ECU DATSUN B110 1973 Service Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 120 of 513

REAR

AXLE

REAR

SUSPENSION

DESCRIPTION

Rear

suspension

consists

of

semi

elliptic

leaf

springs

telescopic

hydraulic

shock

absorbers

and

rubber

bumpers

The

rear

spring

center

pin

is

off

set

110

mm

4

33

in

toward

the

front

from

the

center

of

the

spring

This

is

done

to

reduce

spring

wind

up

and

to

decrease

the

arc

while

the

rear

wheel

swings

through

Thereby

minimizing

the

possibility

of

the

rear

suspension

effecting

vehicle

stability

Iso

clamp

devices

are

used

for

attaching

the

axle

housing

to

the

spring

The

leaf

springs

shock

absorbers

and

rear

axle

housing

are

mounted

on

rubber

bushings

at

each

end

to

minimize

noise

and

vibration

of

the

transmission

to

the

car

body

and

passenger

compartment

REAR

SPRING

Removal

1

Jack

up

the

center

of

the

rear

axle

until

the

wheels

are

clear

from

the

ground

Support

the

rear

end

of

the

frame

on

stands

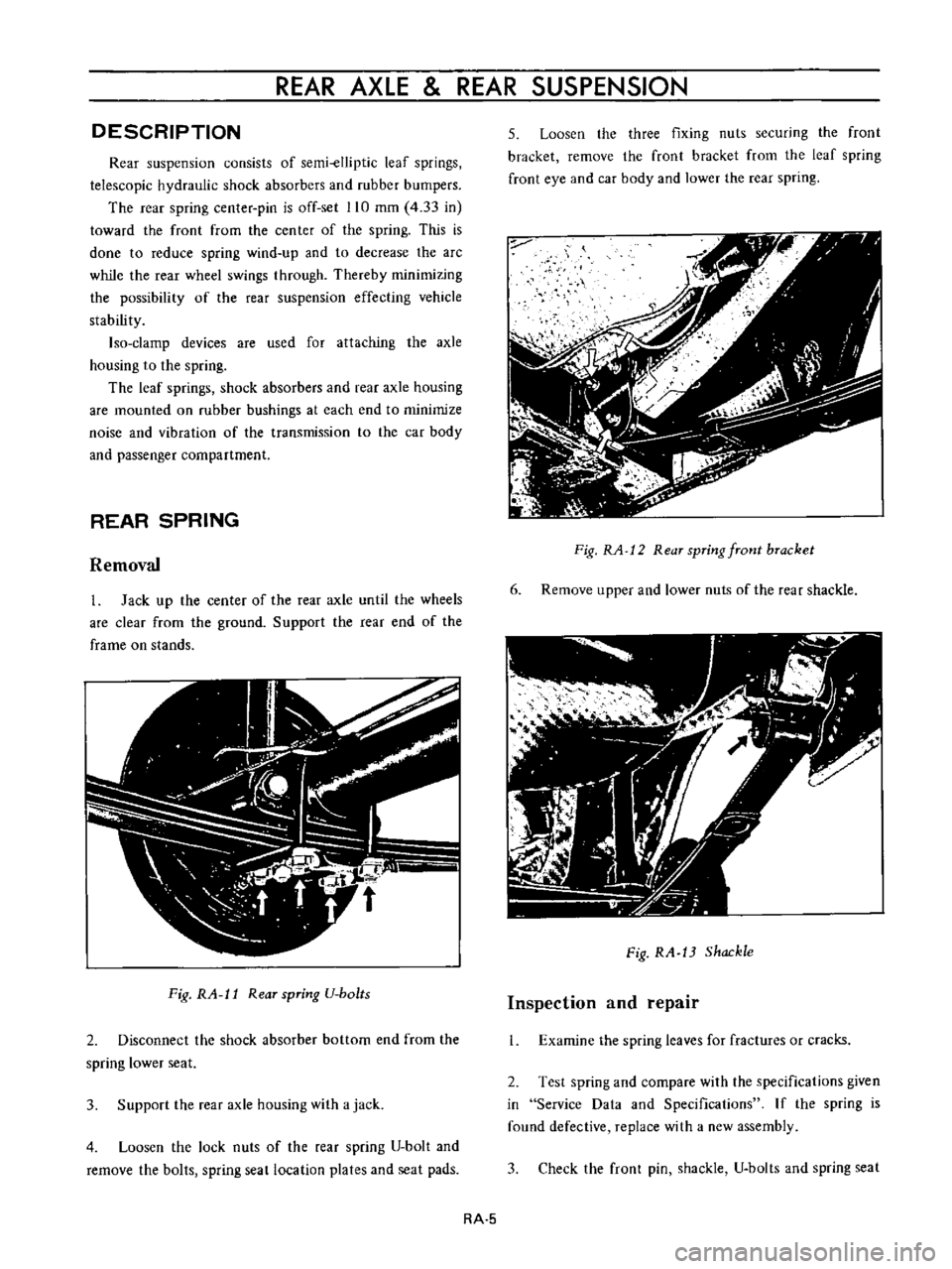

Fig

RA

l1

Rear

spring

U

bo

ts

2

Disconnect

the

shock

absorber

bottom

end

from

the

spring

lower

seat

3

Support

the

rear

axle

housing

with

a

jack

4

Loosen

the

lock

nuts

of

the

rear

spring

U

bolt

and

remove

the

bolts

spring

seat

location

plates

and

seat

pads

5

Loosen

the

three

fixing

nuts

securing

the

front

bracket

remove

the

front

bracket

from

the

leaf

spring

front

eye

and

car

body

and

lower

the

rear

spring

Fig

RA

12

Rear

spring

front

bracket

6

Remove

upper

and

lower

nuts

of

the

rear

shackle

Fig

RA

13

Shackle

Inspection

and

repair

1

Examine

the

spring

leaves

for

fractures

or

cracks

2

Test

spring

and

compare

with

the

specifications

given

in

Service

Data

and

Specifications

If

the

spring

is

found

defective

replace

with

a

new

assembly

3

Check

the

front

pin

shackle

U

bolts

and

spring

seat

RA

5

