ECU DATSUN B110 1973 Service Owner's Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 172 of 513

CHASSIS

The

sliding

block

is

secured

on

the

steering

post

bracket

with

bolts

upper

half

of

the

steering

column

is

supported

on

the

bracket

and

thus

the

steering

post

clamp

is

installed

on

the

body

When

a

large

impact

is

applied

from

the

driver

side

the

plastic

pins

are

cut

off

and

leaving

the

sliding

block

in

the

steering

post

bracket

side

the

clamp

proper

is

disengaged

downward

together

with

the

jacket

tube

For

any

force

applied

from

front

direction

of

the

vehicle

the

steering

post

clamp

sliding

block

does

not

move

rearward

This

construction

is

called

One

way

slide

system

and

with

this

construction

projection

of

the

column

shaft

toward

the

driver

is

prevented

completely

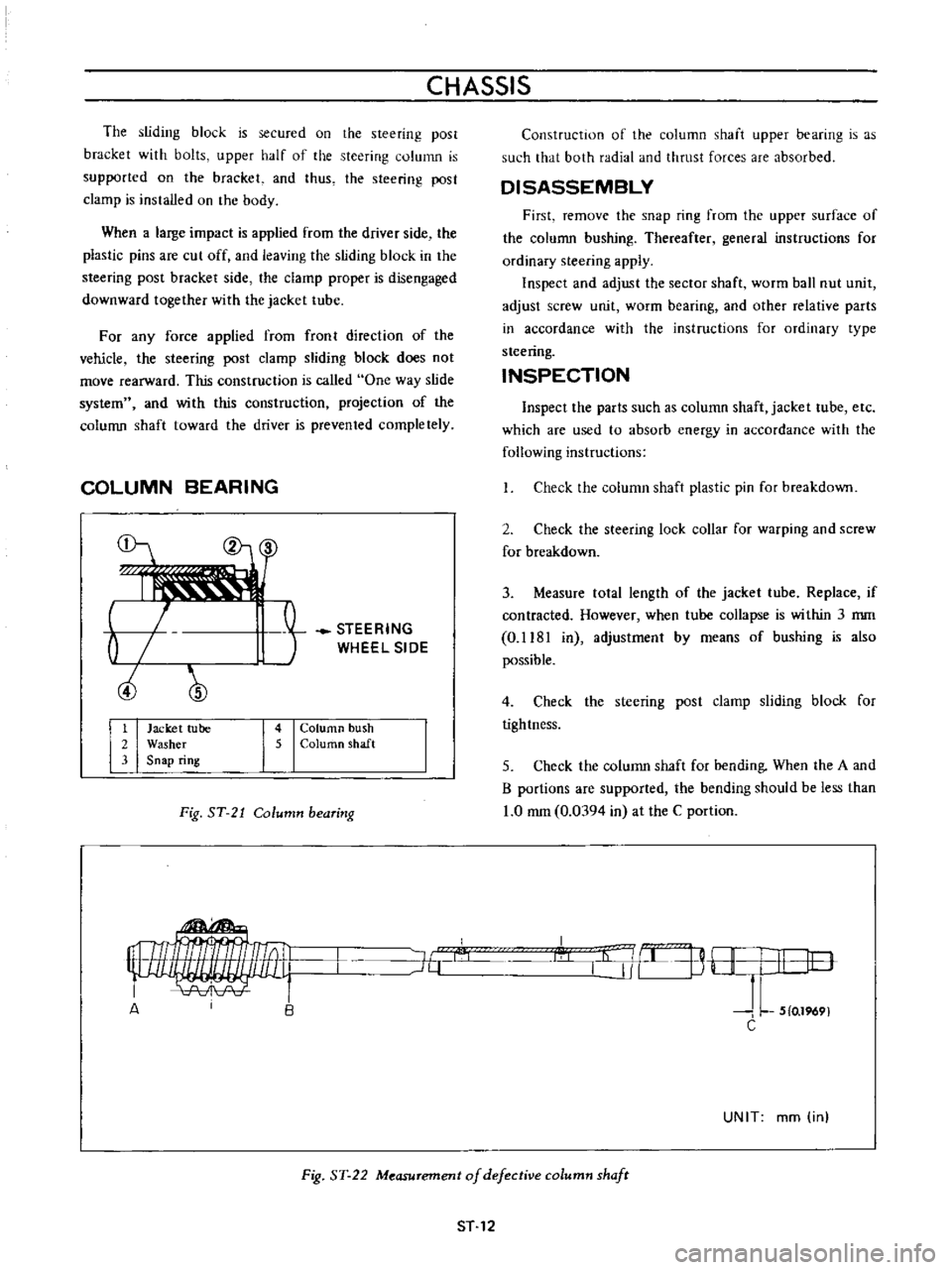

COLUMN

BEARING

b

ciJ

STEERING

WHEEL

SIDE

1

Jacket

tube

2

Washer

3

Snap

ring

4

Column

bush

5

ColurtlO

shaft

Fig

ST

21

Column

bearing

Construction

of

the

column

shaft

upper

bearing

is

as

such

that

both

radial

and

thrust

forces

are

absorbed

DISASSEMBLY

First

remove

the

snap

ring

from

the

upper

surface

of

the

column

bushing

Thereafter

general

instructions

for

ordinary

steering

apply

Inspect

and

adjust

the

sector

shaft

worm

ball

nut

unit

adjust

screw

unit

worm

bearing

and

other

relative

parts

in

accordance

with

the

instructions

for

ordinary

type

steering

INSPECTION

Inspect

the

parts

such

as

column

shaft

jacket

tube

etc

which

are

used

to

absorb

energy

in

accordance

with

the

following

instructions

Check

the

column

shaft

plastic

pin

for

breakdown

2

Check

the

steering

lock

collar

for

warping

and

screw

for

breakdown

3

Measure

tolal

length

of

the

jacket

tube

Replace

if

contracted

However

when

tube

collapse

is

within

3

mm

0

1181

in

adjustmenl

by

means

of

bushing

is

also

possible

4

Check

the

steering

post

clamp

sliding

block

for

tightness

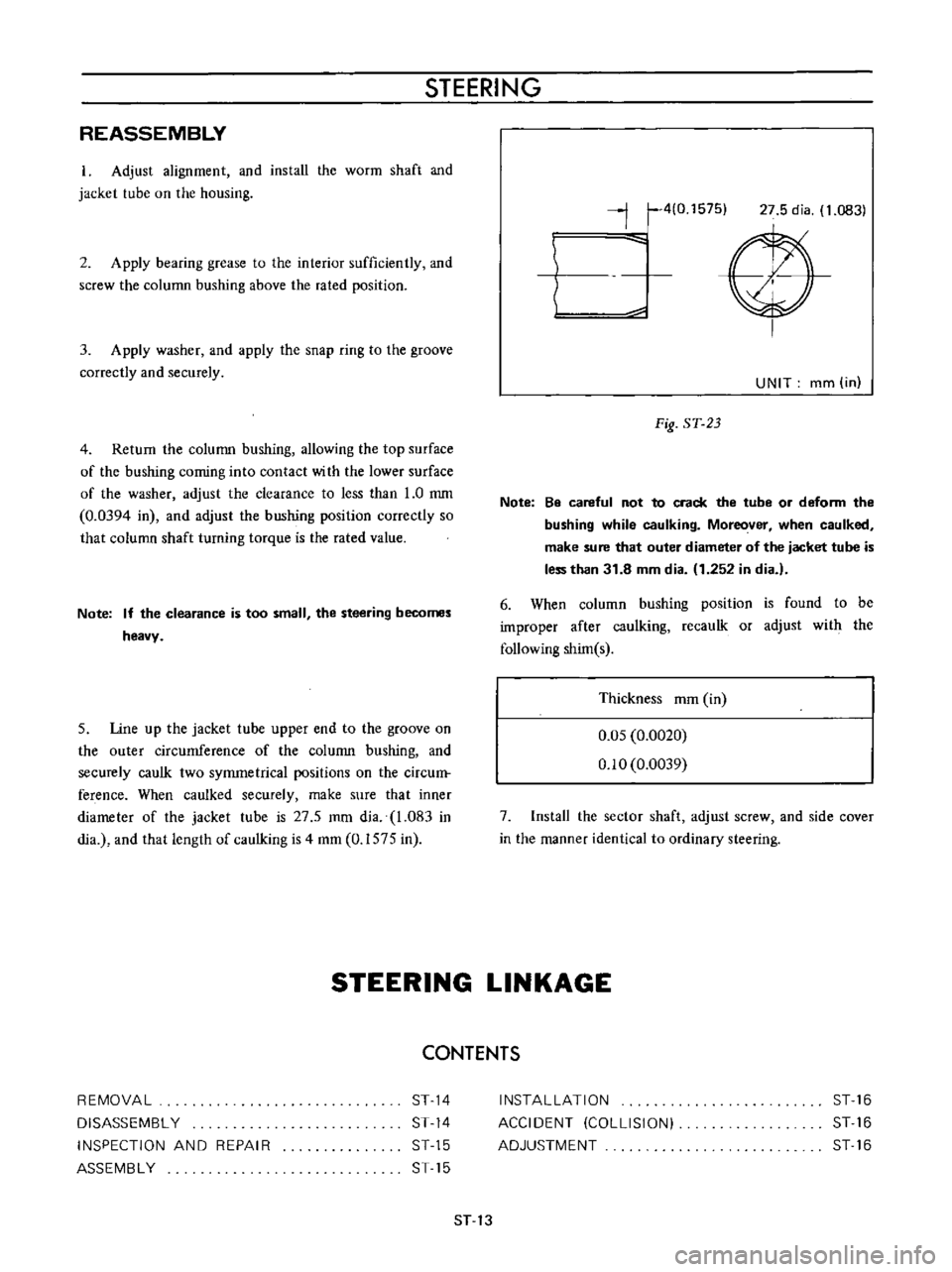

