DATSUN B110 1969 Service Owners Manual

Manufacturer: DATSUN, Model Year: 1969, Model line: B110, Model: DATSUN B110 1969Pages: 136, PDF Size: 5.64 MB

Page 91 of 136

Clutch

DESCRIPTION

The

clutch

IS

a

sIngle

dry

dIsc

diaphragm

prIng

type

clutch

The

major

components

are

clutch

cover

pressure

plate

diaphragm

sprIng

and

wire

rIngs

The

clutch

diSC

IS

provided

WIth

rIveted

plates

on

both

surfaces

and

cot

bprIngs

arranged

In

a

hnk

The

COIl

prIngs

absOl

b

shock

whIle

engagIng

the

clutch

softemng

and

smoothIng

clutch

engagement

Release

bearIng

sleeve

and

WIthdrawal

lever

dre

used

to

control

clutch

engagement

and

disengagement

Each

part

of

the

clutch

assembly

IS

secured

With

rivets

Therefore

when

a

trouble

IS

un

correctable

replace

the

clutch

assembly

With

a

new

assembly

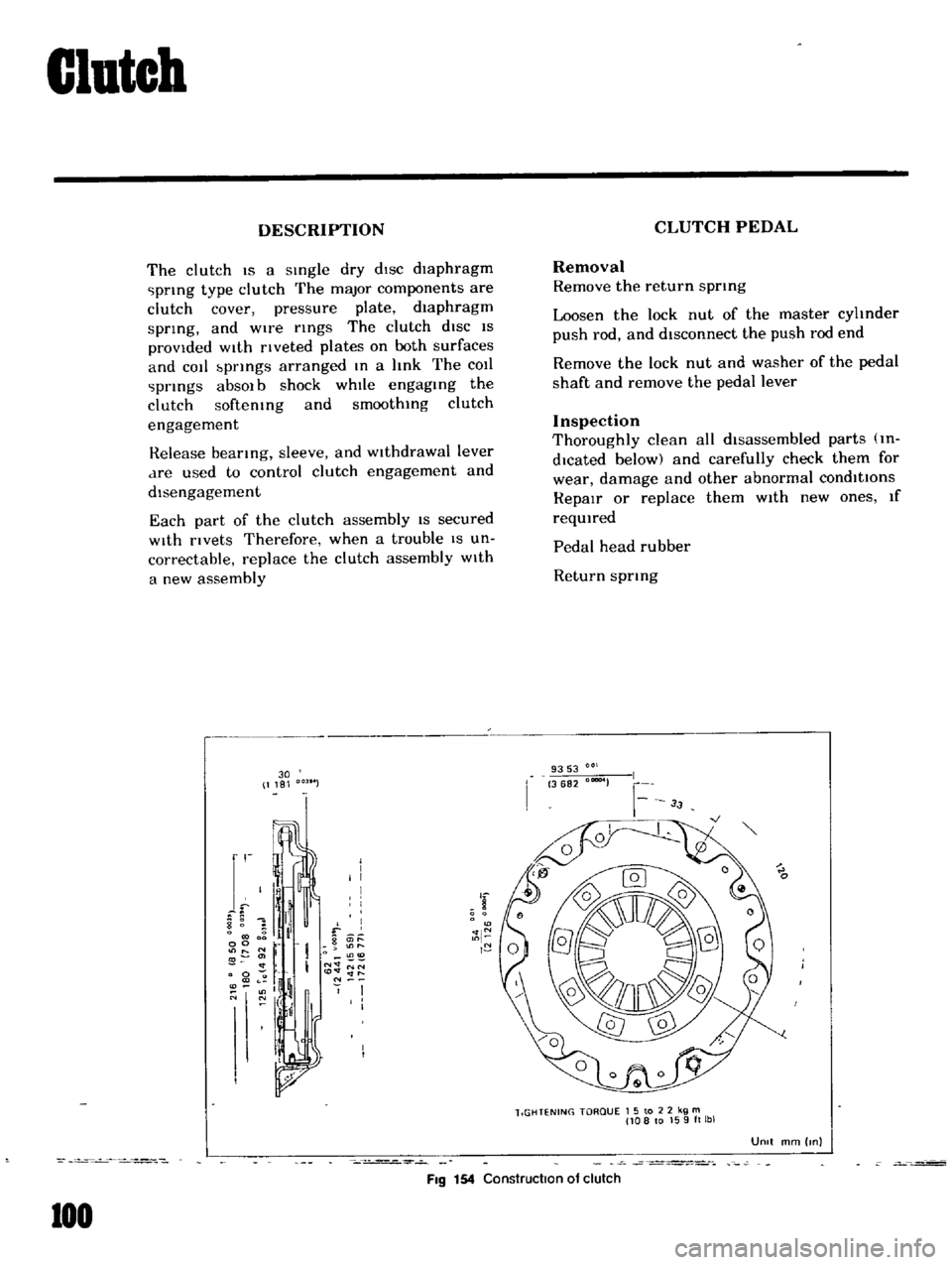

30

1181

r

I

I

I

I

I

8

1

il

f

0

g

it

l

00

r

O

11

I

N

NN

0

to

lt

lt

ll

l

If

N

O

N

I

I

I

I

FIg

154

Construction

of

clutch

100

CLUTCH

PEDAL

Removal

Remove

the

return

sprmg

Loosen

the

lock

nut

of

the

master

cyhnder

push

rod

and

disconnect

the

push

rod

end

Remove

the

lock

nut

and

washer

of

the

pedal

shaft

and

remove

the

pedal

lever

Inspection

Thoroughly

clean

all

disassembled

parts

m

dlcated

below

and

carefully

check

them

for

wear

damage

and

other

abnormal

conditions

RepaIr

or

replace

them

With

new

ones

If

reqUIred

Pedal

head

rubber

Return

