ECU DATSUN B110 1973 Service Manual PDF

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 485 of 513

CLUTCH

Clogged

vent

hole

in

reservoir

cap

promotes

vacuum

in

master

cylinder

allowing

air

to

inf1ltrate

past

the

seal

Abnormal

lining

wear

Insufficient

pedal

free

travel

The

clutch

grabs

The

clutch

slips

Driver

steps

unnecessarily

on

pedal

this

causes

lin

jog

wear

and

damage

to

release

bearing

Weakened

or

snapped

pressure

springs

Incorrectly

installed

linings

Oil

or

grease

on

flywheel

pressure

plate

and

linings

Loose

disc

linings

due

to

poor

rivet

tightness

Clutch

disc

hub

does

not

slide

freely

on

drive

shaft

spline

Warped

or

cracked

pressure

plate

Misalignment

Stiffened

hydraulic

control

mechanism

Wom

out

lining

Insufficient

clutch

pedal

return

travel

due

to

the

control

and

pedal

return

springs

being

weak

or

misadjusted

Weakened

or

broken

diaphragm

spring

Oil

or

grease

on

linings

eLl5

Clean

reservoir

cap

unclog

the

vent

hole

and

bleed

the

system

Adjust

clutch

pedal

free

travel

correctly

Advise

driver

to

discontinue

wrong

practice

and

step

on

clutch

pedal

only

when

ne

cessary

Check

pressure

springs

for

tension

as

speci

fied

and

replace

springs

if

they

are

unserviceable

Replace

linings

with

new

ones

and

install

them

correctly

Check

clutch

disc

for

center

alignment

Remove

cause

of

leakage

clean

flywheel

and

pressure

plate

thoroughly

replace

linings

If

linings

are

not

worn

replace

defective

rivets

Otherwise

replace

linings

and

clench

rivets

securely

Remove

any

foreign

matter

or

dirt

deposits

from

shaft

splines

When

trouble

is

still

present