5

Check

the

column

shaft

for

bending

When

the

A

and

B

portions

are

supported

the

bending

should

be

less

than

1

0

mm

0

0394

in

at

the

C

portion

I

l

j

B

H

I

I

lO

J

L

5

0

1969

C

J6

A

UNIT

mm

in

Fig

ST

22

Measurement

of

defective

column

shafr

ST

12

Page 173 of 513

STEERING

REASSEMBLY

Adjust

alignment

and

install

the

worm

shaft

and

jacket

tube

on

the

housing

2

Apply

bearing

grease

to

the

interior

sufficiently

and

screw

the

column

bushing

above

the

rated

position

3

Apply

washer

and

apply

the

snap

ring

to

the

groove

correctly

and

securely

4

Return

the

column

bushing

allowing

the

top

surface

of

the

bushing

coming

into

contact

wi

th

the

lower

surface

of

the

washer

adjust

the

clearance

to

less

than

1

0

mm

0

0394

in

and

adjust

the

bushing

position

correctly

so

that

column

shaft

turning

torque

is

the

rated

value

Note

If

the

clearance

is

too

small

the

steering

becomes

heavy

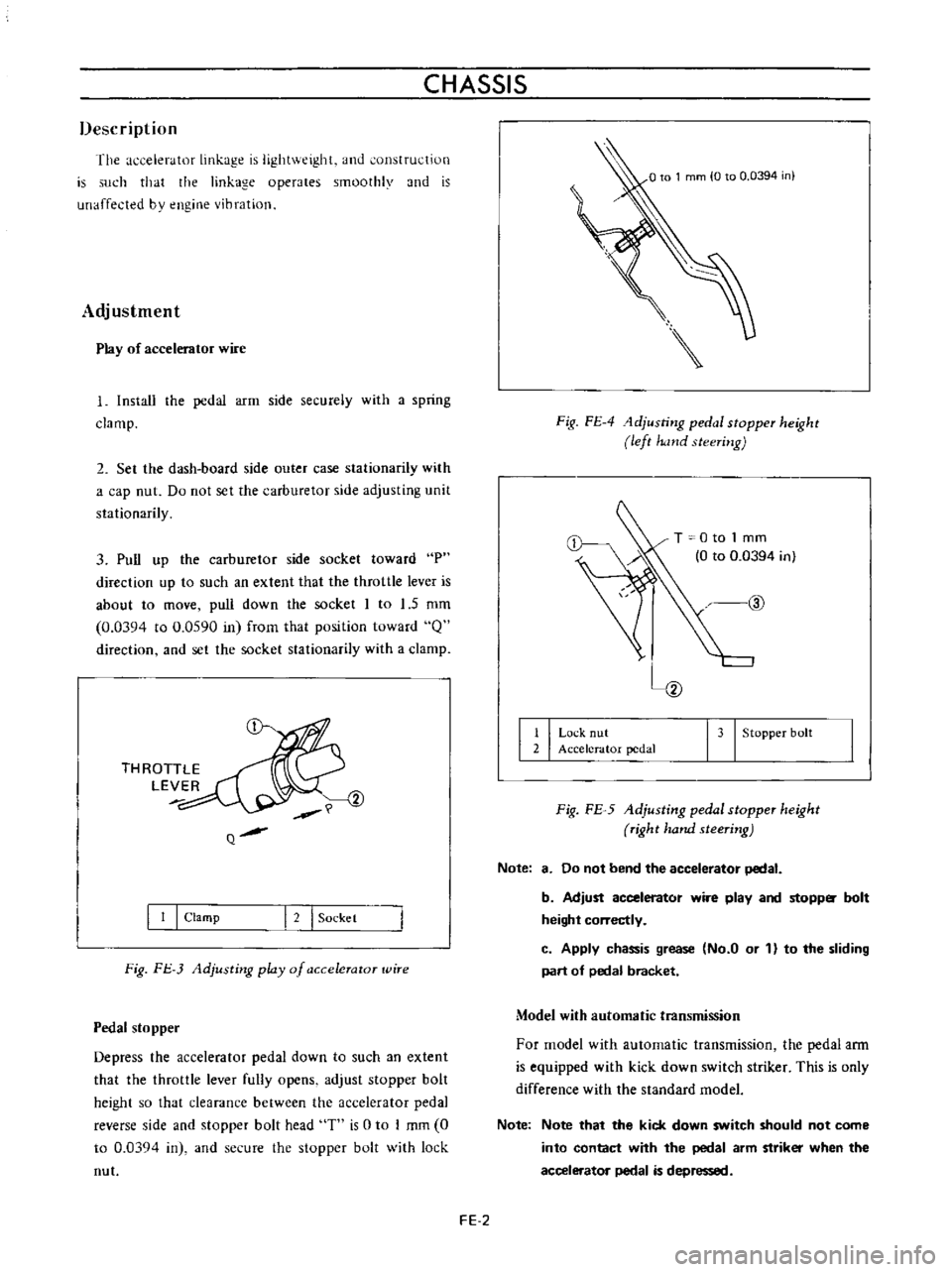

5

Line

up

the

jacket

tube

upper

end

to

the

groove

on

the

outer

circumference

of

the

column

bushing

and

securely

caulk

two

symmetrical

positions

on

the

circum

ference

When

caulked

securely

make

sure

that

inner

diameter

of

the

jacket

tube

is

27

5

mm

dia

1

083

in

dia

and

that

length

of

caulking

is

4

mm

0

1575

in

j

410

1575

27

5

dia

1

0831

V

UNIT

mm

in

Fig

ST

23

Note

Be

careful

not

to

crack

the

tube

or

deform

the

bushing

while

caulking

Moreover

when

caulked

make

sure

that

outer

diameter

of

the

jacket

tube

is

less

than

31

8

mm

dia

1

252

in

dia

6

When

column

bushing

position

is

found

to

be

improper

after

caulking

recaulk

or

adjust

with

the

following

shim

s

Thickness

mm

in

0

05

0

0020

0

10

0

0039

7

Install

the

sector

shaft

adjust

screw

and

side

cover

in

the

manner

identical

to

ordinary

steering

STEERING

LINKAGE

CONTENTS

REMOVAL

DISASSEMBl

Y

INSPECTION

AND

REPAIR

ASSEMBl

Y

ST

14

ST

14

ST

15

ST

15