sprIng

9353

3682

00004

lIGHTENING

TORQUE

1

5

to

2

2

kg

m

108

to

159ft

lbl

UOIt

mm

Inl

Page 92 of 136

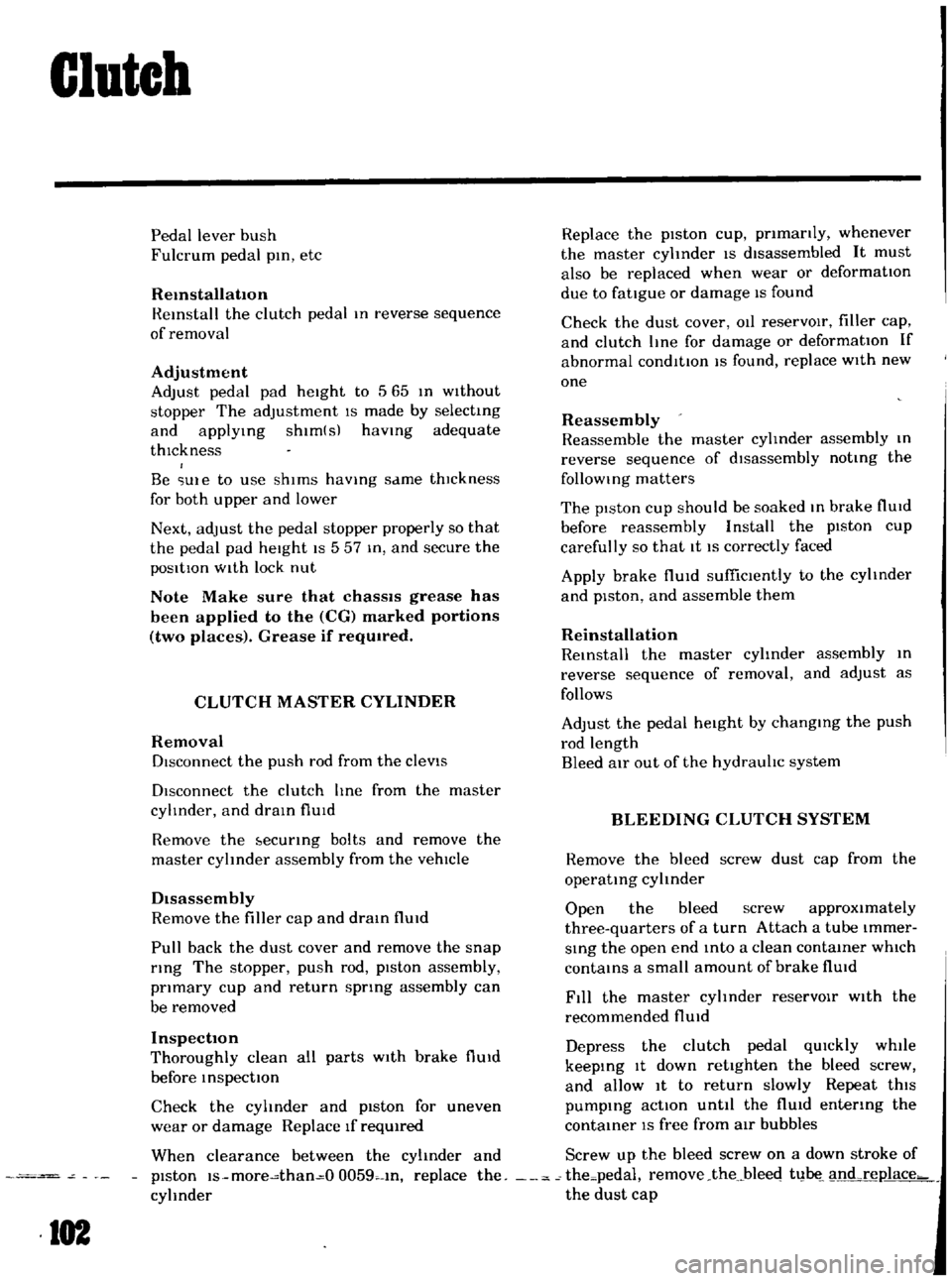

Snap

ring

Dust

over

Push

rod

Clutch

piston

Piston

Spring

Inlel

valve

S

Inlet

valve

pnng

Spnng

retamer

Shun

Inlet

valve

Body

release

pm

011

reservoir

011

reservou

cap

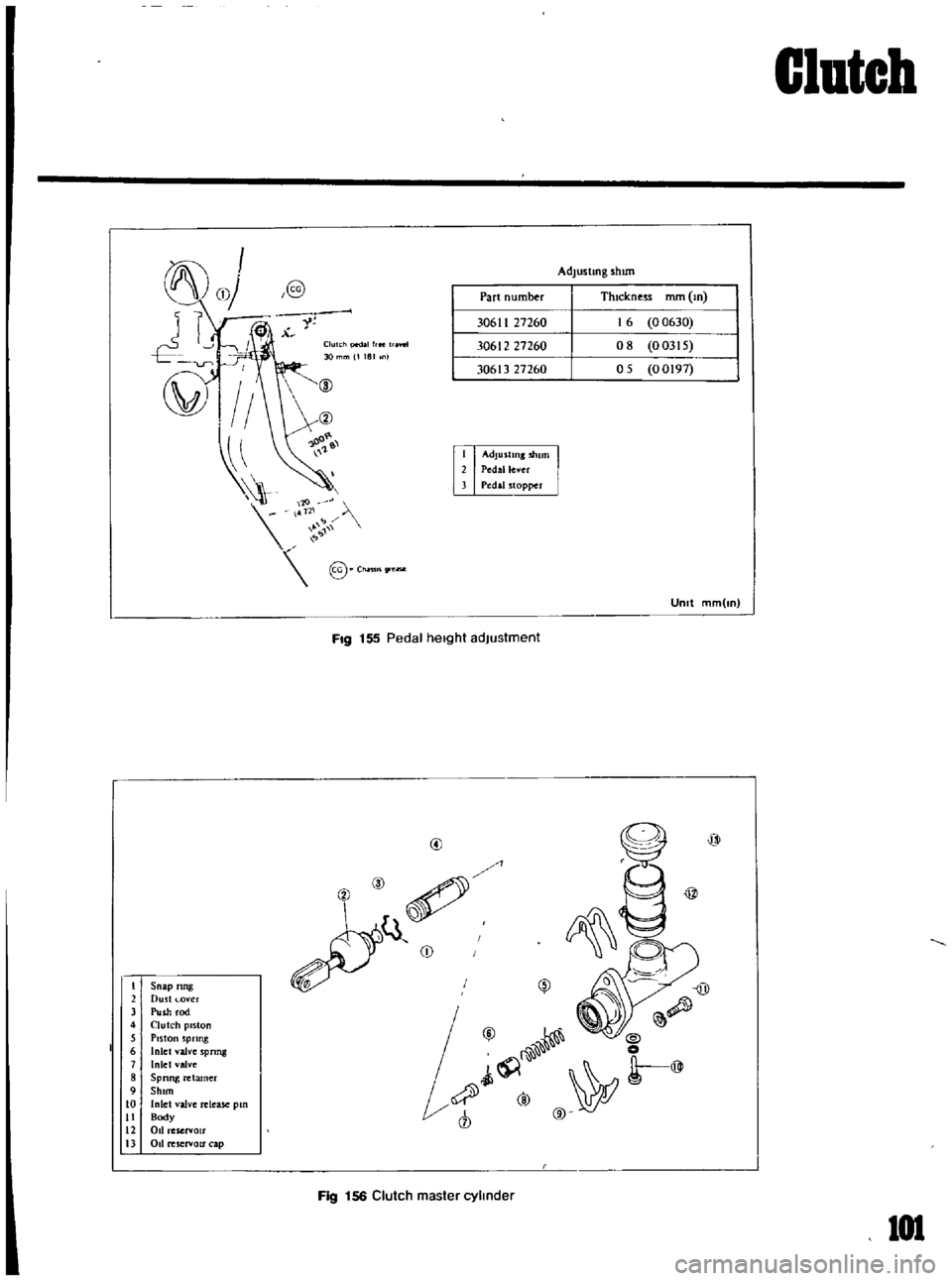

Part

number

Adlustmg

shun

ThIckness

mm

m

00630

00315

05

00197

Clutch

pedallrte

aY

tl

30

mm

1181

n

@

Ch

nl

lSgre

Fig

155

P

edal

height

adjustment

l

@

1

f

I

vy

J

@

W

Il

@

Ji

0

t

@

o

@

1

Fig

156

Clutch

master

cylinder

Clutch

101

Page 93 of 136

Clutch

Pedal

lever

bush

Fulcrum

pedal

pIn

etc

Remstallation

Reinstall

the

clutch

pedal

In

reverse

sequence

of

removal

Adjustment

Adjust

pedal

pad

heIght

to

565

In

Without

stopper

The

adjustment

IS

made

by

selectmg

and

applYIng

shlm

s

haVing

adequate

thIckness

Be

Ule

to

use

shIms

haVIng

same

thIckness

for

both

upper

and

lower

Next

adjust

the

pedal

stopper

properly

so

that

the

pedal

pad

height

IS

557

In

and

secure

the

pOSitIOn

WIth

lock

nut

Note

Make

sure

that

chaSSIS

grease

has

been

applied

to

the

CG

marked

portions

two

places

Grease

if

reqUired

CLUTCH

MASTER

CYLINDER

Removal

DIsconnect

the

push

rod

from

the

cleVIS

DIsconnect

the

clutch

lIne

from

the

master

cylinder

and

draIn

flUid

Remove

the

ecunng

bolts

and

remove

the

master

cyhnder

assembly

