ECU DATSUN B110 1973 Service Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 216 of 513

Removal

I

t

is

recommended

that

the

door

be

removed

from

the

body

with

the

door

hinges

attached

on

the

door

although

the

door

may

be

removed

from

the

body

with

or

without

the

hinges

attached

on

the

door

Front

door

Remove

the

package

tray

2

Remove

the

door

hinge

service

hole

cover

from

the

dash

side

trim

3

With

the

door

fully

opened

support

the

door

by

applying

a

stand

or

jack

beneath

the

door

so

that

the

door

does

not

drop

off

Note

Apply

a

piece

of

rag

between

the

door

and

stand

so

that

the

door

panel

is

protected

from

damaging

4

Remove

the

door

hinge

installation

bolts

at

the

body

side

by

the

use

of

a

box

wrench

and

remove

the

door

from

the

body

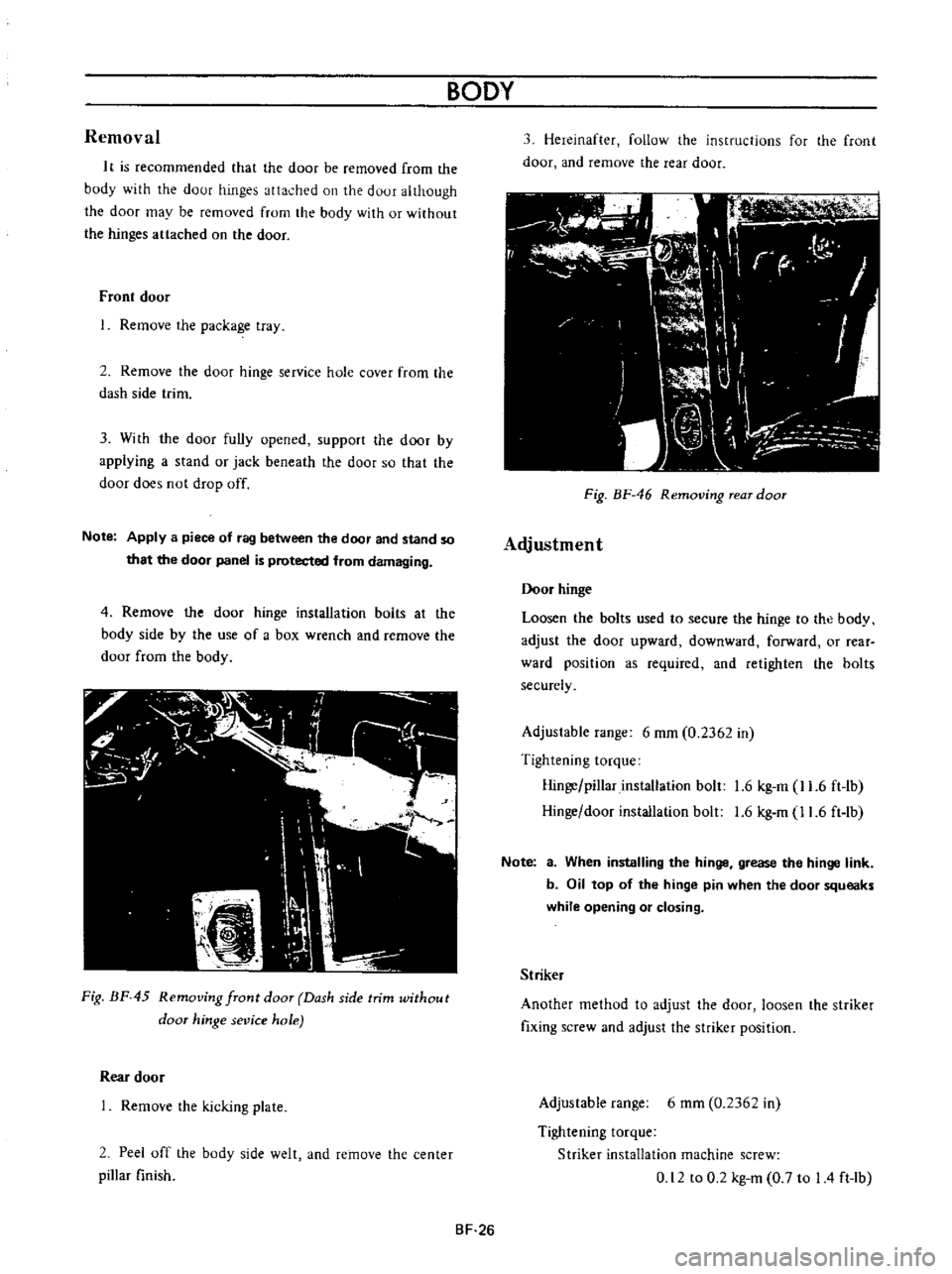

Fig

BF

45

Removing

front

door

Dash

side

trim

without

door

hinge

sevice

hole

Rear

door

Remove

the

kicking

plate

2

Peel

off

the

body

side

welt

and

remove

the

center

pillar

finish

BODY

3

Hereinafter

follow

the

instructions

for

the

front

door

and

remove

the

rear

door

11

I

fl

C

I

r

r

I

W

I

r

I

I

dl

J

Ik

I

h

I

l

i

J

n

Fig

BF

46

Removing

rear

door

Adjustment

Door

hinge

Loosen

the

bolts

used

to

secure

the

hinge

to

the

body

adjust

the

door

upward

downward

forward

or

rear

ward

position

as

required

and

retighten

the

bolts

securely

Adjustable

range

6

mm

0

2362

in

Tightening

torque

Hinge

pillar

installation

bolt

1

6

kg

m

11

6

ft

lb

Hinge

door

installation

bolt

1

6

kg

m

11

6

ft

lb

Note

a

When

installing

the

hinge

grease

the

hinge

link

b

Oil

top

of

the

hinge

pin

when

the

door

squeaks

while

opening

or

closing

Striker

Another

method

to

adjust

the

door

loosen

the

striker

fixing

screw

and

adjust

the

striker

position

Adjustable

range

6

mm

0

2362

in

Tightening

torque

Striker

installation

machine

screw

0

12

to

0

2

kg

m

0

7

to

I

4

ft

lb

BF

26

Page 217 of 513

Fig

BF

47

Adjusting