Page 121 of 513

CHASSIS

for

wear

cra

ks

straightness

and

damaged

thread

s

If

defective

parts

are

found

replace

with

new

ones

4

Inspect

all

rubber

pans

for

wear

damage

separation

and

deformation

Replace

them

if

necessary

Installation

Install

the

rear

spring

in

reverse

sequence

of

removal

noting

the

following

matters

Coat

the

front

bracket

pin

front

bracket

bushing

shackle

pin

and

shackle

bushing

with

a

soap

solution

prior

to

assembly

2

The

front

pin

securing

nut

and

shock

absorber

lower

end

securing

nut

should

be

tightened

with

the

vehicle

unladen

Note

Make

sure

that

the

flange

of

the

shackle

bushing

is

clamped

evenly

on

both

sides

REAR

SHOCK

ABSORBER

Replacement

lack

up

the

center

of

the

rear

axle

and

support

the

axle

housing

with

stands

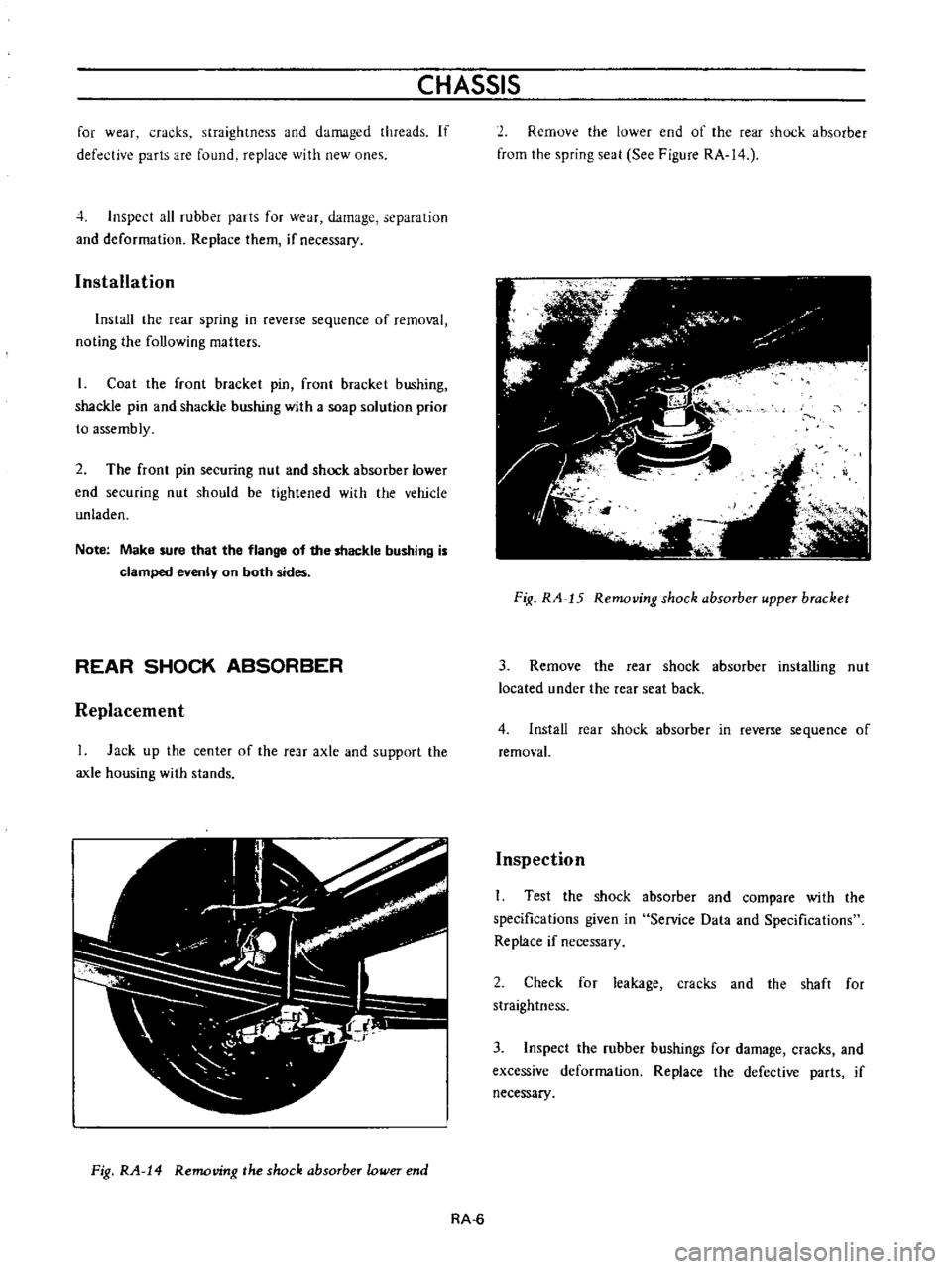

Fig

RA

14

Removing

the

shock

absorber

ower

end

2

Remove

the

lower

end

of

the

rear

shock

absorber

from

the

spring

seat

See

Figure

RA

14

FiK

RA

15

Removing

shock

absorber

upper

bracket

3

Remove

the

rear

shock

absorber

installing

nut

located

under

the

rear

seat

back

4

Install

rear

shock

absorber

in

reverse

sequence

of

removal

Inspection

Test

the

shock

absorber

and

compare

with

the

specifications

given

in

Service

Data

and

Specifications

Replace

if

necessary

2

Check

for

leakage

cracks

and

the

shafl

for

straightness

3

Inspect

the

rubber

bushings

for

damage

cracks

and

excessive

deformation

Replace

the

defective

parts

jf

necessary

RA

6

Page 129 of 513

Removal

and

disassembly

The

single

master

cylinder

is

removed

and

disassembled

in

the

same

manner

as

the

tandem

type

master

cylinder

Inspection

Refer

to

the

section

covering

Inspection

of

tandem

type

master

cylinder

Reassembly

and

reinstallation

The

single

master

cylinder

is

reassembled

and

re

BRAKE

installed

in

the

same

manner

as

the

tandem

type