from

the

vehIcle

DIsassembly

Remove

the

filler

cap

and

draIn

flUId

Pull

back

the

dust

cover

and

remove

the

snap

rIng

The

stopper

push

rod

pIston

assembly

pnmary

cup

and

return

sptlng

assembly

can

be

removed

Inspection

Thoroughly

clean

all

parts

With

brake

flUId

before

InspectIOn

Check

the

cyhnder

and

piston

for

uneven

wear

or

damage

Replace

If

required

When

clearance

between

the

cylinder

and

pIston

IS

more

than

O

0059

In

replace

the

cyhnder

102

Replace

the

pIston

cup

pnmanly

whenever

the

master

cyhnder

IS

dIsassembled

It

must

also

be

replaced

when

wear

or

deformatIOn

due

to

fatIgue

or

damage

IS

found

Check

the

dust

cover

OIl

reservOIr

filler

cap

and

clutch

lIne

for

damage

or

deformatIOn

If

abnormal

condItIOn

IS

found

replace

With

new

one

Reassembly

Reassemble

the

master

cylInder

assembly

In

reverse

sequence

of

dIsassembly

notIng

the

follOWIng

matters

The

pIston

cup

should

be

soaked

In

brake

flUId

before

reassembly

Install

the

pIston

cup

carefully

so

that

It

IS

correctly

faced

Apply

brake

flUId

suffiCIently

to

the

cyhnder

and

pIston

and

assemble

them

Reinstallation

ReInstall

the

master

cyhnder

assembly

In

reverse

sequence

of

removal

and

adjust

as

follows

Adjust

the

pedal

heIght

by

changmg

the

push

rod

length

Bleed

air

out

of

the

hydrauhc

system

BLEEDING

CLUTCH

SYSTEM

Remove

the

bleed

screw

dust

cap

from

the

operatIng

cyhnder

Open