striker

DOOR

TRIM

For

both

the

front

and

rear

doon

the

door

trims

may

be

removed

and

reinsbJled

in

the

same

method

Removal

I

When

removing

the

door

regulator

handle

lock

inside

handle

escutcheon

and

arm

rest

remove

their

installation

screws

2

When

removing

the

ash

tray

outer

case

remove

the

ash

tray

and

remove

the

installation

screws

3

The

door

finish

is

secured

on

the

door

with

clips

When

removing

the

door

finish

pull

it

toward

you

DOOR

LOCK

MECHANISM

BODY

I

I

Regulator

handle

Imide

handle

escu

tcheon

131

Armrest

Fig

BF

48

Door

trim

III

I

2

Outer

case

Ash

tray

Fig

BF

49

Removing

ash

tray

1

1

Door

lock

2

Spring

3

Inside

handle

4

Locking

plate

5

Locking

plate

spring

6

Stopper

7

Outside

handle

8

Ou

tside

handle

rod

9

Nylon

nut

10

Escu

tchcon

11

Knob

grommet

12

Door

lock

knob

13

Door

lock

cylinder

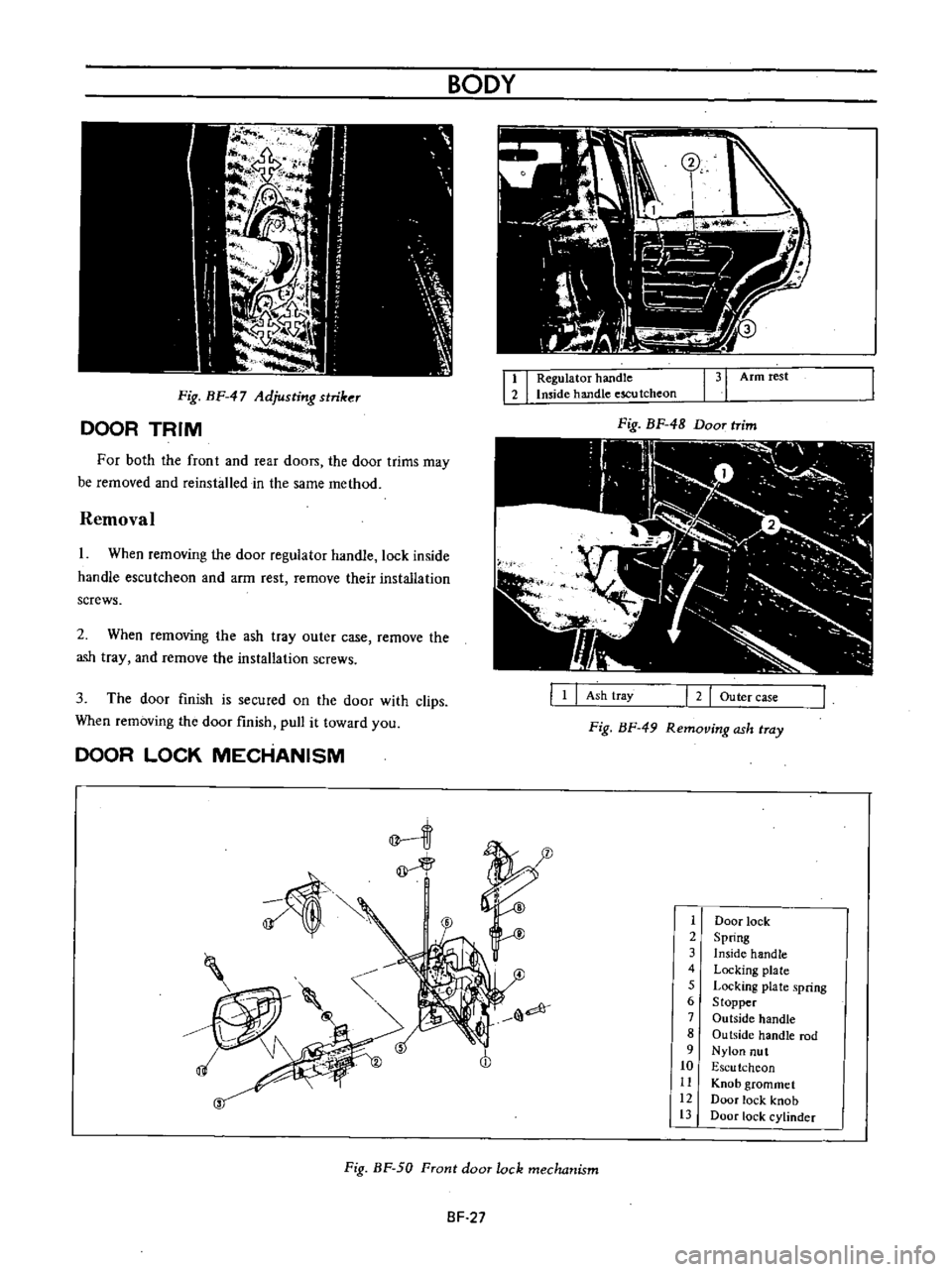

Fig

BF

50

Front

door

lock

mechanism

SF

27

Page 218 of 513

IT

f

r

J

e

@

@

BODY

Door

lock

2

I

nside

handle

3

Escu

tcheon

4

Door

lock

knob

5

Knob

grommet

Front

door

lock

removal

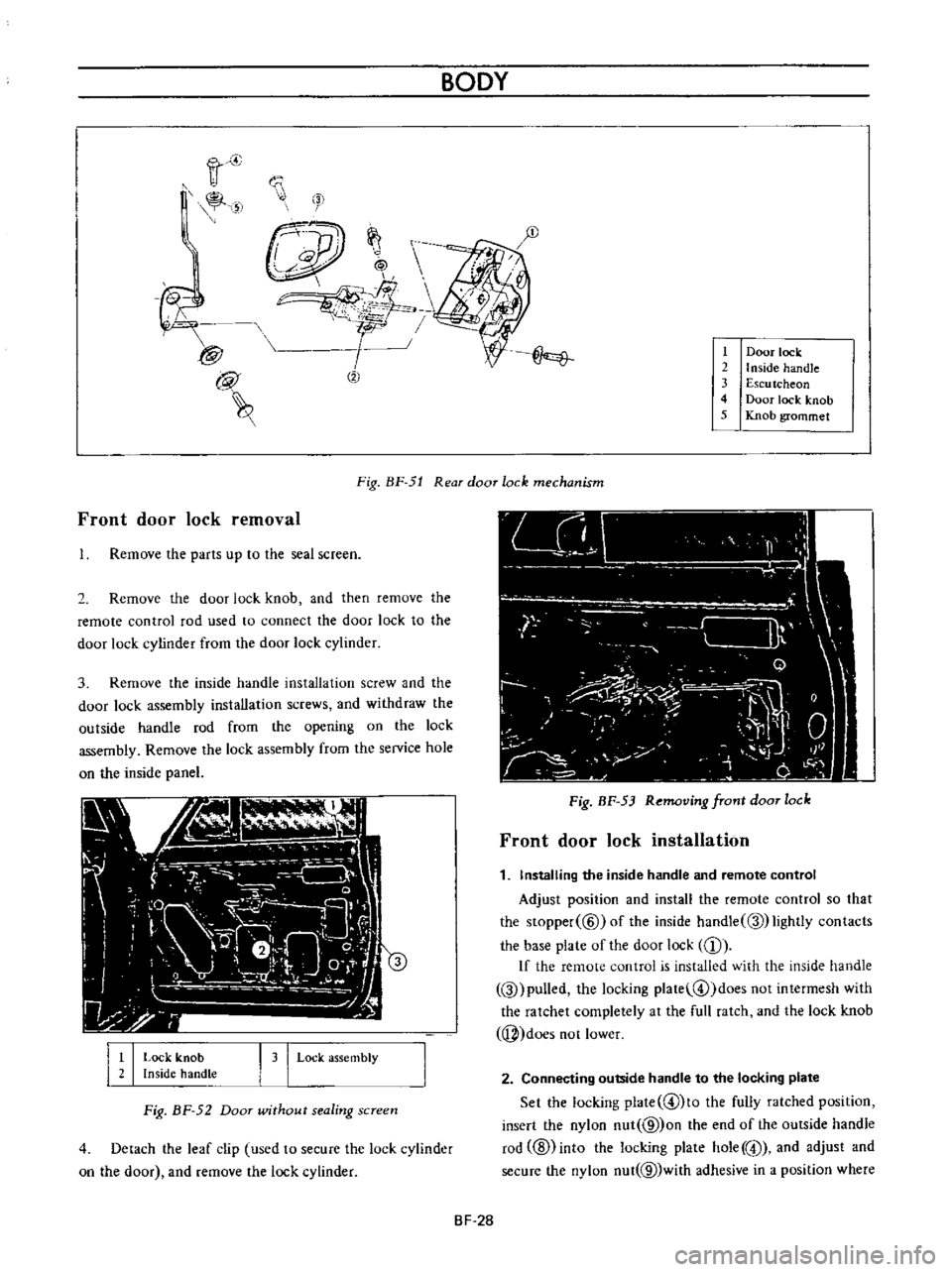

Fig

BF

51

Rear

door

lock

mechanism

Remove

the

parts

up

to

the

seal

screen

2

Remove

the

door

lock

knob

and

then

remove

the

remote

control

rod

used

to

connect

the

door

lock

to

the

door

lock

cylinder

from

the

door

lock

cylinder

3

Remove

the

inside

handle

installation

screw

and

the

door

lock

assembly

installation

screws

and

withdraw

the

outside

handle

rod

from

the

opening

on

the

lock

assembly

Remove

the

lock

assembly

from

the

service

hole

on

the

inside

panel

I

I

Lock

knob

Inside

handLe

I

3

I

Lock

assembly

Fig

BF

52

Door

wUhout

sealing

screen

4

Detach

the

leaf

clip

used

to

secure

the

lock

cylinder

on

the

door

and

remove

the

lock

cylinder

Fig

BF

53

Removing

front

door

lock

Front

door

lock

installation

1

Installing

the

inside

handle

and

remote

control

Adjust

position

and

install

the

remote

control