master

cylinder

BRAKE

LINE

The

bl1lke

pipe

adopts

a

double

wall

construction

steel

tubing

and

with

this

construction

lhe

rigidily

has

been

improved

Moreover

the

portion

of

brake

line

laid

beneath

the

vehicle

floor

is

galvanized

improving

the

corrosion

resistance

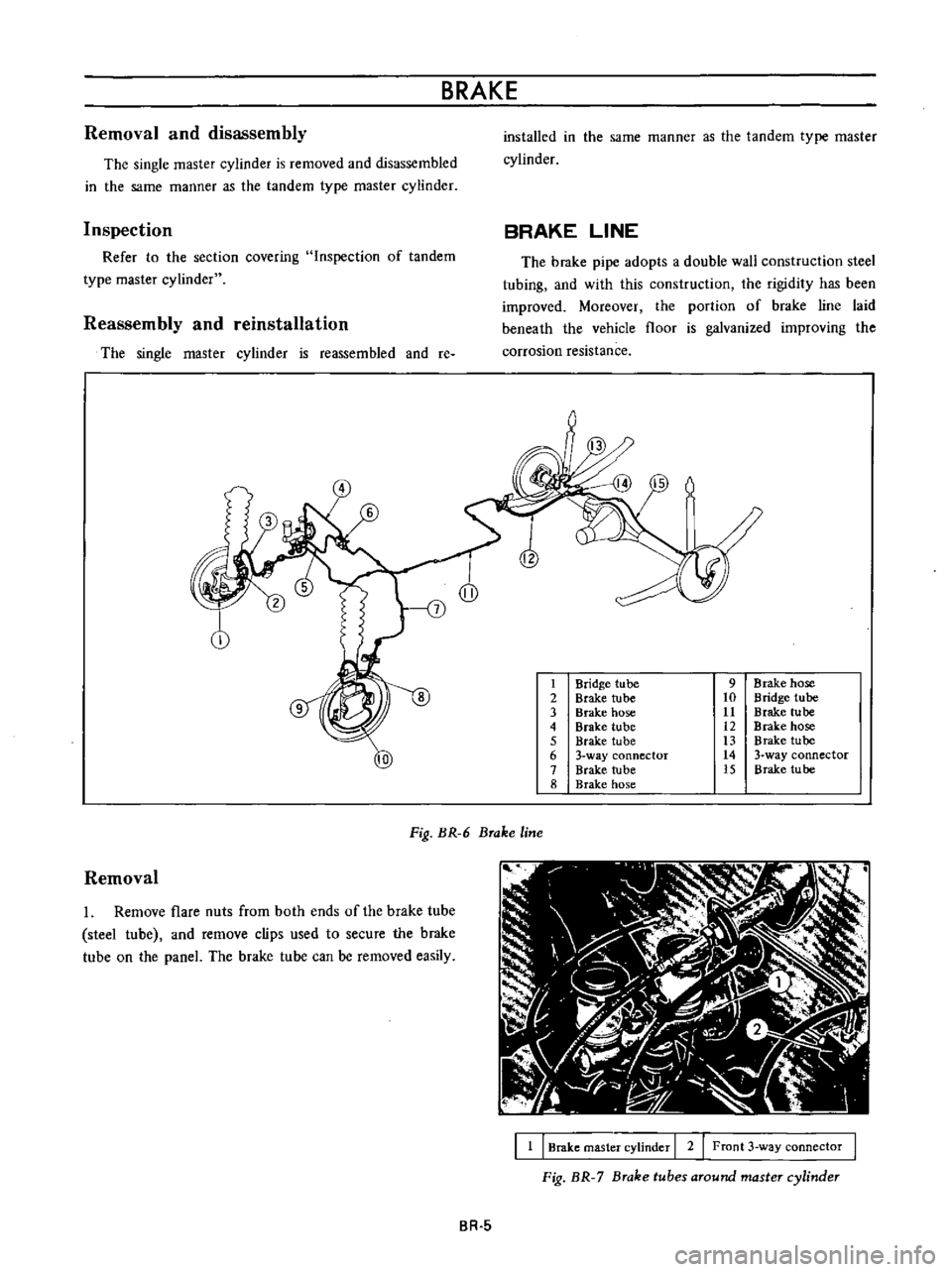

1

Bridge

tube

9

Brake

hose

2

Brake

tube

10

Bridge

tube

3

Brake

hose

11

Brake

tube

4

Brake

tube

12

Brake

hose

5

Brake

tube

13

Brake

tube

10

6

3

way

connector

14

3

way

connector

7

Brake

tube

15

Brake

tu

be

8

Brake

hose

Fig

BR

6

Brake

line

Removal

1

Remove

flare

nuts

from

both

ends

of

the

brake

tube

steel

tube

and

remove

clips

used

to

secure

the

brake

tube

on

the

paneL

The

brake

tube

can

be

removed

easily

I

1

I

Brake

master

cylinder

I

2

Front

3

way

connector

Fig

BR

7

Brake

tubes

around

master

cylinder

BR

5

Page 136 of 513

CHASSIS

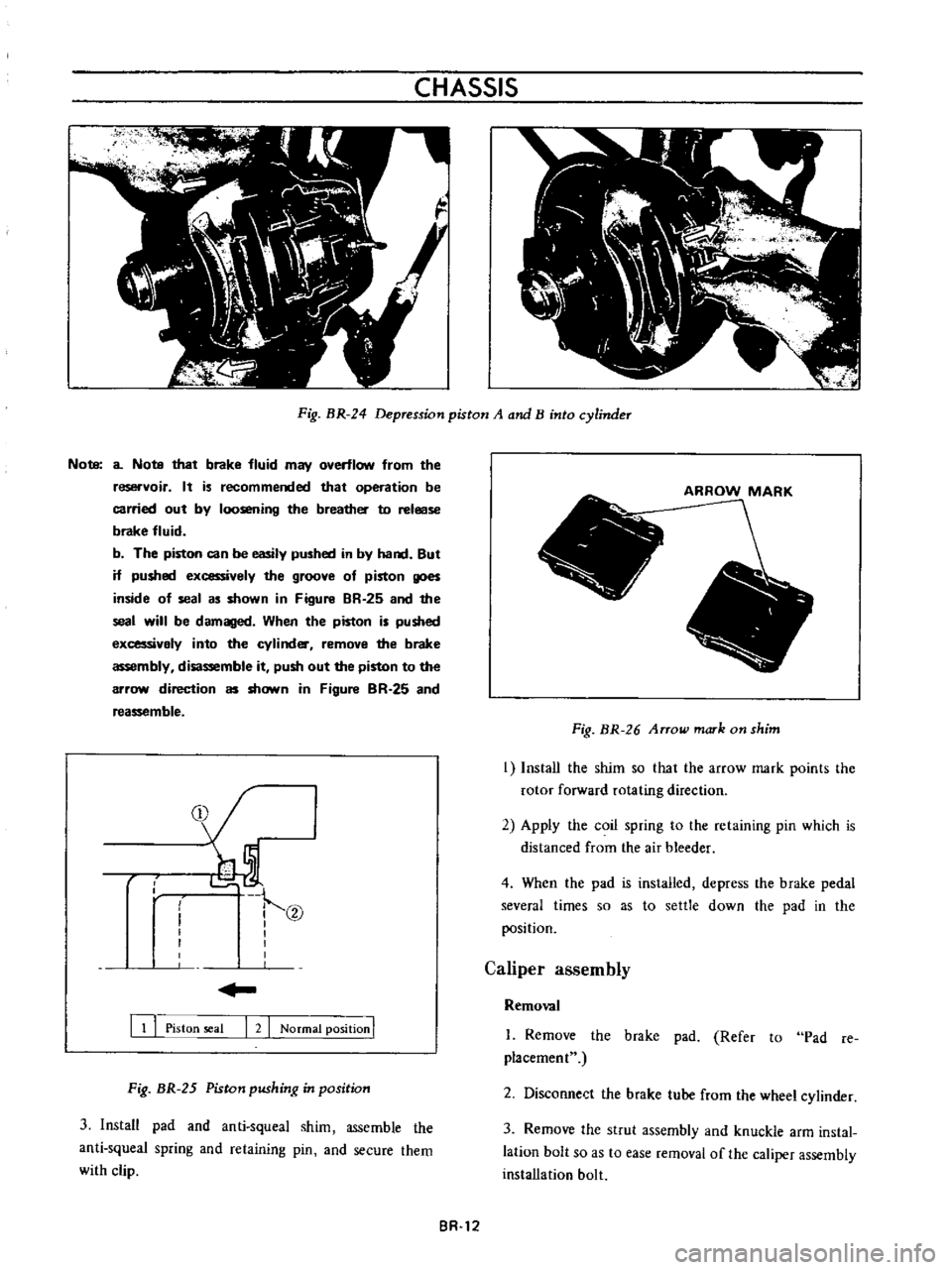

Fig

BR

24

Depression

piston

A

and

B

into

cylinder

Nota

a

Nota

that

brake

fluid

may

overflow

from

the

reservoir

It

is

recommeooed

that

operation

be

carried

out

by

loosening

the

breather

to

release

brake

fluid

b

The

piston

can

be

easily

pushed

in

by

hand

But

if

pushed

excessively

the

groove

of

piston

goes

inside

of

seal

as

shown

in

Figure

BR

25

and

the

seal

will

be

damaged

When

the

piston

is

pushed

excessively

into

the

cylinder

remove

the

brake

assembly

disassemble

it

push

out

the

piston

to

the

arrow

direction

as

shown

in

Figure

BR

25

and

reassemble

r

w

i

@

I

I

I

I

i

I

I

I

1

I

1

1

Piston

ieat

1

2

I

Normal

position

I

Fig

BR

25

Piston

pushing

in

position

3

Install

pad

and

anti

squeal

shim

assemble

the

anti

squeal

spring

and

retaining

pin

and

secure

them

with

clip

ARROW

MARK

Fig

BR

26

Arrow

mark

on

shim

I

Install

the

shim

so

that

the

arrow

mark

points

the

rotor