the

bleed

screw

approximately

three

quarters

of

a

turn

Attach

a

tube

Immer

SIng

the

open

end

mto

a

clean

contaIner

which

contaInS

a

small

amount

of

brake

flUId

Fill

the

master

cyhnder

reservOIr

With

the

recommended

flUId

Depress

the

clutch

pedal

qUIckly

while

keepIng

It

down

retighten

the

bleed

screw

and

allow

It

to

return

slowly

Repeat

thiS

pumpIng

actIOn

unttl

the

flUId

entenng

the

contaIner

IS

free

from

air

bubbles

Screw

up

the

bleed

screw

on

a

down

stroke

of

the

pedal

remove

the

bleec

t1

1

nd

rel1lace

the

dust

cap

Page 94 of 136

Transmission

Page 95 of 136

lransmission

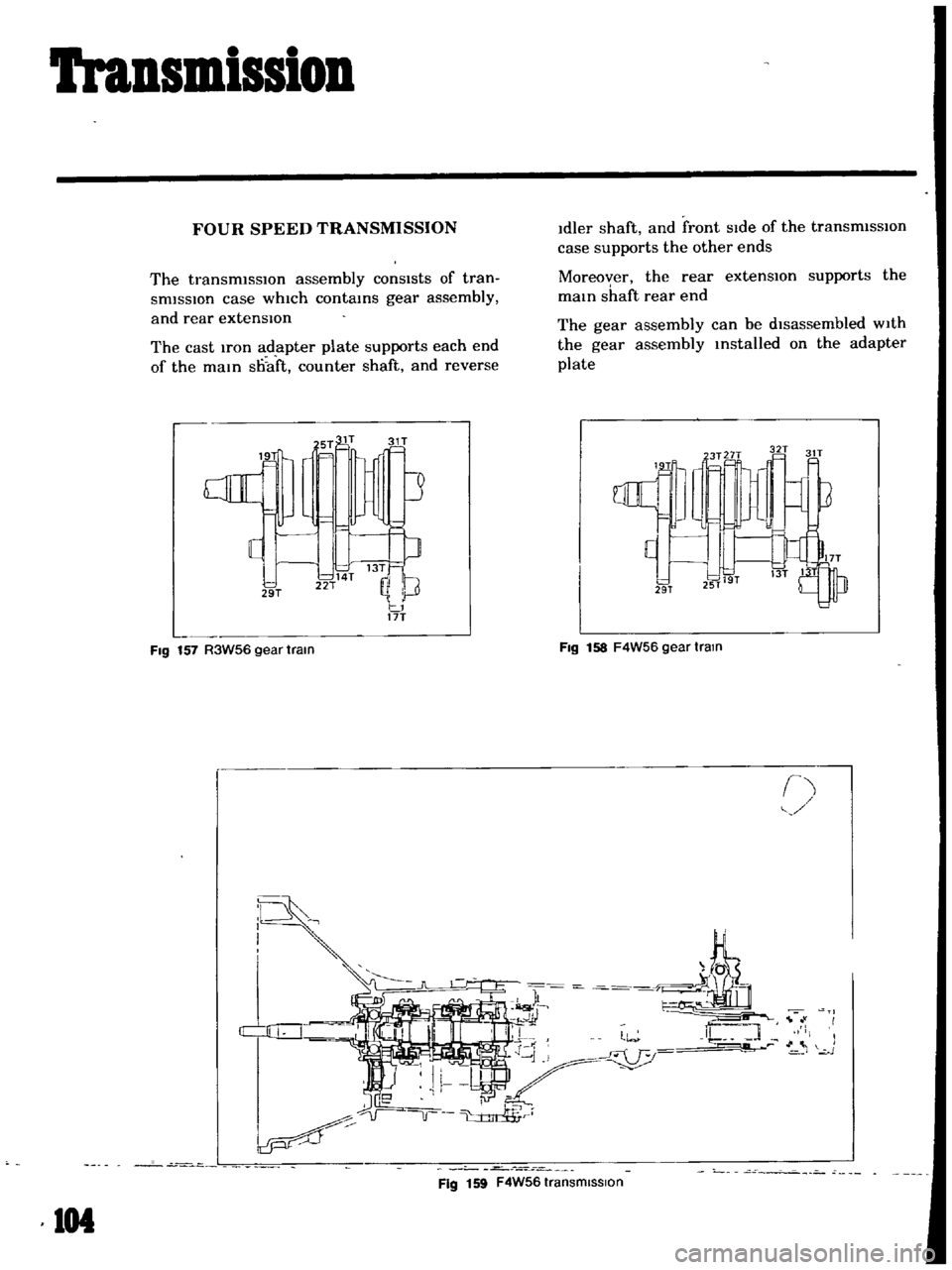

FOUR

SPEED

TRANSMISSION

Idler

shaft

and

front

sIde

of

the

transmiSSIOn

case

supports

the

other

ends

Moreoyer

the

rear

extensIOn

supports

the

mam

shaft

rear

end

The

gear

assembly

can

be

dIsassembled

With

the

gear

assembly

Installed

on

the

adapter

plate

The

transmiSSIOn

assembly

cons1sts

of

tran

smISSIOn

case

whIch

con

tams

gear

assembly

and

rear

extensIOn

The

cast

Iron

adapter

plate

supports

each

end

of

the

mam

sO

aft

counter

shaft

and

reverse

1T

Fig

157

R3W56

gear

tram

Fig

158

F4W56

gear

tram

e

1

l

j

iir

1

1

lkv

t

J

I

If

Jo

rn

r

J

J

v

li

I

v

1

1

rr

v

Fig

159

F4W56

transmisSion

11M

Page 96 of 136

Iransmission

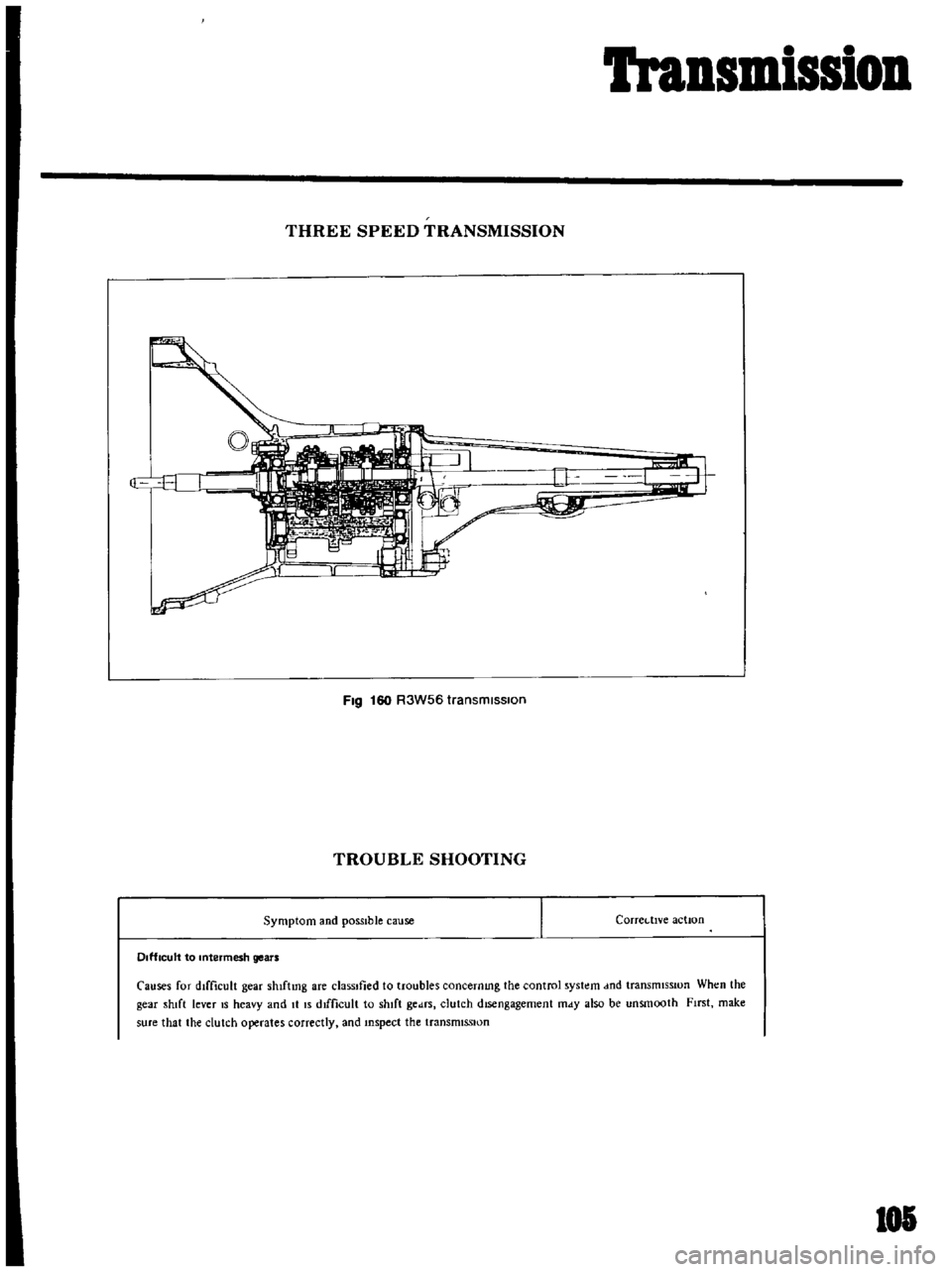

THREE

SPEED

TRANSMISSION

Fig

160

R3W56

transmisSion