so

that

the

Slopper

@

ofthe

inside

handle

Q

lightly

contacts

the

base

plate

of

the

door

lock

CD

If

the

remote

control

is

installed

with

the

inside

handle

Q

pulled

the

locking

plate

@

doesnotintermesh

with

the

ratchet

completely

at

the

full

ratch

and

the

lock

knob

j

does

not

lower

2

Connecting

outside

handle

to

the

locking

plate

Set

the

locking

plate

@lto

the

fully

ratched

position

insert

the

nylon

nut

@

on

the

end

of

the

outside

handle

rod

ID

into

the

locking

plate

hole

@

and

adjust

and

secure

the

nylon

nut

@

with

adhesive

in

a

position

where

BF

28

Page 219 of 513

the

outside

handle

rod

@

is

provided

with

2

to

3

mm

0

0787

to

0

1181

in

play

in

the

stroke

If

the

nylon

nut

@

is

positioned

too

low

the

locking

plate

@

is

depressed

at

the

full

ratch

the

locking

plate

does

not

intermesh

with

the

ratchet

completely

and

the

knob

cannot

be

locked

If

play

in

stroke

of

the

outside

handle

rod

@

is

excessive

may

be

unlocked

up

to

5

mm

0

1967

in

stroke

of

the

outside

handle

will

be

insufficient

If

the

nylon

nut

is

loosened

the

above

described

trouble

occurs

Be

sure

to

secure

the

nut

completely

by

means

of

adhesive

Check

the

springs

@

and

@

for

rust

and

replace

as

required

Tightening

torque

Door

lock

installation

screw

0

12

to

0

2

kg

m

0

9

to

I

4

ft

lb

Door

lock

remote

control

installation

screw

0

12

to

0

2

kg

m

0

9

to

14

ft

lb

Outside

handle

installation

nut

0

2

to

0

3

kg

m

1

4

to

2

2

ft

Ib

Rear

door

lock

removal

1

Remove

the

parts

up

to

the

seal

screen

2

Raise

the

door

glass

to

the

top

and

remove

the

door

DOOR

GLASS

AND

REGULATOR

i

v

BODY

lock

knob

3

Remove

the

bell

crank

installation

screw

Hereinafter

the

instructions

for

removal

of

the

front

door

lock

apply

Fig

BF

54

Door

without

sealing

screen

Rear

door

lock

installation

Install

the

rear

door

lock

in

reverse

sequence

of

removal

Note

Except

for

the

precautions

for

outside