INSTAllATION

ACCIDENT

COLLISION

ADJUSTMENT

ST

16

ST

16

ST

16

ST

13

Page 181 of 513

CHASSIS

Description

The

accelerator

linkage

is

lightv

eighL

and

onstfuction

is

such

that

the

linkage

operates

smoothly

and

is

unaffected

bv

engine

vibration

Adjustment

Play

of

accelerator

wire

I

Install

the

pedal

arm

side

securely

with

a

spring

clamp

2

Set

the

dash

board

side

Quter

case

stationarily

with

a

cap

nut

Do

not

set

the

carburetor

side

adjusting

unit

stationarily

3

Pull

up

the

carburetor

side

socket

toward

P

direction

up

to

such

an

extent

that

the

throttle

lever

is

about

to

move

pull

down

the

socket

I

to

1

5

mm

0

0394

to

0

0590

in

frorn

that

position

toward

Q

direction

and

set

the

socket

stationarily

with

a

clamp

THROTTLE

LEVER

Q

I

I

I

Clamp

I

2

I

Sockel

Fig

FJ

3

Adjusting

play

of

a

ccelerator

wire

Pedal

stopper

Depress

the

accelerator

pedal

down

to

such

an

extent

that

the

throttle

lever

fully

opens

adjust

stopper

bolt

height

so

that

clearance

between

the

accelerator

pedal

reverse

side

and

stopper

bolt

head

T

is

0

to

I

mm

0

to

0

03Q4

in

and

secure

the

stopper

bolt

with

lock

nut

Fig

FE

4

1djusting

pedal

stopper

height

left

hand

steering

T

0

to

1

mm

0

to

0

0394

in

@

I

I

Lo

k

nut

2

Accelerator

pedal

I

3

I

Stopper

bolt

Fig

FE

5

Adjusting

pedal

stopper

height

right

hand

steering

Note

8

Do

not

bend

the

accelerator

pedal

b

Adjust

accelerator

wire

play

and

stopp

bolt

height

correctly

c

Apply

chassis

grease

No

a

or

1

to

the

sliding

part

of

pedal

bracket

Model

with

automatic

transmission

For

model

with

automatic

transmission

the

pedal

ann

is

equipped

with

kick

down

switch

striker

This

is

only

difference

with

the

standard

model

Note

Note

that

the

kick

down

switch

should

not

come

into

contact

with

the

pedal

arm

striker

when

the

accelerator

pedal

is

depressed

FE

2

Page 184 of 513

ENGINE

CONTROL

FUEL

EXHAUST

SYSTEM

For

all

models

fuel

tank

capacity