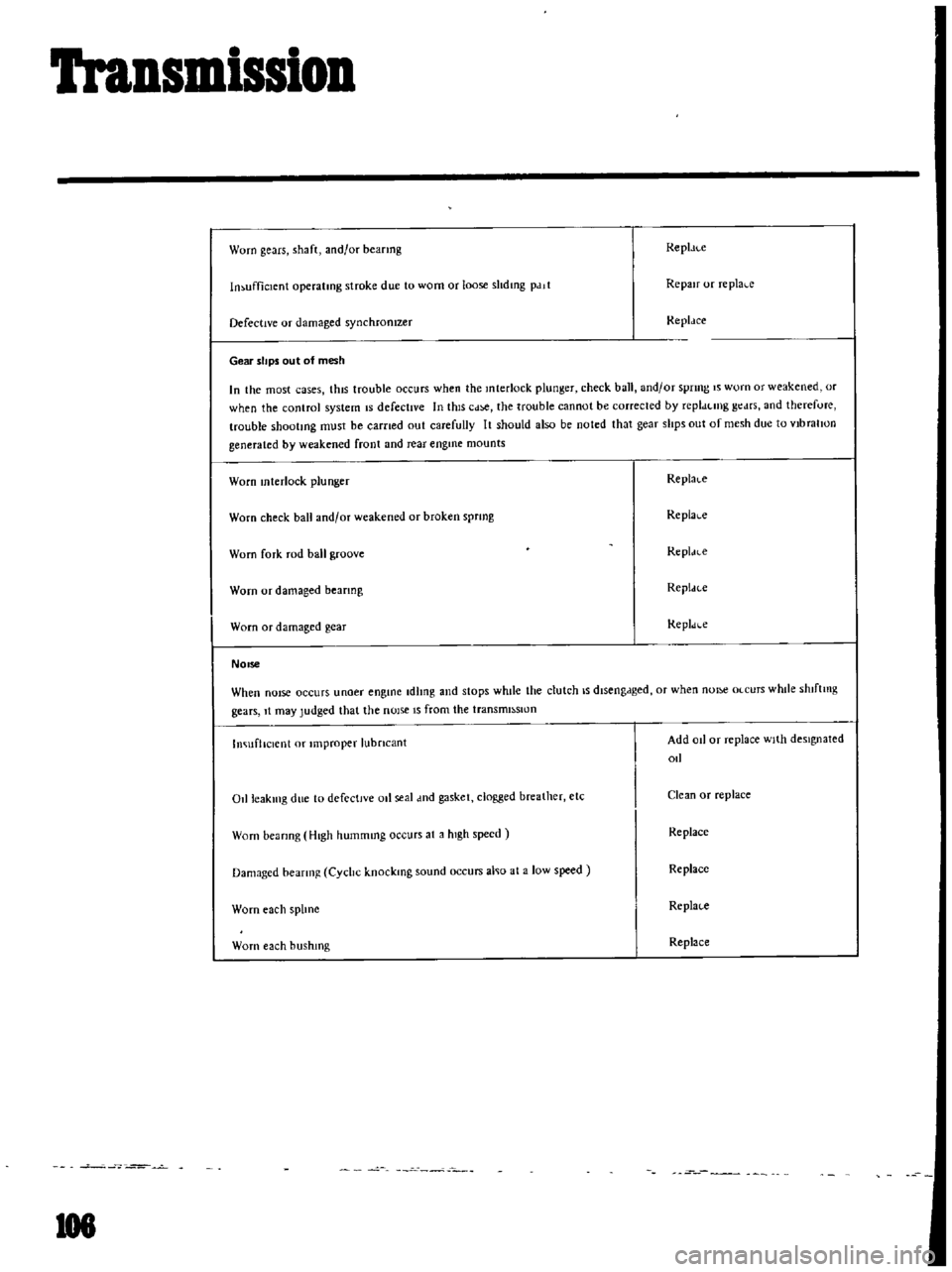

TROUBLE

SHOOTING

Symptom

and

possible

cause

I

Correc

tIve

actIOn

Difficult

to

mtermesh

gears

Causes

for

difficult

gear

shlftmg

are

classIfied

to

troubles

concernmg

the

control

system

md

transmlSSlUn

When

the

gear

shift

lever

IS

heavy

and

It

IS

difficult

to

shift

ge

us

clutch

disengagement

mdY

also

be

unsmooth

First

make

sure

that

the

clutch

operates

correctly

and

Inspect

the

transmiSSion

105

Page 97 of 136

Transmission

Worn

gears

shaft

and

or

heanng

Repl

ll

c

In

ufficlcnt

operatmg

stroke

due

to

worn

or

loose

shdmg

pdll

Repair

or

replal

c

Defective

or

damaged

synchronIzer

Replace

Gear

slips

out

of

mesh

In

the

most

cases

thiS

trouble

occurs

when

the

Interlock

plunger

check

ball

and

or

spnng

IS

worn

or

weakened

or

when

the

control

system

IS

defectIve

In

thiS

Cd

the

trouble

cannot

be

corrected

by

repldtlllg

gt

drs

and

therefore

trouble

shootmg

must

be

earned

out

carefully

It

should

also

be

noted

that

gear

slips

out

of

mesh

due

to

vlbralIon

generated

by

weakened

front

and

rear

engme

mounts

Worn

mterlock

plunger

Replal

c

Worn

check

hall

and

or

weakened

or

broken

sprmg

Replal

c

Worn

fork

rod

ball

groove

RepI

H

e

Worn

or

damaged

beanng

Repldce

Worn

or

damaged

gear

Repldl

c

NOise

When

nOIse

occurs

unoer

engine

Idling

and

stops

whde

the

clutch

IS

dlseng

lged

or

when

nOI

Olcurs

while

shlftmg

gears

It

may

Judged