handle

the

precautions

for

the

front

door

lock

apply

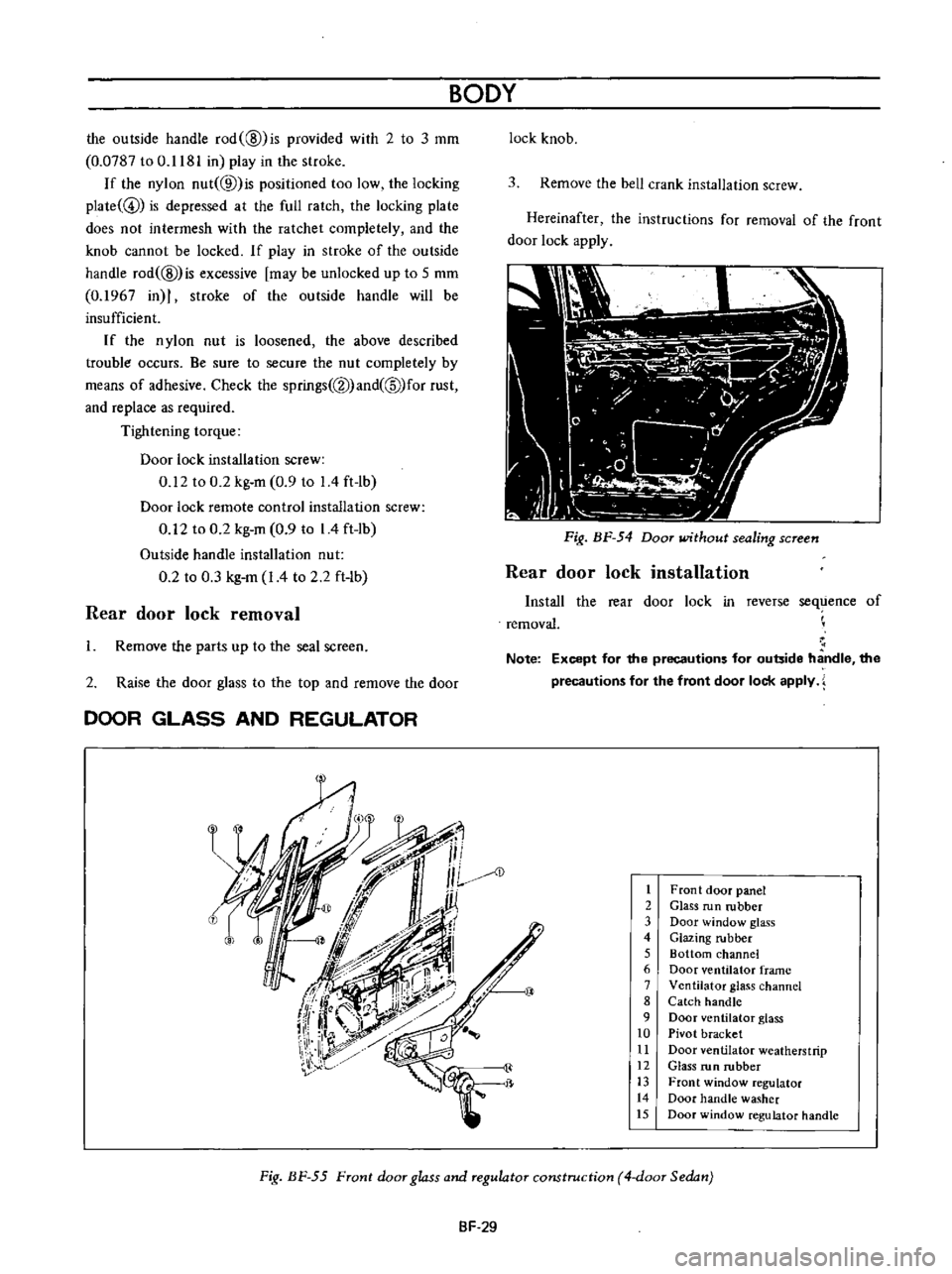

AD

1

Front

door

panel

2

Glass

run

rubber

3

Door

window

glass

4

Glazing

rubber

5

Bottom

channel

6

Door

ventilator

frame

7

Ventilator

glass

channel

8

Catch

handle

9

Door

ventilator

glass

10

Pivot

bracket

11

Door

ventilator

weatherstrip

12

Glass

run

rubber

13

Front

window

regulator

14

Door

handle

washer

15

Door

window

regulator

handle

Fig

BF

55

Front

door

glass

and

regulator

construction

4

door

Sedan

SF

29

Page 230 of 513

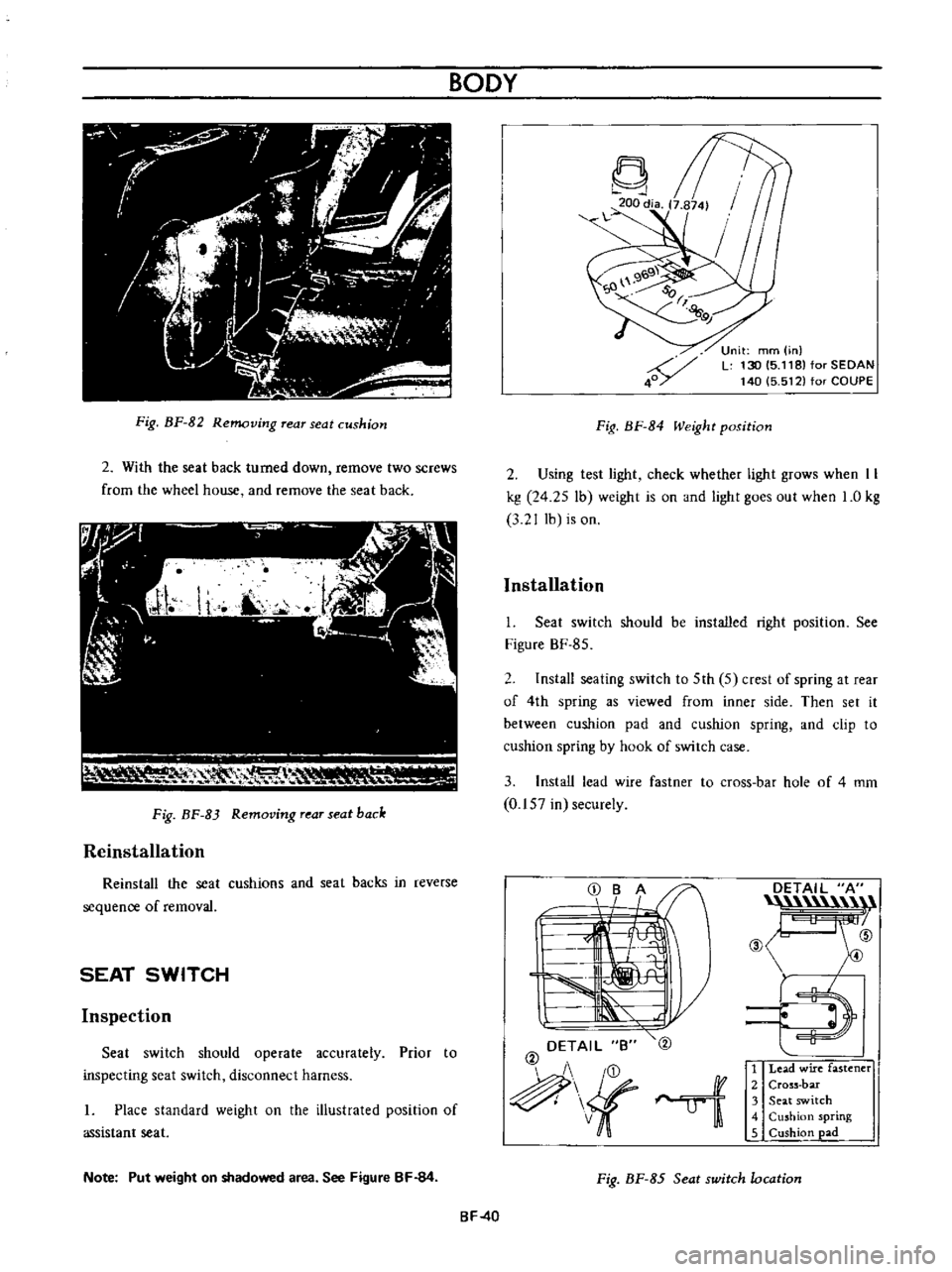

Fig

BF

82

Removing

rear

seat

cushion

2

With

the

seat

back

turned

down

remove

two

screws

from

the

wheel

house

and

remove

the

seat

back

111

I

V

RH

0

1

lr

Fig

BF

83

Removing

rear

seat

back

Reinstallation

Reinstall

the

seat

cushions

and

seat

backs

in

reverse

sequence

of

removal

SEAT

SWITCH

Inspection

Seat

switch

should

operate

accurately

Prior

to

inspecting

seat

switch

disconnect

harness

I

Place

standard

weight

on

the

illustrated

position

of

assistant

seat

Note

Put

weight

on

shadowed

area

See

Figure

BF

84

BODY

Fig

BF

84

Weight

position

Unit

mm

in

L

130

15

118

for

SEDAN

140

5

512

for

COUPE

2

Using

test

light

check

whether

light

grows

when

II

kg

24

25

lb

weight

is

on

and

light

goes

out

when

1

0

kg

3

2

J

lb

is

on

Installation

I

Seat

switch

should

be

installed

right

position

See

Figure

BF

85

2

Install

seating

switch

to

5th

5

crest

of

spring

at

rear

of

4th

spring

as

viewed

from

inner

side

Then

set

it

between

cushion

pad

and

cushion

spring

and

clip

to

cushion

spring

by

hook

of

switch

case

3

Install

lead

wire

fastner

to

cross

bar

hole

of

4

mm

0

157

in

securely

DETAIL

B

@

ui

DETAIL

A

n

@

ID

E

l

1

Lead

wire

fastener

2

Cross

bar

3

Seat

switch

4

Cushion

spring

5

Cushion

pad

Fig

BF

85

Seat

switch

location

BF

40

Page 233 of 513

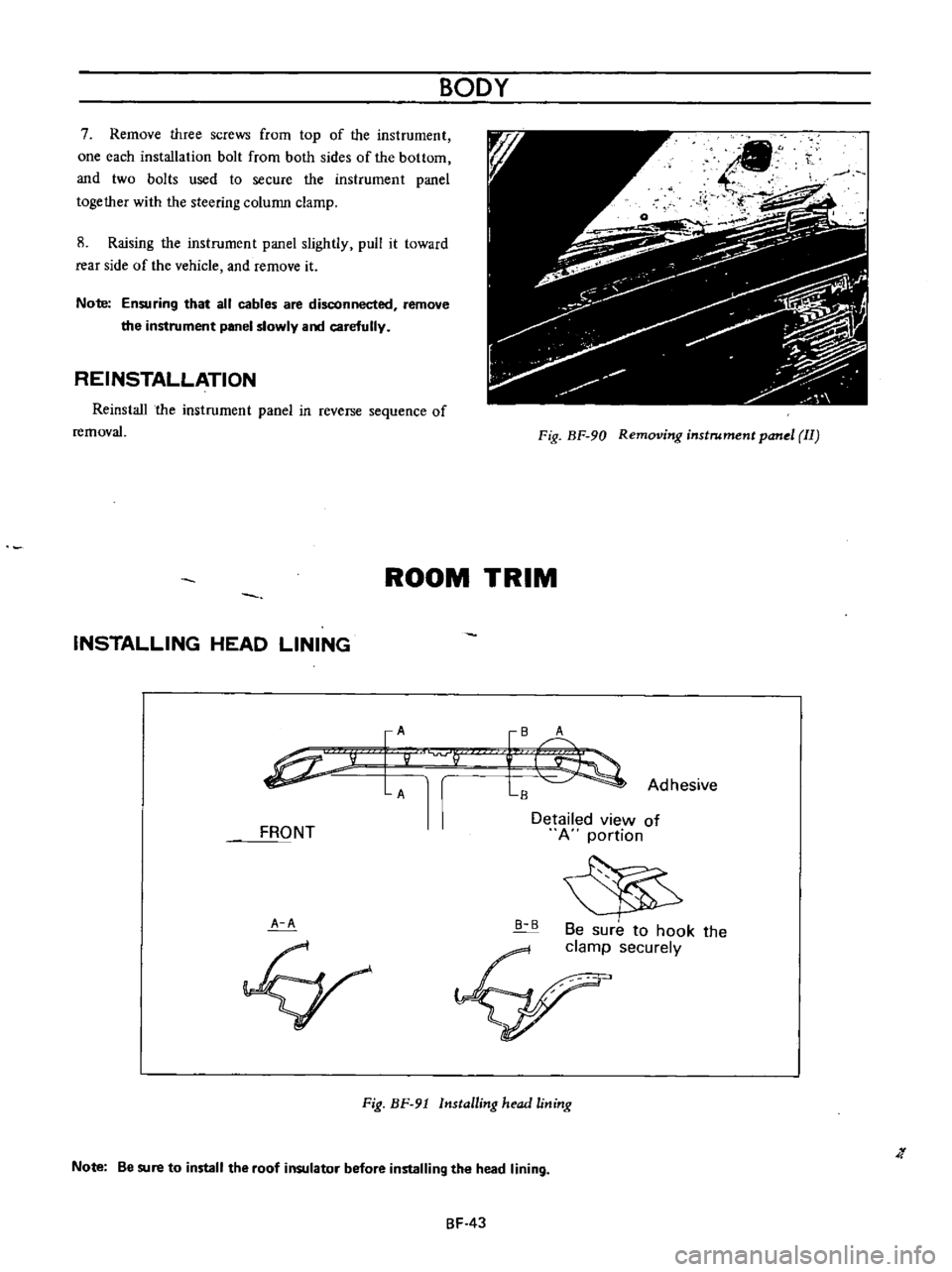

7

Remmre

three

screws

from

top

of

the

