DATSUN B110 1969 Service Manual Online

Manufacturer: DATSUN, Model Year: 1969, Model line: B110, Model: DATSUN B110 1969Pages: 136, PDF Size: 5.64 MB

Page 81 of 136

i

l

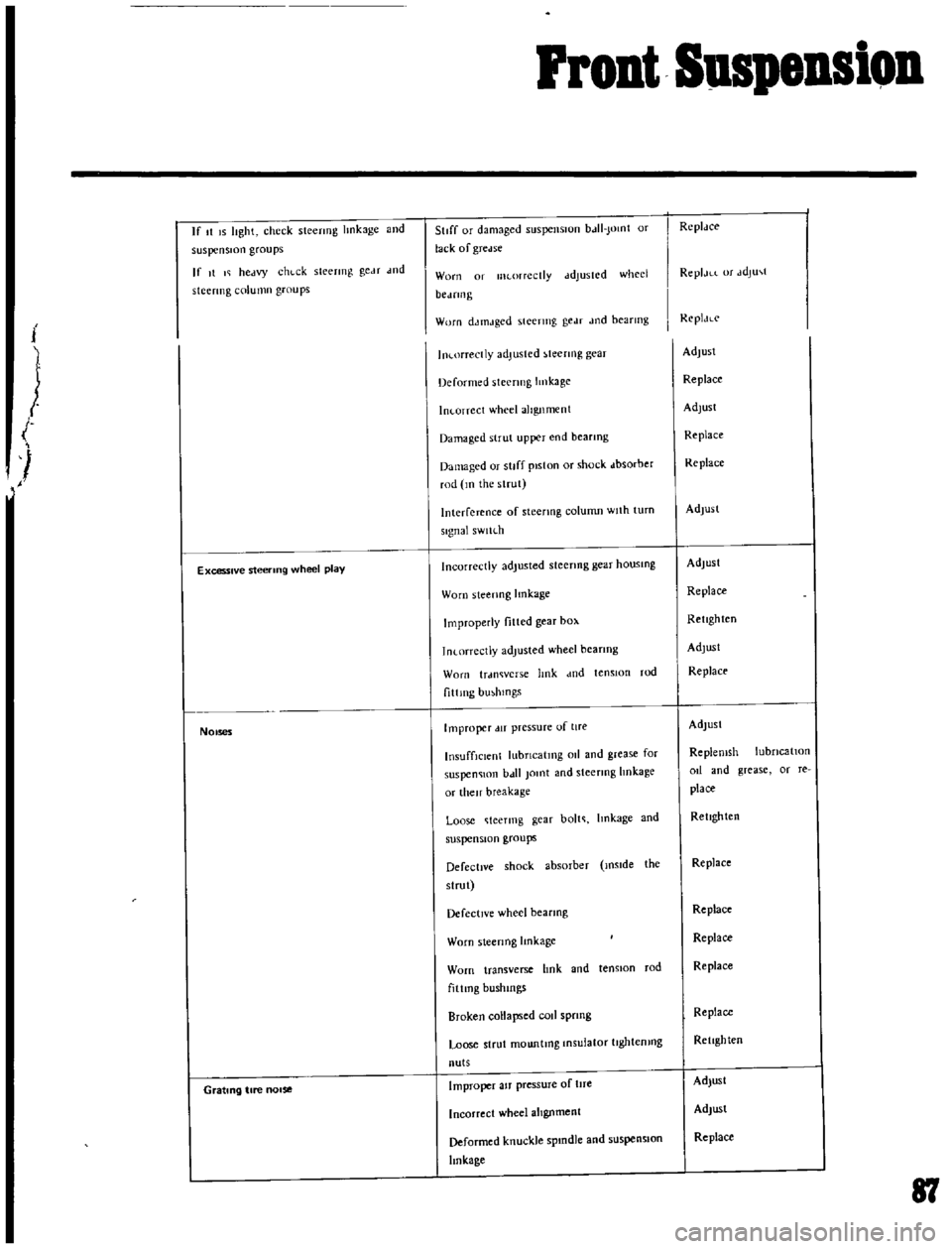

Front

SuspeDsion

If

t

IS

lIght

check

stecrmg

hnkage

and

suspension

groups

If

It

I

hectvy

chl

ck

sleermg

geM

wd

stcermg

column

groups

Excessive

steering

wheel

play

1

NOises

Grating

tire

nOise

StIff

or

dJmaged

5llspenslUn

bJII

Jomt

or

lack

of

gTcelse

Worn

01

lIKorrcctly

ddJuSICd

whed

bCJfIll

g

Worn

dJtnJged

steering

gedf

Jod

bearmg

In

orrectly

adjusted

teenng

gear

Deformed

steering

Imkage

In

orrcct

wheel

alignment

Damaged

strut

upper

end

bearmg

Damaged

or

stiff

piston

or

shock

dbsorber

rod

m

the

strut

Interference

of

steenng

column

Wllh

turn

signal

sWlh

h

Incorrectly

adjusted

steenng

gear

housmg

Worn

steenng

lmkage

Improperly

fitted

gear

box

1n

orrectJy

adjusted

wheel

bearIng

Worn

trdl1Wcrs

e

hnk

dnd

tensIOn

rod

f1ttlllg

bmhlOgs

Improper

lIT

pressure

of

lire

InsuffiCient

lubncatmg

011

and

grease

for

suspen

lOn

b

t11

Jomt

and

steermg

hnkage

or

then

breakage

Loose

teermg

gear

bolt

Imkage

and

suspension

groups

Defective

shock

absorber

mslde

the

slrut

Defective

wheel

bearmg