that

the

nOIse

IS

from

the

tranSmll

lSIUn

Ino

ufllclenl

or

1mproper

lubncant

Add

od

or

replace

With

deSignated

oIl

Ollleaklllg

due

to

defectIve

011

seal

md

gasket

clogged

breather

etc

Clean

or

replace

Worn

beanng

High

hummmg

occurs

at

a

high

speed

Replace

Damaged

beanng

Cychc

knockmg

sound

occurs

alllo

at

a

low

speed

Replace

Worn

each

sphne

Replace

Worn

each

hushmg

Replace

108

Page 98 of 136

Transmission

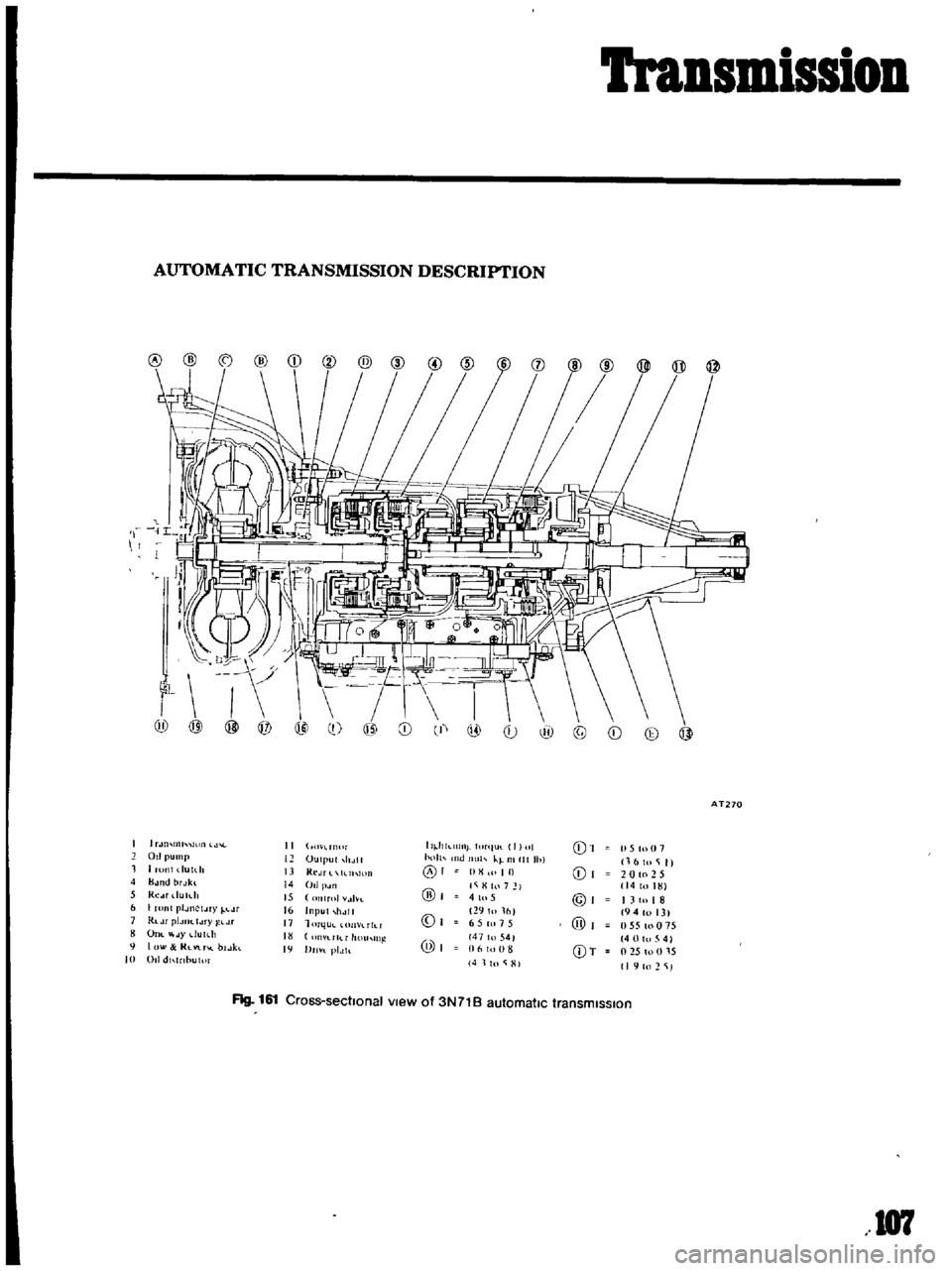

AUTOMATIC

TRANSMISSION

DESCRIPTION

I

Ii

9

0

@

@

AT270

1

U

lllll

II

O

l

rn

lr

II

hkl1lllj

ItlrllUl

I

II

01

15

tu

07

011

pump

12

OUllJllt

holtl

h

llt

Ih

kl

Illllt

Ihl

16

to

i

II

1

1

runl

dUlth

13

Kl

JT

llhlOIl

01

10

01

20

to

2

5

4

B

H1d

brJkl

14

011

p

Jll

l

i

H

hl

7

14toHn

5

Re

u

du

h

15

lIT01

tlvt

@

41u5

@I

I

310

I

8

6

I

ronl

plJllctJry

lJr

16

Input

11

111

0

29101fll

194

013

1

Rldr

pIJIJC

IJ

ry

j

l

Lr

11

1

m

lu

n

lIh

T

6

5

tn

15

@

055toO

5

OIll

JYdutdt

rllT

11

l1

11l

@I

147

to

541

40

0

5

4

9

I

lW

RlVlr

l

bl

Jkl

19

Dm

l

plJh

16

III

8

CDT

l

2S

to

U

l

S

10

011

dl

nbulm

4

11n

i

HI

I

I

to

2

iJ

Flg

161

Cross

sectIonal

view

of

3N71B

automatic

transmIssIon

107

Page 99 of 136

Transmission

AUTOMATIC

TRANSMISSION

The

model

3N71B

automatic

transmiSSIOn

IS

a

fully

automatic

Unit

consisting

pnmanly

of

3

element

hydrauhc

torque

converter

and

two

planetary