has

been

increased

in

response

to

the

increased

engine

output

Location

and

mounting

strength

are

improved

for

improvement

of

safety

Sedan

40

l

101

2

US

gal

8

3

4

Imp

gal

Van

38

l

10

US

gal

8

3

8

Imp

gal

Coupe

38

l

10

US

gal

8

3

8

Imp

gal

and

completely

drain

fuel

2

Remove

the

fuel

line

connector

3

Remove

the

luggage

compartment

finishing

4

Remove

four

bolts

used

to

secure

the

fuel

tank

5

Loosen

the

hose

clamp

f

r

II

J

y

I

0

I

V

Ii

i

iJb

Also

for

piping

consideration

has

been

given

on

the

safety

To

be

more

specifically

the

fuel

line

coming

out

from

the

fuel

tank

is

laid

inside

the

rear

side

member

so

that

the

fuel

line

is

protected

from

gravel

and

other

interferences

from

road

In

the

front

floor

section

the

fuel

line

is

laid

inside

a

tunnel

and

thus

fuel

line

reaches

the

engine

compartment

In

addition

the

fuel

strainer

and

fuel

tank

outlet

units

connect

the

fuel

line

with

rubber

hoses

and

for

aU

other

sections

bandy

tube

is

used

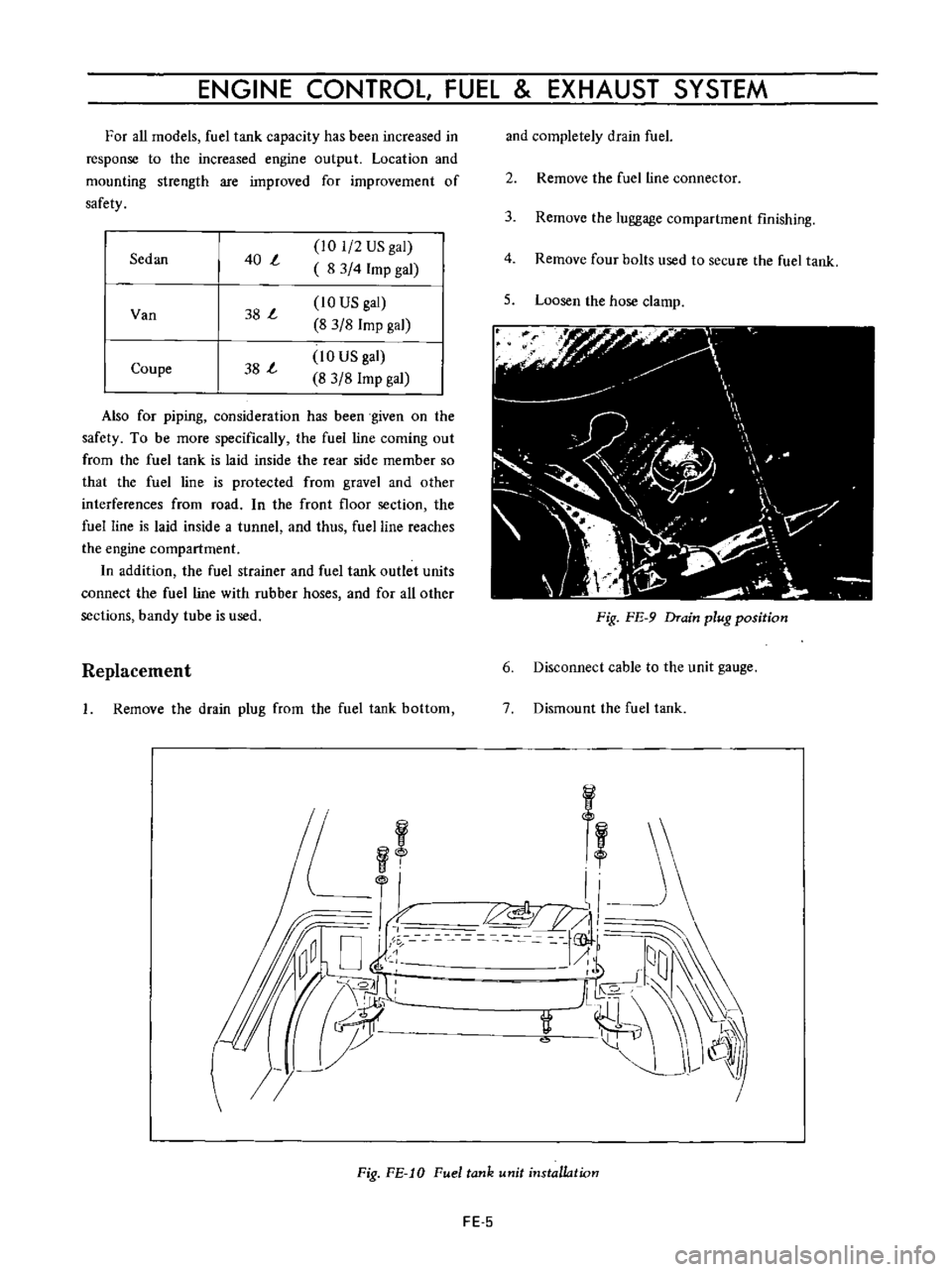

Fig

FE

9

Drain

plug

position

Replacement

Remove

the

drain

plug

from

the

fuel

tank

bottom

6

Disconnect

cable

to

the

unit

gauge

7

Dismount

the

fuel

tank

f

I

Y

L

ll

C

jjhrr

@

Fig

FE

10

Fuel

tank

14nit

installation

FE

5

Page 206 of 513

BODY

Fig

BF

24

Adjusting

dove

tail

bolt

Notes

When

inspecting

the

hood

lock

note

the

following

a

Check

to

be

sure

that

dove

tail

bolt

retaining

nut

VI

is

tightened

securly

with

specified

tightening

torque

b

Check

catcher

of

the

safety

catch

lever

for

wear

and

the

spring

ID

I

for

weakness

and

break

If

the

spring

is

broken

the

hood

may

be

unlocked

and

rapidly

open

during

driving

c

Check

the

female

lever

for

smooth

and

conect

operation

and

the

spring

@

for

weakness

and

break

If

the

female

lever

does

not

mova

smoothly

angaging

stroka

with

tha

dove

tail

bolt

will

ba

reduced

and

it

may

be

disengaged

d

Measure

the

di