replace

damaged

parts

Replace

pressure

plate

Locate

the

defective

point

and

if

possible

adjust

alignment

or

replace

distorted

parts

Check

spring

tension

If

necessary

take

down

pedal

and

lubricate

components

Install

new

linings

and

make

sure

tha

t

the

clutch

disc

pressure

plate

and

flywheel

are

not

damaged

Locate

cause

of

failure

and

replace

defective

springs

Overhaul

clutch

and

replace

springs

Remove

cause

of

leakage

and

replace

linings

if

cleaning

is

ineffective

Page 490 of 513

TRANSMISSION

I

Jack

up

the

vehicle

and

support

it

with

four

stands

If

available

recommend

a

hydraulic

hoist

or

open

pit

be

utilized

2

Disconnect

the

front

exhaust

tube

D

from

the

exhaust

manifold

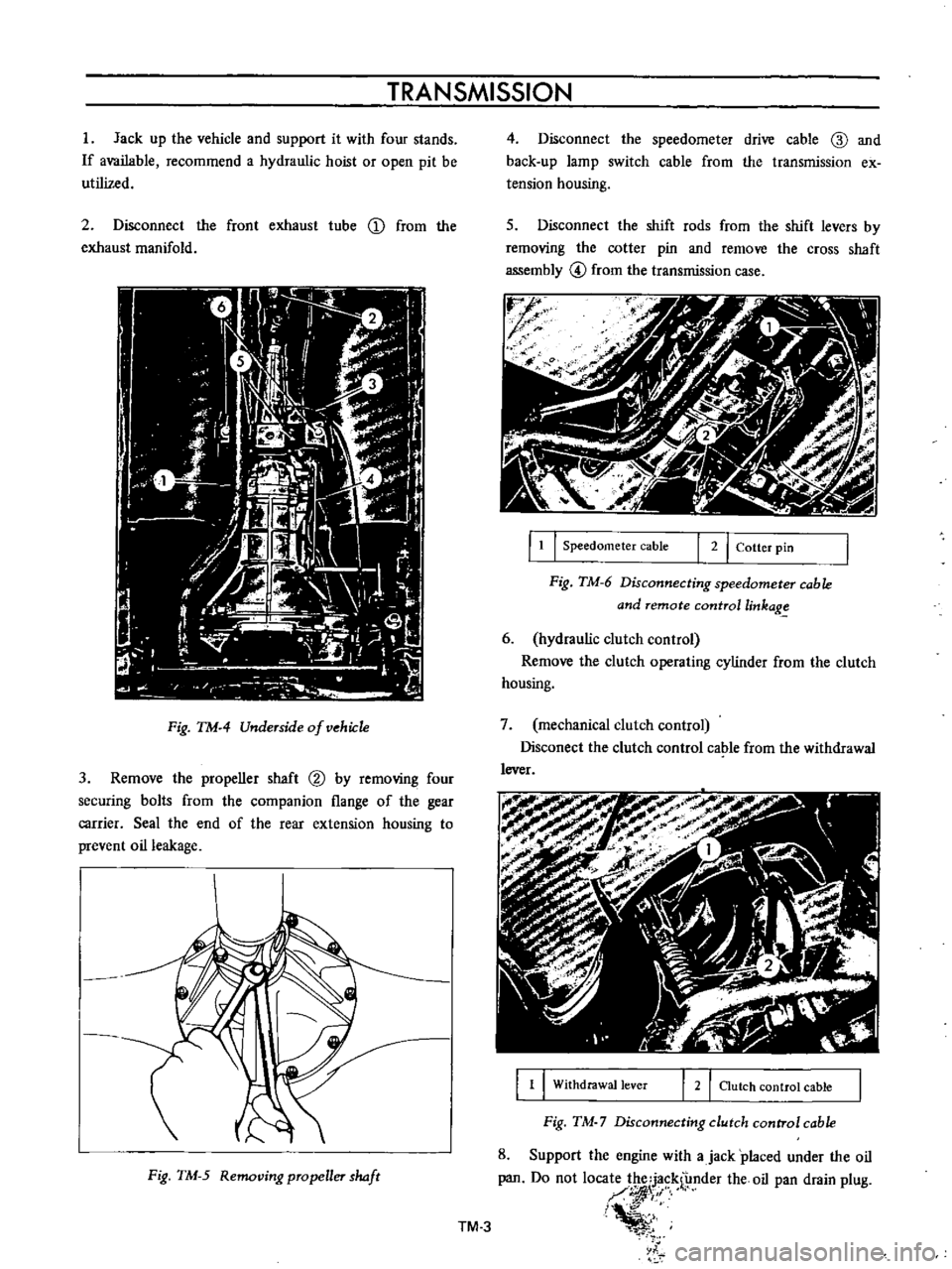

Fig

TM

4

Underside

of

vehiJ

1e

3

Remove

the

propeller

shaft

@

by

removing

four

securing

bolts

from

the

companion

flange

of

the

gear

carrier

Seal

the

end

of

the

rear

extension

housing

to

prevent

oil

leakage

Fig

TM

5

Removing

propeller

haft

4

Disconnect

the

speedometer

drive

cable

ID

and

back

up

lamp

switch

cable

from

the

transmission

ex

tension

housing

s

Disconnect

the

shift

rods

from

the

shift

levers

by

removing

the

cotter

pin

and

remove

the

cross

shaft

assembly

@

from

the

transmission

case

r

J

f

f

1

I

Speedometer

cable

I

2

I

Cotter

pin

Fig

TM

6

Disconnecting

speedometer

cable

and

remote

controllinkag

6

hydraulic

clutch

control

Remove

the

clutch

operating

cylinder

from

the

clutch

housing

7

mechanical

clutch

control

Disconect

the

clutch

control

cable

from

the

withdrawal

lever

1

1

Withdrawal

lever

2

I

Clutch

control

