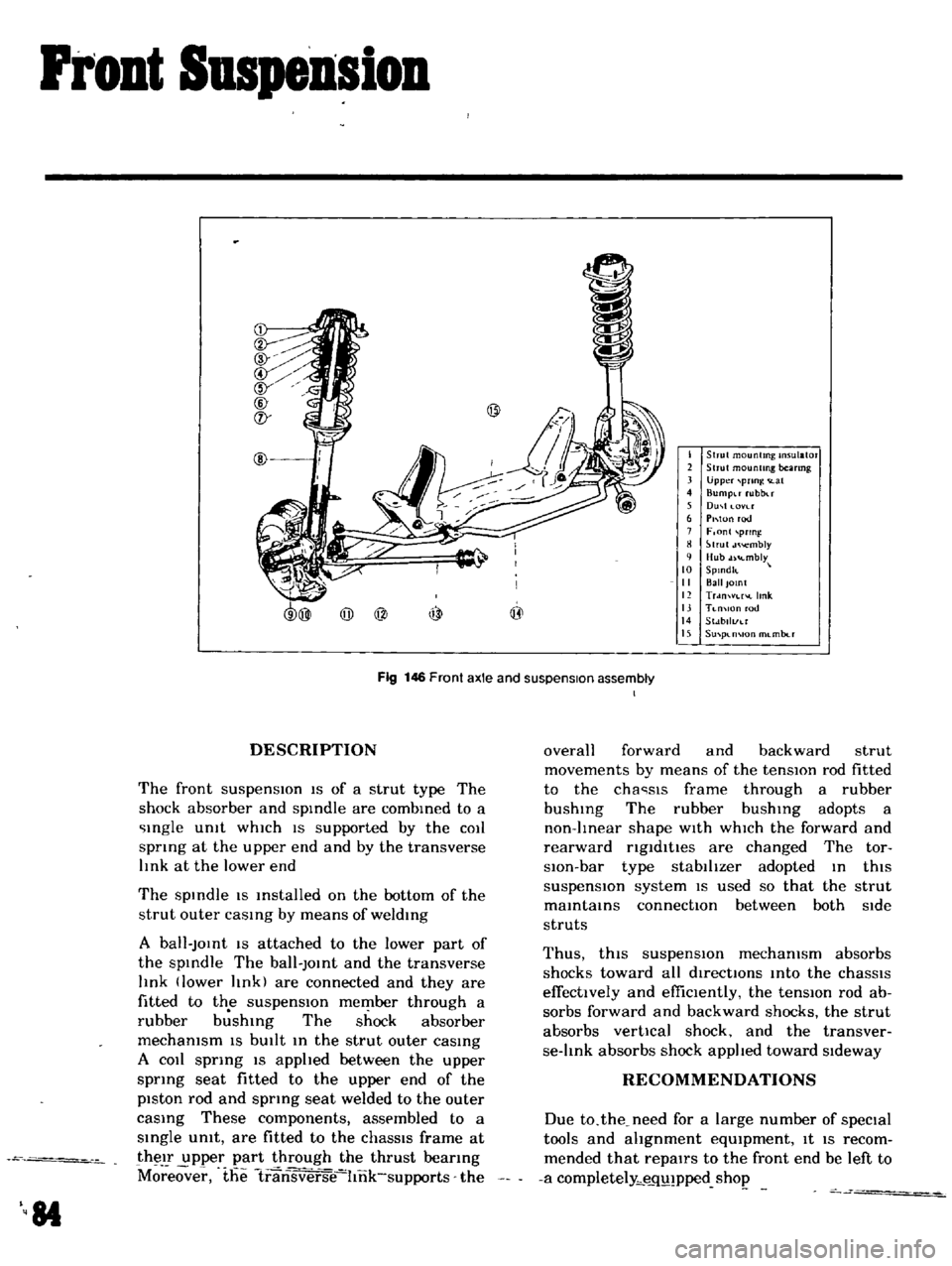

DESCRIPTION

The

front

suspensIOn

IS

of

a

strut

type

The

shock

absorber

and

spIndle

are

combIned

to

a

Ingle

Unit

whIch

IS

supported

by

the

COIl

spnng

at

the

upper

end

and

by

the

transverse

lInk

at

the

lower

end

The

spIndle

IS

Installed

on

the

bottom

of

the

strut

outer

caSIng

by

means

of

weldIng

A

ball

JOInt

IS

attached

to

the

lower

part

of

the

spIndle

The

ball

JOInt

and

the

transverse

lInk

lower

lInk

are

connected

and

they

are

fitted

to

the

suspensIOn

member

through

a

rubber

b

shIng

The

shock

absorber

mechanism

IS

bUIlt

In

the

strut

outer

caSIng

A

COIl

sprIng

IS

apphed

between

the

upper

sprIng

seat

fitted

to

the

upper

end

of

the

piston

rod

and

spring

seat

welded

to

the

outer

caSIng

These

components

assembled

to

a

SIngle

umt

are

fitted

to

the

chaSSIS

frame

at

their

upper

part

through

the

thrust

beanng

M

eover

the

1ransverse

hnk

supports

the

84

overall

forward

and

backward

strut

movements

by

means

of

the

tensIOn

rod

fitted

to

the

cha

sls

frame

through

a

rubber

bushIng

The

rubber

bushIng

adopts

a

non

lInear

shape

WIth

whICh

the

forward

and

rearward

ngldltles

are

changed

The

tor

slOn

bar

type

stabilIzer

adopted

In

thiS

suspensIOn

system