gear

sets

Two

multiple

disc

clut

ches

a

multiple

disc

brake

a

band

brake

and

a

one

way

sprag

clutch

provide

the

fnctlon

elements

reqUired

to

obtain

the

deSired

fun

tlon

of

the

two

planetary

gear

sets

The

two

planetary

gear

sets

give

three

for

ward

ratIOs

and

one

reverse

Changing

of

the

gear

ratIOs

IS

fully

automatic

In

relation

to

vehicle

speed

and

engine

torque

Input

Vehicle

speed

and

engine

mamfold

vacuum

Signals

are

constantly

fed

to

the

transmiSSIOn

to

prOVide

the

proper

gear

ratIO

for

maximum

effiCiency

and

performance

at

all

throttle

openmgs

The

Model

3N71B

has

SIX

selector

poSitIOns

P

R

N

D

2

1

p

Park

pOSitIOn

posItively

locks

the

out

put

shaft

to

the

transmiSSIOn

case

by

means

of

a

lockmg

pawl

to

prevent

the

vehicle

from

rollmg

either

directIOn

ThiS

pOSitIOn

should

be

selected

whenever

the

dnver

leaves

the

vehicle

The

engme

may

be

started

m

Park

pOSition

R

Reverse

range

enables

the

vehicle

to

be

operated

m

a

reverse

direction

N

Neutral

pOSitIOn

enables

the

engine

to

be

started

and

run

Without

dnvIngthe

vehicle

0

Drive

range

IS

used

for

all

normal

driVing

conditions

Dnve

range

has

three

gear

ratios

from

the

startmg

ratIO

to

direct

dnve

2

2

range

prOVides

performance

for

dnvIng

onshppery

surfaces

2

range

can

also

be

used

for

engine

brakmg

2

range

can

be

selected

at

any

vehicle

speed

and

prevents

the

transmlsslOn