instrument

one

each

installation

bolt

frorn

both

sides

of

the

bottorn

and

two

bolts

used

to

secure

the

instrument

panel

together

with

the

steering

column

clamp

8

Raising

the

instrument

panel

slightly

pull

it

toward

rear

side

of

the

vehicle

and

remove

it

Note

Ensuring

that

all

cables

are

disconnected

remove

the

instrument

panel

slowly

aoo

carefully

REINSTALLATION

Reinstall

the

instrument

panel

in

reverse

sequence

of

removal

BODY

Fig

BF

90

Removing

instrument

panel

II

ROOM

TRIM

INSTALLING

HEAD

LINING

IA

P

AV

FRONT

A

A

IB

A

L

Adhesive

Detailed

view

of

A

portion

B

B

Be

sure

to

hook

the

clamp

securely

Fig

BF

91

Installing

head

lining

Note

Be

sure

to

install

the

roof

insulator

before

installing

the

head

lining

J

BF

43

Page 241 of 513

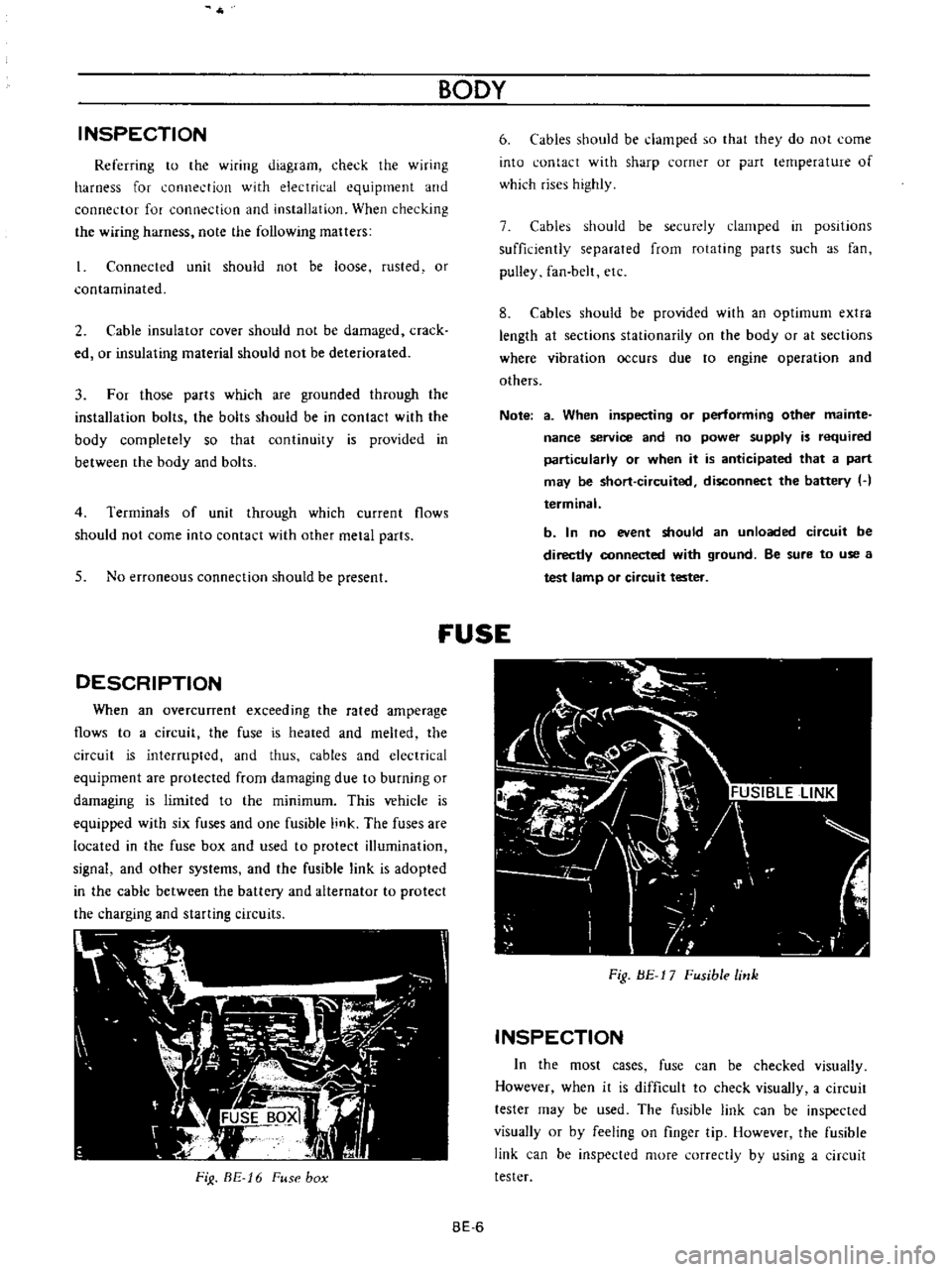

INSPECTION

Referring

to

the

wiring

diagram

check

the

wiring

harness

for

connection

with

electrical

equipment

and

connector

for

conned

ion

and

installation

When

checking

the

wiring

harness

note

the

following

matters

Connected

unit

should

not

be

loose

rusted

or

contaminated

2

Cable

insulator

cover

should

not

be

damaged

crack

ed

or

insulating

material

should

not

be

deteriorated

3

For

those

parts

which

are

grounded

through

the

installation

bolts

the

bolts

should

be

in

contact

with

the

body

completely

so

that

continuity

is

provided

in

between

the

body

and

bolts

4

Terminals

of

unit

through

which

current

flows

should

not

come

into

contact

with

other

metal

parts

5

No

erroneous

connection

should

be

present

DESCRIPTION

When

an

overcunent

exceeding

the

rated

amperage

flows

to

a

circuit

the

fuse

is

heated

and

melted

the

circuit

is

interrupted

and

thus

cables

and

electrical

equipment

are

protected

from

damaging

due

to

burning

or

damaging

is

limited

to

the

minimum

This

vehicle

is

equipped

with

six

fuses

and

one

fusible

link

The

fuses

are

located

in

the

fuse

box

and

used

to

protect

illumination

signal

and

other