S6

to

check

the

dimension

A

The

dimension

B

should

be

mora

than

8

5

mm

10

335

in

BF

16

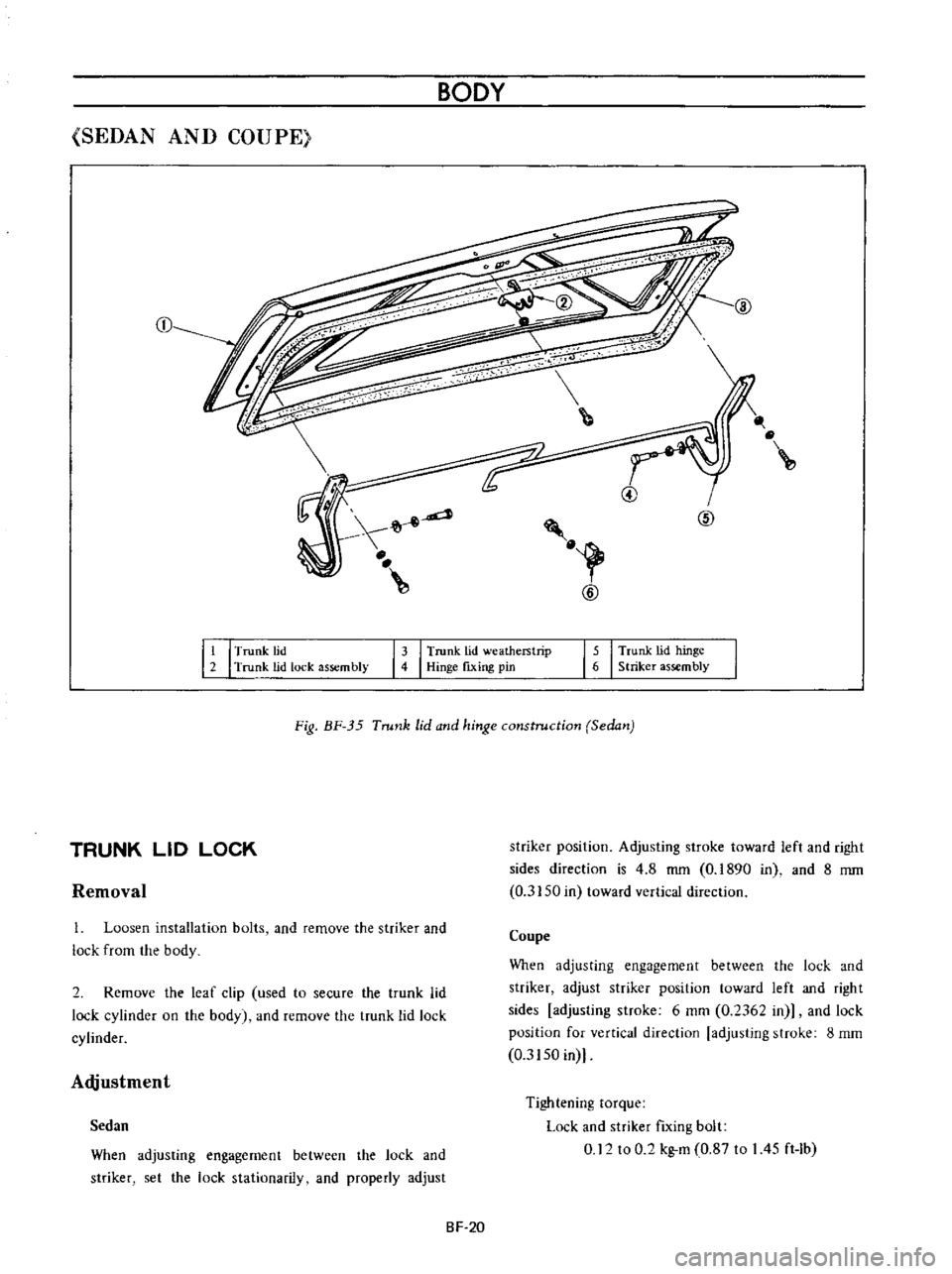

GAUGE

r

B

A

A

5

0

mm

0

197

in

B

8

5

mm

0

335

in

Fig

BF

25

Saftey

catch

ever

position

Lubrication

When

check

or

adjust

the

hood

lock

lubricate

the

pivot

catcher

and

return

spring

ID

of

the

safety

catch

lever

@

thoroughly

Also

lubricate

the

lever

of

the

hood

lock

femel

ID

for

smooth

and

correct

operation

See

Figure

BF

26

LUBRICATING

POINT

Fig

BF

26

Lubricating

points

Page 210 of 513

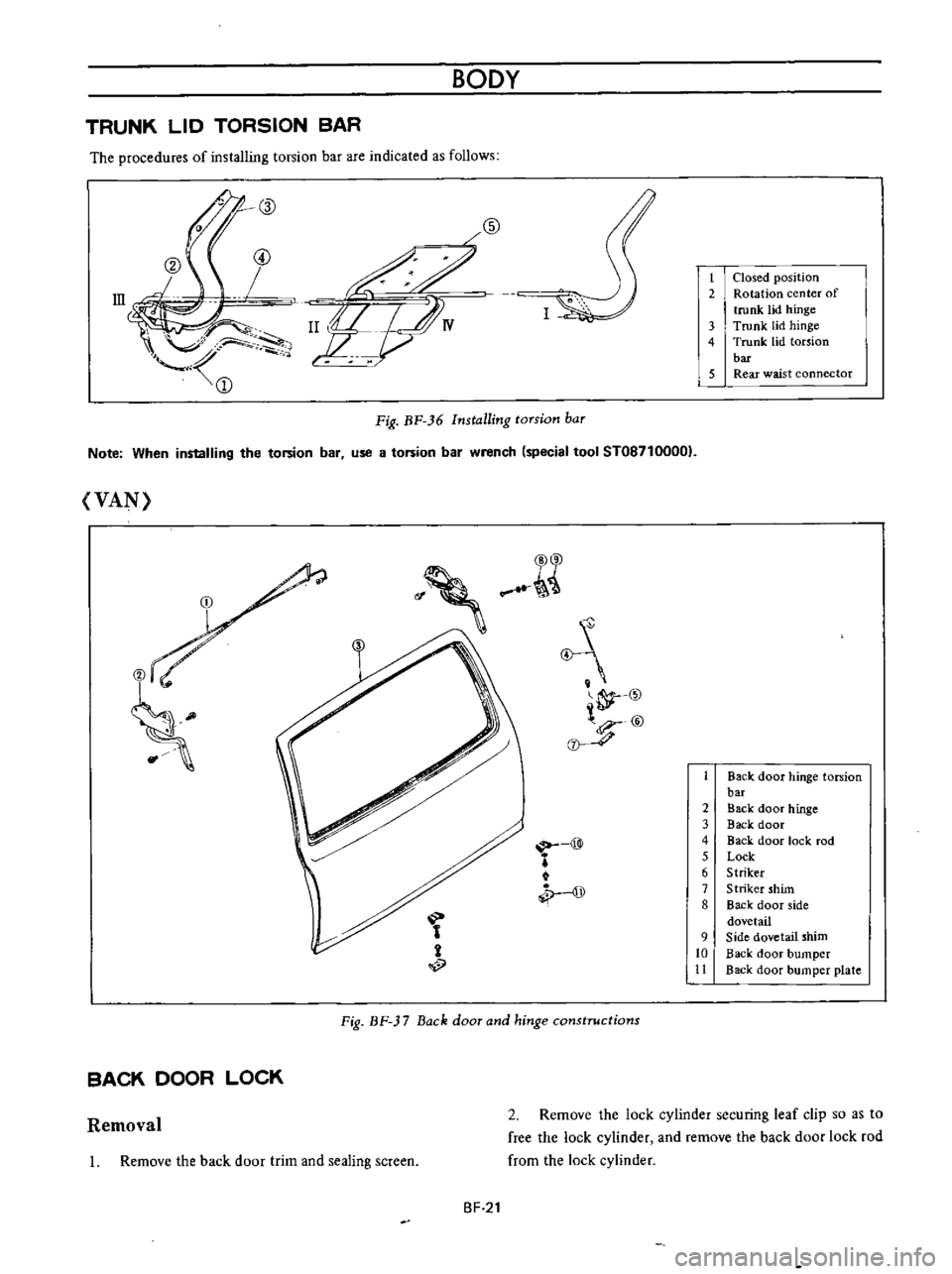

BODY

SEDAN

AND

COUPE

CD

@

h

r

1

@

@

II

I

Trunk

lid

2

Trunk

lid

lock

assembly

13

I

Trunk

lid

weatherstrip

4

Hinge

fixing

pin

15

I

Trunk

lid

hinge

6

Striker

assembly

Fig

BF

35

Trunk

lid

and

hinge

construction

Sedan

Removal

striker

position

Adjusting

stroke

toward

left

and

right

sides

direction

is

4

8

mm

0

1890

in

and

8

mm

0

3150

in

toward

vertical

direction

TRUNK

LID

LOCK

1

Loosen

installation

bolts

and

remove

the

striker

and

lock

from

the

body

Coupe

When

adjusting

engagement

between

the

lock

and

striker

adjust

striker

position

toward

left

and

right

sides

adjusting

stroke

6

mm

0

2362

in

and

lock

position

for

vertical

direction

adjusting

stroke

8

mm

0

3150

in

2

Remove

the

leaf

clip

used

to

secure

the

trunk

lid

lock

cylinder

on

the

body

and

remove

the

trunk

lid

lock

cylinder

Adjustment

When

adjusting

engagement

between

the

lock

and

striker

set

the

lock

stationarily

and

properly

adjust

Tightening

torque

Lock

and

striker

fIxing

bolt

0

12

to

0

2

kg

m

0

87

to

I

45

ft

Ib

Sedan

SF

20

Page 211 of 513

BODY

TRUNK

LID

TORSION

BAR

The

procedures

of

installing

torsion

bar

are

indicated

as

follows

ill

ID

f

Jw

V

@

@

Fig

BF

36

Installing

torsion

bar

1

Closed

position

2

Rotation

center

of

trunk

lid

hinge

3

Trunk

lid

hinge

4

Trunk

lid

torsion

bar

5

Rear

waist

connector

Note

When

installing

the