Worn

sleenng

Imkage

Worn

transverse

hnk

and

tenston

rod

fiUmg

bushmgs

Broken

collapsed

rod

sprmg

Loose

strut

mountmg

Insulator

tJghtemng

nuts

Improper

aJf

pressure

of

tlfe

Incorrect

wheel

alIgnment

Deformed

knuckle

spmdle

and

suspensIOn

linkage

RcplJce

ReplJLL

or

JdJu

t

ReplJLc

AdJusl

Replace

Adlust

Replace

Replace

Adlusl

Adjust

Replace

Retighten

Adjust

Replace

Adlusl

Replemsh

lubncatlOn

od

and

grease

or

re

place

Retighten

Replace

Replace

Replace

Replace

Replace

Retighten

Adjust

Adjust

Replace

81

Page 82 of 136

Front

Suspension

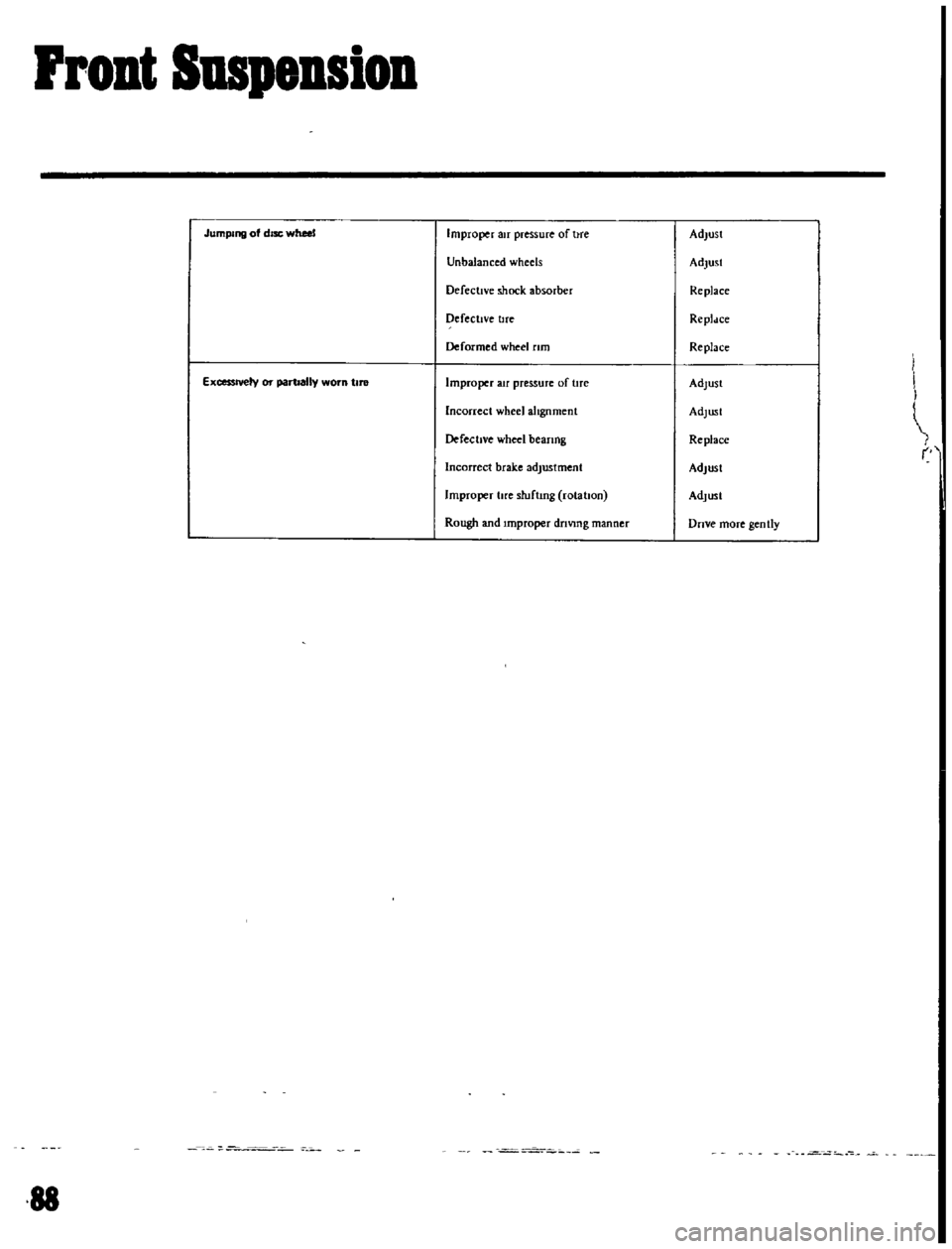

Jumping

of

disc

wheel

Improper

air

pressure

of

hre

Adjust

Unbalanced

wheels

Adjust

Defective

shock

absorber

Replace

DefectIve

tlfe

Repldce

Deformed

wheel

rim

Replace

ExcessIVely

or

partially

worn

tIre

Improper

au

pressure

of

tlfe

Adlust

Incorrect

wheel

alIgnment

Adlusl

DefectIVe

wheel

beanng

Replace

Incorrect

brake

adjustment

Adjust

Improper

lire

sluflmg

rolahon

Adlusl

Rough

and

Improper

driVing

manner

Dnve

more

gen

tly

I

88

Page 83 of 136

0

1

i

Q

f

h

I

tc

I

j

1

w

J

If

y

IJ

l

t

f

1

4i

1

i

J

j

i

t

ij

t

t

t

f

A

lo

f

d

rr

r

f

j

1

tt

4

e

i

t

Ir

ij

j

l

fr

lf

1

r

0

t

9

0

Page 84 of 136