systems

and

the

fusible

link

is

adopted

in

the

cable

between

the

battery

and

alternator

to

protect

the

charging

and

starting

circuits

FiJ

BE

16

Fuse

box

BODY

6

Cables

should

be

damped

so

that

they

do

not

come

into

contact

with

sharp

corner

or

part

lernperature

of

which

rises

highly

7

Cables

should

be

securely

clamped

in

posItions

sufficiently

separated

from

rotating

parts

such

as

fan

pulley

fan

belt

etc

8

Cables

should

be

provided

with

an

optimum

extra

length

at

sections

stationarity

on

the

body

or

at

sections

where

vibration

occurs

due

to

engine

operation

and

others

Note

a

When

inspecting

or

performing

other

mainte

nance

service

and

no

power

supply

is

required

particularly

or

when

it

is

anticipated

that

a

part

may

be

short

circuited

disconnect

the

battery

H

terminal

b

In

no

event

should

an

unloaded

circuit

be

directly

connected

with

ground

Be

sure

to

use

a

test

lamp

or

circuit

tester

fUSE

Fig

BE

17

Fusible

link

INSPECTION

In

the

most

cases

fuse

can

be

checked

visually

However

when

it

is

difficult

to

check

visually

a

circuit

tester

may

be

used

The

fusible

link

can

be

inspected

visually

or

by

feeling

on

finger

tip

However

the

fusible

link

can

be

inspected

more

correctly

by

using

a

circuit

tester

BE

6

Page 251 of 513

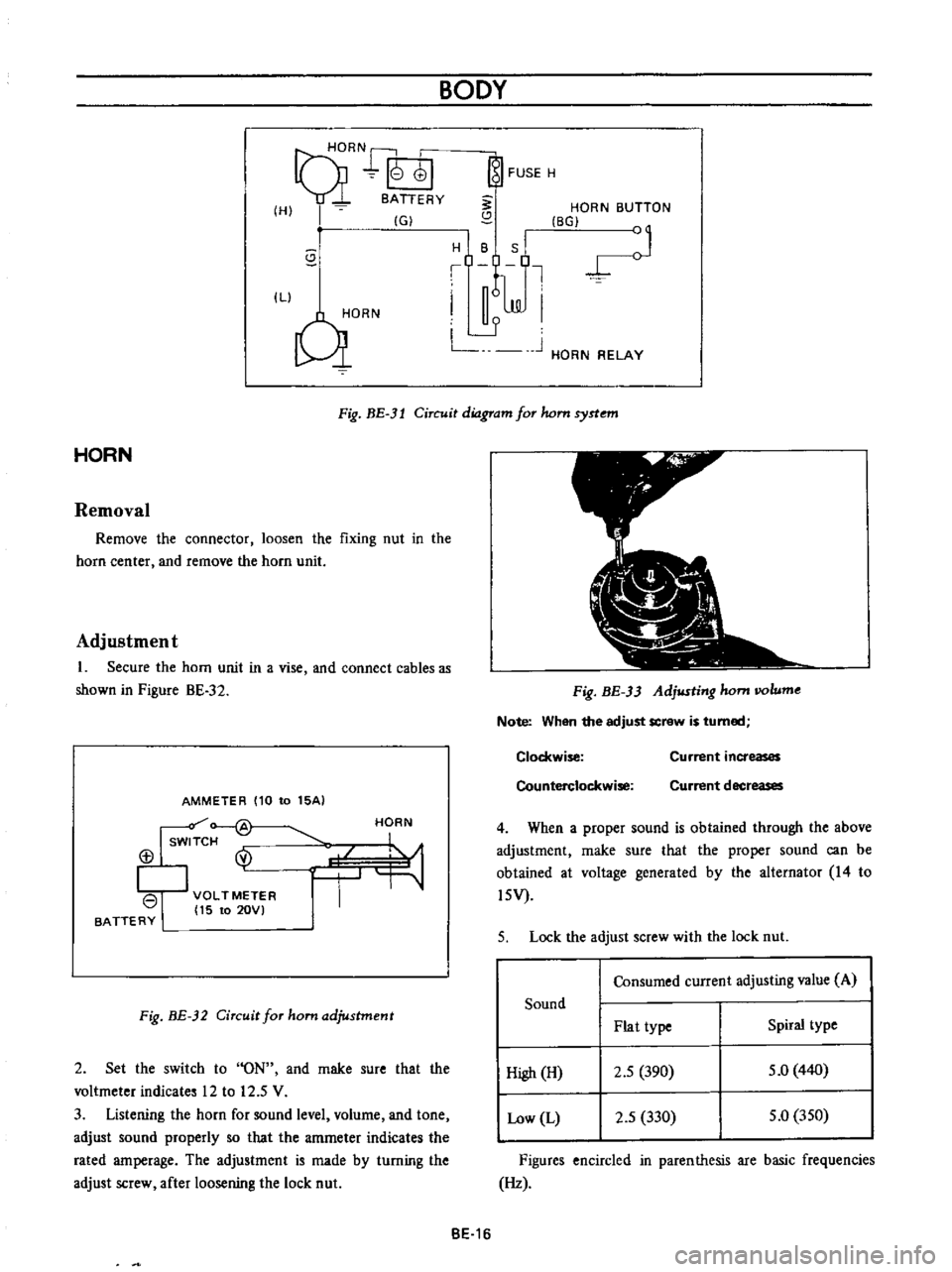

9HORN

r

I

01

8ATTERY

HI

IGI

s

ILl

C

iORN

BODY

FUSE

H

S

HORN

BUTTON

BGI

J

H

B

S

Il

I

n6lm

I

L

J

L

HORN

RELAY

Fig

BE

3l

Circuit

diagram

for

hom

syrtem

HORN

Removal

Remove

the

connector

loosen

the

fixing

nut

in

the

horn

center

and

remove

the

horn

unit

Adjustment

1

Secure

the

horn

unit

in

a

vise

and

connect

cables

as

shown

in

Pigure

BE

32

AMMETER

110

to

15AI

Isw

f

@

113

I

VOLTMETER

I

15

to

20VI

BATTERY

HORN

Fig

BE

32

Circuit

for

ham

adjustment

2

Set

the

switch

to

ON

and

rnake

sure

that

the

voltmeter

indicates

12

to

12

5

V

3

Listening

the

horn

for

sound

level

volurne

and

tone

adjust

sound