forward

rotating

direction

2

Apply

the

coil

spring

to

the

retaining

pin

which

is

distanced

from

the

air

bleeder

4

When

the

pad

is

installed

depress

the

brake

pedal

several

times

so

as

to

settle

down

the

pad

in

the

position

Caliper

assembly

Removal

L

Remove

the

brake

pad

Refer

to

Pad

re

placement

2

Disconnect

the

brake

tube

from

the

wheel

cylinder

3

Remove

the

strut

assembly

and

knuckie

arm

instal

lation

bolt

so

as

to

ease

removal

of

the

caliper

assembly

installation

bolt

BR

12

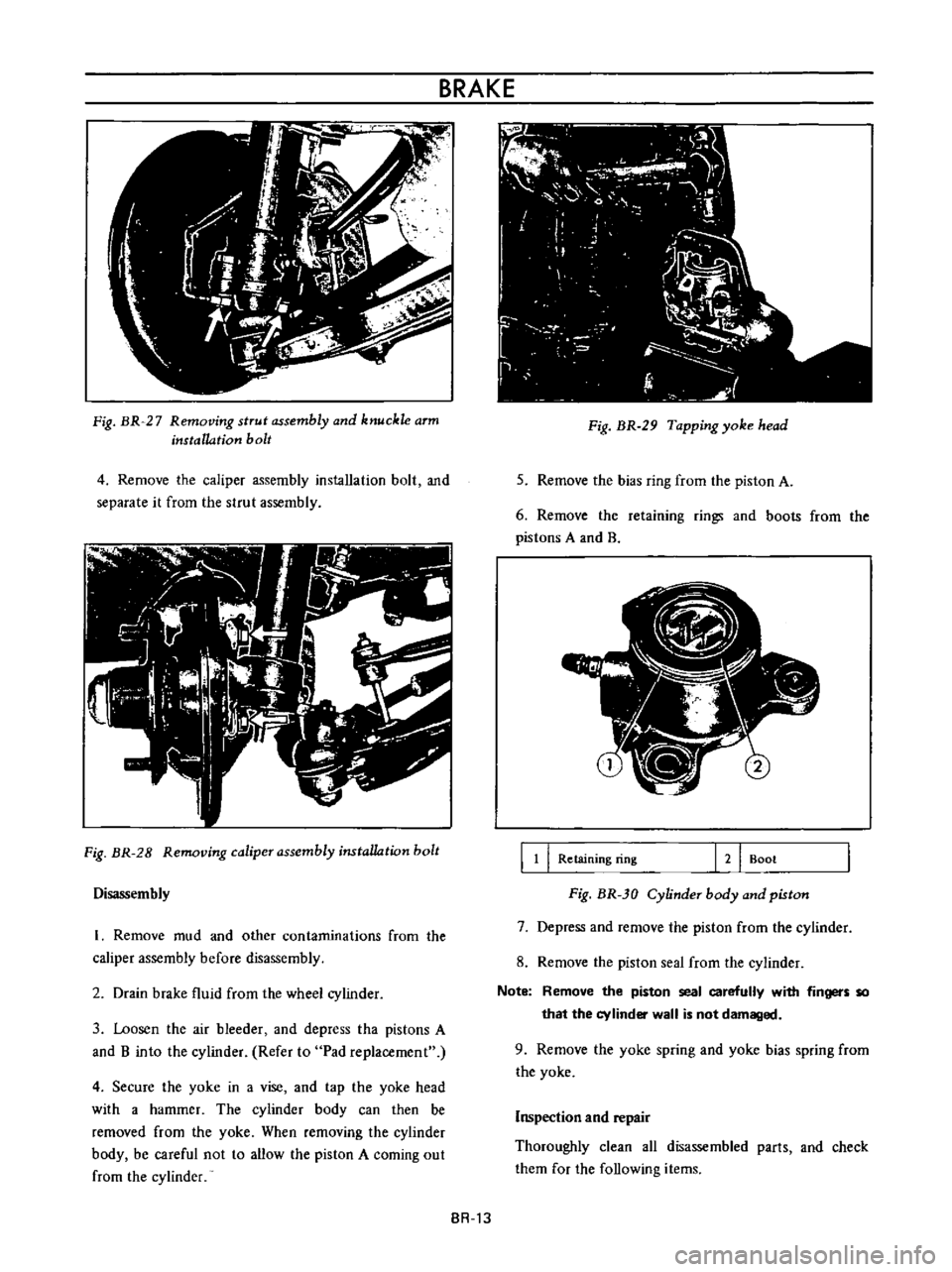

Page 137 of 513

BRAKE

Fig

BR

27

Removing

strut

assembly

and

knuckle

arm

installation

bolt

4

Remove

the

caliper

assembly

installation

bolt

and

separate

it

from

the

strut

assembly

Fig

BR

28

Removing

caliper

assembly

instaUation

bolt

Disassembly

I

Remove

mud

and

other

contaminations

from

the

caliper

assembly

before

disassembly

2

Drain

brake

fluid

from

the

wheel

cylinder

3

Loosen

the

air

bleeder

and

depress

tha

pistons

A

and

B

into

the

cylinder

Refer

to

Pad

replacement

4

Secure

the

yoke

in

a

vise

and

tap

the

yoke

head

with

a

hammer

The

cylinder

body

can

then

be

removed

from

the

yoke

When

removing

the

cylinder

body

be

careful

not

to

allow

the

piston

A

coming

out

from

the

cylinder

BR

13

i

c

J

l

l

7

I

0

I

I

i

I

f

1

1

J

t

1

Fig

BR

29

Tapping

yoke

head

5

Remove

the

bias

ring

from

the

piston

A

6

Remove

the

retaining

rings

and

boots

from

the

pistons

A

and

B

J

l

lj

7

fI

II

l

j

B

11

I

Retaining

ring

121

Boot

Fig

BR

30

Cylinder

body

and

piston

7

Depress

and

remove

the

piston

from

the

cylinder

8

Remove

the

pislon

seal

from

the

cylinder

Note

Remove

the

piston

seal

carefully

with

fingers

so

that

the

cylinder

wall

is

not

damaged

9

Remove

the

yoke

spring

and

yoke

bias

spring

from

the

yoke

Inspection

and

repair

Thoroughly