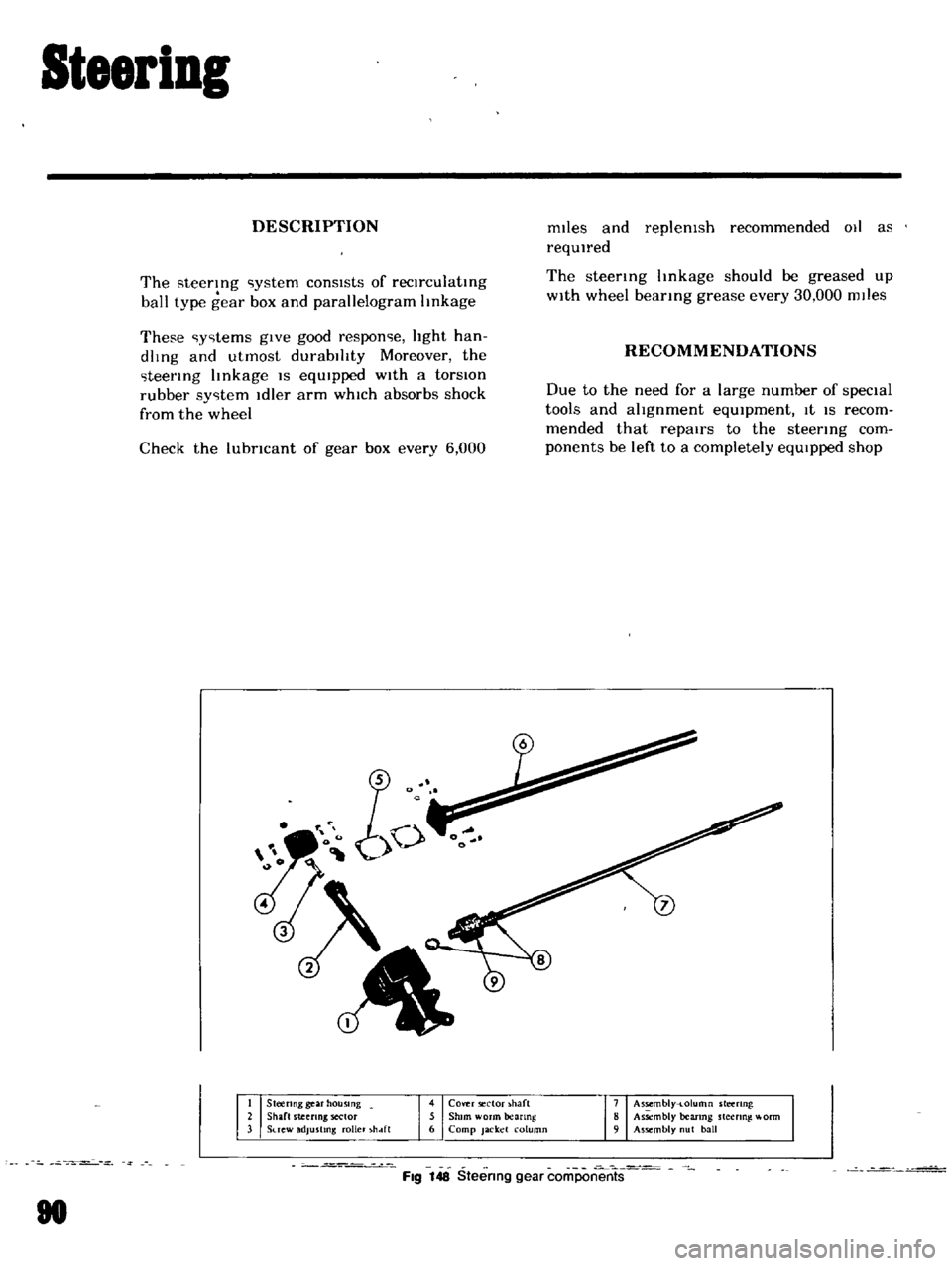

Steering

DESCRIPTION

mtles

and

replenIsh

recommended

011

as

reqUIred

The

steetlng

linkage

should

be

greased

up

WIth

wheel

bearing

grease

every

30

000

mtles

The

steering

ystem

consIsts

of

reclrculatmg

ball

type

gear

box

and

parallelogram

linkage

These

y

tems

gIve

good

respon

e

light

han

dlmg

and

utmost

durabIlity

Moreover

the

teermg

linkage

IS

eqUIpped

With

a

torsIOn

rubber

sy

tem

Idler

arm

whIch

absorbs

shock

from

the

wheel

RECOMMENDATIONS

Check

the

lubricant

of

gear

box

every

6

000

Due

to

the

need

for

a

large

number

of

specIal

tools

and

alignment

eqUIpment

It

IS

recom

mended

that

repairs

to

the

steering

com

ponents

be

left

to

a

completely

eqUIpped

shop

Steenng

gear

housing

Shaft

steeling

sector

Suew

adjusting

roller

hdft

4

Cover

ector

haft

5

Shim

worm

anng

6

Camp

Jacket

column

7

Assembly

t

olumn

steering

8

As

mbly

bearmg

steering

l

orm

9

Assembly

ut

ball

Fig

148

Steering

gear

coriiPon

rrts

80

Page 85 of 136

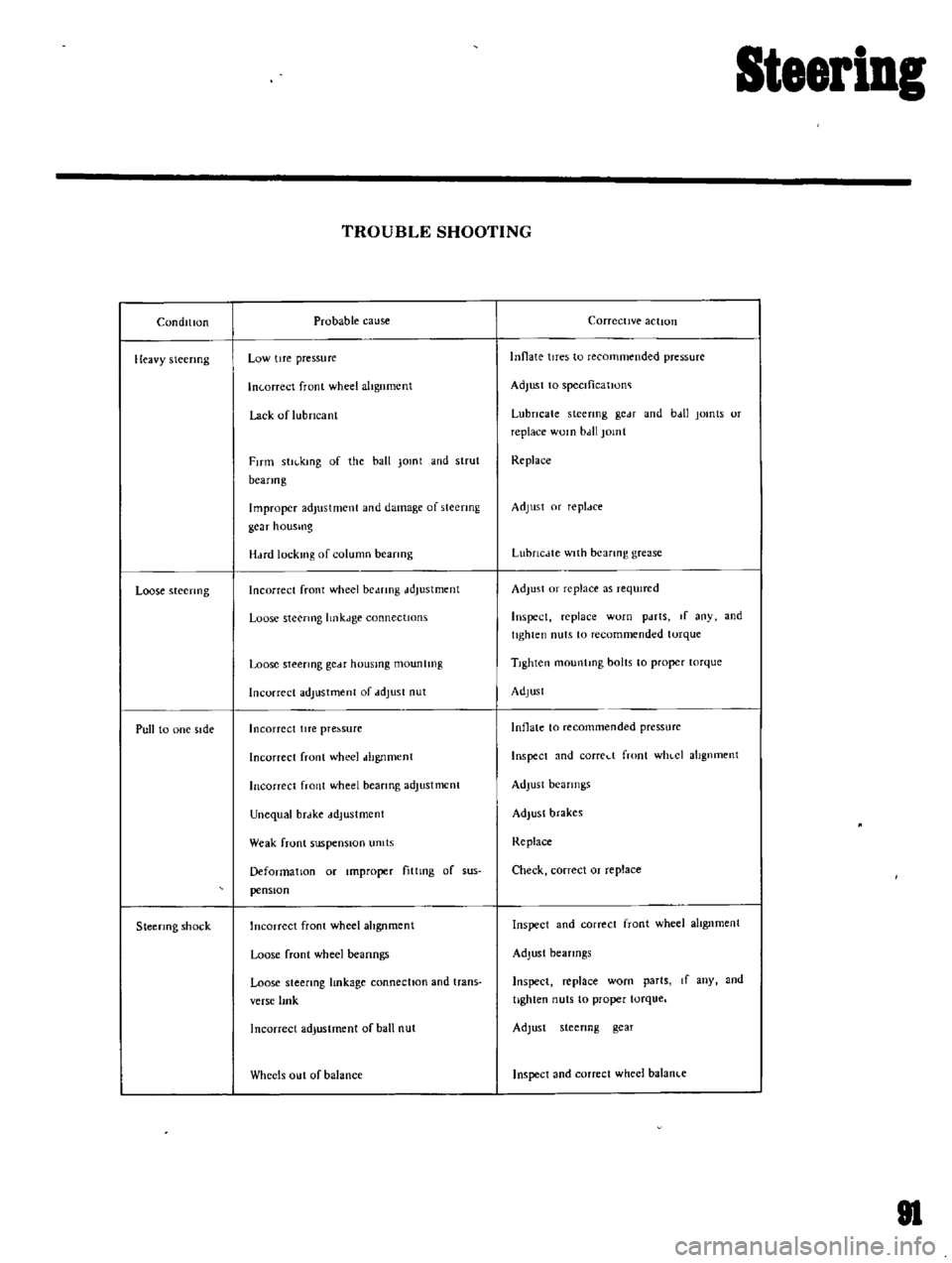

SteeriDg

ConditIon

lIeavy

steering

Loose

steenng

Pull

to

one

side

Steermg

shock

TROUBLE

SHOOTING

Probable

cause

Low

tIre

pressure

In

orreet

front

wheel

altgnmcnt

Lack

of