cable

Fig

TM

7

Disconnecting

clutch

control

cable

8

Support

the

engine

with

ajack

placed

under

the

oil

pan

Do

not

loca

1

f

nder

the

oil

pan

drain

plug

I

i

l

TM

3

Page 491 of 513

CHASSIS

To

prevent

the

oil

pan

from

damaging

insert

a

wooden

block

between

the

pan

and

jack

9

Remove

two

nuts

@

used

to

attach

the

transmission

to

the

rear

engine

mounting

member

Place

a

jack

under

the

transmission

and

remove

two

bolts

@

used

to

fix

the

rear

engine

mounting

member

to

the

body

It

I

Rear

engine

mou

ting

installation

bolts

I

Rear

engine

mounting

bolts

I

2

Fig

TM

8

C

oss

Fberremoval

10

Raise

the

jack

supporting

the

engine

to

incline

the

engine

in

a

rearward

direction

A

sufficient

space

will

be

provided

for

transmission

removal

I

Remove

the

starting

motor

a

d

the

bolts

attaching

the

clutch

housing

to

the

engine

12

Lower

the

jack

under

tlie

and

withdraw

thS

transmission

iJ

DISASSEMBI

Y

trans

fljssion

gradu3Ily

1

j

I

When

disassembling

the

transmission

the

following

procedure

sh

ould

pe

adopted

Since

the

casings

are

made

of

aluminum

alloy

be

careful

not

to

damage

any

of

the

castings

C

t

l

t1

Drain

gear

o

frqrP

the

transmission

I

2

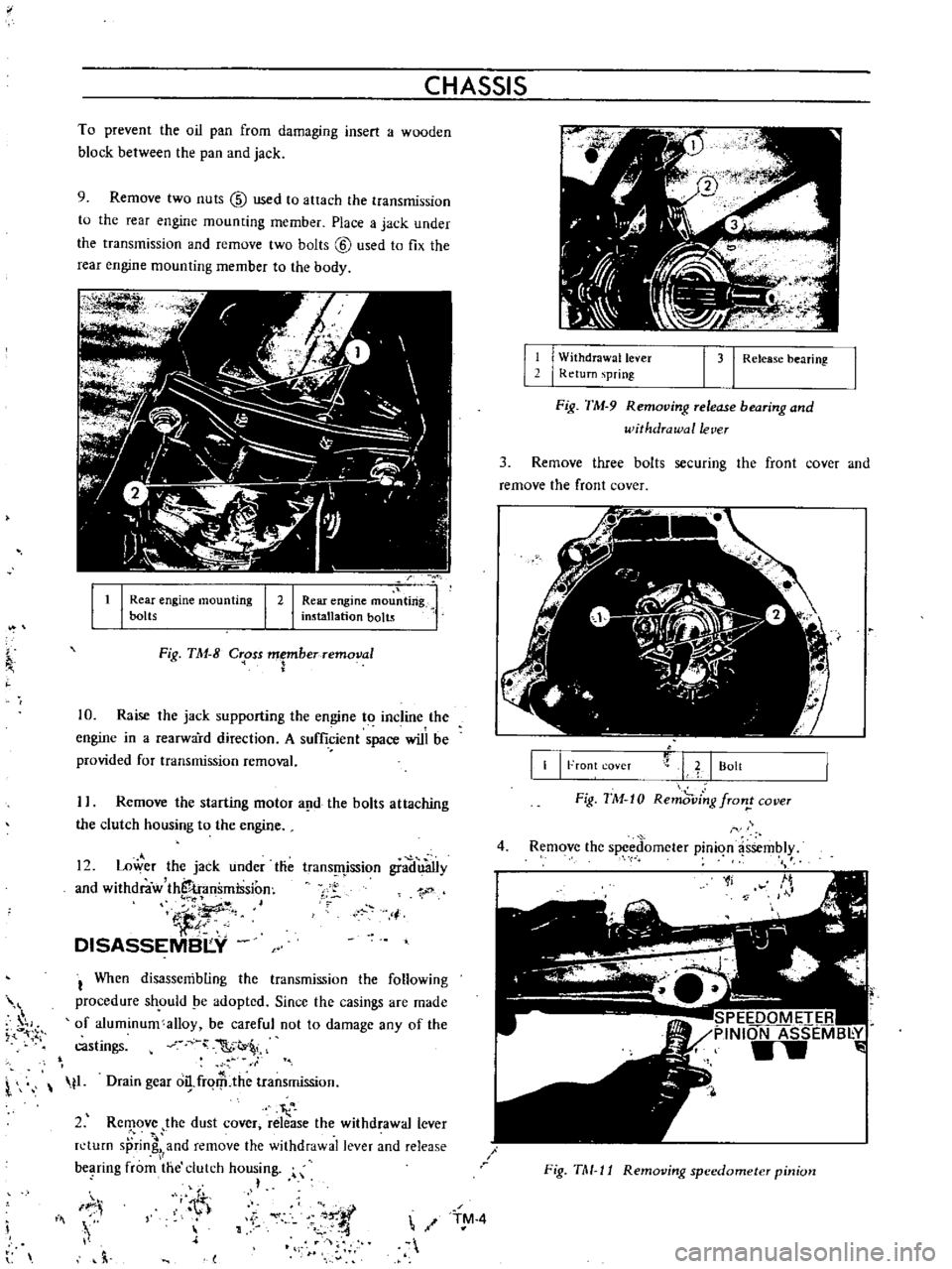

Rc

ove

the

dust

cover

release

the

withdrawal

lever

n

turn

sprin

and

remove

the

withdrawal

lever

and

release

bC

lring

from

the

clutch

housing

h

IF

i

Iii

h

l

11

I

W

ithdrawallever

I

Return

spring

1

31

Release

bearing

Fig

TM

9

Removing

release

bearing

and

withdrawal

lever

3

Remove

three

bolts

securing

the

front

cover

and

remove

the

front

cover

II

I