to

ion

bar

use

to

ion

bar

wrench

special

tool

ST087100001

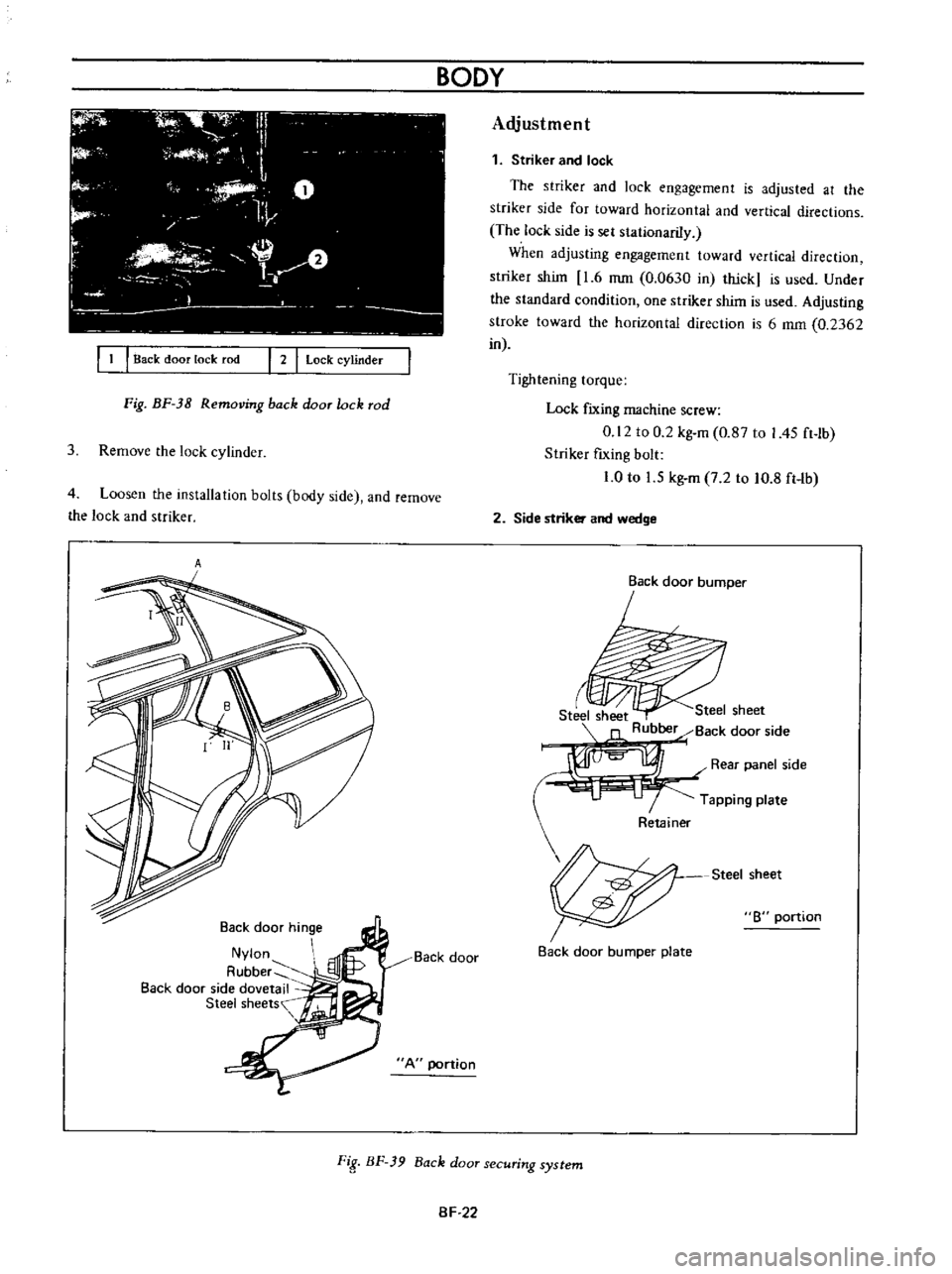

VAN

t

9

@

i

Fig

BF

37

Back

door

and

hinge

constructions

BACK

DOOR

LOCK

1

Back

door

hinge

torsion

bar

2

Back

door

hinge

3

Back

door

4

Back

door

lock

rod

5

Lock

6

Striker

7

Striker

shim

8

Back

door

side

dovetail

9

Side

dovetail

shim

10

Back

door

bumper

11

Back

door

bumper

plate

Removal

2

Remove

the

lock

cylinder

securing

leaf

clip

so

as

to

free

the

lock

cylinder

and

remove

the

back

door

lock

rod

from

the

lock

cylinder

I

Remove

the

back

door

trim

and

sealing

screen

BF

21

Page 212 of 513

I

1

I

Back

door

lock

rod

I

2

I

Lock

cylinder

Fig

BF

38

Removing

back

door

lock

rod

3

Remove

the

lock

cylinder

4

Loosen

the

installation

bolts

body

side

and

remove

the

lock

and

striker

A

Back

door

hinge

Nylon

A

ubber

Back

door

side

dovetail

Steel

sheets

Back

door

A

portion

BODY

Adjustment

1

Striker

and

lock

The

striker

and

lock

engagement

is

adjusted

at

the

striker

side

for

toward

horizontal

and

vertical

directions

The

lock

side

is

sel

stationariIy

When

adjusting

engagement

toward

vertical

direction

striker

shim

1

6

mm

0

0630

in

thick

is

used

Under

the

standard

condition

one

striker

shim

is

used

Adjusting

stroke

toward

the

horizontal

direction

is

6

mm

0

2362

in

Tightening

torque

Lock

fIXing

machine

screw

0

12

to

0

2

kg

m

0

87

to

I

45

ft

lb

Striker

fIxing

bolt

1

0

to

1

5

kg

m

7

2

to

10

8

ft

Ib

2

Side

striker

and

wedge

Back

door

bumper

r

Steel

sheet

Steel

sheet

Rubber

Back

door

side

I

Rear

panel

side

Tapping

plate

Steel

sheet

8

portion

Back

door

bumper

plate

FiS

BF

39

Back

door

securing

system

SF

22

Page 213 of 513

n

order

to

secure

the

back

door

in

the

position

adjust

the

position

in

accordance

with

the

following

instruc

tions

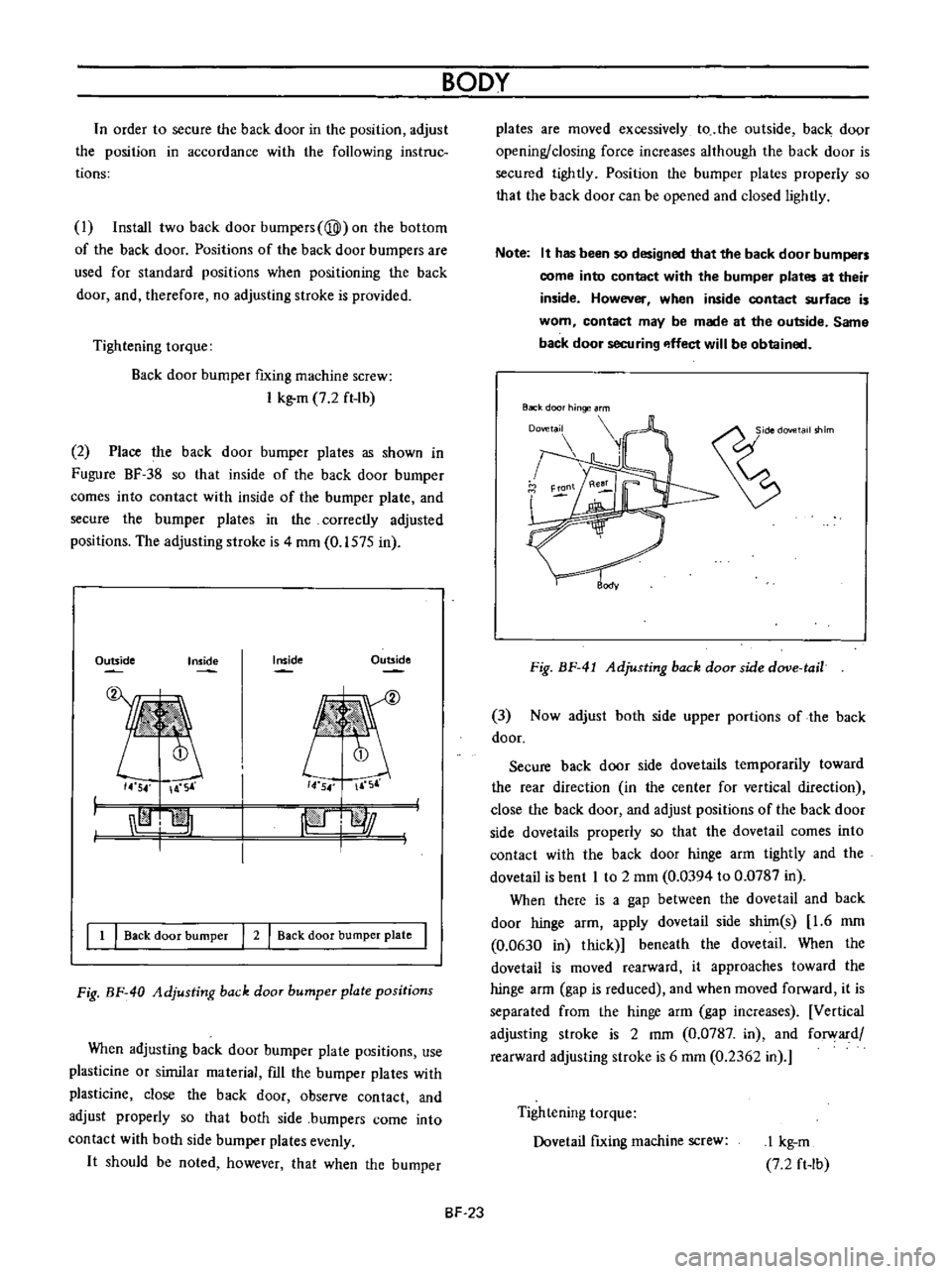

I

Install

two

back

door

bumpers

@

on

the

bottom

of

the

back

door