from

shifting

out

of

second

gear

108

Rg

162

Idenllflcatlon

number

I

1

range

can

be

selected

at

any

vehicle

speed

and

the

transmiSSIOn

will

shift

to

second

gear

and

remain

m

second

until

vehicle

speed

IS

reduced

to

approximately

25

to

31

MPH

1

range

posItion

prevents

the

transmiSSIOn

from

shlftmg

out

of

low

gear

ThiS

IS

par

tlcularly

benefiCial

for

mamtamIng

maximum

engine

brakmg

when

continUOUS

low

gear

operation

IS

deSirable

The

torque

converter

assembly

IS

of

welded

constructIOn

and

can

not

be

dlssassembled

for

service

FlUld

Recommendatwn

Use

automatic

transmiSSIOn

flUid

haVing

DEXRON

IdentificatIOns

only

m

the

3N71B

automatic

transmiSSIOn

denttficatwn

Number

Stamped

posttwn

The

plate

attached

to

the

rIght

hand

Side

of

transmission

case

as

shown

m

Figure

161

denttficatwn

of

number

arrangements

See

Page

109

RECOMMENDATIONS

Due

to

the

compleXity

of

setting

up

a

disassembled

transmissIOn

as

well

as

the

special

tools

necessary

It

IS

recommended

thaL

nternal

epalrs

be

left

to

a

fully

eqUip

ped

shop

Page 100 of 136

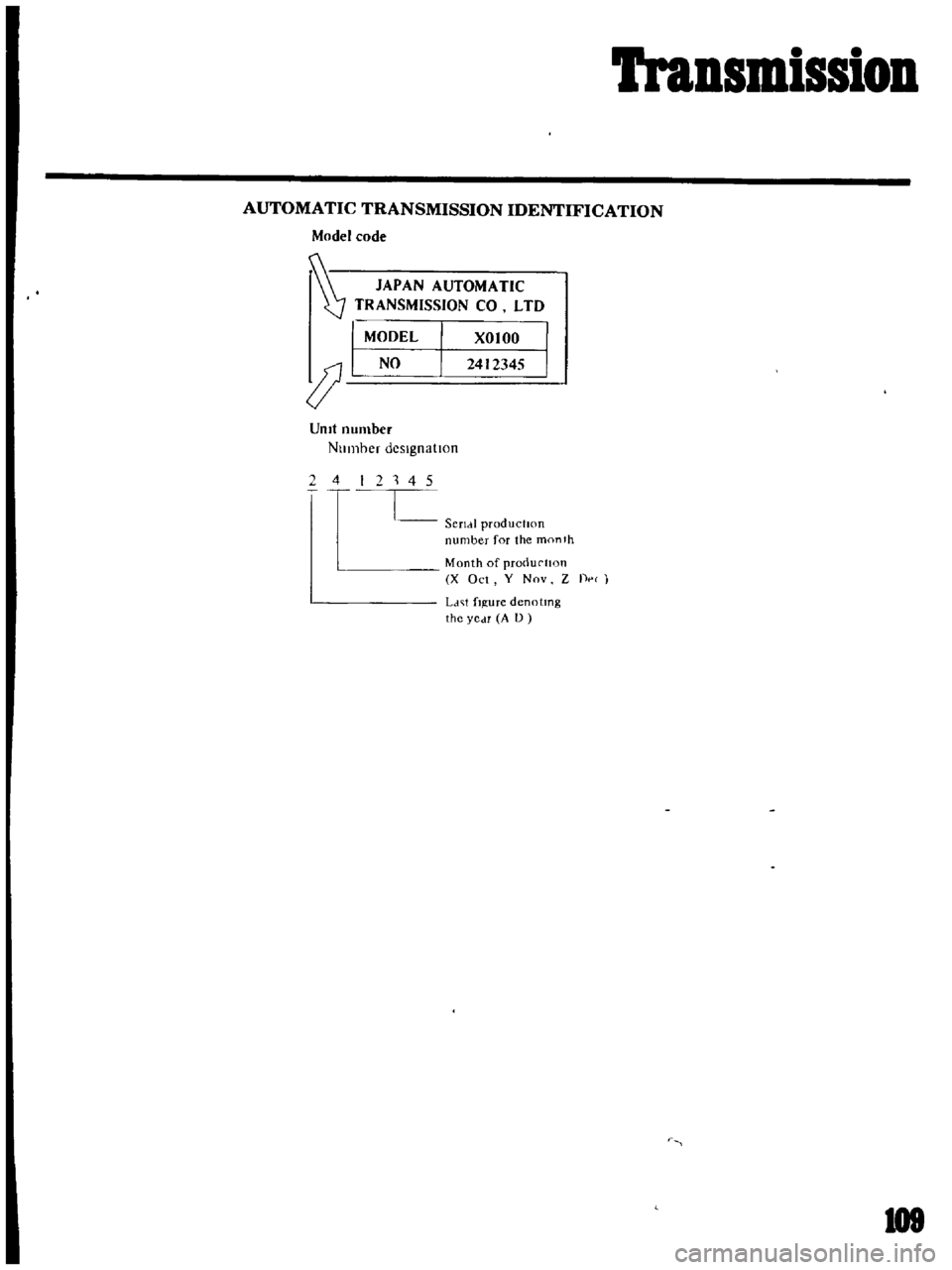

Transmission

AUTOMATIC

TRANSMISSION

IDENTIFICATION

Model

code

JAPAN

AUTOMATIC

I

0

TRANSMISSION

CO

L

TD

MODEL

NO

XOIOO

2412345

Unit

number

NlIlllher

deSignatIOn

2412145

c

l

Sendl

productIOn

number

for

the

monfh

Month

of

production

X

Oct

Y

Nov

Z

Pel

LJ

t

fll

Ure

denotmg

the

yedf

A

D

r

108