Front

coveT

L

I

Bolt

Fig

TM

10

Remd

ving

fron

cover

4

Remove

the

spced

omcter

pinion

assembly

1f

SPEEDOMETER

PINION

ASSEMB

Y

w

Fig

TM

11

Removing

speedometer

pinion

TM

4

Page 492 of 513

eo

TRANSMISSION

5

Remove

the

return

spring

plug

and

remove

the

return

spring

plunger

and

bushing

from

the

inside

I

I

Plunger

2

Bush

I

I

Return

spring

Return

spring

plug

Fig

TM

12

Removing

return

spring

6

Remove

the

striking

rod

pin

from

the

striking

rod

rear

end

and

separate

the

striking

rod

from

the

control

lever

bracket

Fig

TM

i3

Re

ving

striki

g

rtfd

7

Remove

eight

bolts

lr

g

the

rear

extension

housing

and

remove

the

housing

Note

I

li9htly

tllp

the

ci

cumferen

with

a

mallet

and

withdraw

the

h

sin9

wooden

i

l

E

8

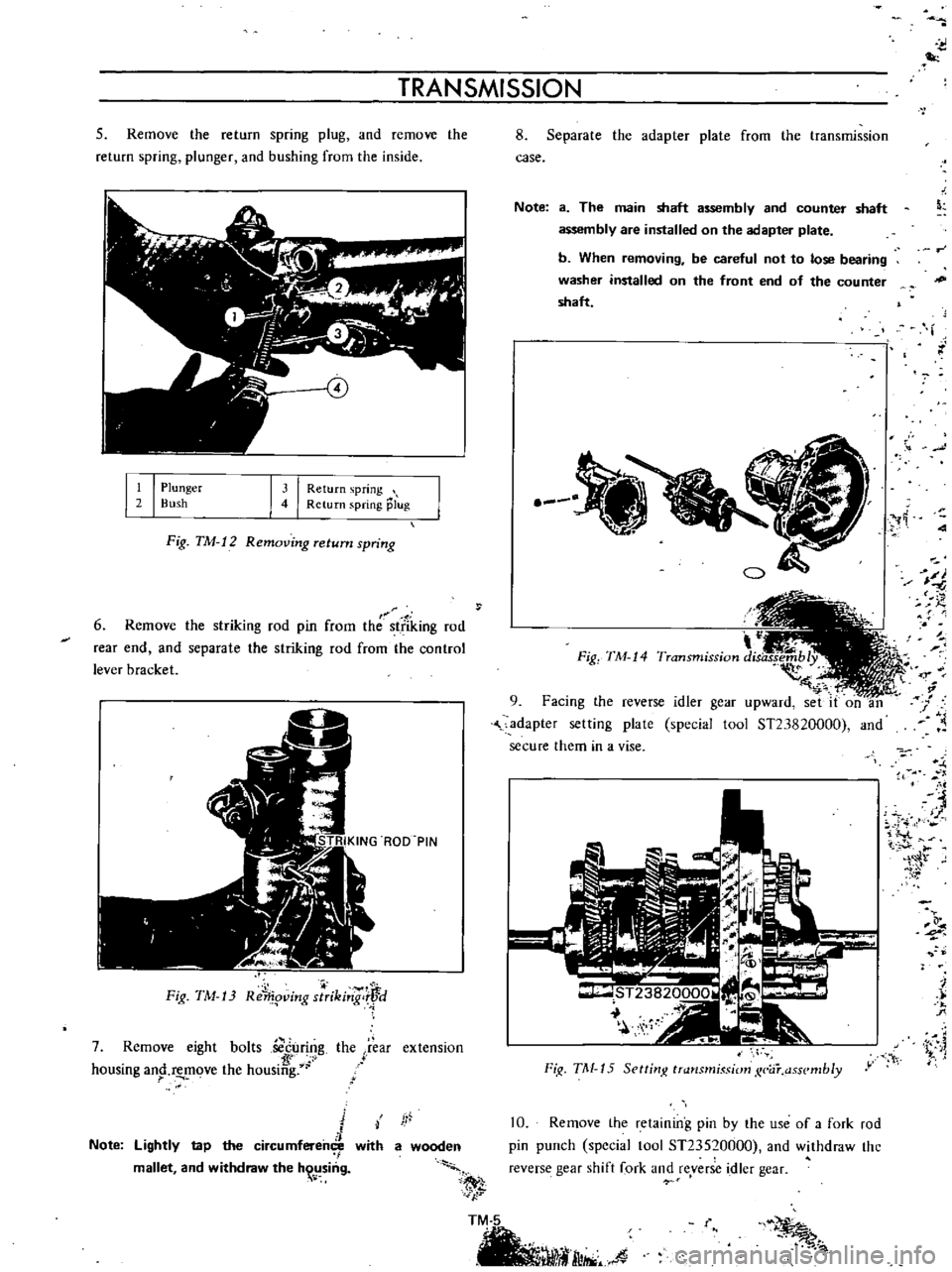

Separate

the

adapter

plate

from

the

transmission

case

Note

a

The

main

shaft

assembly

and

counter

shaft

assembly

are

installed

on

the

adapter

plate

b

When

removing

be

careful

not

to

lose

bearing

washer

installed

on

the

front

end

of

the

counter

shaft

r

i

i

1

il

ti

E

Fig

TAl

i4

Transmission

disasi

IY

9

Facing

the

reverse

idler

gear

upward

set

If

on

an

adapter

setting

plate

special

tool

ST23820000

and

secure

them

in

a

vise

C

j

J

f

f

L

jlor

f

0

1

J

t

1

PiS

TM

15

SettinR

trcw

wli

sion

geei

assembly

1

10

Remove

the

retaining

pin

by

the

use

of

a

fork

rod

pin

punch

special

1001

ST23520000

and

withdraw

Ihe

reverse

gear

shift

fork

and

reverse

idler

gear

TM

5

A

f

Page 499 of 513

fVI

CHASSIS

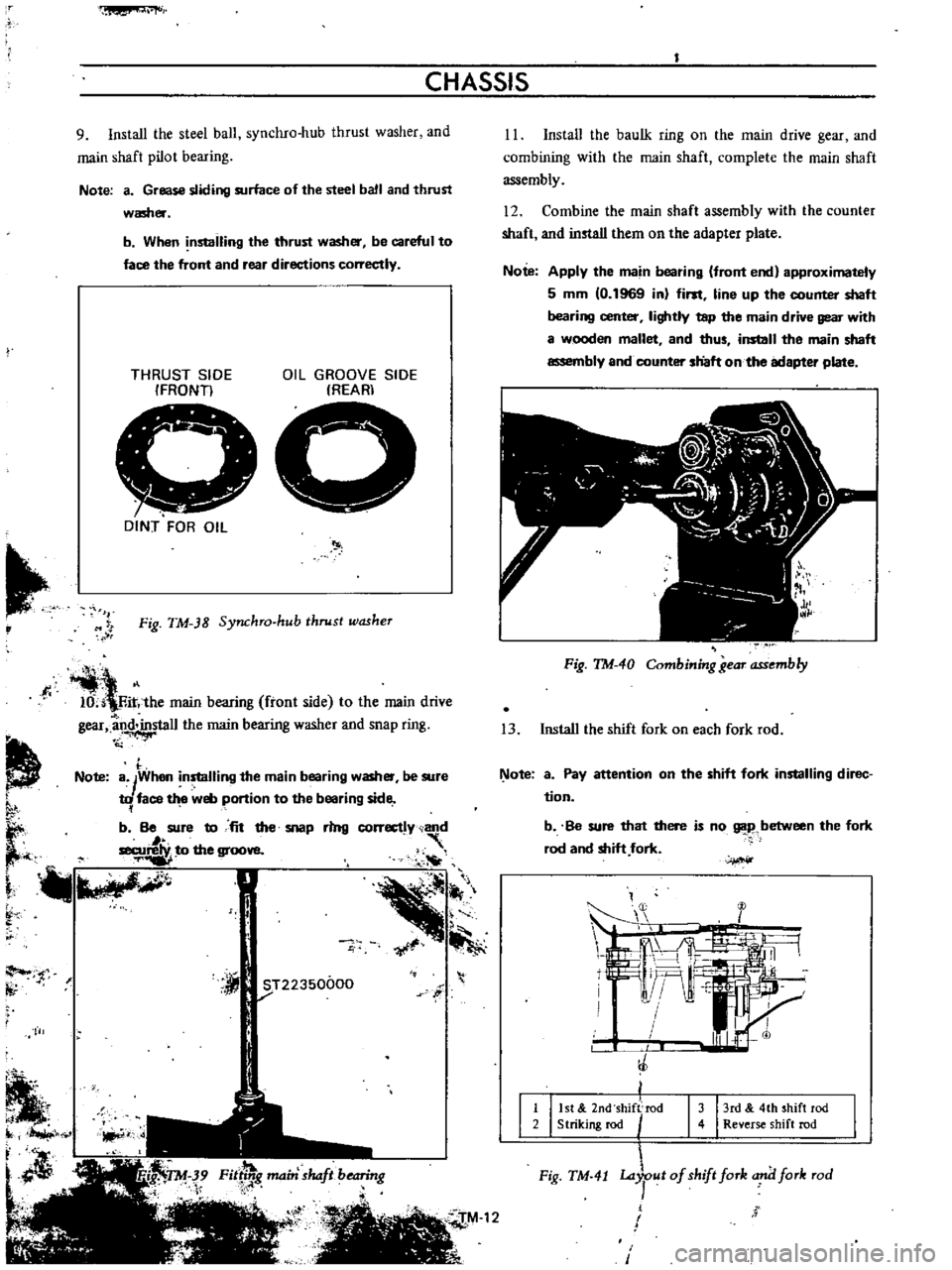

9

Install

the

steel

ball

synchro

hub

thrust