lubricant

FITm

stll

kmg

of

the

ball

Jomt

and

strut

beanog

Improper

adjustment

and

damage

of

steering

gcar

housmg

H

Hd

lock1l1g

of

column

beanng

Incorrect

front

wheel

be

mng

ddJustment

Loose

steermg

hnkJge

connectIOns

Loose

steermg

gCdf

housmg

mountIng

Incorrect

adjustment

of

ddJust

nut

Incorrect

lITe

pre

sure

Incorrect

front

wheel

dhgnment

Incorrect

front

wheel

beanng

adjustment

Unequal

brdke

ddJustment

Weak

front

suspensIOn

umts

Deformation

or

Improper

fittmg

of

sus

pensIOn

Incorrect

front

wheel

ahgnment

Loose

front

wheel

beanngs

Loose

steering

lmkage

connectIOn

and

trans

verse

lmk

Incorrect

adjustment

of

ball

nut

Wheels

out

of

balance

Corrective

action

Innate

tires

to

recommended

pressure

Adjust

to

speclficatJono

Lubricate

steering

gc

H

and

b

dl

jomts

or

replace

WOln

bdll

jomt

Replace

Adjust

or

repldce

LubrlcJte

with

bearing

grease

Adjust

or

replace

as

reqUired

Inspect

replace

worn

pdrts

If

any

and

tighten

nuts

to

recommended

torque

TIghten

mountmg

bolts

to

proper

torque

Adjust

Inflate

to

recommended

pressurc

Inspect

and

corred

front

WhlCI

alignment

Adjust

bearings

Adjust

brakes

Replace

Check

correct

or

replace

Inspect

and

correct

front

wheel

alIgnment

Adjust