Positions

of

the

back

door

bumpers

are

used

for

standard

positions

when

positioning

the

back

door

and

therefore

no

adjusting

stroke

is

provided

Tightening

torque

Back

door

bumper

fixing

machine

screw

I

kg

m

7

2

ft

lb

2

Place

the

back

door

bumper

plates

as

shown

in

Fugure

BF

38

so

that

inside

of

the

back

door

bumper

comes

into

contact

with

inside

of

the

bumper

plate

and

secure

the

bumper

plates

in

the

correctly

adjusted

positions

The

adjusting

stroke

is

4

mm

0

1575

in

Outside

Inside

Outside

Inside

14

54

A

S

14

54

F

r

I

I

jpiJ

l

l

j

I

1

I

Back

door

bumper

I

2

I

Back

door

bumper

plate

I

Fig

BF

40

Adjusting

back

door

bumper

plate

positions

When

adjusting

back

door

burnper

plate

positions

use

plasticine

or

sirnilar

material

fIll

the

bumper

plates

with

plasticine

close

the

back

door

observe

contact

and

adjust

properly

so

that

both

side

bumpers

come

into

contact

with

both

side

bumper

plates

evenly

It

should

be

noted

however

that

when

the

bumper

BODY

BF

23

plates

are

moved

excessively

to

the

outside

back

door

opening

closing

force

increases

although

the

back

door

is

secured

tightly

Position

the

bumper

plates

properly

so

that

the

back

door

can

be

opened

and

closed

lightly

Note

It

has

been

so

designed

that

the

back

door

bumpers

come

into

contact

with

the

bumper

plates

at

their

inside

However

when

inside

contact

surface

is

worn

contact

may

be

made

at

the

outside

Same

back

door

securing

p

ffect

will

be

obtained

Back

door

hinge

rm

Fig

BF

41

Adjusting

back

door

side

dove

tail

3

Now

adjust

both

side

upper

portions

of

the

back

door

Secure

back

door

side

dovetails

temporarily

toward

the

rear

direction

in

the

center

for

vertical

direction

close

the

back

door

and

adjust

positions

of

the

back

door

side

dovetails

properly

so

that

the

dovetail

comes

into

contact

with

the

back

door

hinge

arm

tightly

and

the

dovetail

is

bent

I

to

2

mm

0

0394