properly

so

that

the

amrneter

indicates

the

rated

amperage

The

adjustment

is

made

by

turning

the

adjust

screw

after

loosening

the

lock

nut

Fig

BE

33

Adjusting

hom

IIOlume

Note

When

the

adjust

screw

is

turned

Clockwise

Counterclockwise

Current

increases

Current

decreases

4

When

a

proper

sound

is

obtained

through

the

above

adjustment

rnake

sure

that

the

proper

sound

can

be

obtained

at

voltage

generated

by

the

alternator

14

to

l5V

5

Lock

the

adjust

screw

with

the

lock

nut

Consumed

current

adjusting

value

A

Sound

Plat

type

Spiral

type

High

H

2

5

390

5

0

440

Low

L

2

5

330

5

0

350

Figures

encircled

in

parenthesis

are

basic

frequencies

Hz

BE

16

Page 253 of 513

BODY

METERS

AND

GAUGES

CONTENTS

CLUSTER

LID

Oescri

ption

Removal

SPEEDOMETER

Replacement

FUEL

GAUGE

AND

TEMPERATURE

GAUGE

Description

Replacement

BE

1B

BE

18

BE

18

BE

19

BE

19

BE

19

BE

19

BE

20

CLUSTER

LID

Description

The

cluster

lid

holds

various

rneters

indicators

and

clock

located

around

the

speedorneter

Printed

circuit

board

is

used

at

the

back

of

the

meter

as

shown

in

Figure

BE

38

and

the

printed

circuit

board

is

connected

with

multiple

connectors

Thus

the

meters

Can

be

inspected

and

serviced

extremely

easily

Except

for

the

speed

ometer

all

rneters

are

operated

electrically

The

fuel

gauge

and

therrnometer

are

very

reliable

and

they

are

equipped

with

bimetal

devices

F

a

o

ill

I

1

a

a

Fig

BE

34

Combination

meters

Removal

Disconnect

the

battery

terminal

depressing

the

OIL

PRESSURE

AND

IGNITION

WARNING

LAMPS

HAND

BRAKE

WARNING

LAMP

BULB

SPECIFICATIONS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Speedometer

Thermometer

and

fuel

meter

Oil

pressure

and

ignition

warning

lamps

BE

20

BE

21

BE

21

BE

22

BE

22

BE

23

BE

25

windshield

wiper

switch

lighting

switch

and

choke

lever

knobs

turn

them

counterclockwise

to

remove

Remove

the

escutcheon

2

Inserting

your

hand

into

back

of

the

cluster

lid

disconnect

the