bearings

Inspect

replace

worn

parts

If

any

and

tighten

nuts

to

proper

torque

Adjust

steenng

gear

Inspect

and

correct

wheel

balanl

e

81

Page 86 of 136

f

J

1J

t

j

1

J

i

1

I

j

i

1

n

i

i

1

N

1

f

J

JI

it

J

Jil

r

k

f

4

rt

t

f

l

J

t

t

t

J

1

1

1

J

83

t

u

o

J

w

d

lo

t

f

M

i

U

At

j

i

rd

1

i

il

Page 87 of 136

lear

Drive

Suspension

I

A

le

holft

2

SPdlU

3

Whl

c1

beanng

4

Whcd

be

mng

I

ollar

5

Oll

al

b

Hcanng

adjust

hlOl

7

Axle

a

C

8

BrJ

ke

drum

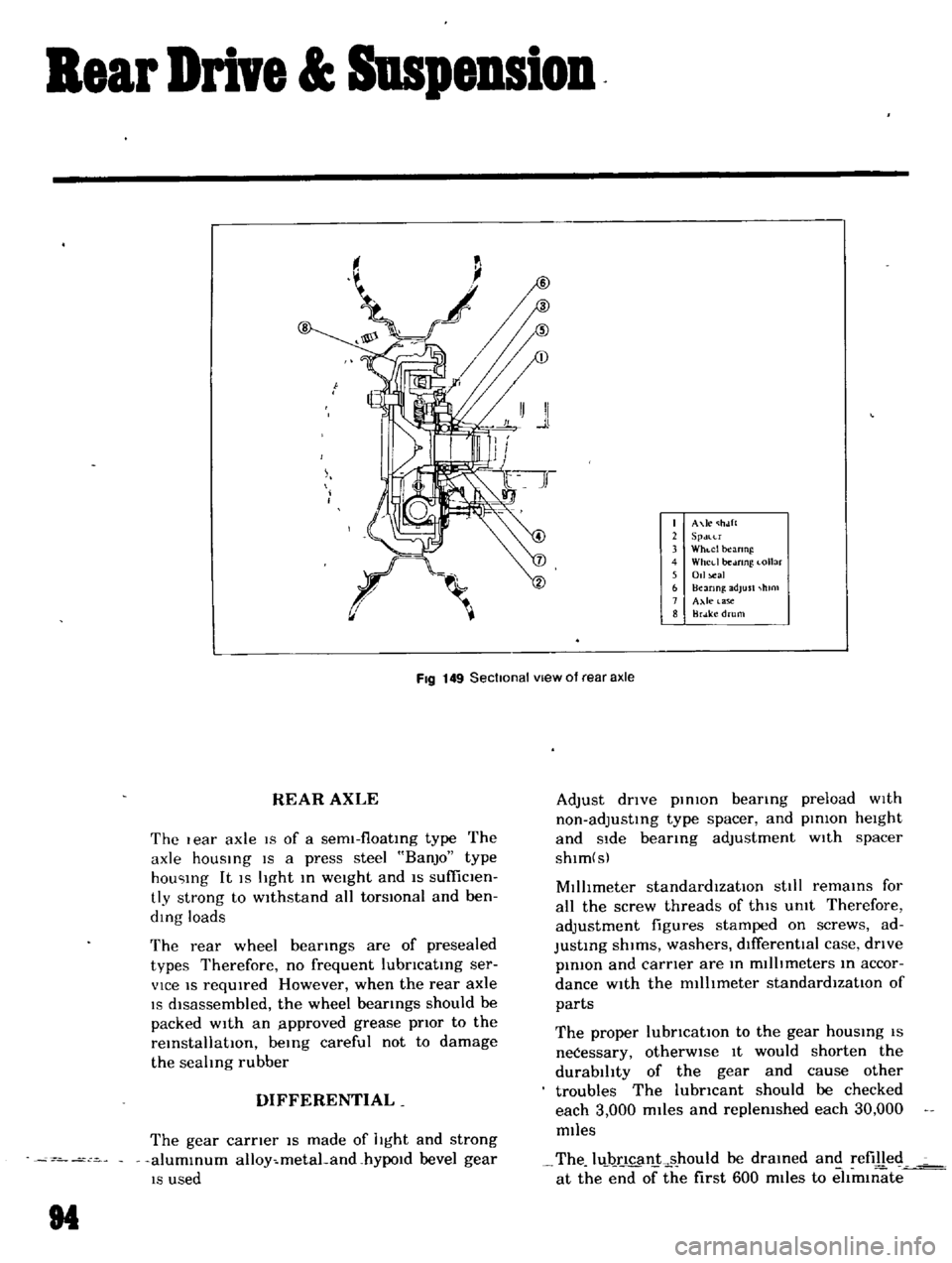

FIg

149

Sectional

vIew

of

rear

axle

REAR

AXLE

The

I

ear

axle

19

of

a

sem1

f10atIng

type

The

axle

hOUSIng

IS

a

press

steel

BanjO

type

hou

Ing

It

IS

light

In

weight

and

IS

sufficlen

tly

strong

to

wIthstand

all

torsIOnal

and

ben

ding

loads

The

rear

wheel

bearIngs

are

of

presealed

types

Therefore

no

frequent

lubncatIng

ser

vice

IS

reqUIred

However

when

the

rear

axle

IS

dIsassembled

the

wheel

bearings

should

be

packed

with

an

lpproved

grease

pnor

to

the

reInstallatIOn

beIng

careful

not

to

damage

the

sealing

rubber

DIFFERENTIAL

The

gear

carner

IS

made

of

light

and

strong

alumInum

alloy

metaLand

hYPOld

bevel

gear

IS

used

M

Adjust

dnve

pInIOn