clean

all

disassembled

parIs

and

check

them

for

the

following

items

Page 145 of 513

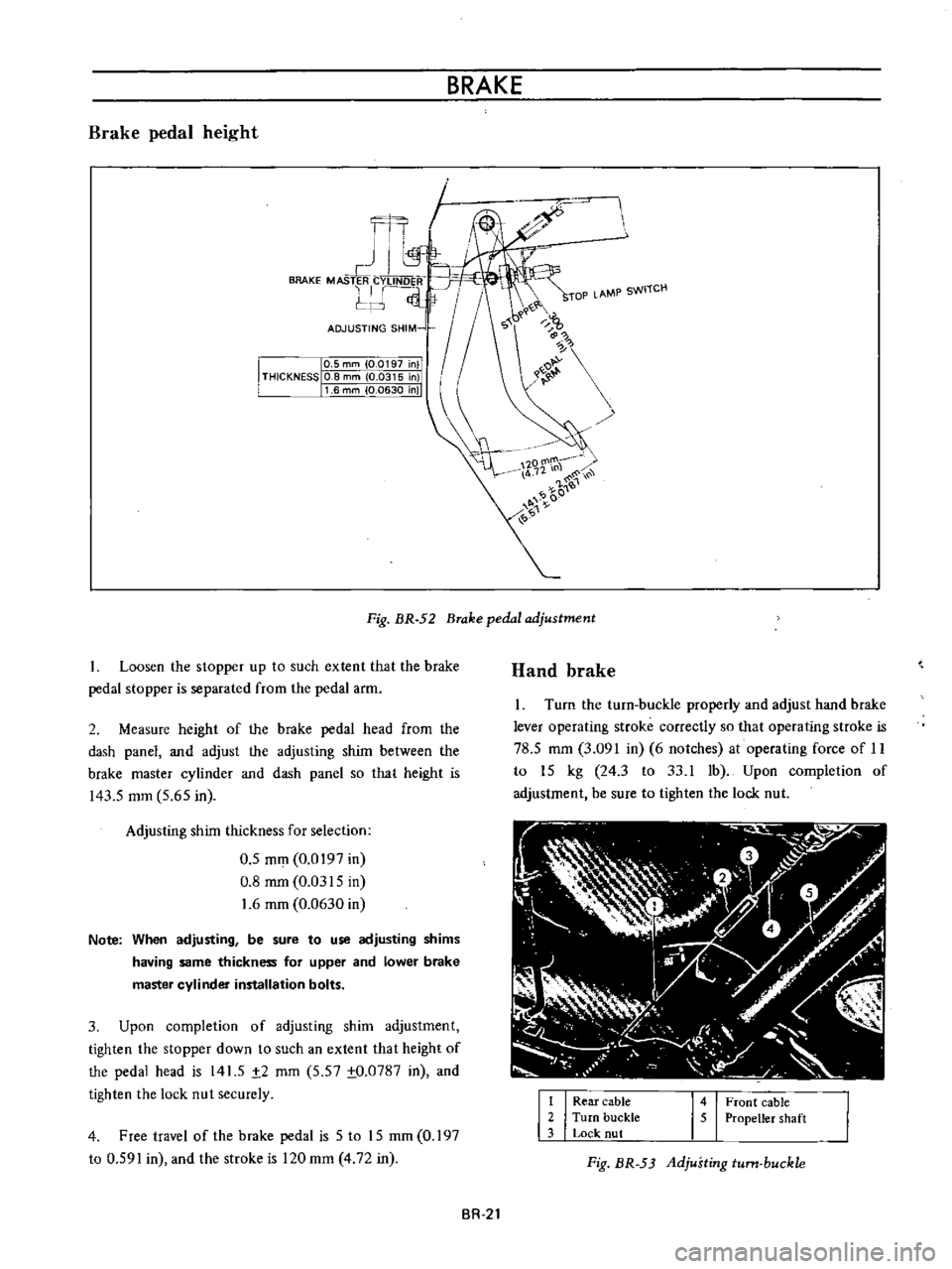

BRAKE

Brake

pedal

height

I

Fl

I

Jl

BRAKE

MASTER

CYllN

ADJU

SHI

1

I

195mm

001971011

THICKNESSIO

8

mm

00315

Inl

116mm

00630In

TOP

LAMP

SWrTCH

r

b

O

ZOlTlI

I

A

12

n

Y

1

O

09

ttr

i

l

Fig

BR

52

Brake

pedal

adjustment

1

Loosen

the

stopper

up

to

such

extent

that

the

brake

pedal

stopper

is

separated

from

the

pedal

arm

2

Measure

height

of

the

brake

pedal

head

from

the

dash

panel

and

adjust

the

adjusting

shim

between

the

brake

master

cylinder

and

dash

panel

so

that

height

is

143

5

mm

5

65

in

Adjusting

shim

thickness

for

selection

0

5

mm

0

0197

in

0

8

mm

0

0315

in

1

6

mm

0

0630

in

Note

When

adjusting

be

sure

to

use

adjusting

shims

having

same

thickness

for

upper

and

lower

brake

master

cylinder

installation

bolts

3

Upon

completion

of

adjusting

shim

adjustment

tighten

the

stopper

down

to

such

an

extent

that

height

of

the

pedal

head

is

141

5

t2

mm

5

57

to

0787

in

and

tighten

the

lock

nut

securely

4

Free

travel

of

the

brake

pedal

is

5

to

15

mm

0

197

to

0

591

in

and

the

stroke

is

120

mm

4

72

in

Hand

brake

Turn

the

turn

buckle

properly

and

adjust

hand

brake

lever

operating

stroke

correctly

so

that

operating

stroke

is

78

5

mm

3

091

in

6

notches

at

operating

force

of

11

to

15

kg

24

3

to

33

1

1b

Upon

completion

of

adjustment

be

sure

to

tighten

the

lock

nut

I

I

Rear

cable

2

Turn

buckle

3

Lock

nut

1451

Front

cable

Propeller

shaft

Fig

BR

53

Adjusting

turn

buckle

BR

21

Page 155 of 513

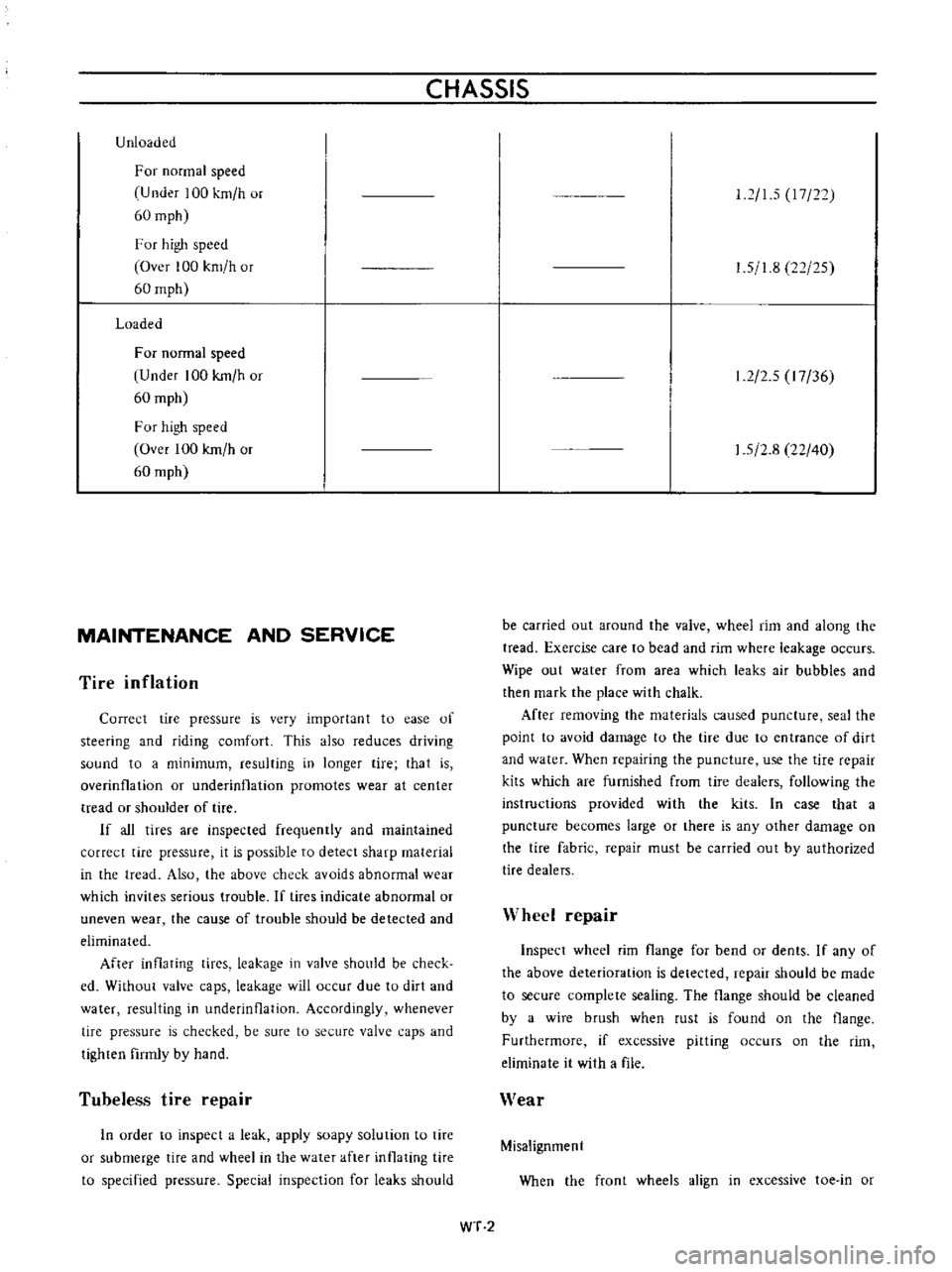

CHASSIS

Unloaded

For

normal

speed

U

nder

100

km

h

or

60

mph

F

or

high

speed

Over

100

km

h

or

60

mph

Loaded

For

normal

speed

Under

100

kmlh

or

60

mph

For

high

speed

Over

100

kmlh

or

60