washer

and

main

shaft

pilot

bearing

Note

a

Grease

sliding

surface

of

the

steel

ball

and

thrust

washer

b

When

nstailing

the

thrust

washer

be

careful

to

face

the

front

and

rear

directions

correctly

THRUST

SIDE

FRONT

OIL

GROOVE

SlOE

REARl

if

c

o

DINT

FOR

OIL

r

1

r

Fig

TM

J8

Synchro

hub

thrust

washer

i

the

main

bearing

front

side

to

the

main

drive

gear

m

stall

the

main

bearing

washer

and

snap

ring

Note

When

installing

the

main

bearing

washer

be

sure

to

face

the

web

portion

to

the

bearing

side

b

Be

SUo

re

to

fit

the

snap

ring

correct

y

r

secu

tDthegroove

t

I

i

II

t

d

l

I

t

iIf

i

c

c

f

1

ST22350000

It

i

r

4

t

r

4

FiftJ

g

mairi

shafi

bearing

A

I

t

T

M

12

II

Install

the

baulk

ring

on

the

main

drive

gear

and

combining

with

the

main

shaft

complete

the

main

shaft

assembly

12

Combine

the

main

shaft

assembly

with

the

counter

shaft

and

install

them

on

the

adapter

plate

Note

Apply

the

main

bearing

front

end

approximately

5

mm

0

1969

in

fim

line

up

the

counter

shaft

bearing

center

lightly

tap

the

main

drive

gear

with

a

wooden

mallet

and

thus

install

the

main

shaft

assembly

and

counter

slieft

on

the

adapter

plate

Fig

TM

40

Combining

gear

assembly

13

Install

the

shift

fork

on

each

fork

rod

1

II0te

a

Pay

attention

on

the

shift

fork

installing

direc

tion

b

Be

sure

that

there

is

no

98

between

the

fork

rod

and

shift

fork

J

b

I

1

lIst

2nd

shift

rod

2

Striking

rod

13

13rd

4th

hift

rod

4

Reverse

shift

rod

Fig

TM

41

La

put

of

shift

fork

and

fork

rod

1

r

J

Page 500 of 513

j

TRANSMISSION

14