bearIng

preload

wIth

non

adjustIng

type

spacer

and

pInion

height

and

Side

bearIng

adjustment

wIth

spacer

shlm

s

MIllimeter

standardIzatIOn

stili

remaInS

for

all

the

screw

threads

of

thIS

Unit

Therefore

adjustment

figures

stamped

on

screws

ad

JustIng

shIms

washers

dIfferentIal

case

dnve

pInIOn

and

carner

are

In

millimeters

In

accor

dance

with

the

millImeter

standardIzatIOn

of

parts

The

proper

lubncatlOn

to

the

gear

hOUSIng

IS

neCessary

otherWIse

It

would

shorten

the

durability

of

the

gear

and

cause

other

troubles

The

lubncant

should

be

checked

each

3

000

miles

and

replenished

each

30

000

miles

The

luJ

ncan

ks

hould

be

draIned

and

refilled

at

the

end

of

the

first

600

miles

to

eltm1l1ate

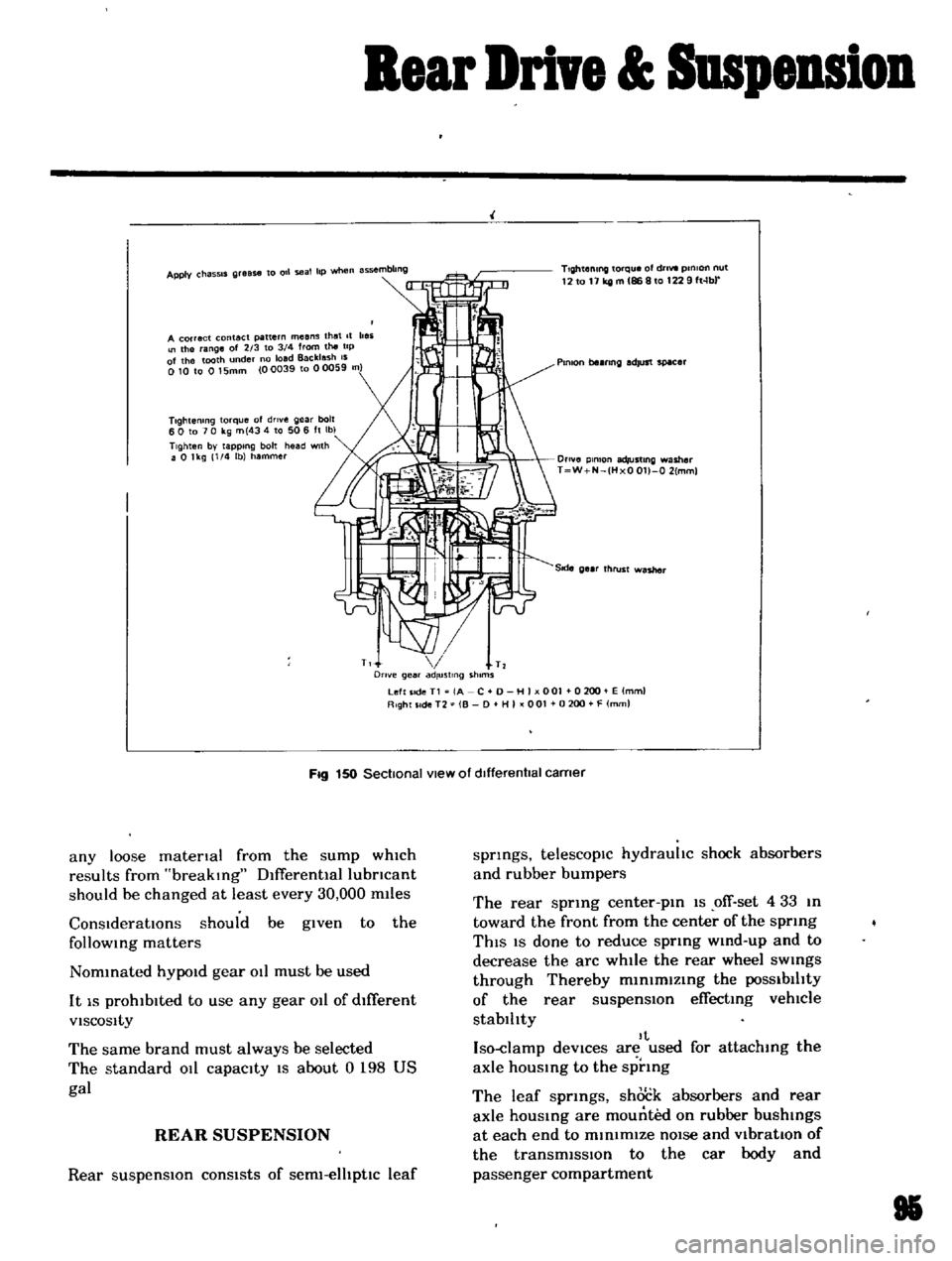

Page 88 of 136

Bear

Drive

Suspension

A

correct

contact

pattern

means

that

It

beii

the

ange

of

2

3

to

3

4

from

the

tip

of

the

tooth

nder

no

load

Backlash

IS

010

to

015mm

00039

to

00059

n

Tlghtemng

torque

of

drlve

gear

bolt

60

to

70

kg

m

434

to

506

ft

Ibl

TIghten

by

tapping

bolt

head

with

a

0

lkg

1

4

lb

hammer

TIghtening

torque

of

dnvt

pmlon

nut

12

to

11

kg

m

86

8

to

1229

ft

lb

Plmon

be

nng

adjust

spacer

O

lve

plmon