IS

used

so

that

the

strut

maIntaInS

connectIOn

between

both

Side

struts

Thus

thiS

suspensIOn

mechanism

absorbs

shocks

toward

all

directIOns

Into

the

chaSSIS

effectively

and

effiCIently

the

tensIOn

rod

ab

sorbs

forward

and

backward

shocks

the

strut

absorbs

vertical

shock

and

the

transver

se

lInk

absorbs

shock

applIed

toward

SIdeway

RECOMMENDATIONS

Due

to

the

need

for

a

large

number

of

speCial

tools

and

ahgnment

eqUIpment

It

IS

recom

mended

that

repairs

to

the

front

end

be

left

to

a

completely

e

q

pped

shop

Page 79 of 136

Pront

Suspension

j

I

t

4

l

I

i

r

t

I

J

l

I

hf

c

a

j

ll

l

l

11

J

1

f

t

r

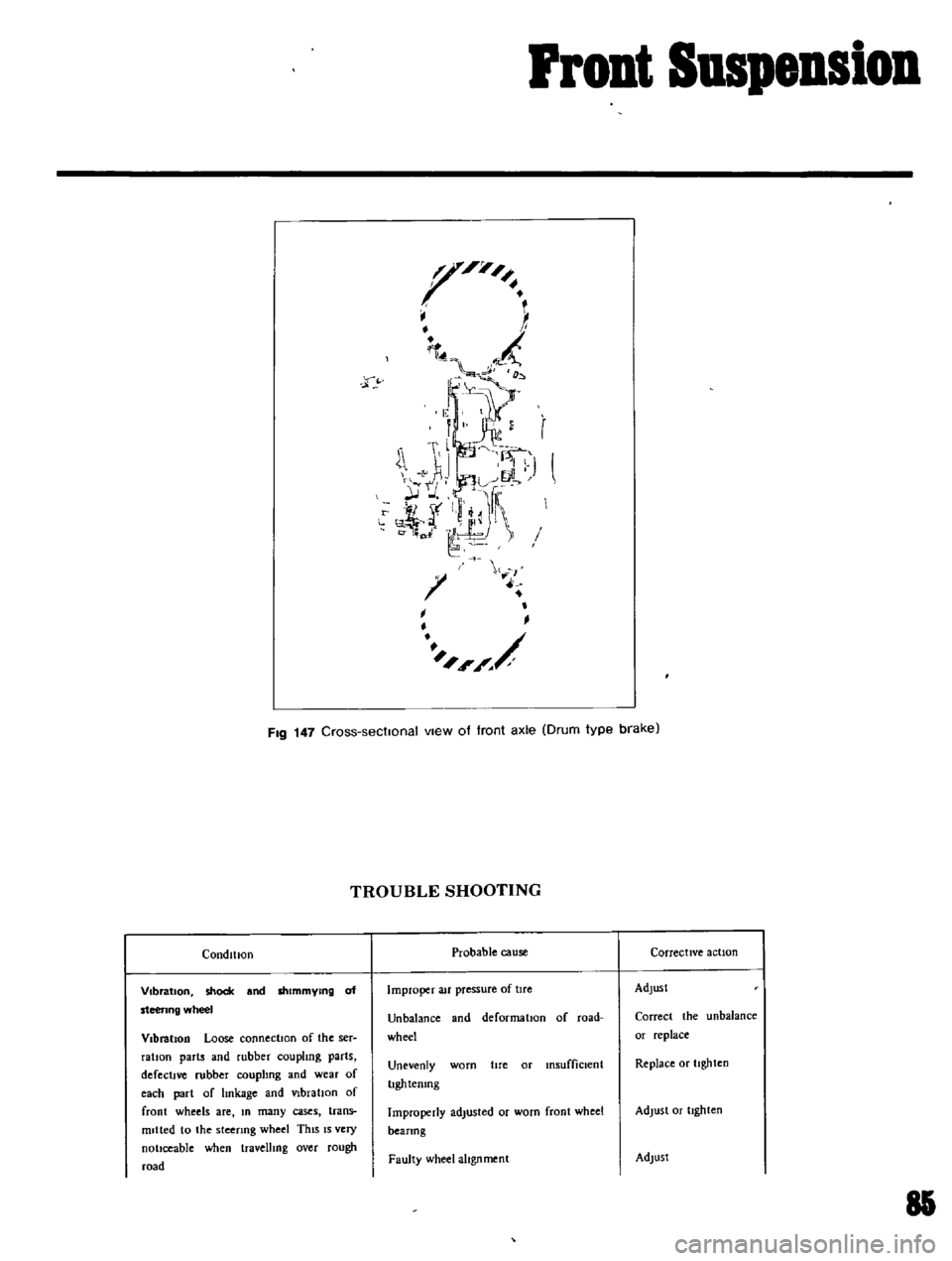

FIg

147

Cross

sectIonal

vIew

of

front

axle

Drum

type

brake

CondltJOn

Vibration

shock

and

shimmYing

of

steenng

wheel

Vibration

Loose

connectIOn

of

the

ser

ratIOn

parts

and

rubber

coupling

parts

defectIve

rubber

couplIng

and

wear

of

each

part

of

hnkage

and

VIbration

of

front

wheels

are

In

many

cases

trans

mitted

to

the

steenng

wheel

ThiS

IS

very

nottceable

when

travellIng

over

rough

road

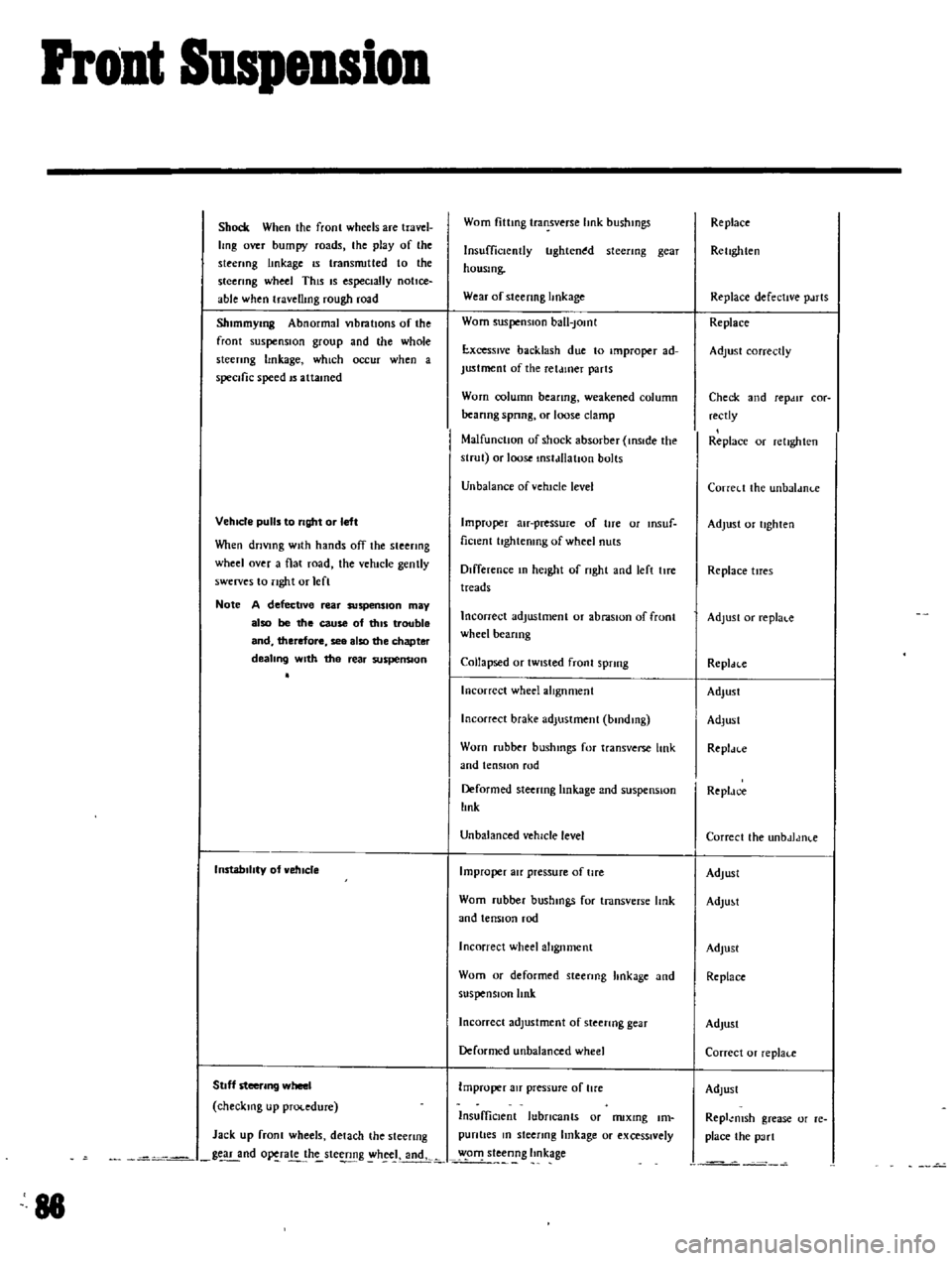

TROUBLE

SHOOTING

Probable

cause

Improper

au

pressure

of

tIre

Unbalance

and

deformatIon

of

road

wheel

Unevenly

worn

hre

or

insufficient