cigarette

lighter

cable

and

turn

and

remove

the

cigarette

lighter

outer

case

3

Remove

the

radio

and

heater

control

knobs

4

Remove

the

shell

cover

from

the

steering

tube

loosen

the

screws

used

to

secure

the

meter

housing

to

the

instrument

panel

and

remove

the

cluster

lid

5

Pull

out

the

l2

pole

round

shape

connector

and

remove

the

speedometer

cable

union

nut

6

Remove

the

cluster

lid

from

the

instrument

panel

Fig

BE

35

Removing

clllSter

jd

BE

18

Page 268 of 513

BODY

ELECTRICAL

Distributor

Secure

ground

of

ignition

coil

Secure

contact

of

carbon

electric

pole

and

rotor

Eliminate

excessive

tip

on

the

rotor

pole

or

cap

pole

by

scrubbing

with

a

screwdriver

Check

stagger

between

rotor

and

stator

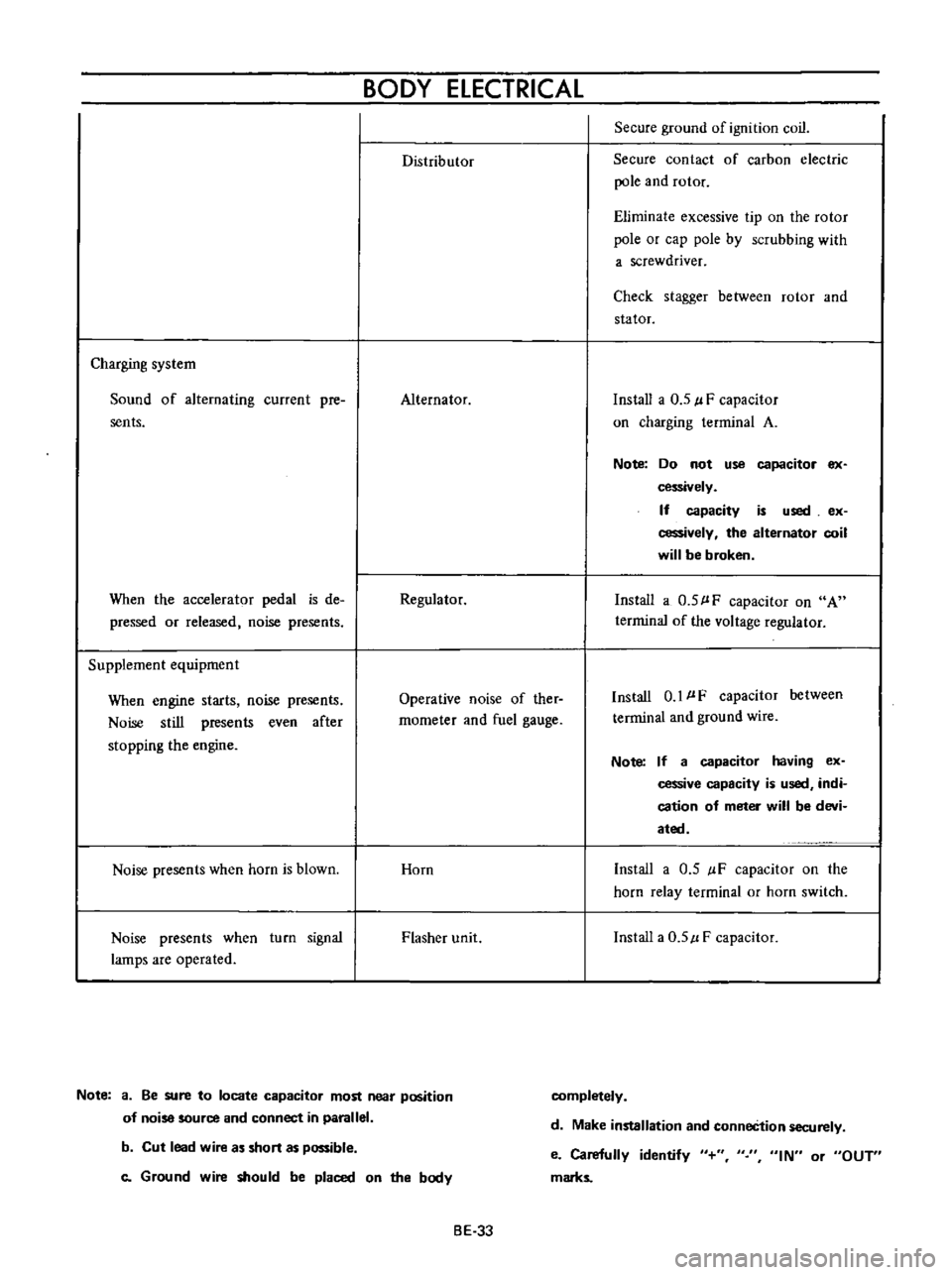

Charging

system

Sound

of

alternating

current

pre

sents

Alternator

Install

a

0

5

l

F

capacitor

on

charging

terminal

A

Note

Do

not

use

capacitor

ex

cessively

If

capacity

is

used

ex

cessively

the

alternator

coil

will

be

broken

When

the

accelerator

pedal

is

de

pressed

or

released

noise

presents

Regulator

Install

a

0

5

l

F

capacitor

on

A

terrninal

of

the

voltage

regulator

Supplement

equipment

When

engine

starts

noise

presents

Noise

still

presents

even

after

stopping

the

engine

Operative

noise

of

ther

rnometer

and

fuel

gauge

Install

0

1

l

F

capacitor

between

terminal

and

ground

wire

Note

If

a

capacitor

having

ex

cessive

capacity

is

used

indi

cation

of

meter

will

be

devi

ated

Noise

presents

when

horn

is

blown

Horn

Install

a

0

5

IF

capacitor

on

the

horn

relay

terminal

or

horn

switch

Noise

presents

when

turn

signal

lamps

are

operated

Flasher

unit

Install

a

0

5

l

F

capacitor

Note

a

Be

sure

to

locate

capacitor

most

near

position

of

noise

source

and

connect

in

parallel

completely

d

Make

installation

and

conneCtion

securely

b

Cut

lead

wire

as

short

as

possible

c

Ground

wire

should

be

placed

on

the

body

e

Carefully

identify

marks

IN

or

OUT

BE

33