adlustlng

washer

T

W

N

HxO

011

0

2

mml

T

T

Drive

gear

ad

ustlng

shims

Left

Ide

T1

jA

C

0

H

I

001

0200

E

lmml

Right

SIde

T2

B

D

HI

001

0

200

F

mml

Fig

150

Sectional

view

of

dIfferentIal

carner

any

loose

matenal

from

the

sump

which

results

from

breaking

Dlfferentlallubncant

should

be

changed

at

least

every

30

000

m11es

ConsIderatIOns

should

be

given

to

the

follOWing

matters

Nommated

hYPOld

gear

011

must

be

used

It

IS

prohibited

to

use

any

gear

011

of

dIfferent

VISCOSity

The

same

brand

must

always

be

selected

The

standard

011

capacity

IS

about

0

198

US

gal

REAR

SUSPENSION

Rear

suspensIOn

consists

of

serm

elhptlc

leaf

springs

telescopIc

hydrauhc

shock

absorbers

and

rubber

bumpers

The

rear

sprmg

center

pm

1S

ofT

set

4

33

m

toward

the

front

from

the

center

of

the

sprmg

ThIS

IS

done

to

reduce

sprmg

wmd

up

and

to

decrease

the

arc

while

the

rear

wheel

sWings

through

Thereby

m1n1mlzmg

the

POSSibilIty

of

the

rear

suspensIOn

effecting

vehlCle

stablhty

It

Iso

damp

deVices

are

used

for

attachmg

the

axle

hOUSing

to

the

sprmg

The

leaf

sprmgs

shock

absorbers

and

rear

axle

housmg

are

mounted

on

rubber

bushings

at

each

end

to

minimIZe

nOIse

and

VibratIOn