IIghtemng

Improperly

adlusted

or

worn

front

wheel

beanng

Faulty

wheel

alignment

Corrective

action

Adjust

Correct

the

unbalance

or

replace

Replace

or

ttghten

Adjust

or

tIghten

Adlust

85

Page 80 of 136

Pront

Suspension

Shock

When

the

fronl

wheels

are

travel

Img

over

bumpy

roads

the

play

of

the

steenng

linkage

IS

transnutted

to

the

steering

wheel

This

IS

especially

notice

able

when

travellmg

rough

road

Shlmmymg

Abnormal

VIbratIOns

of

the

front

suspensIOn

group

and

lhe

whole

sleenng

hnkage

which

occur

when

a

specific

speed

IS

attamed

VehIcle

pulls

to

right

or

left

Vhen

driVing

With

hands

off

the

steering

wheel

over

a

flat

road

the

vehicle

gently

swerves

to

nght

or

lefl

Note

A

defective

rear

suspenSion

may

also

be

the

cause

of

tillS

trouble

and

therefore

see

also

the

chapter

dealing

With

the

rear

suspenSion

InstabilIty

of

vehIcle

Stoff

steering

wheel

checking

up

procedure

Jack

up

fronl

wheels

detach

the

steenng

g

nd

o

ra

h

ste

g

h

J

andk

88

Worn

fittmg

transverse

hnk

bushmgs

Insufficiently

tlghten

d

steenng

gear

housmg

Wear

of

steenng

hnkage

Worn

suspensIOn

ball

Jomt

E

xcesslve

backlash

due

to

improper

ad

Justment

of

the

ret

uner

parts

Worn

column

beanng

weakened

column

beanng

spnng