Install

each

fork

rod

together

with

the

check

ball

plug

check

ball

check

ball

spring

and

interlock

plu

er

by

the

use

of

a

fork

rod

guide

special

tool

ST236200

0

Note

a

Install

the

fori

rod

at

a

p

tion

where

tha

for

rod

check

ball

groove

coincides

with

the

ball

b

In

tha

standard

position

upper

surface

of

the

plug

is

flush

with

upper

surface

of

the

adapter

c

When

installing

the

plug

ba

sure

to

apply

thread

locking

agent

I

1

I

Ch

eck

ball

I

2

I

Special

toot

ST23620000

Fig

TM

42

InstaUing

check

ball

i

l

SET

SCREW

J

r

r

I

1st

2nd

SHIFT

ROD

PLUNGER

3rd

4th

SHIF1

RO

U

BALL

lt

SPRING

r

if

If

f

J

REVERSE

SHIFT

ROD

Fig

TM

43

Layout

of

check

ball

15

Drive

shift

fork

retaining

pin

Fig

TM

44

Driving

retaining

pin

16

Install

the

main

shaft

reverse

gear

thrust

washer

and

secure

them

with

a

snap

ring

Note

When

installing

the

thrust

washer

tha

web

portion

to

the

gear

sid8

be

sure

to

face

I

J

ll

it

ij

I

r

7

I

t

Lt

l

i

JI

h

l

p

II

Si

ap

dng

l

iVf

31

via

I

i

i

2

I

Reverse

gear

rll

f

F

O

1

Ii

ct

I

C

I

jf

1

Fig

TM

45

bista

ling

reveTS

gear

fJ

i

tJ

i

J

I

1

i

4

1

a

ot

j

l

i1i

o

f

tJ

r

w

i6

J

t

F

I

f

1

it

IV

I

17

1

t

1

the

reverse

@Isr

e

r

tilgether

wi1

tJthe

r

shift

k

Oc

shi

k

7i

fN

revers

lO

r

r

1

mg

1

1

f

i

J

4t

z

1

if

f

St

J

f

l

p

t

A

J

t

M

ff

J

1

A

Note

In

order

to

in

re

t

1h

f

t

li

u

r

is

O

cracked

apply

onl

fo

rk

r

id

ope

te

thet6t1ier

fori

J

t

i

fod

an

make

sU

r

e

that

th

gljllr

aoes

nOt

miiSli

J

o

I

t

J

t

if

z

TM

13

1

t

Page 502 of 513