mph

MAINTENANCE

AND

SERVICE

Tire

inflation

Correct

tire

pressure

is

very

importan

t

to

ease

of

steering

and

riding

comfort

This

also

reduces

driving

sound

to

a

minimum

resulting

in

longer

tire

that

is

overinfla

lion

or

underinflation

promotes

wear

at

center

tread

or

shoulder

of

tire

If

all

tires

are

inspected

frequently

and

maintained

correct

tire

pressure

it

is

possible

to

detect

sharp

material

in

the

tread

Also

the

above

check

avoids

abnormal

wear

which

invites

serious

trouble

If

tires

indicate

abnormal

or

uneven

wear

the

cause

of

trouble

should

be

detected

and

eliminated

After

inflating

tices

leakage

in

valve

should

be

check

cd

Without

valve

caps

leakage

will

occur

due

to

dirt

and

water

resulting

in

underinOation

Accordingly

whenever

tire

pressure

is

checked

be

sure

to

secure

valve

caps

and

tighten

firmly

by

hand

Tubeless

tire

repair

In

urder

to

inspect

a

leak

apply

soapy

solution

to

tire

or

submerge

tire

and

wheel

in

the

water

after

inflating

tire

to

specified

pressure

Special

inspection

for

leaks

should

12

15

17

22

1

5

1

8

22

25

1

2

2

5

I

7

36

1

5

2

8

22

40

be

carried

out

around

the

valve

wheel

rim

and

along

the

tread

Exercise

care

to

bead

and

rim

where

leakage

occurs

Wipe

out

water

from

area

which

leaks

air

bubbles

and

then

mark

the

place

with

chalk

After

remuving

the

materials

caused

puncture

seal

the

point

to

avoid

damage

to

the

tire

due

to

entrance

of

dirt

and

water

When

repairing

the

puncture

use

the

tire

repair

kits

which

are

furnished

from

tire

dealers

following

the

instructions

provided

with

the

kits

In

case

that

a

puncture

becomes

large

or

there

is

any

other

damage

on

the

tire

fabric

repair

must

be

carried

out

by

authorized

tire

dealers

Wheel

repair

Inspect

wheel

rim

flange

for

bend

or

dents

If

any

of

the

above