or

loose

clamp

MalfunctIOn

of

shock

absorber

inSIde

the

strut

or

loose

mstdllatJon

bolts

Unbalance

ofvehtcle

level

Improper

au

pressure

of

tire

or

msuf

ficlent

hghtenmg

of

wheel

nuts

Difference

In

height

of

nght

and

left

lIre

treads

Incorrect

adjustment

or

abraSIOn

of

front

wheel

beanng

Collapsed

or

tWisted

front

sprmg

Incorrect

wheel

alIgnment

Incorrect

brake

adjustment

bmdmg

Worn

rubber

bushmgs

for

transverse

link

and

tensIOn

rod

Deformed

steering

linkage

and

suspensIOn

lInk

Unbalanced

vehicle

level

Improper

au

pressure

of

tire

Worn

rubber

bushmgs

for

tmnsverse

Imk

and

tensIOn

rod

Incorrect

wheel

alignment

Worn

or

deformed

steenng

hnkage

and

suspensIOn

link

Incorrect

adjustment

of

steenng

gear

Deformed

unbalanced

wheel

Improper

au

pressure

of

lire

InsuffiCient

lubricants

or

nuxmg

Im

pun

ties

m

sleenng

linkage

or

exceSSively

o

steenng

Imkage

Replace

Rellghten

Replace

defective

p

uts

Replace

Adjust

correctly

Check

and

repdlT

cor

rectly

Replace

or

relighlen

Correl

t

the

unbaldnl

e

Adjust

or

tighten

Replace

tlTes

Adjust

or

replal

c

Repldcc

Adjust

Adlusl

Repl

n

e

Repldc

e

Correcl

the

unbdJdlKe

Adjust

AdlU

t

Adjust

Replace

AdJusl

Correcl

or

replaf

e

Adlust

Repl

msh

grease

or

re

place

the

pa

rt