YO

TRANSMISSION

27

Upon

completion

of

the

reassembly

confIrm

that

Measure

depth

from

the

front

cover

installing

I

The

main

shaft

is

notJ

tiirned

synchronously

when

I

surface

to

end

surface

of

the

main

bearing

outer

gear

is

shifted

to

neutral

and

the

main

drive

gear

is

turned

race

by

the

use

of

vernier

caliper

depth

gauge

nd

light1y

select

shimlsl

from

those

shown

in

the

foIlOW

g

l

table

so

that

the

depth

is

5

g

15

mm

0

1

9

2

Operatin

r

e

is

not

excessive

d

gears

n

be

t

o

0059

in

i

shifted

smoothly

when

Ifjifted

to

the

mdlVldual

speeds

rt

6

1

1

itl

M

il

TM

15

If

tl

Fig

TM

50

Installing

rear

extension

21

Install

the

bushing

plunger

return

spring

and

return

spring

plug

Note

When

installing

apply

adhesive

to

the

return

spring

plug

t

l

4

0

fj

I

t

I

Plunger

2

Bush

I

31

Return

spnng

4

Return

spring

plug

Fig

TM

51

Installing

return

spring

22

23

24

Install

the

stopper

pin

and

E

rjng

Instal

e

speedometer

pinion

Select

main

drive

gear

bearing

shim

s

Note

Part

number

Thickness

mm

in

32208

18000

32208

18001

32208

18002

0

5

0

0197

0

2

0

0079

jeL

J

f

l

r

I

l

0

J

3

I

L

r

1

v

tti

t

4J

m

cv

Shim

thickness

t

5

00

mm

O

1969

n

2

3

J

ib

m

J

i

I

Shim

thickness

f

I

M

r

Fig

TM

52

Seiecti

g

main

drive

7

arbeari

g

s

j

I

25

Install

the

oil

seal

on

the

fronhcover

amtsecure

it

together

with

the

adjusting

shim

4f

J

ring

0

Note

Grease

the

oil

seal

lip

I

26

Install

the

ci

Itc

release

b

aring

luru

rring

and

withdrawal

lever

p

Main

d

ve

gear

Front

cover

Front

cover

adJhsting

shim

i

Ii