to

0

0787

in

When

there

is

a

gap

between

the

dovetail

and

back

door

hinge

arm

apply

dovetail

side

shim

s

1

6

mm

0

0630

in

thick

beneath

the

dovetail

When

the

dovetail

is

moved

rearward

it

approaches

toward

the

hinge

arm

gap

is

reduced

and

when

moved

forward

it

is

separated

from

the

hinge

arrn

gap

increases

Vertical

adjusting

stroke

is

2

mm

0

0787

in

and

forward

rearward

adjusting

stroke

is

6

mm

0

2362

in

Tightening

torque

Dovetail

fIxing

machine

screw

I

kg

m

7

2

ft

Ib

Page 214 of 513

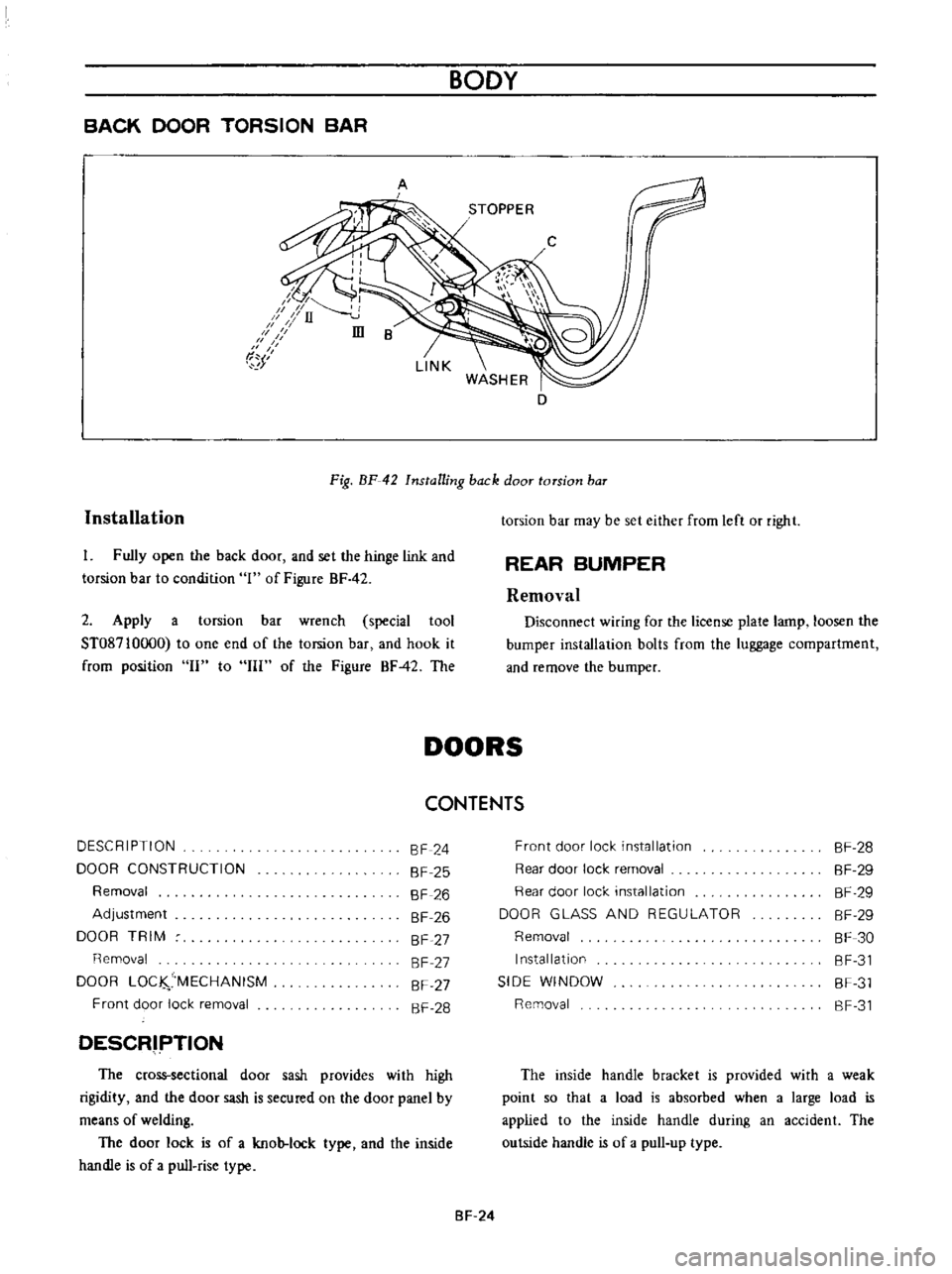

BACK

DOOR

TORSION

BAR

BODY

A

D

Installation

Fig

BF

42

Installing

back

door

torsion

baT

I

Fully

open

the

back

door

and

set

the

hinge

link

and

torsion

bar

to

condition

1

of

Figure

BF

42

2

Apply

a

torsion

bar

wrench

special

tool

ST08710oo0

to

one

end

of

the

torsion

bar

and

hook

it

from

position

II

to

III

of

the

Figure

BF42

The

torsion

bar

may

be

set

either

from

left

or

right

REAR

BUMPER

Removal

Disconnect

wiring

for

the

license

plate

lamp

loosen

the

bumper

installation

bolts

from

the

luggage

compartment

and

remove

the

bumper

DOORS

CONTENTS

DESCRIPTION

DOOR

CONSTRUCTION

Removal

Adjustment

DOOR

TRIM

Removal

DOOR

LOC

MECHANISM

Front

door

lock

removal

SF

24

SF

25

SF

26

SF

26

SF

27

SF

27

SF

27

SF

28

DESCRIPTION

The

cross

sectional

door

sash

provides

with

high

rigidity

and

the

door

sash

is

secured

on

the

door

panel

by

means

of

welding

The

door

lock

is

of

a

knob

lock

type

and

the

inside

handle

is

of

a

pull

rise

type

Front

door

lock

installation

Rear

door

lock

removal

Rear

door

lock

installation

DOOR

GLASS

AND

REGULATOR

Removal

Installation

SIDE

WINDOW

Removal

SF

28

SF

29

SF

29

SF

29

SF

30

SF

31

SF

31

SF

31

The

inside

handle

bracket

is

provided

with

a

weak

point

so

that

a

load

is

absorbed

when

a

large

load

is

applied

to

the

inside

handle

during

an

accident

The

outside

handle

is

of

a

pull

up

type

SF

24