deterioration

is

detected

repair

should

be

made

to

secure

complete

sealing

The

flange

should

be

cleaned

by

a

wire

brush

when

rust

is

found

on

the

flange

Furthermore

if

excessive

pitting

occurs

on

the

rim

eliminate

it

with

a

file

Wear

Misalignment

When

the

front

wheels

align

in

excessive

toe

in

or

WT

2

Page 162 of 513

Iii

I

o

t

I

I

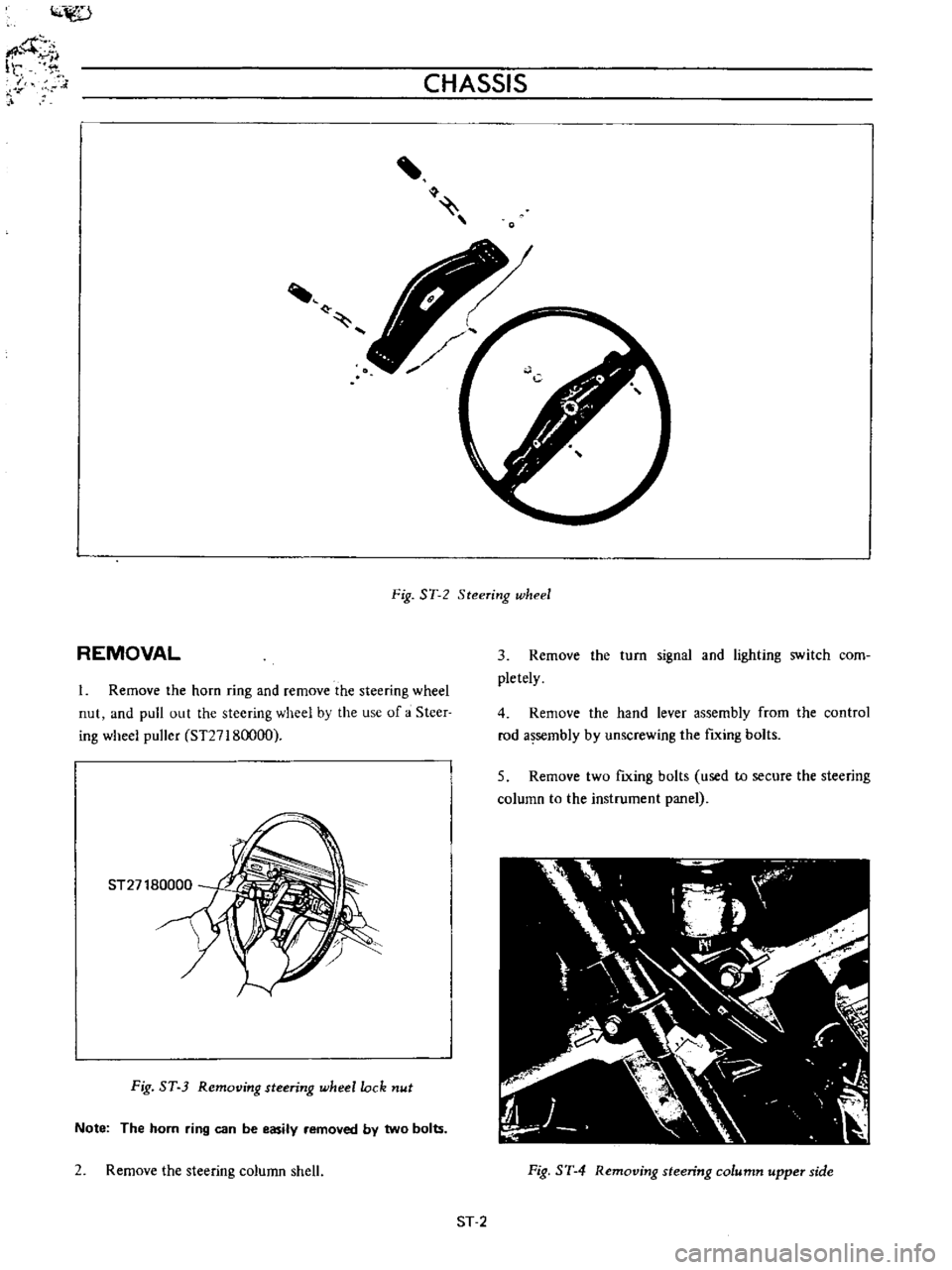

CHASSIS

Fig

ST

2

Steering

wheel

REMOVAL

1

Remove

the

horn

ring

and

remove

the

steering

wheel

nut

and

pull

out

the

steering

wheel

by

the

use

of

a

Steer

ing

wheel

puller

ST27180000

3

Remove

the

turn

signal

and

lighting

switch

com

pletely

4

Remove

the

hand

lever

assembly

from

the

control

rod

assembly

by

unscrewing

the

fIxing

bolts

5

Remove

two

fIxing

bolts

used

to

secure

the

steering

column

to

the

instrument

panel

ST27180000

Fig

ST

3

Removing

steering

wheel

lock

nut

Note

The

horn

ring

can

be

easily

removed

by

two

bolts

2

Remove

the

steering

column

shell

Fig

ST

4

Removing

steering

column

upper

side

ST

2

Page 163 of 513

STEERING

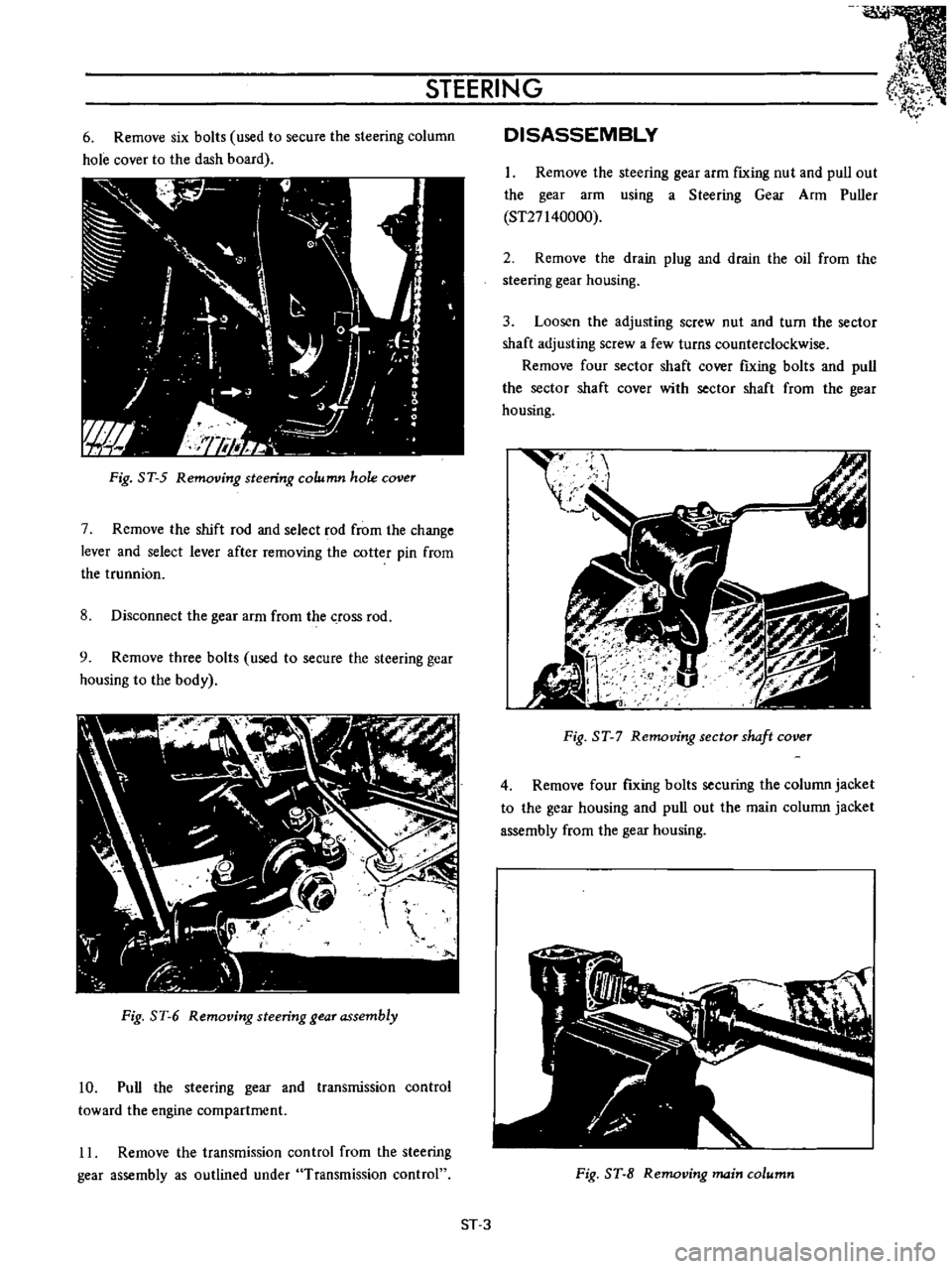

6

Remove

six

bolts

used

to

secure

the

steering

column

hole

cover

to

the

dash

board

Fig

ST

5

Removing

steering

column

hole

cover

7

Remove

the

shift

rod

and

select

rod

from

the

change

lever

and

select

lever

after

removing

the

cotter

pin

from

the

trunnion

8

Disconnect

the

gear

arm

from

the

crOSS

rod

9

Remove

three

bolts

used

to

secure

the

steering

gear

housing

to

the

body

Fig

ST

6

Removing

steering

gear

assembly

10

Pull

the

steering

gear

and

transmission

control

toward

the

engine

compartment

11

Remove

the

transmission

control

from

the

steering

gear

assembly

as

outlined

under

Transmission

control

DISASSEMBLY

1

Remove

the

steering

gear

arm

fIxing

nut

and

pull

out

the

gear

arm

using

a

Steering

Gear

Arm

Puller

ST27140000

2