of

the

transmiSSIon

to

the

car

body

and

passenger

compartment

85

Page 89 of 136

Bear

Drive

Suspension

3

4

5

B

c

16

7

Lx

ll

prill

I

It

111111

3

hJ

ddl

4

hOl

k

oIh

orbu

5

Ji

6

ldr

7

Torqw

arrl

h

r

8

H

md

brah

lrL

9

8rdk

ho

10

Hound

bumplf

Fig

151

Rear

suspension

Fig

152

Removing

the

shock

absorber

lower

end

Fig

153

Removing

shock

absorber

upper

bracket

REAR

SHOCK

ABSORBER

Remove

the

lower

end

of

the

rear

shock

absor

ber

from

the

sprmg

seat

See

FIgure

152

Replacement

Jack

upcthe

center

of

the

rear

axle

and

sup

E

ll1ove

the

rear

shock

absorJ

l

l

pstalhng

nut

port

the

axle

housmg

with

stands

located

under

the

rear

sea

back

88

Page 90 of 136

Bear

Drive

Suspension

Install

rear

shock

absorber

m

reverse

equence

of

removal

cracks

and

exceSSIve

deformatIOn

Replace

the

defectIve

parts

If

necessary

Inspection

Test

the

shock

absorber

and

replace

If

necessary

Check

for

leakage

cracks

and

the

shaft

for

straightness

Inspect

the

rubber

bushmgs

for

damage

RECOMMENDATIONS

Due

to

the

large

number

of

specIal

tools

reqUIred

and

the

advanced

knowledge

necessary

It

IS

recommended

that

the

overhaul

of

the

differential

be

left

to

a

properlv

equipped

shop

97