Remove

the

drain

plug

and

drain

the

oil

from

the

steering

gear

housing

3

Loosen

the

adjusting

screw

nut

and

turn

the

sector

shaft

adjusting

screw

a

few

turns

counterclockwise

Remove

four

sector

shaft

cover

fIxing

bolts

and

pull

the

sector

shaft

cover

with

sector

shaft

from

the

gear

housing

t

I

gJ

I

I

Fig

ST

7

Removing

sector

shaft

cover

4

Remove

four

fIxing

bolts

securing

the

column

jacket

to

the

gear

housing

and

pull

out

the

main

column

jacket

assembly

from

the

gear

housing

Fig

ST

8

Removing

main

column

ST

3

Page 171 of 513

STEERING

The

jacket

tube

is

of

a

mesh

and

a

part

of

which

is

punched

in

rhombus

forming

an

energy

absorbing

part

of

the

collapsible

steering

Upper

and

lower

guide

tubes

two

guide

tubes

joined

with

polyacetal

resin

are

inserted

into

the

mesh

tube

so

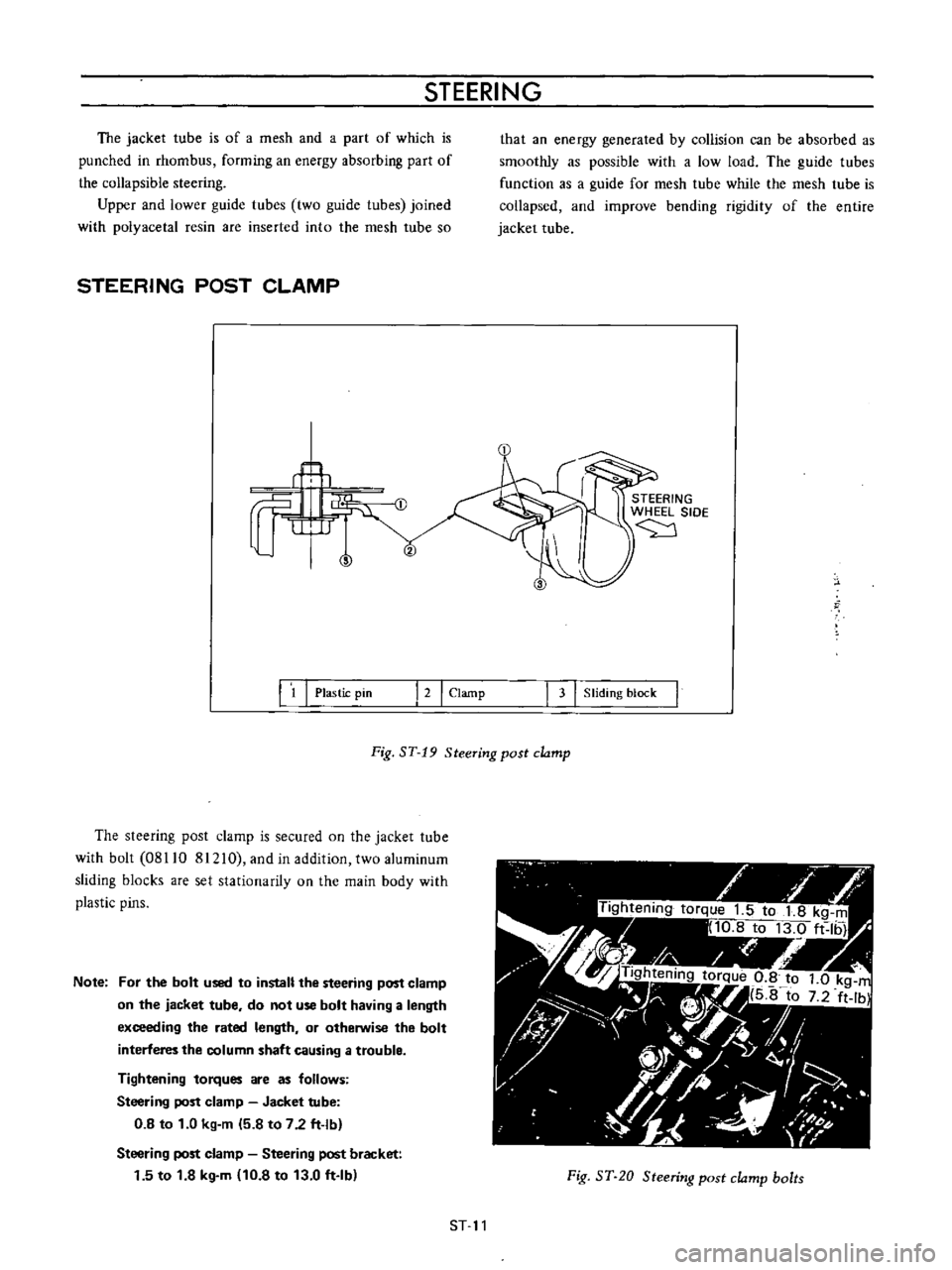

STEERING

POST

CLAMP

that

an

energy

generated

by

collision

can

be

absorbed

as

smoothly

as

possible

with

a

low

load

The

guide

tubes

function

as

a

guide

for

mesh

tube

while

the

mesh

tube

is

collapsed

and

improve

bending

rigidity

of

the

entire

jacket

tube

1

1

Plastic

pin

I

2

I

Clamp

1

3

I

Sliding

block

Fig

ST

19

Steering

post

clamp

The

steering

post

clamp

is

secured

on

the

jacket

tube

with

bolt

08110

81210

and

in

addition

two

aluminum

sliding

blocks

are

set

stationarity

on

the

main

body

with

plastic

pins

Note

For

the

bolt

used

to

install

the

steering

post

clamp

on

the

jacket

tube

do

not

use

bolt

having

a

length

exceeding

the

rated

length

or

otherwise

the

bolt

interferes

the

column

shaft

causing

a

trouble

Tightening

torques

are

as

follows

Steering

post

clamp

Jacket

tube

0

8

to

1

0

kg

m

5

8

to

7

2

ft

lb

Steering

post

clamp

Steering

post

bracket

1

5

to

1

8

kg

m

10

8

to

13

0

ft

Ib

Fig

ST

20

Steering

post

clamp

bolts

ST

11